Page 1

PBD1202

CRIMPING TOOL

USER MANUAL

Safety, Operation and Maintenance

© 2017 STANLEY Black & Decker, Inc.

New Britain, CT 06053

U.S.A.

81154 1/2018 Ver. 1

Page 2

Page 3

TABLE OF CONTENTS

SAFETY SYMBOLS ...............................................................................................................................................4

SAFETY PRECAUTIONS .......................................................................................................................................5

TOOL ANATOMY ....................................................................................................................................................6

SPECIFICATIONS & ACCESSORIES ....................................................................................................................7

OPERATION ...........................................................................................................................................................8

STANLEY CRIMP SOFTWARE ..............................................................................................................................9

TROUBLESHOOTING ...........................................................................................................................................14

PBD1202 PARTS ILLUSTRATION .........................................................................................................................15

PBD1202 PARTS LIST ...........................................................................................................................................16

PBD1202 RESERVOIR UNIT .................................................................................................................................17

PBD1202 HYDRAULIC UNIT .................................................................................................................................18

To ll out a product warranty validation form, and for information on your warranty,

visit www.stanleyinfrastructure.com and select the Company tab > Warranty.

Note: The warranty validation record must be submitted to validate the warranty.

SERVICING: This manual contains safety, operation and routine maintenance instructions. STANLEY Infrastructure

recommends that servicing of hydraulic tools, other than routine maintenance, must be performed by an authorized

and certied dealer. Please read the following warning.

SERIOUS INJURY OR DEATH COULD RESULT FROM THE IMPROPER REPAIR OR

SERVICE OF THIS TOOL.

REPAIRS AND / OR SERVICE TO THIS TOOL MUST ONLY BE DONE BY AN

AUTHORIZED AND CERTIFIED DEALER.

For the nearest certied dealer, call STANLEY Infrastructure at (503) 659-5660 and ask for a Customer Service Representative.

