Page 1

K100 & K300

Wood Pellet Stoves

INSTALLATION AND OPERATING INSTRUCTIONS

This appliance is hot while in operation and retains its heat for a long period of time after use.

Children, aged or infirm persons should be supervised at all times and should not be allowed to touch

the hot working surfaces while in use or until the appliance has thoroughly cooled.

When using the stove in situations where children, aged and/or infirm persons are present a fireguard

must be used to prevent accidental contact with the stove. The fireguard should be manufactured in

accordance with

BS 8423:2002.

Page 2

2

TABLE OF CONTENTS

PAGE NO.

1. Setting the language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. Stanley Pellet Stove Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3. Important Operation/ Maintenance Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4. Installation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5. Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..6

6. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..8

6a. Installation requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

7. Flue / chimney installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..9

8. Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

9. Clearance to Combustibles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

10. Ventilation & Combustion Air Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

11. Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

12. Using the pellet stove . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

13. Remote control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

14. Control and display panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

15. Mode selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

16. Setting time and date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

17. Setting the sleep timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

18. Setting the programmer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

19.

User Information

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

20. Combustion settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

21. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

22. Maintenance / glass cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

23. Weekly maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

24. Additional cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

25. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

26. Maintenance plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

27. Exploded views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

28. Electrical diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

29. Ignition logic flow diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

30. shut down logic flow diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

31. Fixed timer program schedules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Page 3

STANLEY PELLET STOVE WARRANTY

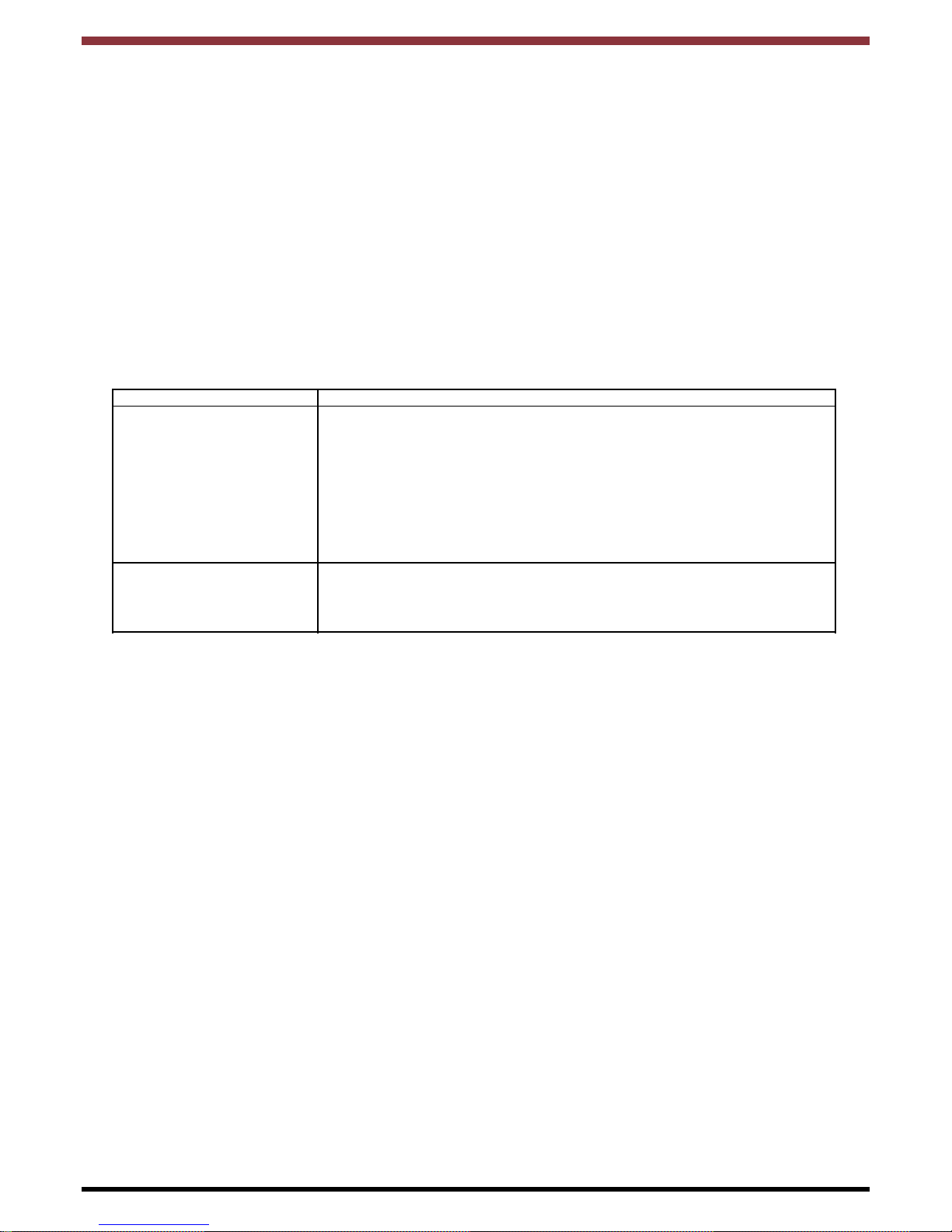

CONDITIONS OF WARRANTY

Your Stanley pellet stove is guaranteed against any part that fails (under normal operating conditions) as detailed in the

following table with timelines specified from the date of installation of the appliance. If the unit is not installed within six

months of date of purchase, the warranty will commence six months from the date of purchase.

Warranty Period Parts Covered (Parts & Labour unless Stated)

