Page 1

Contents:

Page2

Page3

Page5

Page6

Page8

Page9

Page10

Page14

Page15

Page16

Page17

Page18

FactoryOriginalParts

PackageContents/ComponentIdentification

MissingPartsRequestForm

Warnings

Preparation& Assembly-Model1450S,1450S-CAN,

P1600S,P1600S-BB,P1600S-CAN

Preparation& Assembly-Model1750S,1750S-CAN

P1800S,P1800S-BB,P1800S-CAN

Maintenance

Tipsfor Cleaning

Troubleshooting

Warranty

ExtendedWarranty& ProductRegistrationCard

®

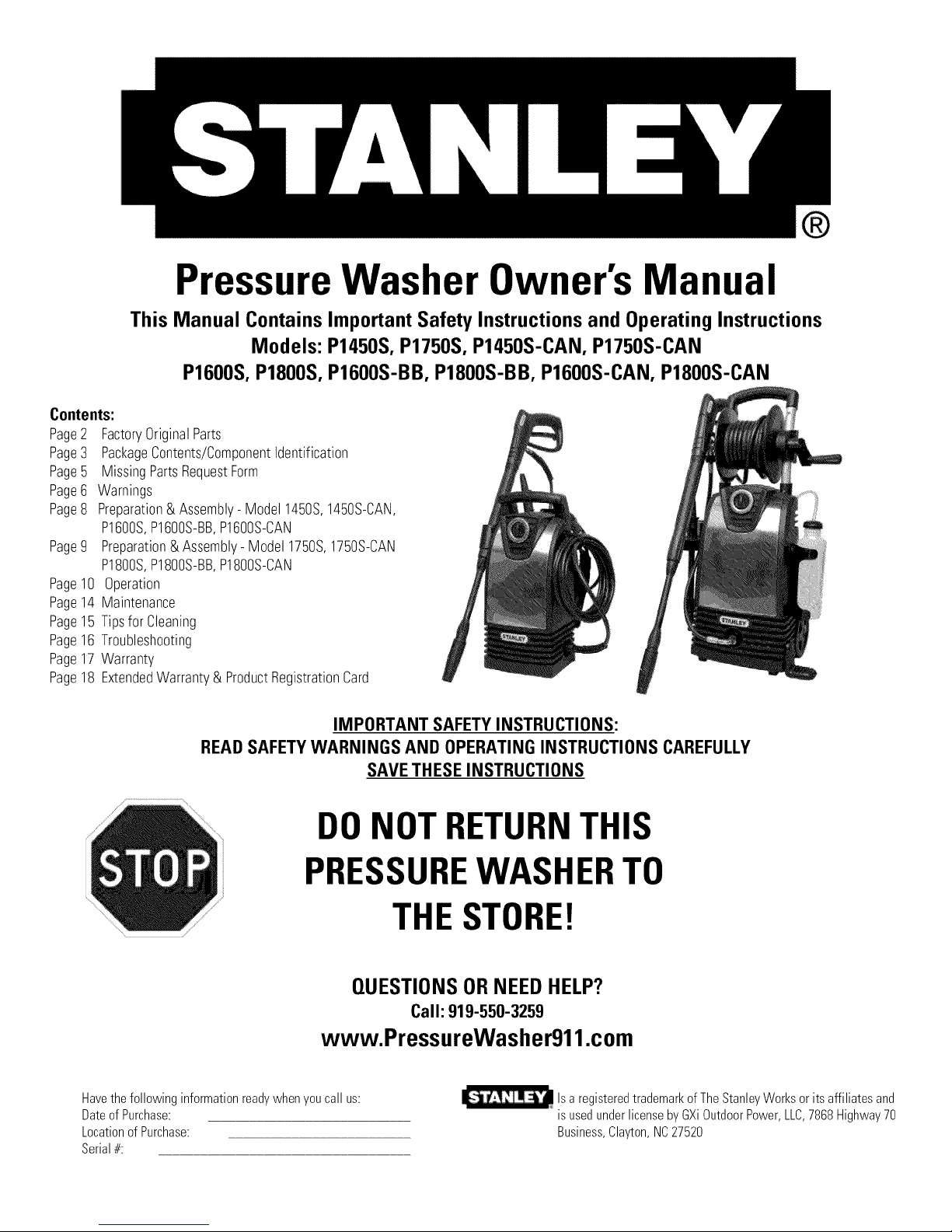

Pressure Washer Owner's Manual

This Manual ContainsImportantSafety Instructionsand Operating Instructions

Models: P1450S,P1750S,P1450S-CAN,P1750S-CAN

P1600S,P1800S,P1600S-BB,P1800S-BB, P1600S-CAN,P1800S-CAN

Operation

IMPORTANT SAFETYINSTRUCTIONS:

READSAFETYWARNINGS AND OPERATING INSTRUCTIONS CAREFULLY

DONOTRETURNTHIS

PRESSUREWASHERTO

www. PressureWasher911.com

Havethefollowinginformationreadywhenyoucallus:

DateofPurchase:

LocationofPurchase:

Serial#:

SAVETHESE INSTRUCTIONS

THESTORE!

QUESTIONSORNEEDHELP?

Call: 919-550-3259

Is a registeredtrademarkof TheStanleyWorks orits affiliates and

is usedunderlicensebyGXiOutdoorPower,LLC,7868Highway70

Business,Clayton,NC27520

Page 2

ORDERONLINE NOW AND SAVE!

www.PressureWasher911.com

Phone orders, call [1] 919-550-3259

Please havethe part number and credit card readywhen calling.

ReplacementGun

PartNumber:SP01009

PhonePrice:$30.00

Web Price: $27.90

ReplacementAdjustableWand

PartNumber:SP00209(ModelP1450S,1450S-CAN,

P1600S,P1600S-BB,P1600S-CAN)

PartNumber:SP00309(ModelP1750S,1750S-CAN,

P1800S,P1800S-BB,P1800S-CAN)

PhonePrice: $30.00

Web Price: $27.90

RotaryBrush StraightBrush

ReplacementTurboWand

PartNumber:SP00409

PhonePrice:$30.00

Web Price: $27.90

ReplacementHighPressureHose

PartNumber:SP00509(ModelP1450S,1750S,P1450S-

CAN,1750S-CAN,P1600S,P1600S-BB,

P1600S-CAN,P1800S,P1800S-BB,

P1800S-CAN)

PhonePrice: $30.00

Web Price: $27.90

ReplacementRotaryandStraightBrush

PartNumber:SP00709(RotaryBrush)

PartNumber:SP00809(StraightBrush)

PhonePrice:$30.00Each

Web Price: $27.90Each

Page 3

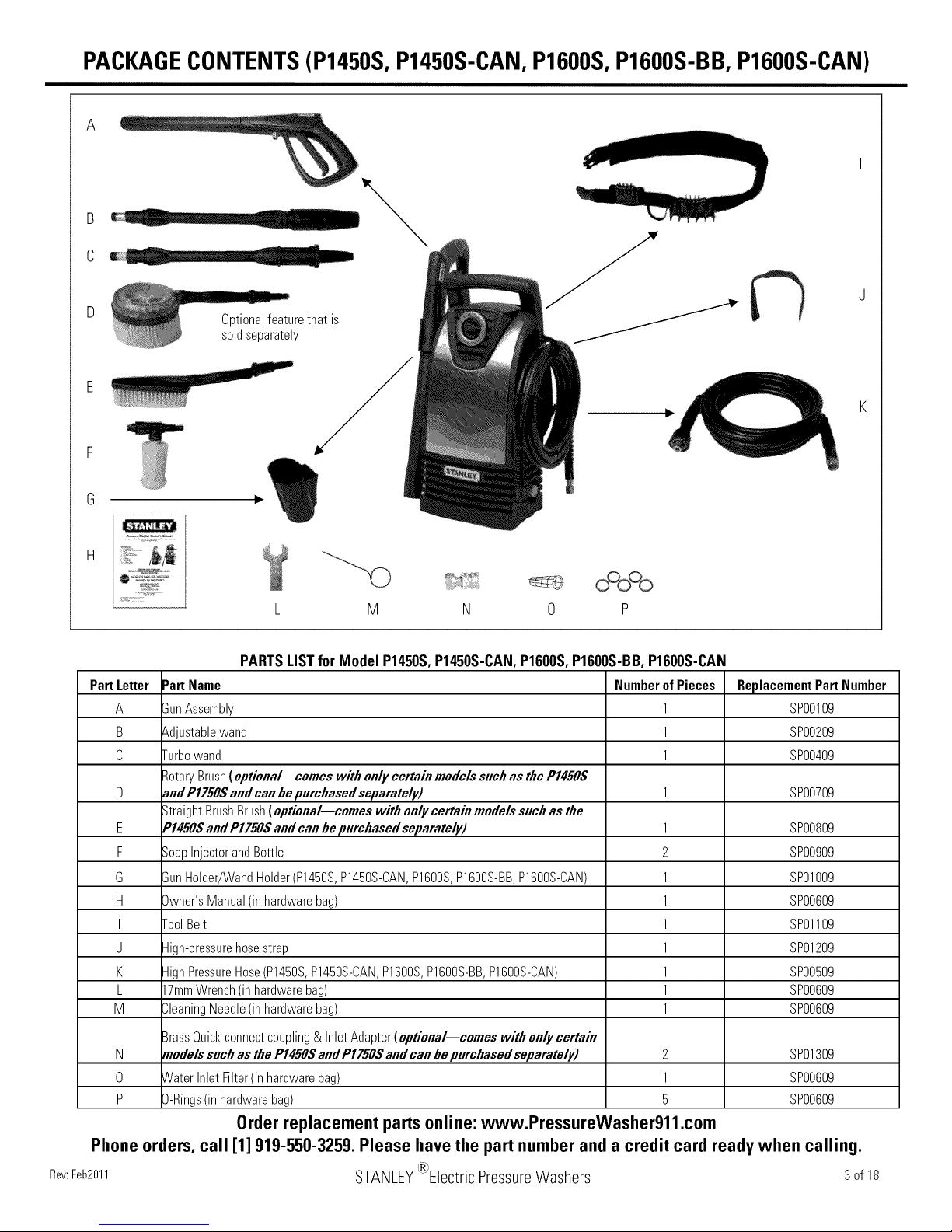

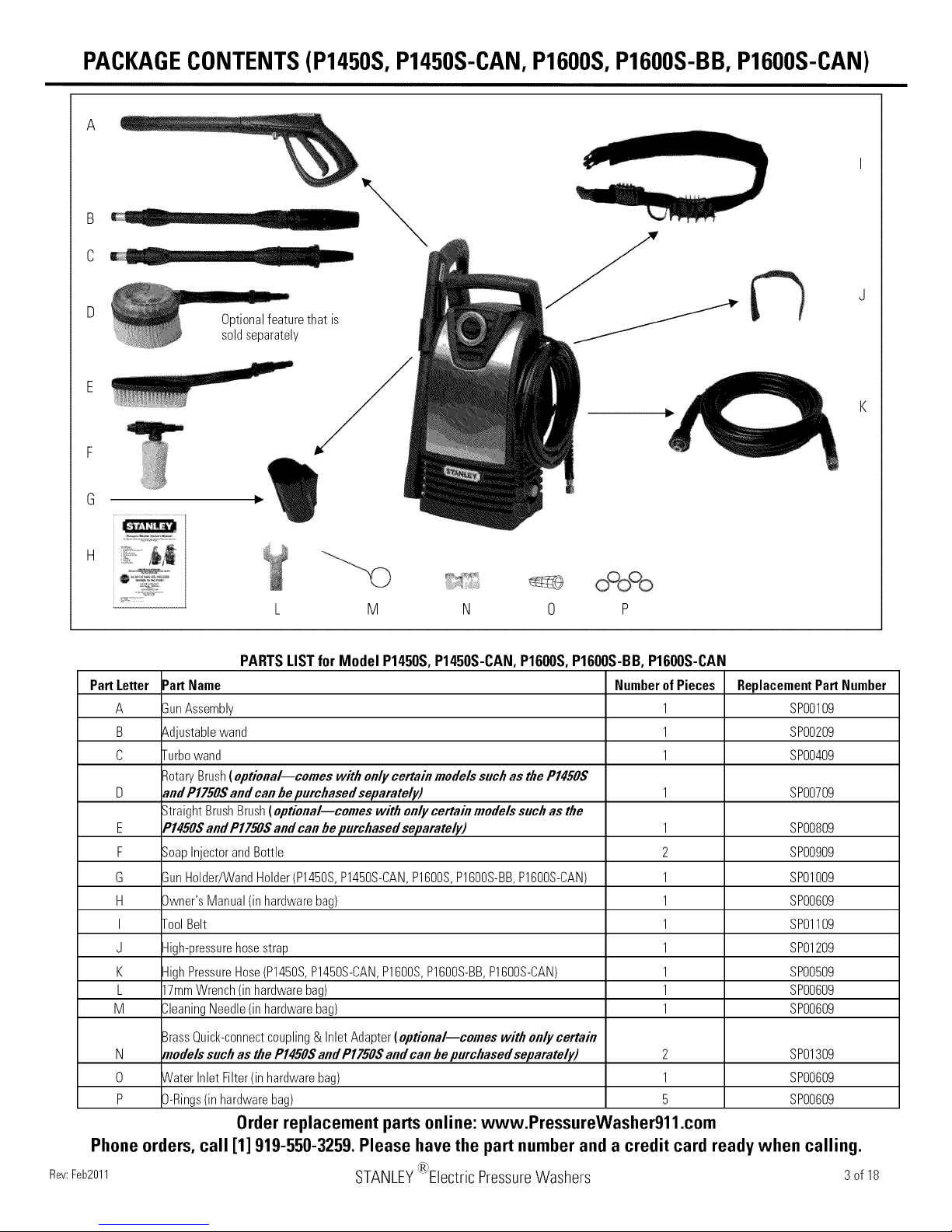

PACKAGECONTENTS(P1450S,P1450S-CAN,P1600S,P1600S-BB,P1600S-CAN)

B

C

PartLetter _art Name NumberofPieces ReplacementPart Number

A 3unAssembly 1 SP00109

B _,djustablewand 1 SP00209

C Furbowand 1 SP00409

D _ndP1750Sandcanhe purchasedseparately) 1 SP00709

E PI450SandP1750Sandcanhe purchasedseparately) 1 SP00809

F _oapInjectorandBottle 2 SP00909

G 3unHolder/WandHolder(P1450S,P1450S-CAN,P1600S,P1600S-BB,P1600S-CAN) 1 SP01O09

H }wner's Manual(inhardwarebag) 1 SP00609

I FoolBelt 1 SP01109

J SP01209

K SP00509

L SP00609

M SP00609

i i [

Optionalfeaturethat is

soldseparately

I,

PARTS LIST for Model P1450S, P1450S-CAN, P1600S, P1600S-BB, P1600S-CAN

_otaryBrush(optional--comes with only certain modelssuch as the PI450S

;traightBrushBrush(optional--comes with only certainmodelssuchas the

4igh-pressurehosestrap 1

4ighPressureHose(P1450S,P1450S-CAN,P1600S,P1600S-BB,P1600S-CAN) 1

17mmWrench(inhardwarebag) 1

}leaningNeedle(inhardwarebag) 1

i

N SP01309

0 SP00609

3rassQuick-connectcoupling& InletAdapter(optional--comes with only certain

wodelssuchasthe PI450S andPI750S and canhe purchasedseparately) 2

/VaterInletFilter(inhardwarebag) 1

P SP00609

}-Rings(inhardwarebag) 5

Order replacement parts online: www.PressureWasher91

Phone orders, call [1] 919-550-3259.Please have the part number and a credit

Rev:Feb2011 STANLEY i Electric PressureWashers

@

1.com

card ready when calling.

