Page 1

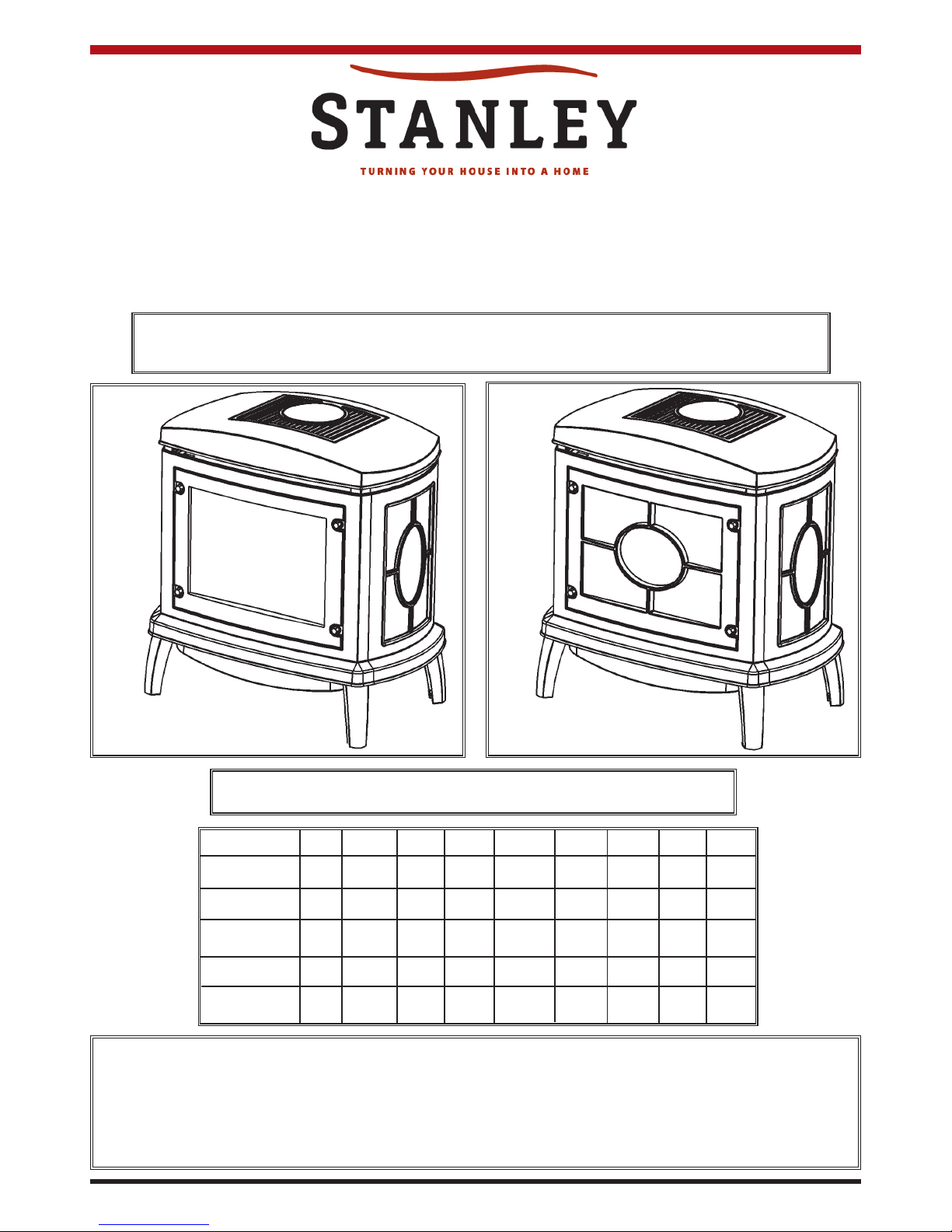

MAEVE

STOVE RANGE

Operation, Installation & Servicing Instructions

IMPORTANT

Please read these instructions carefully and keep them in a safe place.

They will be needed when servicing this appliance.

STOVES REQUIRED TO HAVE THE GRILL OPTION MUST BE

ORDERED AS THEY ARE FACTORY FITTED.

STANDARD FLUE MEDIUM MAEVE STOVE

WITHOUT GRILL

STANDARD FLUE MEDIUM MAEVE STOVE

WITH GRILL

Country AT BE DK FI FR DE GR IS IE

Natural Gas

***** *

LPG **** **

Country IT LU NL NO PT ES SE GB

Natural Gas *** ****

LPG * ******

WARNING

Do not attempt to burn rubbish in this stove. This stove must only be operated with the door secured firmly

in position. The outer casting of this stove will become hot whilst in operation, it is therefore recommended

that the appliance be guarded to protect the young and infirm using a suitable fire guard. Ensure that fabrics

such as curtains are not positioned above or near to the stoves outer casting.