Up to 1 Year • Refractory materials (supply only)

• Rope seals, glass seals and cement seals.

• Surface Finish on Seno models.

• Grates and fire bars.

• Ceramic glass is covered for Thermal breakage (supply only).

• Rust (if reported before installation)

• Aesthetic Damage (provided reported on date of receipt)

• Electrical components under normal operation.

Up to 2 Years • All external casings & enamel finishes (excluding impact damage or

damage caused by overfiring). Pictures of damage must be submitted to

WS Service Department.

All warranty claims must be reported to the Waterford Stanley Service Department and must be submitted with the product serial number (located on the data plaque at the rear of the product), date of purchase, proof of purchase (if requested) and details of the specific nature of the problem.

The warranty is given only to the original consumer/purchaser only and is non- transferable. The appliance must be

installed by a suitable qualified person and installed as per the requirements of the manual. Failure to comply with the

Installation requirements or Building Regulations will void your warranty. Waterford Stanley reserve the right to replace any

part due to manufacturing defect that fails within the warranty period under the terms of the warranty. The unit must be

used for normal domestic purposes only and in accordance with manufacturer's operation instructions.

LIMITS OF LIABILITY

The warranty does not cover:

* Special, incidental or consequential damages, injury to persons or Property, or any other consequential loss.

* Any issue caused by negligence, misuse, abuse or circumstances beyond Waterford Stanley’s control.

* Any issue with wear and tear, modification, alteration, or servicing by anyone other than an authorized service

engineer.

* Installation and operational related problems such as draught related issues external to the stove, inadequate

venting or ventilation, excessive flue offsets, negative air pressure caused by insufficient burning of improper

fuel.

* Damage caused to the unit while in transit.

* Discolouration due to over firing, damage caused by impact, damage to baffles caused by

over firing and fading of surface finish on casting.

* Stress fractures on bricks.

* Rust on cast iron parts unless reported prior to unit being installed.

* Aesthetic damage, rust & missing parts on units purchased off display.

* Electrical components where voltage variations are in excess of 10% of nominal 230V

Note: Adequate clearance must be maintained around the appliance to ensure the ease of part removal in the possible

event of their damage/failure. Waterford Stanley are not responsible for any costs incurred in the removal of items installed

in the vicinity of the appliance that have to be moved to facilitate a part replacement.

3

Setting the Language for the first time.

To set the Language to English on the controller.

Press the menu button until “ set” is displayed beside the menu button.

Press the “ +” button 4 times , display shows “configura.......”.

Press the set button twice until abbreviation for languages in the top and centre of the screen.

Press the “ +” button until abrreviation “EN” is displayed.

Press the Menu button to set the language to English.

Page 4

IMPORTANT OPERATION / MAINTENANCE NOTES

N.B.: The information in this manual is given as guidance, all local, national or EC regulations must also be

complied with.