3of18

Page 4

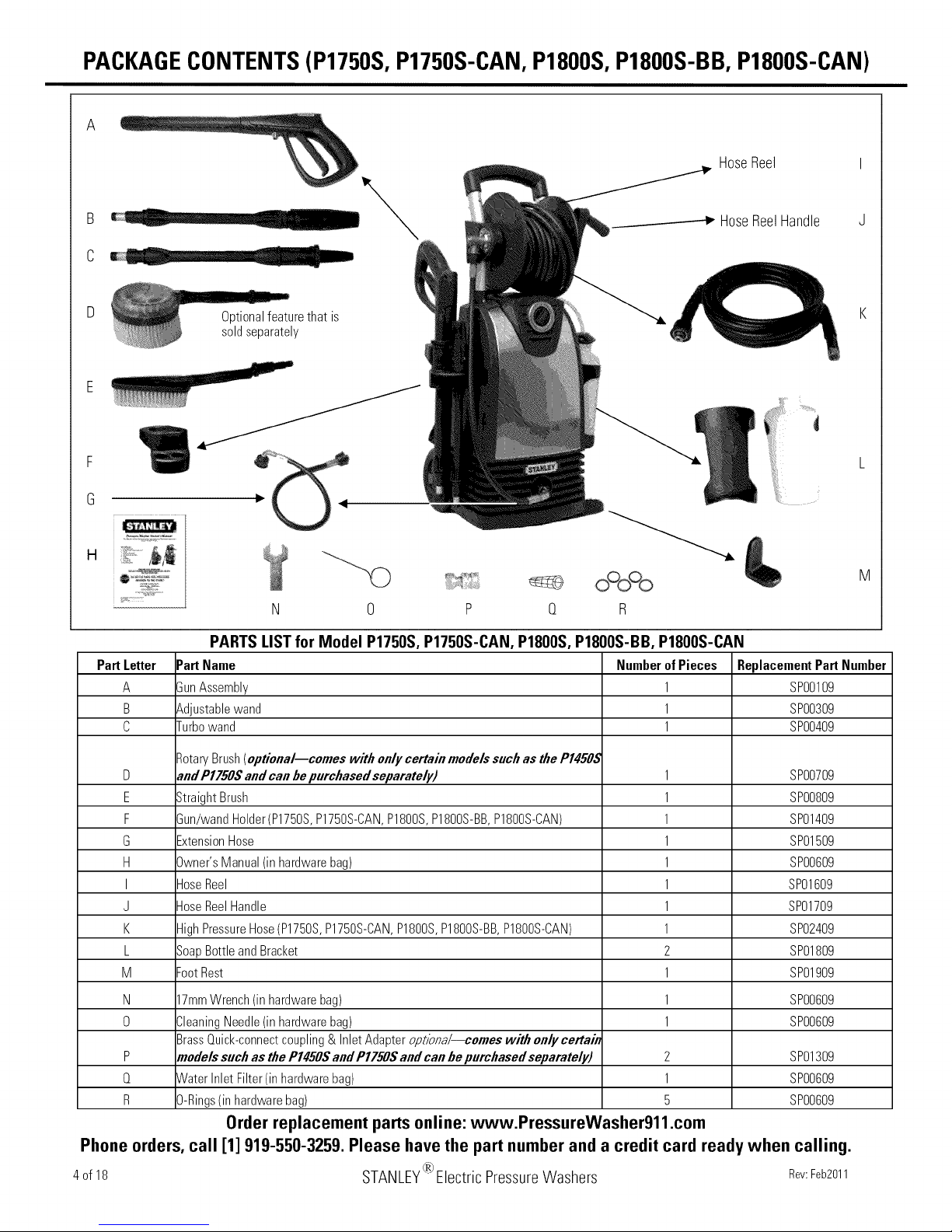

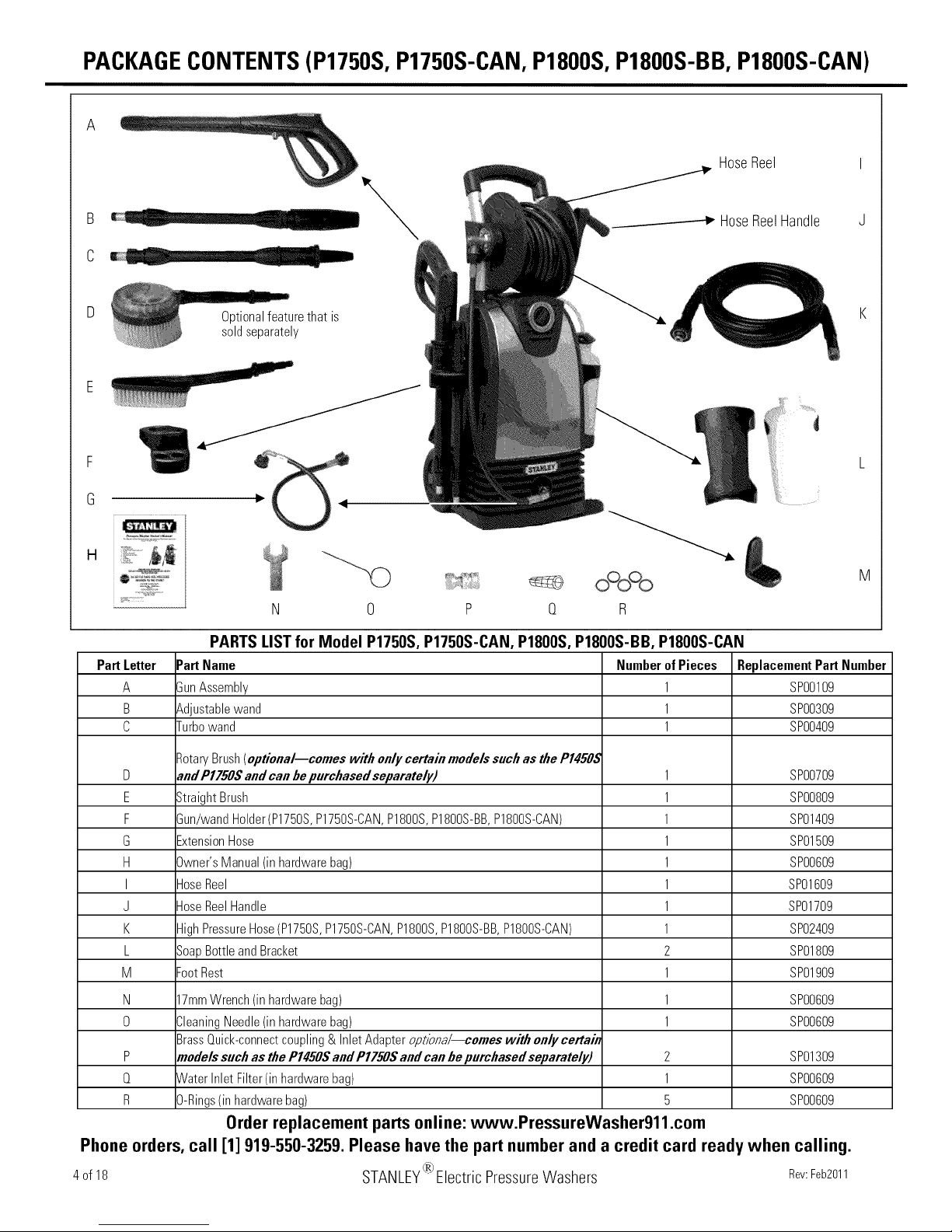

PACKAGECONTENTS(P1750S,P1750S-CAN,P1800S,P1800S-BB,P1800S-CAN)

HoseReel

B

HoseReelHandle J

C

Optionalfeaturethat is

soldseparately

G

N 0 P Q R

PARTS LISTfor Model P1750S,P1750S-CAN, P1800S, P1800S-BB, P1800S-CAN

PartLetter PartName NumberofPieces ReplacementPart Number

A GunAssernbly 1 SP00109

B Adjustablewand 1 SP00309

C Turbowand 1 SP00409

M

Phone

4of18

RotaryBrush(optional--comes with only certain modelssuch asthe PI450S

D andP1750Sandcan bepurchasedseparately) 1 SP00709

E StraightBrush 1 SP00809

F Gun/wandHolder(P1750S,P1750S-CAN,P1800S,P1800S-BB,P1800S-CAN) 1 SP01409

G ExtensionHose 1 SP01509

H Owner'sManual(inhardwarebag) 1 SP00609

I HoseReel 1 SP01609

J HoseReelHandle 1 SP01709

K HighPressureHose(P1750S,P1750S-CAN,P1800S,P1800S-BB,P1800S-CAN) 1 S%2409

L SoapBottleandBracket 2 SP01809

M FootRest 1 SP01909

N 7rnrnWrench(in hardwarebag) 1 SP00609

0 CleaningNeedle(inhardwarebag) 1 SP00609

BrassQuick-connectcoupling& InletAdapteropt/ona/--comes with only certain

P modelssuchas thePI450S andP1750Sandcan bepurchasedseparately) 2 SP01309

Q WaterInletFilter(inhardwarebag) 1 SP00609

R O-Rings(inhardwarebag) 5 SP00609

Order replacement parts online: www.PressureWasher911 .com

orders, call [1] 919-550-3259. Please have the part number and a credit card ready when calling.

STANLEY{R}Electric PressureWashers Rev:Feb2011

Page 5

Missing PartsRequestForm

Pleaseindicate the part that you aremissing:

[] Hardwarebag

[] Other Address

[] Dateof purchase

Model#:

[] Serial#:

Comments:

Name

Phone

Email

IMPORTANT:Please includeyourreceipt. Without a receipt, your

orderwill be delayed. You mayalso email us at:

customerservice@gxioutdoorpower.com

Fax: 1-919-550-3277

If emailing, please scan in your proof of purchase.

Otherfine productsoffered by

Electric Pressure Washer

Rev:Feb2011 STANLEY i Electric PressureWashers 5of18

Generators

®

Commercial Mowers

Page 6

WARNINGS

Thisowner'smanualisconsidereda permanentpartofthe pressure

washerandshouldremainwith thepressurewasherif resold.The

informationandspecificationsincludedinthis publicationwerein

effectat the timeof approvalfor printing.

GXiOutdoorPower,LLCreservestheright to discontinueor change

specificationsor designatanytimewithout noticeandwithout

recurringanyobligationwhatever.Nopart ofthis publicationmaybe

reproducedwithout written permission.

SAFETYLABELLOCATIONS

Theselabelswarnyouof potentialhazardsthat cancauseserious

injury.Readthemcarefully. If alabelcomesoffor becomeshardto

read,contactCustomerCarefora replacement.

SAFETYINFORMATION

STANLEYpressurewashersaredesignedtogivesafeanddependable

serviceif operatedaccordingto instructions.Readandunderstandthis

owner'smanualbeforeoperatingyourpressurewasher.

OPERATORRESPONSIBILITY

Knowhowto stopthepressurewasherquicklyincaseofemergency.

Understandthe useof all productcontrols,outputreceptacles,and

connections.Besurethat anyonewhooperatesthepressurewasher

receivesproper instruction.Donotlet childrenoperatethepressure

washer.

• Tominimizethe amountof watergetting intothepressurewasher,

theunitshouldbeplacedasfar aspossiblefromthecleaningsite

duringoperation.

• Nevercarryyour pressurewasherbythe cord.Donotpull onthe

cordto disconnectfromthe outlet.

• Toallow free aircirculation,the pressurewashershouldnotbe

coveredduringoperation.

• CaliforniaProposition65:Thisproductor itspowercordcontains

lead,achemicalknowntothe StateofCaliforniatocausecancer,

birthdefectsorotherreproductiveharm.Washhandsafter use.

SAVETHESE INSTRUCTIONS

Servicingof a double-insulationproduct:

Inadouble-insulationproduct,two systemsofinsulationareprovided

insteadofgrounding.Nogroundingmeansisprovidedonadouble

insulated,product,norshoulda meansforgroundingbe addedtothe

product.Servicinga double-insulatedproductrequiresextremecareand

knowledgeof thesystem,andshouldbedoneonlybyqualifiedservice

personnel.Replacementpartsof adouble-insulatedproductmustbe

identicaltothepartstheyreplace.A double-insulatedproductismarked

with thewords"DOUBLEINSULATION"or "DOUBLEINSULATED".

[] Thesymbolmayalsobemarkedonthe product.

Useof pressurewasher cancreatepuddlesandslippery

surfaces.

• Thecleaningareashouldhaveadequateslopesanddrainageto

reducethepossibilityofa fall dueto slipperysurfaces.

Highpressurespraycouldcauseyouto fall ifyouare too close

tothe cleaningsurface.

Keepspraynozzlebetween8to 24 inchesawayfromcleaning

surface.

Operatethisunit onastablesurface.

Beextremelycarefulif youmustusethepressurewasherfroma

SAFETYFEATURESAND ELECTRICALPOWER

INFORMATION

Thepressurewasherisequippedwith astopdevicethatwill sense

whenthe triggeronthegunis released.Itwill openthepowercircuitto

themotorandcausethepressurewashermotorto stop. Motorwill

resumeagainwhentriggeris pulled.

pressure equipped

OFF"switch locatedonthe unit,It shouldalways be movedto

the "OFF"positionwhen thepressurewasher isnotbeingused

IThe washer isalso with main "ON/

to preventpossibleinjuryordamage,

ladder,scaffoldingor anyotherrelativelyunstablelocation.Firmly

graspspraygunwithbothhandswhenusinghighpressuresprayto

avoidinjuryif gunkicksback.

Ground Fault Circuit Interrupter:

Thispressurewasherhasa ground-faultcircuit-interrupter(GFCI)built

intotheplugof thepowersupplycord.Thisdeviceprovidesadditional

Somechemicalsor detergentsmaybeharmfulif inhaled or

ingested,causingseverenausea,faintingor poisoning.

protectionfromthe riskofshock.Shouldreplacementof the plugorcord

becomenecessary,useonlyidenticalreplacementpartsthat include

GFCIprotection.

• Usea respiratorormaskwheneverthereis achancethatvapors

maybeinhaled.

• Readall instructionswith masksoyouarecertainthemaskwill

WHEN OPERATINGEQUIPMENT

intoa groundfault circuit-interrupterfoundincircuit boxesor

Extensioncordsare notrecommendedunlesstheyare plugged

protectedreceptacles,

• Avoidaccidentalstarts.Shutpower"OFF"beforeconnectingor

disconnectingcordto electricaloutlets.

• DONOTsprayflammableliquids.

• Donot useacidsandsolventsinthis product.Theseproductscan

causephysicalinjuriesto theoperatorandirreversibledamageto

the machine.

• Donot usewith flammableliquidsandtoxicchemicals.

6of18 STANLEYi Electric PressureWashers

a

Rev:Feb2011

power

Page 7

WARNINGS

ExtensionCords

If possible,donot useextensioncordswith this

product.However,if youmustuseone,observeall

thewarningsandinstructionslistedbelow:Usea sufficientgauge:

• Maximumcablelength:50ft =14AWG

• Useonlyextensioncordsthatare intendedforoutdooruse.These

extensioncordsare identifiedby amarking"Acceptableforuse

with outdoorappliances;storeindoorswhile not in use."

• Useonlyextensioncordshavinganelectricalratingnotlessthan

the ratingoftheproduct.

• Donot usedamagedextensioncords.Examineextensioncord

beforeusingandreplaceif damaged.

• Donot abuseextensioncordanddonotyankonanycordto

disconnect.

• Keepcordawayfromheatandsharpedges.

• Alwaysdisconnecttheextensioncordfromthe receptaclebefore

disconnectingtheproductfromtheextensioncord.

• Toreducetheriskof electrocution,keepallconnectionsdry andoff

the ground.Donottouchplugwith wet hands.

Impropertreatmentofthe pressurewashercan damageit and

shortenitslife.

• Ifyouhavequestionsaboutintendeduse,askdealeror contact

CustomerServiceat[1]919-550-3259.

• NEVERoperateunitswith brokenormissingparts,orwithout

protectivehousingorcovers.

• DONOTbypassanysafetydeviceonthismachine.

• Beforestartingpressurewasherin coldweather,checkallpartsof

theequipmentto besureicehasnotformedthere.

• NEVERmovemachinebypullingonhighpressurehose.Usehandle

providedon unit.

• Thisequipmentis designedtobeusedwith STANLEYauthorized

partsONLY.If equipmentis usedwith partsthatDONOTcomply

with minimumspecifications,userassumesall risksandliabilities.

WARNING

Thepressurewasherisalsoequippedwith a mainpower"ON/OFF"

switchlocatedonthe unit.It shouldalwaysbemovedtothe "'OFF"

positionwhen thepressurewasherisnotbeingusedtopreventpossible

injuryordamage.

A pressurewasher producesa highpressurespraywhich

increasesrisk ofinjuryanddamagetounit.

• GunKicksBack-Holdwith bothhands!

• Thetriggergunsafetylockpreventsthetriggerfromaccidentally

beingengaged.ThesafetyfeatureDOESNOTlocktriggerinthe ON

position.

• DONOTsecurespraygunin openposition.

• DONOTleavespraygununattendedwhile machineisrunning.

• NEVERuseaspraygunwhich doesnothaveatrigger lockor

triggerguardin placeandinworkingorder.

• Alwaysbe certainspraygun,nozzlesandaccessoriesarecorrectly

attached.

Highpressurespraymaydamagefragile itemsincludingglass.

• DONOTpointspraygunat glasswheninjet spraymode.

• NEVERaimspraygunatplants.

Thehighpressurestreamof water thatthis equipmentproduces

canpierceskin anditsunderlyingtissues,leadingto serious

injuryand possibleamputation.

Sprayguntrapshighwater pressure,evenwhen pumpis not

runningandwater is disconnected,which cancauseinjury.

• NEVERaimspraygunat people,animals,plants,electricaldevices,

orthe unit itself.

• DONOTallowCHILDRENtooperatepressurewasher.

• Toreducethe riskof injury,donotoperatethemachinenear

children

• NEVERrepairhighpressurehose.Replaceit.

• NEVERrepairleakingconnectionswith sealantof anykind.

Replaceo-ringor seal.

• Keephighpressurehoseconnectedto pumpandspraygunwhile

systemispressurized.

• ALWAYSpointguninsafedirectionandsqueezesprayguntrigger,

toreleasehighpressure,everytimeyoustopengine. Engage

triggerloci<whennotin use.

Riskof Electrocution

Inspectcordbeforeusing-Donotuseif cordis damaged.

Keepall connectionsdryandoff theground.

Donot touchplugwith wet hands.

Donot useextensioncordswith theproduct.

Waterspraymustneverbedirectedtowardsanyelectricwiring,

devicesor directlytowardsitself.

Riskof Explosion

Highpressurespraycan causepaint chipsor otherparticlesto

becomeairborne.

• Alwayswear eyeprotectionwhen usingthisequipmentorin

vicinity ofwhere equipmentisin use.

Rev:Feb2011 STANLEY i Electric PressureWashers 7 of 18

®

Donot sprayflammableliquids

Donouseacidsandsolventsin thisproduct.Theseproductscan

causephysicalinjuriesto theoperatorandirreversibledamageto

themachine.

