Page 1

Page 2

1

Page 3

2

Page 4

3

Page 5

4

Page 6

5

Page 7

1.1 GENERAL SAFETY

Do not use outside the design intent of Placing STANLEY Engineered Fastening Blind Fasteners.

Use only parts, fasteners, and accessories recommended by the manufacturer.

Use Power Tool only with specifically designated battery packs.

6

Page 8

1.2 POWER TOOL USE AND CARE

The tool must be maintained in a safe working condition at all times and examined at regular intervals for damag e and

function by trained personnel. Any dismantling procedure will be undertaken only by trained personnel. Do not dismantle

this tool without prior reference to the maintenance instructions.

Do not modify the tool in any way. Any modification to the tool is undertaken by the customer and will be the customer’s

entire responsibility and void any applicable warranties.

Disconnect the battery from the tool before performing any maintenance, attempting to adjust, fit or remove a nose

assembly.

Prior to use, check for misalignment or binding of moving parts, breakage of parts, and any other condition that affects the

tool’s operation. If damaged, have the tool serviced before using. Remove any adjusting key or wrench before use.

Prior to use, inspect battery for damage. Do not drop battery. A sharp impact may cause internal damage and lead to

premature battery failure.

Keep work area clean and well lit.

Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and gloves away from moving parts. Loose

clothes, jewelry or long hair can be caught in moving parts.

Adopt a firm footing or a stable position before operating the tool.

Operators and others in work area must wear ANSI Z87.1 CAN/CSA Z94.3 approved safety glasses with side shields. Always

wear safety glasses and ear protection during operation.

Adequate clearance is required for the tool operator’s hands before proceeding.

Do not operate a tool that is directed towards any person(s).

DO NOT operate tool with the nose housing removed.

Do not operate the tool or the charger in an explosive atmosphere or environment allowing exposure to combustible fluids

or gasses.

Do not operate the tool or the charger in an environment allowing exposure to moisture or rain to avoid risk of electric

shock.

Do not abuse the tool by dropping or using it as a hammer.

Keep dirt and foreign matter out of the air vents of the tool as this will cause the tool to malfunction.

Keep tool handles dry, clean, and free from oil and grease.

When carrying the tool from place to place keep hands away from the trigger to avoid inadvertent activation.

Never leave operating tool unattended.

Disconnect battery when tool is not in use.

1.3 IMPORTANT SAFETY INSTRUCTIONS FOR ALL BATTERY CHARGERS

SAVE THESE INSTRUCTIONS: This manual contains important safety and operating instructions for compatible battery chargers

(refer to Technical Data).

Before using charger, read all instructions and cautionary markings on charger, battery pack, and product using battery

pack.

WARNING: Shock hazard. Do not allow any liquid to get inside charger. Electric shock may result.

WARNING: We recommend the use of a residual current device with a residual current rating of 30mA or less.

CAUTION: Burn hazard. To reduce the risk of injury, charge only DEWALT/POP-Avdel rechargeable batteries. Other types of

batteries may burst causing personal injury and damage.

7

Page 9

CAUTION: Children should be supervised to ensure that they do not play with the appliance.

NOTICE: Under certain conditions, with the charger plugged into the power supply, the exposed charging contacts inside the

charger can be shorted by foreign material. Foreign materials of a conductive nature such as, but not limited to, steel wool,

aluminium foil or any build-up of metallic particles should be kept away from charger cavities. Always unplug the charger from

the power supply when there is no battery pack in the cavity. Unplug charger before attempting to clean

DO NOT attempt to charge the battery pack with any chargers other than the ones in this manual. The charger and battery

pack are specifically designed to work together.

These chargers are not intended for any uses other than charging DEWALT/POP-Avdel rechargeable batteries. Any other

uses may result in risk of fire, electric shock or electrocution.

Do not expose charger to rain or snow.

Pull by plug rather than cord when disconnecting charger. This will reduce risk of damage to electric plug and cord.

Make sure that cord is located so that it will not be stepped on, tripped over, or otherwise subjected to damage or stress.

Do not use an extension cord unless it is absolutely necessary. Use of improper extension cord could result in risk of fire,

electric shock, or electrocution.

Do not place any object on top of charger or place the charger on a soft surface that might block the ventilation slots and

result in excessive internal heat. Place the charger in a position away from any heat source. The charger is ventilated

through slots in the top and the bottom of the housing.

Do not operate charger with damaged cord or plug—have them replaced immediately.

Do not operate charger if it has received a sharp blow, been dropped, or otherwise damaged in any way. Take it to an

authorised service centre.

Do not disassemble charger; take it to an authorised service centre when service or repair is required. Incorrect reassembly

may result in a risk of electric shock, electrocution or fire.

Disconnect the charger from the outlet before attempting any cleaning. This will reduce the risk of electric shock. Removing

the battery pack will not reduce this risk.

NEVER attempt to connect two chargers together.

The charger is designed to operate on standard household electrical power (refer to charger specifications). Do not attempt

to use it on any other voltage. This does not apply to the vehicular charger.

1.4 IMPORTANT SAFETY INSTRUCTIONS FOR ALL BATTERY PACKS

When ordering replacement battery packs, be sure to include catalog number and voltage.

The battery pack is not fully charged out of the carton. Before using the battery pack and charger, read the safety instructions

below. Then follow charging procedures outlined.

READ ALL INSTRUCTIONS

Do not charge or use battery in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Inserting

or removing the battery from the charger may ignite the dust or fumes.

Never force battery pack into charger. Do not modify battery pack in any way to fit into a non-compatible charger as battery

pack may rupture causing serious personal injury.

Charge the battery packs only in DEWALT/POP-Avdel chargers.

DO NOT splash or immerse in water or other liquids.

Do not store or use the tool and battery pack in locations where the temperature may reach or exceed 40 ˚C (104 ˚F) (such as

outside sheds or metal buildings in summer).

When battery pack is not in use, keep it away from other metal objects like paper clips, coins, keys, nails, screws or other

small metal objects that can make a connection from one terminal to another.

Do not discard batteries into water.

8

Page 10

WARNING: Never attempt to open the battery pack for any reason. If battery pack case is cracked or damaged, do not

insert into charger. Do not crush, drop or damage battery pack. Do not use a battery pack or charger that has receiv ed a sharp

blow, been dropped, run over or damaged in any way (i.e., pierced with a nail, hit with a hammer, stepped on). Electric shock or

electrocution may result. Damaged battery packs should be returned to service centre for recycling.

WARNING: Fire hazard. Do not store or carry the battery pack so that metal objects can contact exposed battery

terminals. When transporting individual battery packs, make sure that the battery terminals are protected and well insulated

from materials that could contact them and cause a short circuit.

CAUTION: When not in use, place tool on its side on a stable surface where it will not cause a tripping or falling hazard.

Some tools with large battery packs will stand upright on the battery pack but may be easily knocked over.

1.5 SPECIFIC SAFETY INSTRUCTIONS FOR LITHIUM-ION (LI-ION)

1. Do not incinerate the battery pack even if it is severely damaged or is completely worn out. The battery pack can explode

in a fire. Toxic fumes and materials are created when lithium-ion battery packs are burned.

2. If battery contents come into contact with the skin, immediately wash area with mild soap and water. If battery liquid

gets into the eye, rinse water over the open eye for 15 minutes or until irritation ceases. If medical attention is needed, the

battery electrolyte is composed of a mixture of liquid organic carbonates and lithium salts.

3. Contents of opened battery cells may cause respiratory irritation. Provide fresh air. If symptoms persists, seek medical

attention.

WARNING: Burn hazard. Battery liquid may be flammable if exposed to spark or flame.