PBD1202 User Manual ◄ 3

Page 4

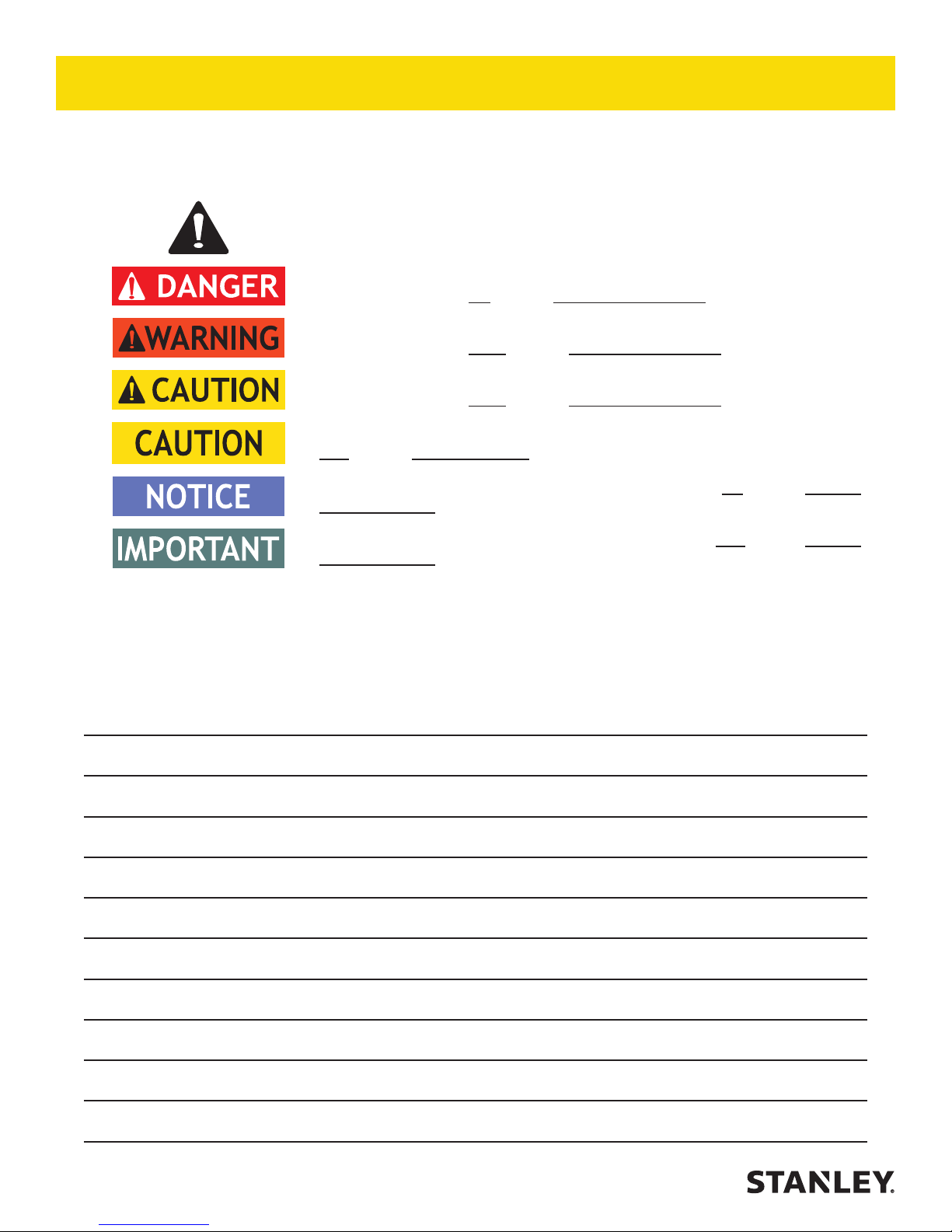

SAFETY SYMBOLS

Safety symbols and signal words, as shown below, are used to emphasize all operator, maintenance and repair

actions which, if not strictly followed, could result in a life-threatening situation, bodily injury or damage to equipment.

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid possible

injury or death.

This safety alert and signal word indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

This safety alert and signal word indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

This safety alert and signal word indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

This signal word indicates a potentially hazardous situation which, if not avoided,

may result in property damage.

This signal word indicates a situation which, if not avoided, will result in damage

to the equipment.

This signal word indicates a situation which, if not avoided, may result in damage

to the equipment.

Always observe safety symbols. They are included for your safety and for the protection of the tool.

LOCAL SAFETY REGULATIONS

Enter any local safety regulations here. Keep these instructions in an area accessible to the operator and

maintenance personnel.