Page 8

PREPARATION& ASSEMBLY- Model P1450S,P1450S-CAN,P1600S,P1600S-BB,P1600S-CAN

Assembly Time: 5 minutes

Tools Required: 17mmor Adjustable Wrench

SurfacePreparation

• Beforestartinganycleaningtask,it is importanttoinspectthearea

for objectswhichcouldcreatea hazard.

• Removeanyobjectsfromthework areawhichcouldbetripped

over,suchastoysor outdoorfurniture.

• Ensurethat all doorsandwindowsareclosedtightly.

Step 1

• Removeorpeeloff blueprotectivefilmontile front ofthe pressure

washerandonthe wands(if applicable).Also, removeanybubble

wrap. Discardblueprotectivefilmandbubblewrap.

Step 2

• Attachtile QuickConnectInletcouplingto watersupplyinlet on

pressurewasher,asshownin Figurebelow.

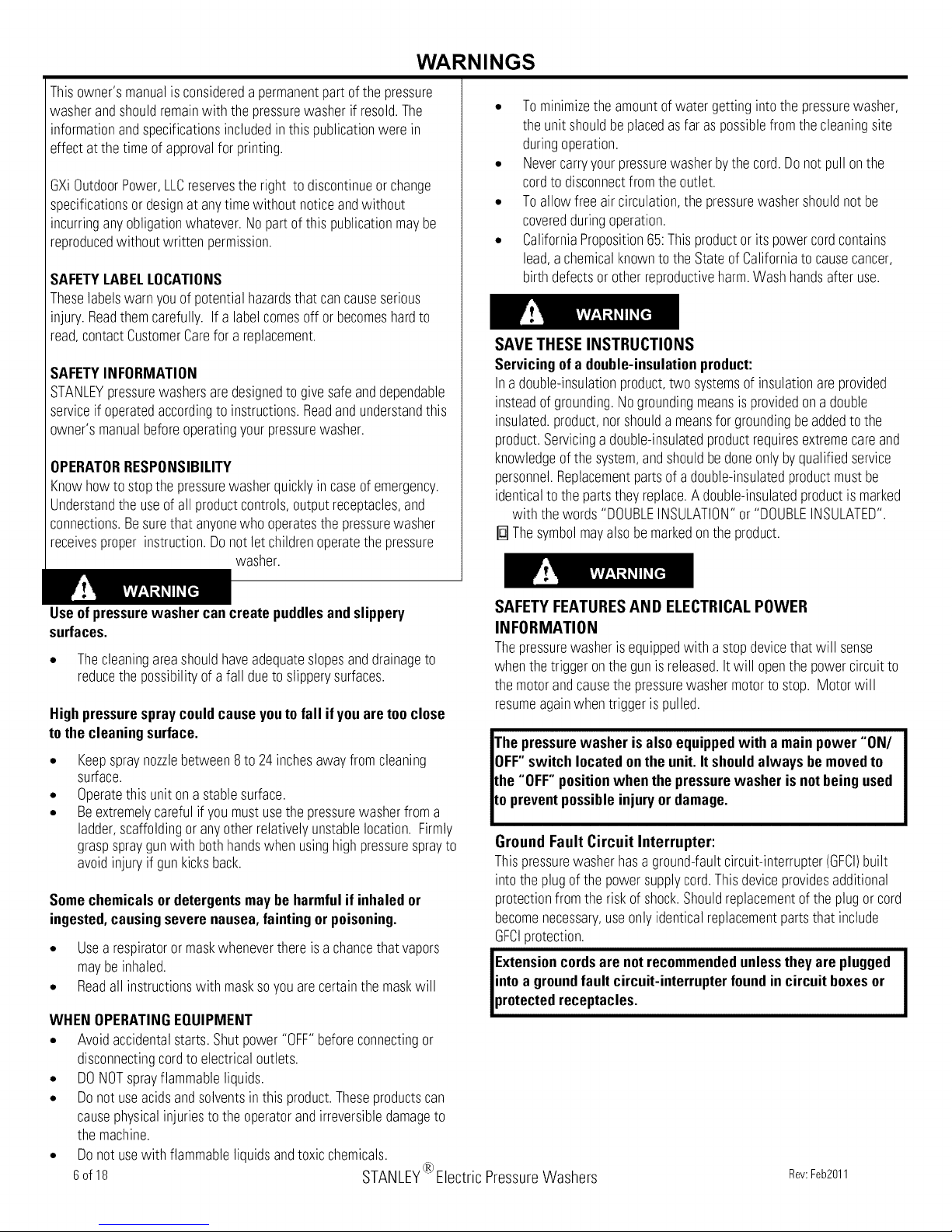

Step 5

• Attachotherendof HighPressureHosetoGunasshownin Figure

below. Fastentightlywith 17mmwrenchto avoidleakage.

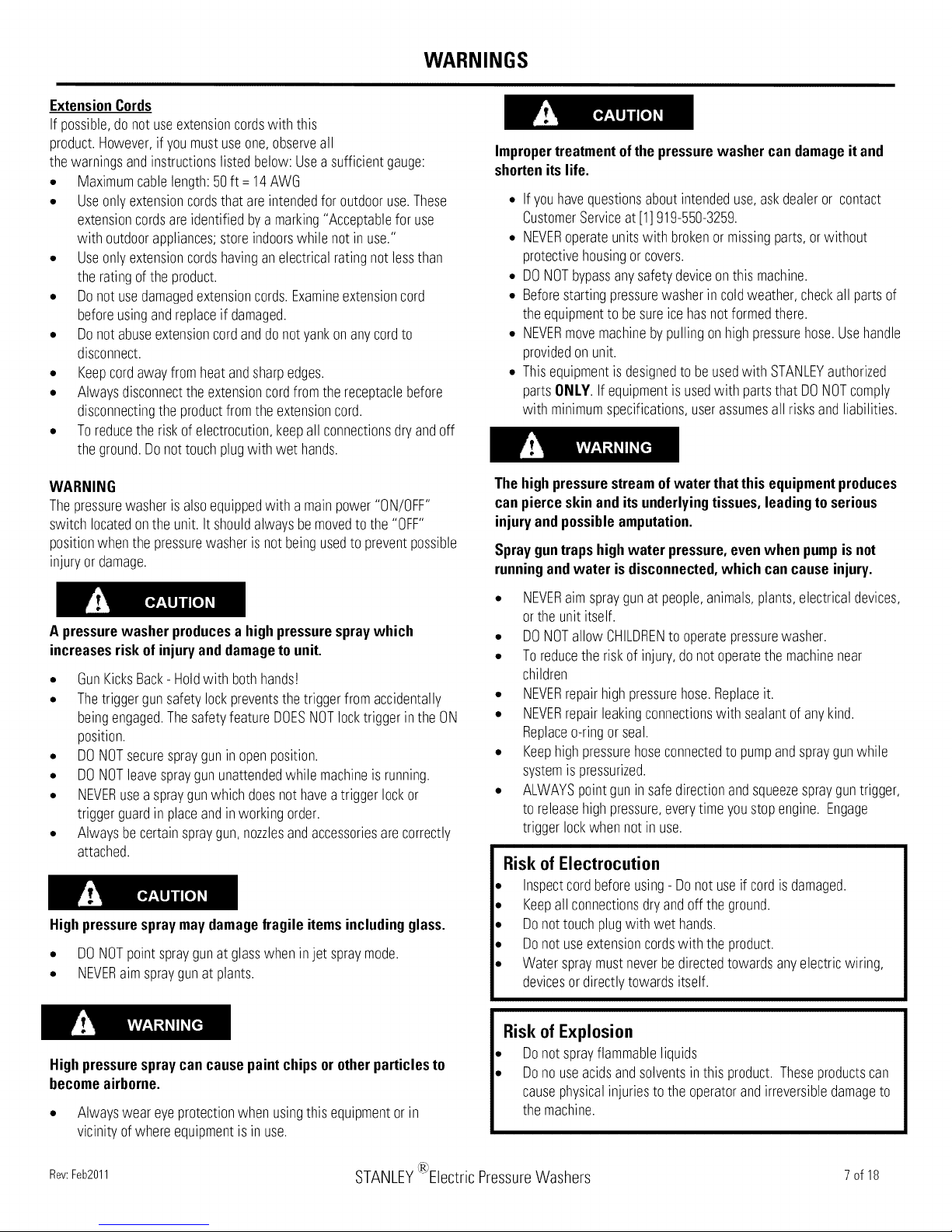

Step 6

• AttachShoulderStrapto tile StrapBracketas showninFigure

below.

Step 3

• Attach WandBrackettotile unitasshowninFigurebelow.

Step4

• Attach HighPressureHoseto MainUnitasshownin Figurebelow.

Step 7

• Attachtile hoseholderstraptotile sideof tile unit asshownin

Figurebelow.

ForOperating Instructions, proceed to page 9.

8of18 STANLEYi Electric PressureWashers Rev:Feb2011

{m

Page 9

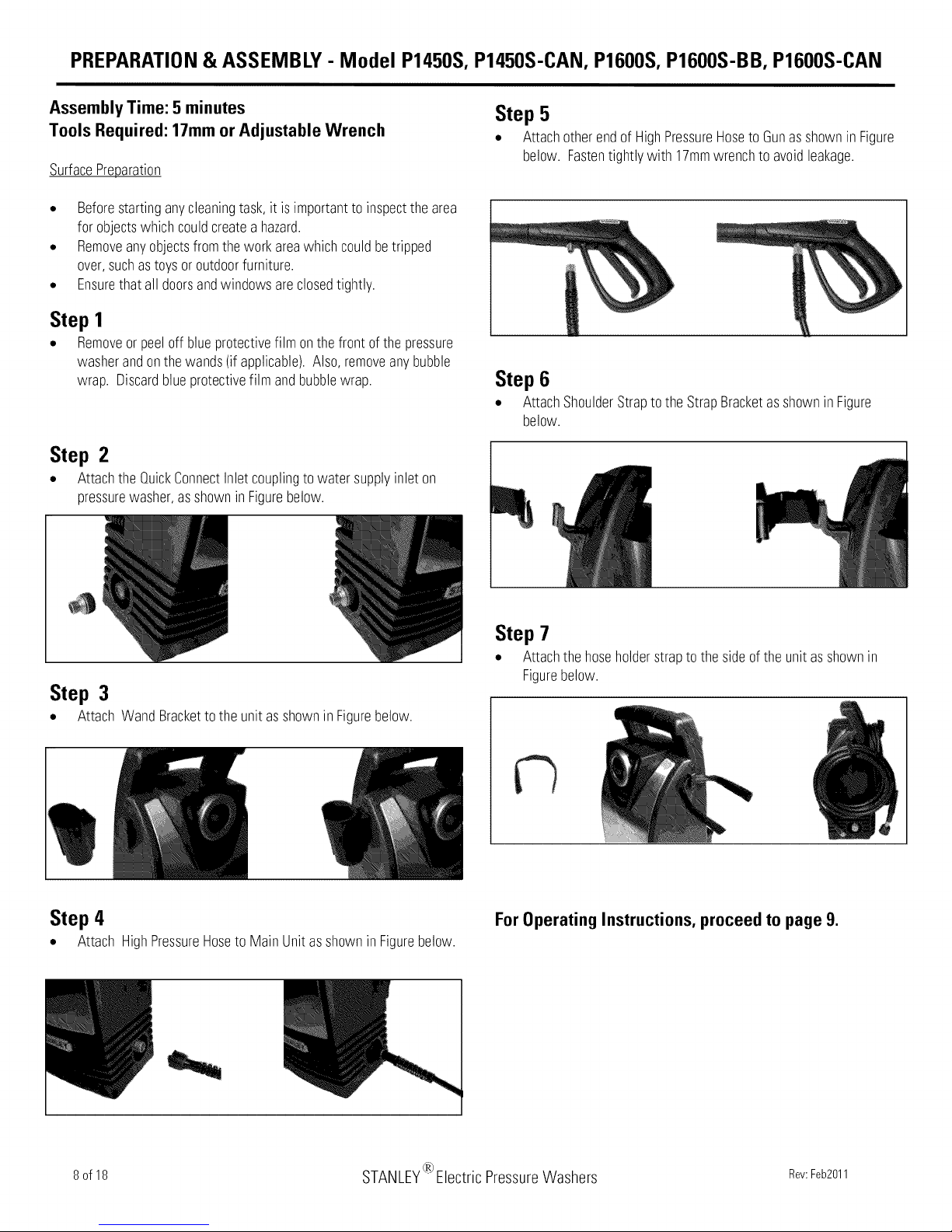

PREPARATION& ASSEMBLY- Model P1750S,P1750S-CAN,P1800S,P1800S-BB,P1800S-CAN

Assembly Time: 5 minutes

Tools Required: 17mm or Adjustable Wrench

SurfacePreparation

• Beforestartinganycleaningtask,it is importanttoinspectthearea

for objectswhichcouldcreatea hazard.

• Removeanyobjectsfromthework areawhichcouldbetripped

over,suchastoysor outdoorfurniture.

• Ensurethat all doorsandwindowsareclosedtightly.

Step 1

• Removeorpeeloff blueprotectivefilmontile front ofthe pressure

washerandonthe wands(if applicable).Also, removeanybubble

wrap. Discardblueprotectivefilmandbubblewrap.

Step 2

• Attachtile QuickConnectInletcouplingto watersupplyinlet on

pressurewasherasshownin Figurebelow.

Step 5

• Attachtile L-shapecouplerendof tile extensionhose(F)intothe

wateroutlet asshowninFigurebelow. Fastentightly to avoid

leakage.

Step 6

• Attachtile straightcouplerendof tile extensionhoseintotile hose

reelinletas shownin Figurebelow. Fastentightlyto avoid

leakage.

Step 3

• Attachtile gun/wandholderasshownin Figurebelow.

Step 4

• Attachtile soap/detergentbracket,bottle,siphonhose,asshown

in Figurebelow.

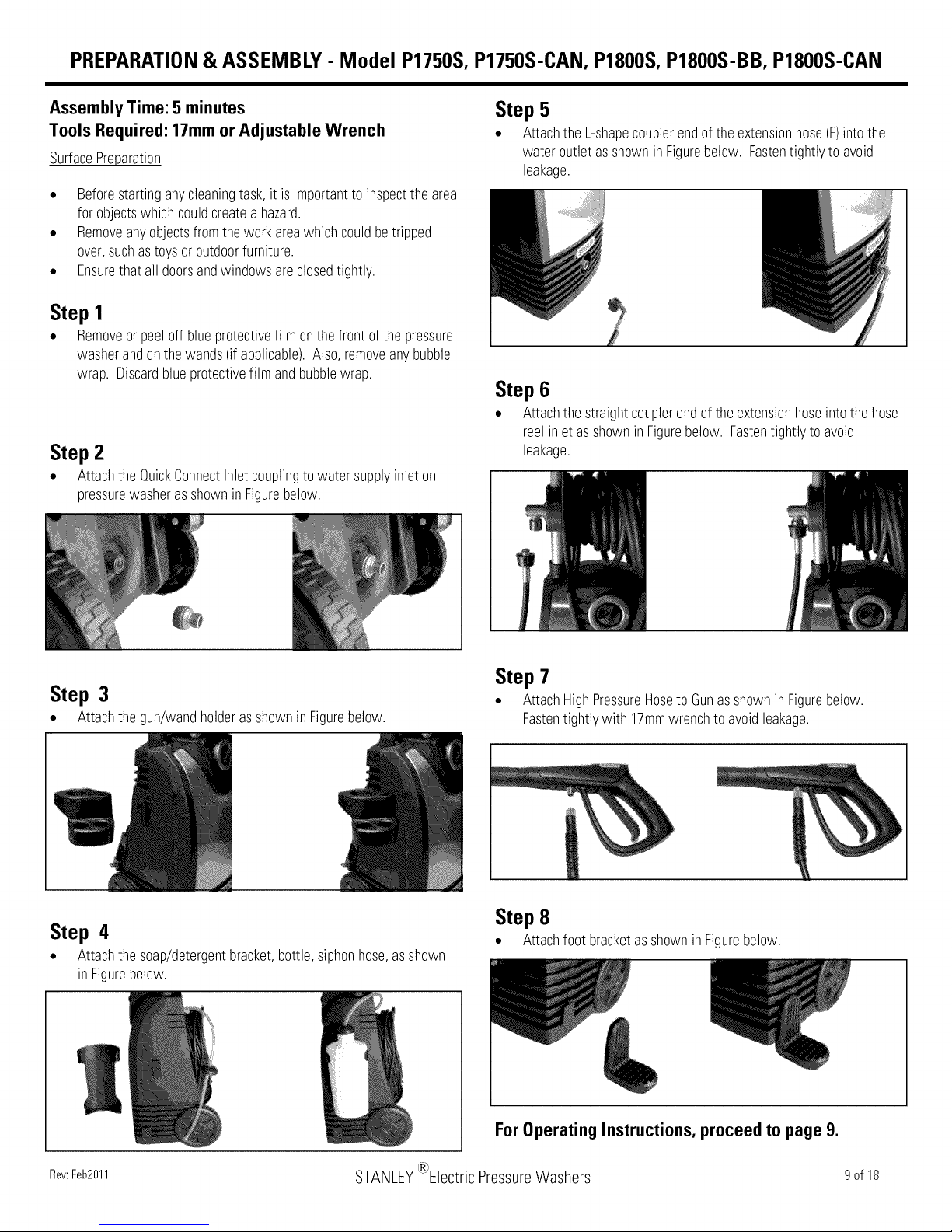

Step 7

• AttachHighPressureHoseto Gunasshownin Figurebelow.

