Page 1

www.stanleytools.com

User Manual

Page 2

Directly plug the power cord in the receptacle on the wall. Do not use extension cord.

If the power cable or plug is worn or damaged, pull out the power plug.

The exposure of the interior of the machine can cause electric shock or burns.

Do not remove covers or screws other than specified in this manual.

Please be cautious. In the process of printing, the temperature of the nozzle and the heated

bed rise higher than 100 degrees Celsius.

Do not place the machine in a highly moist environment as it may cause deformation and

malfunction.

Avoid contact of electrical terminal with metal product such as necklaces, coins, keys,

watches, etc.

Do not hold the shaft for lifting or moving of the printer.

For the following situations turn off power and pull out the power plug

-

When in contact with liquid

-

When in need for a service or repair request

-

When the device cover is damaged

For the method of disposal contact local service center or use a proper collection site.

Please turn off power when leaving the office after business hours or in circumstances where

machine is unoccupied for a long period of time as it may cause abrupt fire accidents.

Protect device from humid or wet conditions eg. rain, snow, etc

Remove power cord from receptacle on the wall before moving device.

Be careful not to damage power cord while device is being translocated.

When removing the power cord, please pull the plug and not the power cable.

Be cautious of clips, staples and any other small metal objects from falling inside the device.

Please be cautious on safety when touching the interior of the machine, e.g. cleaning the

interior.

Do not dispose of device or consumables together with household waste.

For the method of disposal, please contact local service center or use a proper collection site.

Interior of device may be very hot. Please do not touch the part with “Caution: High

Temperature” sign or its surrounding areas as it may cause burns.

Our product maintains high quality standards and performance.

It is recommended to use genuine components only, components can be acquired from any

authorized distributors.

Safety Instructions

Warning:

Failure to observe the instructions may lead to death or serious injury.

Caution:

Failure to observe instructions may cause injuries or damages to property.

Be sure to observe the followIng instructions when using the device.

Page 3

Thank you for purchasing our product.

This user manual contains detailed information about correct use of device and easy

maintenance to maintain the optimal state, and to contribute to the rationalization of

office work of your company.

Carefully read the user manual before using the device and keep close at hand.

In order to use device correctly and safely, please carefully note the precautions before use.

Before use

Prohibition and limitation

1. This User Manual has been created for the convenience of the user, actual product

may differ from image and explanations shown.

2. The contents of this user manual is subject to change without notice. We are not

responsible for the direct and/or indirect loss or damages caused by results of handling

or operating the product in any case and for results occurring from user’s negligence.

3. The copyrighted literary works can be duplicated and used for personal use or

household use and within the same parameter. In other cases than the

aforementioned, it is prohibited by law.

4. The above details present only a part of the applicable laws and regulations.

Details on these laws/regulations may not be stated as they are. We do not guarantee

its correctness and completeness. Please consult a legal advisor to check if the object

you intend to print is legal.

5. User is responsible for all loss derived from modification of the product executed by

the user or third party.

Page 4

Before using the Machine

1. Preface ---------------------------------------------------------------------------------------------------------------------------------- 1

2. Conventions --------------------------------------------------------------------------------------------------------------------------- 2

2.1 Symbols ------------------------------------------------------------------------------------------------------------------------- 2

3. Safety Information ------------------------------------------------------------------------------------------------------------------- 3

4. Precautions ---------------------------------------------------------------------------------------------------------------------------- 5

4.1 Installation --------------------------------------------------------------------------------------------------------------------- 5

4.2 Moving the Machine -------------------------------------------------------------------------------------------------------- 6

5. Consumables Handling ------------------------------------------------------------------------------------------------------------- 7

6. Instructions for Use ----------------------------------------------------------------------------------------------------------------- 8

7. Ventilation ----------------------------------------------------------------------------------------------------------------------------- 9

8. Notices ------------------------------------------------------------------------------------------------------------------------------- 10

9. Disposal of Used Battery --------------------------------------------------------------------------------------------------------- 12

10. Wifi Module Disclaimer ---------------------------------------------------------------------------------------------------------- 13

11. USB Memory Disclaimer ---------------------------------------------------------------------------------------------------------- 15

Chapter 1 Preparations for Machine Operation

1. Machine Specifications ---------------------------------------------------------------------------------------------------------- 1-2

1.1 Printing ---------------------------------------------------------------------------------------------------------------------- 1-2

1.2 Temperature/Speed ----------------------------------------------------------------------------------------------------- 1-2

1.3 Machine --------------------------------------------------------------------------------------------------------------------- 1-2

1.4 Software/Support ------------------------------------------------------------------------------------------------------- 1-2

1.5 Default Setting of Print layer Width ------------------------------------------------------------------------------- 1-2

2. Basic Components ---------------------------------------------------------------------------------------------------------------- 1-3

3. Understanding the Device Parts ----------------------------------------------------------------------------------------------- 1-4

4. Installation (Product connection, Cartridge Setup and includes Software Installation) ------------------------ 1-6

4.1 Device Connection ------------------------------------------------------------------------------------------------------- 1-6

4.2 Program Installation ---------------------------------------------------------------------------------------------------- 1-6

Chapter 2 UI Menu Functions

1. UI Menu Function description -------------------------------------------------------------------------------------------------- 2-2

1.1 CARTRIDGE ------------------------------------------------------------------------------------------------------------------ 2-3

LOAD ------------------------------------------------------------------------------------------------------------------------- 2-4

Contents

Page 5

UNLOAD -------------------------------------------------------------------------------------------------------------------- 2-5

UNLOCK --------------------------------------------------------------------------------------------------------------------- 2-7

1.2 Settings -------------------------------------------------------------------------------------------------------------------2-10

X, Y, Z -----------------------------------------------------------------------------------------------------------------------2-11

EXTRUDER -----------------------------------------------------------------------------------------------------------------2-13

BED LEVELING ------------------------------------------------------------------------------------------------------------2-15

Z OFFSET -------------------------------------------------------------------------------------------------------------------2-17

NOZZLE CLEANING ------------------------------------------------------------------------------------------------------2-19

CLEANING CASE ---------------------------------------------------------------------------------------------------------2-21

NETWORK ----------------------------------------------------------------------------------------------------------------2-22

LAMP ------------------------------------------------------------------------------------------------------------------------ 2-26

BED LOWERING ---------------------------------------------------------------------------------------------------------- 2-28

TEST PRINT ----------------------------------------------------------------------------------------------------------------2-29

POWER SAVING MODE ------------------------------------------------------------------------------------------------2-31

BEEP SOUND -------------------------------------------------------------------------------------------------------------- 2-32

NOZZLE SETTING --------------------------------------------------------------------------------------------------------2-34

LANGUAGE ---------------------------------------------------------------------------------------------------------------- 2-36

E-MAIL ---------------------------------------------------------------------------------------------------------------------- 2-38

UNIT -------------------------------------------------------------------------------------------------------------------------2-42

TIME SETTING ------------------------------------------------------------------------------------------------------------2-43

TIME ZONE ---------------------------------------------------------------------------------------------------------------2-45

SOFTWARE UPDATE ----------------------------------------------------------------------------------------------------2-46

1.3 Information ---------------------------------------------------------------------------------------------------------------2-48

Chapter 3 Printing

1. Printing ------------------------------------------------------------------------------------------------------------------------------ 3-2

1.1 Printing from USB Flash Drive ---------------------------------------------------------------------------------------- 3-2

1.2 Printing Via PC ------------------------------------------------------------------------------------------------------------ 3-6

1.3 Next print job ------------------------------------------------------------------------------------------------------------- 3-6

Chapter 4 Printed Output Check

1. Printed Output Check ------------------------------------------------------------------------------------------------------------- 4-2

1.1 Detaching Printable ----------------------------------------------------------------------------------------------------- 4-2

1.2 Improving Printing Quality ------------------------------------------------------------------------------------------- 4-4

Page 6

2. When Printer Cannot be Turned On ------------------------------------------------------------------------------------------ 4-5

Chapter 5 Maintenance

1. Machine Cleaning ---------------------------------------------------------------------------------------------------------------- 5-2

1.1 Cleaning Case Maintenance ------------------------------------------------------------------------------------------ 5-2

1.2 Printer Interior Cleaning ----------------------------------------------------------------------------------------------- 5-2

1.3 Periodical Inspection ---------------------------------------------------------------------------------------------------- 5-2

Oil/Grease Inspection ---------------------------------------------------------------------------------------------------- 5-2

2. Error Message and Solutions -------------------------------------------------------------------------------------------------- 5-3

3. Problems and Solutions -------------------------------------------------------------------------------------------------------- 5-6

3.1 If filament does not come out of the nozzle (Fix for EC401) ----------------------------------------------- 5-6

3.2 In Cases where Filament is Cut Between the Extruder and Nozzle --------------------------------------- 5-7

3.3 When Filament End is Visible Outside the Cartridge After Unloading ---------------------------------- 5-7

4. Replenishing Consumables ---------------------------------------------------------------------------------------------------- 5-8

4.1 Bed Replacement --------------------------------------------------------------------------------------------------------- 5-8

Removing Aluminum Bed --------------------------------------------------------------------------------------------- 5-8

Installing Aluminum Bed ---------------------------------------------------------------------------------------------- 5-8

4.2 Filter Replacement ------------------------------------------------------------------------------------------------------- 5-8

4.3 Cartridge Replacement ------------------------------------------------------------------------------------------------5-10

4.4 Nozzle Replacement ---------------------------------------------------------------------------------------------------5-10

Methods of Detaching Nozzle --------------------------------------------------------------------------------------5-10

Assembling the Nozzle ------------------------------------------------------------------------------------------------5-12

Chapter 6 Appendix

1. Type of Consumables (Material, Color) ------------------------------------------------------------------------------------- 6-2

Page 7

1

Before using the Machine

1. Preface

This User Manual describes detailed explanations and points to note in connection with operating and using

the machine. Please read the User Manual carefully before using machine, and keep it for reference purpose.

Important

- The content of the User Manual is subject to change without any prior notification.

Sindoh shall not be liable for consequential, special, indirect damages or losses caused by the handling or

operating of the machine or by the user’s negligence.

-

Copyrighted works can be printed and used for home and/or personal use; other usage is prohibited by

law.

-

The above details present only a part of the applicable laws and regulations and the details of the law

may not be stated as they are. Sindoh is not responsible for its correctness and completeness.

Please consult your legal advisor to check if the object you intend to print is legal.

Note

- The User Manual may include a little different descriptions of the machine from the actual one.

Some options may not be available in some countries. Please contact local distributor for details.

Some standard units are optional in some countries.

Please consult your local service center.

-

In some countries some models are not available.

Please consult your local sales office.

-

This manual uses metric units of measurement

Page 8

Before using the Machine

2

2. Conventions

2.1 Symbols

This manual uses the following symbols and meanings.

Warning

- Indicates importance safety notes.

Ignoring these notes could result in serious injury or death.

Be sure to read these notes carefully for your safe operations of the machine.

Caution

-

Indicates important safety notes.

Ignoring these notes could result in minor injury, or damage to the machine or to property.

Be sure to read these notes for your safe operations of the machine.

Important

- Indicates points to pay attention to when using the machine, and explanations of likely causes of filament

misfeeds, damage to originals, or loss of data.

Be sure to read these explanations before operating the machine.

Note

- Indicates supplementary explanations of the machine`s functions, and instructions on resolving user errors.

Reference

- This symbol is located at the end of sections. It indicates where you can find further relevant information.

[ ]

Indicates the messages or menus that appear on the machine`s LCD display panel.

Indicates the names of each function key on the machine control panel and the display window.

Page 9

3

Before using the Machine

3. Safety Information

Plug the power cord into a properly grounded outlet which is near and quickly accessible from the machine.

Do not use or place the machine in wet or humid environment.

Caution

Hot Surface

- The inside of the machine may be hot. To reduce the risk of injury from a hot component,

allow some time to cool down.

