Page 1

Stanley Omnilock

a Product Group of Stanley Security Solutions, Inc.

1

Planning the installation

T83325/Rev A ER-7991-12 Jan 2010

Contents

These installation instructions describe how to install

your QAXOM Exit Device Lock. Topics covered

include:

Planning the installation...........................................1

Preparing the trim.......................................................3

Finishing the installation...........................................6

Site survey

Use the following survey to record information

about the installation site. You need this information

to determine how to prepare the door for the lock.

Door information

Door handing and bevel:

If a handing change is required, see “Set the hand”

on page 2.

❐ Left hand, reverse bevel (LHRB)

❐ Right hand, reverse bevel (RHRB)

Door thickness: 1-3/4 to 3 inches (44 to 75 mm).

Environment information

Model

Side of

door

Temperature

Range

Exposure

Standard Outside

+32°F to +129°F

0°C to +54°C

Drip proof.

Inadvertent

splashing of

water spray

acceptable.

Weatherized Outside

-4°F to +129°F

-20°C to +54°C

Direct exposure

to rain and snow

Extreme

Weatherized

Outside

-40°F to +129°F

-40°C to + 54°C

Direct exposure

to rain and snow

Inside

+32°F to +129°F

0°C to +54°C

N/A

Installation Instructions for

Stanley Omnilock QAXOM

Exit Device Locks

Components checklist

Your Stanley Omnilock package comes with the template, tailpiece and adapter plate for the model of

exit device being replaced. Use the following checklist to make sure that you have the items necessary to

install your Stanley QAXOM Exit Device Lock.

Components provided in the box:

❐ Adapter plate and tailpiece

❐ Outside escutcheon assembly

❐ Outside lever and spindle assembly

❐ Installation template and instructions

❐ Screw package

❐ Batteries

❐ 3/32 hex driver

Other components:

❐ Programming Default ID Card (provided with

software)

Page 2

Installation Instructions for Stanley Omnilock QAXOM Exit Device Locks

Stanley Omnilock

a Product Group of Stanley Security Solutions, Inc.

2

Planning the installation

1 Set the hand

Your Omnilock Exit Device Lock comes preset for

right hand use. Should you need to change the lever

hand, please follow these steps:

Exit Device side (See Figure 2.)

1 Remove the spindle from the escutcheon

housing.

2 Release the four screws holding the back plate

onto the escutcheon housing. Retain these screws

for reinstallation.

3 Release the three screws holding the bearing on

to the escutcheon back plate. Retain these screws

for reinstallation.

4 Rotate the bearing 120 degrees, so that the

opening is in the correct hand position.

5 Reinstall the bearing to the back plate with the

retained screws.

6 Reinstall the back plate with the retained screws.

7 Replace the spindle, insuring the flange at the

rear of the spindle is properly in the bearing

groove.

Lever side (See Figure 3.)

1 Position the driver with the key slot in the desired

position. Rotate the spindle so that the lever catch

is opposite the driver key slot. The driver will set

flush to the escutcheon housing.

2 Place driver key in the slot.

3 See section 2 or 3 for installing the core or

cylinder in the lever.