Fastentightlywith 17mmwrenchto avoidleakage.

Step 8

• Attachfoot bracketasshownin Figurebelow.

ForOperating Instructions, proceed to page 9.

Rev:Feb2011 9 of 18

STANLEY i Electric PressureWashers

{m

Page 10

HOW TO USETHE PRESSUREWASHER

OPERATION

If youhaveanyproblemsoperatingyourpressurewasher,

pleasecallthe pressurewasherhelp-lineat [1] 919-550-3259.

PressureWasherClearance

Prevailingwindsandaircurrentsshouldbetakenintoconsideration

whenpositioningpressurewasher.

• Keepspraynozzlebetween8to 24 inchesawayfromcleaning

surface.

• Operatethisunit onastablesurface.

• Beextremelycarefulif youmustusethepressurewasherfroma

ladder,scaffoldingor anyotherrelativelyunstablelocation.

• Firmlygraspspraygunwith bothhandswhen usinghighpressure

sprayto avoidinjuryif gunkicksback.

High pressure spray could cause you to fall if you are too

close to the cleaning surface.

Thehighpressurestreamof water thatthis equipmentproduces

canpierceskin anditsunderlyingtissues,leadingto serious

injuryand possibleamputation.

Sprayguntrapshighwater pressure,evenwhen motoris

stoppedandwater is disconnected,which can causeinjury.

Keephighpressurehoseconnectedto pumpandspraygunwhile

systemispressurized.

ALWAYSpointguninsafedirectionandsqueezesprayguntrigger,

toreleasehighpressure,everytimeyoustopengine.Engage

triggerlockwhen not inuse.

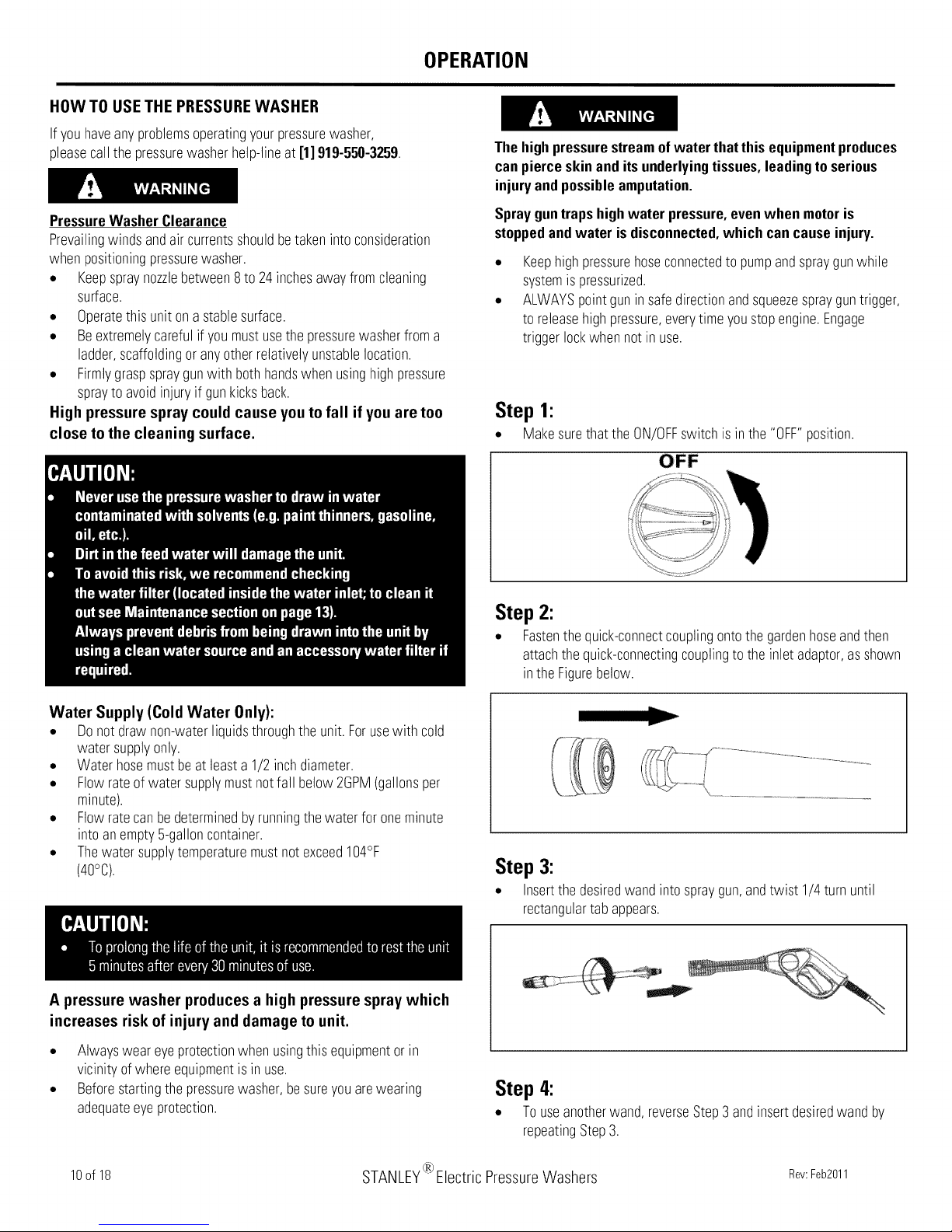

Step 1"

• Makesurethatthe ON/0FFswitchis inthe "'OFF"position.

Water Supply (ColdWater Only):

• Doriotdrawnon-waterliquidsthroughtile unit.Forusewith cold

water supplyonly.

• Water hosemustbeat leasta 1/2inchdiameter.

• Flowrateofwater supplymustnotfall below2GPM(gallonsper

minute).

• Flowratecanbedeterminedby runningthewater for oneminute

intoanempty5-galloncontainer.

• Thewater supplytemperaturemustnot exceed104°F

(4O°0).

A pressure washer produces a highpressure spray which

increases risk of injury and damage to unit.

• Alwayswear eyeprotectionwhen usingthisequipmentorin

vicinity ofwhere equipmentisin use.

• Beforestartingthepressurewasher,besureyouarewearing

adequateeyeprotection.

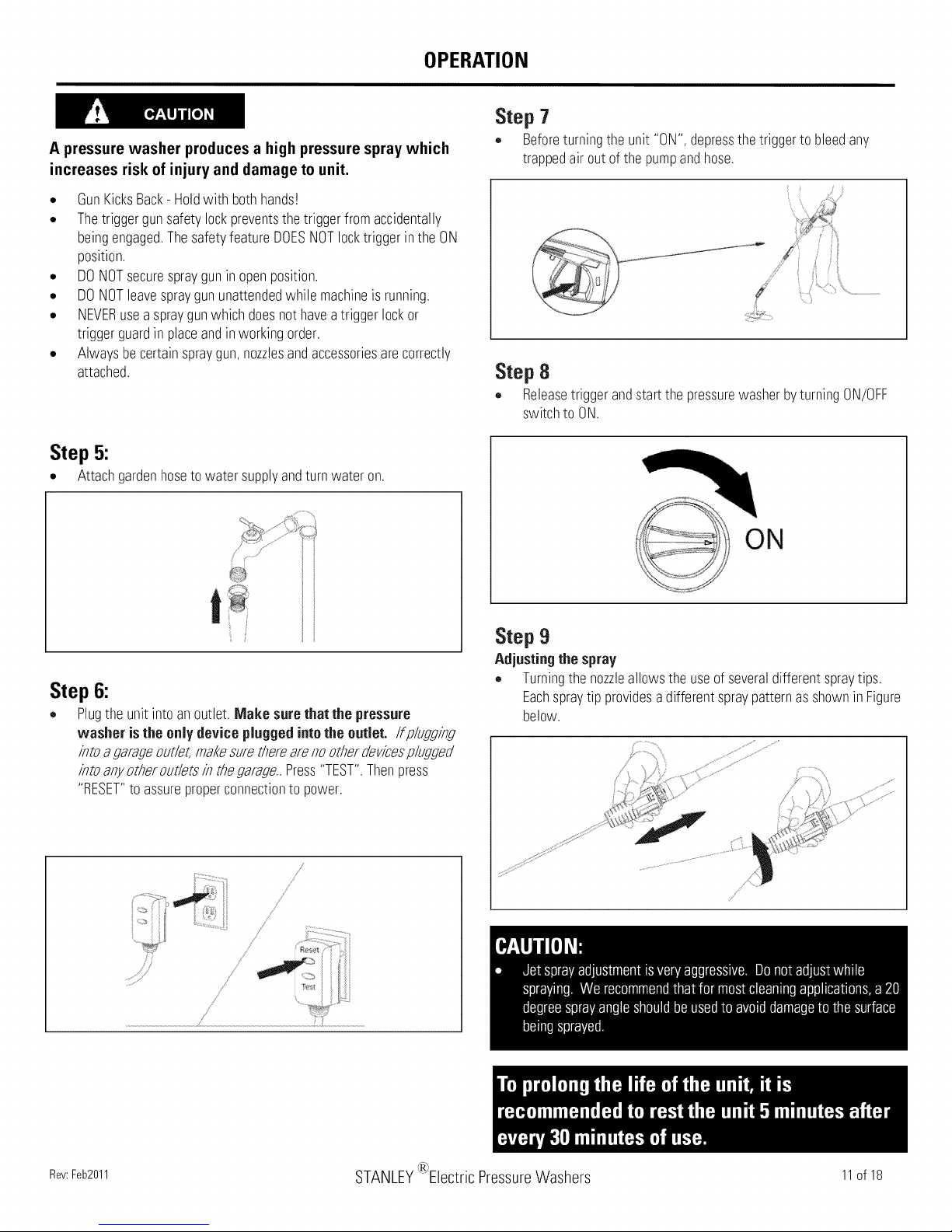

Step 2:

• Fastentile quick-connectcouplingontotile gardenhoseandthen

attachthe quick-connectingcouplingto theinlet adaptor,asshown

inthe Figurebelow.

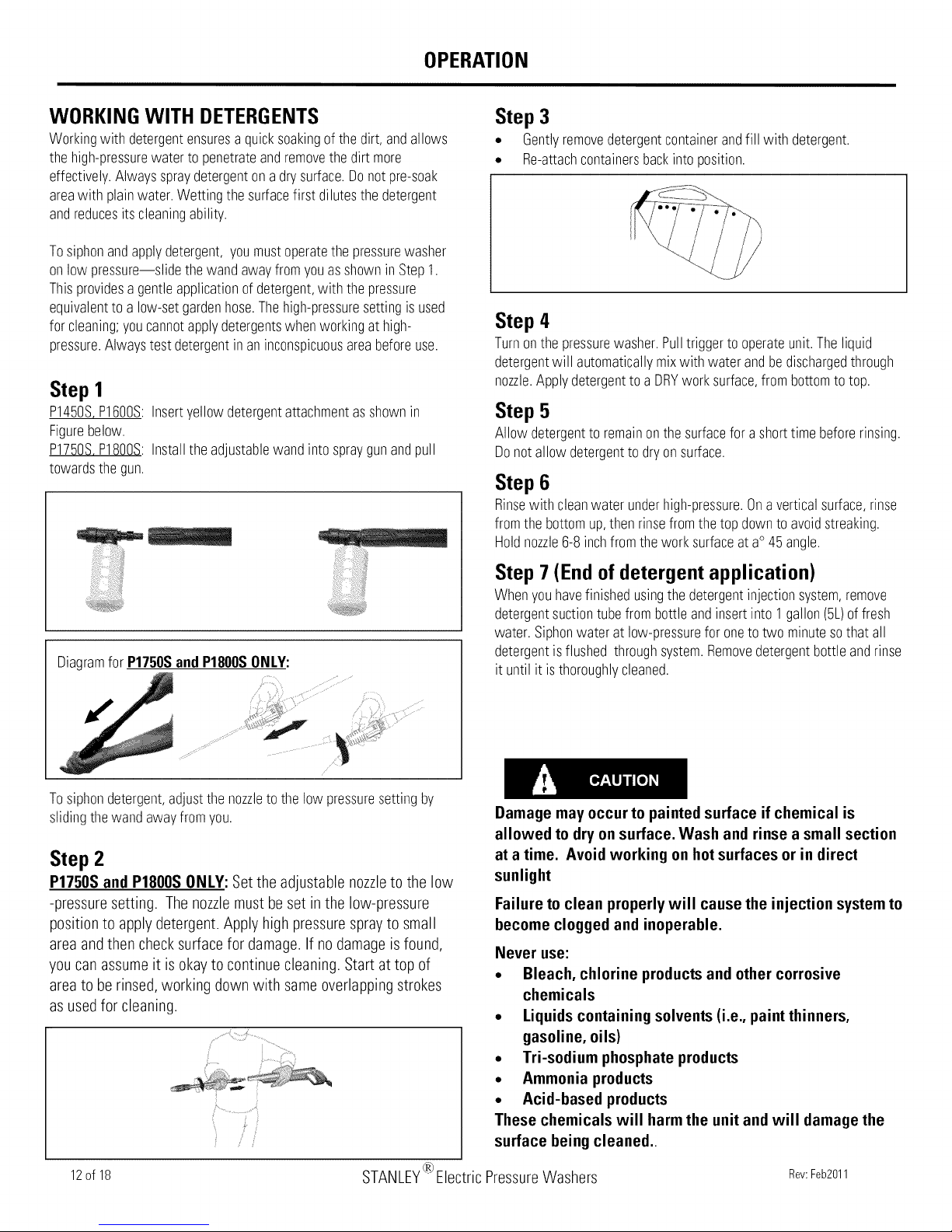

Step 3:

• Insertthedesiredwandinto spraygun,andtwist 1/4turnuntil

rectangulartabappears.

Step 4:

• Touseanotherwand, reverseStep3 andinsertdesiredwandby

repeatingStep3.

10of18 STANLEYi Electric PressureWashers Rev:Feb2011

®

Page 11

OPERATION

A pressure washer produces a highpressure spray which

increases risk of injury and damage to unit.

• GunKicksBack-Holdwith bothhands!

• Thetriggergunsafetylockpreventsthetriggerfromaccidentally

beingengaged.ThesafetyfeatureDOESNOTlocktriggerinthe ON

position.

• DONOTsecurespraygunin openposition.

• DONOTleavespraygununattendedwhile machineisrunning.

• NEVERuseaspraygunwhich doesnothaveatrigger lockor

triggerguardin placeandinworkingorder.

• Alwaysbe certainspraygun,nozzlesandaccessoriesarecorrectly

attached.

Step5:

• Attachgardenhosetowater supplyandturnwater on.

Step 7

• Beforeturningtheunit"ON",depressthetriggertobleedany

trappedairoutof thepumpandhose.

Step 8

• Releasetriggerandstarttile pressurewasherbyturning0N/OFF

switchto ON.

Step6:

• Plugtile unitintoanoutlet.Make surethat the pressure

washer isthe only device pluggedintotheoutlet. Ifplugg#Tg

#7toagarageout/et,makesurethereare/7ootherdevicesp/ugged

#Ttoamyotherout/ets#7thegarage..Press"TEST".Thenpress

"RESET"to assureproperconnectionto power.

ON

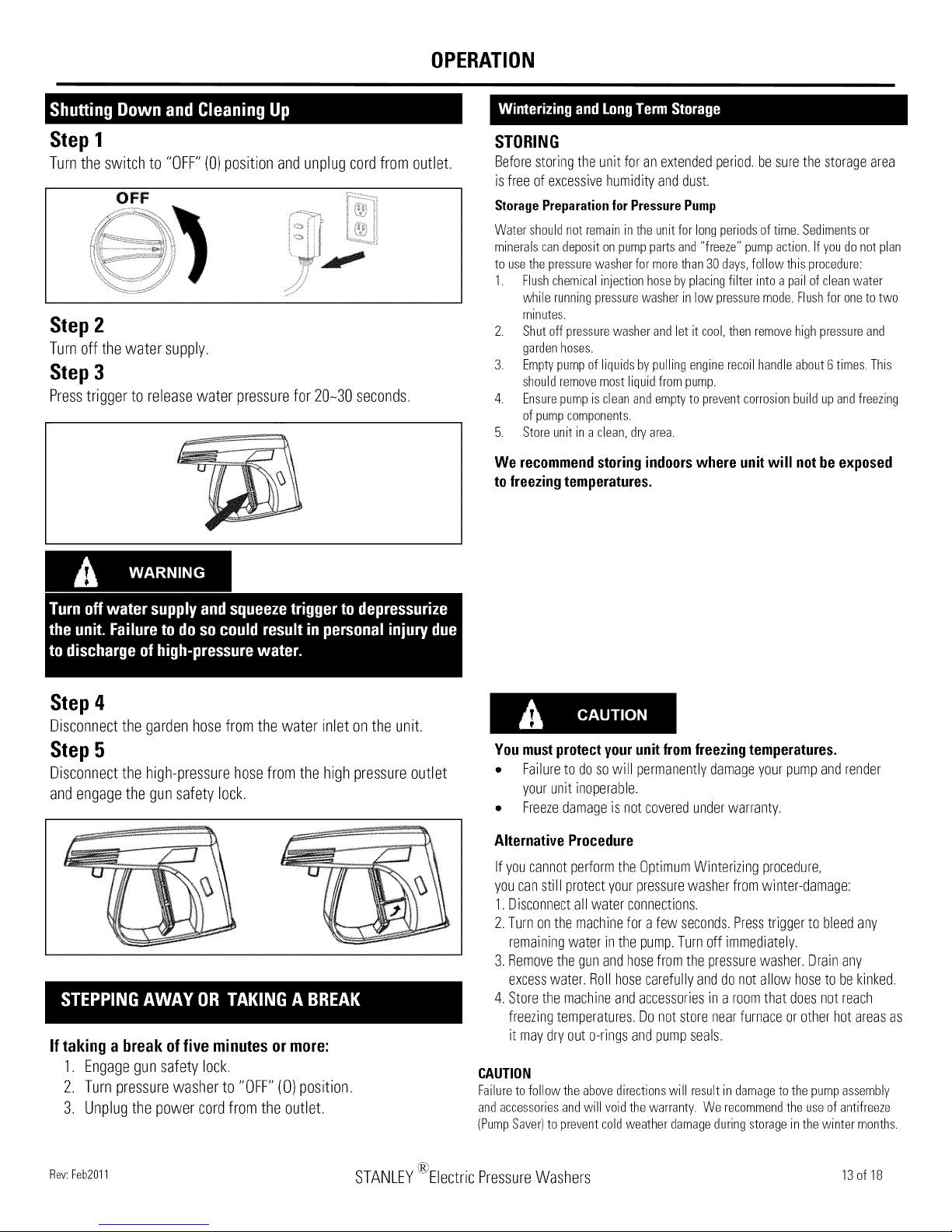

Step 9

Adjustingthespray

• Turningtile nozzleallowsthe useofseveraldifferentspraytips.

