Page 1

To ensure safety, satisfaction and maximum service, this quality Cooker should be installed by a competent

person. The provision of a Central Heating or Domestic Hot Water facility requires that the hot water system involved

conforms fully to good plumbing practice and established standards.

INSTALLATION AND OPERATING INSTRUCTIONS

To Be Left With End User

Mourne

Solid Fuel Cooker

Page 2

1

TABLE OF CONTENTS

PAGE NO.

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2. Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3. Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4. Mourne Installation Instructions for Plumber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

5. Site Assembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

6. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

7. Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

8. Pre-Installation Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

9. Chimney / Flues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

10. Cooker Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

11. Flue Pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

12. Chimney Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

13 Hearth Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

14 Down Draughts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

15. Use of Existing Flues and Chimneys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

16. Ventilation & Combustion Air Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

17. Top & Rear Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

18. Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

19. Heating System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

20. Boiler Output (Central Heating). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

21. Gravity Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

22. Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

23. Pipe Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

24. Fuels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

25. Water Circuit Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

26. Care for your Central Heating System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

27. Injector Tee. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

28. Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 & 12

29. Draining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

30. General Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

31. Draught Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

32. Important Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

33. Lighting The Fire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

34. Operating the Cooker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

35. Fuelling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

36. Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

37. Direct Flue Damper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

38. Oven Damper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

39. Over Firing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

40. The Hotplate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

41. Main Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

42. Overnight Burning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

43. Boiler (Summer Conditions) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

44. Domestic Boiler Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

45. Riddling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

46. Emptying the Ashpan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

47. Cooker Flue Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

48. Cleaning Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

49. Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

50. Mild Steel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

51. Ovens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

52. Hot Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

53. CO Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

54. Fault Finding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

55. Installation Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Page 3

2

INTRODUCTION

Congratulations on purchasing this fine Irish made Solid Fuel cooker which is built to exacting standards.

Please read the following information before operating this product.

This appliance is hot while in operation and retains its heat for a long period of time after use. Children, aged

or infirm persons should be supervised at all times and should not be allowed to touch the hot working surfaces

while in use or until the appliance has thoroughly cooled.

As manufacturers and suppliers of cooking and heating appliances, we take every possible care to ensure as

reasonably practicable, that these appliances are so designed and constructed as to meet the general safety

requirement when properly used and installed.

The complete installation must be done in accordance with current Standards and Local Codes. It should be

noted that the requirements and these publications may be superseded during the life of this manual.

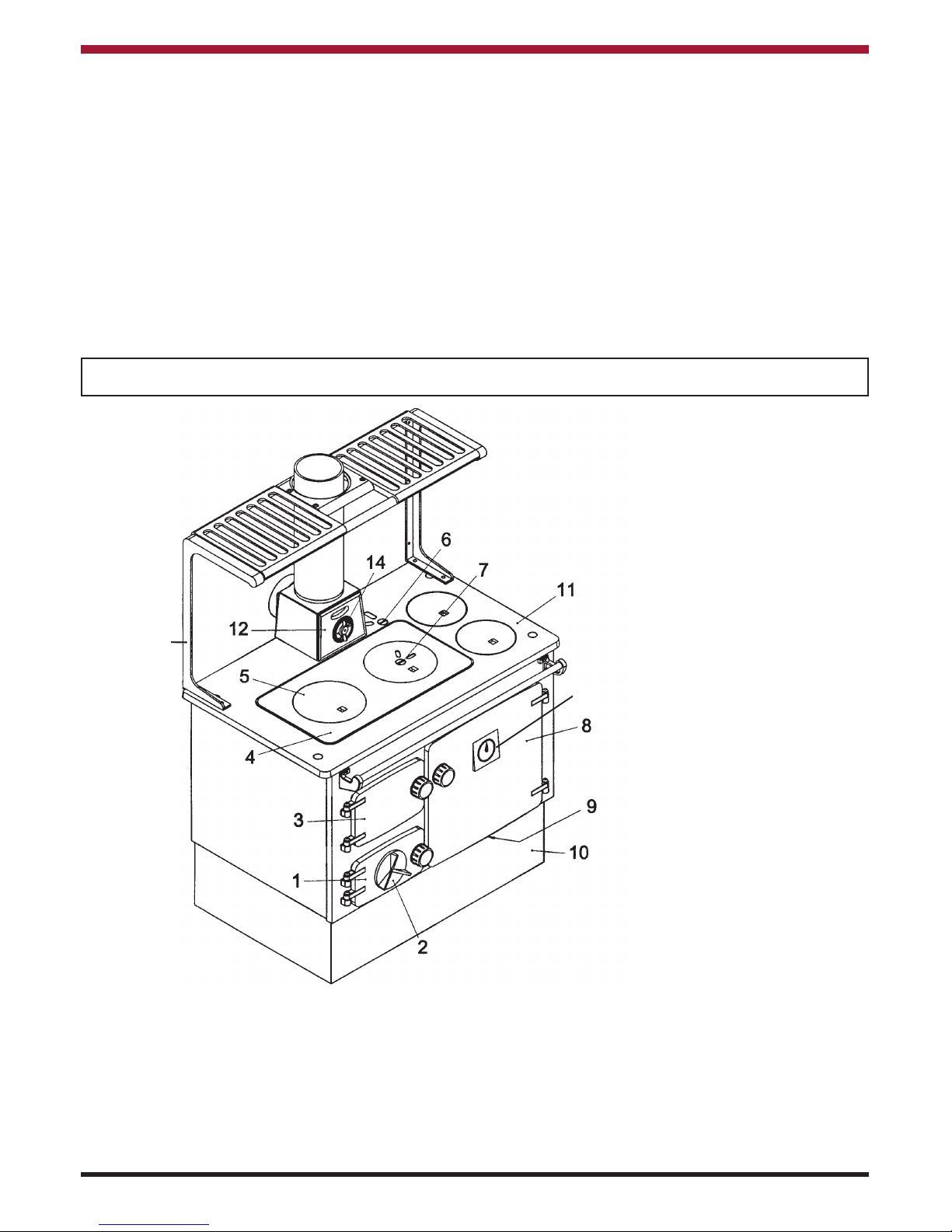

1. Ash Door

2. Spin Wheel

3. Fire Door

4. Hot Plate

5. Fuelling Cup

6. Chimney Damper

7. Oven Damper

8. Oven Door

9. Cleaning Door

10. Front Plinth

11. Hob

12. Bonnet

13. Plate Rack (optional)

14. Spin Valve

15. Oven Thermometer

Cooker Outputs: At 2.7 kg = 6 lbs coal / hr = 12,300 Btu’s / lb = 7.9 kW / kg

At 2.7 kg = 6 lb timber or peat = 8,600 Btu’s = 5.54 kW / kg

Heat to Water Domestic 10,000 Btu’s = 2.9 kW

Heat to Water 15K Central Heating 15,000 Btu’s = 4.4 kW Burning Coal

Heat to Water 21K Central Heating 21,000 Btu’s = 6.2 kW Burning Coal

Cooker Weight 163Kgs

IMPORTANT NOTICE: Any alteration to this appliance that is not approved in writing by Waterford Stanley will

render the guarantee void.

TECHNICAL DATA

All technical data are taken under laboratory conditions and may vary in use.

