Page 1

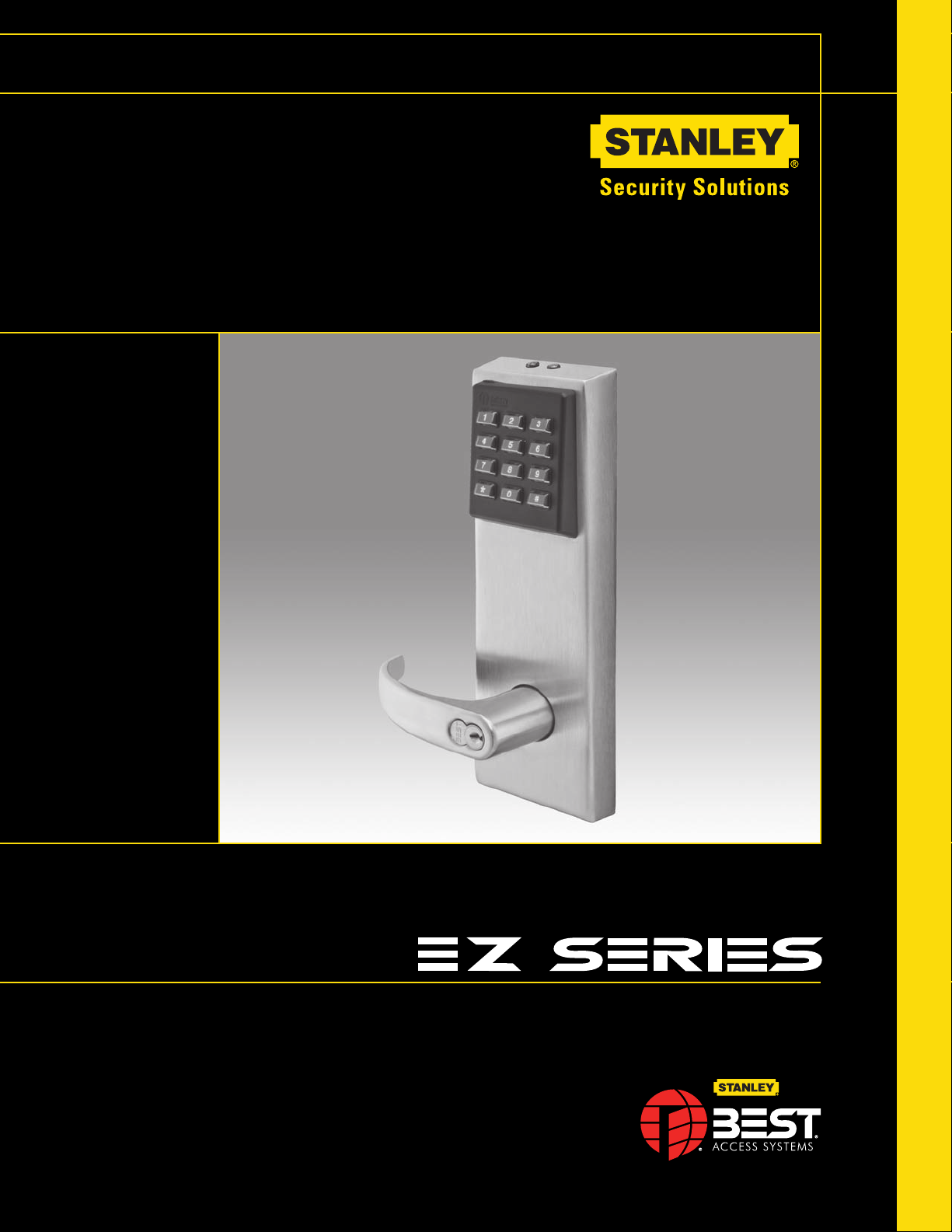

KEYPAD EZ LOCKS

KEYPAD EZ LOCKS

Page 2

tAbLE Of COntEntS & fEAturES

TAblE of coNTENTs

Hardware / Software Features . . . . . . . . . . . . . . . . . . . .2

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

HZ mortise specifications . . . . . . . . . . . . . . . . . . . . . . .3

HZ mortise functions . . . . . . . . . . . . . . . . . . . . . . . . . . .4

HZ mortise levers/knob . . . . . . . . . . . . . . . . . . . . . . . . .4

HArdwArE fEATurEs

KZ cylindrical specifications . . . . . . . . . . . . . . . . . . . . . .5

KZ cylindrical functions . . . . . . . . . . . . . . . . . . . . . . . . .6

KZ cylindrical levers . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

EXZ exit hardware specifications & trim chart . . . . . . . .6

Order procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Patented keying system . . . . . . . . . . . . . . . . . . . . . . . . .8