Eachspraytip providesa differentspraypatternasshownin Figure

below.

Rev:Feb2011 STANLEY i Electric PressureWashers 11of 18

®

Page 12

OPERATION

WORKING WITH DETERGENTS

Workingwith detergentensuresa quicksoakingoftile dirt,andallows

the high-pressurewaterto penetrateandremovethedirt more

effectively.Alwaysspraydetergentonadry surface.Donotpre-soak

areawith plainwater.Wetting the surfacefirst dilutesthe detergent

andreducesits cleaningability.

Tosiphonandapplydetergent,youmustoperatethe pressurewasher

onlowpressure--slide thewand awayfromyouasshownin Step1.

Thisprovidesagentleapplicationofdetergent,with thepressure

equivalentto a low-setgardenhose.Thehigh-pressuresettingis used

for cleaning;youcannotapplydetergentswhenworkingat high-

pressure.Alwaystestdetergentinan inconspicuousareabeforeuse.

Step 1

P1450SP1600S:

Figurebelow.

P1750SP1800S:

towardsthe gun.

Insertyellowdetergentattachmentasshownin

Installtheadjustablewandintospraygunandpull

Step 3

• Gentlyremovedetergentcontainerandfill with detergent.

• Re-attachcontainersbackintoposition.

Step 4

Turnonthe pressurewasher.Pulltriggerto operateunit.Theliquid

detergentwill automaticallymixwith waterandbedischargedthrough

nozzle.Applydetergentto a DRYworksurface,frombottomtotop.

Step 5

Allowdetergentto remainontile surfacefora shorttime beforerinsing.

Donot allow detergentto dryonsurface.

Step 6

Rinsewith cleanwater underhigh-pressure.Ona verticalsurface,rinse

fromthe bottomup,thenrinsefromthetop downtoavoidstreaking.

Holdnozzle6-8inchfromthe worksurfaceata° 45angle.

Step 7 (End of detergent application)

Whenyouhavefinishedusingthedetergentinjectionsystem,remove

detergentsuctiontubefrombottleandinsertinto 1gallon(5L)offresh

water.Siphonwaterat low-pressureforoneto two minutesothat all

Diagramfor P1750SandP1800SONLY:

Tosiphondetergent,adjustthe nozzletothe low pressuresettingby

slidingthewandawayfromyou.

Step 2

P1750S and P1800S ONLY: Set the adjustable nozzleto the low

-pressuresetting. The nozzlemust beset in the low-pressure

position to apply detergent. Apply high pressure sprayto small

area and then check surface for damage. Ifno damage isfound,

you can assumeit is okayto continue cleaning. Startat top of

area to be rinsed,working down with sameoverlapping strokes

asusedfor cleaning.

................

i i!" f

12of18 STANLEYi Electric PressureWashers Rev:Feb2011

®

detergentis flushedthroughsystem.Removedetergentbottleandrinse

it until it is thoroughlycleaned.

Damage may occur to painted surface if chemical is

allowed to dry on surface. Wash and rinse asmall section

at atime. Avoid working on hotsurfaces or in direct

sunlight

Failure to clean properly will cause the injection system to

become clogged and inoperable.

Never use:

• Bleach, chlorine products and other corrosive

chemicals

• Liquids containing solvents (i.e., paint thinners,

gasoline, oils)

• Tri-sodium phosphate products

• Ammonia products

• Acid-based products

These chemicals will harm the unit and will damage the

surface being cleaned.

Page 13

OPERATION

Step 1

Turnthe switch to "OFF"(0)position and unplugcordfrom outlet

OFF

Step 2

Turn off the water supply.

Step3

Presstrigger to releasewater pressurefor 20-30 seconds.

STORING

Before storing the unit for an extended period be sure the storage area

is free of excessive humidity and dust.

StoragePreparationforPressurePump

Watershouldnot remaininthe unitfor longperiodsoftime. Sedimentsor

mineralscandepositonpumpparts and"freeze"pumpaction.If youdonotplan

to usethepressurewasherfor morethan30days,follow this procedure:

1. Flushchemicalinjectionhoseby placingfilter intoapail of cleanwater

while runningpressurewasherin low pressuremode.Flushfor oneto two

minutes.

2. Shutoff pressurewasherandlet it cool,then removehighpressureand

gardenhoses.

3. Emptypumpof liquidsbypullingenginerecoilhandleabout6times.This

shouldremovemost liquidfrompump.

4. Ensurepumpiscleanandemptytopreventcorrosionbuildupandfreezing

ofpumpcomponents.

5. Storeunitin a clean,dryarea.

We recommendstoringindoorswhere unitwill notbe exposed

tofreezingtemperatures.

Step 4

Disconnectthe garden hosefrom the water inlet onthe unit.

Step 5

Disconnectthe high-pressurehose from the high pressureoutlet

and engagethe gun safety lock.

If taking a break of five minutes or more:

1. Engagegun safety lock.

2. Turn pressurewasher to "OFF"(0) position.

3. Unplugthe power cord from the outlet.

Youmustprotectyourunitfromfreezingtemperatures.

• Failureto dosowill permanentlydamageyourpumpandrender

yourunit inoperable.

• Freezedamageisnotcoveredunderwarranty.

AlternativeProcedure

If youcannotperformtheOptimumWinterizingprocedure,

youcanstill protectyourpressurewasherfromwinter-damage:

1.Disconnectall waterconnections.

2.Turnonthe machinefor afew seconds.Presstriggerto bleedany

remainingwater inthepump.Turnoff immediately.

3.Removethe gunandhosefromthe pressurewasher.Drainany

excesswater.Roll hosecarefullyanddonot allow hoseto bekinked.

4.Storethemachineandaccessoriesin a roomthatdoesnotreach

freezingtemperatures.Donotstorenearfurnaceor otherhot areasas

it maydryouto-ringsandpumpseals.

CAUTION

Failuretofollow the abovedirectionswill result in damageto thepumpassembly

andaccessoriesandwill voidthe warranty. We recommendthe useof antifreeze

(PumpSaver)to preventcoldweatherdamageduringstorageinthewinter months.

Rev:Feb2011 STANLEY i Electric PressureWashers 13of 18

Page 14

MAINTENANCE

Connections

Connectionson pressurewasherhoses,gunandspraywand shouldbe

cleanedregularlyandlubricatedwith non-watersolublegrease.

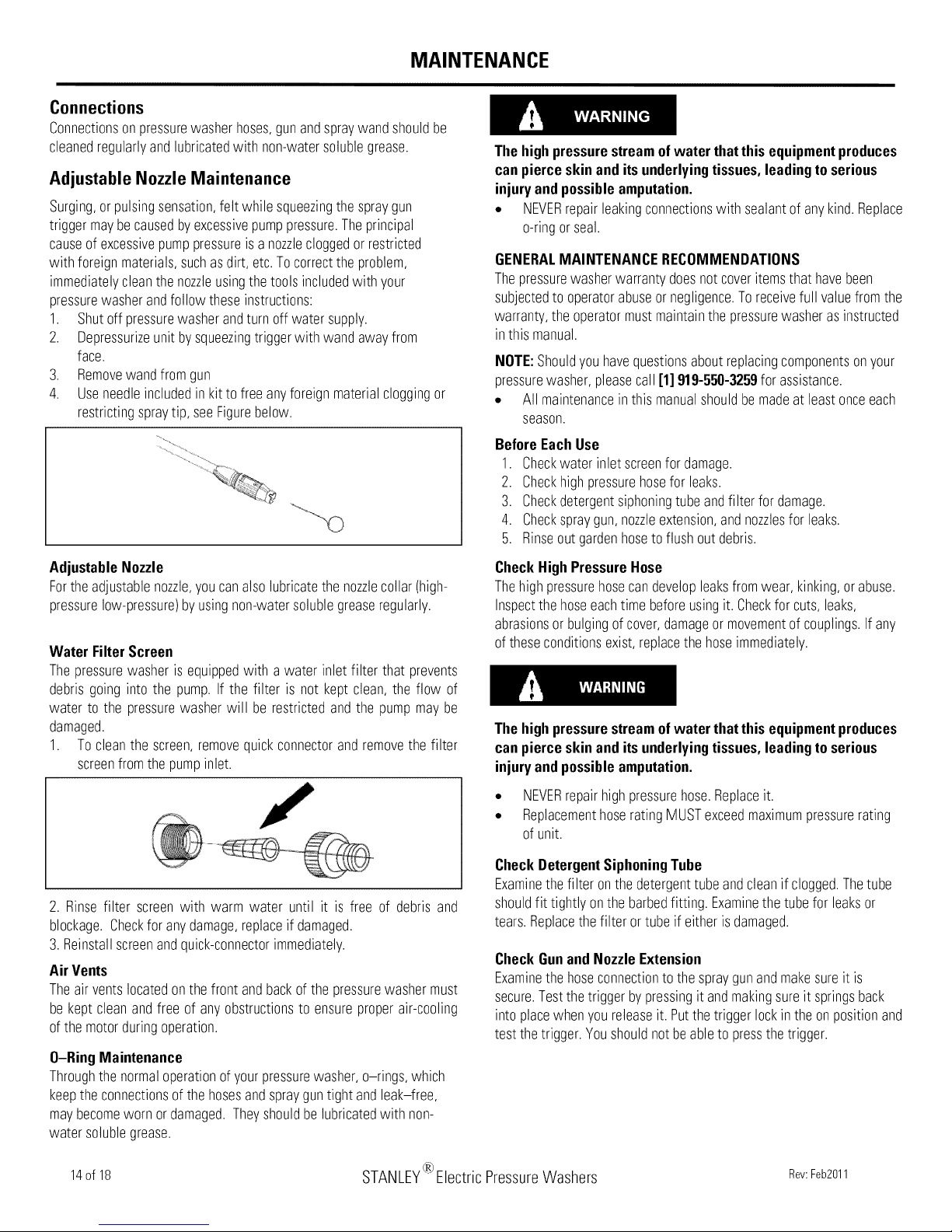

Adjustable Nozzle Maintenance

Surging,orpulsingsensation,felt while squeezingthespraygun

triggermaybecausedbyexcessivepumppressure.Theprincipal

causeof excessivepumppressureis anozzlecloggedorrestricted

with foreignmaterials,suchasdirt, etc.Tocorrecttheproblem,

immediatelycleanthenozzleusingthetoolsincludedwith your

pressurewasherandfollow theseinstructions:

1. Shutoff pressurewasherandturnoff water supply.

2. Depressurizeunitbysqueezingtriggerwith wandawayfrom

face.

3. Removewandfromgun

4. Useneedleincludedin kit tofree anyforeignmaterialcloggingor

restrictingspraytip, seeFigurebelow.

Thehighpressurestreamof water thatthis equipmentproduces

canpierceskin anditsunderlyingtissues,leadingto serious

injuryand possibleamputation.

• NEVERrepairleakingconnectionswith sealantof anykind.Replace

o-ringor seal.

GENERALMAINTENANCERECOMMENDATIONS

Thepressurewasherwarrantydoesnotcoveritemsthat havebeen

subjectedto operatorabuseornegligence.To receivefull valuefromthe

warranty,the operatormustmaintainthepressurewasherasinstructed

inthis manual.

NOTE:Shouldyouhavequestionsaboutreplacingcomponentsonyour

pressurewasher,pleasecall[1] 919-550-3259forassistance.

• All maintenancein thismanualshouldbemadeatleastonceeach

season.

BeforeEachUse

1. Checkwater inletscreenfor damage.

2. Checkhighpressurehosefor leaks.

3. Checkdetergentsiphoningtubeandfilter for damage.

4. Checkspraygun,nozzleextension,andnozzlesfor leaks.

5. Rinseoutgardenhoseto flushoutdebris.

AdjustableNozzle

Fortheadjustablenozzle,youcanalsolubricatethe nozzlecollar(high-

pressurelow-pressure)byusingnon-watersolublegreaseregularly.

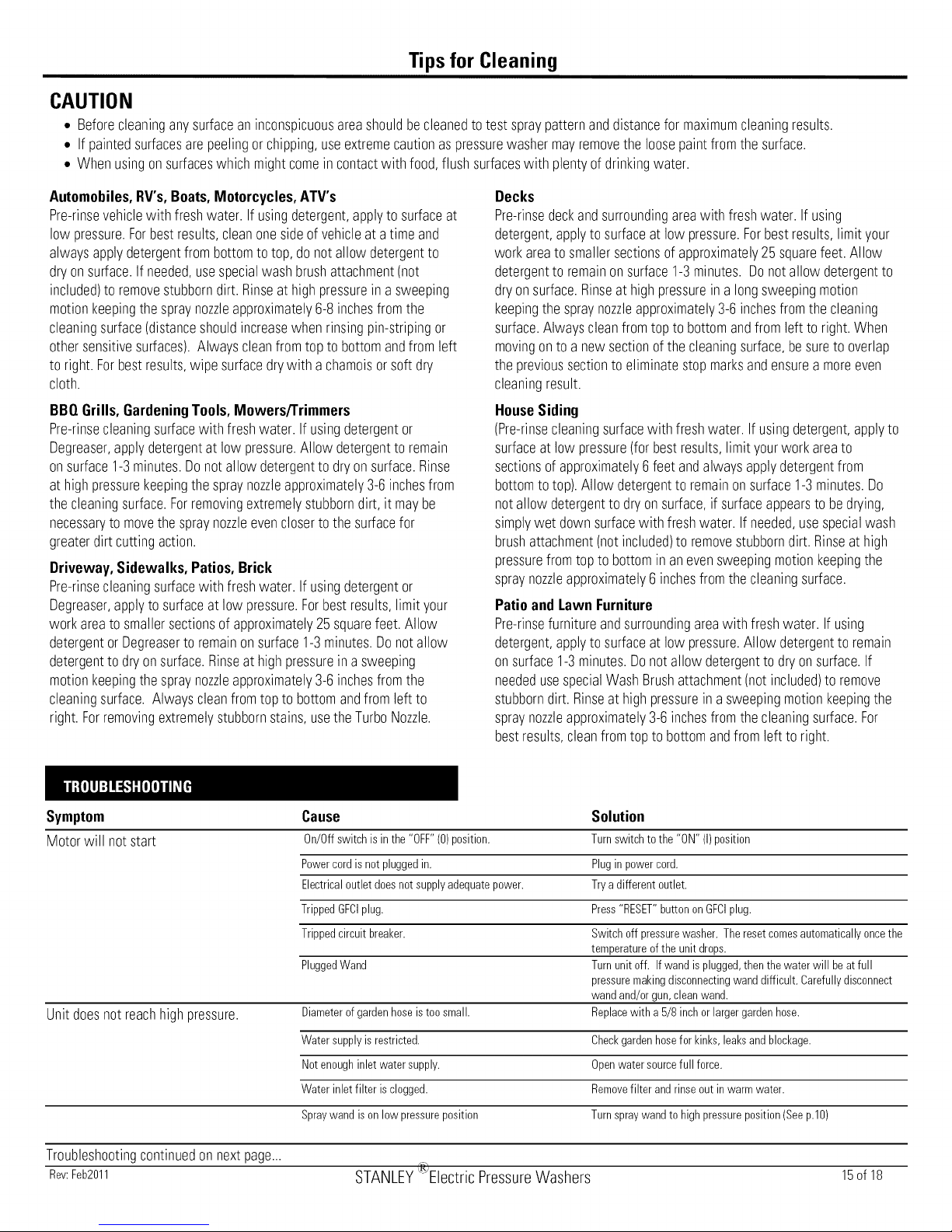

Water FilterScreen

Thepressurewasher isequippedwith awater inletfilter thatprevents

debrisgoing into the pump.If the filter is not kept clean,the flow of

water to the pressurewasherwill be restrictedandthe pumpmaybe

damaged.

1. Tocleanthe screen,removequickconnectorandremovethe filter

screenfromthe pumpinlet.

2. Rinsefilter screenwith warm water until it is free of debrisand

blockage.Checkfor anydamage,replaceif damaged.

3.Reinstallscreenandquick-connectorimmediately.