Before using this appliance, please read all parts of this instruction manual carefully, as the information it

contains, is essential in order to use the appliance correctly,

Make sure you fully read and understand the instructions contained in this manual before using the Pellet Stove

as a biomass heating unit.

Do not touch the stove especially the control panel with wet or damp hands.

Do not burn fuel with a high moisture content, ie damp pellets.

Do not tamper with the safety devices or adjustment features without prior authorization from Waterford Stanley

During the first firings it is recommended to ventilate the room as an unpleasant (not toxic) odour may be emitted as the paint is completing curement.

Empty the ash container and clean the combustion chamber after burning of every 30kg of pellets.

Check flueways before lighting especially after a shut down period.

Allow adequate air ventilation to ensure plenty of air for combustion at all times.

Never turn off an operating pellet stove unit by disconnecting the electric plug. Disconnecting the plug will prevent the extraction of combustion fumes;

The only fuel that should be used for operation of the pellet stove are pellets certified by EN 14961-2 grade A1

with a diameter of 6 mm and a length that can range from 10 to 30 mm.

Keep all combustible materials a safe distance away from unit, please see section for clearances

to combustibles.

Never use aerosol spray near the appliance when it is in operation.

For safety reasons never leave children or the elderly unaccompanied while stove is in use. Use a

fire guard.

This appliance should be regularly maintained by a competent service engineer.

Please keep the packing materials away from children;

The manufacturer will not be responsible for any modifications made to this appliance by or on behalf of the

user. The manufacturer will not be responsible for any eventual damage or loss as a result of unauthorised

modifications. In the event that parts need to be replaced, only use parts recommended by Waterford

Stanley.

4

Page 5

Flue System

1. Minimum Flue Height of 2 metres.

2. Tee piece fitted at base of flue.

3. Appliance should be connected using an 80mm connecting flue pipe, increasing to 125mm

within 1.5 metres of the appliance

4. Horizontal run of connecting pipe must not exceed 600mm.

5. All flue pipework passing through walls must be sleeved & adequately insulated in line

with current Building Regulations.

6. An appliance connected to a chimney must be lined with an 125mm flue liner.

7. The chimney/ flue termination must be located in accordance with building regulations part J.

8. The chimney serving this appliance should not serve any other appliance.

9. Access should be provided to the chimney serving the appliance to allow for cleaning.

10. It is a requirement by Building Regulations to have a carbon monoxide alarm

fitted to any room with a solid fuel appliance.

11. A suitable cowl must be fitted at the flue termination to prevent excessive wind effects and

rain entering the flue.

Location

11. Clearance to combustible materials must be adhered to as described in the Clearance

to Combustible section.

12. The stove must be installed on a floor protector that covers the area under the stove

and extends 9” to the front and 6” to the sides.

13. Clearance must be maintained to allow for maintenance and part replacement.

Ventilation & Combustion Air Requirements

14. The room in which the appliance is located should have an air vent of adequate

size to support correct combustion (see Ventilation & Combustion Air Requirement

Section for specific details).

15. The stove must not be installed in the same room as an extractor fan.

5

INSTALLATION CHECKLIST

Page 6

6

Technical Specifications

Parameters K100 K300 Units

Height 910 965 mm

Width 558 542 mm

Depth 555 565 mm

Weight 82 101 kg

Diameter of the fume discharge pipe 80 80 mm

Hopper capacity 15 15 kg

Maximum heating capacity 180 180 m³

Maximum heat output 8 8 kW

Minimum heat output 3 3 kW

Minimum fuel consumption 1,1 1,1 kg / h

Maximum fuel consumption 1,9 1,9 kg / h

Rated electrical current 106 106 W

Electric power at start-up (<10 min.) 362 362 W

Rated voltage 230 230 V

Nominal frequency 50 50 Hz

Efficiency at nominal output 91,3 91,3 %

Efficiency at reduced output 96 96 %

Max. flue gas temperature 189 189 °C

Min. flue gas temperature 143,7 143,7 ºC

CO emissions at rated thermal power 0,036 0,036 %

CO emissions at reduced thermal power 0,03 0,03 %

Combustion gas mass flow 7 7 g/s

Flue draught 12 12 Pa

Test results obtained from independent test laboratory using fuel of calorific value 4.9 kWh/kg.