Fig.1

13

15

Page 4

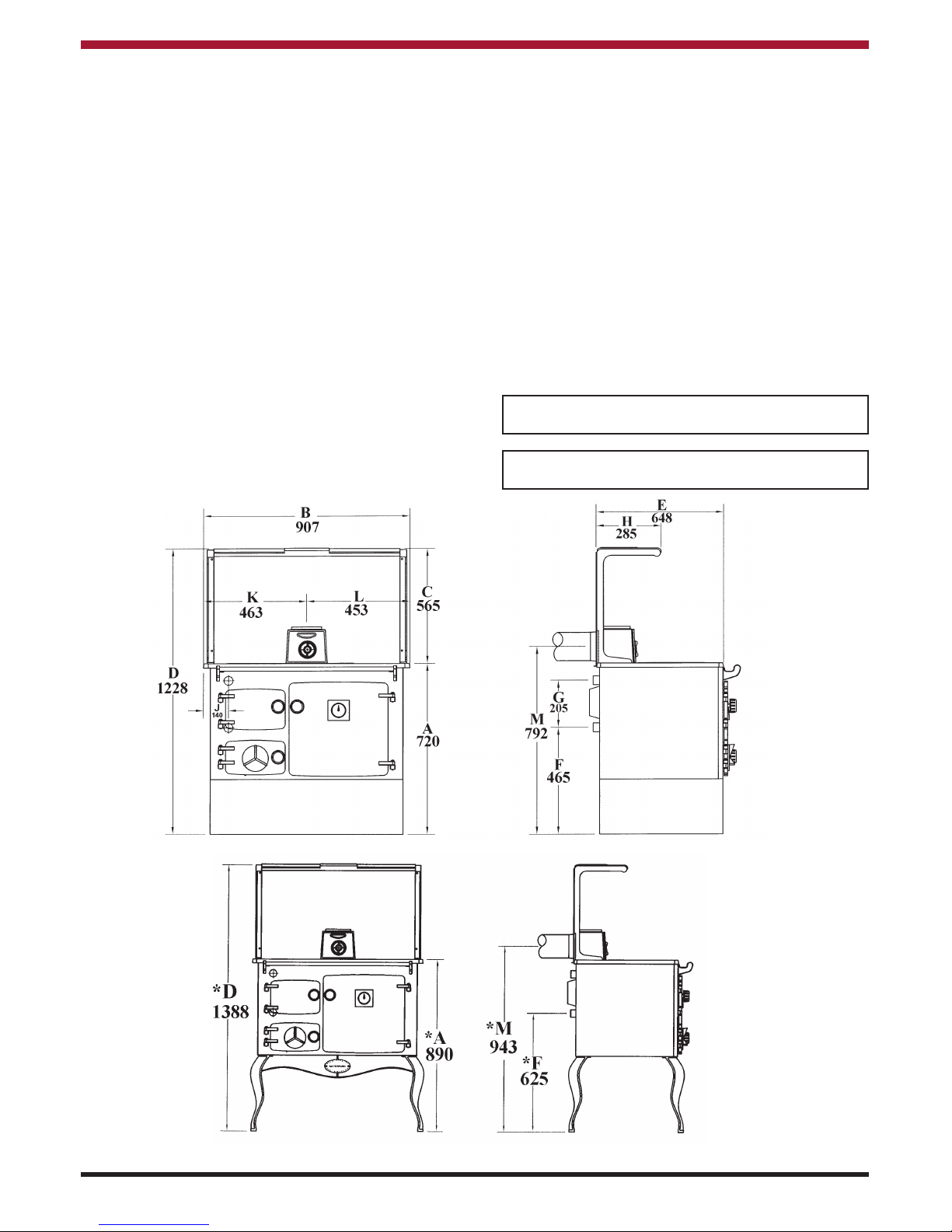

SPECIFICATION

BOILER TAPPINGS:

10K Domestic Boiler:

F = 450 (17

3

/4”) G = 210 (81/4”)

15K Central Heating Boiler:

G = 205 (8”) F = 465 (18

1

/4”)

21K Central Heating Boiler:

F = 475 (18

3/

4”) G = 200 (8”)

IMPORTANT - Control of Substances Harmful to Health:

It is the Users/Installers responsibility to ensure that the necessary personal protective clothing is worn when

handling materials that could be interpreted as being injurious to health a and safety.

When handling Firebricks, Fire Cement or Fuels, use disposable gloves. Exercise caution and use disposable

masks and gloves when handling glues and sealants. When working with fibre glass, mineral wool, insulation

materials, ceramic blanket/board or kerosene fuel oil, avoid inhalation as it may be harmful. Avoid contact with

skin, eyes, nose and throat. Use disposable protection. Installation should be carried out in a well ventilated

area.

Manufacturers reserve the right to make alterations to design, materials and construction for manufacturing or other reasons subsequent to publication.

* Note:Optional legs are available for this cooker.

See Fig.3.

Note: Dimensions stated are in millimetres and

may be subject to a slight +/- variation.

3

Fig.2

Fig.3

Page 5

4

INSTALLATION INSTRUCTIONS FOR PLUMBER.

The installation must comply with the following:

The Building Regulations: Part J England & Wales,

Part F Section III Scotland, Part L Northern Ireland.

The Building Regulations: Part J Ireland

Health & Safety at Work Act.

B.S. 8303: Part 1, 2 & 3 - Installation of domestic

heating & cooking appliances using solid mineral

fuels.

B.S. 7593: Treatment of Water in Domestic Hot

Water Systems.

B.S. 7074: Part 1 & 2 - Hot water supply.

I.S. 258: Part 1 & 2 - Domestic Solid Fuel Cookers

with integral boilers.