Air Vents

Theairventslocatedonthe frontandbackofthe pressurewashermust

bekept cleanand freeof anyobstructionsto ensureproperair-cooling

ofthemotorduringoperation.

0-Ring Maintenance

Throughthenormaloperationofyourpressurewasher,o-rings,which

keeptheconnectionsof the hosesandsprayguntight andleak-free,

maybecomewornordamaged.Theyshouldbelubricatedwith non-

water solublegrease.

CheckHighPressureHose

Thehighpressurehosecandevelopleaksfromwear,kinking,or abuse.

Inspectthe hoseeachtimebeforeusingit. Checkforcuts,leaks,

abrasionsor bulgingof cover,damageor movementof couplings.If any

oftheseconditionsexist,replacethehoseimmediately.

Thehighpressurestreamof water thatthis equipmentproduces

canpierceskin anditsunderlyingtissues,leadingto serious

injuryand possibleamputation.

• NEVERrepairhighpressurehose.Replaceit.

• ReplacementhoseratingMUSTexceedmaximumpressurerating

ofunit.

CheckDetergentSiphoningTube

Examinethefilter onthedetergenttubeandcleanif clogged.Thetube

shouldfit tightlyonthe barbedfitting. Examinethetubefor leaksor

tears.Replacethefilter ortube if eitherisdamaged.

CheckGunandNozzle Extension

Examinethe hoseconnectionto thespraygunandmakesureit is

secure.Testthe triggerbypressingitandmakingsureit springsback

intoplacewhenyoureleaseit.Putthetriggerloci<intheon positionand

testthetrigger.Youshouldnotbeableto pressthetrigger.

14of18 STANLEYi Electric PressureWashers Rev:Feb2011

®

Page 15

Tips for Cleaning

CAUTION

• Beforecleaninganysurfacean inconspicuousareashouldbecleanedtotestspraypatternanddistancefor maximumcleaningresults.

• If paintedsurfacesarepeelingorchipping,useextremecautionaspressurewashermayremovethe loosepaintfromthe surface.

• Whenusingonsurfaceswhich mightcomeincontactwith food,flushsurfaceswith plentyof drinkingwater.

Automobiles,RV's,Boats,Motorcycles,ATV's

Pre-rinsevehiclewith freshwater. If usingdetergent,applyto surfaceat

low pressure.Forbestresults,cleanonesideofvehicleat atime and

alwaysapplydetergentfrombottomtotop,do notallowdetergentto

dryonsurface.If needed,usespecialwashbrushattachment(not

included)to removestubborndirt. Rinseat highpressureina sweeping

motionkeepingthespraynozzleapproximately6-8inchesfromthe

cleaningsurface(distanceshouldincreasewhen rinsingpin-stripingor

othersensitivesurfaces).Alwayscleanfromtop tobottomandfrom left

to right.Forbestresults,wipesurfacedrywith achamoisorsoftdry

cloth.

BBQGrills,GardeningTools,Mowers/Trimmers

Re-rinsecleaningsurfacewith freshwater.If usingdetergentor

Degreaser,applydetergentat lowpressure.Allow detergentto remain

onsurface1-3minutes.Donotallow detergentto dryonsurface.Rinse

athighpressurekeepingthespraynozzleapproximately3-6inchesfrom

the cleaningsurface.Forremovingextremelystubborndirt, it maybe

necessarytomovethespraynozzleevencloserto thesurfacefor

greaterdirtcuttingaction.

Driveway,Sidewalks, Patios,Brick

Re-rinsecleaningsurfacewith freshwater.If usingdetergentor

Degreaser,applytosurfaceat lowpressure.Forbestresults,limit your

work areato smallersectionsof approximately25squarefeet.Allow

detergentorDegreaserto remainon surface1-3minutes.Donotallow

detergentto dryonsurface.Rinseat highpressureina sweeping

motionkeepingthespraynozzleapproximately3-6inchesfromthe

cleaningsurface.Alwayscleanfromtopto bottomandfromleft to

right.Forremovingextremelystubbornstains,usetheTurboNozzle.

Decks

Re-rinsedeckandsurroundingareawith freshwater. If using

detergent,applyto surfaceat lowpressure.Forbestresults,limit your

workareato smallersectionsofapproximately25 squarefeet.Allow

detergentto remainonsurface1-3minutes.Donotallow detergentto

dryonsurface.Rinseathighpressurein alongsweepingmotion

keepingthespraynozzleapproximately3-6inchesfromthe cleaning

surface.Alwayscleanfromtopto bottomandfromleft to right.When

movingonto a newsectionof the cleaningsurface,besureto overlap

theprevioussectiontoeliminatestopmarksandensurea moreeven

cleaningresult.

HouseSiding

(Re-rinsecleaningsurfacewith freshwater. Ifusingdetergent,applyto

surfaceatlow pressure(forbestresults,limityourworkareato

sectionsof approximately6feet andalwaysapplydetergentfrom

bottomto top).Allow detergenttoremainonsurface1-3minutes.Do

notallowdetergentto dryonsurface,if surfaceappearsto bedrying,

simplywet downsurfacewith freshwater.If needed,usespecialwash

brushattachment(notincluded)to removestubborndirt.Rinseathigh

pressurefromtop tobottomin anevensweepingmotionkeepingthe

spraynozzleapproximately6 inchesfromthecleaningsurface.

Patioand LawnFurniture

Re-rinsefurnitureandsurroundingareawith freshwater.If using

detergent,applyto surfaceat low pressure.Allowdetergentto remain

onsurface1-3minutes.Donot allow detergentto dryonsurface.If

neededusespecialWashBrushattachment(notincluded)to remove

stubborndirt. Rinseat highpressurein a sweepingmotionkeepingthe

spraynozzleapproximately3-6inchesfromthe cleaningsurface.For

bestresults,cleanfromtoptobottomandfrom leftto right.

Symptom

Motorwill not start

Unitdoesnotreachhighpressure.

Cause

On/Offswitch is ill the "OFF"(0)position.

Powercordisnot pluggedin.

Electricaloutletdoesnot supplyadequatepower.

TrippedGFCIplug.

Trippedcircuit breaker.

PluggedWand

Diameterofgardenhoseistoosmall.

Watersupplyis restricted.

Notenoughinlet watersupply.

Water inletfilter isclogged.

Spraywand ison low pressureposition

Solution

Turnswitch tothe "ON" (1)position

Plugin powercord.

Tryadifferent outlet.

Press"RESET"button on GFCIplug.

Switchoff pressurewasher. Theresetcomesautomaticallyoncethe

temperatureoftheunit drops.

Turnunit off. If wandisplugged,thenthe waterwill be at full

pressuremakingdisconnectingwand difficult. Carefullydisconnect

wandand/or gun,cleanwand.

Replacewith a 5/8 inchor largergardenhose.

Checkgardenhosefor kinks, leaksandblockage.

Openwatersourcefull force.

Removefilter andrinse outin warm water.

Turnspraywand to highpressureposition(Seep.10)

Troubleshootingcontinuedonnextpage...

Rev:Feb2011 STANLEY - Electric PressureWashers 15of 18

Page 16

Symptom

Outputpressurevarieshighandlow.

Nodetergent.

Cause

Notenoughinletwater supply.

Pumpis suckingair.

Waterinletfilter isclogged.

Dischargenozzleisobstructed.

Calcifiedgun,hoseorspraywand.

Detergentsuctiontubenotproperlyconnectedto

themachine.

Solution

Turnwateronfull force.Checkgardenhosefor kinks,

leaksor blockage.

Checkthat hosesandfittings areair tight.Turnoff ma-

chine. Purgepumpbysqueezingtriggergununtil a

steadyflow ofwateremergesthroughthenozzle.

Removefilter andrinseoutinwarmwater.

Blowoutorremovedebriswith afineneedle.

Rundistilledvinegarthroughdetergentsuctiontube.

Checkconnection.

Gardenhoseconnectionleaks.

Spraywand,orextension,ornozzleleaks.

Pumpisnoisy.

Water leaksfrompump(upto 10dropsper

minuteispermissible).

OilDrips.

Motorbuzzesbutfailsto run.

Detergentistoothick.

Filteron detergentsuctiontubeisclogged.

Damagedorcloggeddetergentsuctiontube.

Spraywandis inhighpressureposition.

Dischargenozzleisobstructed.

Loosefittings.

Missing/wornrubberwasher.

Spraynozzlenot properlyattached.

Brokeno-ringor plasticinsert.

Pumpis suckingair.

Loosefittings.

Watersealsaredamagedorworn.

Oilsealsaredamagedorworn.

Supplyvoltagebelowminimum.

Dilutedetergent,for bestresultsuserecommended

detergent.

Runwarmwaterthroughfilter toremovedebris.

Removeobstructionorreplacedetergentsuctiontube.

Turnspraywandtip to lowpressureposition.

Blowoutorremove

Tightenfittings.

Insertnewwasher.

Insertthespraynozzleinto thetriggerCarefullypressin

againstthespringtensionandtwist intothe locked

position.

CallCustomerSupport

Checkthat hosesandfittings areair tight.Turnoff

machineandpurgepumpbysqueezingtriggergununtil a

steadyflow ofwateremergesthroughthenozzle.

Checkthat allfittings aretight.

CallCustomerSupport

CallCustomerSupport

Verifythat onlythe pressurewasheris runningonthis

circuit.

Systemhasresidualpressure.

Voltagelossdueto extensioncord.

Pressurewashernotusedfor longperiods

IF YOU ENCOUNTERANY ADDITIONAL DIFFICULTIESNOT LISTED,CALLCUSTOMERSERVICEAT

16of18 STANLEYi Electric PressureWashers Rev:Feb2011

Turnunit "'OFF",squeezetriggeronspraywantto release

pressure,then turn unit"'ON".

Donot useextensioncordwith this unit--plug directly

intopoweroutlet.

CallCustomerService.

[1] 919-550-3259FORASSISTANCE.

Page 17

LimitedWarranty & Service

LIMITED I YEARWARRANTY

TERMOFTHISWARRANTY:

Thispressurewasheriswarrantedto befree of defectsin materialsandworkmanshipundernormalresidentialusefor aperiodof 1year. Thiswarrantyappliesto the

electricmotorandthe pumpfor 1year.(Normalwearandmaintenanceitemssuchas the cord,GFCIbreaker,wand,hose,tips,seals,and otherattachmentsare

warrantedfor 90days.)Warrantyrepairswill bemadewithout chargeforpartsand laborfor thefirst 90 daysfromthe dateof purchase.After thefirst 90days,this

limitedwarrantycoversthe costsofreplacementpartsonthe pressurewasherunitonly. Anycommercial,industrialorrentaluseof the productwill reducethe termof

thiswarrantyto 30daysfor all components.

TOQUALIFYFORTHISWARRANTY:

Theproductmustbepurchasedinthe UnitedStates,Canadaor Mexicofroma retailstore authorizedby GXiOutdoorPowerEquipmentLLCto sellthe product.This

warrantyappliestofirst retail purchaser/ ownerduringthe applicablewarrantytimeperiod.Aproofof purchasereceiptshowingdateof purchaseandauthorizedretail

storeanda valid productserialnumberarerequiredtodemonstratewarrantyeligibility.

WHATGXIPARTSANDSERVICELLCWILLREPAIRORREPLACEUNDERWARRANTY:

GXIPARTSANDSERVICELLCwill repairor replace,atits option,anypartthat is provento bedefectivein materialorworkmanshipundernormaluseduringthe

applicablewarrantytime periodsubjectto the exclusionsstatedherein. Thiswarrantyisvoidif the ownerfails to followthe prescribedmaintenanceandoperating

proceduresdescribedin this manual.Onlyfailureswhereanidentifiablemanufacturingdefectcanbe identifiedwill becoveredunderthetermsofthis warranty.

GXIPARTSANDSERVICELLChasthe rightto recoverwarranty administrationcostsfrom theowner if the root causeofthe malfunctionwasfoundto beotherthan

defectivematerialorworkmanship.Anythingreplacedunderwarrantybecomesthepropertyof GXIPARTSANDSERVICELLC. Partsreplacedunderwarrantywill be

consideredas partofthe originalproductandanywarrantyonthosepartswill expirecoincidentwith theoriginalproductwarranty.

TOOBTAINWARRANTYSERVICE:

ContactGXIPARTSAND SERVICELLCto obtainwarrantyreturnauthorizationanddirectionsasto whereto sendyourproductfor evaluation.Haveyourproofof

purchaseandthe productserial numberavailable whenyoucall. Two optionsfor warrantyserviceareavailable:

EasyReturnService- ContactGXIPARTSANDSERVICELLCfor apre-paidreturnshippinglabel andinstructionsto shipthe productto ourrepairfacility. If

there isa manufacturingdefectidentified,the productwill berepairedandreturnedtothe customerfree of allcharges.Intheeventthere is a non-warranted

repairrequired,GXIPARTSANDSERVICELLCwill notifythe customerof the repairandreturnshippingcostspriorto proceedingwith repairs.If paymentis

notreceivedwithin 60daysthe productwill bedisposedof.

Advance ExchangeService -ContactGXIPARTSANDSERVICELLCandprovidea valid creditcard,a $75pre-authorizationwill be madeagainstyour

card.GXIPARTSANDSERVICELLCwill ship a replacementunitcompletewith accessoriestoyou with apre-paidreturnshippinglabeland instructionsto

shipthe faultyproductandcompletesetof accessoriesto ourrepairfacility. If thereisamanufacturingdefect,the pre-authorizedchargeswill becancelled.

Inthe eventthereis a nonwarrantedrepairrequiredoraccessoriesare missing,GXIPARTSANDSERVICELLCwill chargethe customer'scardfor the repairs

andthemissingaccessories.

Ifyouarenot satisfiedwith warrantyservice,contactGXiPARTSANDSERVICELLC.Ifyouareunableto resolveproblemsandrequirefurtherassistance,write to GXI

PARTSANDSERVICELLCCustomerService.

EXCLUSIONS:

THISWARRANTYDOESNOTEXTENDTOPARTSAFFECTEDORDAMAGEDBYACCIDENTAND/ORCOLLISION,NORMALWEAR,CONTAMINATION,USEINAN

APPLICATIONFORWHICHTHEPRODUCTWASNOTDESIGNEDORANYOTHERMISUSE,NEGLECT,INCORPORATIONORUSEOFUNSUITABLEATTACHMENTSOR

PARTS,UNAUTHORIZEDALTERATION,ORANY CAUSESOTHERTHANDEFECTSIN MATERIALORWORKMANSHIPOFTHEPRODUCT.INPARTICULAR,THIS

WARRANTYDOESNOTCOVERDAMAGECAUSEDBYFAILURETOFOLLOWPRESCRIBEDWARNINGSANDOPERATINGPRACTICES;FAILURETOFOLLOWPROPER

MAINTENANCEANDSTORAGEPROCEDURES;ANDPHYSICALDAMAGEDUETOSHIPPING,HANDLINGORSTORAGE.

DISCLAIMEROFCONSEQUENTIALDAMAGEANDLIMITATIONOFIMPLIEDWARRANTIES:

GXIPARTSANDSERVICELLCDISCLAIMSANYRESPONSIBILITYFORLOSSOFTIMEORUSEOFTHEPRODUCT,TRANSPORTATION,COMMERCIALLOSS,ORANY

OTHERINCIDENTALORCONSEQUENTIALDAMAGE.ANYIMPLIEDWARRANTIESARELIMITEDTOTHEDURATIONOFTHISWRITTENLIMITEDWARRANTY.

Commercial LawnMowers Heaw DutyPressureWashers Chipper Shredders GeneratorAccessories

M_E SOM_HING GREAT_°

Page 18

Extended Protection Plan

TERMOFTHISAGREEMENT:

GXlPARTSAND SERVICELLCwill repairor replacethe pressurewasher shouldthe pump,motor,orframecomponentsfail undernormalresidentialusagewithin theFiveYearCoverage

Period(fromthe originaldateof purchase).Upto two replacementswill beprovidedduringthelife of theagreement.

Thecord,GFCIbreaker,wand,hose,trigger assemblyandotherattachmentsarewarrantedunderthetermsof the standardwarrantyfor 90days.Any commercial,industrialor rentaluseof

the productwill void this agreement.

TOQUALIFYFORREPAIRSUNDERTHISAGREEMENT:

TheProductProtectionPlanmustbe purchasedand paidin full a residentialcustomer.Productmustbe purchasedin the UnitedStates, MexicoorCanadafromadealerauthorizedby GXi

OutdoorPowerEquipmentLLCtosell thoseproducts.Thiswarranty appliesto first retail purchaser/ ownerand isnon-transferable.Aserialnumberandproof ofpurchasereceiptshowing

dateof purchaseandauthorizeddealeris requiredtodemonstratewarrantypurchaseeligibility.

WHATGXIPARTSAND SERVICELLCWILLREPAIRORREPLACEUNDERAGREEMENT:

GXIPARTSAND SERVICELLCwill repairor replacewith a newor reconditionedproduct,at its option,any part thatfails undernormaluseduringthe applicablewarrantytime periodsubject

to theexclusionsstatedherein. Thisagreementis voidif the ownerfails to follow the prescribedmaintenanceandoperatingproceduresdescribedinthe productmanual.

GXIPARTSAND SERVICELLChasthe right to recoveradministrationcostsfromthe ownerif the rootcauseofthe failure isfoundto beother thanconditionscoveredbythis

agreement. Anythingreplacedunderthis agreementbecomesthe propertyof GXIPARTSANDSERVICELLC. Partsreplacedunderthisagreementwill onlybecoveredfor the term ofthe

agreement.Nowarranty of anykind beyondthetermof thisagreementis implied.