Page 7

K300

K100

7

Page 8

8

Contents

The package of this unit contains:

Free Standing Pellet Stove K100, or K300

Instruction manual

Power cable;

Infrared remote control;

Cleaning bar handle;

Covers according to selected model.

Unpacking the Unit

To unpack the equipment, you must first

remove the retractable bag that surrounds the

cardboard box. Then remove the box, lifting it

up, and remove the bag that surrounds the

stove and the packaging. To complete the procedure, unscrew the four brackets that secure

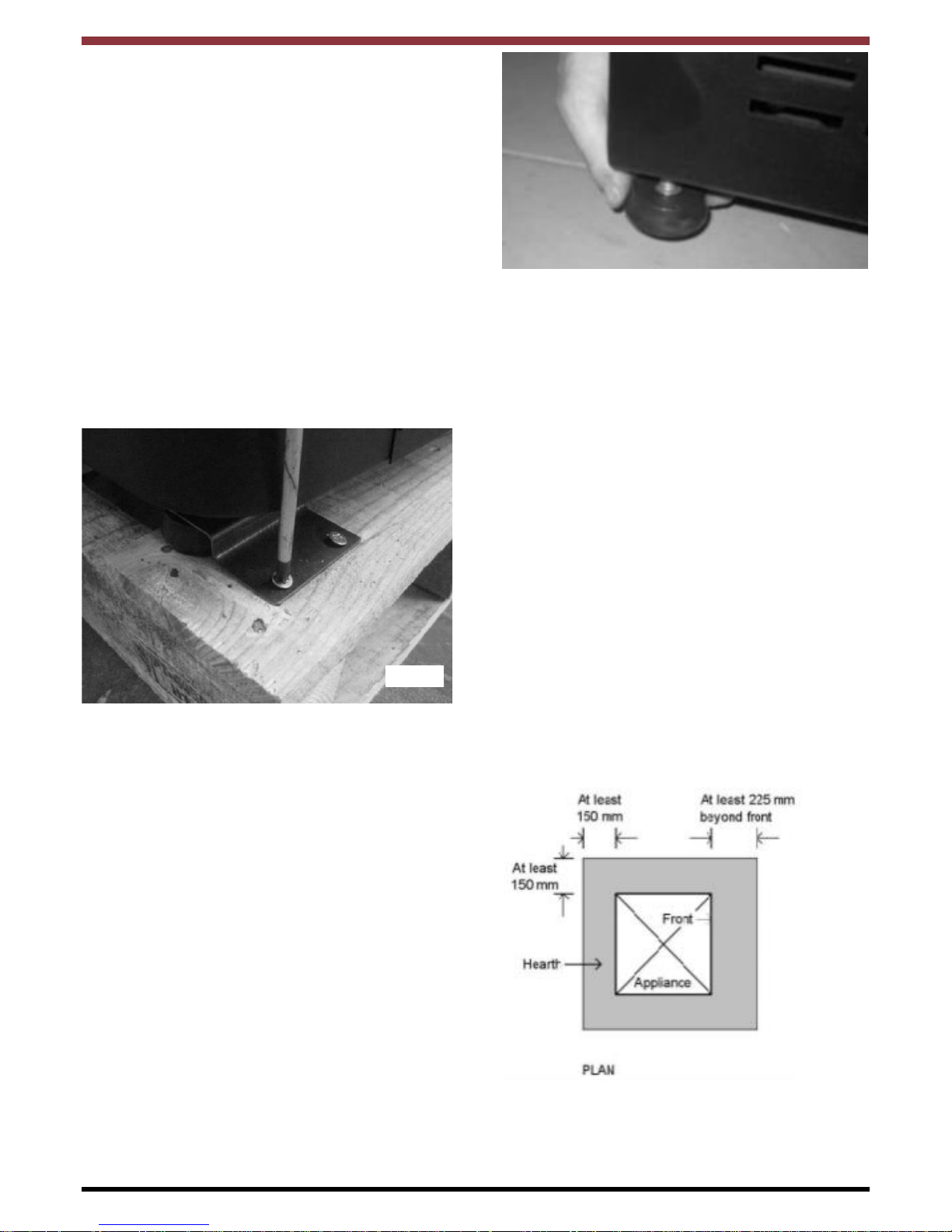

the unit to the wood pallet (Figure 1).