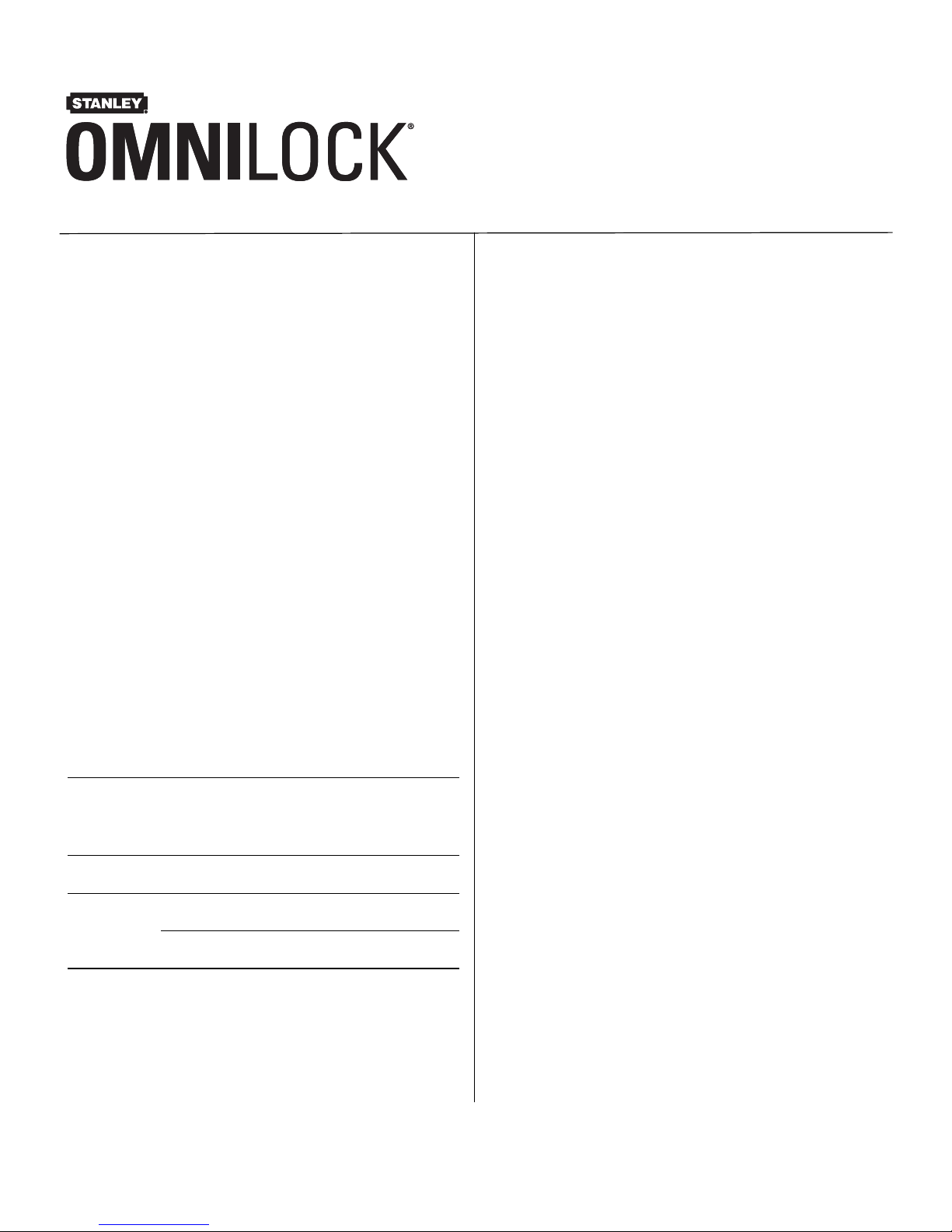

Figure1 Door handing chart

LHRB

RHRB

Outside

Left Hand

Reverse

Bevel

Right Hand

Reverse

Bevel

Back plate

hex screws

Bearing

screws

Opening

Figure 2 Changing hand on the Exit Device side

Bearing

Right hand position shown

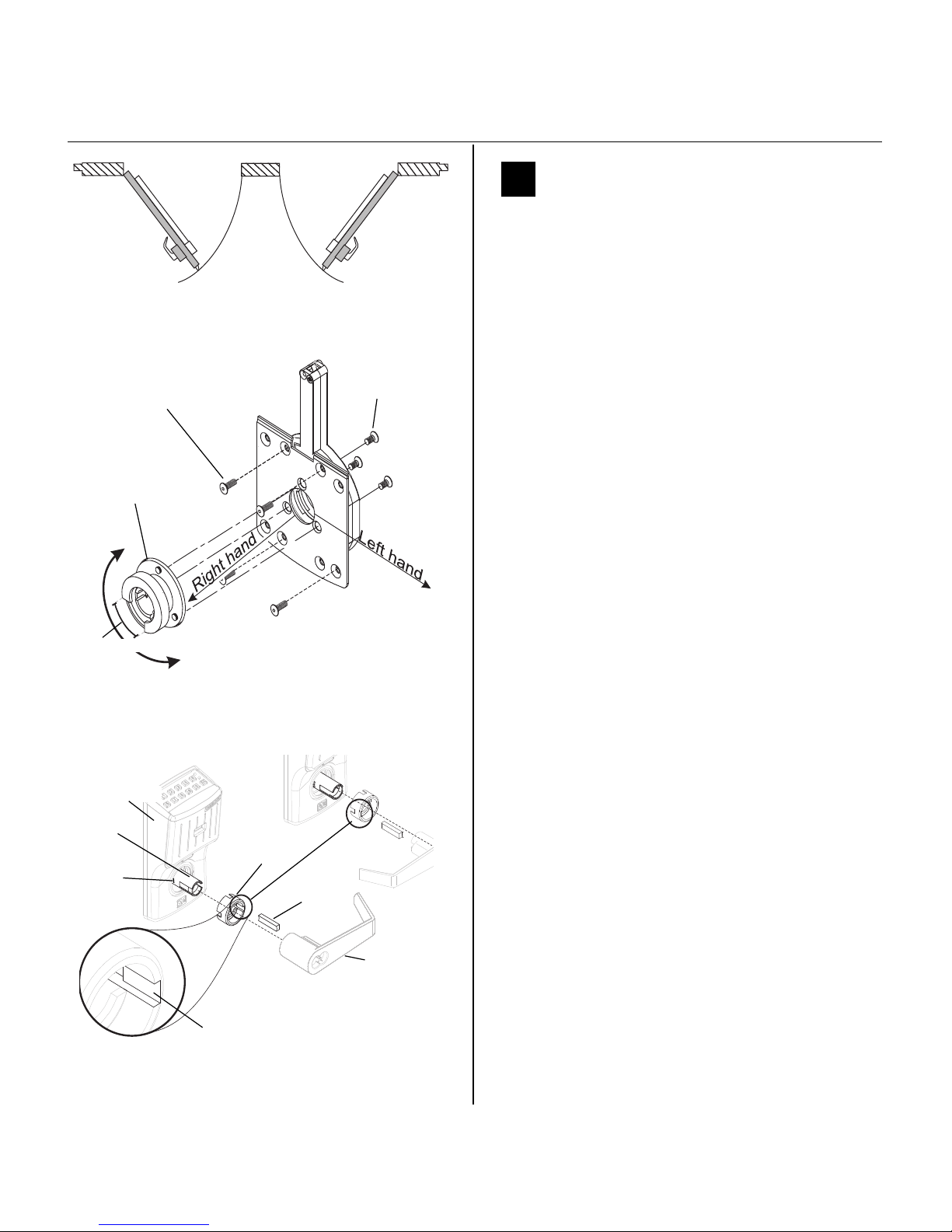

Figure 3 Changing hand on the levers

Driver key slot

Driver

Driver key

Escutcheon

Spindle

Lever

Right hand

Left hand

Lever

catch

Page 3

Installation Instructions for Stanley Omnilock QAXOM Exit Device Locks

Stanley Omnilock

a Product Group of Stanley Security Solutions, Inc.