TOOBTAINSERVICE:

ContactGXIPARTSAND SERVICELLCto obtainreturnauthorizationanddirectionsasto wheretosendyourproductfor evaluation.Have yourProduct ProtectionPlan receipt andthe

productserial numberavailable when you call.

EasyReturnService - ContactGXIPARTSAND SERVICELLCfor a pre-paidreturnshippinglabelandinstructionstoshipthe productto ourrepair facility. If thereisa failure

coveredundertheterms ofthis agreement,theproductwill be repairedandreturnedtothe customerfreeof allcharges.In the eventthere isa repairrequiredthat is not

coveredundertheterms ofthis agreement,GXIPARTSANDSERVICELLCwill notify thecustomerofthe repairand returnshippingcostspriorto proceedingwith repairs.If

paymentis not receivedwithin 60daystheproductwill be disposedof.

Advance Exchange Service- ContactGXIPARTSAND SERVICELLCandprovideavalidcredit card,a$75pre-authorizationwill be madeagainstyourcard.GXIPARTSAND

SERVICELLCwill shipa replacementunitto youwith a pre-paidreturnshippinglabelandinstructionstoshipthe faulty productto ourrepairfacility. If thereis a failurethat is

coveredundertheterms ofthis agreement,thepre-authorizedchargeswill be cancelled.Inthe eventthere isa non-coveredrepairrequiredor accessoriesare missing,GXI

PARTSANDSERVICELLCwill chargethecustomer'scardfor the repairsandthe missingaccessories(oneway freight?)Theother guypaysfor this.

Ifyouare notsatisfiedwith serviceunderthis agreement,contact GXIPARTSAND SERVICELLC.However,if youshouldrequirefurtherassistance,write to GXIPARTSANDSERVICELLC,

attention customerService.

EXCLUSIONS:

THISAGREEMENTDOESNOTEXTENDTOPARTSAFFECTEDORDAMAGEDBYACCIDENTAND/ORCOLLISION,CONTAMINATION,USEINAN APPLICATIONFORWHICHTHEPRODUCT

WASNOTDESIGNEDORANYOTHERMISUSE,NEGLECT,INCORPORATIONORUSEOFUNSUITABLEATTACHMENTSORPARTS,UNAUTHORIZEDALTERATION,ORANYCAUSESOTHER

THANNORMALUSEOFTHEPRODUCT.IN PARTICULAR,THISWARRANTYDOESNOTCOVERDAMAGECAUSEDBYFAILURETOFOLLOWPRESCRIBEDWARNINGSAND OPERATING

PRACTICES;FAILURETOFOLLOWPROPERMAINTENANCEANDSTORAGEPROCEDURES;ANDPHYSICALDAMAGEDUETOSHIPPING,HANDLINGORSTORAGE.

DISCLAIMEROFCONSEQUENTIALDAMAGEAND LIMITATIONOBLGATIONSUNDERTHISAGREEMENT:

GXIPARTSAND SERVICELLCDISCLAIMSANYRESPONSIBILITYFORLOSSOFTIMEORUSEOFTHEPRODUCT,TRANSPORTATION,COMMERCIALLOSS,ORANYOTHERINCIDENTALOR

CONSEQUENTIALDAMAGE.

THISAGREEMENTISVOIDIFTHEMANUFACTURINGDATEAND THESERIALNUMBERONTHEEQUIPMENTHASBEENREMOVEDORTHEEQUIPMENTHASBEENMODIFIED.THE

AGREEMENTISNOTTRANSFERABLE,NON-REFUNDABLEANDHASNOCASHVALUE.

ProductProtectiT;nPlanfeatures,prlci/7_7andspeclficatiT;nsaresublectto changewithoutnotice. PleasecontactOXIPAHTSAND SEHVICELLCat I'1!919-558-3259or ViSl?

ww_pressurewashergl l.comto verlT_vprl_l_7_andavalYablTiT!_

Product RegistrationCard

Name:

Address:

City,State,ZipCode:

PhoneNumber:

FaxNumber:

E-mail:

PressureWasherModel:

P1450S P1450S-CAN P1600S P1600S-BB P1600S-CAN

P1750S P1750S-CAN P1800S P1800S-BB P1800S-CAN

Serial Number:

Storeof Purchase:

DateofPurchase:

Pleaseattacha copyofyoursales receipt.

I would like topurchasethe ExtendedProtectionPlan:

Within 30daysfromdate ofpurchase:$89.99

Within 12monthsfromdateof purchase:$109.99

Within 18monthsfromdateof purchase:$129.99

No,thankyou. Noproductprotectionplanselected.

FormofPayment:

Paymentenclosed.Pleasemakepayableto: GXiPartsandService

ChargeMyCreditCard: VISA MASTERCARD

CreditCardNumber:

ExpirationDate:

Mail To: GXiPartsandService

7868USHighway70, SuiteC

or FaxTo:

[1]919-550-3277

Clayton,NO27520

Page 19

Contents:

Page2

Page3

Page5

Page6

Page8

Page9

Page10

Page14

Page15

Page16

Page17

Page18

FactoryOriginalParts

PackageContents/ComponentIdentification

MissingPartsRequestForm

Warnings

Preparation& Assembly-Model1450S,1450S-CAN,

P1600S,P1600S-BB,P1600S-CAN

Preparation& Assembly-Model 1750S,1750S-CAN

P1800S,P1800S-BB,P1800S-CAN

Maintenance

Tipsfor Cleaning

Troubleshooting

Warranty

ExtendedWarranty& ProductRegistrationCard

®

Pressure Washer Owner's Manual

This Manual ContainsImportantSafety Instructionsand Operating Instructions

Models: P1450S,P1750S,P1450S-CAN,P1750S-CAN

P1600S,P1800S,P1600S-BB,P1800S-BB, P1600S-CAN,P1800S-CAN

Operation

IMPORTANT SAFETYINSTRUCTIONS:

READSAFETYWARNINGS AND OPERATING INSTRUCTIONS CAREFULLY

DONOTRETURNTHIS

PRESSUREWASHERTO

www. PressureWasher911.com

Havethefollowing informationreadywhenyoucallus:

DateofPurchase:

LocationofPurchase:

Serial#:

SAVETHESE INSTRUCTIONS

THESTORE!

QUESTIONSORNEEDHELP?

Call: 919-550-3259

Is a registeredtrademarkof TheStanleyWorksorits affiliates and

is usedunderlicensebyGXiOutdoorPower,LLC,7868 Highway70

Business,Clayton,NC27520

Page 20

ORDERONLINE NOW AND SAVE!

www.PressureWasher911.com

Phone orders, call [1] 919-550-3259

Please havethe part number and credit card readywhen calling.

ReplacementGun

PartNumber:SP01009

PhonePrice: $30.00

Web Price: $27.90

ReplacementAdjustableWand

PartNumber:SP00209(ModelP1450S,1450S-CAN,

P1600S,P1600S-BB,P1600S-CAN)

PartNumber:SP00309(ModelP1750S,1750S-CAN,

P1800S,P1800S-BB,P1800S-CAN)

PhonePrice: $30.00

Web Price: $27.90

RotaryBrush StraightBrush

ReplacementTurboWand

PartNumber:SP00409

PhonePrice: $30.00

Web Price: $27.90

ReplacementHighPressureHose

PartNumber:SP00509(ModelP1450S,1750S,P1450S-

CAN,1750S-CAN,P1600S,P1600S-BB,

P1600S-CAN,P1800S,P1800S-BB,

P1800S-CAN)

PhonePrice: $30.00

Web Price: $27.90

ReplacementRotaryandStraightBrush

PartNumber:SP00709(RotaryBrush)

PartNumber:SP00809(StraightBrush)

PhonePrice: $30.00Each

Web Price: $27.90Each

Page 21

PACKAGECONTENTS(P1450S,P1450S-CAN,P1600S,P1600S-BB,P1600S-CAN)

B

C

PartLetter _art Name NumberofPieces ReplacementPart Number

A 3unAssembly 1 SP00109

B _,djustablewand 1 SP00209

C Furbowand 1 SP00409

D _ndP1750Sand can he purchasedseparately) 1 SP00709

E PI450SandP1750Sand canhe purchasedseparately) 1 SP00809

F _oapInjectorandBottle 2 SP00909

G 3unHolder/WandHolder(P1450S,P1450S-CAN,P1600S,P1600S-BB,P1600S-CAN) 1 SP01O09

H }wner's Manual(inhardwarebag) 1 SP00609

I FoolBelt 1 SP01109

J SP01209

K SP00509

L SP00609

M SP00609

i i [

Optionalfeaturethat is

soldseparately

I,

PARTS LIST for Model P1450S, P1450S-CAN, P1600S, P1600S-BB, P1600S-CAN

_otaryBrush(optional--comes with only certain modelssuch as the PI450S

;traightBrushBrush(optional--comes with only certainmodelssuchas the

4igh-pressurehosestrap 1

4ighPressureHose(P1450S,P1450S-CAN,P1600S,P1600S-BB,P1600S-CAN) 1

17mmWrench(inhardwarebag) 1

}leaningNeedle(inhardwarebag) 1

i

N SP01309

0 SP00609

3rassQuick-connectcoupling& InletAdapter(optional--comes with only certain

wodelssuchas the PI450S andPI750S andcanhe purchasedseparately) 2

/VaterInletFilter(inhardwarebag) 1

P SP00609

}-Rings(inhardwarebag) 5

Order replacement parts online: www.PressureWasher91

Phone orders, call [1] 919-550-3259. Please have the part number and a credit

Rev:Feb2011 STANLEY i Electric PressureWashers

@

1.com

card ready when calling.

3of18

Page 22

PACKAGECONTENTS(P1750S,P1750S-CAN,P1800S,P1800S-BB,P1800S-CAN)

HoseReel

B

HoseReelHandle J

C

Optionalfeaturethat is

soldseparately

G

N 0 P Q R

PARTS LISTfor Model P1750S,P1750S-CAN, P1800S, P1800S-BB, P1800S-CAN

PartLetter PartName NumberofPieces ReplacementPartNumber

A GunAssernbly 1 SP00109

B Adjustablewand 1 SP00309

C Turbowand 1 SP00409

M

Phone

4of18

RotaryBrush(optional--comes with only certain modelssuch asthe PI450S

D andP1750S andcan bepurchasedseparately) 1 SP00709

E StraightBrush 1 SP00809

F Gun/wandHolder(P1750S,P1750S-CAN,P1800S,P1800S-BB,P1800S-CAN) 1 SP01409

G ExtensionHose 1 SP01509

H Owner'sManual(inhardwarebag) 1 SP00609

I HoseReel 1 SP01609

J HoseReelHandle 1 SP01709

K HighPressureHose(P1750S,P1750S-CAN,P1800S,P1800S-BB,P1800S-CAN) 1 S%2409

L SoapBottleandBracket 2 SP01809

M FootRest 1 SP01909

N 7rnrnWrench(in hardwarebag) 1 SP00609

0 CleaningNeedle(inhardwarebag) 1 SP00609

BrassQuick-connectcoupling& InletAdapteropt/ona/--comes with only certain

P modelssuchas the PI450S andP1750S andcan bepurchasedseparately) 2 SP01309

Q WaterInletFilter(inhardwarebag) 1 SP00609

R O-Rings(inhardwarebag) 5 SP00609

Order replacement parts online: www.PressureWasher911 .com

orders, call [1] 919-550-3259. Please have the part number and a credit card ready when calling.

STANLEY{R}Electric PressureWashers Rev:Feb2011

Page 23

Missing PartsRequestForm

Pleaseindicate the part that you aremissing:

[] Hardwarebag

[] Other Address

[] Dateof purchase

Model#:

[] Serial#:

Comments:

Name

Phone

Email

IMPORTANT:Please include yourreceipt. Without a receipt, your

orderwill be delayed.Youmayalso email us at:

customerservice@gxioutdoorpower.com

Fax: 1-919-550-3277

If emailing, please scan in your proof of purchase.

Otherfine productsoffered by

Electric Pressure Washer

Rev:Feb2011 STANLEY i Electric PressureWashers 5of18

Generators

®

Commercial Mowers

Page 24

WARNINGS

Thisowner'smanualisconsidereda permanentpartofthe pressure

washerandshouldremainwith thepressurewasherif resold.The

informationandspecificationsincludedinthis publicationwerein

effectat the timeof approvalfor printing.

GXiOutdoorPower,LLCreservestheright to discontinueor change

specificationsor designatanytimewithout noticeandwithout

recurringanyobligationwhatever.Nopart ofthis publicationmaybe

reproducedwithout written permission.

SAFETYLABELLOCATIONS

Theselabelswarnyouof potentialhazardsthat cancauseserious

injury.Readthemcarefully. If alabelcomesoffor becomeshardto

read,contactCustomerCarefora replacement.

SAFETYINFORMATION

STANLEYpressurewashersaredesignedtogivesafeanddependable

serviceif operatedaccordingto instructions.Readandunderstandthis

owner'smanualbeforeoperatingyourpressurewasher.

OPERATORRESPONSIBILITY

Knowhowto stopthepressurewasherquicklyincaseofemergency.

Understandthe useof all productcontrols,outputreceptacles,and

connections.Besurethat anyonewhooperatesthepressurewasher

receivesproper instruction.Donotlet childrenoperatethepressure

washer.

• Tominimizethe amountof watergetting intothepressurewasher,

theunitshouldbeplacedasfar aspossiblefromthecleaningsite

duringoperation.

• Nevercarryyour pressurewasherbythe cord.Donotpull onthe

cordto disconnectfromthe outlet.

• Toallow free aircirculation,the pressurewashershouldnotbe

coveredduringoperation.

• CaliforniaProposition65:Thisproductor itspowercordcontains

lead,achemicalknowntothe StateofCaliforniatocausecancer,

birthdefectsorotherreproductiveharm.Washhandsafter use.

SAVETHESE INSTRUCTIONS

Servicingof a double-insulationproduct:

Inadouble-insulationproduct,two systemsofinsulationareprovided

insteadofgrounding.Nogroundingmeansisprovidedonadouble

insulated,product,norshoulda meansforgroundingbe addedtothe

product.Servicinga double-insulatedproductrequiresextremecareand

knowledgeof thesystem,andshouldbedoneonlybyqualifiedservice

personnel.Replacementpartsof adouble-insulatedproductmustbe

identicaltothepartstheyreplace.A double-insulatedproductismarked

with thewords"DOUBLEINSULATION"or "DOUBLEINSULATED".

[] Thesymbolmayalsobemarkedonthe product.

Useof pressurewasher cancreatepuddlesandslippery

surfaces.

• Thecleaningareashouldhaveadequateslopesanddrainageto

reducethepossibilityofa fall dueto slipperysurfaces.

Highpressurespraycouldcauseyouto fall ifyouare too close

tothe cleaningsurface.

Keepspraynozzlebetween8to 24 inchesawayfromcleaning

surface.

Operatethisunit onastablesurface.

Beextremelycarefulif youmustusethepressurewasherfroma

SAFETYFEATURESAND ELECTRICALPOWER

INFORMATION

Thepressurewasherisequippedwith astopdevicethatwill sense

whenthe triggeronthegunis released.Itwill openthepowercircuitto

themotorandcausethepressurewashermotorto stop. Motorwill

resumeagainwhentriggeris pulled.

pressure equipped

OFF"switch locatedonthe unit,It shouldalways be movedto

the "OFF"positionwhen thepressurewasher isnotbeingused

IThe washer isalso with main "ON/

to preventpossibleinjuryordamage,

ladder,scaffoldingor anyotherrelativelyunstablelocation.Firmly

graspspraygunwithbothhandswhenusinghighpressuresprayto

avoidinjuryif gunkicksback.

Ground Fault Circuit Interrupter:

Thispressurewasherhasa ground-faultcircuit-interrupter(GFCI)built

intotheplugof thepowersupplycord.Thisdeviceprovidesadditional

Somechemicalsor detergentsmaybeharmfulif inhaled or

ingested,causingseverenausea,faintingor poisoning.

protectionfromthe riskofshock.Shouldreplacementof the plugorcord

becomenecessary,useonlyidenticalreplacementpartsthat include

GFCIprotection.

• Usea respiratorormaskwheneverthereis achancethatvapors

maybeinhaled.

• Readall instructionswith masksoyouarecertainthemaskwill

WHEN OPERATINGEQUIPMENT

intoa groundfault circuit-interrupterfoundincircuit boxesor

Extensioncordsare notrecommendedunlesstheyare plugged

protectedreceptacles,

• Avoidaccidentalstarts.Shutpower"OFF"beforeconnectingor

disconnectingcordto electricaloutlets.

• DONOTsprayflammableliquids.

• Donot useacidsandsolventsinthis product.Theseproductscan

causephysicalinjuriesto theoperatorandirreversibledamageto

the machine.

• Donot usewith flammableliquidsandtoxicchemicals.

6of18 STANLEYi Electric PressureWashers

a

Rev:Feb2011

power

Page 25

WARNINGS

ExtensionCords

If possible,donot useextensioncordswith this

product.However,if youmustuseone,observeall

thewarningsandinstructionslistedbelow:Usea sufficientgauge:

• Maximumcablelength:50ft =14AWG

• Useonlyextensioncordsthatare intendedforoutdooruse.These

extensioncordsare identifiedby amarking"Acceptableforuse

with outdoorappliances;storeindoorswhile not in use."

• Useonlyextensioncordshavinganelectricalratingnotlessthan

the ratingoftheproduct.