Fig. 1

Remove the instruction manual from the

package, it must be passed to the homeowner following installation.

Before installing the unit, please follow

these steps:

Check immediately after receipt if the delivered product is complete and in good state.

Any defects should be noted before

installing the appliance.

The unit is equipped with four feet at the

base, adjustable in height, allowing for the

easy regulation when installing the unit on a

non-levelled surface.

Installation Requirements

Installing the Pellet Stove

1 Location, Suitable area to be heated.

Floor support / Hearth.

2 Flue connection capable of producing

12pa flue draught.

3 Electrical requirements

4 Clearances

a) To combustibles

b) For servicing/ maintenance

5 Adequate air supply for combustion/

ventilation

Location

The floor should be capable of supporting the

weight of the product and hearth.

A solid non combustible hearth of minimum

thickness 12 mm, The hearth should extend

150 to the side and 225mm to the front

The appliance should be installed centrally in

the area to be heated.

Fig. 2

Page 9

9

Important: The appliance MUST be earthed.

Before installing the appliance, the power supply

system must be checked to ensure it has an effective earth circuit.

Important: the power supply cable must be of sufficient cross-section for the power requirement of

the appliance.

The supply voltage required for the stove is 220240 V at 50 Hz. Voltage variations greater than

10% of the rated value may cause irregular operation, or damage to the electrical system. The appliance must be positioned so that the domestic

power supply plug remains accessible.

If the power supply cable becomes damaged,

switch off the power and have it repaired by an

authorised Stanley service agent.

Flue/ chimney installation

Electrical connection

The appliance must be connected using a connecting pipe of diameter 80mm. . A Tee piece must be

installed at the base of the chimney to allow for

cleaning/ inspection. The main section of the flue

should be installed using a diameter 125mm flue

pipe which must begin within 1.5 metres of the appliance flue outlet

Single wall flue is permitted in the area to be heated,

outside of that area the flue must be insulated.

If the flue is to be routed though an existing

chimney it can be done using a flexible stainless

steel pipe with a register plate at the base of the

chimney , the area in the chimney external to the

flue liner must be back filled with insulation.

Where the flue pipe is installed external to

the dwelling, it must use twin wall insulated stainless

steel flue. The flue must have a vertical length of at

least 2 metres. A horizontal length is not recommended other than at the rear of the appliance, the

horizontal run should be no more than 600mm, on

all other sections of flue it is recommended that they

make an angle to the vertical of no more than 45

degrees.

The flue termination point/outlet must be above roof

level and in accordance with building regulations

part J.

IMPORTANT: All sections of the flue pipe must be

accessible for inspection, and allow for internal

cleaning, removal or replacement.

Fig. 3

Page 10

Clearances to combustibles

A clearance to combustibles of 100cm must be

maintained above the stove see Fig 5

A clearance to combustible of 50cm must be

maintained to either side of the stove , 30 cm

to the rear and 150 cm to the front of the stove

see Fig 10

In the event that the product is installed in a

non combustible recess, clearances for servicing,must be provided, 200mm to the rear

and 300mm to the sides.

VENTILATION/COMBUSTION AIR

The process of combustion requires oxygen, and

therefore air. When in operation, the stove draws air

through the 50mm diameter intake pipe at the rear

of the appliance. The external air can be connected

through a straight pipe of maximum length 60cm.

Otherwise the appliance will draw air from the room

in which case provision must be made for the air

requirement providing an air vent in the room. Poor

combustion may result if the room is insufficiently

ventilated.

A room containing an appliance (other than a room

sealed appliance) should have a permanent ventilation opening of

free area of at least:

6,500 mm² where air

permeability is greater than 5.0 m³/(hr.m2),

8,150 mm² where air

permeability is less than 5.0 m³/(hr.m2).

Where a flue draught stabilizer is used the total free

area should be

increased by 300 mm2

for each kW of rated output.

If the stove is located in a room containing another

air using appliance, it is essential to provide ventilation equivalent to the sum of the air requirement for

all appliances. the stove should not be installed in

the same room as an extractor fan.