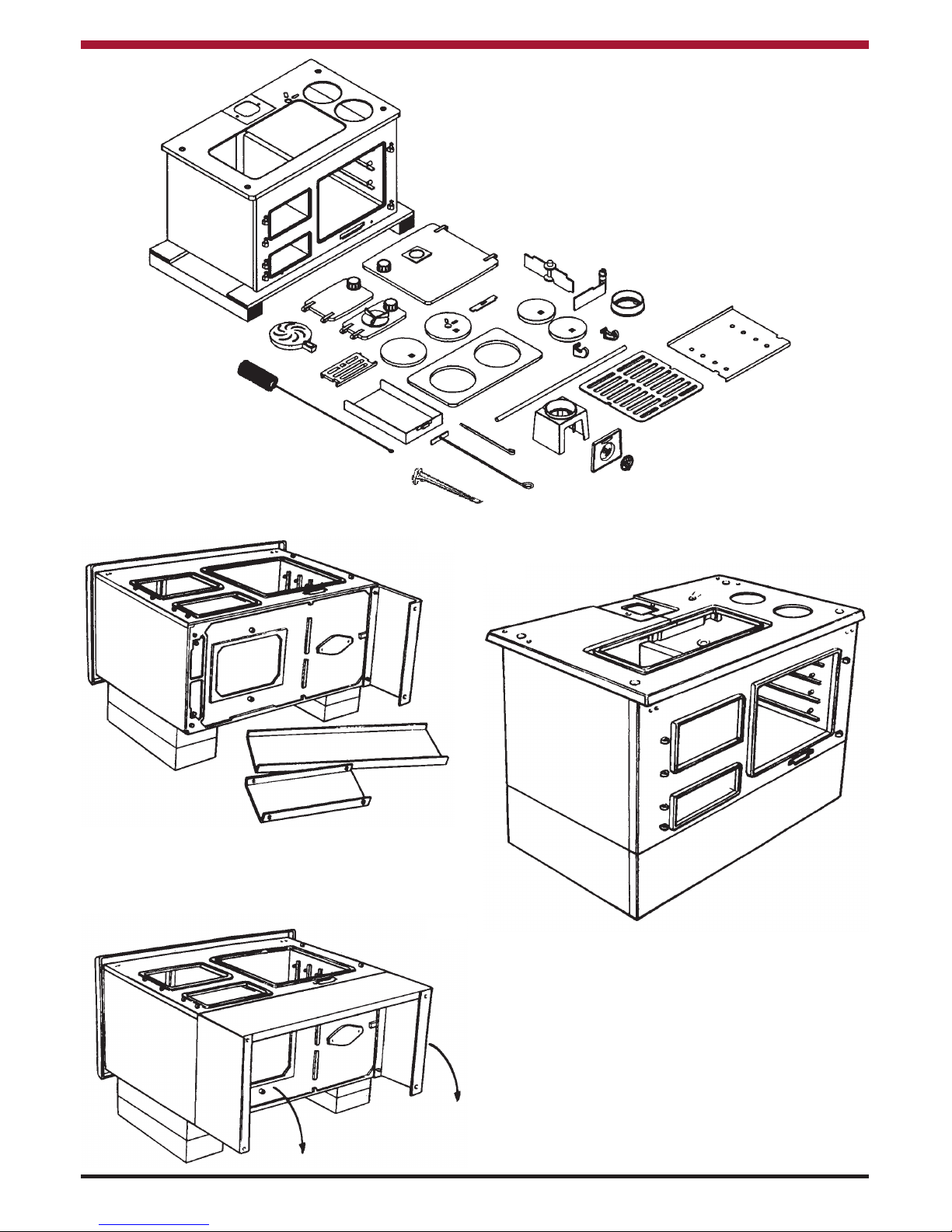

SITE ASSEMBLY INSTRUCTIONS

1. Remove carton by breaking banding straps.

2. Remove all loose items from Cooker.

3. Carefully lay Cooker on its back.

4. Unwrap Base Assembly Sheet Metal (3

pieces).

5. Bolt Angle End Plates to Cast Iron Cooker

Base using 4 x 5/16” screws provided in

envelope.

6. Fit Front Panel and fix with 4 Self-Tap

Screws, also provided in envelope.

7. Position Assembled Base Unit centrally on

Cooker and tighten all attachment screws.

The hot water available with normal usage of the

range is sufficient for normal domestic

requirements, provided the following conditions of

installation are fulfiled:

(a)The capacity of the storage cylinder does not

exceed 30 gallons.

(b)The cylinder is lagged and is fixed upright.

(c) The cylinder is connected by 1” (25mm) flow and

return pipes with a continual rise and not more

than 8.8 mts. (30 ft.) each in total length. Also if

they exceed 4.5 mts. (15ft.) each in total length

they must be lagged.

(d)Draw off pipes must be ‘dead-leg’ connections,

i.e. there must be no circuit in the draw off: the

user should be advised that the fire should be

continuous burning.

The Flue Connection

Two methods of installation are illustrated in the

diagrams. All joints must be sealed. Square bends

and horizontal runs must not be used. Means of

sweeping the chimney must be provided.

The Boiler

Flow and return connections can be made to run

either L.H. or R.H. from the back of the boiler.

Make good any breakage in the firebox cement

joints between the firebricks and the boiler.

The Hotplate

See that this is firmly bedded to the hob by the

fireproof rope provided.

Lighting Test

Check the installation before leaving the site. Allow

the Range to heat up slowly at first. Check that the

flow pipe from the boiler is assembled in the correct

way. Check the dampers and catches. See that

the user has a copy of the working instructions.

Note: Where a Stanley Range is installed in a

recess which is closed off by a register plate, the

flue pipe should be carried up into the throat of the

chimney to ensure satisfactory results. All flue

joints must be airtight - air should enter the chimney

only by passing through the firebox, or spin valve

item No.3 in the exploded view.

Page 6

5

1. Lay cooker on it’s back on an old blanket.

2. Attach end plates and front with screws

provided.

3. Stand cooker on it’s base.

4. Move cooker into it’s location and replace all

parts removed.

Parts removal before attaching the base.

Fig.4

Fig.5

Fig.6

Fig.7

Page 7

6

INSTALLATION

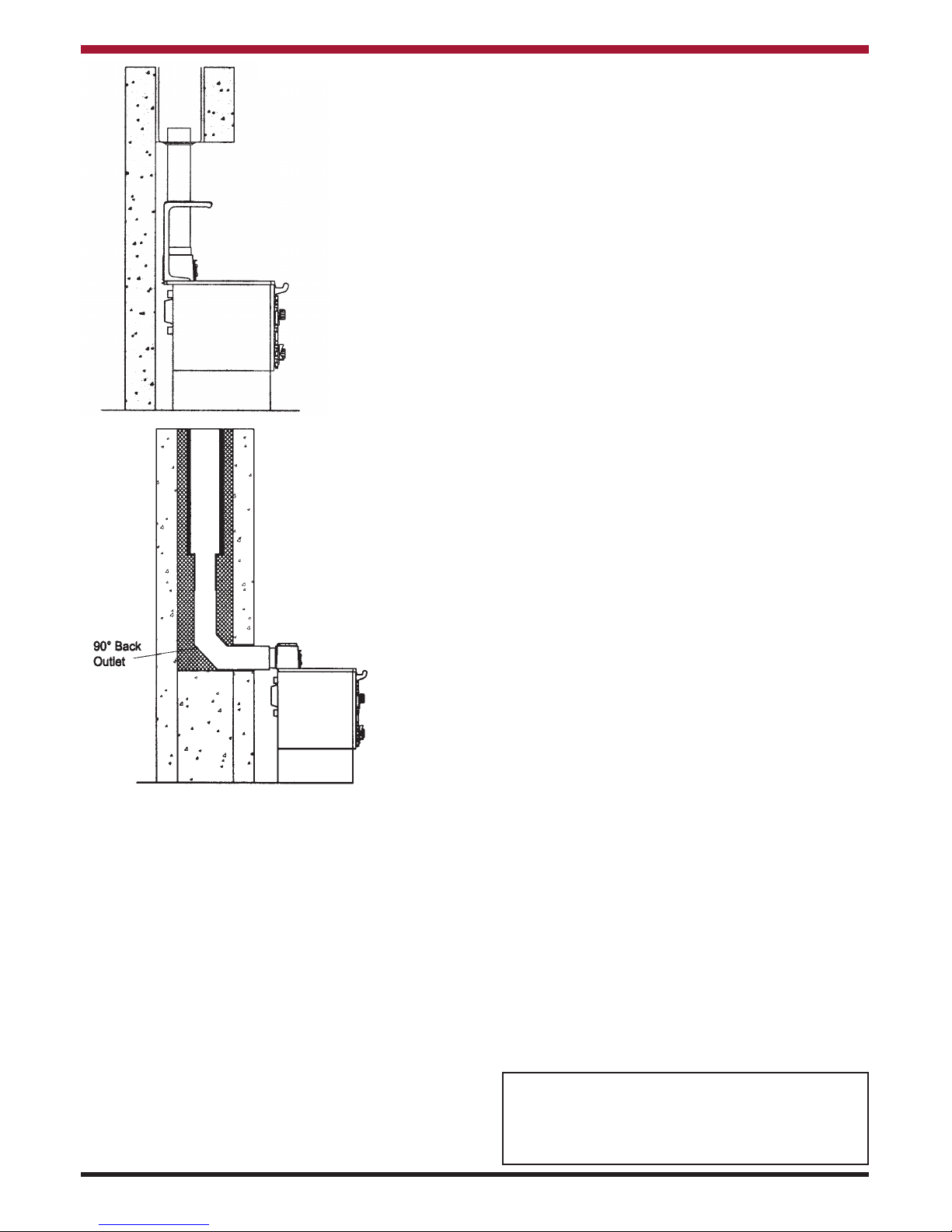

Fig.8

Fig.8a

LOCATION

When choosing a location for this appliance you

must have:

(a) Sufficient room for the installation (see

clearances), a satisfactory flue, and an

adequate air supply for correct

combustion and operation.