KEEP THESE INSTRUCTIONS IN A SAFE PLACE

Page 2

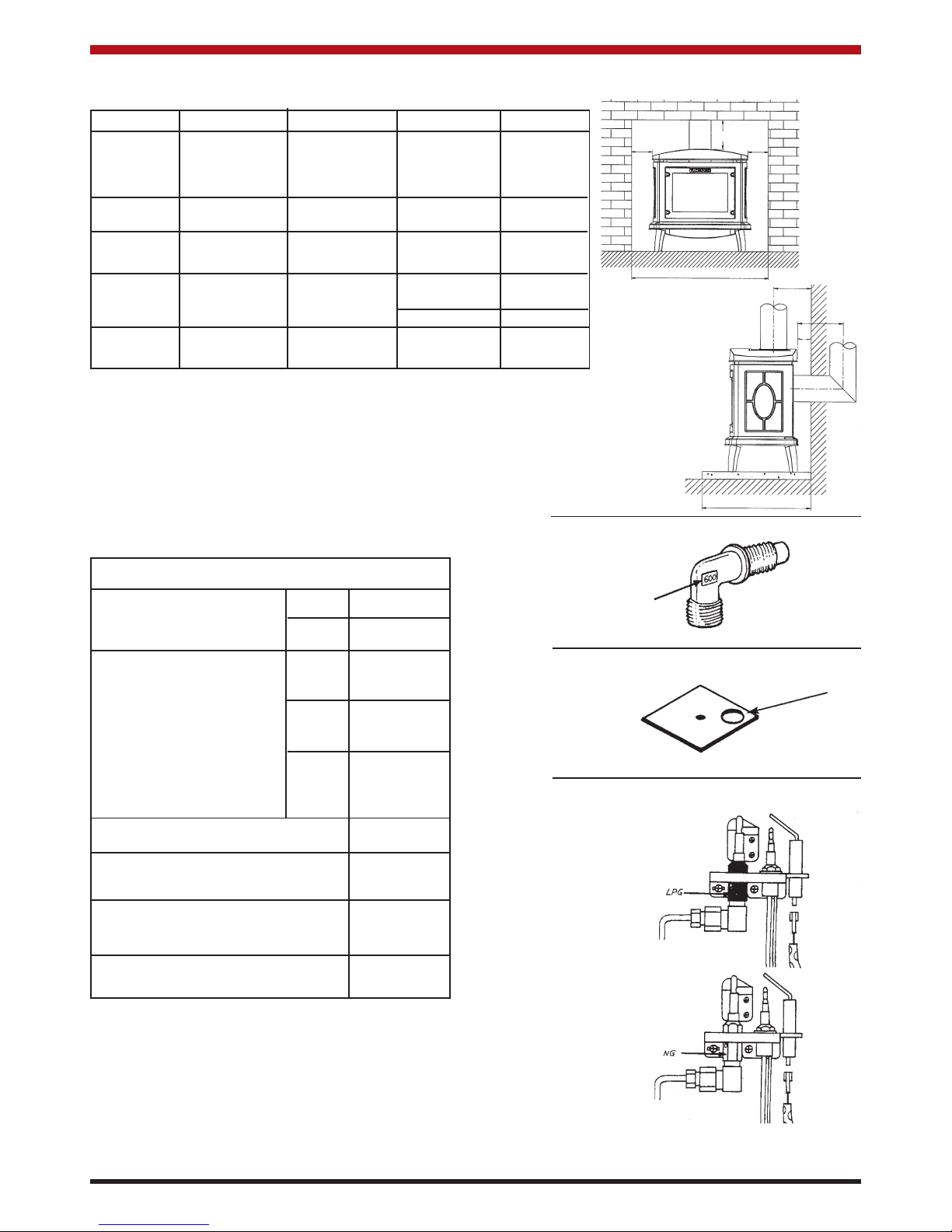

GAS CAT. GAS TYPE PRESSURE INPUT kW COUNTRY

AT, DK, ES,

I2 H G20 20MB 6.60 Gross FI, GB, IE, IT,

PT, SE.