• Donot usedamagedextensioncords.Examineextensioncord

beforeusingandreplaceif damaged.

• Donot abuseextensioncordanddonotyankonanycordto

disconnect.

• Keepcordawayfromheatandsharpedges.

• Alwaysdisconnecttheextensioncordfromthe receptaclebefore

disconnectingtheproductfromtheextensioncord.

• Toreducetheriskof electrocution,keepallconnectionsdry andoff

the ground.Donottouchplugwith wet hands.

Impropertreatmentofthe pressurewashercan damageit and

shortenitslife.

• If youhavequestionsaboutintendeduse,askdealeror contact

CustomerServiceat[1]919-550-3259.

• NEVERoperateunitswith brokenormissingparts,orwithout

protectivehousingorcovers.

• DONOTbypassanysafetydeviceonthismachine.

• Beforestartingpressurewasherin coldweather,checkallpartsof

theequipmentto besureicehasnotformedthere.

• NEVERmovemachinebypullingonhighpressurehose.Usehandle

providedon unit.

• Thisequipmentisdesignedto beusedwith STANLEYauthorized

partsONLY.If equipmentis usedwith partsthatDONOTcomply

with minimumspecifications,userassumesall risksandliabilities.

WARNING

Thepressurewasherisalsoequippedwith a mainpower"ON/OFF"

switchlocatedonthe unit.It shouldalwaysbemovedtothe "'OFF"

positionwhen thepressurewasherisnotbeingusedtopreventpossible

injuryordamage.

A pressurewasher producesa highpressurespraywhich

increasesrisk ofinjuryanddamagetounit.

• GunKicksBack-Holdwith bothhands!

• Thetriggergunsafetylockpreventsthetriggerfromaccidentally

beingengaged.ThesafetyfeatureDOESNOTlocktriggerinthe ON

position.

• DONOTsecurespraygunin openposition.

• DONOTleavespraygununattendedwhile machineisrunning.

• NEVERuseaspraygunwhich doesnothaveatrigger lockor

triggerguardin placeandinworkingorder.

• Alwaysbe certainspraygun,nozzlesandaccessoriesarecorrectly

attached.

Highpressurespraymaydamagefragile itemsincludingglass.

• DONOTpointspraygunat glasswheninjet spraymode.

• NEVERaimspraygunatplants.

Thehighpressurestreamof water thatthis equipmentproduces

canpierceskin anditsunderlyingtissues,leadingto serious

injuryand possibleamputation.

Sprayguntrapshighwater pressure,evenwhen pumpis not

runningandwater is disconnected,which cancauseinjury.

• NEVERaimspraygunat people,animals,plants,electricaldevices,

orthe unit itself.

• DONOTallowCHILDRENtooperatepressurewasher.

• Toreducethe riskof injury,donotoperatethemachinenear

children

• NEVERrepairhighpressurehose.Replaceit.

• NEVERrepairleakingconnectionswith sealantof anykind.

Replaceo-ringor seal.

• Keephighpressurehoseconnectedto pumpandspraygunwhile

systemispressurized.

• ALWAYSpointguninsafedirectionandsqueezesprayguntrigger,

toreleasehighpressure,everytimeyoustopengine. Engage

triggerloci<whennotin use.

Riskof Electrocution

Inspectcordbeforeusing-Donotuseif cordis damaged.

Keepall connectionsdryandoff theground.

Donot touchplugwith wet hands.

Donot useextensioncordswith theproduct.

Waterspraymustneverbedirectedtowardsanyelectricwiring,

devicesor directlytowardsitself.

Riskof Explosion

Highpressurespraycan causepaint chipsor otherparticlesto

becomeairborne.

• Alwayswear eyeprotectionwhen usingthisequipmentorin

vicinity ofwhere equipmentisin use.

Rev:Feb2011 STANLEY i Electric PressureWashers 7 of 18

®

Donot sprayflammableliquids

Donouseacidsandsolventsin thisproduct.Theseproductscan

causephysicalinjuriesto theoperatorandirreversibledamageto

themachine.

Page 26

PREPARATION& ASSEMBLY- Model P1450S,P1450S-CAN,P1600S,P1600S-BB,P1600S-CAN

Assembly Time: 5 minutes

Tools Required: 17mmor Adjustable Wrench

SurfacePreparation

• Beforestartinganycleaningtask,it is importanttoinspectthearea

for objectswhichcouldcreatea hazard.

• Removeanyobjectsfromthework areawhichcouldbetripped

over,suchastoysor outdoorfurniture.

• Ensurethat all doorsandwindowsareclosedtightly.

Step 1

• Removeorpeeloff blueprotectivefilmontile front ofthe pressure

washerandonthe wands(if applicable).Also, removeanybubble

wrap. Discardblueprotectivefilmandbubblewrap.

Step 2

• Attachtile QuickConnectInletcouplingto watersupplyinlet on

pressurewasher,asshownin Figurebelow.

Step 5

• Attachotherendof HighPressureHosetoGunasshownin Figure

below. Fastentightlywith 17mmwrenchto avoidleakage.

Step 6

• AttachShoulderStrapto tile StrapBracketas showninFigure

below.

Step 3

• Attach WandBrackettotile unitasshowninFigurebelow.

Step4

• Attach HighPressureHoseto MainUnitasshownin Figurebelow.

Step 7

• Attachtile hoseholderstraptotile sideof tile unit asshownin

Figurebelow.

ForOperating Instructions, proceed to page 9.

8of18 STANLEYi Electric PressureWashers Rev:Feb2011

{m

Page 27

PREPARATION& ASSEMBLY- Model P1750S,P1750S-CAN,P1800S,P1800S-BB,P1800S-CAN

Assembly Time: 5 minutes

Tools Required: 17mm or Adjustable Wrench

SurfacePreparation

• Beforestartinganycleaningtask,it is importanttoinspectthearea

for objectswhichcouldcreatea hazard.

• Removeanyobjectsfromthework areawhichcouldbetripped

over,suchastoysor outdoorfurniture.

• Ensurethat all doorsandwindowsareclosedtightly.

Step 1

• Removeorpeeloff blueprotectivefilmontile front ofthe pressure

washerandonthe wands(if applicable).Also, removeanybubble

wrap. Discardblueprotectivefilmandbubblewrap.

Step 2

• Attachtile QuickConnectInletcouplingto watersupplyinlet on

pressurewasherasshownin Figurebelow.

Step 5

• Attachtile L-shapecouplerendof tile extensionhose(F)intothe

wateroutlet asshowninFigurebelow. Fastentightly to avoid

leakage.

Step 6

• Attachtile straightcouplerendof tile extensionhoseintotile hose

reelinletas shownin Figurebelow. Fastentightlyto avoid

leakage.

Step 3

• Attachtile gun/wandholderasshownin Figurebelow.

Step 4

• Attachtile soap/detergentbracket,bottle,siphonhose,asshown

in Figurebelow.

Step 7

• AttachHighPressureHoseto Gunasshownin Figurebelow.

Fastentightlywith 17mmwrenchto avoidleakage.

Step 8

• Attachfoot bracketasshownin Figurebelow.

ForOperating Instructions, proceed to page 9.

Rev:Feb2011 9 of 18

STANLEY i Electric PressureWashers

{m

Page 28

HOW TO USETHE PRESSUREWASHER

OPERATION

If youhaveanyproblemsoperatingyourpressurewasher,

pleasecallthe pressurewasherhelp-lineat [1] 919-550-3259.

PressureWasherClearance

Prevailingwindsandaircurrentsshouldbetakenintoconsideration

whenpositioningpressurewasher.

• Keepspraynozzlebetween8to 24 inchesawayfromcleaning

surface.

• Operatethisunit onastablesurface.

• Beextremelycarefulif youmustusethepressurewasherfroma

ladder,scaffoldingor anyotherrelativelyunstablelocation.

• Firmlygraspspraygunwith bothhandswhen usinghighpressure

sprayto avoidinjuryif gunkicksback.

High pressure spray could cause you to fall if you are too

close to the cleaning surface.

Thehighpressurestreamof water thatthis equipmentproduces

canpierceskin anditsunderlyingtissues,leadingto serious

injuryand possibleamputation.

Sprayguntrapshighwater pressure,evenwhen motoris

stoppedandwater is disconnected,which can causeinjury.

Keephighpressurehoseconnectedto pumpandspraygunwhile

systemispressurized.

ALWAYSpointguninsafedirectionandsqueezesprayguntrigger,

toreleasehighpressure,everytimeyoustopengine.Engage

triggerlockwhen not inuse.

Step 1"

• Makesurethatthe ON/0FFswitchis inthe "'OFF"position.

Water Supply (ColdWater Only):

• Doriotdrawnon-waterliquidsthroughtile unit.Forusewith cold

water supplyonly.

• Water hosemustbeat leasta 1/2inchdiameter.

• Flowrateofwater supplymustnotfall below2GPM(gallonsper

minute).

• Flowratecanbedeterminedby runningthewater for oneminute

intoanempty5-galloncontainer.

• Thewater supplytemperaturemustnot exceed104°F

(4O°0).

A pressure washer produces a high pressure spray which

increases risk of injury and damage to unit.

• Alwayswear eyeprotectionwhen usingthisequipmentorin

vicinity ofwhere equipmentisin use.

• Beforestartingthepressurewasher,besureyouarewearing

adequateeyeprotection.

Step 2:

• Fastentile quick-connectcouplingontotile gardenhoseandthen

attachthe quick-connectingcouplingto theinlet adaptor,asshown

inthe Figurebelow.

Step 3:

• Insertthedesiredwandinto spraygun,andtwist 1/4turnuntil

rectangulartabappears.

Step 4:

• Touseanotherwand, reverseStep3 andinsertdesiredwandby

repeatingStep3.

10of18 STANLEYi Electric PressureWashers Rev:Feb2011

®

Page 29

OPERATION

A pressure washer produces a high pressure spray which

increases risk of injury and damage to unit.

• GunKicksBack-Holdwith bothhands!

• Thetriggergunsafetylockpreventsthetriggerfromaccidentally

beingengaged.ThesafetyfeatureDOESNOTlocktriggerinthe ON

position.

• DONOTsecurespraygunin openposition.

• DONOTleavespraygununattendedwhile machineisrunning.

• NEVERuseaspraygunwhich doesnothaveatrigger lockor

triggerguardin placeandinworkingorder.

• Alwaysbe certainspraygun,nozzlesandaccessoriesarecorrectly

attached.

Step5:

• Attachgardenhosetowater supplyandturnwater on.

Step 7

• Beforeturningtheunit"ON",depressthetriggertobleedany

trappedairoutof thepumpandhose.

Step 8

• Releasetriggerandstarttile pressurewasherbyturning0N/OFF

switchto ON.

Step6:

• Plugtile unitintoanoutlet.Make surethat the pressure

washer isthe only device pluggedintotheoutlet. Ifplugg#Tg

#7toagarageout/et,makesurethereare/7ootherdevicesp/ugged

#Ttoamyotherout/ets#7thegarage..Press"TEST".Thenpress

"RESET"to assureproperconnectionto power.

ON

Step 9

Adjustingthespray

• Turningtile nozzleallowsthe useofseveraldifferentspraytips.

Eachspraytip providesa differentspraypatternasshownin Figure

below.

Rev:Feb2011 STANLEY i Electric PressureWashers 11of 18

®

Page 30

OPERATION

WORKING WITH DETERGENTS

Workingwith detergentensuresa quicksoakingoftile dirt,andallows

the high-pressurewaterto penetrateandremovethedirt more

effectively.Alwaysspraydetergentonadry surface.Donotpre-soak

areawith plainwater.Wetting the surfacefirst dilutesthe detergent

andreducesits cleaningability.

Tosiphonandapplydetergent,youmustoperatethe pressurewasher

onlowpressure--slide thewand awayfromyouasshownin Step1.

Thisprovidesagentleapplicationofdetergent,with thepressure

equivalentto a low-setgardenhose.Thehigh-pressuresettingis used

for cleaning;youcannotapplydetergentswhenworkingat high-

pressure.Alwaystestdetergentinan inconspicuousareabeforeuse.

Step 1

P1450SP1600S:

Figurebelow.

P1750SP1800S:

towardsthe gun.

Insertyellowdetergentattachmentasshownin

Installtheadjustablewandintospraygunandpull

Step 3

• Gentlyremovedetergentcontainerandfill with detergent.

• Re-attachcontainersbackintoposition.

Step 4

Turnonthe pressurewasher.Pulltriggerto operateunit.Theliquid

detergentwill automaticallymixwith waterandbedischargedthrough

nozzle.Applydetergentto a DRYworksurface,frombottomtotop.

Step 5

Allowdetergentto remainontile surfacefora shorttime beforerinsing.

Donot allow detergentto dryonsurface.

Step 6

Rinsewith cleanwater underhigh-pressure.Ona verticalsurface,rinse

fromthe bottomup,thenrinsefromthetop downtoavoidstreaking.

Holdnozzle6-8inchfromthe worksurfaceata° 45angle.

Step 7 (End of detergent application)

Whenyouhavefinishedusingthedetergentinjectionsystem,remove

detergentsuctiontubefrombottleandinsertinto 1gallon(5L)offresh

water.Siphonwaterat low-pressureforoneto two minutesothat all

Diagramfor P1750SandP1800SONLY:

Tosiphondetergent,adjustthe nozzletothe low pressuresettingby

slidingthewandawayfromyou.

Step 2

P1750S and P1800S ONLY: Set the adjustable nozzleto the low

-pressuresetting. The nozzlemust beset in the low-pressure

position to apply detergent. Apply high pressure sprayto small

area and then check surface for damage. Ifno damage isfound,

you can assumeit is okayto continue cleaning. Startat top of

area to be rinsed,working down with sameoverlapping strokes

asusedfor cleaning.

................

i i!" f

12of18 STANLEYi Electric PressureWashers Rev:Feb2011

®

detergentis flushedthroughsystem.Removedetergentbottleandrinse

it until it is thoroughlycleaned.

Damage may occur to painted surface if chemical is

allowed to dry on surface. Wash and rinse asmall section

at atime. Avoid working on hotsurfaces or in direct

sunlight

Failure to clean properly will cause the injection system to

become clogged and inoperable.

Never use:

• Bleach, chlorine products and other corrosive

chemicals

• Liquids containing solvents (i.e., paint thinners,

gasoline, oils)

• Tri-sodium phosphate products

• Ammonia products

• Acid-based products

These chemicals will harm the unit and will damage the

surface being cleaned.

Page 31

OPERATION

Step 1

Turnthe switch to "OFF"(0)position and unplugcordfrom outlet

OFF

Step 2

Turn off the water supply.

Step3

Presstrigger to releasewater pressurefor 20-30 seconds.

STORING

Before storing the unit for an extended period be sure the storage area

is free of excessive humidity and dust.

StoragePreparationforPressurePump

Watershouldnot remaininthe unitfor longperiodsoftime. Sedimentsor

mineralscandepositonpumpparts and"freeze"pumpaction.If youdonotplan

to usethepressurewasherfor morethan30days,follow this procedure:

1. Flushchemicalinjectionhoseby placingfilter intoapail of cleanwater

while runningpressurewasherin low pressuremode.Flushfor oneto two

minutes.

2. Shutoff pressurewasherandlet it cool,then removehighpressureand

gardenhoses.

3. Emptypumpof liquidsbypullingenginerecoilhandleabout6times.This

shouldremovemost liquidfrompump.

4. Ensurepumpiscleanandemptytopreventcorrosionbuildupandfreezing

ofpumpcomponents.

5. Storeunitin a clean,dryarea.

We recommendstoringindoorswhere unitwill notbe exposed

tofreezingtemperatures.

Step 4

Disconnectthe garden hosefrom the water inlet onthe unit.

Step 5

Disconnectthe high-pressurehose from the high pressureoutlet

and engagethe gun safety lock.

If taking a break of five minutes or more:

1. Engagegun safety lock.

2. Turn pressurewasher to "OFF"(0) position.

3. Unplugthe power cord from the outlet.

Youmustprotectyourunitfromfreezingtemperatures.

• Failureto dosowill permanentlydamageyourpumpandrender

yourunit inoperable.

• Freezedamageisnotcoveredunderwarranty.

AlternativeProcedure

If youcannotperformtheOptimumWinterizingprocedure,

youcanstill protectyourpressurewasherfromwinter-damage:

1.Disconnectall waterconnections.

2.Turnonthe machinefor afew seconds.Presstriggerto bleedany

remainingwater inthepump.Turnoff immediately.

3.Removethe gunandhosefromthe pressurewasher.Drainany

excesswater.Roll hosecarefullyanddonot allow hoseto bekinked.

4.Storethemachineandaccessoriesin a roomthatdoesnotreach

freezingtemperatures.Donotstorenearfurnaceor otherhot areasas

it maydryouto-ringsandpumpseals.

CAUTION

Failuretofollow the abovedirectionswill result in damageto thepumpassembly

andaccessoriesandwill voidthe warranty. We recommendthe useof antifreeze

(PumpSaver)to preventcoldweatherdamageduringstorageinthewinter months.

Rev:Feb2011 STANLEY i Electric PressureWashers 13of 18

Page 32

MAINTENANCE

Connections

Connectionson pressurewasherhoses,gunandspraywand shouldbe

cleanedregularlyandlubricatedwith non-watersolublegrease.

Adjustable Nozzle Maintenance

Surging,orpulsingsensation,felt while squeezingthespraygun

triggermaybecausedbyexcessivepumppressure.Theprincipal