(b) Adequate space for maintenance and

air circulation.

(c) Solid floor or base of non-combustible

material which is capable of supporting

the total weight.

PRE-INSTALLATION CHECK

Before installing your new Cooker, check that the

chimney is clean and clear of obstructions.

Cracked brickwork and leaking joints should be

made good and tested accordingly. The chimney

should have a cross sectional area of at least 176

sq. cm (28.28 ins) or an inner diameter of 15 to

23cm (6 to 9 ins). A similar direct air inlet is

required in the room to support combustion.

CHIMNEY/FLUES

The chimney should have a cross sectional area of

at least 176 sq. cm (28 sq. ins) or an inner diameter

of 150mm to 230mm. (6” to 10”). (See fig. 8 & 8a).

Do not connect to a chimney serving another

appliance. Always ensure that the connection is to

a chimney of the same size, never connect to one

of smaller dimensions. Chimneys wholly

constructed of single skin are not recommended

under any circumstances. Due to their inability to

retain heat, such chimneys will inevitably give rise

to smoking, down draught and the formation of

condensation.

The flue must be high enough (more than 4.6m

(15ft.) in any case) to allow the flue gasses to vent

into clear air, away from the turbulence that may be

caused by roof structures, other chimney stacks

etc. The venting position should be 1.0m (3’3”)

above any obstruction within a 7.6m (24’9”) radius,

if down draughts are to be avoided.

COOKER CLEARANCE

The Cooker should not be installed at zero

clearance to combustible materials. The sides

should have a minimum clearance of at least 7.5

cm (3”) from combustible materials unless

otherwise fully insulated.

FLUE PIPES

Where the standard masonry chimney is not

available, a proprietary type of non-combustible or

non-corrosive material 125mm (5”) twin wall, fully

insulated pipe may be used. The pipe must

terminate at a point not lower than the main ridge or

adjacent outside obstructions. With such

installations access to the chimney must be

provided for cleaning purposes.

Horizontal runs more than 150mm (6”) and 90

o

bends numbering more than 2 per installation

should be avoided.

Flues should be vertical wherever possible and

where a bend is necessary, it should not make an

angle of more than 37.5owith the vertical.

IMPORTANT: ALL FLUE CONNECTIONS MUST

BE THOROUGHLY SEALED: BLOCKED

CHIMNEY’S ARE DANGEROUS, USE ONLY

RECOMMENDED FUELS, KEEP CHIMNEYS

AND FLUEWAYS CLEAR.

Page 8

NOTE: Where the appliance spigot or flue pipes

protrudes into the chimney, care should be taken to

ensure that it does not block the chimney.

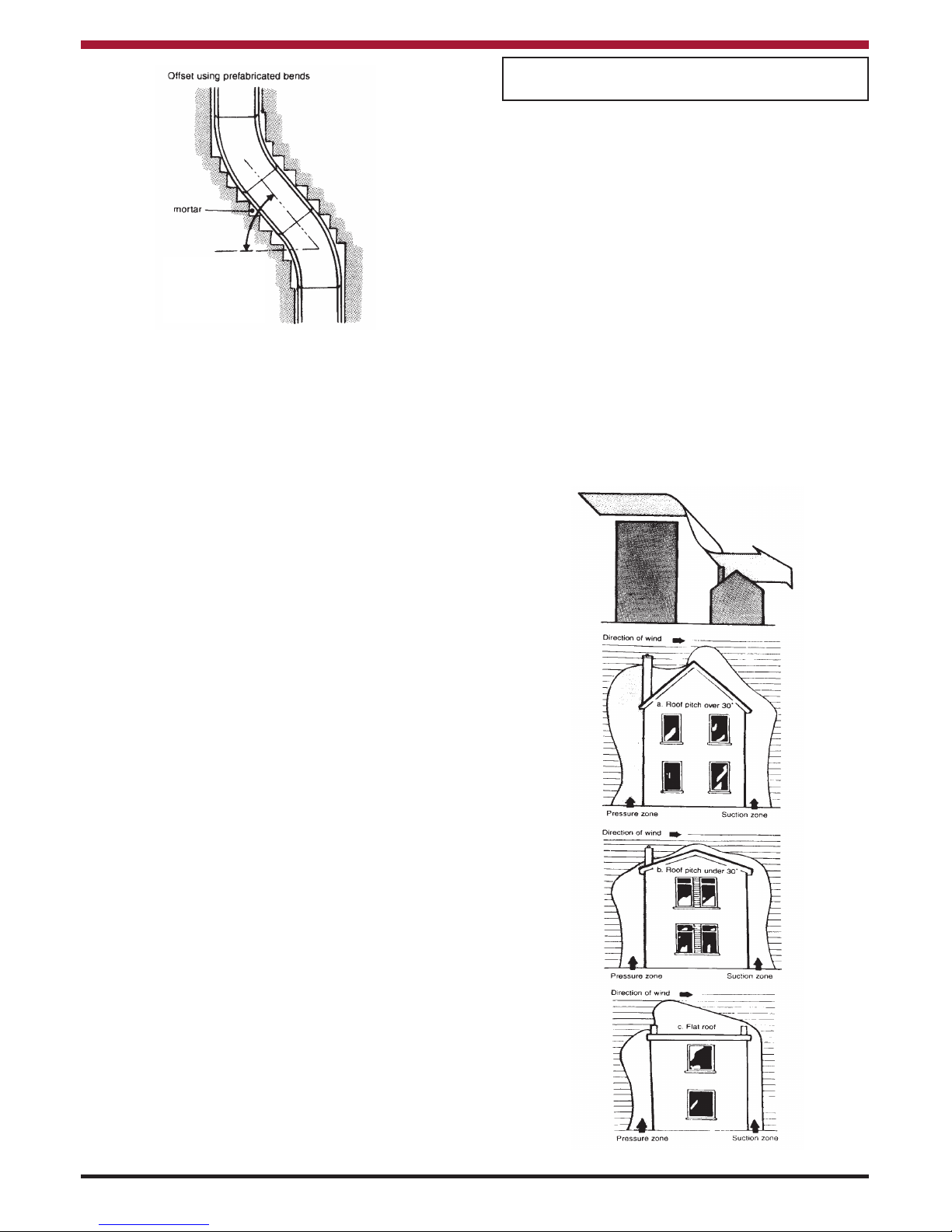

DOWN DRAUGHTS

However well designed, constructed and

positioned, the satisfactory performance of the flue

can be adversely affected by down draught caused

by nearby hills, adjacent tall buildings or trees.

These can deflect wind to blow directly down the

flue or create a zone of high pressure over the

terminal.

A suitable anti-down draught terminal or cowl will

usually effectively combat direct down blow but no

cowl is likely to prevent down blow due to a high

pressure zone. Ensure that any cowl used will not

restrict the flue exit.

CHIMNEY CLEANING

Whichever type of flue is chosen, there must be

cleaning access to the whole of the flue system.