(Please be cautious of getting burns during printing as the Nozzle and the heating bed

will maintain a high temperature of over 100 degrees.)

-

Do not put any portion of your body or objects on any part during machine operation as the motor and

bed can be in very high temperature and can cause burns/injuries. Please be cautious.

-

When the power is on, do not let any of your body touch the machine except the bed.

If you have to touch the bed while the power is on, please do so after the bed temperature has been

lowered to room temperature.

-

If you have to touch any parts other than the bed, please do so after the bed and nozzle temperature have been

lowered to room temperature.

Caution

Electric Shock

- Proceed your work after turning off the machine and unplugging the power cord

from the outlet in case of accessing the system board, or installing hardware or

optional memory devices. If the machine is connected with other device, turn it off and

separate the cables from the machine.

-

This product has been designed, tested and approved to meet strict safety requirements

of international safety standard. Some safety features of parts may not be guaranteed.

Sindoh is not liable for problems caused by using an unauthorized spare parts or consumables.

-

Disconnect the power cord and all the cables connected to the machine to prevent from any electrical shock

when cleaning the outside or inside of the machine.

Caution

Injuries

- Do not twist, fold, step or place heavy objects on the powercord.

-

Be careful with the power cord peeled off or overloaded.

-

Do not let the power cord pinched by furniture or walls.

-

Misusing the cord could result in fire or electrical shock.

-

Check the cord regularly. When checking the cord, unplug the cord from the outlet first.

-

Please consult a qualified engineer for services or repairs not stated in this User Manual.

Page 10

Before using the Machine

4

Caution

Injuries

- To prevent personal injuries or damages to the machine, you need to follow the below

instructions before moving the machine.

Do not open the front and top door during machine operation.

When the power is on, do not let any of your body touch the machine except the bed.

If you have to touch any parts other than the bed, please do so after turning the

power off, removing the power cord from the plug and after the bed and nozzle

temperature have been lowered to room temperature.

Turn the power switch off, then unplug the power cord from the power outlet.

Unplug and release all the cords and cables before moving the machine.

Only use the power cords provided with this machine or cords that are approved by the manufacturer.

Do not put any portion of your body or objects during machine operation, as the bed, motor, nozzle will be in

operation and moving. Small objects such as neckless, hair, etc may cause personal injuries or

damages to the machine.

If any problems occur(malfunction, body part being caught inside the machine, etc) during machine operation,

quickly press the pause

or stop button located on the on the bottom right of the touch screen located on

the bottom right of the upper side.

Nozzle

Bed UI

Page 11

5

Before using the Machine

4. Precautions

Please comply with the following instructions and the “Safety Information” provided with the purchase of this

product.

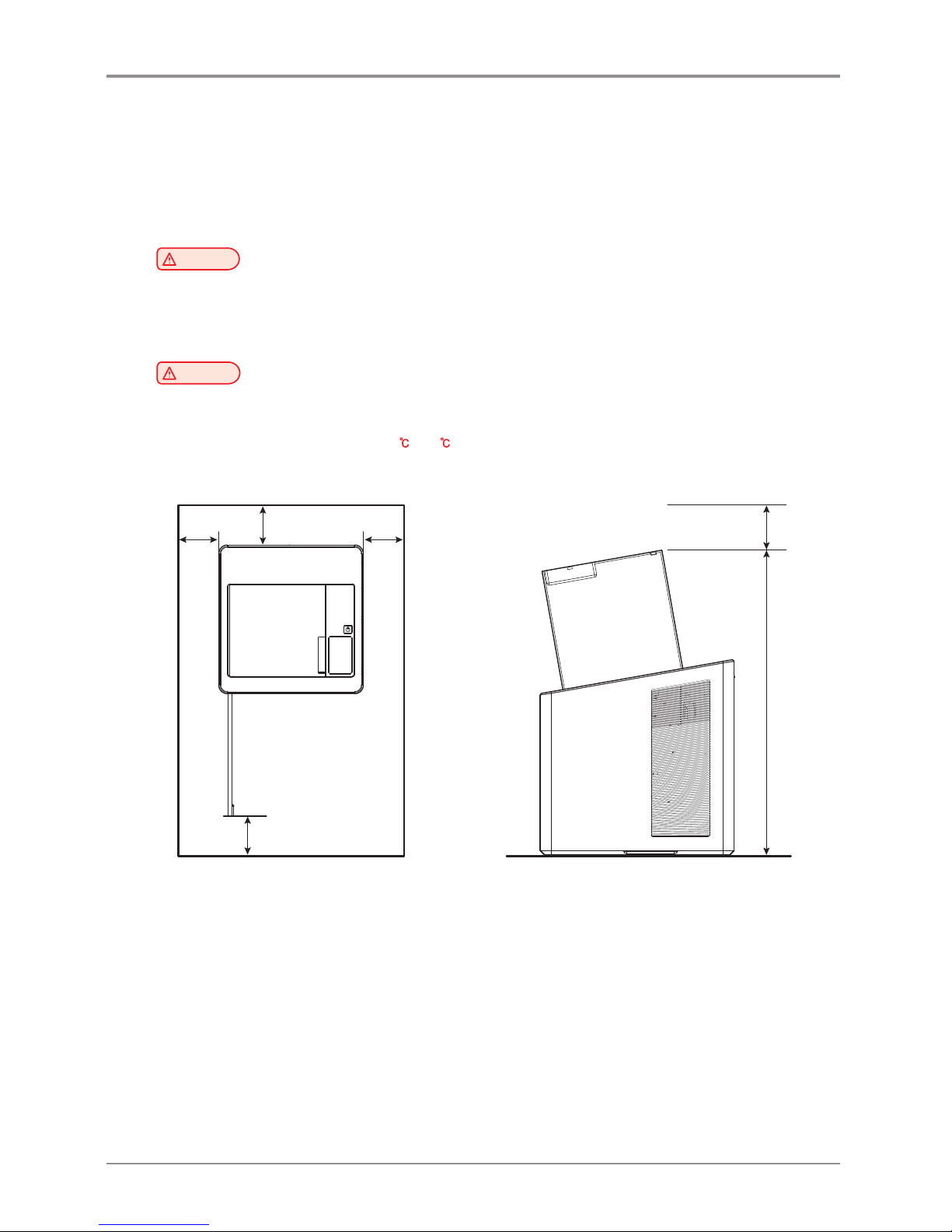

4.1 Installation

Warning

- Install the machine in a well ventilated area.

You can small odor during machine operation. It should not be harmful; however, if the area of where the machine

is located is not ventilated, make sure to ventilate the area appropriately time to time.

Caution

- Install the machine with its vents spaced at least 10 cm away from walls and other equipments.

Secure properly sufficient space around the machine for easy ventilation and operation.

Use the machine at temperatures of 16

~ 29 and relative humidity of 20% ~ 70%.

Do not install or use the machine outdoor.

100 mm

100 mm

100 mm

680 mm

100 mm

100 mm

Top View Side View

Page 12

Before using the Machine

6

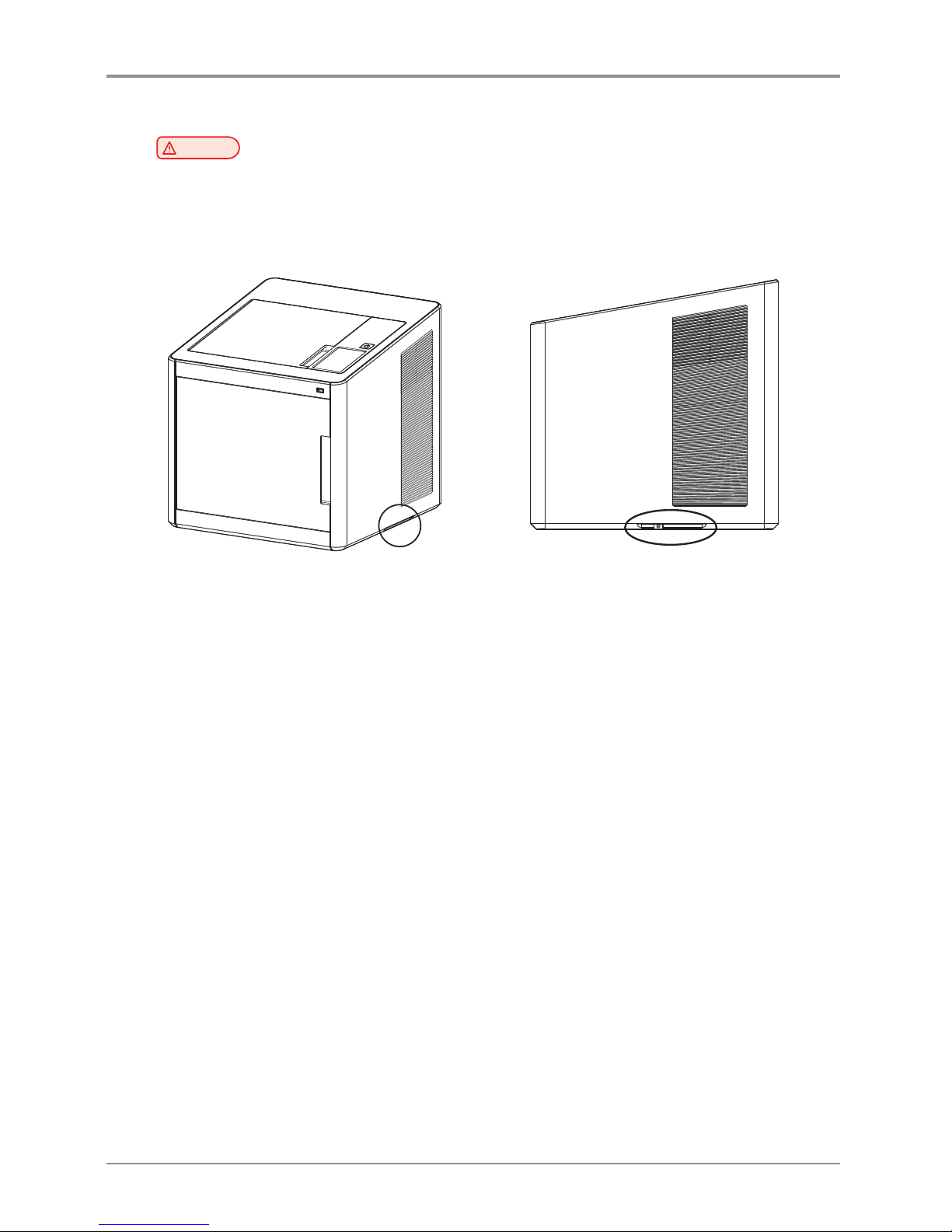

4.2 Moving the Machine

Warning

-

Before moving the machine, be sure to unplug the power cord from the outlet.

When moving the printer, it is recommended that two people lift and move the printer for safety.

-

Hold the bottom handles of the machine when moving it.

Bend your knees enough to protect your spine when lifting the machine.

Handle

Handle

Page 13

7

Before using the Machine

5. Consumables Handling

Warning

-

Do not burn the Cartridge unit or filament. It may be a cause of big fire or burn by ignition.

Caution

- Keep them out of the reach of children.

-

If skin irritation occurs after touching the filament, please see a doctor.

Important

- Do not keep the cartridge unit in the following places.

Exposed to fire

Exposed to direct sunlight;

Where temperature or humidity may rise;

Where sharp change of temperature may occur;

Covered with dust;

Inside a vehicle for extended time.

-

Keep cartridges away from physical impact or vibration.

-

Do not unpack cartridges until you are just ready to use them.

Page 14

Before using the Machine

8

6. Instructions for Use

Caution

- The nozzle and the bed that are inside the machine are very hot during machine operation.

Please be cautious not to touch the nozzle or the bed during removal of the printed objected or during

inspection of the machine inside. It may become the cause of injuries or burns.

-

Never operate the machine in the way this manual does not specifically instruct.