1.6 RESIDUAL RISKS

1.7 LABELS AND ICONS

9

Page 11

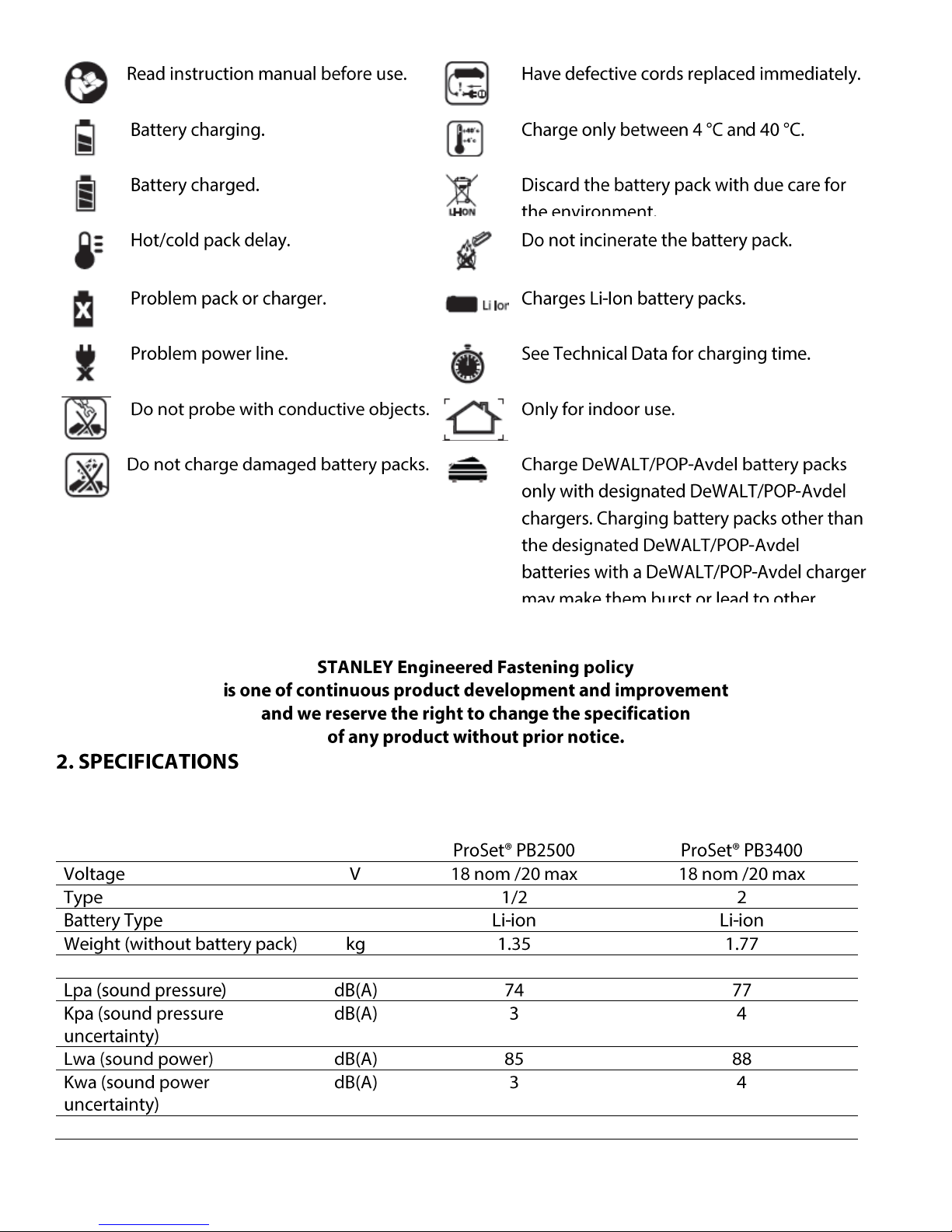

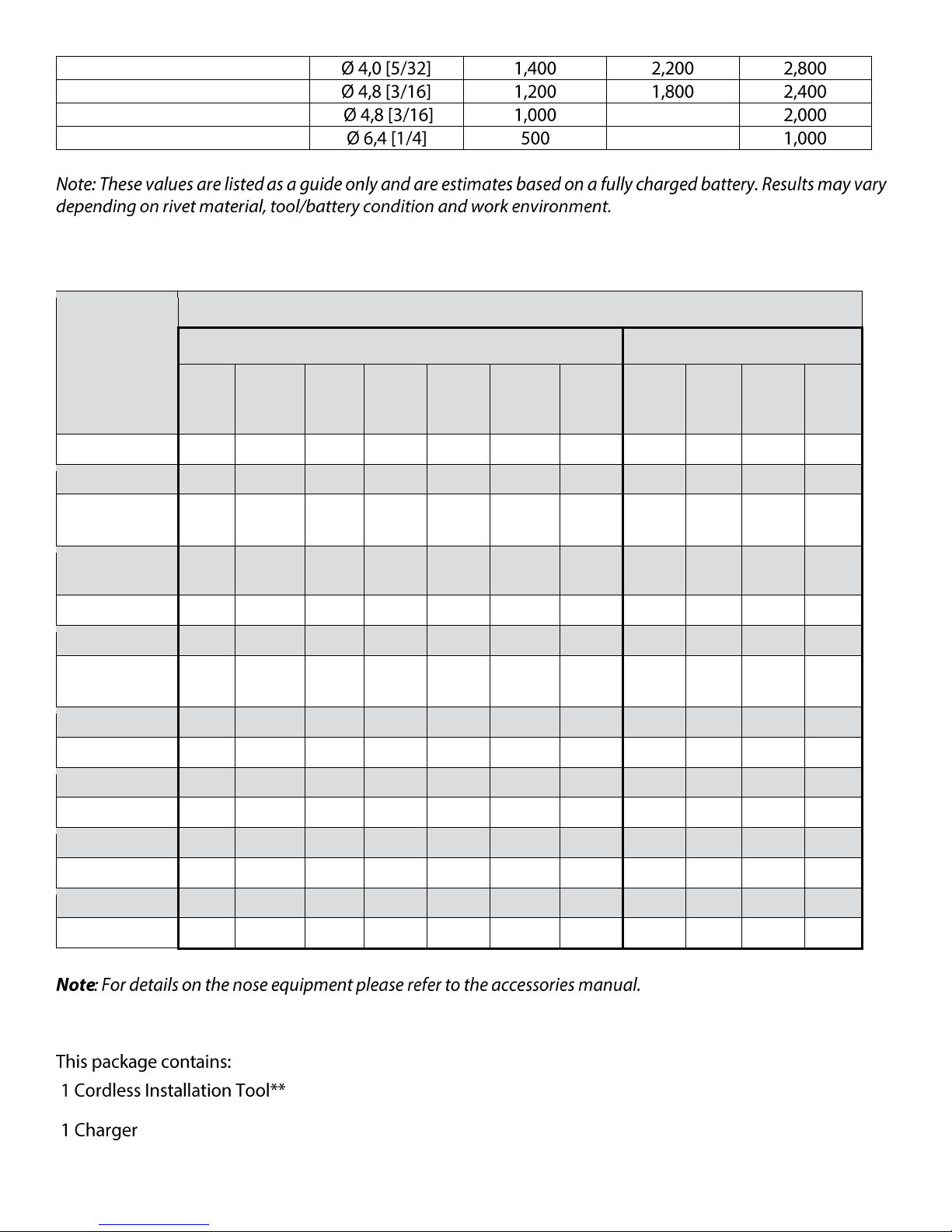

2.1 TECHNICAL DATA

2.1.1.

10

Page 12

11

Page 13

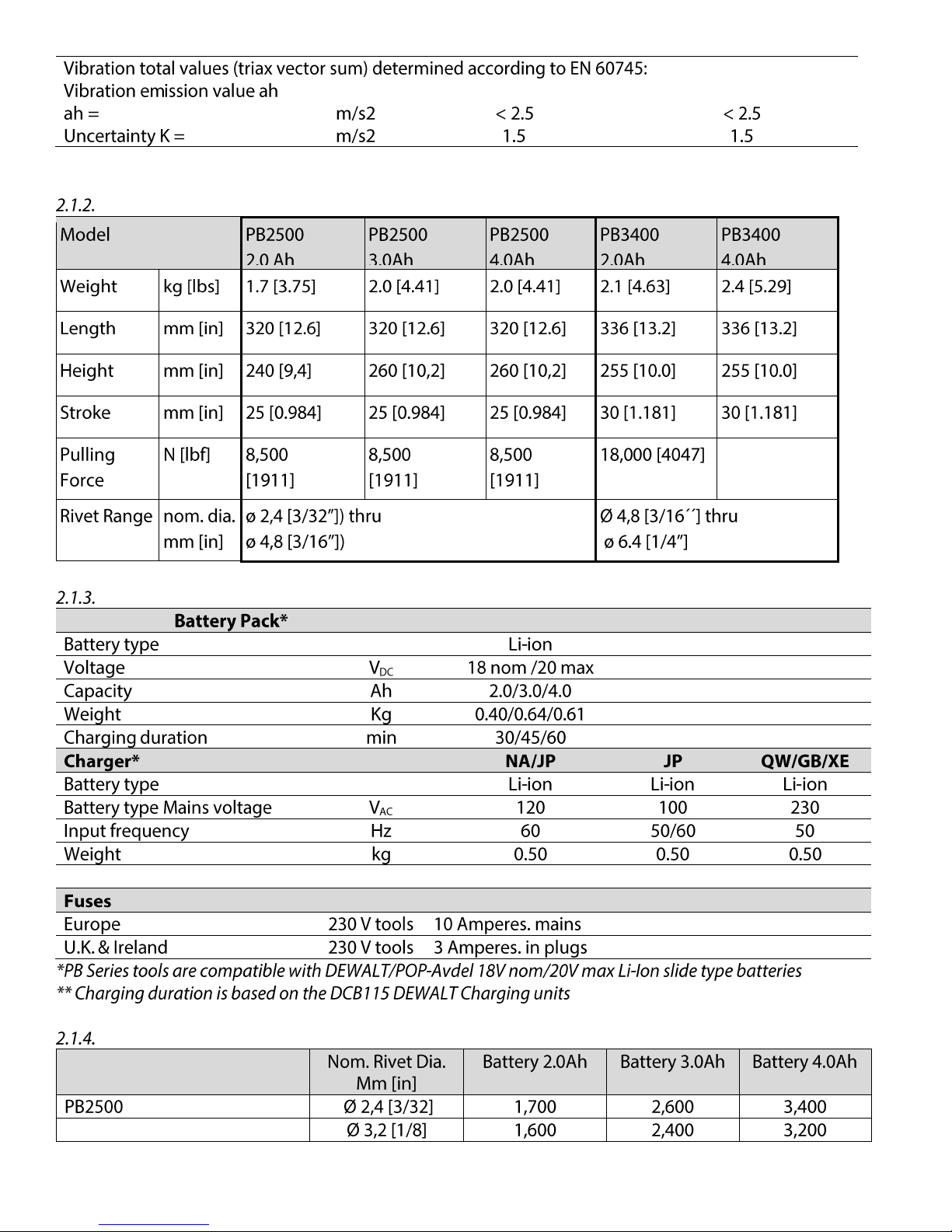

Rivet Type

PLACING CAPACITY

PB2500

PB3400

2.0

mm

2.4mm

[3/32´´]