The flue of the chimney will need to be cleaned

regularly. How often will depend a lot on how your

Cooker is run, but, to start with, make a point of

inspecting the flue system every one or two weeks.

This period may well be extended as time goes by

if there is little sign of deposits. Some people find

they need to sweep the flue every six to eight

weeks.

HEARTH CONSTRUCTION

Hearth should be strong enough to support total

weight of cooker. When a properly constructed

hearth is not available we recommend that the

Cooker be placed on a slab of foamed concrete 7.5

cm (3”) or a slab of other insulating material. This

hearth must extend at least 40 cm (16”) to the front

and 30 cm (12”) to each side.

A flue pipe should only be used to connect an

appliance to a chimney and should not pass

through any roof space.

Flue pipes may be of any of the following materials:

(a) Cast iron as described in BS 41:1973

(1981)

(b) Mild steel with a wall thickness of at least

3mm.

(c) Stainless steel with a wall thickness of at

least 1mm and as described in BS EN

10095:1999 specification for stainless and

heat resisting plate sheet and strip, for

grade 316, S11, 316 S13, 316 S16, 316

S31, 316 S33, or equivalent Euronorm

88-77 designation.

(d) Vitreous enamelled steel complying with BS

6999: 1989.

STANLEY CAST IRON PIPES ARE HIGHLY

RECOMMENDED FOR INTERIOR USE.

7

Fig.10

Fig.9

A bend should not

make an angle of

more than 37.5

o

with the vertical.

Page 9

USE OF EXISTING FLUES OR CHIMNEY’S

An existing flue pipe or chimney that has proven to

be satisfactory when used with another solid fuel

appliance can normally be used for this appliance

provided that its construction, condition and

dimensions are acceptable. Flues that have proved

to be unsatisfactory, particularly with regard to

down draught, should not be considered for venting

this appliance until they have been examined and

any faults corrected. If there is any doubt about an

existing chimney a smoke test should be carried

out.

Before connecting this appliance to a chimney or

flue pipe which has previously been used with

another flue, the chimney or flue pipe should be

thoroughly swept.

When a chimney is not to be lined a suitable void

should be provided at the base to contain any

debris which may fall from the inside wall, so as to

prevent the debris from obstructing the appliance

flue outlet. (Removal of debris should be facilitated

by the provision of an access door).

VENTILATION & COMBUSTION AIR

REQUIREMENTS

It is imperative that there is sufficient air supply to

the cooker in order to support correct combustion.

The air supply to this appliance must comply with

B.S. 8303: Part 1.

A permanent air entry or opening with a total free

area of at least 550mm

2

per kW of rated output

above 5kW shall be provided but in no case less

than 6500mm2. Where a flue draught stabiliser is

used the total free area should be increased by

300mm2for each kW of rated output as per Building

Regulations Part J.

If there is another appliance using air fitted in the

same or adjacent room, it will be necessary to

calculate additional air supply.

All materials used in the manufacture of air vents

should be such that the vent is dimensionally stable

and corrosion resistant.

The effective free area of any vent should be

ascertained before installation. The effect of any

screen should be allowed for when determining the

effective free area of any vent.

Air vents direct to the outside of the building should

be located so that any air current produced will not

pass through normally occupied areas of the room.

An air vent outside the building should not be

located less than the dimensions specified within

the Building Regulations from any part of any flue

terminal. These air vents must also be fire proofed

as per Building Regulations.

Air vents in internal walls should not communicate

with bedsits, toilets, bathrooms or rooms containing

a shower.

Air vents traversing cavity walls should include a

continuous duct across the cavity. The duct should

be installed in such a manner as not to impair the

weather resistance of the cavity.

Joints between air vents and outside walls should

be sealed to prevent the ingress of moisture.

Existing air vents should be of the correct size and

unobstructed for the appliance in use.

If there is an air extraction fan fitted in the room or

adjacent rooms where this appliance is fitted,

additional air vents will be required to eleviate the

possibility of spillage of products of combustion

from the appliance/flue while the fan is in operation.

Where such a installation exists, a test for spillage

should be made with the fan or fans and other

appliances using air in operation at full rate, (i.e.

extraction fans, tumble dryers) with all external

doors and windows closed.

If spillage occurs following the above operation, an

additional air vent of sufficient size to prevent this

occurrence should be installed.

TOP & REAR OUTLET

Fig.11

Flue collar to be

connected to top or rear

exit of bonnet ONLY.

Seal joint between back

outlet spigot (item 4)

and bonnet (item 1) with

fire cement.

8

Page 10

9

PLUMBING

Diagrams illustrate the basic principles of water systems and are not to be regarded as working drawings.

Central Heating and Indirect Domestic Hot Water.

Recommended indirect cylinder 135 litres, depending on domestic requirements with a 28mm flow and return

pipes not exceeding 7.8m each in length. Cylinder and pipework should be lagged to minimise heat losses.

NOTE: We strongly advise the use

of pipe lagging and also the use of

a frost thermostat if the installation

is likely to be exposed to situations

where the temperatures will drop to

a level consistent with frost.

Fig.12

MOURNE

STANLEY

COOKER

HEATING SYSTEM

The system must include a gravity circuit with

expansion pipe, open to the atmosphere. The

central heating will normally be pump-driven as with

other types of boilers. The primary air valve

controls the heating rate of the boiler, Closed =

minimum, Open = maximum output.

See operating instructions.

BOILER OUTPUT (Central Heating)

High output cannot be maintained unless fuel is

being burned at a rate of 2.7 kg. per hour of coal.

When burning wood or peat, reduced outputs will

apply because of the lower calorific value of the

fuels.

GRAVITY CIRCUIT

The gravity circuit consists of a domestic hot water

tank of 135 litres Indirect Cylinder for central

Heating units and Direct Cylinder for Domestic Hot

Water Unit fixed in an upright position,

recommended for hot water storage and it should

be connected to the boiler by 28mm diameter flow

and return piping. The pipes should not exceed

7.8m each in length and anything in excess of 4.6m

must be fully lagged. The shorter the run of pipe

work the more effective the water heating efficiency

and to this end, the cylinder should be fully lagged.

In the interest of safety do not have any valves on

this circuit.

Page 11

HEATING

Care should be taken to ensure that the heating

installation is correctly installed and that it complies

with all relevant codes of practice. If this appliance

is being connected to an existing system, it is

strongly recommended to check the following.

(a) That the pipework is adequately insulated

(where applicable).

(b) Check all controls e.g. pump, radiator

valves etc, are operating satisfactorily and

are compatible with the requirements of the

cooker.

(c) Cleanse the system and add suitable

inhibitor.

Only competent personnel should be employed to

carry out your heating installation.

PIPE FITTINGS

Materials used for installation work should be fire

resistant, sound and should conform to the current

editions of the following or their equivalent:

1. Ferrous Materials

B.S. 1387: Steel Tubes

B.S. 4127: Stainless Steel Tubes

B.S. 1740: Steel Pipe Fittings

B. S. 6956: Jointing Materials

2. Non-Ferrous Materials

EN 29453: Soft Solder Alloys

B.S. 864: Compression Tube Fittings

B.S. 2871 & EN 1057: Copper & Copper

Alloys.

FUELS

The Cooker output levels are assessed on standard

House Coal of good quality. Reduced outputs will

result when fuels of low calorific values are used.

Wood logs up to 21cm long are suitable.

All fuel should be stored under cover and kept as

dry as possible prior to use.