3

Installation Instructions for Stanley Omnilock QAXOM Exit Device Locks

Preparing the trim

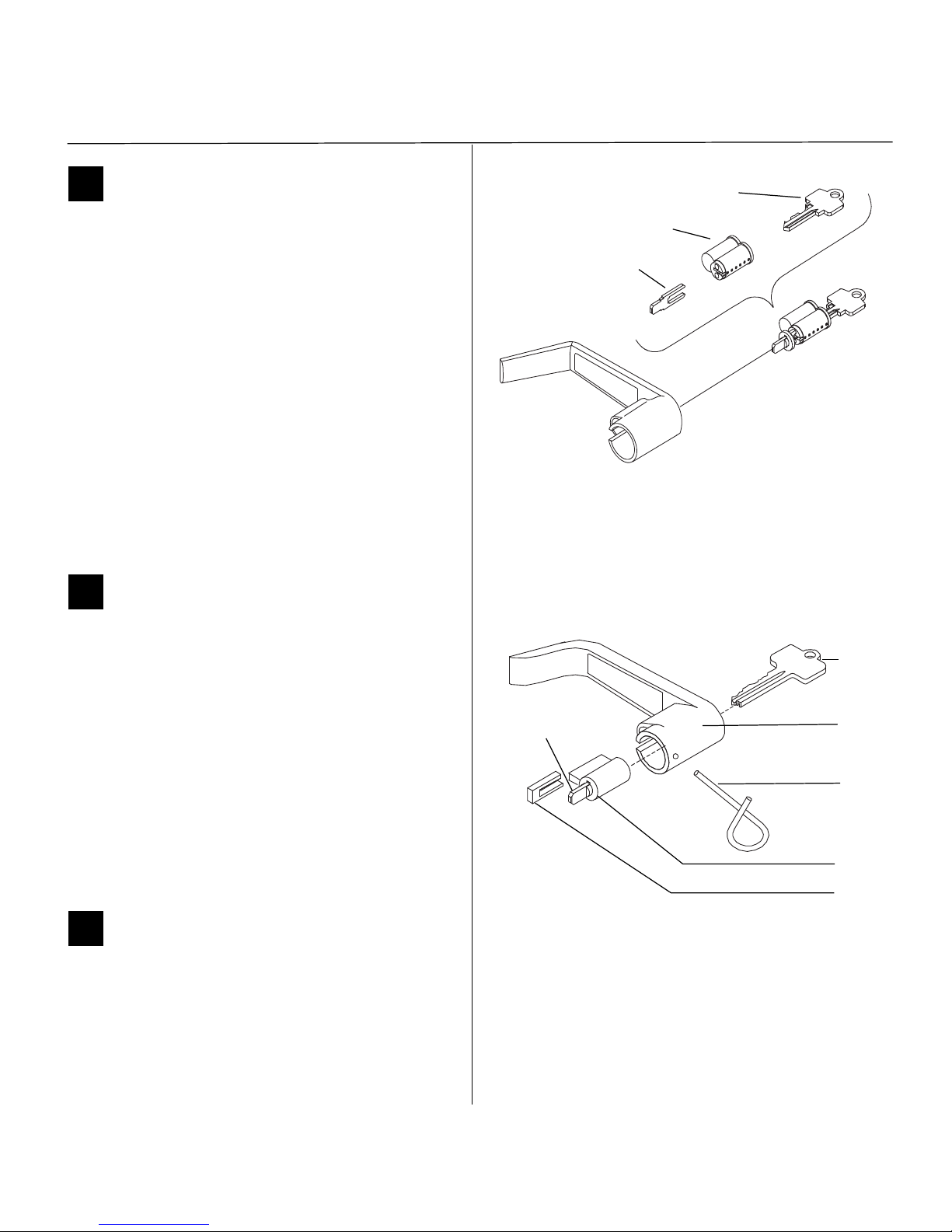

2 Install IC core and throw member

1 Slide the lever over the spindle up to the lever

catch. With a screwdriver in the center of the

spindle, retract the lever catch and slide on the

lever until it catches.

2 Insert the control key into the core and rotate the

key 15 degrees to the right.

3 Insert the throw member into the core.

4 Insert the core and throw member into the lever

with the control key

5 Return the control key to the original position

and withdraw the key.

6 To remove the lever, reverse steps 1 through 6.

Caution: The control key can be used to

remove cores and to access doors. Provide

adequate security for the control key.

3 Install standard key cylinder

1 Place the cylinder inside the lever. See Figure 5.

2 Install the retainer into the lever.

3 Insert the key into the cylinder and rotate the key

90 degrees clockwise. Slide the lever assembly

onto the spindle until the lever clicks as it

engages against the lever catch.

4 Pull on the lever to test that the lever catch is

engaged. Turn the key back to the original

position and remove it from the cylinder.

5 To remove the lever, insert the key and turn 90

degrees, then use the push pin to disengage the

lever catch on the spindle.