I2L G25 25MB 6.00 Gross NL

I2E+ G20 20MB 5.94 Nett BE, FR

G25 25MB

ES, IT, IE

I3+ G30 29MB 6.25 Gross GB, PT

G31 37MB 5.62 Nett BE, FR

I3B/P G30 29MB 6.25 Gross DK, FI, IS

G31 NL, NO, SE

TECHNICAL SPECIFICATION

MEDIUM

INJECTOR SIZE NG 400

LPG 170

AERATION SIZE Ø

NG 11mm

Ø

I

2L 8mm

Ø

LPG 15.5 x 2

EFFICIENCY CLASS II

FLUE T.T.B SENSOR 100

o

C

FLUE OUTLET SIZE Ø

127mm

INLET CONNECTION SIZE Ø

8mm

150

150

225

1007

127

50

470

1

Fig.1

Fig.2

Fig.3

Fig.4

Fig.5

Fig.6

176

Page 3

1. GENERAL

1.1 Installation and servicing must only be

carried out by a competent person.

1.2 In all correspondence, please quote the

appliance type and serial number which

can be found on the data badge located at

the rear of the stove.

1.3 Ensure that curtains are not positioned

above the stove, and that there is at least

a clearance of 300mm between the sides

of the stove and any curtains.

1.4 If any cracks are observed in the glass

panel, do not use the appliance until the

glass has been replaced.

2. LIGHTING THE STOVE

2.1 Ensure the control is pointing to the off

2.2 Depress control knob and rotate anticlockwise until a click is heard and the

knob is pointing at the ignition symbol (

*

),

the pilot should now be lit.

2.3 Depress for 5 to 10 seconds and then

release, the pilot should remain alight. If

the pilot does not light, repeat the above

procedure.

2.4 If it will not light after repeated attempts,

contact the retailer or installer from whom

the appliance was purchased.

2.5 The appliance may now be turned to the

high position to ignite the main burner,

then controlled between high and low as

desired.

3. TURNING THE STOVE OFF

3.1 Depress the control knob and turn clockwise until the knob is pointing at the off

NOTE: THE YELLOW FLAMES WILL

APPEAR WHEN THE FIRE HAS GAINED

SUFFICIENT HEAT - TYPICALLY 10 TO

20 MINUTES.

IF THE APPLIANCE IS EXTINGUISHED

OR GOES OUT IN USE, WAIT 3 MINUTES BEFORE ATTEMPTING TO RELIGHT THE APPLIANCE.

4. CLEANING THE STOVE

4.1 Remove the ceramic coals and place on a

dry, clean surface. Remove the front coal

ceramic, please handle with care.

4.2 Clean the flame baffle ceramic piece and

burner using a vacuum cleaner with soft

brush attachment, ensure all debris are

removed from the burner ports.

4.3 Replace the ceramics by referring to

Section 5.

5. ARRANGEMENT OF FUEL-BED COMPONENTS

The major ceramic components can be

found inside the firebox, remove the cast

iron door and remove all the protective

packaging from these components.

NOTE: THE CAST IRON DOOR IS

HEAVY, TAKE EXTREME CARE WHEN

HANDLING.

The loose coals should be arranged as

specified in the following steps, care

should be taken to ensure that there is

sufficient space between the coals to

allow flames to pass through.

5.1 Place the flame baffle onto the shelf at the

rear of the tray and push up against the

rear ledge, see Fig 11.

5.2 Locate the front coal moulding in front of

the flame baffle ensuring that the end legs

sit flat against the burner skin, see Fig 12.

5.3 Place three large coals on the front coal

so that they lean against the flame baffle,

and four large coals on the flame baffle so

that they sit on the fingers, see Fig 13.

5.4 Place two small coals at each end of the

front coal so that they lean against the

flame baffle, and a further two large coals

on the flame baffle, one at each end, see

Fig 14.

5.5 Place five small coals along the rear of

the flame baffle, resting against the rear

ledge, see Fig 15.

NOTE: ENSURE THAT THE COALS ARE

POSITIONED, AS DETAILED ABOVE.

ONLY USE THE CORRECT AMOUNT OF

COALS, AS SPECIFIED IN THE DIAGRAMS.

INSTRUCTIONS FOR USE

2

position (

).

position (

).

Page 4

6. THE FLAME FAILURE DEVICE

6.1 This is a safety feature incorporated in all

WATERFORD fires which automatically

switches off the gas supply if the pilot

light goes out and fails to heat the thermocouple.

7. 'RUNNING IN'

7.1 The surface coating on the coals used in

your WATERFORD fire will "burn off" during the first few hours of use, producing a

harmless and temporary odour. This will

disappear after a short period of use. If

the odour persists, ask your installer for

advice.

8. SERVICING

8.1 The fire must be serviced every 12

months by a qualified Gas Engineer. In all

correspondence, always quote the appliance type and the serial number, which

may be found on the data badge.

9. ENAMEL CLEANING

General cleaning must be carried out when the

stove is cool.

If this stove is finished in a high gloss vitreous

enamel, to keep the enamel in the best condition

observe the following tips:

9.1 Wipe over daily with a soapy damp cloth,

followed by a polish with a clean dry

duster.