3.0

mm

3.2mm

[1/8´´]

4.0mm

[5/32´´]

4.8mm

[3/16´´]

5.0/6.0

/7.0

mm

4.8mm

[3/16´´]

6.0 mm

6.4mm

[1/4´´]

8.0/9.0

mm

OPEN END

CLOSED END

AVEX/

STAVEX

● ● ● ● ● ●

AVINOX/

AVIBULB

● ● ● ● ● ●

HR/HT

INTERLOCK

KLAMP-TITE/

KTR

● ● ●

BULBEX/LS/TL

MONOBOLT

MULTI-GRIP

PULL-THRU (PT)

Q RIVET

T LOK

T-RIVET

AVSEAL II

2.2 PLACING SPECIFICATIONS

2.3 PACKAGE CONTENTS

12

Page 14

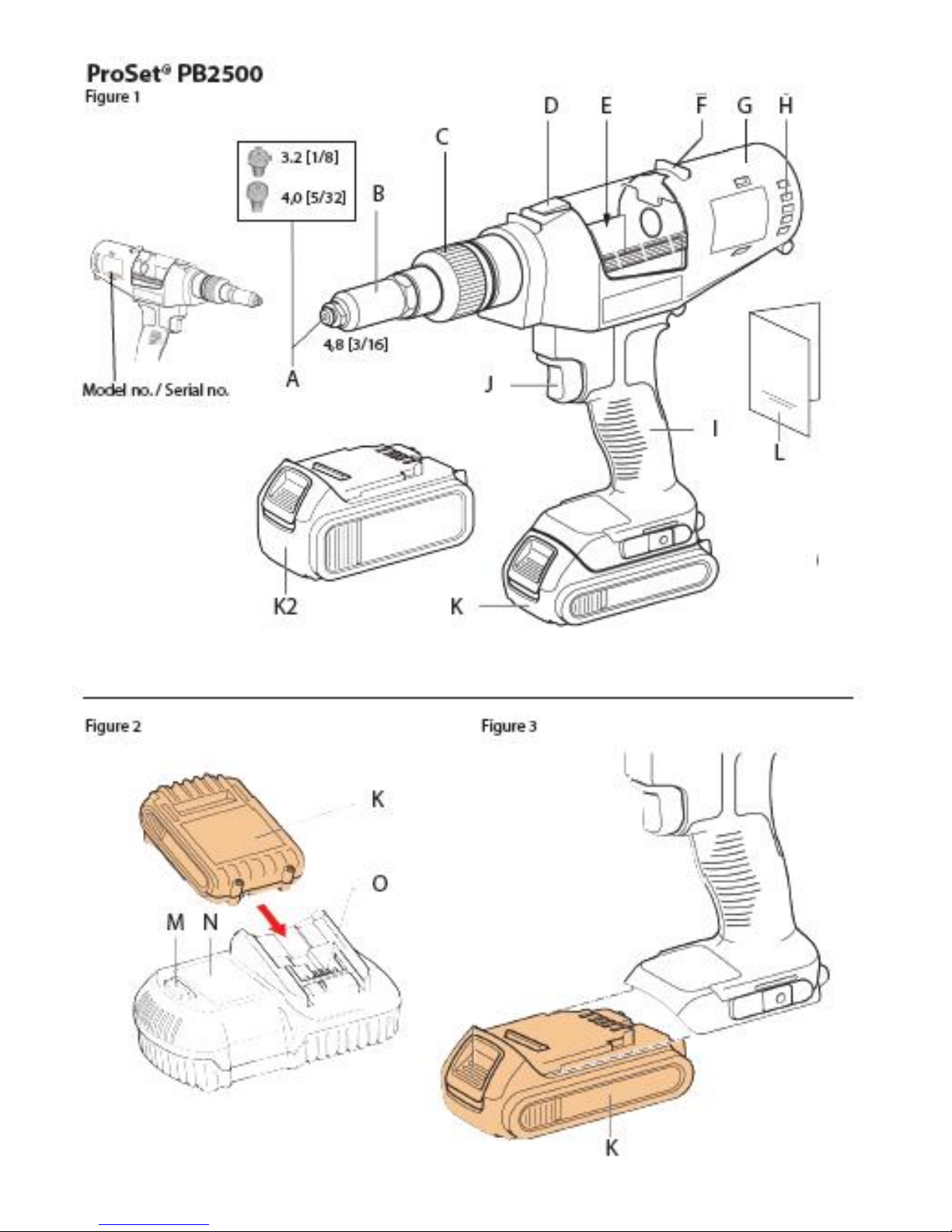

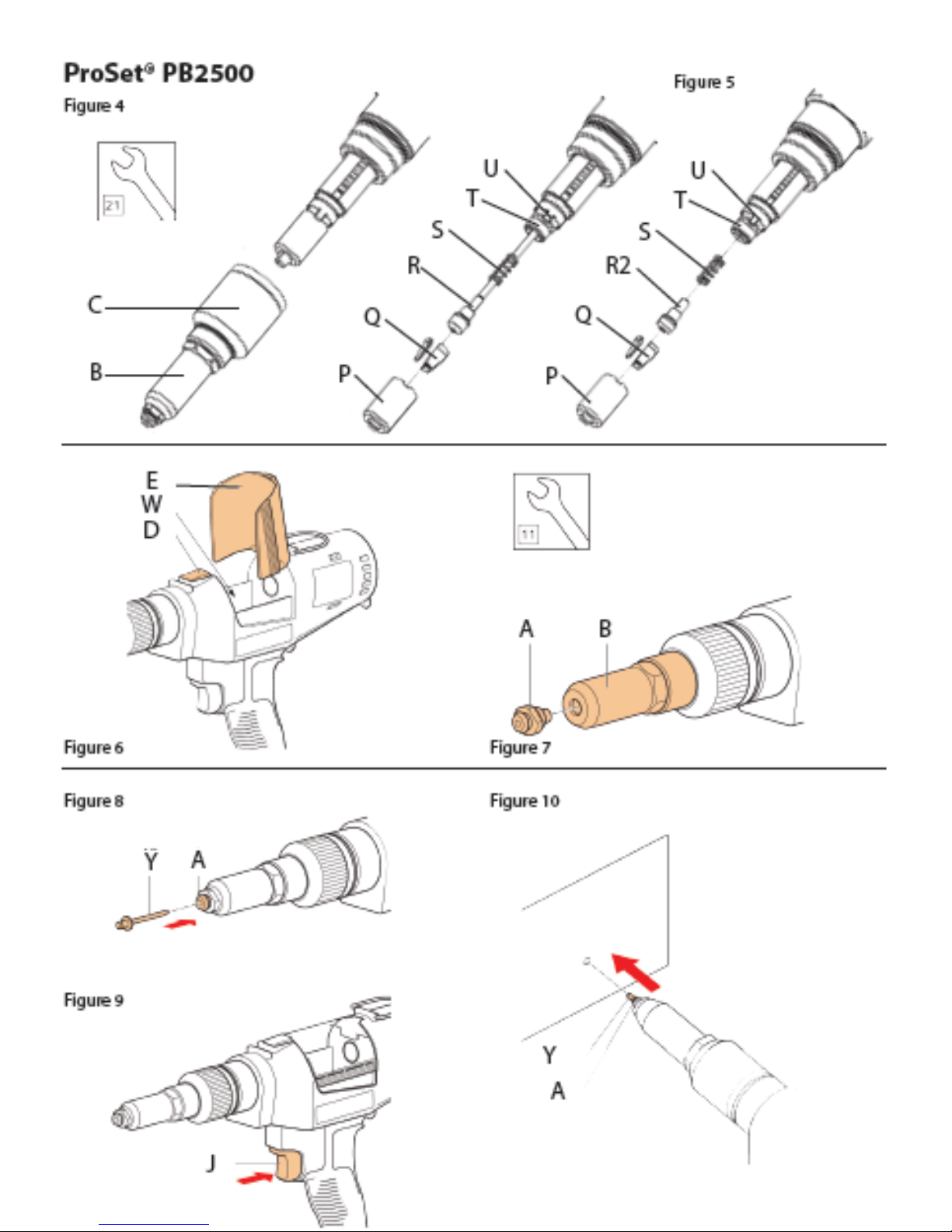

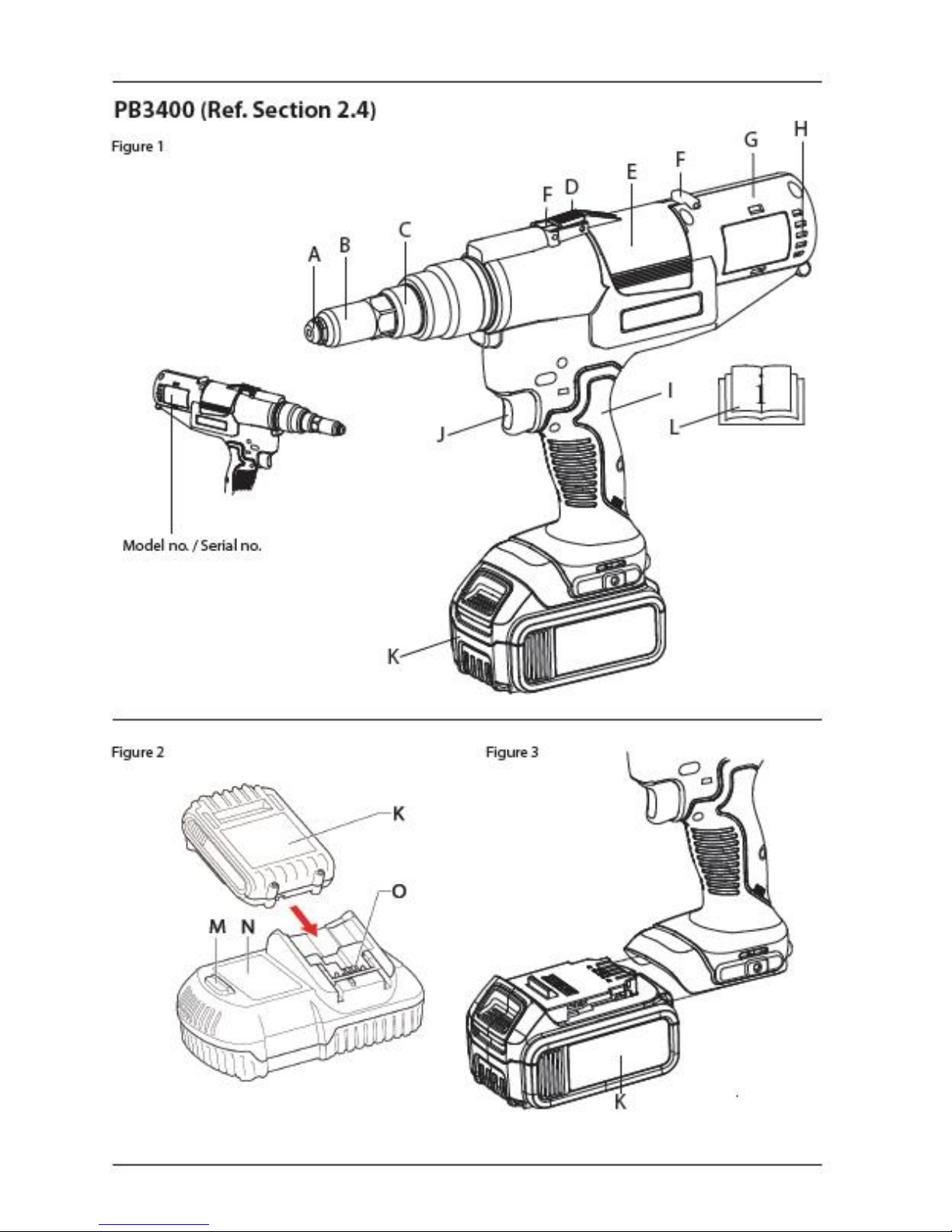

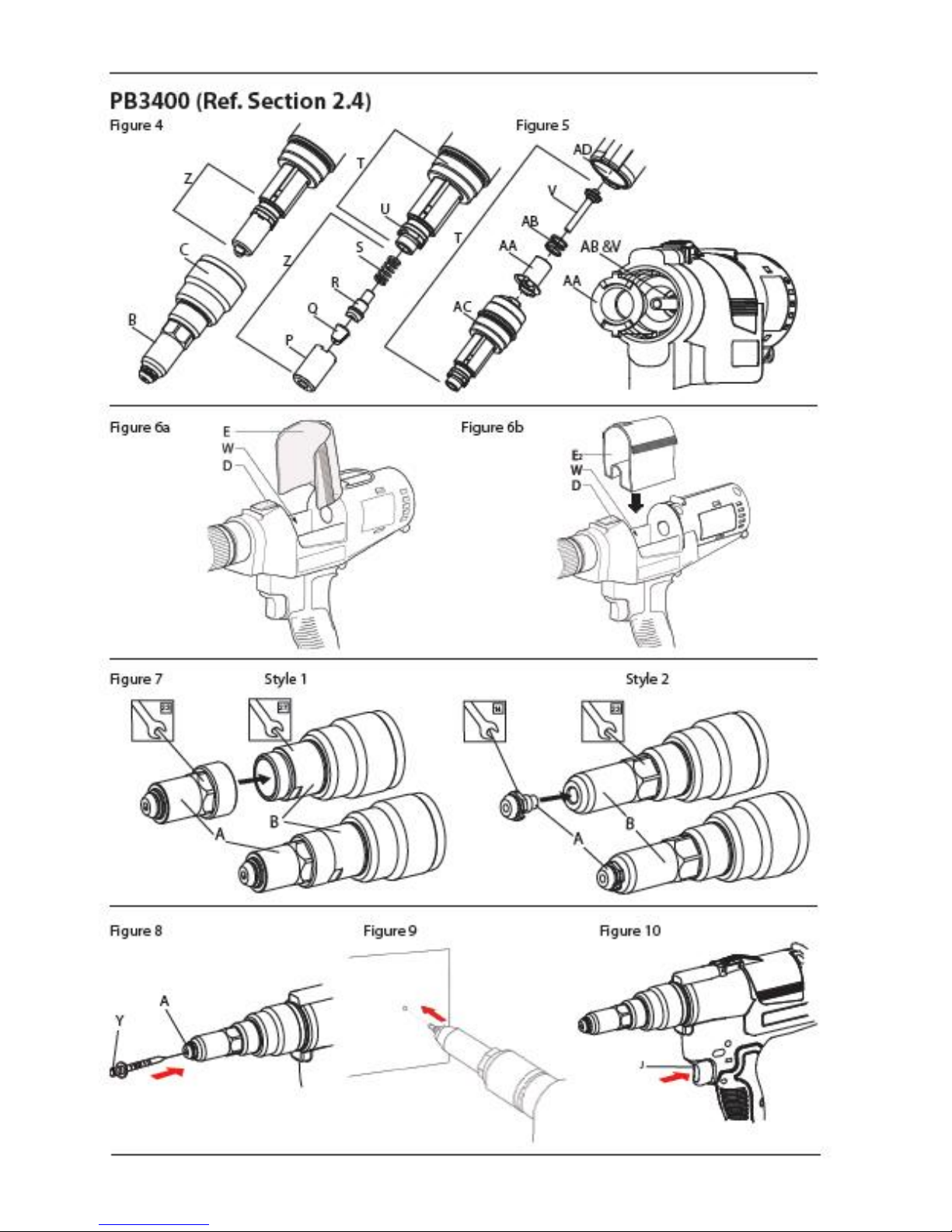

2.4 MAIN COMPONENTS LIST (for complete tool explosion and Bill of Material please see service manual)

ProSet® PB2500 drawing can be found inside the front cover

ProSet® BB3400 drawing can be found inside the back cover

2.5 OPTIONAL ACCESSORIES

13

Page 15

14

Page 16

4.1. NOSE EQUIPMENT

4.2. CHARGERS

15

Page 17

4.3 BATTERY PACKS

16

Page 18

17

Page 19

18

Page 20

19

Page 21

20

Page 22

7. Motor and Module Assembly and SA Planetary Carrier

MOTOR AND MODULE ASSEMBLY

TRM00127

1

SA MOTOR AND MODULE, PB3400

TP152-519

1

RING GEAR

N112877

1

O RING

TP124-511

1

SA PLANETARY CARRIER

TP143-625

1

O-ring

SA Motor and Module

Ring Gear

SA Planetary Carrier

Ring Gear

Motor housing

BOM for Motor and Module Assembly and SA Planetary Carrier

Fit the Ring Gear on to the Motor housing in

the SA Motor and Module assembly

21

Page 23

Ring Gear

Motor housing

O-ring

O-ring

Apply grease

Ring Gear

Motor Pinion

Boss on Ring gear

Top side

Set the O-ring onto the groove between the

Motor housing and Ring Gear

Align the middle boss on the Ring Gear to the

top side of the Motor Housing

Apply grease to the Ring Gear and Motor

Pinion.

Grease recommended: HIWIN G01

22

Page 24

Insert the SA Planetary Carrier into the Ring

Memo

Gear.