4 ► PBD1202 User Manual

Page 5

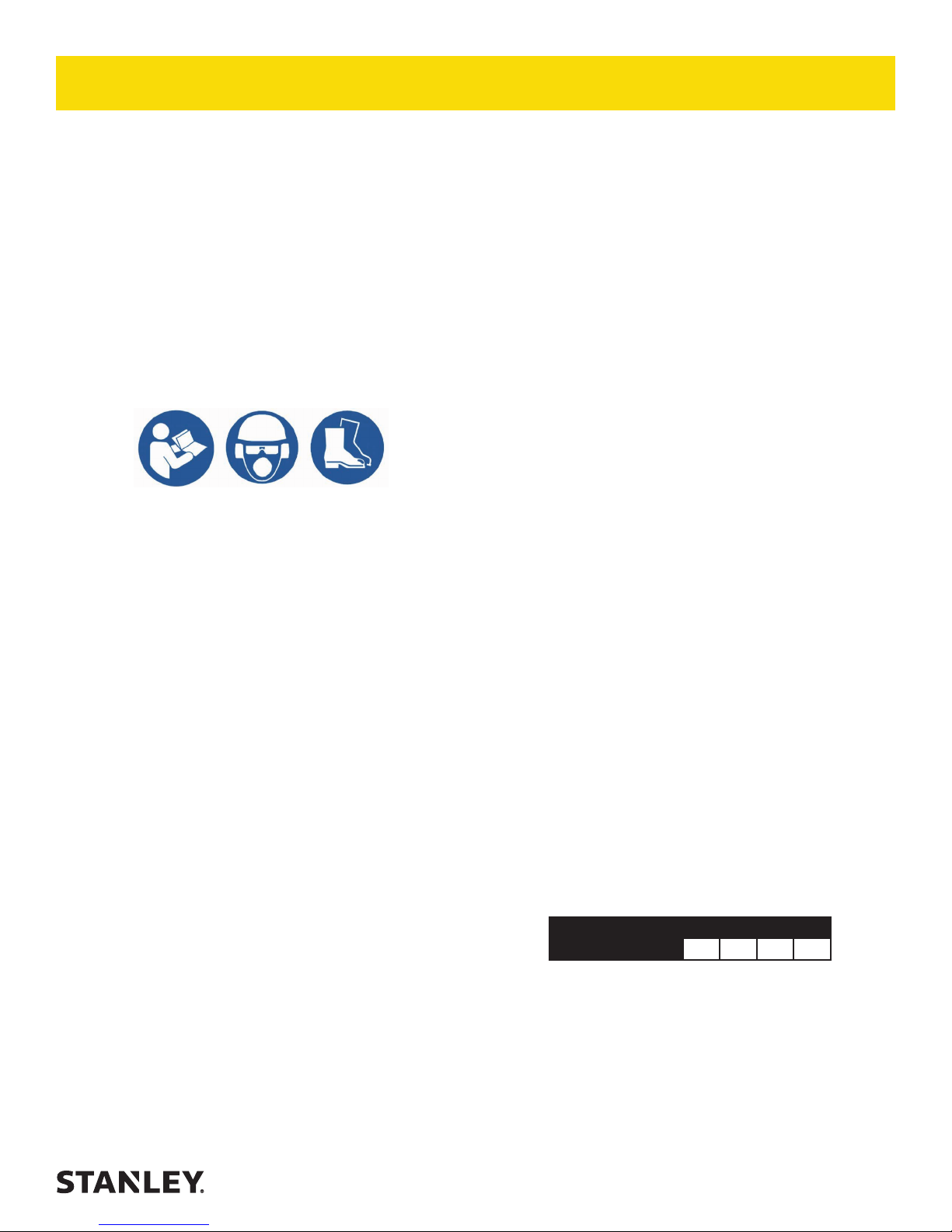

SAFETY PRECAUTIONS

Tool operators must comply with precautions given in this

manual and on the stickers attached to the tool.

These precautions are given for your safety. Review them

carefully before operating the tool.

Supervising personnel should develop additional precautions

relating to the specic work area and local safety regulations.

Place the added precautions in the space provided on page

4.

The PBD1202 12-Ton crimping tool will provide safe and

dependable service if operated in accordance with the

instructions in this manual. Read and understand this

manual and stickers attached to the tool before operation.

Failure could result in injury or tool damage.

• Do not operate the tool unless thoroughly trained or

under the supervision of an instructor. Establish a training

program for all operators to ensure safe operation.

• Always wear safety equipment such as eye protection,

ear protection, head protection and safety shoes at all

times when operating the tool. Use gloves if necessary.

• The operator must be familiar with all prohibited work

areas such as excessive slopes and dangerous terrain

conditions. Ensure that your footing is rm and in

balance at all times.

• Do not inspect, clean or replace tool jaw parts while the

battery is connected. Accidental engagement of the tool

can cause serious injury.

• Do not operate a damaged, improperly adjusted or

incompletely assembled tool.

• Never wear loose clothing that can become entangled in

the working parts of the tool.

• Keep all parts of your body away from pinch points. Long

hair or loose clothing can become drawn into the tool.

• To avoid personal injury or equipment damage, all tool

repair, maintenance and service must be performed by

an authorized service center.

• Never use the tool in the vicinity of ammable materials

or gases.

• Do not use the tool or charge the tool battery in an

explosive atmosphere.

• Cutting or severing of body parts is possible if proper

procedures are not followed.

• Do not use the tool, battery or battery charger for

purposes other than what is described in this manual.

• Always keep critical tool markings, such as labels

and warning stickers, legible. Contact STANLEY for

replacement labels.

• Do not use the tool while under the inuence of drugs

or alcohol.

• Do not use accessories or attachments other than those

recommended by STANLEY.