9.2 For stubborn deposits a soap impregnated

pad can be carefully used on the vitreous

enamel.

9.3 Use only products recommended by the

Vitreous Enamel Association, these products carry the vitramel label.

9.4 DO NOT USE ABRASIVE PADS OR

OVEN CLEANSERS CONTAINING CIT

RIC ACID ON ENAMELLED SURFACES.

ENSURE THAT THE CLEANSER MANU

FACTURERS INSTRUCTIONS ARE

ADHERED TO.

3

ASSOCIATION

Page 5

NOTE: IF IT IS INTENDED TO FIT THE

STOVE INTO AN EXISTING BRICK

CHIMNEY, A 127mm LINER MUST BE

USED.

2.2 The minimum effective height of the flue or

chimney must be 3 metres (10ft).

2.3 The chimney or flue must be free from any

obstruction. Any damper plates should be

removed or secured in the fully open position, and no restrictor plates should be fitted.

2.4 The chimney should be swept immediately

prior to the installation of the appliance.

However, where it can be seen that the

chimney is clean and unobstructed

through-out its entire length, it need not be

swept.

3. VENTILATION & COMBUSTION AIR

REQUIREMENTS

This stove has a heat input of less than 7 kW and

therefore does not normally require any additional

ventilation. However, consideration must be given

to the local rules in force.

3.1 Any air vent must either be connected

direct to an outside air supply or to adja

cent rooms having a permanent vent to

the outside.

3.2 If there is another combustion appliance

fitted in the same or adjacent room, it will

be necessary to refer to the rules in force

to calculate the additional air supply.

3.3 If there is an air extraction fan fitted in the

room or adjacent rooms where this appliance is fitted, additional air vents may be

required to elleviate the possibility of

spillage of products of combustion from

the appliance/flue while the fan is in operation. Refer to the rules in force.

3.4 Where such an installation exists, a test for

spillage should be made with the fan or

fans and other gas burning appliances in

operation at full rate.

3.5 If spillage occurs following the above operation, an additional air vent of sufficient

size to prevent this occurrence should be

installed.

4. INSTALLATION OF THE GAS SUPPLY

4.1 Before installation, ensure that the local

distribution conditions (identification of

the type of gas and pressure) and the

adjustment of the appliance are compatible.

IMPORTANT: ENSURE THAT THE APPLI

ANCE IS CORRECTLY ADJUSTED FOR

THE GAS TYPE AND CATEGORY

APPLICABLE IN THE COUNTRY OF USE.

REFER TO DATA BADGE AND TECHNI

CAL SPECIFICATIONS AT THE FRONT

OF THE BOOKLET.

FOR DETAILS OF CHANGING BETWEEN

GAS TYPES, REFER TO SECTION 18.

1. SAFETY PRECAUTIONS

1.1 This appliance must be installed in accordance with the rules in force, and used

only in a sufficiently ventilated space.

Please read these instructions before

installation and use of this appliance.

1.2 These instructions must be left intact with

the user.

1.3 Do not attempt to burn rubbish in this

appliance.

1.4 In your own interest, and those of safety,

this appliance must be installed by competent persons in accordance with local

and national codes of practice. Failure to

install the appliance correctly could lead to

prosecution.

1.5 Keep all plastic bags away from young

children.

1.6 Do not place any object on or near to the

stove. Allow adequate clearance above

the stove. See Figs 7, 8, 9.

1.7 The stove is fitted with the Waterford Flue

T.T.B System which will act to cut off the

gas supply to the appliance in the event of

incorrect operation of the flue. If the system acts to shut off the gas supply, this

indicates that there is insufficient flue pull.

Continued operation of this safety device

means that there may be a serious problem with the flue system, and this should

be inspected by a qualified gas engineer.

Do not use the stove until an engineer

says it is safe to do so.

The Waterford T.T.B System must not be

tampered with. Use only genuine

Waterford replacement parts when servic

ing the system - refer to section 16.

2. FLUE AND CHIMNEY REQUIREMENTS

2.1 The chimney or flue system must comply

with the rules in force, and must be a minimum of 127mm (5”) in diameter.

INSTRUCTIONS FOR INSTALLATION & SERVICING

4

Page 6

4.2 Ensure that the gas supply is capable of

delivering the required amount of gas, and

is in accordance with the rules in force.

4.3 Soft copper tubing and soft soldered joints

can be used but must not be closer than

50mm (2”) to the base of the tray.

4.4 A means of isolating the gas supply to the

appliance must be provided independent of

any appliance control.

4.5 All supply gas pipes must be purged of any

debris that may have entered, prior to connection to the appliance.