WATER CIRCUIT TEMPERATURE

The return water temperature must be maintained

at not less than 50º C so as to avoid condensation

on the boiler and return piping. Fitting a pipe

thermostat to the return from the gravity circuit and

wiring it into the pump control will ensure than no

cold water will be returned from the central heating

circuit before the water from the gravity circuit has

warmed up the common return pipe and boiler. If

this is not sufficient to keep the boiler temperatures

above the required minimum, a three-way mixing

valve may be fitted to the flow pipe to divert some

CARE FOR YOUR CENTRAL HEATING

SYSTEM

We strongly recommend the use of suitable

corrosion inhibitors and anti-freeze solution in your

heating system, in an effort to minimise black oxide,

sludge and scale build-up, which effects efficiency.

In hard water areas the use of a suitable limescale

preventer / remover is advised.

Use only quantities specified by the water treatment

product manufacturer. Only add to the heating

system after flushing and finally refilling. Refer to

BS 7953.

INJECTOR TEE (Central Heating)

10

Fig.13

Fig.14

hot water straight back into the return. Such a

valve can be operated either manually or

electrically in conjunction with a return pipe

thermostat.

Page 12

EXPLODED VIEW

11

1. Bonnet

2. Bonnet Door

3. Spin Valve

4. Back Outlet Spigot

5. Top Flue Spigot

6. Hot Plate Cup (LH)

7. Hot Plate Cup (RH)

8. Hot Plate

9. Cleaning Cups

10. Hot Plate Cord

11. Hob

12. Sheet Iron Back (LH)

13. Back Sealing Plate

14. Sheet Iron Back (RH)

15. Oven Back Insulation

16. Flue Back

17. Boiler Back Insulation

18. Oven Back

19. Hob Protection Plate (Large)

20. Hob Protection Plate (Small)

21. Sheet Iron Side

22. Side Insulation

23. Oven End Flue Top

24. Back Flue Guide

25. Damper Guide (RH)

26. Direct Damper

27. Damper Guide (LH)

28. Oven End Flue Bottom

29. Oven Side (RH)

30. Front Flue Guide

31. Steam Escape

32. Oven Damper

33. Oven Top

34. Oven Shelf Cast Iron

35. Oven Shelf Sheet Iron

36. Oven Bottom

37. Mild Steel Glass Lined Boiler

38. Plastic Boiler Plugs

39. Oven Side Brick M3-980

40. Oven Side (LH)

41. Boiler Zest

42. Fire Box LHS Top Brick

43. Fire Box LHS Bottom Brick

44. Sham Cheek

45. Fire Box Front Top Brick

46. Grate

47. Fire Box Base Insert

48. Fire Box Base

49. Ash Tray

50. Ashpit Back

51. Ashpit Side (LH)

52. Ashpit Bottom

53. Ashpit Side (RH)

54. Fall Bar Frame Back

55. Stay Rods

56. Fall Bar

57. Fall Bar Frame Front

58. Fire Box Front Bottom Brick

59. Serial Number Plate

60. Front

61. Towel Rail Bracket (RH)

62. Towel Rail

63. Oven Door Panel Sheet Iron

64. Fire Door Lining

65. Fire Door Insulation

66. Fire Door Rope

67. Fire Door Insulation Panel

68. Oven Door Rope

69. Oven Door Insulation

70. Fire Door

71. Ashpit Door Rope

72. Ashpit Door

73. Ashpit Spin Valve

74. Oven Door

75. Thermometer

76. Door Handles (3)

77. Cleaning Door Clip

78. Cleaning Door

79. Towel Rail Bracket (LH)

80. Base

81. Flue Check

82. Front Plinth (Sheet Iron)

83. Side Legs (2) Sheet Iron

84. Poker

85. Scraper

86. Cast Iron Cup Lifter

87. Non Boiler Back Top

88. Non Boiler Back Bottom

89. Non Boiler Brick

90. 15K Central Heating Boiler

91. 21K Central Heating Boiler

92. Pipe }

93. Bend } - Special Order

94. Cleaning Brush

95. Optional Legs

Page 13

12

MOURNE EXPLODED VIEW

Page 14

13

Where the gravity and central heating circuits join

together to return to the Cooker we recommend the

use of an injector tee connection, situated as close

to the unit as possible. This type of tee encourages

a stable flow of hot water through both circuits and

helps to prevent priority being given to the stronger

flow, which is most commonly the pumped central

heating circuit. This way, there will be no shortage

of hot water to the taps when the heating is on.

DRAINING

Key - operated drain taps to B.S. 2879 should be

provided in accessible positions in all low parts of

the system. However it should be noted that there

may be short sections of pipework e.g. when

passing under doorways that may be possible to

drain.

GENERAL MAINTENANCE

It is important that the user is familiar with their

heating system and that they ensure regular checks

and maintenance which can limit unnecessary

break-downs.

We recommend that you evaluate the overall

insulation in your house, i.e. attic, external walls,

windows, external doors. Insulation and draught

proofing can greatly reduce running costs, while

equally enhancing living conditions.

DRAUGHT REQUIREMENTS

Remember, a proper flue is necessary for the

efficient operation of your solid fuel cooker to

provide a steady draught of:

0.06 INS. TO 0.10 INS. W.G.

1.52 MM TO 2.54 W.G.

Page 15

IMPORTANT NOTES

Now that your Stanley solid fuel cooker is installed and no doubt you are looking forward to many comforts it

will provide, we would like to give you some tips on how to get the best results from your cooker.

1. We would like if you could take some time to read the operating instructions/hints, which we are

confident, will be of great benefit to you.

2. Do not burn fuel with a high moisture content, such as a damp peat or unseasoned timber. This

will only result in a build up of tar in the cooker and in the chimney.

3. Clean the flue-ways of the cooker every week and ensure that there are no blockages. Please

refer to manual for instructions.

4. Before loading fresh fuel into the firebox, riddle fully to remove all ashes this will allow better and

cleaner burning. See directions in manual.

5. Never allow a build up of ashes in the ash pan, as this will cause the grate to burn out prematurely.

6. Avoid slow burning of damp or unseasoned fuel as this will result in tarring flue ways and chimney i.e. peat or timber.

7. Allow adequate air ventilation to ensure plenty of air for combustion.

8. Do not burn rubbish/household plastic.

9. Do not leave ash-door open for long periods as this will over heat the unit causing unnecessary

damage.

10. Clean the chimney at least twice a year.

11. When burning peat or timber, it will be helpful to burn a few fires of “Anthracite” which will help

to dry and burn off tar and soot deposits. This will be helpful before cleaning.

12. Burning soft fuels such as timber and peat will stain the glass. Regular cleaning will prevent permanent staining.

13. Keep all combustible materials a safe distance away from unit, please consult manual for clearance to combustible table.

14. For safety reasons never leave children unaccompained while stove/cooker is in use.

15. Avoid contact with unit when in use as cooker/stove reaches very high operating temperatures.

FUEL CALORIFIC VALUES - SOLID FUELS

Anthracite 25-50mm C.V.: 8.2kW/Kg 14,000 BTUs/lb

House Coal 25-75mm C.V.: 7.2kW/Kg 12,000 BTUs/lb

Timber - Firebox size C.V.: 5.0kW/Kg 8,600 BTUs/lb

Peat Briquettes C.V.: 4.8kW/Kg 8,300 BTUs/lb

Bog Peat C.V.: 3.4kW/Kg 6,000 BTUs/lb

14

Page 16

LIGHTING THE FIRE

1. Open the Fire Door and lower the Fire Fence or open the top fuelling

cup.