PagePage

• Heavy-duty mechanical platform designed and manufactured for the toughest applications.

• When the deadbolt is projected, deadbolt sensing prevents access by unauthorized PIN’s.

(Key override feature standard on Keypad EZ.)

• Mechanical override allows for emergency access.

• Available in common finishes and trims to match Stanley/BEST’s 9K cylindrical series and 40H mortise series, providing

aesthetic continuity.

• Available in cylindrical, mortise, and exit device trim platforms to meet most common applications.

• 12 position keypad design with audible and visual feedback.

• Standard battery pack yields a minimum of 65,000 cycles / 2–5 year battery life for cylindrical chassis, 130,000 cycles /

3–5 year battery life for mortise or exit trim platform.

• Optional extended battery pack yields twice the battery life as the standard battery pack.

• Local factory-trained technical services are available 24 hours a day to meet any emergency need.

• Replacement parts available.

• Features Stanley/BEST’s standard 3 Year warranty.

• Weather-resistant for versatile applications, including doors exposed to inclement weather.

• Remote unlock standard.

sofTwArE fEATurEs

• Variable PIN length from 3 – 6 digits.

• Maximum of 50 users.

• All programming occurs through the keypad.

• Passage Mode privilege – authorized users can unlock device for extended periods of time.

• Deadbolt Override privilege – authorized users can gain access even when a mortise deadbolt is thrown.

• Provides for 1 Administrator PIN and 5 Supervisor PIN’s to allow easy management of groups of users.

EZ – OPtiOnS

EZ – oPTioNs

AL– Besides complying with a wide variety of accessibility codes and ordinances, Stanley/BEST lever handles are available with a

special abrasive feature. Abrasive strip on the lever im me di ate ly identifies warnings on doors to hazardous areas for the blind.

EXBB– Extended life battery pack for double the operating life. (93KZ & 45HZ ONLY)

LM– Lost motion feature allows the lever handle to move 45 degrees from parallel to the horizontal plane without engaging the

latchbolt assembly. When the lockset is in the locked mode, this feature makes over-torque or over-leverage abuse more

difficult to achieve.

Non-IC– The 9KZ may be adapted to existing keying systems by using a special retrofit lever and throw member that will accept

6-pin single shear-line cylinders from the following manufacturers: Corbin-Russwin, Medeco, Sargent, Schlage, Yale.

Note: Available in #15 lever style only. (Cylinder not supplied).

SH– Security head provided for all exposed screws.

Thick door–Specify thickness if other than 1 3⁄4".

TL– Tactile levers may be used in areas where improved grip is required or as a warning in hazardous or Safety First areas.

Grooves are machined into the back of the hand grasp portion of the lever to improve grip and/or provide a sensory warning.

This option can be used for blind, safety, or accessibility applications.

EZ – AccEssoriEs

Part Description Catalog Number

McGard™ Battery Door Screw (Specify Finish) VPD - HS - SCRW

McGard™ Driver Bit VPD - HS - DRVR

Standard Driver Bit VPD - T15

Replacement Battery Pack VPD-BB

Extended Battery Pack VPD-EXBB

Note: Available in 9K cylindrical only.

(not shown)

EZ–ACCESSOriES

2

E L E C t r O n i C

Page 3

HZ – MorTisE sPEcificATioNs

MEcHANicAl

Case: 0.095" cold rolled steel, 5 7/8" H x 7/8" D x 4 1/16" W. Steel is zinc dichromate plated

for corrosion protection.