5. APPLIANCE LOCATION

5.1 This appliance must stand on a non-combustible hearth that is at least 12mm thick;

the minimum dimensions are shown in

Fig.7.

5.2 This appliance must not be installed in a

room that contains a bath or shower.

5.3 This stove is not suitable for installation

onto a combustible wall; all combustible

materials must be removed from the area

behind the stove.

5.4 Ensure that all clearances to combustible

materials are complied with, in particular,

there must be 50mm clearance to any rear

wall and 150mm either side of the stove. If

there is any combustible materials directly

above the unit, a minimum distance of

225mm must be maintained. See Fig. 8 &

9.

NOTE: ATTENTION MUST BE GIVEN TO

ALLOWING ADEQUATE CLEARANCE

AT THE SIDES AND REAR OF THE

STOVE, SO THAT A SPILLAGE TEST

CAN BE PERFORMED.

6. INSTALLATION OF THE STOVE

6.1 Remove the outer carton, take the stove off

the pallet, and remove the accessory carton. It will now be necessary to decide

upon top or rear flue exit, the stove is factory built for rear flue exit, but it may be

changed to top exit by simply interchanging

the flue spigot and blanking plate located

on the stove.

6.2 Position the stove ensuring all appropriate

clearances are observed.

NOTE: THE STOVE LID IS LOOSE, BE

CAREFUL WHEN MOVING THE UNIT.

6.3 Having run the gas supply to the stove,

PURGE THE SUPPLY PIPE, this is essential to expel any debris that may block the

gas controls. Connect the gas supply to

the 8mm-compression elbow at the right

hand rear corner of the stove, see Fig.10.

6.4 Check the pull of the flue system by applying a lighted smoke pellet to the flue system opening. If there is a definite flow into

the chimney, proceed with the installation,

if not; warm the chimney for a few minutes.

IF THERE IS STILL NO DEFINITE FLOW,

THE FLUE MAY REQUIRE ATTENTION SEEK EXPERT ADVICE.

6.5 The flue system may now be connected to

the stove, ensure that all joints are sealed

with a suitable fire resistant sealant. It is

also recommended that a physical retention method be used at the flue spigot joint,

self-tapping screws being favoured.

6.6 Connect a suitable pressure gauge to the

test point located on the inlet fitting, and

turn the gas supply on. Light the appliance

and check all gas joints for possible leaks.

Turn the appliance to maximum and check

that the supply pressure is as stated on the

data badge. Turn the gas off and replace

the test point screw, turn the gas on and

check the test point for leaks.

7. FUELBED ARRANGEMENT

The major ceramic components can be

found inside the firebox, remove the cast

iron door using the tool provided, and

remove all the protective packaging from

these components.

NOTE: THE CAST IRON DOOR IS

HEAVY, TAKE EXTREME CARE WHEN

HANDLING.

The loose coals should be arranged as

specified in the following steps, care

should be taken to ensure that there is sufficient space between the coals to allow

flames to pass through.

7.1 Place the flame baffle onto the shelf at the

rear of the tray and push up against the

rear ledge, see Fig. 11.

7.2 Locate the front coal moulding in front of

the flame baffle ensuring that the end legs

sit flat against the burner skin, see Fig.12.

7.3 Place three large coals on the front coal so

that they lean against the flame baffle, and

four large coals on the flame baffle so that

they sit on the fingers, see Fig.13.

7.4 Place two small coals at each end of the

front coal so that they lean against the

5

Page 7

flame baffle, and a further two large coals

on the flame baffle, one at each end, see

Fig. 14.

7.5 Place five small coals along the rear of the

flame baffle, resting against the rear ledge,

see Fig. 15.

NOTE: ENSURE THAT THE COALS ARE

POSITIONED, AS DETAILED ABOVE.

ONLY USE THE CORRECT AMOUNT OF

COALS, AS SPECIFIED IN THE

DIAGRAMS.

7.6 Ensure that the fibreglass seal on the back

of the door is intact, locate the door on the

four studs and slide back to the firebox.

Secure in place using the four brass dome

nuts, do not overtighten the nuts. See

Fig.17.

NEVER OPERATE THE STOVE WHEN

THE DOOR IS REMOVED.

7.7 The top flue blanking plate is fitted to the

stove (see Fig.16). If rear exit is chosen,

top blanking plate must be kept in place.

8. COMMISSIONING

NOTE: LIGHTING INSTRUCTIONS ARE

GIVEN IN SECTION 2 OF THE INSTRUCTIONS FOR USE CHAPTER.