2. Fully open all dampers and the Primary Air Inlet Spin Valve.

3. Kindle with paper and sticks in the usual way.

4. Ignite by using a taper or rolled wad of paper inserted into the ashpan.

5. Under no circumstances should any flammable liquid i.e. petrol,

paraffin etc. be used to light the fire.

6. When the fire is well established close the Direct Flue Damper fully and

keep it closed.

7. Add fuel to the firebox as required.

8. Adjust primary air opening to suit the current requirements.

Note: Do not operate with ashpit door open.

15

Page 17

16

OPERATING THE COOKER

Fig.15

FUELLING

Using the recommended fuels, access is through

the fire door or the fuelling cup. To fuel, lift and tilt

the Fire Fence outwards. Note: When burning

timber logs the fire fence may be removed to

simplify front loading, make sure that the logs are

no longer than the recommended size so that the

fire door can be fully closed.

When refuelling open the fire damper. After

refuelling be sure to close the damper otherwise

oven temperature will drop and the fire box may

overheat.

CONTROL

The air supply to the fire is controlled by the spin

valve situated on the ash door. Depending on the

setting a high or low firing condition will be

determined by the volume of air passing through at

any one time.

DIRECT FLUE DAMPER

The direct damper as already advised must be kept

closed at all times except when kindling a new fire

or refuelling.

A secondary flue damper position can be used

which allows the damper to be partly opened to

give better burning in marginal draught conditions.

OVEN DAMPER

When using oven, operate damper in open position.

OVER-FIRING

When using anthracite, coke or coal avoid

excessive firing conditions. High temperatures are

unnecessary and can only do serious harm to the

cooker. The first indication that overheating is

taking place will be the formation of Clinker (Melted

Ash) in the firebox and this should be removed

immediately otherwise damage will occur not only

to the cooker components but also to the fire bricks

and any damage here should be repaired without

delay.

THE HOTPLATE

For best results use heavy based, flat bottomed

utensils. When cleaning your cooker ensure that

the underside of the hot plate is also attended to as

hard carbon and soot can build up here to such a

degree that the surface of the hotplate is being

insulated from the fire and this will, of course,

drastically reduce efficiency.

MAIN OVEN

When baking or roasting, open the oven damper

and Spin Valve fully until the thermometer shows a

temperature about 50oF (10ºC) higher than that

which is required. Then close the Spin Valve to a

point where the required temperature is sustained

(a little practice will soon show how much

adjustment is necessary). Much will also depend

on the strength of the chimney draught. Remember

the direct flue damper must be kept fully closed as

a by-pass is provided to allow waste gases through

at all times. When baking or roasting, if it is found

that the surface of the food is cooking too quickly

then position the plain steel shelf in the top of the

oven so as to act as a heat shield which will protect

the food on the shelf beneath.

Fig.16

Page 18

Fig.17

Spin Valve

17

EMPTYING THE ASHPAN

The ashpan must be emptied regularly otherwise

ash will build up to a point where it interferes with

the natural flow of cool air through the fire bars and

as a consequence these will be damaged.

COOKER FLUE CLEANING

Your Stanley Cooker should be cleaned out at least

once a week although this may be extended to two

weeks if smokeless fuel is used. e.g. anthracite,

phurnacite or similar manufactured fuels.

This procedure is as follows: Remove all loose

sections on top of the Cooker. Open the direct

damper. Where a flue chamber is fitted in

conjunction with a vertical flue pipe remove the

cleaning door from the front of this fitting in order to

obtain access.

All deposits from the flue pipe and the top of the

oven may be brushed both into the firebox and

down the right hand side of the oven. Deposit

which has accumulated on the side of the oven

must also be brushed downward and particular

attention must be paid to the back flueway

which runs from the top flue outlet down to the

bottom left corner immediately underneath the

oven. To remove the accumulated ash and soot

take off the cleaning plate situated immediately

under the oven on the front of the Cooker and

thoroughly clean out the residue from the side flue,

back flue and base plate - this operation is

essential otherwise the flow of hot gases will be

obstructed and satisfactory oven temperatures

will not be maintained, apart from which such

deposits may contribute to smoking. Replace all

the loose parts which have been removed making

sure that all cooking surfaces have been thoroughly

cleaned on the underside.

OVERNIGHT BURNING

Open the spin valve by a quarter turn and close the

oven damper; riddle the fire and refuel. In the

morning open the air valve and damper and riddle

the fire; when it is again burning brightly, refuel. If

it is found that the fire is completely burned out then

new settings should be tried in respect of the spin

valve. On the other hand if the fire is out and the

fuel unburned then the reverse should apply.

BOILER SUMMER CONDITIONS (Central

Heating)

To obtain a reduction in boiler output during the

summer the central heating model is supplied with

a set of cast iron heat shield plates as standard

equipment. Two of them are positioned on the

hooks welded to the face of the boiler and boiler

back and are easily positioned and removed.

Maximum heat reduction is achieved by using all

the plates provided. If, however, increased output

is desired then plates can be removed

progressively to the point where the required output

is obtained.

These heat shield plates have no function other

than to reduce the boiler output.

DOMESTIC BOILER UNIT

A normal fire will provide sufficient hot water to

meet your needs. Increase the burning rate to heat

oven up to the required temperature.

RIDDLING

Open the ashpit door and direct damper to their

fullest extent. Fit the riddling tool on to the spigot

provided at the front of the fire bar and move the

bar vigorously to and fro. It is recommended that

the fire bed itself be thoroughly raked at regular

intervals thus loosening up such debris as Clinker,

Stones, etc., which are then easily removed.

Page 19

Remove all loose fitting parts, hotplate, bonnet door

from the top of the cooker. Open the direct damper.

Where a flue chamber is fitted in conjunction with a

vertical flue pipe remove the cleaning door from the

front of this fitting in order to obtain access. See

Fig.18.

To remove all the accumulated deposits take off the

cleaning plate situated immediately under the oven

on the front of the cooker and thoroughly clean out

the residue from the side flue, back flue and base

plate. This operation is essential otherwise the flow

of combustion gases will be obstructed or even

stopped, and satisfactory oven temperature will not

be maintained, apart from which such deposits will

cause smoking. See Fig.22.

Replace all loose parts which have been removed

making sure that all cooking surfaces have been

thoroughly cleaned on the underside. See Fig.23.

18

CLEANING INSTRUCTIONS

Fig.18

Fig.19

Fig.20

Fig.21

Fig.22

Fig.23

All deposits from the flue pipe and the top of the

oven may be brushed both into the firebox and

down the back flue passage way. See Fig. 19 & 20.

Deposits which have accumulated on the side of

the oven must also be brushed downward and

particular attention must be paid to the back

flueway which runs from the bonnet down to the

bottom left corner immediately underneath the

oven. See Fig.21.

Flue Way Cleaning Brush

Flue Way Cleaning

Brush

Flue Way Cleaning

Brush

Page 20

CLEANING

IMPORTANT: BE CAREFUL OF THE HOT

APPLIANCE.

General cleaning must be carried out when the

cooker is cool.

This cooker is finished in a high gloss vitreous

enamel. To keep the enamel in the best condition

observe the following tips:

1. Wipe over daily with a soapy damp cloth,

followed by a polish with a clean dry duster.

2. If milk, fruit juice or anything containing acid is

spilt on the top plate or down the cooker, be

sure to wipe it immediately or the vitreous

enamel may be permanently discoloured. Jam

and preservatives containing sugar can

permanently damage the vitreous enamel.