23

Page 25

9. Main Unit Assembly

MAIN UNIT ASSEMBLY

NA

1

MOTOR AND MODULE ASSEMBLY AND SA

PLANETARY CARRIER

NA

1

SA HOUSINGS

TP142-628

1

FRONT UNIT ASSEMBLY

TP143-683

1

SA SECOND SHAFT

TP143-620

1

MANDREL PLATE

TP144-681

1

SHUTTER GUIDE SLEEVE

TP114-676

1

COLLECTOR SHUTTER LOCK SPRING

TP114-677

1

COLLECTOR LOCK

TP124-532

1

COLLECTOR SHUTTER

TP143-627

1

CROSS RECESSED PAN HEAD TAPPING SCREW

TP124-513

14

3x16L

CROSS RECESSED PAN HEAD TAPPING SCREW

TP124-514

2

3x20L

Collector Lock

Shutter Guide Sleeve

Collector Shutter

Lock Spring

Front Unit Assembly

Mandrel Plate

SA Second

Shaft

Collector Shutter

Cross Recessed Pan

Head Tapping Screw

SA Housings

Motor and Module Assembly

SA Planetary Carrier

BOM for Main Unit Assembly

24

Page 26

Mandrel Plate

Upper side

Ring Gear is

fitted correctly

Housing (Left side)

Wires are fitted inside

this harness

Wire harnesses

are set correctly

Boss is set in this slit

Boss is set in this slit

Battery terminal is set correctly

Set the Mandrel Plate into the groove of the

SA Housing (left side).

Set the Motor and Module Assembly, with the SA Planetary Carrier, in to the SA

Housing (left side).

Check the following pictures to ensure a clean fit inside the SA Housing.

25

Page 27

Collector Lock

Collector Shutter Lock Spring

SA Second Shaft

Gear Housing

SA Second shaft

Front Unit Assembly

Pipe Bridge

Set the Collector Shutter Lock Spring on the

Boss of the Collector Lock.

Insert the SA Second Shaft into the hole on the

Gear Housing for the Front Unit Assembly.

Fit the Front Unit Assembly with the SA Second

Shaft in to the SA Housing (left side).

Be careful on the position of the Pipe Bridge.

26

Page 28

Collector Lock with spring

Collector Lock with spring

SA Housing (right side)

Electric Screw Driver etc.

Tapping Screw (TP124-514, 3-20)

For Collector Lock

Fit the Collector Lock, with spring, on to the SA

Housing (left side).

Be careful that the Spring does not drop off.

Place the SA Housing (right side) over the SA

Housing (left side).

Be careful that the Spring does not drop off.

Tighten the Cross Recessed Tapping Screw

(TP124-514, 3-20) in to the position of the

Collector Lock by using a screw driver (electric

recommended).

Set Torque: 0.95Nm

27

Page 29

Places for Tapping Screw (TP124-513, 3-16)

Collector Shutter

Shutter Guide Sleeve

Collector Shutter

Shutter Guide Sleeve

Tighten the Cross Recessed Tapping Screws

(TP124-513 3-16) to the 14 places shown in

the adjacent picture by using a screw driver

(electric recommended).

Set Torque: 0.95Nm

Insert Shutter Guide Sleeve into the hole of the

Collector Shutter.

Be careful that the Shutter Guide Sleeve does

not take off the hole.

Set the Collector Shutter, with the Shutter

Guide Sleeve, on to the SA Housing.

Be careful that the Shutter Guide Sleeve does

not take off the hole.

28

Page 30

Tapping Screw (TP124-514, 3-20)

Electric Screw Driver etc.

Memo

Tighten the Cross Recessed Tapping Screw

(TP124-514, 3-20) by using a screw driver

(electric recommended).

Set Torque: 0.95Nm

29

Page 31

10. Jaws, Jaw Guide, Jaw Pusher and Jaw Pusher Spring

JAWS

NA

1 JAW GUIDE

TP142-628

1 SA JAW PUSHER, 8

TP143-683

1

JP, NA, XE, XD

SA JAW PUSHER, 8K

TP144-655

1

QW, GB

SA JAW PUSHER, 6

TRM00157

1

OPTION

JAW PUSHER SPRING

TP143-620

1

SA Jaw Pusher, 8

Jaws

Jaw Pusher Spring

Jaw Guide

SA Jaw Pusher,8K

SA Jaw Pusher, 6

Apply grease

Jaw Guide

Grease

BOM for Jaws, Jaw Guide, SA Jaw pusher and Jaw Pusher Spring

Apply grease to the inside of the Jaw Guide.

Grease recommended:

Molybdenum disulfide grease

30

Page 32

Jaw Guide

Jaws

Jaw Guide

Jaws

Jaw Pusher Spring

Pulling Head

Put the Jaws into the Jaw Guide (as shown) so

that the teeth are on the inside.

After inserting the Jaws, check that they are

set correctly.

Put the Jaw Pusher Spring into the Pulling

Head.

31

Page 33

Jaw Pusher Spring

SA Jaw Pusher

Jaw Guide

Jaw Case Lock

Pulling Head

Jaw Case Lock

Jaw Guide

Lock

Put the SA Jaw Pusher through the Jaw Pusher

Spring.

Tighten the Jaw Guide, with Jaws, to the

Pulling Head, with pulling Jaw Case Lock, by

hand until it stops.

Turn back a little until the rotation is locked by

the boss of the Jaw Case Lock.

32

Page 34

Battery

Set a battery on to the tool to check the

operation.

Check the tool operates correctly by pulling

and releasing the trigger .

Check for:

Pulling operation

Return operation

Reset operation

Full stroke → Stroke end clutch operation →

Return to home position→Front end clutch

operation

Remove the battery after checking.

33

Page 35

4. SA Nose Housing and SA Nose Piece

SA NOSE HOUSING

TP143-594

1

SA NOSE HOUSING

TP143-643

1 SA NOSEPIECE

Many

1

A type

SA NOSEPIECE

Many

1

B type

SCREW WRENCH

TP144-682

1

Accessory

SA Nosepiece A type

SA Nose Housing(TP143-594)

SA Nosepiece B type

SA Nose Housing(TP143-643)

SA Nosepiece A type

SA Nose Housing(TP143-594)

Screw Wrench

BOM for SA Nose Housing and SA Nosepiece

Special tool for Assembling

Insert the SA Nosepiece A type on to the SA

Nose Housing (TP143-594) and screw on by

hand.

34

Page 36

SA Nosepiece A type

SA Nose Housing(TP143-594)

Spanner 14mm

Spanner 23mm

SA Nosepiece B type

SA Nose Housing(TP143-643)

SA Nosepiece B type

SA Nose Housing(TP143-643)

Spanner 23mm

Spanner 27mm

Nose Hosuing Nut

Tighten up the SA Nosepiece A type securely

with spanners (see adjacent picture)

Width across flats: 14mm and 23mm

Insert the SA Nosepiece B type on to SA the

Nose Housing (TP143-643) and screw on by

hand.

Tighten up the SA Nosepiece B type securely

by using the Screw wrench provided in the kit

box and another spanner (see adjacent

picture).

Width across flats: 27mm and 23mm

Apply grease to the inside of Nose Housing Nut

(see adjacent picture).

35

Page 37

Apply grease

SA Nose Hosuing

Mast Hosuing

SA Nose Hosuing

Mast Hosuing

Insert the SA Nose Housing on to the Mast

Housing of the tool.

Tighten the SA Nose Housing on to the thread

of the Mast Housing by hand.

36

Page 38

11. Operation Test and Appearance check

Memo

Operation Check

Set 30 rivets of 8 size steel to check:

The tool does not slip

Rivet setting is done in one stroke

There is no protruding mandrels

There is no abnormal noise

The next rivet introduced to the front of the

tool is inserted smoothly.

The jaws do not bite

The waste mandrel is ejected to the

Collector

The collector shutter operates normally

(Open→Close)

Appearance check

Any scratches on the housings

Loose components and screws

Any oil spots on the housings

Peeling of the outer mold (Rubber grip)

37

Page 39

12 Labels

A(Serial label)

B C D

JP

TRM00128

TRM00132

TRM00133

TRM00133

QW, GB, XD

TRM00130

↑

↑

TP123-629

XE

TRM00131

↑

↑

TRM00133

NA

TRM00129

TRM00188

↑

TP123-629

Left side

Right side

A B C

D

Tool

Place the labels on to the tool correctly.

38

Page 40

JP

NA

QW

TRM00145

TRM00146

TRM00147

GB

XE

XD

TRM00148

TRM00149

TRM00150

Place the label here

Memo

Kit Box

Place the label on to the kit box correctly.