Faceplate: Brass or bronze material, 8" H x 1 1/4" W x 1/16" T. Lock face automatically

adjusts to proper bevel during installation.

Strike: Brass, bronze, or stainless steel base material, 4 7/8" H x 1 1/4" W x 3/32" T. Fits

standard door frame cut out as specified in ANSI A115.1. Universal (non-handed) strike

supplied standard with lock.

Backset: 2 3/4"

Certification: UL listed for GYQS electrically controlled single point locks or latches for

use on 3 hour A label doors. The listing applies for both U.S. and Canadian applications.

Door Thickness: Standard lock configuration designed for doors 1 3/4" thick. Thick door

configuration available for doors up to 3" thick (specify thickness when ordering).

Latchbolt: Solid stainless steel, 3/4" throw. Latch is oil-impregnated for anti-friction

operation. Reversible without opening case.

Deadbolt: Stainless steel, 1" throw.

Auxiliary bolt: Stainless steel, non-handed.

Lever handle: Brass, bronze, or stainless steel base material. Lever styles 3, 14, and 15

return to a minimum of 1/2" of door surface. Lever 12, 16 and 17 do not return.

Escutcheon: 10 3/8" H x 3 1/4" W x 1" D (1" at the top, sloping down to 3/4" at the bottom)

Finishes: 605 - bright brass, clear coated; 606-satin brass, clear coated; 611-bright bronze,

clear coated; 612-satin bronze, clear coated; 613*-oxidized satin bronze, oil rubbed; 619-satin

nickel plated; 625-bright chromium plated (brass base material); 626-satin chromium plated

(brass base material); 690*-dark bronze coated (brass base material)

* 613 finish is designed to wear over time, providing an “antique” appearance.

690 finish will continue as a dark brown appearance over time.

HZ SPECifiCAtiOnS

40HZ

ElEcTroNic

Primary power: Alkaline battery pack.

Memory backup: Maintains programming 100 years.

User feedback indicators: Visual and audible.

Operating & Storage temperature: -30°C to +60°C (-22°F to +140°F).

Relative humidity: 10% to 90% non-condensing.

Shock: 2000 Gs RMS (maximum door-slam shock).

Compliance to FCC, Canadian, EMC requirements; for interference FCC Class A digital ap pa ra tus.

KEYPAd

Bezel size: 2 5⁄8" x 3 1⁄4" .

Material: Bezel–High impact ABS,

Keypad–Encapsulated elastomer.

ESD Protection: 15KV

Button operating life: 3-5 million cycles.

Button operating force: 3.88 ounces.

Operating & Storage temperature: -35°C to +65°C

(-31°F to +149°F).

Sealing: Weatherproof lens and gasket provides protection for out door use. (Usable in all environmental/exterior applications.)

3

Page 4

HZ – MorTisE fuNcTioNs

Diagram Function Mechanical Electronic

Code

Deadbolt w/

key override

TV

Latchbolt operated by lever either side,except

when outside lever is locked by internal motor

drive mechanism; latchbolt is re tract ed by key

outside. Deadbolt operated by key outside

and turn lever inside. When deadbolt is

extended, turning inside le ver or electronically

unlocked out side lever re tracts both deadbolt

and latchbolt simultaneously. Auxiliary latch

dead locks latchbolt.

Internal motor

op er at ed by electronic signal when

presenting valid token. Green light

indicates valid ac cess. Red light and

sounder in di cate invalid access

attempt. Elec tron ic sensor recognizes

whether dead bolt is retracted or

thrown. Lock grants access only to

deadbolt-authorized per son nel when

deadbolt is thrown.

drive mechanism

Deadbolt w/o

key override

HZ – mOrtiSE funCtiOnS

Latch w/key

override

Latch w/o

key override

LV

DV

NV

Latchbolt operated by lever either side, except

when outside lever is locked by internal motor

drive mech a nism. Deadbolt operated by turn

knob inside. When deadbolt is extended,

turning inside lever or elec tron i cal ly unlocked

outside lever retracts both deadbolt and

latchbolt simultaneously. Auxiliary latch

dead locks latchbolt.