BATTERIES

• Only charge batteries with a STANLEY recommended

battery charger.

• Do not store batteries with metal objects, such as coins,

nails or keys. Fire can result if battery terminals are

shorted.

• Do not charge a damaged battery. Recycle and replace

damaged batteries with batteries recommended by

STANLEY.

• Do not incinerate or dispose of batteries in the garbage.

Recycle the batteries.

• Do not expose the battery to temperatures over 265°F.

Batteries may explode at high temperatures.

• Leakage of liquid from the battery may occur under

extreme use or high temperatures. If battery liquid gets

on your skin:

1. Wash quickly with soap and water.

2. If the liquid gets in your eyes, ush your eyes

with clean water for 10 minutes. Seek medical

attention immediately.

• Never open the battery.

BATTERY CHARGER

• Do not use the battery charger if the cord is damaged.

• Do not place the charger, or set items on or near the

charger, in such a way as to block airow to the charger.

• Do not use the charger with an extension cord unless

absolutely necessary. Use a cord with the proper wire

size for its length, as described in Table 1.

Length of Cord (Feet) 25 50 100 150

Wire Size (AWG) 18 18 18 16

Table 1: Extension Cord Wire Size

• Do not open the charger or attempt to modify it in any

way.

• Disconnect the charger from power before attempting

to clean it.

• Do not connect the charger to a transformer or engine

generator.

PBD1202 User Manual ◄ 5

Page 6

TOOL ANATOMY

WHAT IS THE PBD1202 CRIMPING TOOL?

The PBD1202 is a battery powered 12-Ton cable crimping tool with a Kearney style head. The PBD1202 accepts

Kearney style WH2 and WH3 style dies. It is capable of crimping copper and aluminum connectors to 750 MCM.

DO NOT put ngers, hands or other body parts inside the

crimping head. Serious injury will result!