Notification for California customers, USA

Warning

-

This product uses chemicals known to the State of California to cause cancer and birth defects or other

reproductive harm. This appliance and its accessories can cause low-level exposure to chemicals during

operation, which can be reduced by operating the appliance in a well ventilated area.

Page 15

9

Before using the Machine

7. Ventilation

Caution

- Use the machine in a place with good ventilation. If the machine is used in a place without good ventilation,

this may be harmful for your health. Ventilate it on a regular basis.

-

Do not block vents. Inappropriate cooling may lead to high temperatures inside the machine.

-

In general, a new machine may produce small amount of gaseous components, so ensure good ventilation when

the machine is used for the first time. If the machine is in operation for an extended time, do not stay in the same

room for a long time.

Page 16

Before using the Machine

10

8. Notices

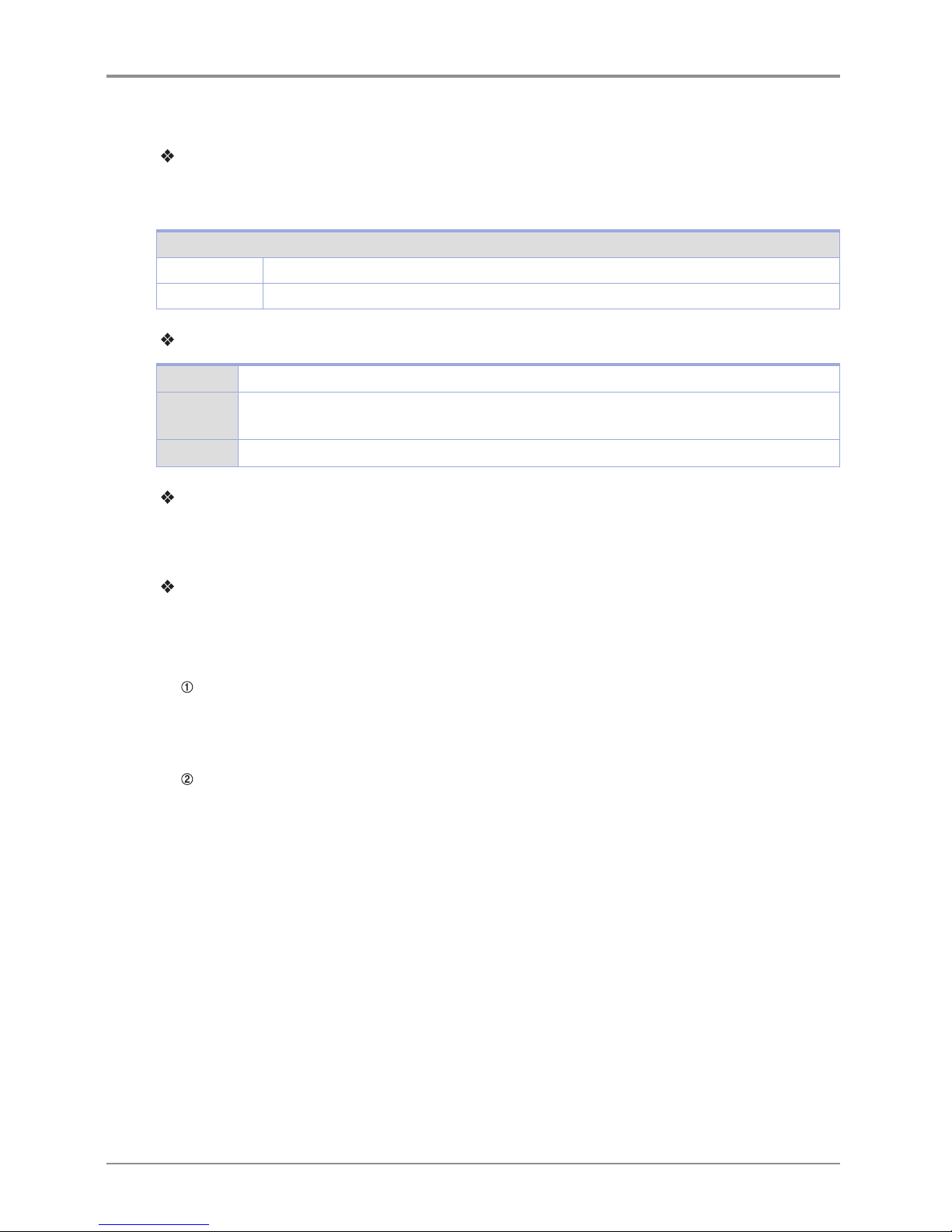

Noise Emission Level

The following are measured in accordance of ISO 7779 and reported to meet ISO 9296.

Some modes may not be available in your purchased products.

Average Sound Pressure at 1 Meter Away

Printing 53dBA(Normal Print Condition - Printing speed 40 mm/s, Travel speed 100 mm/s)

Standby under 30 dBA

Temperature/Humidity

Operation 16 °C ~ 29 °C 20%RH~70%RH

Shipping

-30 °C ~ 50 °C, 15%RH~95%RH(for 0 °C or lower temperature, room’s temperature should be

higher than the outdoor’s; must not touch the floor)

Storage -30 °C ~ 50 °C, Below 80%RH(No condensation, must not touch the floor)

Disposal of The Products

Do not dispose the machine and consumables together with household wastes.

For disposal or recycling, contact your local sales office.

EMI(Electromagnetic Interference) Notice

This machine complies with the limits for Class B.

Class B (Home Device): This device is designated to Class B. This equipment can be used in all areas

including residential area as it has obtained EMC registration for household use.

FCC COMPLIANCE STATEMET

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and (2) this device must accept any interference

received, Including interference that may cause undesired operation.

INFORMATION TO USER

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference in a residential installation.

This equipment generates uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications. However, there

is no guarantee that interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by turning the equipment

off and on, the user is encouraged to try to correct the interference by one m ore of the following

measures:

- Reorient or relocate the receiving antenna.

-

Increase the separation between the equipment and receiver.

-

Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

-

Consult the dealer or an experienced radio/TV technician for help.

Page 17

11

Before using the Machine

CAUTION

Any changes or modifications not expressly approved by the manufacturer responsible for compliance

could void the user’s authority to operate the equipment.

DECLARATION OF CONFORMITY (DOC Letter): 12page

Wireless LAN Specifications

The wireless device may be affected by electromagnetic interference so it should not be used for life

saving services.

WLAN Notice

Exposure to radio frequency radiation

The following notice is applicable if your printer has a wireless network card installed.

The radiated output power of this device is far below the FCC radio frequency exposure limits.

A minimum clearance of 20 cm (8 inches) must be maintained between the antenna and any persons for

this device to satisfy the RF exposure requirements of the FCC.

Power Consumption

Power Consumption of the Products

The below table shows power consumption.

Mode Description Power Consumption(W)

Printing A device is printing using electronic input data. 150W

Standby A device is in standby mode. 21W

Power Off A power plug is plugged into the outlet with the machine’s

switch off .

0.05W

The above power consumption is the hourly average value.

Instant power consumption can be much higher than the average value.

Deactivated Mode

The machine consumes power even in the deactivated mode. Unplug the power cord to completely stop the

power consumption.

Total Energy Usage

It would be useful to calculate the Total energy usage of the machine.

Since the electricity bill is charged in Watt unit, you have to multiply time spent in each mode by power

consumption in order to calculate the energy use.

Total energy usage is the sum of energy used in each mode.

Condensation

Dramatic change of the ambient temperature may produces water droplets on the interior and exterior of the

machine.

Wipe the water droplets on the outer surface, but for the inside please let them dry off by leaving front

door and cover opened.

Page 18

Before using the Machine

12

9. Disposal of Used Battery

Control board uses a Lithium battery.

Please discard used batteries following the environmentally friendly procedure stated on the manufacturer

guidelines.

To replace batteries, please contact a qualified service engineer.

Page 19

13

Before using the Machine

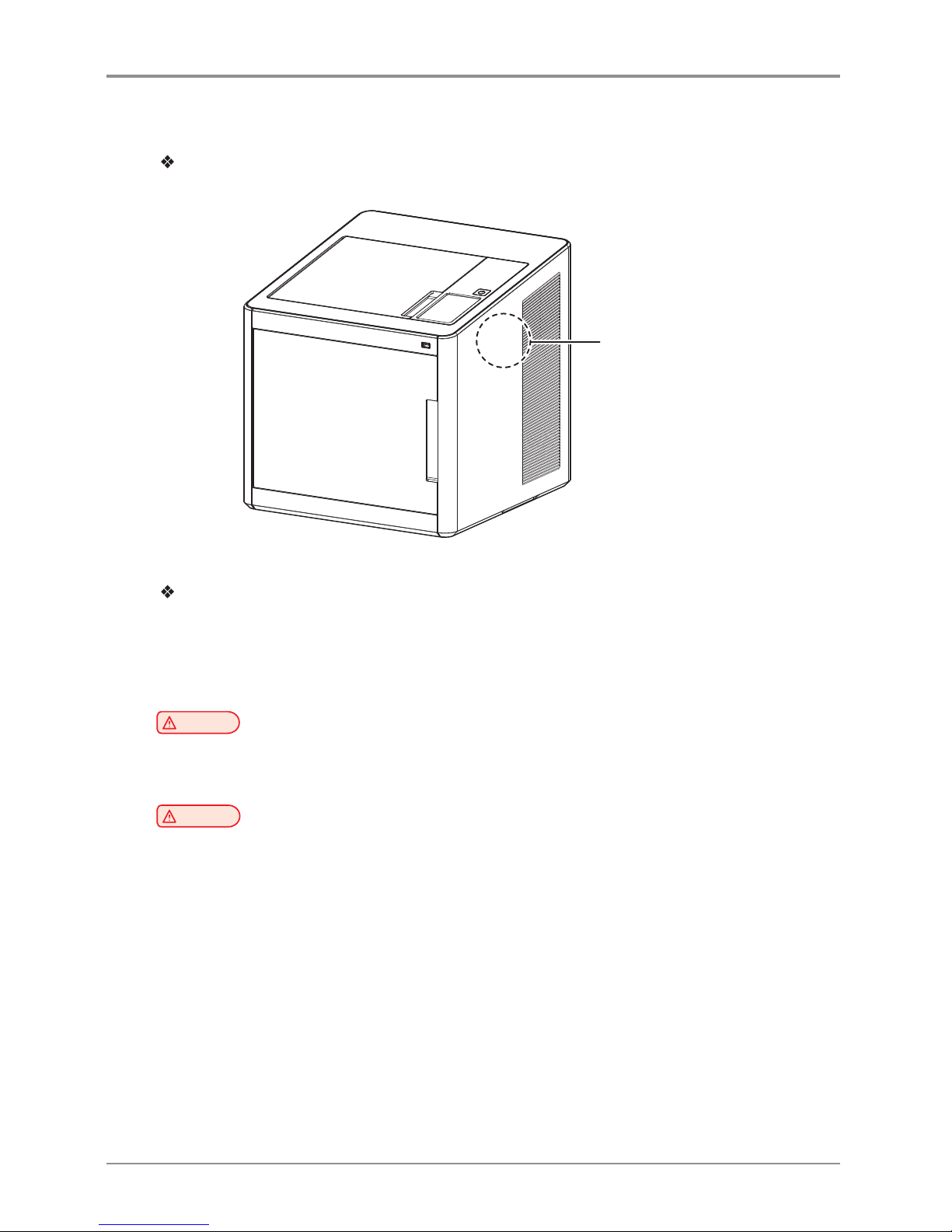

10. Wifi Module Disclaimer

This Product contains the Wifi module that is only compatible with STANLEY MODEL 1 3D printer.

Wifi module inside

Precautions

This Wifi module can cause radio interference, therefore it should not be used for any purposes related to

human lives.

Do not expose this product to water, humidity or liquid.

Do not expose this product to direct light, hot temperature or fire.