39

Page 41

13. Accessories

Model number

PB3400-JP1831

PB3400-JP1832

BATTERY PACK

DCB183-JP(1PC)

←(2PCS)

CHARGER

DCB105-JP

or DCB115-JP

←

SA NOSEPIECE, 8F

TP143-646

←

SA NOSEPIECE, 8P

TRM00115

←

SA NOSE HOUSING

TP143-643

←

SCREW WRENCH

TP144-682

←

FOAM SPACER

TRM00194(1PC)

←(2PC)

INSTRUCTION MANUAL

PB3400-JP

MANUAL

←

BRIEF INSTRUCTION MANUAL

PB3400-JP

S-MANUAL

←

Model number

PB3400-NA2031

PB3400-NA2032

PB3400-NA2041

PB3400-NA2042

BATTERY PACK

DCB203-NA(1PC)

←(2PCS)

DCB204-NA(1PC)

←(2PC)

CHARGER

DCB115-NA

← ← ←

SA NOSEPIECE, 8M

TP143-652

← ← ←

SCREW WRENCH

TP144-682

← ← ←

FOAM SPACER

TRM00194(1PC)

←(2PC)

NA

NA

INSTRUCTION MANUAL

TRM00203

← ← ←

Model number

PB3400-QW1831

PB3400-QW1832

PB3400-QW1821

PB3400-QW1822

BATTERY PACK

DCB183-QW(1PC)

←(2PCS)

DCB182-QW(1PC)

←(2PC)

CHARGER

DCB105-QW

or DCB115-QW

← ← ←

SCREW WRENCH

TP144-682

← ← ←

FOAM SPACER

TRM00194(1PC)

←(2PC)

NA

NA

INSTRUCTION MANUAL

TRM00201

← ← ←

JP (JAPAN)

NA (NORTH AMERICA)

QW (EUROPEAN STANDARD)

40

Page 42

QW (EASTERN EUROPE)

Model number

PB3400-QW1831A

PB3400-QW1832A

PB3400-QW1821A

PB3400-QW1822A

BATTERY PACK

DCB183-QW(1PC)

←(2PCS)

DCB182-QW(1PC)

←(2PC)

CHARGER

DCB105-QW

or DCB115-QW

← ← ←

SCREW WRENCH

TP144-682

← ← ←

FOAM SPACER

TRM00194(1PC)

←(2PC)

NA

NA

INSTRUCTION MANUAL

TRM00202

← ← ←

Model number

PB3400-GB1831

PB3400-GB1832

PB3400-GB1821

PB3400-GB1822

BATTERY PACK

DCB183-QW(1PC)

←(2PCS)

DCB182-QW(1PC)

←(2PC)

CHARGER

DCB105-GB

or DCB115-GB

← ← ←

SCREW WRENCH

TP144-682

← ← ←

FOAM SPACER

TRM00194(1PC)

←(2PC)

NA

NA

INSTRUCTION MANUAL

TRM00201

← ← ←

Model number

PB3400-XE1832

PB3400-XE1822

BATTERY PACK

DCB183-QW(2PC)

DCB182-QW(2PCS)

CHARGER

DCB105-GB

or DCB115-GB

←

SCREW WRENCH

TP144-682

←

FOAM SPACER

TRM00194(2PC)

NA

INSTRUCTION MANUAL

TRM00204

←

Model number

PB3400-XD1832

PB3400-XD1822

BATTERY PACK

DCB183-QW(2PC)

DCB182-QW(2PCS)

CHARGER

DCB105-XD

or DCB115-XD

←

SCREW WRENCH

TP144-682

←

FOAM SPACER

TRM00194(2PC)

NA

INSTRUCTION MANUAL

TRM00204

←

GB (GREAT BRITAIN)

XE (AUSTRALIA)

XD (MALAYSIA)

41

Page 43

14. Exploded View

61

21

1

11

72

25

29

37

40

28

27

26

25

24

22

20

19

17

18

15

33

30

32

31

38

39

36

35

42

40

41 41

42

41

41

41

41

41

14

13

12

10

9

62

4

3

2

23

PB3400

59

67

66

71

70

68

69

65

63

64

60

42

Page 44

15. BOM

*

TP144-593 SA Nosepiece, 811 1

*

2

DPN900-074 O ring 1

*

**

DCB183-JP Battery Pack 2.0Ah 1 or 2

*

3 TP143-642 Nosepiece, 811 1 DCB105-JP Charger 1

*

4 TP144-645 Pin 1

TP142-633 Kit Box 1

TP143-594 SA Nose Housing 1 TP143-643 SA Nose Housing 1

*

DPN276-001 Jaw Guide 1

*

TP143-646 SA Nosepiece, 8F 1

*

PRG540-44 Jaws 1set

*

TRM00115 SA Mosepiece, 8P 1

*

TP144-595 SA Jaw Pusher, 8 1 TP144-682 Screw Wrench 1

*

12 TP144-596 Jaw pusher, 8 1

*

13

TP144-597 O ring 1

*

TP144-600 Jaw Pusher Spring 1

*

TP144-602 O ring 1

TP143-601 Pulling Head Assembly 1

TP143-611 Spindle Clutch 1

* TP143-648

SA Nosepiece, 6F 1

TP144-676 Spindle Clutch Spring 1

*

TP143-650 SA Nosepiece, 6M 1

*

TP144-659 Tail Guid, 8 1

*

TRM00119 SA Nosepiece, 6P 1

TP143-612 Gear Housing Assembly 1

*

TP143-652 SA Nosepiece, 8M 1

22 TP143-654 Spindle 1

*

TP143-665 SA Nosepiece, 8AVXT 1

23 TP144-661 Thrust Washer 1

*

TRM00157 Jaw Pusher Assembly, 6 1

24

TP144-613 Thrust Roller Bearing 1

*

TP144-647 Tail Guide, 6,8K 1

25

TP144-614 Thrust Race 1

*

TP124-542 SA Nosepiece, 614 1

26 TP143-615 SA Gear Housing 1

*

TP124-543 SA Nosepiece, 6K 1

27 TP143-618 Spur Gear 1

*

TP124-546 SA Nosepiece, 624 1

28

TP144-619 Snap Ring 1

*

TP144-657 SA Nosepiece, 8K 1

TP143-620 SA Second Shaft 1

* TP144-640

SA Nosepiece, 822 1

TP143-625 SA Planetary Carrier 1

*

TP144-655 SA Jaw Pusher, 8K 1

N112877 Ring Gear 1

*

DCB182-JP Battery Pack 4.0Ah 1

TP124-511 O ring 1

PNT600-132 Hook 1

TP152-519 SA Motor and Module 1

TP134-500 Belt Hook Kit 1

*

TP144-681 Mandrel Plate 1

TP114-676 Shutter Guide Sleeve 1

TP114-677 Collector Shutter Lock Spring 1

TP124-532 Collector Lock 1

*

TP143-627 Collector Shutter 1

TP142-684 Housing Assembly 1

TP124-513

Cross Recessed Pan Head Tapping Screw(3-16)

14

TP124-514

Cross Recessed Pan Head Tapping Screw(3-20)

2

42

414039

38917

29

30

37

10

PB3400-JP

S-MANUAL

PB3400-JP

MANUAL

Brief Manual

Instruction Manual

56411

15

Description

Qty

1

Accessories

14

60

No.

Description

Qty

No.

68

1

1

61

●

59

67●64

652131

20

Option

631819

696670353633327172

*Consumable

**PB3400-JP1831 1pc 2.0Ah Battery

**PB3400-JP1832 2pcs 2.0Ah Battery

PB3400-JP

43

Page 45

PB3400-NA

*

DPN276-001 Jaw Guide 1

*

PRG540-44 Jaws 1set

*

**

DCB203-NA Battery Pack 2.0Ah 1 or 2

*

TP144-595 SA Jaw Pusher, 8 1 DCB115-NA Charger 1

*

12 TP144-596 Jaw pusher, 8 1

TRM00140 SA Kit Box 1

*

13

TP144-597 O ring 1

*

TP143-652 SA Nosepiece, 8M 1

*

TP144-600 Jaw Pusher Spring 1 TP144-682 Screw Wrench 1

*

TP144-602 O ring 1

*

**

DCB204-NA Battery Pack 4.0Ah 1 or 2

TP143-601 Pulling Head Assembly 1

TRM00203 Instruction Manual 1

TP143-611 Spindle Clutch 1

TP144-676 Spindle Clutch Spring 1

*

TP144-593 SA Nosepiece, 811 1

*

TP144-659 Tail Guid, 8 1

TP143-594 SA Nose Housing 1

TP143-612 Gear Housing Assembly 1

* TP143-648

SA Nosepiece, 6F 1

22 TP143-654 Spindle 1

*

TP143-650 SA Nosepiece, 6M 1

23 TP144-661 Thrust Washer 1

*

TRM00119 SA Nosepiece, 6P 1

24

TP144-613 Thrust Roller Bearing 1

*

TRM00115 SA Nosepiece, 8P 1

25

TP144-614 Thrust Race 1

*

TP143-665 SA Nosepiece, 8AVXT 1

26 TP143-615 SA Gear Housing 1

*

TRM00157 Jaw Pusher Assembly, 6 1

27 TP143-618 Spur Gear 1

*

TP144-647 Tail Guide, 6,8K 1

28

TP144-619 Snap Ring 1

*

TP124-542 SA Nosepiece, 614 1

TP143-620 SA Second Shaft 1

*

TP124-543 SA Nosepiece, 6K 1

TP143-625 SA Planetary Carrier 1

*

TP124-546 SA Nosepiece, 624 1

N112877 Ring Gear 1

*

TP144-657 SA Nosepiece, 8K 1

TP124-511 O ring 1

* TP144-640

SA Nosepiece, 822 1

TP152-519 SA Motor and Module 1

*

TP144-655 SA Jaw Pusher, 8K 1

*

TP144-681 Mandrel Plate 1

PNT600-132 Hook 1

TP114-676 Shutter Guide Sleeve 1 TP134-500 Belt Hook Kit 1

TP114-677 Collector Shutter Lock Spring 1

TP124-532 Collector Lock 1

*

TP143-627 Collector Shutter 1

TRM00158 Housing As sembly 1

TP124-513

Cross Recessed Pan Head Tapping Screw(3-16)

14

TP124-514

Cross Recessed Pan Head Tapping Screw(3-20)

2

TP143-643 SA Nose Housing 1

*

TP143-646 SA Nosepiece, 8F 1

*

2

DPN900-074 O ring 1

*

- TP143-644 Nosepiece, 8F 1

*

4 TP144-645 Pin 1

40

414264

64

●

*Consumable

**PB3400-NA2031 1pc 2.0Ah Battery

**PB3400-NA2032 2pcs 2.0Ah Battery

**PB3400-NA2041 1pc 4.0Ah Battery

**PB3400-NA2042 2pcs 4.0Ah Battery

35

36

3738393170

3271337265

66

67

29

30

68

17

Option

18641920211415

9

10

11691

Accessories

59

60

61563

No.