Crimping Head

InteLED

USB Port

Tool Identication &

Warning Decal

Battery

6 ► PBD1202 User Manual

Pressure Release

Trigger

Trigger Lock

Page 7

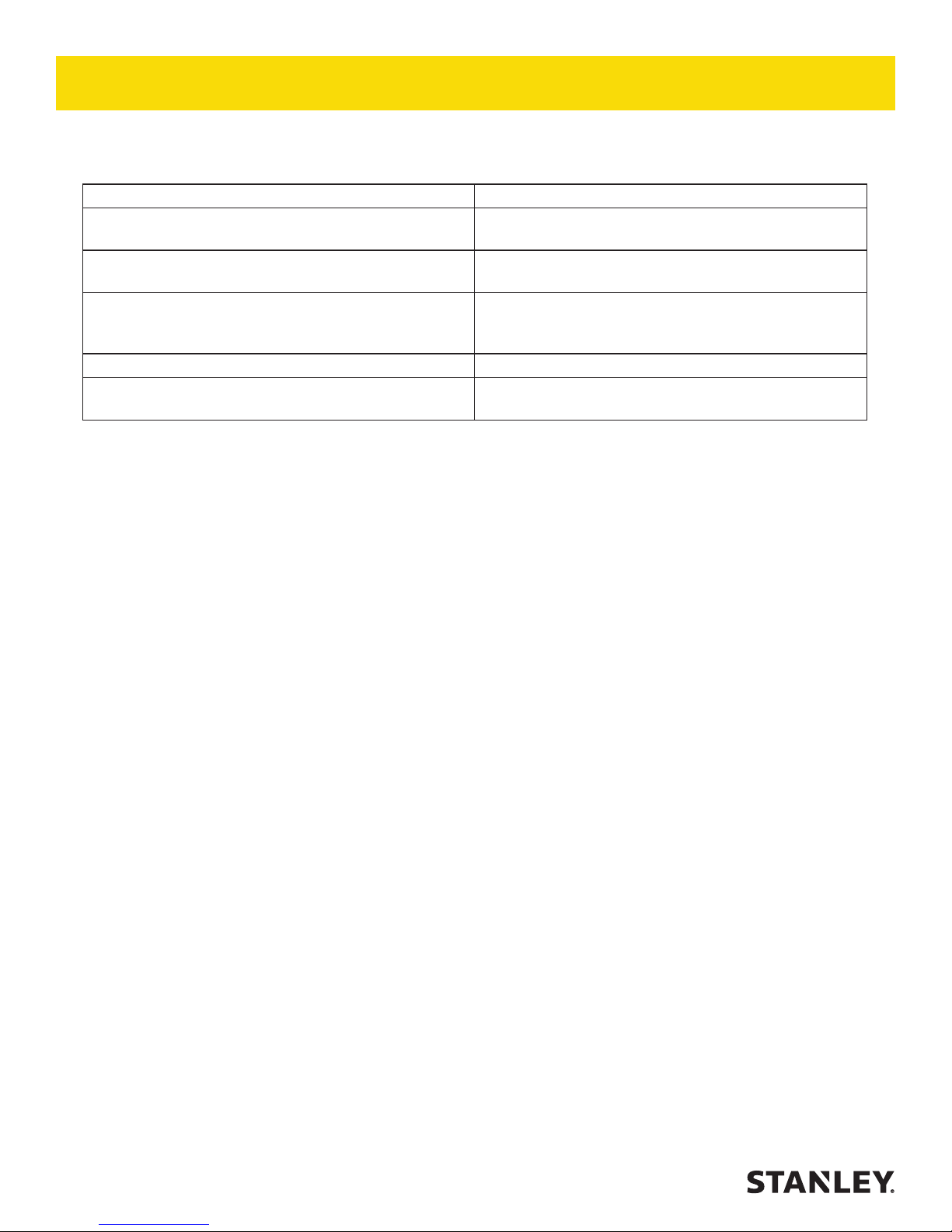

SPECIFICATIONS & ACCESSORIES

SPECIFICATIONS

Crimping Force .............................................................................................................................. 12 Tons (117.6 kN)

Crimping Capacity ................................................................................Copper & Aluminum connectors to 750 MCM

Jaw Type ...............................................................................................................................................Kearney Style

Die Type .........................................................................................................................Kearney Stype WH2 & WH3

Battery Type ..............................................................................................................DEWALT 20V Max, 5 amp/hour

Estimated Crimps per Battery Charge ................................................................................................................... 100

Tool Cycle Time .......................................................................................................................................... 7 Seconds

Tool Weight ................................................................................................................................................. 15.85 Lbs.

Tool Length ............................................................................................................................................... 16.5 Inches

Maintenance Interval ............................................................................................................................ 15,000 Cycles

ACCESSORIES

5 Amp/hour DEWALT 20V Max Battery ............................................................................................................DC205

5 Amp/hour DEWALT 20V Max Battery 2-pack .......................................................................................... DCB205-2

120V AC Charger ...........................................................................................................................................DCB115

12V DC Charger .............................................................................................................................................DCB119

Note: Only use battery chargers recommended by STANLEY.

Bucket Bag ......................................................................................................................................................... BB01

PBD1202 User Manual ◄ 7

Page 8

CHARGE BATTERY

OPERATION

Battery Charging

Battery Charged

Hot/Cold Delay

USING THE PBD1202

354

Pressure

Release

1

Set the Trigger Lock BEFORE

inserting or removing dies from

the Crimping Head.

1. Set the trigger lock.

2. Insert battery.

3. Insert the die into the crimping head.

4. Insert the cable ends into the die.

5. Release the trigger lock. Press and

hold the trigger until the die is crimped.

Press and hold the pressure release to

open the crimping head.

Note: Release the trigger to immediately

stop the tool. Press the pressure release

at any time to open the jaws.

8 ► PBD1202 User Manual

2

Page 9

OPERATION

INTELED SYSTEM

The InteLED light ring shows you the status of the crimp in real-time.

White - The tool is crimping. InteLED will stay lit for 30 seconds after the crimp is complete.

Green - The tool has developed full hydraulic pressure during the crimp. The crimp is good.

Red - The tool did not develop full pressure during the crimp. Crimp again.