Warning

-

If the machine has been modified by an unauthorized personnel, Sindoh is not liable for the

machine trouble or failure.

Caution

- To prevent RF signals that exceed FCC RF exposure limits from being exposed to human, this module has been

mounted in a place that minimizes human access.

Page 20

Before using the Machine

14

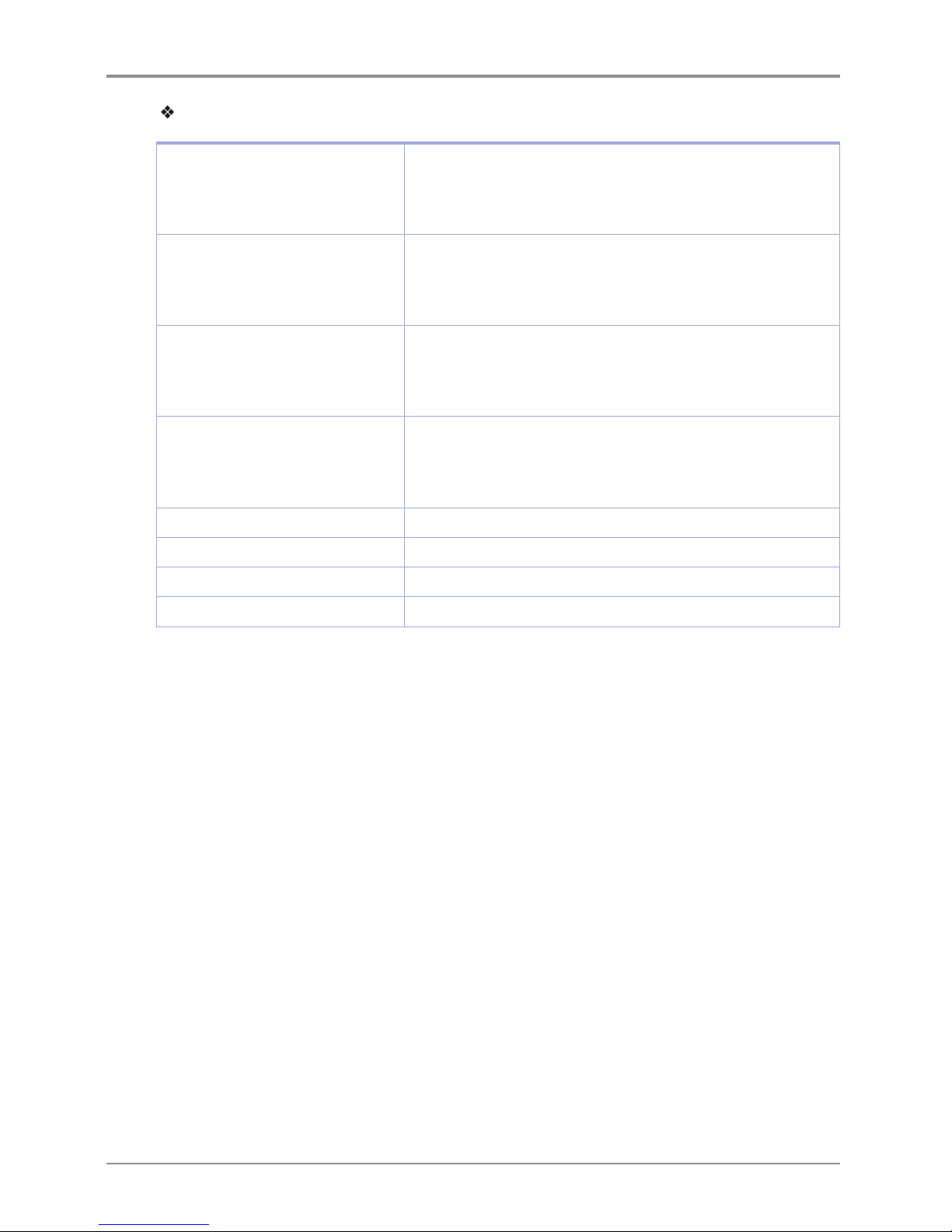

Precautions

Frequency

IEEE 802.11b : 2400MHz ~ 2484MHz

IEEE 802.11g : 2400MHz ~ 2484MHz

IEEE 802.11n(20MHz) : 2400MHz ~ 2483MHz

IEEE 802.11n(40MHz) : 2400MHz ~ 2483MHz

Antenna Power Density IEEE 802.11b : 10mW(10dbm)/MHz

IEEE 802.11g : 10mW(10dbm)/MHz

IEEE 802.11n(20MHz) : 10mW(10dbm)/MHz

IEEE 802.11n(40MHz) : 10mW(10dbm)/MHz

No. of Channels IEEE 802.11b : 14

IEEE 802.11g : 14

IEEE 802.11n(20MHz) : 14

IEEE 802.11n(40MHz) : 9

Modulation IEEE 802.11b : DSSS/CCK

IEEE 802.11g : OFDM

IEEE 802.11n(20MHz) : OFDM

IEEE 802.11n(40MHz) : OFDM

Power Consumption 5V 500mA(Maximum)

Dimension 37.0mm X 28.0mm X 3.7 mm

Operation Temperature 0 ~ 60 °C

Storage Temperature -10 ~ 80 °C

Page 21

15

Before using the Machine

11. USB Memory Disclaimer

FCC COMPLIANCE STATEMENT

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and (2) this device must accept

any interference received, including interference that may cause undesired operation.

INFORMATION TO USER

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant

to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation.

This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the interference

by one more of the following measures:

-

Reorient or relocate the receiving antenna.

-

Increase the separation between the equipment and receiver.

-

Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

-

Consult the dealer or an experienced radio/TV technician for help.

CAUTION

Any changes or modifications not expressly approved by the manufacturer responsible for compliance

could void the user’s authority to operate the equipment.

Specification of compatible USB flash drive for MODEL 1.

- Please use the enclosed USB flash drive.

-

The enclosed USB flash drive is in FAT32 format.

The MODEL 1 3D printer does not support USB flash drives in NTFS format.

-

The warranty will not be valid if a 3rd party USB drive is used.

Page 22

Before using the Machine

16

IC Identification on Class of ITE

CAN ICES-3 (B)/NMB-3 (B)

DECLARATION OF CONFORMITY

Product name : USB Flash Drive

Model name : 8GB-WJ004, 4GB-WJ004

FCC Rules : Tested to comply with FCC Part 15, Class B

Operating Environment : For HOME OR OFFICE USE

FCC COMPLIANCE STATEMENT

This device complies with part 15 of the FCC Rules. Operation is subject to the following two condi

-

tions: (1) this device may not cause harmful interference, and (2) this device must accept any inter-

ference received, including interference that may cause undesired operation.

RESPONSIBLE P

AR

TY

Name : Sindoh America, Ltd.

Address : 6047 Tyvola Glen Circle, Suite #115, Charlotte, NC 28217

Phone No. : 1-704-414-6690

We hereby declare that the above specified equipment with the trade name and model number

was tested conforming to the applicable FCC Rules under the most accurate measurement standards

possible, and that all the necessary steps have been taken and are in force to assure that production

units of the same equipment will continue to comply with the Commission’s requirements.

Manufacturer : Sindoh Co., Ltd.

Address : 3, Seongsuiro24(isipsa)-gil, Seongdong-gu, Seoul, 04797 REPUBLIC OF KOREA

Page 23

1

Preparations for Machine

Operation

MODEL 1

User Manual

Page 24

Preparations for Machine Operation

1-2

1

1. Machine Specifications

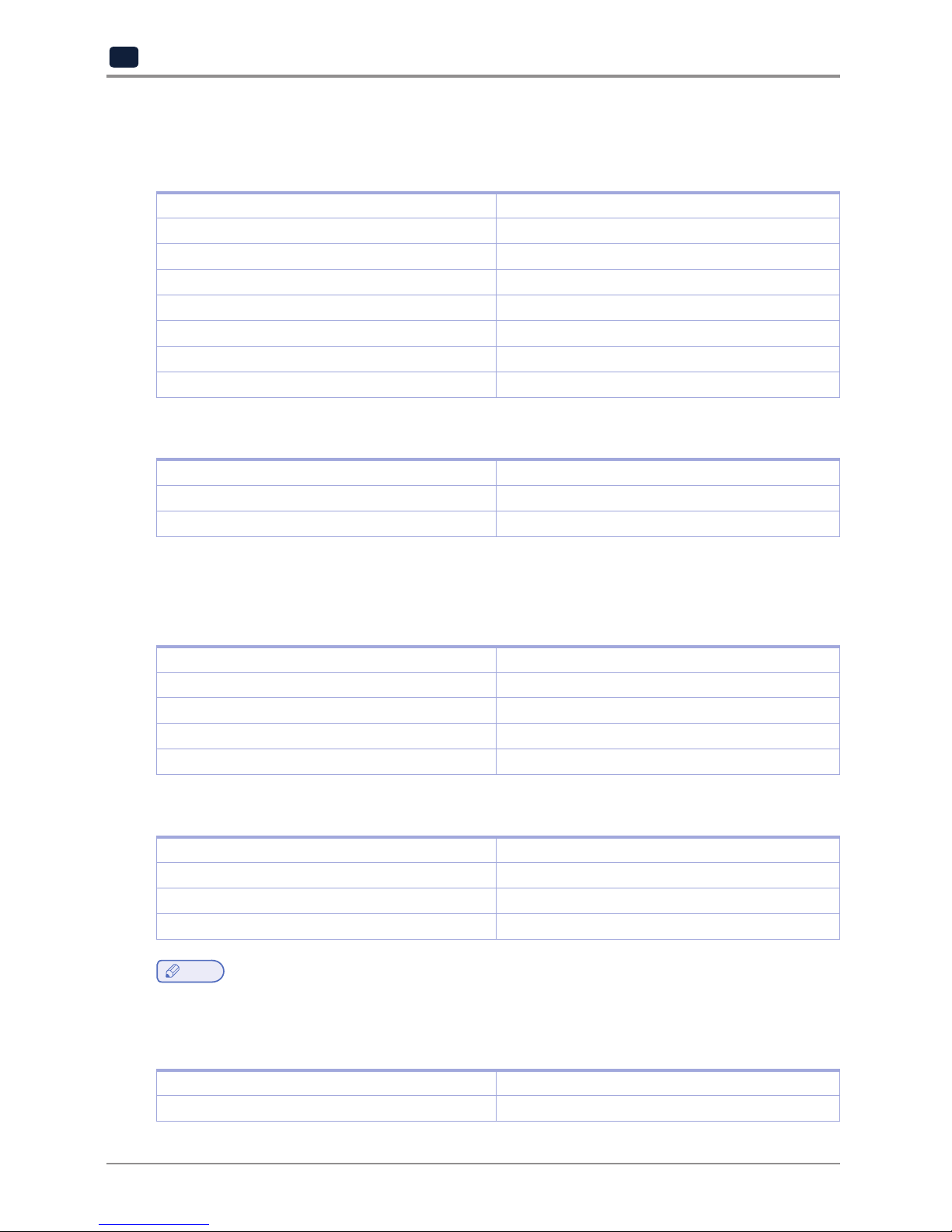

1.1 Printing

Printing Method Fused Filament Fabrication

Max. Print Length(mm) W(max):210, D(max):200, H(max):195

Print Layer Thickness Setting 0.05~0.4mm

Basic Nozzle diameter 0.4mm

Filament width 1.75mm

Printable materials PLA, ABS

Printable color White, Black, Gray, Red, Yellow, Green, Blue

Bed leveling Auto measuring + Manual leveling

1.2 Temperature/Speed

Continuous Nozzle Usage/ Maximum Temperature 250 °C Recommended / 260 °C max

Continuous Bed Usage/ Maximum Temperature 80 °C Recommended / 100 °C max

Recommended printing speed/maximum speed 40mm/s Recommended / 200mm/s max

* Continuous operation at maximum temperature can cause malfunction, Please use in case of nozzle

clogging or other troubles.