8.1 Close all openable doors and windows in

the room, ignite the stove and operate on

maximum for 5 minutes. Position a lighted

smoke match just inside the draught diverter opening and check that all the smoke is

drawn into the opening, see Fig.18. If

there is any doubt, run the stove for a further 10 minutes, and repeat the test.

8.2 If there are any extractor fans in the room

of adjacent rooms, the test must be repeated with the fans running on maximum.

IF SPILLAGE PERSISTS, DISCONNECT

THE APPLIANCE AND SEEK EXPERT

ADVICE.

SERVICING

9. GENERAL

9.1 This appliance must be serviced at least

once a year by a competent person.

9.2 All principal components can be replaced

without removing the stove from its installation, although it is essential that the gas

supply to the appliance is turned off at the

isolation device before proceeding further.

10. PILOT UNIT

10.1 Turn the gas supply off at the isolation

6

device, remove the door and place to one

side, carefully remove the ceramic fuelbed

components.

10.2 Undo the pilot compression nut, remove

the ignition lead from the electrode by gently pulling downwards, and undo the thermocouple from the back of the gas valve ,

see Fig 19. Undo the main injector

compression nut and pull pipe clear of the

injector, see Fig 23.

10.3 Remove the two pozidriv screws which

retain the burner and remove the burner

unit, see Fig 20. Remove the two screws

holding the heat shield in place to

reveal the pilot unit.

10.4 Remove the two screws holding the pilot,

and replace with a new unit. Replace the

heat shield and secure the burner unit in

position ensuring that the front of the tray

sits on top of the tabs at the sides of the

firebox. Reconnect the thermocouple, ignition lead and pilot pipe, turn the gas supply

on and check the joints for any leaks.

10.5 Replace the ceramic components by refer

ring to Section 7, replace the door and

secure in position.

11. IGNITION LEAD AND PIEZO

Due to the method of manufacture, these

components can only be replaced as an

integral unit.

11.1 Turn the gas supply off at the isolation

device. Pull the control knob off the gas

valve spindle to reveal the piezo securing

screw access holes. Using a small pozidriv

screwdriver, remove the two screws, see

diagram 26.

11.2 Pull the piezo body down and remove from

the valve, disconnect the ignition lead from

the electrode, see diagram 24.

11.3 Replace the assembly with a new unit, refit

the screws and connect the ignition lead to

the electrode. Check the operation of the

new piezo, turn the gas supply on and with

the pilot running, check for leaks, especially where the two halves of the valve join.

Replace the control knob.

NOTE: WHILST PERFORMING THE

PIEZO REPLACEMENT, YOU WILL BE

BREAKING THE SEAL BETWEEN THE

TOP AND BOTTOM HALVES OF THE

VALVE. ENSURE THAT THIS JOINT IS

CORRECTLY SECURED AND LEAK

TESTED.

Page 8

12. GAS FILTER

The gas filter is located just inside the inlet

boss of the control valve, to replace the filter, proceed as follows:

13.1 Turn the gas supply off at the isolation

device. Undo the inlet compression nut

and pull the pipe clear of the valve, see Fig

22. Prise the small retaining ring out and

remove the filter.

13.2 Replace with a new filter and push into

position ensuring that it sits on the shoulder, replace the retaining ring and push into

position.

13.3 Replace the inlet pipe, turn the gas supply

on and check for leaks.

14. MAGNETIC SAFETY VALVE

14.1 Turn the gas supply off at the isolation

device. Undo the thermocouple connection from the back of the gas valve, pull the

sensor leads clear and remove the interruptor block.

14.2 Undo the mag valve retaining nut at the

back of the control valve, gently tap out the

mag valve and replace with a new unit.

Replace the retaining nut and tighten, see

Fig.22.

14.3 Reassemble the interrupter block and

leads, secure in place with the thermocouple. Turn the gas supply on and check the

entire pipework and valve joints for any

leaks.

15. MAIN INJECTOR

15.1 Turn the gas supply off at the isolation

device. Locate the main injector on the left

hand side of the airbox, undo the compression nut and pull the pipe clear of the injector body, see Fig.23.

15.2 Rotate the injector until it is fully removed,

and install the correct replacement injector.

Reassemble and turn the gas supply on,

check for any leaks.

16. WATERFORD FLUE T.T.B SYSTEM

If the stove has been installed in a restrictive location, it may be necessary to

remove the stove from its location.

16.1 Locate the sensor in the draught diverter

opening, and gently pull the two wires off

the terminals. Undo the two taptite screws

and remove the sensor and the two plastic

spacers, see Fig.24.

16.2 Refit a new sensor ensuring that the spacers are located between the sensor and the

bracket, replace the two leads.

7

If it has been necessary to remove the

stove, ensure that all disturbed gas joints

are leak tested when reinstalled, and

repeat the flue clearance test as detailed in

section 9.