CHECKING BATTERY CHARGE

Battery Charge Button

75 - 100% Charged

51 - 74% Charged

Less than 50% Charged

STANLEY CRIMP SOFTWARE

STANLEY Crimp software provides valuable data about

each crimp. It is also required to update the tool rmware.

INSTALLATION

1. Download the STANLEY Crimp software from the

STANLEY Infrastructure website.

www.stanleyinfrastructure.com/products/cordless-td

Note: STANLEY Crimp software requires a minimum

of Windows XP SP3 running with administrator

rights.

2. Follow the prompts on screen to complete

installation.

3. Connect PBD1202 to a PC using a micro USB cable.

Note: InteLED will shine blue when connected.

FIRST RUN

1. Run the software using the STANLEY Crimp

software icon on your Windows desktop.

2. You will be prompted to register your software. Left

click the “User Registration” button.

3. Fill out the registration form and click “Register”.

Charge Battery

USB Connection

PBD1202 User Manual ◄ 9

Page 10

OPERATION

USER SELECTION

1. Click the “New User” button

2. Enter the required user information and click “Create”.

3. Select a user and click “OK”.

TOOL INFORMATION

1 2

The Tool Information tab displays important data about the PBD1202.

1. Displays the product type, serial number and rmware version of the tool.

2. Basic data relating to the life and service interval of the tool.

10 ► PBD1202 User Manual

Page 11

TOOL USAGE DATA

OPERATION

1

2

The Tool Usage Data tab displays information about individual tool cycles.

1. Displays the total number of tool cycles, as well as completed and incomplete cycles.

1. The data log shows each cycle, up to 250,000 cycles. Each entry into the log includes;

• Date and time of each crimp

• If the cycle completed successfully

• Amperage and Voltage of the tool during each crimp

• Tool temperature at the end of each crimp

2. Data log sorting lters. Allows you to sort the crimp data in the data log.

3

WORKSITE REPORTS

1

PBD1202 User Manual ◄ 11

Page 12

OPERATION

The Worksite Reports tab allows you to group data log entries into a complete tool cycle report.

2

4

3

1. Click “Create Report”.

2. Select the date range of the job you are reporting.

3. Select the crimp cycles you want to include in the report.

4. Select a user and a worksite.

Note: If this is the rst time using the software, press the “Worksites” button to create a worksite.

5. Enter notes about the job in the Remarks eld.

6. Click “OK” when nished.

5

7

7. Select a report from the reports list.

8. Click “Print Report to PDF” to export the Worksite Report.

12 ► PBD1202 User Manual

Page 13

AVAILABLE UPDATES

OPERATION

1

2

The Available Updates tab will allow you to update the tool rmware and update STANLEY Crimp software.

1. Tool Firmware Update button. When clicked, this will begin to tool rmware update process. Do not unplug the

tool during this process.

2. Software Update button. When clicked, this will update the STANLEY Crimp software, if an update is available.

PBD1202 User Manual ◄ 13

Page 14

TROUBLESHOOTING

Problem Solution

The tool won’t crimp when I press the trigger. Ensure the battery is charged. Disengage the trigger

lock.

The InteLED ashes yellow when I activate the tool. The maintenance interval is about to elapse. Have the

tool serviced as soon as possible.

The tool repeatedly give me bad crimps / The InteLED

ashes red after every crimp.

The tool is leaking hydraulic oil. Have the tool serviced immediately.

The tool is not saving data or will not connect to

STANLEY Crimp software.

Ensure the battery is fully charged. Ensure the dies

are inserted properly into the crimping head. If problem

persists, have the tool serviced as soon as possible.

Have the tool serviced as soon as possible.