1.3 Machine

Power 150W

Dimensions 421 x 433 x 439

Weight 15kg

Port USB, Wifi, Ethernet

Cartridge Auto Load / Unload

1.4 Software/Support

Supported Software STANLEY 3D Slicing Software

Supported File Format *.stl, *.ply, *.obj

Supported Operating System Windows 7 or above, Mac OSX 10.10 or above

Recommended Memory Requirements DRAM 4 GB+

Note

- Graphics must support OpenGL 2.0 or higher.

1.5 Default Setting of Print layer Width

Nozzle Width 0.4mm

Print Layer Width 0.2mm

Page 25

1-3

Preparations for Machine Operation

1

2. Basic Components

Please check all basic components are in the box.

Caution

- Please keep the box and packaging material; they are needed for product exchange or repair service.

3D Printer

USB Cable

Cartridge

Scrapper

Please attach the Core to the LAN cable in use.

Reference Guide

Power Cable

USB Drive

Cable Ferrite Core Filter

Warning

- The blades of the scrapper can be very sharp. Please be cautious. Please do not use for other than removing

printables.

Please do not touch the blade of the scrapper.

Page 26

Preparations for Machine Operation

1-4

1

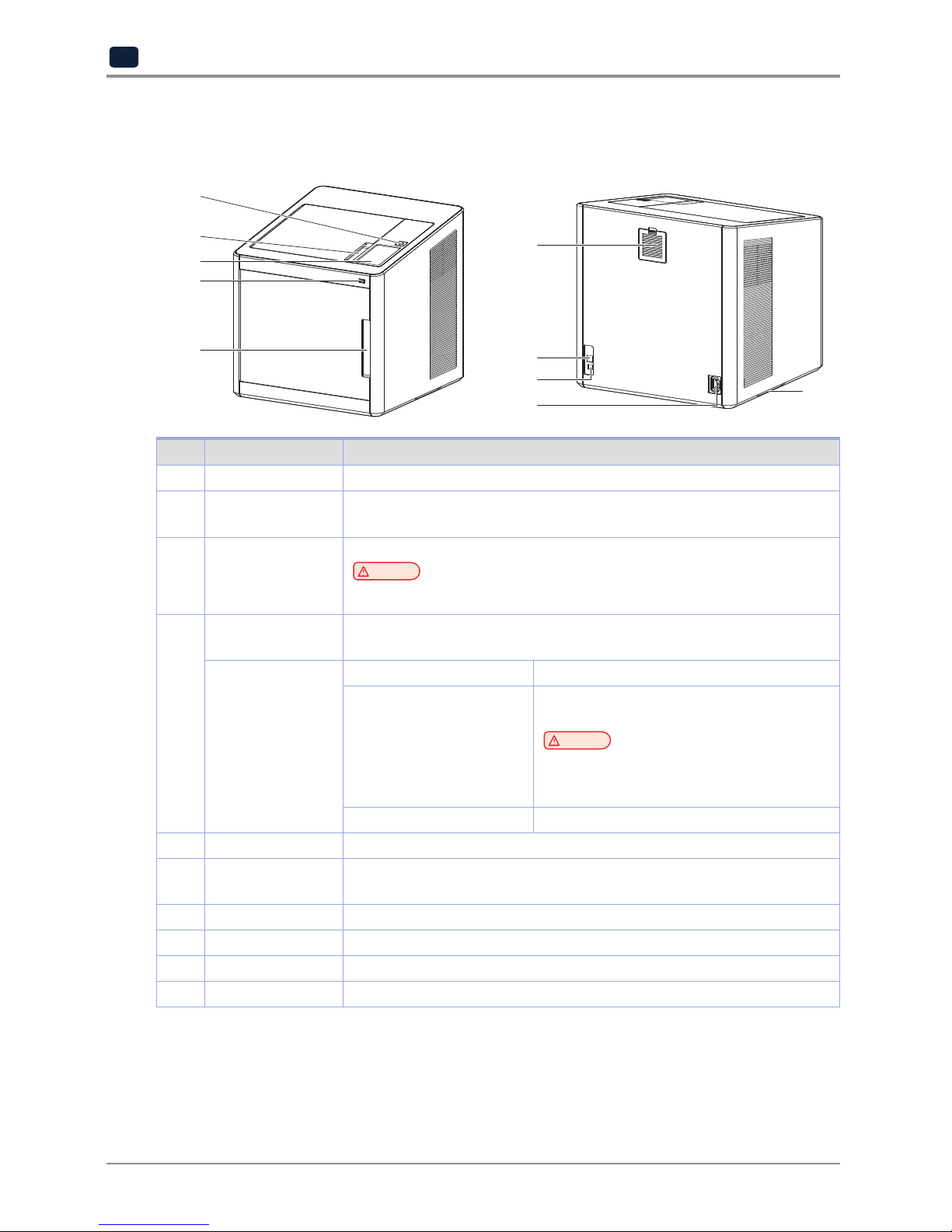

3. Understanding the Device Parts

1

6

7

8

9

10

2

3

4

5

<Front> <Rear>

No. Part Name Description

1 Front door handle A handle to open the front door.

2 USB port Connect USB flash drive containing printing information and print directly

from USB flash drive.

3 LCD Control panel Screen used to control printer.

Caution

-

Usage of printer is recommended after removing the protection film on LCD control panel.

If the film is not removed, the touch screen may not work properly.

4 Power Button Briefly press this button to turn on printer.

Press and hold for 2 seconds to turn off the printer

Power Button

Indicator

Lamp On Power is On.

1 second interval flickering Can be turned on instantly.

(power cable is connected)

Caution

-

If in case of not using the printer for long period of time,

please unplug the power cord.

-

The lamp may flicker for a few seconds after the power

cord is disconnected.

Lamp Off Inactive Mode. (Power cord is unplugged)

5 Top door handle A handle to open top door.

6 Ventilator fan(Odor

removing filter)

Discharges heat from interior.

Filters out odor created through printing.

7 Lan Port Allows a device to connect to a network using a LAN cable.

8 USB Port Used to connect printer to computer with a USB cable.

9 Power port Power cord connector.

10 Carrying Handles Handles to use when moving the printer.

Page 27

1-5

Preparations for Machine Operation

1

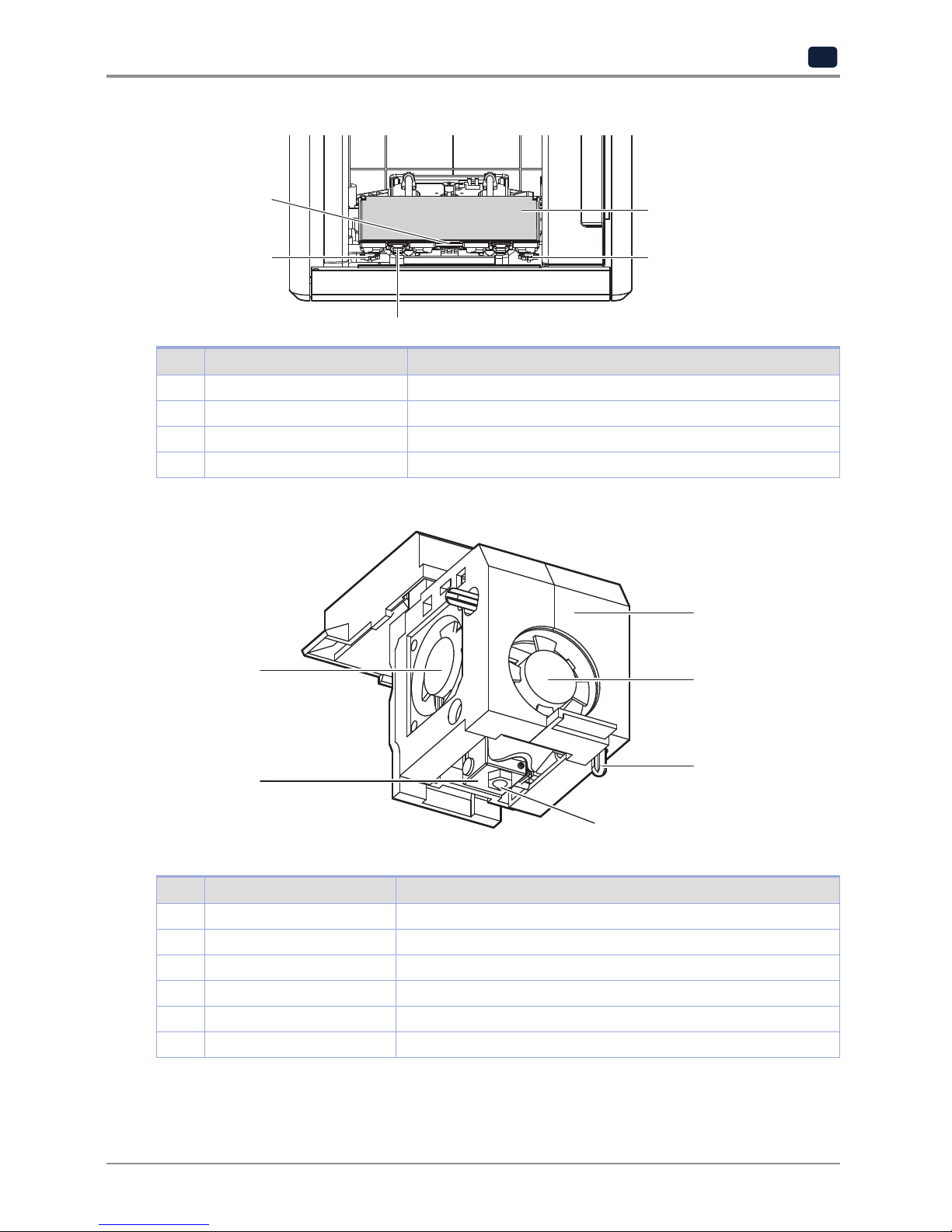

<Interior>

3

1

2

1

4

No. Part Name Description

1 Bed height adjustment Knob Used to level the aluminum bed.

2 Removable bed handle Used to assemble and dismantle aluminum bed

3 Bed heater Heats the printables' bottom surface to stabilize it on the bed.

4 Aluminum bed (bed sheet) Seating space for Printable

1

<Nozzle>

2

6

4

3

5

No. Part Name Description

1 Body Main body of the nozzle part.

2 Fan 1 Cooling fan for extrusion.

3 Fan 2 Cooling fan for Nozzle heatsink.

4 Nozzle Nozzle for printing.

5 Heater block Nozzle part for filament heating.

6 Levelling sensor Sensor for bed levelling sensor.

Page 28

Preparations for Machine Operation

1-6

1

4. Installation(Product connection, Cartridge Setup and

Software installation)

4.1 Device Connection

1

On the rear side of the machine, connect the power cable to the power socket.

Next, connect the power cable to the power outlet.

2

Press the power button, located on top of the machine.