Description

Qty

No.

Description

Qty

44

Page 46

PB3400-QW

*

DPN276-001 Jaw Guide 1

*

PRG540-44 Jaws 1set

*

**

DCB183-XJ Battery Pack 2.0Ah 1 or 2

*

TP144-655 SA Jaw Pusher, 8K 1

DCB105-QW/D CB115-QW

Charger 1

*

12 TP144-656 Jaw pusher, 8K 1

TRM00141 SA Kit Box 1

*

13

TP144-597 O ring 1 TP144-682 Screw Wrench 1

*

TP144-600 Jaw Pusher Spring 1

*

**

DCB182-XJ Battery Pack 4.0Ah 1 or 2

*

TP144-602 O ring 1

TP143-601 Pulling Head Assembly 1

TP143-611 Spindle Clutch 1

TP144-676 Spindle Clutch Spring 1

*

TP144-593 SA Nosepiece, 811 1

*

TP144-647 Tail Guid, 6,8K 1

TP143-594 SA Nose Housing 1

TP143-612 Gear Housing Assembly 1

* TP143-648

SA Nosepiece, 6F 1

22 TP143-654 Spindle 1

*

TP143-650 SA Nosepiece, 6M 1

23 TP144-661 Thrust Washer 1

*

TRM00119 SA Nosepiece, 6P 1

24

TP144-613 Thrust Roller Bearing 1

*

TP143-652 SA Nosepiece, 8M 1

25

TP144-614 Thrust Race 1

*

TRM00115 SA Nosepiece, 8P 1

26 TP143-615 SA Gear Housing 1

*

TP143-665 SA Nosepiece, 8AVXT 1

27 TP143-618 Spur Gear 1

*

TRM00157 Jaw Pusher Assembly, 6 1

28

TP144-619 Snap Ring 1

*

TP144-659 Tail Guide, 8 1

TP143-620 SA Second Shaft 1

*

TP124-542 SA Nosepiece, 614 1

TP143-625 SA Planetary Carrier 1

*

TP124-543 SA Nosepiece, 6K 1

N112877 Ring Gear 1

*

TP124-546 SA Nosepiece, 624 1

TP124-511 O ring 1

*

TP144-657 SA Nosepiece, 8K 1

TP152-519 SA Motor and Module 1

* TP144-640

SA Nosepiece, 822 1

*

TP144-681 Mandrel Plate 1

*

TP144-595 SA Jaw Pusher, 8 1

TP114-676 Shutter Guide Sleeve 1 PNT600-132 Hook 1

TP114-677 Collector Shutter Lock Spring 1 TP134-500 Belt Hook Kit 1

TP124-532 Collector Lock 1

*

TP143-627 Collector Shutter 1

TRM00159 Housing As sembly 1

TP124-513

Cross Recessed Pan Head Tapping Screw(3-16)

14

TP124-514

Cross Recessed Pan Head Tapping Screw(3-20)

2

TP143-643 SA Nose Housing 1

*

TP143-646 SA Nosepiece, 8F 1

*

2

DPN900-074 O ring 1

*

- TP143-644 Nosepiece, 8F 1

*

4 TP144-645 Pin 1

40

414263

64

*Consumable

**PB3400-QW1831 1pc 2.0Ah Battery

**PB3400-QW1832 2pcs 2.0Ah Battery

**PB3400-QW1821 1pc 4.0Ah Battery

**PB3400-QW1822 2pcs 4.0Ah Battery

**PB3400-QW1831A 1pc 2.0Ah Battery

**PB3400-QW1832A 2pcs 2.0Ah Battery

**PB3400-QW1821A 1pc 4.0Ah Battery

**PB3400-QW1822A 2pcs 4.0Ah Battery

***TRM00201 for EU Standard, TRM00202 for Eastern Europe

3768387139

723066

316732

33

35

36

20215

29

656417

18

Option

19

1

TRM00201

OR TRM00202

●

Instruction Manual

1

611469

15

70

***

9

Accessories

10

59

11

60

No.

Description

Qty

No.

Description

Qty

45

Page 47

PB3400-GB

*

DPN276-001 Jaw Guide 1

*

PRG540-44 Jaws 1set

*

**

DCB183-XJ Battery Pack 2.0Ah 1 or 2

*

TP144-655 SA Jaw Pusher, 8K 1

DCB105-GB/DCB11 5-GB

Charger 1

*

12 TP144-656 Jaw pusher, 8K 1

TRM00142 SA Kit Box 1

*

13

TP144-597 O ring 1 TP144-682 Screw Wrench 1

*

TP144-600 Jaw Pusher Spring 1

*

**

DCB182-XJ Battery Pack 4.0Ah 1 or 2

*

TP144-602 O ring 1 TRM00201 Instruction Manual 1

TP143-601 Pulling Head Assembly 1

TP143-611 Spindle Clutch 1

*

TP144-593 SA Nosepiece, 811 1

TP144-676 Spindle Clutch Spring 1

TP143-594 SA Nose Housing 1

*

TP144-647 Tail Guid, 6,8K 1

* TP143-648

SA Nosepiece, 6F 1

TP143-612 Gear Housing Assembly 1

*

TP143-650 SA Nosepiece, 6M 1

22 TP143-654 Spindle 1

*

TRM00119 SA Nosepiece, 6P 1

23 TP144-661 Thrust Washer 1

*

TP143-652 SA Nosepiece, 8M 1

24

TP144-613 Thrust Roller Bearing 1

*

TRM00115 SA Nosepiece, 8P 1

25

TP144-614 Thrust Race 1

*

TP143-665 SA Nosepiece, 8AVXT 1

26 TP143-615 SA Gear Housing 1

*

TRM00157 Jaw Pusher Assembly, 6 1

27 TP143-618 Spur Gear 1

*

TP144-659 Tail Guide, 8 1

28

TP144-619 Snap Ring 1

*

TP124-542 SA Nosepiece, 614 1

TP143-620 SA Second Shaft 1

*

TP124-543 SA Nosepiece, 6K 1

TP143-625 SA Planetary Carrier 1

*

TP124-546 SA Nosepiece, 624 1

N112877 Ring Gear 1

*

TP144-657 SA Nosepiece, 8K 1

TP124-511 O ring 1

* TP144-640

SA Nosepiece, 822 1

TP152-519 SA Motor and Module 1

*

TP144-595 SA Jaw Pusher, 8 1

*

TP144-681 Mandrel Plate 1

PNT600-132 Hook 1

TP114-676 Shutter Guide Sleeve 1 TP134-500 Belt Hook Kit 1

TP114-677 Collector Shutter Lock Spring 1

TP124-532 Collector Lock 1

*

TP143-627 Collector Shutter 1

TRM00159 Housing As sembly 1

TP124-513

Cross Recessed Pan Head Tapping Screw(3-16)

14

TP124-514

Cross Recessed Pan Head Tapping Screw(3-20)

2

TP143-643 SA Nose Housing 1

*

TP143-646 SA Nosepiece, 8F 1

*

2

DPN900-074 O ring 1

*

- TP143-644 Nosepiece, 8F 1

*

4 TP144-645 Pin 1

38

*Consumable

**PB3400-GB1831 1pc 2.0Ah Battery

**PB3400-GB1832 2pcs 2.0Ah Battery

**PB3400-GB1821 1pc 4.0Ah Battery

**PB3400-GB1822 2pcs 4.0Ah Battery

3940414263

643568

36

71

377265

66

29

67

30

313233191205

216417

18

Option

●

61

69

14

70159

Accessories

10

59

11

60

No.

Description

Qty

No.