Latchbolt operated by lever ei ther side,except

when outside lever is locked by internal motor

drive mech a nism; latchbolt is retracted by key

outside. Auxiliary latch deadlocks the latch bolt.

Latchbolt operated by lever ei ther side, except

when outside lever is locked by internal motor

drive mech a nism. Auxiliary latch deadlocks the

latch bolt.

Internal motor drive mechanism operated

by electronic signal, when pre sent ing

valid token. Green light in di cates valid

access. Red light and sound er in di cate

invalid access attempt.

HZ – lEVErs/KNob

HZ – mOrtiSE LEVErS

4

#3 lever #12 lever

#15 lever

#4 knob

#16 lever #17 lever

E L E C t r O n i C

#14 lever

Page 5

KZ – cYliNdricAl sPEcificATioNs

MEcHANicAl

Materials: Internal parts are brass, zinc or corrosion-treated steel.

Chassis: 2 1⁄16" diameter to fit 2 1⁄8" diameter hole in door.

Strike: Brass or bronze, 4 7⁄8" x 1 1⁄4" x 3⁄32". Fits standard door frame cut out as spec i fied in ANSI

A115.1. Correct strike automatically supplied with unit.

Backset: 2 3⁄4" standard, 3 3⁄4" and 5" available.

Door thickness: For doors 1 3⁄4" - 2 1⁄4" thick.

Installation: Lock dimensions requires modified door prep ANSI A156.2 Series 4000, Grade 1 to

mount housing.

Latchbolt:9⁄16" throw.

Forged trim housing: Dimensions: 10 3⁄8" H x 3 1⁄4" W x 1" D sloping down to 3⁄4".

Lever: Made from high-quality zinc alloy. Body is approximately 1 5⁄8" in diameter: Handle

is approximately 4 3⁄4" in length (from center-line of chassis). (#14 and #15 conform to

Cal i for nia Titles 19 and 24.)

Certification: UL listed For GYQS Electrically controlled single point locks or latches for

use on 3 hour A label doors. The listing applies for both U.S. and Canadian applications.

Finish: 605 - bright brass, clear coated; 606-satin brass, clear coated; 611-bright bronze,

clear coated; 612-satin bronze, clear coated; 613*-oxidized satin bronze, oil rubbed;

619-satin nickel plated; 625-bright chromium plated (brass base material); 626-satin

chromium plated (brass base material); 690*-dark bronze coated (brass base material).

* 613 finish is designed to wear over time, providing an “antique” appearance.

690 finish will continue as a dark brown appearance over time.

ElEcTroNic

9KZ

Primary power: Alkaline battery pack.

Memory backup: Maintains programming 100 years.

User feedback indicators: Visual and Audible.

Operating & Storage temperature: -30°C to +60°C (-22°F to +140°F).

Relative humidity: 10% to 90% non-condensing.

Shock: 2000 Gs RMS (maximum door-slam shock)

Compliance to FCC , Canadian, EMC requirements; for in ter fer ence FCC Class A digital apparatus.

KZ SPECifiCAtiOnS

KEYPAd

Bezel size: 2 5⁄8" x 3 1⁄4"

Material: Bezel–high impact ABS, Keypad–silicone rubber.

ESD Protection: 15KV.

Button operating life: 3-5 million cycles.

Button operating force: 3.88 ounces.

Operating temperature: -35°C to +55°C (-31°F to +131°F).

Storage temperature: -40°C to +55°C (-40°F to +131°F).

Sealing: Weatherproof gasket provides protection for outdoor use. (Usable in all environmental/exterior applications.)

KZ – cYliNdricAl fuNcTioNs

Diagram Function Mechanical Electronic

Code

DV Dead locking latchbolt operated by lever either Internal motor drive mechanism operated by

Cylindrical lever either side, except when outside le ver is electronic signal when presenting valid token.

Latch w/key locked by internal motor drive mech a nism; Green light in di cates valid access. Red light

override latchbolt is deadlocked. and sound er in di cate invalid access attempt.