3

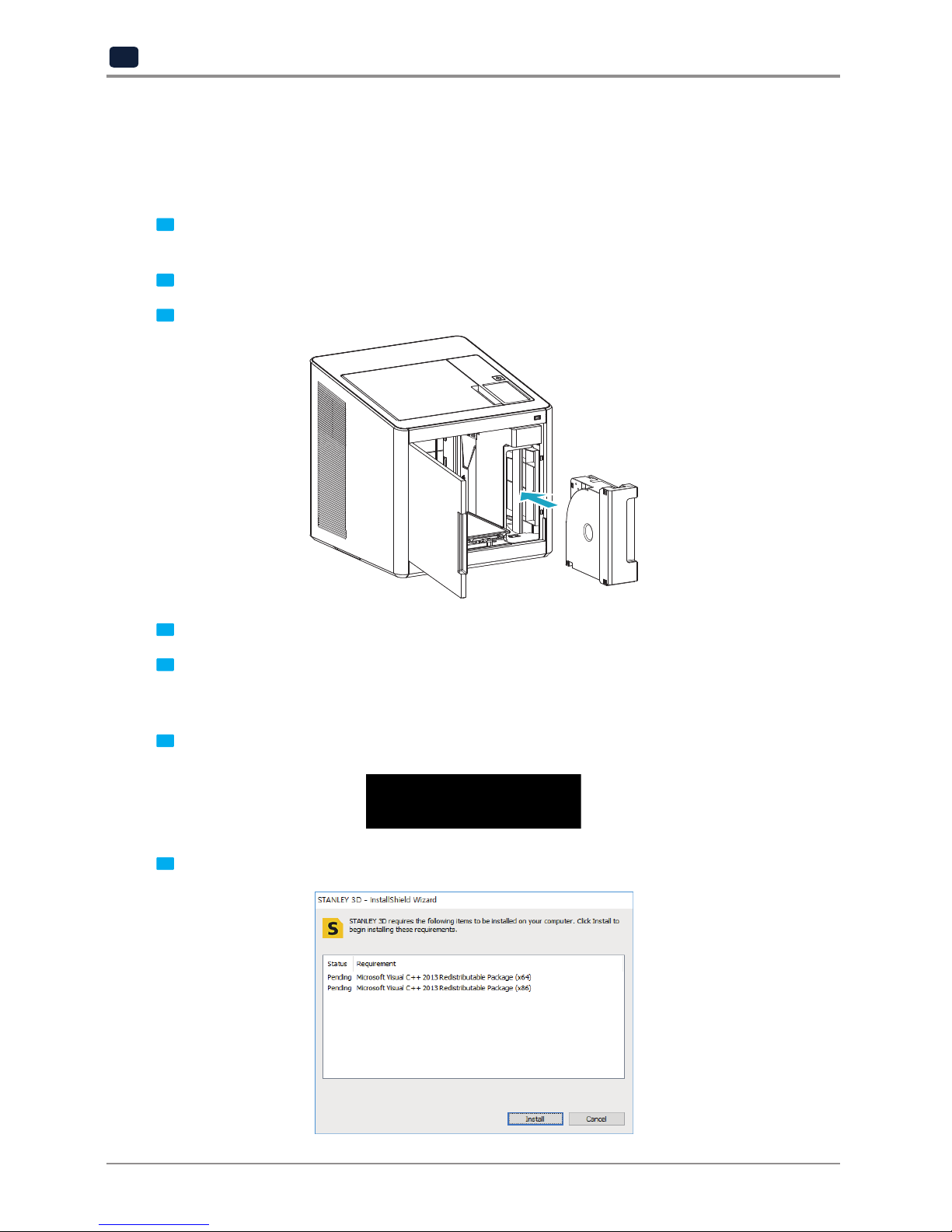

After main menu is displayed on the LCD screen, install the cartridge (Refer to UI manual “LOAD”).

4

Connect the one end of the USB cable to the back of the printer and the other to the computer.

5

Plug USB flash drive in, and install machine drivers and Slicer program.

4.2 Program Installation

1

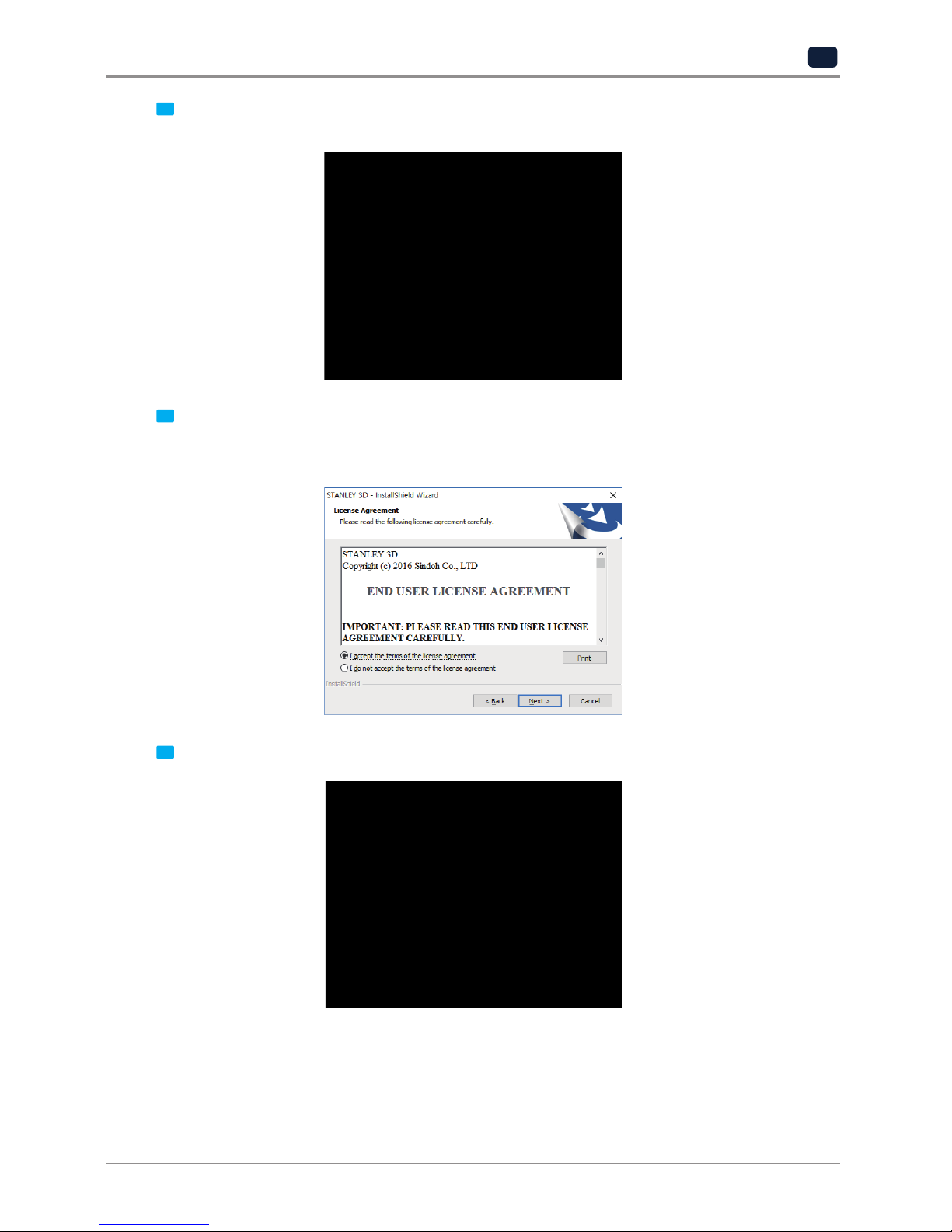

Start the installation of STANLEY 3D program by clicking on “STANLEY_3D.exe” file in the enclosed USB

thumb drive.

2

Install the additional files required by the software first.

Page 29

1-7

Preparations for Machine Operation

1

3

When installation of the file is complete, a pop-up window shows up as picture below. Press [Next] button

to initiate the installation of STANLEY 3D program.

4

A window that shows the End User License Agreement will appear as shown below.

The [Next] button will be activated upon accepting the terms of the license agreement.

Please be sure to read the terms and conditions before installation of the software.

5

Choose the destination location of the file and press [Next] to proceed.

Page 30

Preparations for Machine Operation

1-8

1

6

The file gets saved and the installation starts.

7

After all installation is complete, you can see that the “STANLEY 3D” created on the desktop of your

computer.

Page 31

2

UI Menu Functions

MODEL 1

User Manual

Page 32

UI Menu Function description

2-2

2

1. UI Menu Function description

CARTRIDGE LOAD

UNLOAD

UNLOCK

SETTING X,Y,Z ALL,X,Y,Z

EXTRUDER

BED LEVELING

Z OFFSET Move

Save

NOZZLE CLEANING

CLEANING CASE

NETWORK Wifi (Options)

Wifi On

Off

SELECT NETWORK LIST

DHCP

Static

Clear SSID

Wired (Options)

DHCP

Static

LAMP (Options)

*Always On

Always Off

On only in printing

BED LOWERING

TEST PRINT (Options) SELECT FILE START/PAUSE

CANCEL

POWER SAVING MODE (Options)

0~100 min

BEEP SOUND (Options)

Low

*Middle

High

Off

NOZZLE SETTING

* indicates factory set value.

Page 33

2-3

UI Menu Function description

2

LANGUAGE *English

Español

Francés

E-MAIL e-mail Address

e-mail Server Info Address

Port

ID

PW

UNIT Celsius(˚C)

Fahrenheit(˚F)

meter(m)

feet(ft)

TIME SETTING YYYY, MM, DD, HR,

MIN

TIME ZONE

SOFTWARE UPDATE

INFORMATION Name

PW

Change Name & PW Name

PW

Reconfirm PW

Cancel

OK

Model Name

Serial No.

Version

Wired IP

MAC

Wireless IP

Wireless MAC

HISTORY

Guide

* indicates factory set value.

1.1 CARTRIDGE

CARTRIDGE LOAD

UNLOAD

UNLOCK

Page 34

UI Menu Function description

2-4

2

LOAD

This function automatically loads filament to the Nozzle.

1

From the HOME screen press [CARTRIDGE].

2

Press [LOAD] to activate Cartridge load.

Page 35

2-5

UI Menu Function description

2

3

When [OK] is pressed at the cartridge load confirming message, cartridge load will automatically proceed.

The filament reaches to the nozzle and it is heated up to the specified temperature. Then the filament is

inserted into the heated nozzle. After the process has finished, screen will automatically return to

the [HOME] screen.

UNLOAD

This function automatically unloads filament from the nozzle.

1

From the HOME screen press [CARTRIDGE].

Page 36

UI Menu Function description

2-6

2

2

Press [UNLOAD] to activate Cartridge unloading.

3

When [OK] is pressed at the cartridge unload confirming message, cartridge unloading will automatically

procceed. To remove filament, the nozzle is heated up to the specified temperature and the filament

unload starts.

After the filament has been removed, the screen will automatically turn to the [UNLOCK] screen to let the

user remove the cartridge.

Page 37

2-7

UI Menu Function description

2

UNLOCK

This Function is to remove the cartridge out of the printer. Cartridge unlock automatically initiates when

filament unload is finished. Cartridge unlock can also be manually done by the user.

When unlock screen automatically appears after cartridge unload.

1

For 10 seconds [LOCK] state is deactivated and the user can detach cartridge from printer. If the cartridge

can’t be pulled out even after “unlock”, gently push it forward and then try to pull out again.

2

After 10 seconds printer will automatically change to [LOCK] state and [UNLOCK] appears.

Page 38

UI Menu Function description

2-8

2

To manually unlock later.

1

From home screen press [CARTRIDGE].

2

Press [UNLOCK] to activate UNLOCK function.

Page 39

2-9

UI Menu Function description

2

3

For 10 seconds [LOCK] state is deactivated and the user can detach cartridge from printer. If the cartridge

can’t be pulled out even after “unlock”, gently push it forward and then try to pull out again.

4

After 10 seconds printer will automatically change to [LOCK] state and [UNLOCK] appears.

Page 40

UI Menu Function description

2-10

2

1.2 Settings

SETTING X, Y, Z ALL,X,Y,Z

EXTRUDER

BED LEVELING

Z OFFSET Move

Save

NOZZLE CLEANING

CLEANING CASE

NETWORK Wifi (Options)

Wifi On

Off

SELECT NETWORK LIST

DHCP

Static

Clear SSID

Wired (Options)

DHCP

Static

LAMP (Options)

*Always On

Always Off

On only in printing

BED LOWERING

TEST PRINT (Options) SELECT FILE START/PAUSE

CANCEL

POWER SAVING MODE (Options)

0~100 min

BEEP SOUND (Options)

Low

*Middle

High

Off

NOZZLE SETTING

LANGUAGE *English

Español

Francés

* indicates factory set value.