14 ► PBD1202 User Manual

Page 15

PBD1202 PARTS ILLUSTRATION

105

101

47

42

136

37

48

38

263

43

103

270

44

137

135

253

94

31

87

151

46

99

152

87

150

64

93

89

250

37

43

252

50

265

49

264

41

105

104

102

98

PBD1202 User Manual ◄ 15

Page 16

PBD1202 PARTS LIST

ITEM P/N QTY DESCRIPTION

31 85085 1 Spring

37 91649 2 Side Membrane

38 91650 2 Rear Membrane

41 91655 1 Trigger Lock

42 77058-01 1 Shackle

43 91593-STA 1 Housing Set

44 91439 1 Lens LED

46 JUP404865 1 Leap Seal

47 77051-01 1 Shackle Holder

48 91410 1 USB Cover

49 AIG4X19.8BP 1 Calibrated Pin

50 77061 1 Spring

64 AAIS60 1 Retaining Pin

87 71372DUB 2 Screw

89 VAV04CB006 4 Screw

93 VAV05HC025 2 Screw

94 VAV05HC040 2 Screw

98 VAV3.5TC014ZN 13 Screw

99 91350 1 Protection Cover

101 91633 1 Stanley Label

102 91641 1 PBD1202 Label

103 91634 1 “Powered By DEWALT” Label -

Right

104 91635 1 “Powered By DEWALT” Label - Left

105 91636 2 InteLED Label

135 ACKR0204 1 Grooved Pin

136 91465 1 Strap Ring

137 85029DUB 1 Key

150 71341-02 1 Crimping Head Unit

151 VAV06TT010 1 Screw

250 91856 1 Motor Reduction Unit

252 See page 17 1 Reservoir Unit

253 See page 18 1 Hydraulic Body Unit

263 92886 1 Electronic Device

264 77853-STA 1 Advance Trigger Unit

265 77854-DEW 1 Release Trigger Unit

270 92870C 1 Piston Unit

`

16 ► PBD1202 User Manual

Page 17

PBD1202 RESERVOIR UNIT

74

78

262

78

74

13

254

7

75

2

80

81

71

97

71

97

25

86

68

263

85

90

ITEM P/N QTY DESCRIPTION

2 30176DUB 1 Reservoir Plug

7 91569 1 Oil Reservoir

13 77009-02 1 Reservoir Body

25 VAV04CB015 1 Screw

68 AIG4X29.8BP 1 Calibrated Pin

71 BILL4.76 2 Ball

74 J0640190 2 O-Ring

75 91576 1 Metal Clamp

78 JAE0700150 2 Anti-extrusion Ring

80 J0420250 1 O-Ring

81 ZBINA420 1 Magnet Pin

85 VAR04W 1 Washer

86 91232 1 Release Trigger

90 VAE04 1 Washer

97 VAV08BP008 2 Screw

254 92884-15 1 Overload Valve

262 77851C 1 Bodies Connector Unit

263 77852-DEW 1 Release Lever Unit

PBD1202 User Manual ◄ 17

Page 18

PBD1202 HYDRAULIC UNIT

65

83

256

82

28

6

5

67

69

63

95

96

73

77

257

118

119

267

21

260

256

258

125

259

76

ITEM P/N QTY DESCRIPTION

5 77286 2 Cam Roller

6 70048DUB 1 Sleeve

21 77013-01-AP 1 Hydraulic Body

28 77026-04 1 Spring

63 87213 1 Spring

65 AAIN30 1 Circlip

67 AIG4X23.8BR 1 Calibrated Pin

69 J0720190 1 O-Ring

73 J0290178PU70 2 O-Ring

76 J4300200 1 O-Ring

77 JAE0500100 1 Anti-extrusion Ring

82 JSR1927205 1 Wiper Ring

83 R1B12.30.08Z 1 Ball Bearing

95 VIV08TT008 2 Screw

96 VAV06TT008 1 Screw

ITEM P/N QTY DESCRIPTION

118 77030 1 Spring

119 77016 1 Sliding Part

125 BILL03.175 1 Ball

256 77803 1 Release Device

257 77805-01 2 Deliver Valve Unit

258 77806-01 2 Succion Valve Unit

259 77848C-02 1 Spring Collar Unit

260 77849C 1 Cam Compartment

Unit

267 77804C 1 Commutator

18 ► PBD1202 User Manual

Page 19

Page 20

STANLEY Infrastructure

6430 SE Lake Road

Portland, Oregon 97222 USA

(503) 659-5660 / Fax (503) 652-1780

www.stanleyinfrastructure.com

Loading...

Loading...