KZ – cYliNdricAl lEVErs

KZ funCtiOnS

#14 lever #15 lever #16 lever

KZ trimS

5

Page 6

EXZ – EXiT HArdwArE sPEcificATioNs

EXIT HARDWARE SUPPORTED

• Adapts to Precision’s 1000 & 2000 series and Von Duprin 98/99 series

Devices supported:

– Rim device

– Surface vertical rod

– Concealed vertical rod

– Mortise

MEcHANicAl

ExZ SPECifiCAtiOnS

Materials: Internal parts are brass, zinc or corrosion-treated steel.

Brass or bronze, 4

spec i fied in ANSI A115.1. Correct strike automatically supplied with unit.

Strike box sup plied stan dard. Forged trim housing

Lever handle: Brass or bronze. (Lever #14 and #15 conform to California Titles 19 and 24.)

Certification: UL listed For GYQS Electrically controlled single point locks or latches for use on 3 hour A label doors. The

listing applies for both U.S. and Canadian applications.

Finish: 606-Satin brass, clear coated; 613*-oxidized satin bronze, oil rubbed; 626-satin chromium plated; 690*-dark bronze

coated (brass base material).

* 613 finish is designed to wear over time, providing an “antique” appearance. 690 finish will continue as a dark brown appearance over time.

7

⁄8" x 1 1⁄4" x 3⁄32". Fits standard door frame cut out as

EXZ Keypad

ElEcTroNic

Primary power: Alkaline battery pack.

Memory backup: Maintains programming to 100 years.

User feedback indicators: Visual and Audible.

Operating & Storage temperature: -30°C to +60°C (-22°F to +140°F).

Relative humidity: 10% to 90% non-condensing.

Shock: 2000 Gs RMS (maximum door-slam shock)

Compliance to FCC , Canadian, EMC requirements; for in ter fer ence FCC Class A digital apparatus.

KEYPAd

Bezel size: 2 5⁄8" x 3 1⁄4"

Material: Bezel–high impact ABS, Keypad–silicone rubber.

ESD Protection: 15KV.

Button operating life: 3-5 million cycles.

Button operating force: 3.88 ounces.

Operating temperature: -35°C to +55°C (-31°F to +131°F).

Storage temperature: -40°C to +55°C (-40°F to +131°F).

Sealing: Weatherproof gasket provides protection for outdoor use. (Usable in all environmental/exterior applications.)

EX TriM cHArT

Ex trim CHArt

6

E L E C t r O n i C

Page 7

ordEr ProcEdurE

HZ – MorTisE

45HZ 7 TV 14 MS 626 RH

Series Core Function Lever Trim Finish Door Options

Housing Code Style Style Hand

45HZ– lever DV– latch

0**–

keyless

7– 7 pin

housing;

accepts

all BEST

cores

with key

TV– deadbolt

with key

LV– deadbolt

without key

NV– latch

without key

Levers:

3**– solid tube/

w/return

12*– solid tube/

no return

14– curved

return

15– contour

angle return

16– curved

no return

17*– gull wing

Knobs:

4– round

* Extra cost option. Must specify keymark and number of keys.

** Cost deduction.

KP– keypad

KPA– other cylinder

626 690

RHRB

Satin*

606 612

LHRB

613 619

Bright*

605 611

625

KZ – cYliNdricAl

EXBB*– extended

RH

life battery pack

LH

(Battery door

available in 622

finish only)

SH*– security

head screws

Thick Door*–

specify thickness

TAC*– tactile lever

7/8" LTC*– flat lip

strike

93KZ 7 DV 14 MS STK 626

Backset Core Function Lever Rose Strike Finish Options

Housing Code Style Style Package

3

93KZ– 2

/4"

94KZ*– 33/4"

95KZ*– 5"

0– keyless

6– 6 pin

non-IC cyl.

7– 7 pin

housing;

accepts

all BEST

cores

DV– latch

with key

14– curved

return

1

5– contour

angle return

16– curved

no return

KP– keypad 626 690

STK–

standard

S3– ANSI

Satin*

606 612

613 619

Bright*

605 611

625

* Extra cost option. Must specify keymark and number of keys.

