Oscar Solid Fuel Stove

INSTALLATION AND OPERATING INSTRUCTIONS

This appliance is hot while in operation and retains its heat for a long period of time after use.

Children, aged or infirm persons should be supervised at all times and should not be allowed

to touch the hot working surfaces while in use or until the appliance has thoroughly cooled.

When using the stove in situations where children, aged and/or infirm persons are

present a fireguard must be used to prevent accidental contact with the stove. The fireguard

should be manufactured in accordance with BS 6539.

2

TABLE OF CONTENTS

PAGE NO.

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Fire Cement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Asbestos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Metal Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. Pre-Installation Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3. Flues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4. Chimney . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

5. Top Flue Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

6. Rear Flue Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

7. Down Draughts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

8. Ventilation & Combustion Air Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

9. Permanent Air Vent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Extractor Fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

10. Commissioning & Handover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

11. Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

12. Clearance to Combustibles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

13. Stove Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

14. Floor Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

15. Lighting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

16. Primary Air Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

17. Recommended Fuels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

18. Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

19. Re-Fuelling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

20. Slow Burning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

21. Important Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

22. Lighting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

23. De-Ashing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

24. Disposal of Ash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

25. Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

26. Chimney Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

27. Fire Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

28. Brick Replacement / Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

29. Glass - Cleaning & Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

30. CO Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

31. Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

OSCAR SOLID FUEL NON-BOILER STOVE

INSTALLATION & OPERATING INSTRUCTIONS

GENERAL

When installing, operating and maintaining your

stove respect basic standards of fire safety.Read

these instructions carefully before commencing the

installation. Failure to do so may result in damage to

persons or property. Consult your local Municipal

office and your insurance representative to determine what regulations are in force. Save these

instructions for future reference.

Special care must be taken when installing the stove

such that the requirements of the Health & Safety at

Work Act are met.

Handling

Adequate facilities must be available for loading,

unloading and site handling.

Fire Cement

Some types of fire cement are caustic and should

not be allowed to come into contact with the skin. In

case of contact with the skin wash immediately with

plenty of water.

Asbestos

This stove contains no asbestos. If there is a possibility of disturbing any asbestos in the course of

installation then please seek guidance and use

appropriate protective equipment.

Metal Parts

When installing or servicing this stove care should

be taken to avoid the possibility of personal injury.

3

NOTE: Please note that it is a legal requirement

under England & Wales Building Regulations that

the installation of the stove is either carried out

under Local Authority Building Control approval or

is installed by a Competent Person registered with

a Government approved Competent Persons

Scheme. HETAS Ltd operate such a Scheme and

a listing of their Registered Competent Persons

can be found on their website at www.hetas.co.uk.

IMPORTANT WARNING: This stove must not be

installed into a chimney that serves any other

heating appliance. There must not be an extractor fan fitted in the same room as the stove as

this can cause the stove to emit fumes into the

room.

PRE-INSTALLATION ASSEMBLY

1. After removing the stove from the packaging,

open the fire door and remove all contents from

inside.

2. Fit the fire door handle using the screw provided.

3. Remove the stove from the pallet and position it

in the final installation position (See Location

& Clearance to Combustibles Section).

FLUES

Flues should be vertical wherever possible and

where a bend is necessary, it should not make an

angle of more than 45

o

with the vertical. Horizontal

flue runs should be avoided except in the case of a

back outlet from the appliance, when the length of

the horizontal section should not exceed 150mm.

In order to minimise flue resistance and to make

sweeping easier it is recommended to use 2 x 45

o

bends rather than a 90obend.