17. PRIMARY AERATION PLATE

17.1 Turn the gas supply off at the isolation

device.

17.2 Locate the aeration plate on the underside

of the airbox and remove the Nyloc nut,

see Fig.25.

17.3 Remove the plate and replace with the correct size, ensure that the hole(s) in the

plate align correctly with the holes in the

underside of the airbox and replace the

Nyloc nut.

18. CHANGING BETWEEN GAS TYPES

In order to change between gas types, it

will be necessary to change the following

items:

* Pilot Unit

* Control Valve

* Injector

* Aeration Plate

* Data Badge

The relevant parts can be ordered from the

parts list, always quote the appliance type

and serial number when ordering spare

parts.

19. SHORT SPARES LIST

Component Medium

Stove

NG LPG

Pilot Unit P10036 P10037

Injector IN0007 IN0006

Aeration Plate ME1096 ME0834

Gas Valve GC0056**

Flue Sensor EL0001

Sensor Lead EL0064

Interrupter GC0026

Mag Unit GC0016

Piezo and GC0062

Ignition Lead

Gas Filter GC0065

Rear Panel -

Flame Baffle CE0120

Front Coal CE0124

Coal Set CE0136

Note: The Control Valve is Factory preset for the

correct gas type and model, a new unit will need to

be ordered when changing between gas types.

Page 9

FAULT CAUSE POSSIBLE REMEDY

Pilot will not light Various Refer to Ignition

Functional Check 1

No Spark Various Refer to Ignition

Functional Check 2

Pilot will not stay lit or goes Various Refer to Flame Failure

out in use Check 2-

Stove goes out while Flue blockage Insufficient flue pull or

warming or in operation Sensor has been activated partial blockage - flue must be

checked by an engineer.

Uneven flame pattern Ceramics not Check front coal and flame

positioned correctly baffle are positioned as shown

in Section 7.

Coals not laid correctly The coals may require slight

adjustment, see Section 7.

Debris in burner Clean burner ports, refer to

ports Users Manual for guidance.

Blue Flame Warming Up Stove will burn blue until run

ning temperature has been

achieved - typically 20 minutes.

Aeration plate Ensure that the aeration plate

is tight and sits flat.

Insufficient gas pressure Check the gas pressure and

correct if necessary.

Airbox QC label removed Ensure QC seal on front of air-

box is correctly sealed.

Low flame height Blockage in supply pipe Disconnect pipe and purge,

ensure no debris has entered

the stove pipework.

Blocked gas filter Replace filter - refer to

Section 12

Insufficient gas pressure Check the gas pressure and

correct if necessary.

Empty supply tank or LPG only - ensure adequate

clylinder supply of gas in cylinders.

Short pilot flame length (see Insufficient gas Check the gas pressure and

diagram 26) pressure correct if necessary.

Blocked pilot flame Replace Unit - refer to section 10

IGNITION FUNCTIONAL CHECK 1

PILOT WILL NOT LIGHT

Ensure there is no debris around the pilot assembly e.g. coal, soot, etc

which could short the spark, clean the area.

There is a blockage in the system, check the inlet test point, the mag

seating, valve and pilot filter.

Operate the valve.

Is there a spark?

Is the control being

operated correctly?

Consult users book

and retry

Will the pilot light

with a match?

Is the gas turned on to

the appliance?

Check isolation tap and

gas meter, retry

Correct and retry.

Is the gas pressure

correct?

Has the system got any

air in it?

Purge the gas pipes

and retry.

GO TO THE NEXT

CHART IGNITION

FUNCTIONAL CHECK

SYSTEM OK

Ensure gap between

electrode and thermo-

couple is 3.5mm and

retry. If the gap is OK

then first change the

ignition lead and retry, if

still no good then change

the piezo.

Does the pilot light?

YES

YES

NO

NO

YES

YES

YES

NO

YES

NO

NO

NO

YES

NO

8

Page 10

IGNITION FUNCTIONAL CHECK 2

NO SPARK

Ensure there is no debris around the pilot assembly e.g. coal, soot, etc

which could short the spark, clean the area.

From Ignition Fault

Finding Chart Pt 2

Is the valve being

operated correctly?

Operate the valve to light

the pilot, does the valve

‘click?

Reset the electrode

gap, retry.

Correct and retry.

Has ignition lead

become detached or is

connection poor?

Remove the electrode

lead from electrode with

insulated pliers hold the

tip 3.5mm from the pilot

pipework, is there a

spark when the valve

‘click’?

Check for defective or damaged

control knob spindle or cam

operation. Check for correct

location of piezo components.