** Six-pin cylinder in Schlage “C” keyway included with 0B, KA, KD options. Must specify “6” for core housing.

*** Cylinder not included with COR, MED, SAR, SCH, YAL, or SCHRC options. Must specify “0” for core housing.

EXBB*– extended life battery pack

(Battery door available in 622

finish only)

LM– lost motion

SH*– security head screws

TAC*– tactile lever

3/4*– 3/4" throw latch

7/8" LTC*– flat lip strike

0B**– non-IC zero-bitted

KA**– non-IC keyed alike

KD**– non-IC keyed different

COR***– non-IC

MED***– non-IC

SAR***– non-IC

SCH***– non-IC

YAL***– non-IC

Corbin-Russwin

Medeco

Sargent

Schlage

Yale

SCHRC***– Schlage

OrDEr PrOCEDurE

EXZ – EXiT HArdwArE

EXZ 7 EV 14 MS 626 RHR PH1 RM

Series Core Function Lever Trim Finish Door Manufacturer Locking Options

Housing Code Style Style Hand Type

EXZ–

Keypad EZ

* Extra cost option. Must specify keymark and number of keys

** EV function (key override) is not available on PH1000 (all models) Von Duprin (mortise type), or Sargent (rim type) device.

*** SA8– available (only) with rim type device.

0** –

keyless

7– 7 pin

housing;

accepts

all BEST

cores

EV– with

key**

NV– w/out

key

14– curved

return

15– contour

angle return

KP– keypad 626 690

satin*

606 613

RHRB

LHRB

VD9– VonDuprin

98/99 series

PH1– Precision

hardware 1000

PH2– Precision

hardware 2000

SA8– Sargent

8000 series ***

RM– rim***

MO–mortise

RD– surface

& concealed

vertical rods

SH*–

security

head

screws

Thick

Door*–

specify

thickness

7

Page 8

CORMAX™ PAtented KeYInG SYSteM

BEST®CORMAX™is the premier patented keying system offered by Stanley Security Solutions.

CORMAX will meet your needs for security, key control, and convenience. A simple solution

with no compromising allowed.

CORMAX is the upgrade path for existing BEST Standard, Premium, and MX8 customers;

and it is an essential element of non-residential access control as security administrators

strive to eliminate the unauthorized duplication of keys.

CORMAX offers the following features and benefits:

long-term US utility patent that guarantees the extended useful life of the system through 2027.

• A

• A second, independent locking mechanism that utilizes a patented set of built-in side pins to provide higher security.

• Several levels of geographical exclusivity, including national exclusivity, are available via the patented side pin feature.

• CORMAX cores and keys are available exclusively through Stanley sales offices. Key blanks are only sold to individuals

uthorized by the customer to ensure key blanks do not end up in the possession of unauthorized personnel either inside

a

or outside the customer’s facility.

• CORMAX cores are certified to meet the security, safety, and reliability requirements of BHMA A156.5 Grade 1.

• Picking and drilling resistance options are available if higher levels of security are desired.

• Complete factory masterkeying service offered, and at no charge with purchase of BEST locksets and PHI exit devices.

• Keyways are organized in families of four keyways each, with double-milled and quad-milled key levels to facilitate the

design of masterkey systems in multi-building campuses.

• BEST CORMAX cores are compatible with all existing BEST interchangeable core housings, eliminating the need for new

or modified locksets.

CORMAX™ PATENTED KEYING SYSTEM

CORMAX

Patented Keying System

™

For more information on Stanley Security Solutions’ products, services, and office locations visit our web site at www.stanleysecuritysolutions.com

Product information contained in this catalog has been com piled and presented with as much care and com plete ness as is reasonably possible. Errors or

mistakes may be present, and in many cases, reliance has been placed on information supplied by other manufacturers which may be in error or which may

be subject to changes or mod i fi ca tions by the man u fac tur er with out no tice and without obligation. Therefore, no guar an tee can be made or should be

assumed or implied with regards to product in for ma tion con tained in this catalog.

Stanley Security Solutions, Inc.

6161 E. 75th Street Indianapolis, Indiana 46250

© 2011 Stanley Security Solutions, Inc. • www.stanleysecuritysolutions.com

10M R311

BAS023

Loading...

Loading...