4 Prepare the door

1 Remove outside exit device trim and hardware

and discard.

2 Remove inside exit device chassis and retain for

reinstallation.

Figure 4 Installing the IC core

Throw member

Core

Control key

Figure 5 Installing a standard key cylinder

Key

Lever

Push pin

Retainer

Cylinder

Tab in

vertical position

Page 4

Installation Instructions for Stanley Omnilock QAXOM Exit Device Locks

Stanley Omnilock

a Product Group of Stanley Security Solutions, Inc.

4

Preparing the trim

5 Center punch and drill holes

Your Stanley Omnilock package comes with the template, tailpiece and adapter plate for the exit device

model you ordered.

1 Determine the location for the outside template

in accordance with instructions on the template.

2 Tape the template to the door.

3 Center punch the necessary drill points, or modify

existing holes as necessary.

4 Drill the holes.

5 Remove the template and follow steps 1 through

4 on the inside door.

Note: If installing the Extreme Weatherized

QAXOM, use the Extreme Weatherized template on

the inside door and repeat steps 1 through 4 for the

inside module as well.

6 Install batteries

Four alkaline AA batteries (or two weatherized packs

if installing a weatherized unit) are furnished with

your Omnilock system and must be installed before

proceeding with operation verification and system

installation.

Note: For the Extreme Weatherized model, see

section 8 on page 5.

1 Remove the gasket and battery cover from the

rear of the housing assembly as shown in Figure

6.

2 Install batteries with proper polarity as shown in

Figure 7. (For weatherized battery packs, simply

connect the wires from the battery pack to the

circuit board as shown in Figure 8.)

3 Press and hold the reset button on the circuit

board (as shown in Figure 7) until the green light

on the keypad flashes (about three seconds) then

release the button.

4 Replace the battery cover. See Figure 6. Make sure

that the tabs on the lower edge of the battery

cover are hooked over the edge of the back plate

and secure the cover with the screw.

Figure 6 Installing batteries

Housing assembly

AA Batteries

Battery cover

Gasket

Screw

EXTERNAL

Figure 7 Wall Mount System circuit board

Reset

button

Figure 8 Installing weatherized batteries

Reset Button

Page 5

Installation Instructions for Stanley Omnilock QAXOM Exit Device Locks

Stanley Omnilock

a Product Group of Stanley Security Solutions, Inc.

5

Installation Instructions for Stanley Omnilock QAXOM Exit Device Locks

Preparing the trim

5 Replace the gasket. See Figure 6. Make sure that it

is inside the edge of the housing.

7 Install the adapter plates

Note: The adapter plate shipped with your unit is

correct for the model ordered. It may not match the

illustration.

1 Line up the screws as shown in Figure 9.

2 Make sure the gasket is inside the edge of the

escutcheon housing.

3 For Extreme Weatherized models, thread the

connecting wires through the corresponding

hole. Ensure no wires are pinched.

4 Tighten screws.

8 Install the batteries for the Extreme

Weatherized module

1 On the inside module, thread the connecting

wires through the wire inlet hole near the bottom

center of the module.

2 Connect the pins and grounding wire as shown in

Figure 10.

3 Attach inside Extreme Weather module and cover

as shown in Figure 11.

Figure 9 Installing the adapter plate

Screws

Adapter plate

Escutcheon

Extreme

Escutcheon

Connecting wires

Weatherized

10 Pin

Connector

Grounding

wire

12 Pin

Connector

Cover

grounding

Wire inlet

Figure 10 Wire connections to circuit module

Figure 11 Installing the Extreme Weather module

Extreme Weatherized Module

Cover

Vertical

Centerline

Connecting wires

Place module close to exit device chassis

Page 6

Installation Instructions for Stanley Omnilock QAXOM Exit Device Locks

Stanley Omnilock

a Product Group of Stanley Security Solutions, Inc.

6

Finishing the installation

9 Tailpiece assembly

Note: The tailpiece assembly shipped with your unit

is correct for the model ordered. It may not match

the illustration.

1 Align the slot of the tailpiece driver vertically with

the throw member of the core.