Page 41

2-11

UI Menu Function description

2

E-MAIL e-mail Address

e-mail Server Info Address

Port

ID

PW

UNIT Celsius(˚C)

Fahrenheit(˚F)

meter(m)

feet(ft)

TIME SETTING YYYY, MM, DD, HR, MIN

TIME ZONE

SOFTWARE UPDATE

X, Y, Z

Use to change the position on the X, Y, and Z axes of the Nozzle.

1

From home screen press [SETTING].

Page 42

UI Menu Function description

2-12

2

2

Press the [X,Y,Z] button to enter X, Y, Z.

3

Press [0.1], [1], [10], [100] to select the distance user to move.

To move to each axis' home location, press [All], [X], [Y] or [Z].

Page 43

2-13

UI Menu Function description

2

EXTRUDER

This function is used to fine control the filament to its position.

1

From home screen press [SETTING].

2

Press [EXTRUDER] to enter EXTRUDER settings.

Page 44

UI Menu Function description

2-14

2

3

To Control [EXTRUDER], Nozzle temperature needs to be raised.

4

Press (1, 10, 50, 100) to select an amount.

In the image shown below, press the direction to move the filament.

Page 45

2-15

UI Menu Function description

2

BED LEVELING

This function is used to perform the leveling of the bed.

1

From home screen press [SETTING].

2

Press the [BED LEVELING] button to enter BED LEVELING settings.

If nozzle's temperature is higher than 80°C, a process to cool down the nozzle is added.

Page 46

UI Menu Function description

2-16

2

3

On the SETTING page, user is able to perform bed leveling. The bed leveling process consists of 3 steps.

From the center, the top side is measured first, and then both sides of the bottom level are measured.

If the height of the bed is perfect then levelling process will be finished but if the height of the bed and

nozzle does not match, screws will appear informing user the direction and the number of screw rotation.

4

Turn the screw and press [OK]. The measuring is performed and the value to fix appears again.

Page 47

2-17

UI Menu Function description

2

5

When all settings are done the program returns to the previous screen.

Z OFFSET

After bed leveling, it is highly recommended to check the z-offset.

This Menu allows user to control the GAP in between Nozzle and BED. Standard is 0.25mm and can be customi

zed.

[+] button widens the GAP, [-] button shortens the GAP.

For higher adhesive strength between the print output and the bed, shorten the distance of the z-offset.

For less adhesive strength, widen the distance of the z-offset.

1

From home screen press

[SETTING]

.

Page 48

UI Menu Function description

2-18

2

2

Press the [Z OFFSET] button to access Z Offset screen.

3

Default value is 0.25mm, Use [+], [-] buttons to move in 0.05 mm unit.

Page 49

2-19

UI Menu Function description

2

4

Use the [MOVE] and [SAVE] buttons to adjust the gap and to save the setting.

The saved value is applied when next time the print starts.

These values will be reset if bed leveling is initiated.

NOZZLE CLEANING

Function used when nozzle needs cleaning of left over filament residue.

1

From home screen press [SETTING].

Page 50

UI Menu Function description

2-20

2

2

Press the [NOZZLE CLEANING] button to access nozzle cleaning settings.

3

In order to get rid of filament residue, the nozzle needs to be heated.

When the specified temperature is reached, it moves on to the next step to remove filament residue.

Once finished message will appear press [OK], printer will return to the settings screen.

Page 51

2-21

UI Menu Function description

2

CLEANING CASE

Function used to clean out the case for the collected filament residue.

1

From home screen press [SETTING].

2

Press the [CLEANING CASE] button to enter CLEANING CASE settings.

Page 52

UI Menu Function description

2-22

2

3

Entering Cleaning Case, the nozzle will automatically position itself to the left side to be visible and

accessible. Like shown in the image, empty the CASE, press [OK] when done and user will be returned to

the settings screen.

NETWORK

This is a menu to configure users network setting. IP address can be set up manually or automatically via DHCP

setting. Wifi network is also supported.

1

From home screen press [SETTING].

Page 53

2-23

UI Menu Function description

2

2

Press the [NETWORK] button to access network configuration screen.

3

The default network setting is Wired (connection using LAN line).

Press [DHCP] for automatic IP address setup. To manually input a fixed IP address press [Static] and enter an

IP address. Press [Connect] to save the changes.

Page 54

UI Menu Function description

2-24

2

4

In any case to use Wifi press the [Wifi] tab.

Wifi setting can be turned ON or OFF.

5

To select a Wifi network, click [Choose a network…] and the printer shows all available Wifi connections.

Page 55

2-25

UI Menu Function description

2

6

Select a wireless network from the list to connect to the network. For a password-protected network,

a dialog pops up and asks for the password.

You can refresh the network list by clicking [Search].

7

After successful connection printer may ask for [DHCP], [Static] similar to the WIRED setting.

When all settings are finalized press [Connect] to save settings.

Page 56

UI Menu Function description

2-26

2

LAMP

Menu to configure settings for machine lamp.

1

From home screen press [SETTING].

2

Press [Next] to enter [LAMP] setting screen.

Page 57

2-27

UI Menu Function description

2

3

Settings available for [LAMP] are [Always On], [Always Off], and [On only in printing]. Use arrow buttons to

select an option and press [OK].

Page 58

UI Menu Function description

2-28

2

BED LOWERING

Use this function, in times of moving printer to a different location.

Bed will be lowered to the bottom and will be locked into position.

1

Press [SETTING] from the home screen.

2

Press [Next] to move to next page, where the [BED LOWERING] button is located.

Page 59

2-29

UI Menu Function description

2

3

Upon selection, the bed will automatically be lowered.

TEST PRINT

This function allows the user to test print a sample model already saved in the printer.

1

From home screen press [SETTING].

Page 60

UI Menu Function description

2-30

2

2

Press [Next] button to move to the next page and press [TEST PRINT].

3

Select the test file to print.

Page 61

2-31

UI Menu Function description

2

POWER SAVING MODE

Function to set timer for printer energy saver mode.

1

From home screen press [SETTING].

2

Press [Next] button to move to the next page and press [POWER SAVING MODE].

Page 62

UI Menu Function description

2-32

2

3

The adjustable values of energy savor mode are [0 ~ 100 min]. The time can be adjusted in 5 min unit,

select the desired time using the [ +, - ] then press [OK] button to save changes.

BEEP SOUND

The volume level of beep sound can be adjusted using this menu.

1

Press [SETTING] button from the home screen.

Page 63

2-33

UI Menu Function description

2

2

Tap on the [Next] button to move to next page, and press [BEEP SOUND].

3

Currently available sound settings are Low, Middle, High and Off.

Select the desired setting and press the [OK] button to save settings.

Page 64

UI Menu Function description

2-34

2

NOZZLE SETTING

Use this menu only when the nozzle has been replaced.(Refer to P.5-10 4.4 Exchanging Nozzle )

1

Press [SETTING] button from the home screen.

2

Tap on the [Next] button to move to next page, and press [NOZZLE SETTING].

Page 65

2-35

UI Menu Function description

2

3

“NOZZLE SETTING” menu is a function that should be used after replacement to a new nozzle.

Entering the menu, a notification message will pop up. Press the [OK] button to move to the next screen.

4

Click inside the input field to insert the values for the new nozzle.

Each nozzle has own value and it influences the GAP between nozzle and bed after bed leveling.

(P.5-9

4.4 Exchanging Nozzle )

Page 66

UI Menu Function description

2-36

2

LANGUAGE

Menu to set language for machine.

1

From home screen press [SETTING].

2

Press [Next] 2 times to go to the screen where the [LANGUAGE] menu is.

Page 67

2-37

UI Menu Function description

2

3

Currently supported languages are [English, Spanish, French].

Using the arrows select a language and press [OK].

Page 68

UI Menu Function description

2-38

2

E-MAIL

The printer takes an image of the current printing status and sends the information to the email address

specified.

Printer will send information of completion (%) based on the PC program standard settings. Maximum of 10

emails can be sent.

1

From the home screen, press [SETTING].

2

Press the [Next] 2 times and select [E-MAIL].

Page 69

2-39

UI Menu Function description

2

3

Configure the setting for email notification to be sent out from the device.

Only the information that is required for sending the email is set up from the printer and the recipient

information has to be configured in the Slicer program.

Catergory Description

E-mail Address The sender info to be seen by the recipient(e.g. sender@domain.com)

The recipient can reply to this email address

Address SMTP server address (e.g. smtp.domain.com)

- This is the server address of the email service (xxxx@gmail.com)

Port SMTP Server Port (e.g. 25)

- Normally the port number 25, 587 or 465 is used.

Due to the increased security, some service providers do not allow the use of

port number 465. If port number 465 is not available, please use 25, 587 or the

port number that the service provider recommends.

ID SMTP server login ID (e.g. sender)

- Enter the ID for your email.

- Depending on the service provider, a full email address may be requested.

Please contact server administrator or email service provider for more information.

PW SMTP server login password (e.g. ********)

- Enter the password for your email

Inquire your email server administrator or services provider for detailed information of the input information

on each category. Especially for SMTP server log in ID, it may be needed to enter the entire email address

which includes the domain name.

This setting is for the SMTP (Simple Mail Transfer Protocol) server to be used for sending emails. The SMTP

setting may have to be enabled depending on the system.

Page 70

UI Menu Function description

2-40

2

To check the detailed setting values, please refer to the setup information from your email service provider.

For the set up to use the outgoing email service, please find information by internet search or your email

service provider’s instructions.

A certain amount of interval time may be required after setting up the SMTP service before using.

For more details, please inquire your email provider for the service policies.

4

Configure the recipient email information from the STANLEY 3D slicer program.

Under [E-mail], input the recipient email address(es) and select the number times that you wish to send the

notification emails.

Additional recipient addresses can be added by using semicolon.

e.g. recipient1@test.com; recipient2@test.com; recipient3@test.com

The maximum number of notification emails that can be sent is 10.

Regardless of the number entered for the email notification, an email will be sent out for the user to see if

the initial email notification is working properly by default. e-mail will be sent out one more time than the

number that the user entered. However, the total number of e-mail that is sent will not exceed 10 times.

(When user selects 10 times, the notification e-mail will be sent out 10 times)

In the case of using a Google email account.

According to Gmail policies, the following settings have to be met.

Google account setting

1

Log into your Google account that you are planning to use.

2

Click on the apps button on the top right hand corner.

After click on "My Account"

Page 71

2-41

UI Menu Function description

2

3

Under "Sign-In&Secruity" click "Device activity & notifications"

4

Scroll down and there is a "Allow less scure apps" criteria. Set it to "On" to enable the option.

Printer Setting

1

Set "smtp.google.com" for the settings of the email address.

2

For Google, 25 and 587 ports are compatible.

Caution

- According to the service provider, the email address and port number may be changed. For more

information please contact service administrator.

Page 72

UI Menu Function description

2-42

2

UNIT

Settings for the units of measurments displayed on the printer.

1

From the home screen, press [SETTING].

2

Press [Next] 2 times and select [UNIT].

Page 73

2-43

UI Menu Function description

2

3

The units for temperature and length can be changed.

TIME SETTING

You can view or change the time setting.

1

From the home screen, press [SETTING].

Page 74

UI Menu Function description

2-44

2

1

Press [Next] 2 times and select [TIME SETTING].

3

The time setting can be changed in this screen.

Page 75

2-45

UI Menu Function description

2

TIME ZONE

You can view or change the time zone setting.

1

From the home screen, press [SETTING].

2

Press [Next] 2 times and select [TIME ZONE].

Page 76

UI Menu Function description

2-46

2

3

A preferred time zone can be selected from the time zone list.

Once Time Zone has been set, the printer will restart to apply the new settings.

S/W UPDATE

With the printer connected to the internet user is able to download the latest software.

1

From the home screen, press [SETTING].