3. Keep a damp cloth to hand while cooking, to

wipe up any spills as they occur, so they do not

harden and become more difficult to remove

later.

4. If spills do become baked on a cream cleanser

can be used. For stubborn deposits a soap

impregnated pad can be carefully used on the

vitreous enamel.

5. Use only products recommended by the

Vitreous Enamel Association, these products

carry the Vitramel label.

6. In the oven, spills and fat splashes are

carbonised at high temperatures: occasionally

brush out with a stiff brush. The shelves can be

soaked and cleaned with a cream cleanser.

7. Use a wire brush to keep the cast iron hotplate

clean.

DO NOT USE ABRASIVE PADS OR OVEN

CLEANERS CONTAINING CITRIC ACID ON

ENAMELLED SURFACES. ENSURE THAT

THE CLEANSER MANUFACTURERS

INSTRUCTIONS ARE ADHERED TO.

10K Domestic Boiler

21K Central Heating Boiler

19

Fig.24

Fig.25

Your new Stanley Cooker will give you every

possible satisfaction in use and many years of

service provided it is properly installed and

maintained in accordance with our published

instructions.

Page 21

20

15K Central Heating Boiler

Optional Plate Rack Installation

MILD STEEL

The steel side panels and splash back must not be

cleaned with steel wool. Use only washing up liquid

in hot water with a lint free cloth. dry off and apply

a coat of good quality furniture polish.

OVENS

Grease spillages will burn off from the oven interior,

when the oven is hot and any other loose materials

can be wiped out with a cloth, when cold. Stubborn

stains in the oven and on the shelves in the oven

can be cleaned off with a paste of bread soda and

water.

HOT PLATE

The hotplate may be cleaned using a small amount

of paraffin oil or fine steel wool to remove rust and

cooking stains. Dry off with a lint free cloth and

apply a light coat of cooking oil to preserve the

finish.

Fig.26

Fig.27

IMPORTANT

It is of the utmost importance to keep the flue pipe and chimney clear of deposits by regular sweeping

of the chimney irrespective of whether the fuel used is classed as smokeless or not. All fuels give rise

to soot or ash deposits and regular cleaning is essential for safe operation.

Blocked or partially obstructed flueways and chimneys will cause dangerous fumes to be emitted into

the room, these may well be invisible if a smokeless fuel is burned.

CO ALARM

Waterford Stanley recommend the fitting of a CO

Alarm in the same room as the appliance, this is a

requirement under UK Building Regulations.

Further guidance on the installation of a carbon

monoxide alarm is available in BS EN 50292:2002

and from the alarm manufacturers instructions.

Provision of an alarm must not be considered a

substitute for either installing the appliance

correctly or ensuring regular servicing and

maintenance of the appliance and chimney

system.

WARNING:-

If the CO Alarm sounds unexpectedly:-

1. Open Doors and windows to ventilate the

room and then leave the premises.

2. Let the fire go out.

Page 22

21

FAULT FINDINGS

1. Poor Chimney Draught (a) Obstruction (a) Clear and Clean

(b) Too Low (b) Raise Height above Ridge

(c) Too Wide (c) Fit Flue Liner 15 to 23 cm

(d) Crack in Wall (d) Repair Cracks

(e) Shared by another unit (e) Cut off other unit

2. Excessive Chimney Draught (a) High chimney (a) Adjust bonnet spin valve

3. Down Draught (a) High Trees (a) Raise Chimney Height

(b) High Buildings (b) Raise Chimney Height

(c) Low Chimney (c) Raise Chimney Height

(d) Negative Pressure Zone (d) Fit Cowl

4. Cooker Smoking (a) Insufficient Primary Air (a) Provide Room Air Inlet

(b) Chimney Choked (b) Clean Chimney

(c) Side and/or Back Flueways Choked (c) Clean Flueways

(d) Down Draught (d) Raise Chimney Height

5. Hot Plate Not Heating (a) Soot Under Hot Plate (a) Remove and Clean

(b) Fire Too Low (b) Build Better Fire

(c) Utensils not Flat (c) Use machined based Utensils

6. Oven Not Heating (a) Poor Chimney Draught (a) Raise Height or Fit Cowl

(b) Flue ways blocked with soot (b) Clean Out

(c) Damper open to Chimney (c) Close Damper

7. Radiators not Heating

(Central Heating)

(a) Pump not Working (a) Check and replace if defective

(b) Air in Radiators (b) Vent Radiators

(c) Pipe System Faulty (c) Check Pipe Sizes and Circuit

(d) Excessive Number of Radiators (d) Turn off un-needed Radiators

(e) Radiator Valves not Adjusted (e) Adjust Valves to Give even flow

8. Domestic Hot Water (a) Cylinder too Large (a) Lag Cylinder or use smaller cylinder

(b) Flow Pipe too small (b) Use 25mm Bore Pipe

(c) Flow Pipe crossed (c) Reverse Flow Pipe

(d) Cylinder too far away (d) Not more than 7.8m fully lagged

(e) Hot water from boiler not reaching

boiler

(e) Adjust Flow Control Valves or fit

injector-tee - Central Heating

9. Intermittent Performance (a) Cooker starved of Primary Air (a) Provide Air Inlet in Room

(b) Extraction Fan in room (b) Provide additional air inlet in room

(c) Cooker subjected to wind change (c) Raise Chimney or fit Cowl

(d) Dirty Flueways (d) Clean flueways frequently

(e) Poor Fire (e) Burn more fuel

(f) Uncontrolled Burning (f) Repair or replace Air Valve in Ash

door or replace sealing rope

10. Domestic Hot Water Rusty

(Central Heating Only)

(a) Leak in Indirect Cylinder Coil (a) Replace Cylinder

(b) Incorrect Cylinder Fitted (b) Check with installer

Page 23

COOKER INSTALLATION CHECK LIST

Flue System

1. Minimum Flue Height of 4.6 metres (15 feet).

2. Appliance should be connected to a minimum of 1.8 metres (6 feet) of 125mm (5”)

flue pipe with a horizontal run not exceeding 150mm (6”).

3. Appliance should be connected to a chimney of less than 250mm (8”) in diameter

(otherwise the chimney must be lined with a 6” flue liner).

4. The chimney venting position must be above the main ridge of the roof or adjacent

outside obstructions.

Location

5. Clearance to combustible materials must be maintained at 75mm (3”).

6. Clearance to non combustible materials must be maintained at 75mm (3”).

7. Clearance to combustible materials must be maintained as specified in the

Clearance to Combustibles section.

8. If the cooker is located on a combustible surface, a floor protector must be used to

cover the area underneath the heater, extending 18” from the front of the cooker

and 8” from the back & sides.

Plumbing

9. Appliance must be connected to a gravity circuit using 1” ID flow & return piping.

10. The length of pipes from the cylinder to the cooker should not exceed 7.8 metres

(25

1

/2 feet).

11. A circulation pump should be fitted to the return pipe and controlled by a pipe stat

fitted to the flow pipe of the gravity circuit to the cylinder.

Ventilation & Combustion Air Requirements

12. The room in which the appliance is located should have an air vent of adequate

size to support correct combustion (see Ventilation & Combustion Air Requirement

Section).

Tick

22

Page 24

Rev:010 DP130913

N00118AXX

24

Manufactured by

Waterford Stanley Ltd.,

Unit 401-403, IDA Industrial Estate, Cork Road,

Waterford, Ireland.

Tel: (051) 302300 Fax (051) 302315

www.waterfordstanley.com

www.stanleystoves.com

Loading...

Loading...