Correct and retry

Remove the electrode lead from

the piezo. Operate the valve.

Does a spark jump from the

piezo to the valve body?

Is the electrode wire

detachable from piezo in

the valve?

Replace the combined

lead and piezo, retry.

Replace the pilot unit

Replace the electrode

lead and retry

Replace the piezo and

retry.

Is the gap between

electrode and

Thermocouple 3.5mm?

Consult the users

instructions, retry.

NO

YES

YES

YES

NO

NO

NO

NO

YES

YES

YES

YES

NO

FLAME FAILURE FUNCTIONAL CHECK

PILOT WILL NOT STAY LIT OR FIRE GOES OUT IN USE

If the appliance goes out in use continually, this may mean that

the Waterford Flue T.T.B System has been activated. The

appliance should not be used until the cause has been found

and rectified.

Ensure there is no debris around the pilot assembly, e.g. coal,

soot, etc which could short the spark, clean the area.

Light the pilot and keep the control knob pushed in at least 10

seconds before letting go.

With the fire

running on full is

the gas at the

pressure started

on the data

badge?

Will pilot

stay alight?

With the pilot running

is the gas pressure as

stated on the data

badge?

Is the pilot flame

of the correct

length?

See Diagram 26

Problem is with

the pipework or

fittings which

lead to the fire.

Correct and

retry.

Is thermocouple

connection good

in back of valve

Run for 3 mins, turn off,

time interval until mag

unit shuts with a click.

Is this greater than 7

seconds?

Change the

pilot unit

Replace pilot unit

will pilot stay alight?

Change mag unit

Tighten the

connection and retry.

SYSTEM OK

Run for 3 mins,

turn off, time

interval until

mag unit shuts

with a click. Is

this greater than

7 seconds?

NO

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

9

Page 11

AB

Medium 1007 470

A = 225mm

B = 150mm

A = 50mm

B = 150mm

10

DIAGRAMS

Fig.7

Fig.8

Fig.9

Page 12

11

Fig.10

Fig.11

Fig.12

Fig.13

Fig.15

Fig.14

COAL LAYOUT

Page 13

12

Fig.16

Fig.17

Fig.18

Page 14

13

Fig.19

Fig.21

Fig.20

Page 15

14

Fig.22

Fig.23

Fig.24

Fig.26

Fig.25

Page 16

Rev: 004 DP 070129

INSTALLATION CHECK LIST

Flue System

1. The flue height should not be less than 3 metres and no more than 11 metres.

2. If connecting to an existing chimney, the appliance should be connected to a 125mm (5”)

diameter continuous, rigid or flexible flue pipe that terminates in excess of 0.6 metres from

the nearest point on the roof measured vertically, and in excess of 2.3 metres measured

horizontally.

3. If using an external flue, the appliance should be connected to a 125mm (5”) diameter rigid

insulated flue pipe that terminates in excess of 0.6 metres from the nearest point on the

roof measured vertically and in excess of 2.3 metres measured horizontally.

4. Any horizontal flue sections should not exceed 300mm (12”).

5. The chimney serving this appliance should not serve any other appliance.

6. A suitable flue terminal should be fitted at the flue termination point.

7. If using an internal flue or chimney, closure-clamping plates should be used to seal the top

& bottom of the chimney.

8. Access should be provided to the chimney serving the appliance to allow for cleaning.

9. If the flue passes through a combustible wall, a twin wall insulated connector must be used

and come flush to the external surface of the wall.

10. The flue should be capable of producing a continuous draught of between 0.06” w.g. during

normal operation.

Location

1. Clearance to combustible materials must be adhered to as described in the Clearance to

Combustibles section.

2. The stove should be installed as to allow adequate air circulation around the stove and to

allow access for installation & servicing.

3. The stove must be installed on a non-combustible insulated floor protector that covers the

area of 1007mm x 470mm around and under the stove.

Ventilation & Combustion Air Requirements

1. The room in which the appliance is located should have an air vent of adequate size to

support correct combustion, including all other air using devices fitted in the same or

adjacent rooms. (see Ventilation & Combustion Air Requirement Section for specific details).

Gas Supply

1. A 8mm rigid gas supply pipe must be used to connect directly from the gas meter to the stove.

In the event of a number of appliances using the same supply pipe, the pipe size may need

to be increased.

2. A shut off valve must be used to connect the gas supply as close as possible to the stove and

should be accessible at all times.

3. A soundness test must be conducted to check all joints for gas tightness.

Tick

√

15

Manufactured by

Waterford Stanley Ltd.,

Unit 210, IDA Industrial Estate, Cork Road,

Waterford, Ireland.

Tel: (051) 302300 Fax (051) 302315

Loading...

Loading...