Description

Qty

46

Page 48

PB3400-XE

*

DPN276-001 Jaw Guide 1

*

PRG540-44 Jaws 1set

*

**

DCB183-XE Battery Pack 2.0Ah 1 or 2

*

TP144-595 SA Jaw Pusher, 8 1 DCB115-XE Charger 1

*

12 TP144-596 Jaw pusher, 8 1

TRM00141 SA Kit Box 1

*

13

TP144-597 O ring 1 TP144-682 Screw Wrench 1

*

TP144-600 Jaw Pusher Spring 1

*

**

DCB182-XE Battery Pack 4.0Ah 1 or 2

*

TP144-602 O ring 1 TRM00204 Instruction Manual 1

TP143-601 Pulling Head Assembly 1

TP143-611 Spindle Clutch 1

*

TP144-593 SA Nosepiece, 811 1

TP144-676 Spindle Clutch Spring 1

TP143-594 SA Nose Housing 1

*

TP144-659 Tail Guid, 8 1

* TP143-648

SA Nosepiece, 6F 1

TP143-612 Gear Housing Assembly 1

*

TP143-650 SA Nosepiece, 6M 1

22 TP143-654 Spindle 1

*

TRM00119 SA Nosepiece, 6P 1

23 TP144-661 Thrust Washer 1

*

TP143-652 SA Nosepiece, 8M 1

24

TP144-613 Thrust Roller Bearing 1

*

TRM00115 SA Nosepiece, 8P 1

25

TP144-614 Thrust Race 1

*

TP143-665 SA Nosepiece, 8AVXT 1

26 TP143-615 SA Gear Housing 1

*

TRM00157 Jaw Pusher Assembly, 6 1

27 TP143-618 Spur Gear 1

*

TP144-647 Tail Guide, 6,8K 1

28

TP144-619 Snap Ring 1

*

TP124-542 SA Nosepiece, 614 1

TP143-620 SA Second Shaft 1

*

TP124-543 SA Nosepiece, 6K 1

TP143-625 SA Planetary Carrier 1

*

TP124-546 SA Nosepiece, 624 1

N112877 Ring Gear 1

*

TP144-657 SA Nosepiece, 8K 1

TP124-511 O ring 1

* TP144-640

SA Nosepiece, 822 1

TP152-519 SA Motor and Module 1

*

TP144-655 SA Jaw Pusher, 8K 1

*

TP144-681 Mandrel Plate 1

PNT600-132 Hook 1

TP114-676 Shutter Guide Sleeve 1 TP134-500 Belt Hook Kit 1

TP114-677 Collector Shutter Lock Spring 1

TP124-532 Collector Lock 1

*

TP143-627 Collector Shutter 1

TRM00160 Housing Assembly 1

TP124-513

Cross Recessed Pan Head Tapping Screw(3-16)

14

TP124-514

Cross Recessed Pan Head Tapping Screw(3-20)

2

TP143-643 SA Nose Housing 1

*

TP143-646 SA Nosepiece, 8F 1

*

2

DPN900-074 O ring 1

*

- TP143-644 Nosepiece, 8F 1

*

4 TP144-645 Pin 1

37

*Consumable

**PB3400-XE1832 2pcs 2.0Ah Battery

**PB3400-XE1822 2pc 4.0Ah Battery

38

39404142636433

68

35

71

367220

64

216566

67

29

30

313217

Option

18119561

69

14

70

15

●

9

Accessories

10

59

11

60

No.

Description

Qty

No.

Description

Qty

47

Page 49

PB3400-XD

*

DPN276-001 Jaw Guide 1

*

PRG540-44 Jaws 1set

*

**

DCB183-XJ Battery Pack 2.0Ah 1 or 2

*

TP144-595 SA Jaw Pusher, 8 1 DCB115-XD Charger 1

*

12 TP144-596 Jaw pusher, 8 1

TRM00141 SA Kit Box 1

*

13

TP144-597 O ring 1 TP144-682 Screw Wrench 1

*

TP144-600 Jaw Pusher Spring 1

*

**

DCB182-XJ Battery Pack 4.0Ah 1 or 2

*

TP144-602 O ring 1 TRM00204 Instruction Manual 1

TP143-601 Pulling Head Assembly 1

TP143-611 Spindle Clutch 1

*

TP144-593 SA Nosepiece, 811 1

TP144-676 Spindle Clutch Spring 1

TP143-594 SA Nose Housing 1

*

TP144-659 Tail Guid, 8 1

* TP143-648

SA Nosepiece, 6F 1

TP143-612 Gear Housing Assembly 1

*

TP143-650 SA Nosepiece, 6M 1

22 TP143-654 Spindle 1

*

TRM00119 SA Nosepiece, 6P 1

23 TP144-661 Thrust Washer 1

*

TP143-652 SA Nosepiece, 8M 1

24

TP144-613 Thrust Roller Bearing 1

*

TRM00115 SA Nosepiece, 8P 1

25

TP144-614 Thrust Race 1

*

TP143-665 SA Nosepiece, 8AVXT 1

26 TP143-615 SA Gear Housing 1

*

TRM00157 Jaw Pusher Assembly, 6 1

27 TP143-618 Spur Gear 1

*

TP144-647 Tail Guide, 6,8K 1

28

TP144-619 Snap Ring 1

*

TP124-542 SA Nosepiece, 614 1

TP143-620 SA Second Shaft 1

*

TP124-543 SA Nosepiece, 6K 1

TP143-625 SA Planetary Carrier 1

*

TP124-546 SA Nosepiece, 624 1

N112877 Ring Gear 1

*

TP144-657 SA Nosepiece, 8K 1

TP124-511 O ring 1

* TP144-640

SA Nosepiece, 822 1

TP152-519 SA Motor and Module 1

*

TP144-655 SA Jaw Pusher, 8K 1

*

TP144-681 Mandrel Plate 1

PNT600-132 Hook 1

TP114-676 Shutter Guide Sleeve 1 TP134-500 Belt Hook Kit 1

TP114-677 Collector Shutter Lock Spring 1

TP124-532 Collector Lock 1

*

TP143-627 Collector Shutter 1

TRM00159 Housing As sembly 1

TP124-513

Cross Recessed Pan Head Tapping Screw(3-16)

14

TP124-514

Cross Recessed Pan Head Tapping Screw(3-20)

2

TP143-643 SA Nose Housing 1

*

TP143-646 SA Nosepiece, 8F 1

*

2

DPN900-074 O ring 1

*

- TP143-644 Nosepiece, 8F 1

*

4 TP144-645 Pin 1

37

*Consumable

**PB3400-XD1832 2pcs 2.0Ah Battery

**PB3400-XD1822 2pc 4.0Ah Battery

38

39404142636433

68

35

71

367220

64

216566

67

29

30

313217

Option

18119561

69

14

70

15

●

9

Accessories

10

59

11

60

No.

Description

Qty

No.

Description

Qty

48

Page 50

16. Troubleshooting Guide

Symptom

Cause

Remedy

Tool does not operate when switch

is pressed.

Battery is defective

Replace battery

Battery is not fully charged

Charge battery

Battery is not fully seated

Remove battery and re-insert. Reset

tool to home.

Battery pack has reached operating

temperature limit through

continuous use or defect.

Remove battery & allow to cool.

Mount battery and reset tool to

home.

Tool does not return to initial

position when switch is released.

Electrical malfunction.

Remove battery, wait 5 seconds and

reinsert. Reset tool to home.

Stuck Spindle Clutch.

Clean Spindle clutch and Spindle to

operate smoothly.

Tool stops before rivet is fully set

Battery pack has reached operating

temperature limit through

continuous use or defect.

Remove battery & allow to cool.

Mount battery and reset tool to

home.

Improper nosepiece selection.

Reset tool to home, remove rivet &

fit proper nose piece.

Setting load of rivet is beyond tool

capacity.

Reset tool to home, remove rivet &

use appropriate tool to set rivet.

Tool fails to operate

Issue with Trigger Module

Replace.

Tool does not return fully

Buildup of debris inside the Nose

Equipment.

Service and clean Nose Assembly.

More than one operation of the

trigger needed to place rivet

Buildup of debris inside the Nose

Equipment.

Service and clean Nose Assembly.

Worn or broken Jaws.

Fit new Jaws.

Improper rivet being used for

application grip thickness

Review application details and verify

fastener requirement

Jaw Guide or Pulling Head Adapter

not seated correctly.

Correctly assemble affected parts

Tool will not grip stem of rivet

Buildup of debris inside the Nose

Equipment.

Service and clean Nose Assembly.

Worn or broken Jaws.

Fit new Jaws.

Loose Jaw Guide.

Tighten jaw guide against Pulling

Head.

Week or broken Spring.

Fit new spring.

Incorrect Nose Piece for rivet.

Refer to Accessories Manual. Select

and install correct nose piece

Incorrect Nose Equipment for rivet.

Refer to Accessories Manual. Select

and install correct nose equipment

Jaws will not release broken stem of

rivet

Buildup of debris inside the Nose

Equipment.

Service and clean Nose Assembly.

Week or broken Spring.

Fit new spring.

Jaw Guide, Nose Piece or Nose

Housing not seated correctly.

Correctly assemble affected parts

Stem retention/removal feature worn

out on Nose Piece

Inspect Nose Piece and replace O-ring

and ball/pin as required

49

Page 51

Cannot insert rivet

Incorrect Nose Piece for rivet.

Refer to Accessories Manual. Select

and install correct nose piece

Broken rivet stems jammed in Nose

Equipment.

Service and clean Nose Assembly.

Refer to Accessories Manual.

Check Nose Equipment is correct for

rivet

Broken rivet stems jammed in Pulling

Head Assembly.

Empty Stem Collector and clear

Pulling Head Assembly.

Debris in Nose Piece.

Service and clean Nose Assembly.

Rivet stem does not break

Battery is low voltage.

Charge battery

Setting load of rivet is beyond tool

capacity.

Reset tool to home, remove rivet &

use appropriate tool to set rivet.

Incorrect Nose Equipment for rivet.

Refer to Accessories Manual. Select

and install correct nose equipment

Nose Equipment and Stem Collector

full of stems.

Empty Stem Collector and check Nose

Equipment for damage before re-use

Rev

Description

Date

0

Released

1-Nov-2016

1

Added Troubleshooting Guide

7-Nov-2016

2

Re-pharsed sentences and descriptions

22-Nov-2016

Revison History

50

Page 52

51

Loading...

Loading...