2 Adjust the tailpiece to the proper depth for your

door.

• Hole A is used for doors sized 1 3/4, 2 1/4 or 2

3/4 inches thick

• Hole B is used on doors sized 2, 2 1/2 or 3

inches thick.

3 Adjust the tailpiece tab for the proper rotation,

according to the hand of the door.

• For LHRB doors, the tailpiece tab generally falls

at approximately the 1 to 3 o’clock position.

• For RHRB doors, the tailpiece tab falls

approximately at the 11 to 12 o’clock position.

4 Test fit the tailpiece with the exit device.

5 When correctly positioned, insert the roll pin.

Ensure that it is flush with the surface of the

tailpiece driver.

10 Exit device reassembly

Note: The tailpiece and adapter plate shipped with

your unit is correct for the model ordered. It may not

match the illustration.

1 Re-install the exit device on the door with

mounting screws.

2 Install the tailpiece assembly into the slot of the

exit device cam. (If your device is a Von Duprin

product, remove the plastic tailpiece guide, if

installed).

3 Install the adapter on the door so that the

tailpiece assembly enters the spindle of the lever

and the throw member of the key cylinder enters

the slot in the tailpiece driver. The posts on the

adapter plate enter the holes in the door. Do not

force.

Core throw

member

Tailpiece driver

Slot

Tailpiece

Roll pin

Hole A

Hole B

Tab

Figure 12 Assembling the tailpiece

Right hand position

Left hand position

Roll pin

Vertical position

Exit device cover

Exit device chassis

Tailpiece

Adapter

Figure 13 Reinstalling the exit device

Mounting screws

Adapter

screws

Page 7

Stanley Omnilock

a Product Group of Stanley Security Solutions, Inc.

7

Installation Instructions for Stanley Omnilock QAXOM Exit Device Locks

Finishing the installation

4 Install the screws to secure the exit device and the

adapter to the door.

5 Check for proper operation of the key bypass

feature by rotating the key to retract the latch.

Remove the key.

6 Install the exit device cover.

11 Check operation

Check the operation of the lock. For example, check

that:

❐ exit device latches and opens properly

❐ lever handle works

❐ key bypass feature works

For assistance, contact your local Stanley Omnilock

dealer.

12 Test Lock

To test the lock for proper operation before the lock

is programmed, follow these instructions:

For keypad locks

1 Press 1234 for the 2000 series, or 5011234

for the 500 series.

The green light flashes and the latch unlocks.

2 Turn the lever and open the door.

During the unlock time, the green light flashes. Then

the red light flashes and the latch relocks.

For magnetic stripe cards

1 Align the magnetic stripe card with the V mark by

the card slot.

2 Insert and then remove the card.

The green light flashes and the latch unlocks.

3 Turn the lever and open the door.

During the unlock time, if using the Programming

Default ID Card, the green light flashes. Then the red

light flashes and the latch relocks.

A label on the housing assembly battery cover

indicates the pre-set magnetic card track (track 2

or track 3) that the system is set to read.

For proximity cards

1 Align the proximity card over the recess on the

front of the escutcheon.

The green light flashes and the latch unlocks.

2 Turn the lever and open the door.

During the unlock time, if using the Programming

Default ID Card, the green light flashes. Then the red

light flashes and the latch relocks.

13 Troubleshooting

If the mechanism does not unlock, remove the battery cover and check for proper orientation and seating of the batteries and motor connector. Ensure

that wires are not pinched. Reset the electronics by

pressing and holding the reset button on the circuit

board until the light flashes green (approximately 3

seconds), then releasing the button. See Figure 14.

Note: The system will go through a self-test and the

green light will flash five times. You will hear the

lock unlock, then relock three times. A red flash

indicates a PC board or drive system problem. If a

red flash or no flash is observed, check for proper

orientation and seating of the batteries and motor

connector, ensure that wires are not pinched, then

repeat the reset process.

Figure 14 Using the reset button

Reset button

Motor connector

Red wire

Black wire

Page 8

Stanley Omnilock

a Product Group of Stanley Security Solutions, Inc.

8

Loading...

Loading...