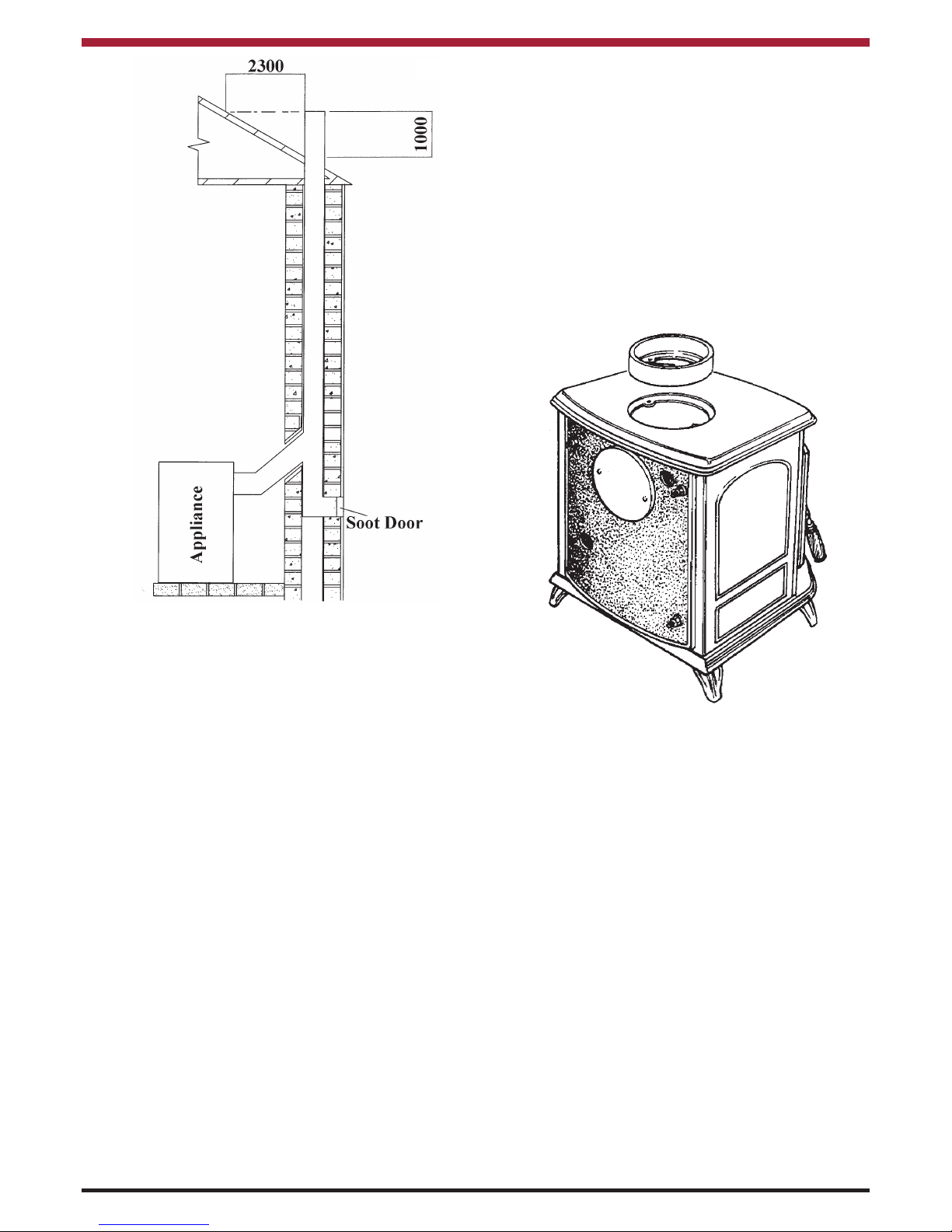

The flue termination point must be located to minimise any wind effects. Wind effects of suction,

pressure zones and turbulence can be created by

the roof and adjacent objects. Wind effects can also

be created by natural land contours.

To minimise the wind effects, the flue termination

point should be located a minimum of 600mm from

the roof measured vertically and 2300mm measured

horizontally. Where this termination point does not

suffice it may be necessary to extend the flue pipe

so that the termination point is above the apex. See

Fig.1.

The installation must be completed in accordance

with current National and European Standards and

Local Codes. It should be noted that the requirements and these publications may be superseded

during the life of this manual.

CHIMNEY

The stove is a radiant room heater and must be connected to a chimney of the proper size and type. The

chimney must have a cross-sectional area of at least

124cm

2

or a diameter of at least 125mm. Never

connect to a smaller size chimney. Do not connect

to a chimney serving another appliance. Minimum

chimney height 4.5 meters from floor on which stove

is installed.

A flue that has proved to be unsatisfactory, particularly with regard to down draught should not be used

for venting this appliance until it has been examined

and any faults corrected.

An existing masonry chimney should be inspected

and if necessary repaired by a competent mason or

relined using an approved lining system. The stove

must be connected to a chimney with a minimum

continuous draught of 12 Pascal’s. Poor draught

conditions will result in poor performance. All register plates, restrictor plates, damper etc., which could

obstruct the flue at a future date should be removed

before connecting this appliance. If connecting to

an existing chimney with a flue diameter of more

than 150mm it is necessary to line the flue using a

suitable stainless steel flue liner. Where a masonry

Fig.1

chimney is not available a proprietary type 125 –

150mm twin wall, fully insulated pipe may be used.

The pipe must terminate at a point not lower than the

main ridge of adjacent outside obstructions. With

such installation, access to the chimney must be

provided for cleaning purposes. (See Fig.1)

When flue piping passes through a closure plate

with a sliding door, ensure that the pipe continues

up and is ultimately connected to the flue liner and

well sealed with fire cement.

TOP FLUE EXIT

For the top outlet configuration, remove the blanking

plate (part no.10) from the hob, remove the flue

spigot (part no.11) from the back plate and fix it to

the hob. Fix the outlet blanking plate to back plate

(see Fig. 2). Push the flue outlet connector pipe (not

supplied) into the flue spigot and cement into place

using approved fire cement, ensuring that no

cement is blocking the flue passageway.

REAR FLUE EXIT

Push the flue connector pipe (not supplied) into the

flue spigot and cement into place using approved

fire cement ensuring that no cement is blocking the

flue passageway.

Fig.2

4

Loading...

Loading...