Page 77

2-47

UI Menu Function description

2

2

Press [Next] 2 times and select [S/W UPDATE].

3

Press the [Start Update] button, and printer will start updating. After it has finished, restart the printer and

updates will be applied.

Page 78

UI Menu Function description

2-48

2

1.3 Information

INFORMATION Name

Change Name & PW Name

PW

Reconfirm PW

Cancel

OK

Model Name

Serial No.

Version

Wired IP

MAC

Wireless IP

Wireless MAC

HISTORY

Guide

In this menu user is able to view the detail information of the printer, and set device name & password.

In [HISTORY] screen, user is able to view all the records of past works.

1

From home screen, press [INFO].

Page 79

2-49

UI Menu Function description

2

2

To set password and name for printer, select [Change Name & PW].

3

By entering the password, you can edit name and set a new password. Pressing [OK] saves the changes.

*Initial password is ‘0000’.

Page 80

UI Menu Function description

2-50

2

4

In [INFO] screen, press [Guide] to access to the "Quick Guide" for the printer.

5

Other useful information is also available in [INFO] screen.

Page 81

3

Printing

MODEL 1

User Manual

Page 82

Printing

3-2

3

1. Printing

User can print printables via USB flash drive, USB cable, or over the network.

The following on the printer means it is ready to start print.

1.1 Printing from USB Flash Drive

1

Connecting USB flash drive to the printer.

In order to print using an USB flash drive, insert the flash drive into the USB port.

When the USB flash drive is connected while in the home screen, a list of files in the USB appears.

When [PRINT] is selected without the USB flash drive connected, a message requesting for USB connection

will pop up and once USB flash drive is connected a list of the USB files will emerge.

Page 83

3-3

Printing

3

2

Printing Files

Select a file to print in the USB list.

3

Print Preview

Once selected, a preview of the model appears on the screen.

Page 84

Printing

3-4

3

4

Printing

Once [

] is pressed the nozzle starts to be heated. When the specified temperature is reached, the

printing starts.

5

Pausing Print

Pressing [

] during a print will pause the progress.

Press [

] again and nozzle is heated again, and the printer will continue printing.

6

Exchanging Cartridge during print

While printing, press the [change] button to replace with a new cartridge.

Page 85

3-5

Printing

3

7

Print Cancelation

During print pressing [

] button a message pops up and asks for confirmation on the print canceling.

When confirmed, the rest printing job is canceled.

Another message requesting the removable of left print will popup press [OK] and screen will return to

home screen.

8

Printing Completion

After printing has completed, follow the instructions and remove the printed product. Press the [OK] to

return to home screen.

Reference

- Methods of removing printables refer to P. 4-2 “1. Printed Output Check”.

Page 86

Printing

3-6

3

1.2 Printing Via PC

1

Prepare PC connected to the same network where the printer is connected to.

2

Run STANLEY 3D Slicer program.

3

Press the “Print” button.

4

Following Steps (Same as steps 3~7 of printing via USB)

Note

- For fan speed configuration, Pause, print cancelation, please refer to "USB printing" section.

1.3 Print Job Management

You can manage print jobs in queue.

1

Press the [Queue] button on the upper left hand corner while printing.

Page 87

3-7

Printing

3

2

The print jobs in queue are listed.

3

You may click the list to look at the information of the print job and delete it if necessary.

Page 88

Page 89

4

Printed Output Check

MODEL 1

User Manual

Page 90

Printable Verification

4-2

4

1. Printed Output Check

1.1 Detaching Printed Output

To safely detach the printed model, first let the bed cool down. Bed top plates must be detached as well.

Caution

Hot Surface

- Without sufficient cooling the bed can be very hot. Please be cautious coming into contact .

It may cause burns.

1

Cooling the Bed

After the printing, check the LCD screen and wait until temperature goes below 50 ºC or 122 ºF.

2

Detaching Bed

Press [Bed Lock] on the screen to fix the bed in place. Pressing and holding the [PUSH] buttons on the bed

handles, pull the bed out.

3

Detaching the printed output

Caution

Risk of Injuries

- The scrapper is very sharp. Handle with care.

Please be cautious of inuries when removing printed objects with the scrapper.

Detach the printed output from the bed. Using the scrapper provided with the printer will be useful.

Be careful not to apply too much pressure while using the scrapper could damage the bed sheet and the

aluminum bed. Depending on the filament material the printed output may easily break or damage,

please be cautious.

Page 91

4-3

Printable Verification

4

4

Aluminum Bed Installation

After a period of time bed locking will automatically released, if bed is unlocked, press the lock button

again to fix the bed into position before installation.

(1) Like the picture gently place the aluminum bed’s end corners on top of the bed heater.

(2) Lay the aluminum bed on the bed heater.

(3) Grab and press the handles to push and lock the bed into shackles.

Page 92

Printable Verification

4-4

4

(4) Push the handles until they click in place.

1.2 Improving Printing Quality

1

Nozzle, Bed temperature

Depending on the material (PLA, ABS etc.), optimum temperature for the nozzle and bed can be different.

Environmental factors (temperature, humidity) can affect the quality of the printed product.

There is no absolute value for optimum temperature. Testing various temperatures and finding the

optimum temperature are needed.

Material Appropriate nozzle temperature Appropriate bed temperature

PLA 190 °C ~ 210 °C 40 °C ~ 60 °C

ABS 220 °C ~ 240 °C Above 80 °C

2

Support

For higher printing quality, minimize the use of supports.

However, shapes that are located in midair needs a support. If it’s the case, control the distance so it can

easily separate.

Page 93

4-5

Printable Verification

4

2. When Printer Cannot be Turned On

1

Open the Front door shown below and turn the belt counter-clockwis.

2

After the bed is lowered, remove printed output and turn the power on.

3

If the problem persists, please dial toll free customer service at 1-855-237-6848.

Page 94

Page 95

5

Maintenance

MODEL 1

User Manual

Page 96

Maintenance

5-2

5

1. Machine Cleaning

1.1 Cleaning Case Maintenance

1

On the LCD, if a message requesting for the cleaning of the cleaning case pops up, detach the cleaning

case and clean all the filament residue inside the case.

-

If in need for further cleaning, on the menu, under settings, select cleaning case. The cleaning case can be

detached.

1.2 Printer Interior Cleaning

Over time, there will be a build up of filament residue within the printer.

If the residue goes into conveyor belt or fan wings, it can cause printer malfunction.

Please clean the inside of the printer regularly or right after a print job.

1.3 Periodical Inspection

Oil/Grease Inspection

During manufacturing grease/oil is applied to the gears.

After a period of time, grease and oil can dry and cause printer noises during operation.

At least once a month inspect the condition of grease and oil.

Especially, If printer begins to make noises during operation, immediately check if oil and grease are applied

properly. If necessary contact service center for inspection.

Page 97

5-3

Maintenance

5

2. Error Message and Solutions

Message Description What To Do

Booting

Please wait until booting is com-

plete.

Message means on the first boot

user must wait until the booting

is finished.

Once the boot up process is over and

machine is ready, this message

disappears automatically.

EC301~308 (Nozzle)

EC351~355 (Bed)

Malfunction of temperature

sensor of nozzle and bed heater.

Reboot the printer. If problem presist

then request A/S.

EC311, EC312, EC313

Please Reboot Machine.

Error related with leveling sen-

sor operation.

Please check and remove residue left

around the nozzle area or printable left

on the bed, anything that might

interfere with the operation of the

machine. Then reboot the printer. If

problem persists, please contact service

center.

EC321

Please Reboot Machine.

Error related with cooling fan

(fan 2) of nozzle heatsink.

Remove any thing that might be

interfering with the operation of the

fan. If problem persists after reboot,

please contact service center.

EC322

Please Reboot Machine.

Error related with the printed

output cooling fan (fan 1).

Remove any thing that might be

interfering with the operation of the

fan. If problem persists after reboot,

please contact service center.

ERROR

EC 5XX. Please Reboot machine.

Error related with motor travel

on X, Y, and Z axes.

Check if there are any debris or any

particles left on the bed and the nozzle.

Clean the bed and reboot the printer.

EC401 Filament is not transfered

properly.

Following the instructions on the LCD

screen, start recovery process.

However, if problem does persist, follow

the instructions on P.5-6, remove

cartridge, remove filament debris and

re-install the cartridge for use.

Filament End

Not enough filament.

Message appears when there is

not enough filament in cartrid-

ge.

Following the instructions on the LCD,

first clean any filament debris, then

install and load a new cartridge.

Filament Break

Filament break has been

detected. Please remove.

There remain some filament but

it's cut in the middle.

Following the instructions on the LCD,

first clean any filament debris, then

install and load a new cartridge.

Cartridge is already loaded. Filament is loaded already and

the load button was pushed

again.

Automatically return to normal state.

Cartridge is already

unloaded.

Filament is unloaded already

and the unload button was

pushed again.

Automatically return to normal state.

Page 98

Maintenance

5-4

5

Message Description What To Do

Notification 431

Cartridge cannot be detected.

Re-insert cartridge after

cartridge removal.

Occurs when printer is unable to

detect cartridge.

Automatically UNLOCK screen will be

displayed. Reinstall cartridge.

Notification 432

Cartridge cannot be detected.

Re-insert cartridge after

filament UNLOAD.

Occurs when printer is able to

detect filament inside but is

unable to detect cartridge.

UNLOAD screen. Reinstall cartridge.

Notification 471

Cartridge loading as been detect-

ed as incomplete. Go to Extruder

menu and move the filament to

the end of the

nozzle through manual

control.

After boot up, the cartridge

load was detected incomplete.

Load was incomplete.

Pressing [OK] displays EXTRUDER screen.

Feed the filament to the end of Nozzle.

Notification 481

Cartridge unloading has been de-

tected as incomplete. Please retry

UNLOAD again.

Message appears when unload

was incomplete.

Pressing [OK] printer performs unload

again.

Notification 433

Cartridge quantity sensor has

detected a malfunction. Please

exchange cartridge.

Message will appear if there

are more than 5% difference

between the cartridge quantity

and

recorded usage levels.

Replace Cartridge.

Notification 472, 473, 476, 482,

483, 484, 487, 488

Remove cartridge. Is there any

remaining filaments in the tube

or on the entrance of filament

insertion (front of printer)?.

Problem has occurred during the

load/unload process, remaining

filament must be removed.

Follow the on-screen instructions and

remove all remaining filament.

(Refer to the image in P. 5-6)

Notification 411

Please check leftover filament

after cartridge removal.

Occurs when filament is not

correctly inserted during LOAD.

Follow the on-screen instructions and

remove cartridge, cut filament, reinstall

and run again.

Notification 412

Remove cartridge. Is there any

remaining filaments in the tube

or on the entrance of filament

insertion (front of printer)?

Occurs when filament is not

correctly inserted during LOAD.

Following the on-screen instructions,

first remove the cartridge, then cut the

filament and re-install the cartridge.

Notification 422, EC 423

Remove cartridge. Is there any

remaining filaments in the tube

or on the entrance of filament

insertion (front of printer)?

Occurs when filament does not

come out during UNLOAD.

Follow the on-screen instructions and

remove cartridge, and any filament

residue.

Page 99

5-5

Maintenance

5

Message Description What To Do

Notification (408)

Model has exceeded the

minimum print range of the

"X" axis.

Notification (408)

Model has exceeded the

minimum print range of the

"Y" axis.

Notification (408)

Model has exceeded the

minimum print range of the

"Z" axis.

The printing job has exceeded

the minimum printable range.

Press the [OK] button, and the pop up

message will disappear.

Notification (408)

Model has exceeded the

maximum print range of the

"X" axis

Notification (408)

Model has exceeded the

maximum print range of the

"Y" axis

Notification (408)

Model has exceeded the

maximum print range of the

"Z" axis

The printing job has exceeded

the maximum printable range.

Press the [OK] button, and the pop up

message will disappear.

Page 100

Maintenance

5-6

5