FUEL

The appliance is suitable for use with wood pellets

certified to EN 14961-2 grade A1 with a diameter of

6 mm and a length that can range from 10 to 30

mm.

As fuel, pellets are completely environmentally

friendly, as they are made entirely of natural wood,

without glue or other chemical compounds. Pellets

have a high calorific value (4.7 to 5.3 kW/kg), and

low moisture content.

IMPORTANT: Pellets must be stored in a dry place.

Use only good quality pellets, without sawdust.

IMPORTANT NOTICE: The small quantities of

sawdust normally present at the bottom of the bags

should not be emptied into the tank, but should be

held inside the bag while pouring the pellets carefully so that the sawdust remains inside.

If sawdust accumulates in the tank, it should be

removed periodically with a vacuum cleaner (with

the door open and disconnecting the power plug

from the electricity supply), to prevent it entering the

loading system and causing serious malfunctions.

10

Fig. 6

Fig. 5

Page 11

Using the Pellet Stove

Before starting up the unit, please check the

following:

Ensure the unit is properly connected to the

power mains using the 230V AC power cable.

Check if the pellet reservoir is supplied with

pellets. Inside the pellet reservoir is a safety

grid to prevent users from reaching the worm

screw.

The combustion chamber of the stove and the

door are built in steel sheet painted with high

temperature paint, releasing fumes during the

first ignition due to the cure of the paint.

Avoid touching the equipment during the first

burn so as not to leave permanent marks on

the paint because it’s going through a plastic

phase during its curing process.

The stove has a probe for measuring the room

temperature. This probe is attached to the grid

on the rear panel For a good reading of the

room temperature, avoid the contact between

the end of the probe and the unit surfaces. You

may also attach the probe to the wall beside

the unit.

Remote Control

The infrared remote control allows the user to

turn the unit ON and OFF, control the fan airflow and increase or decrease the unit's power

level.

11

F

i

g

.

7

Fig. 8

Fig. 9

Page 12

12

Control and Display Panel

Button Function

Mode/ Esc Toggle between manual and automatic mode /

escape or exit menus .

Menu / OK when flashing Access menus /

ok -accept value

On / OFF Start unit when it is off ,

stop unit when it is on,

Resets error messages

Minus sign “-” scroll menus to te left,

increase and reduce the fan speed,

increase or reduce the set-point temperature

Plus sign “+” scroll menus to the right

increase or reduce the heat output

Selecting the Manual or Automatic Mode

To select the operating mode, press the

“Mode” key to select “Manu” for manual mode

or “Auto” for automatic mode.

“Manual mode”: In this mode, the unit will operate at the heat output selected using the "-"

key, ranging between 1 (minimum fire ) and 5

(maximum fire)

Auto mode: In this mode, the unit is turned on

at maximum power until reaching a temperature 1ºC above the selected temperature

(set point temperature). After reaching the

selected temperature, the unit switches to the

minimum operating power. The set-point temperature can be set between 5 and 40ºC by

pressing the "-" key.

The "+" key allows the user to set the

fan speed between 1-5 or to “A” for automatic operation.

Page 13

Setting the Date and Time

Setting the date:

press the Menu key twice until “Day and Time

is displayed.

Press “set” to see the following menu:

To set the year press “set”. The display starts

to flash. Press the “+” or “-” key to select the

desired year and then “ok” to confirm.

Press "+" to scroll to the next menu. The

“Month” is displayed.

To set the “month” press “set”. The display

starts to flash. Press the “+” or “-” key to select

the desired month and then “ok” to confirm

Press "+" to scroll to the next menu. The “Day

number” is displayed. This is the date / day of

the month.

To set the “Date” press “set”. The display starts

to flash. Press the “+” or “-” key to select the

desired date and then “ok” to confirm

Repeat the same steps to set the

Day of the Week ,Hour and minutes.

Setting the sleep Timer

This option is only displayed on the menu

when the stove is on. Press the “ menu “ button” until “ day and time “ is displayed , then

press the “ok “ button twice which will scroll to

the right to show the display as below

Press "set". The display starts to flash. Select

the desired time using the "-" and "+" keys.

After choosing the time, press "ok" to confirm.

Press “ esc” when finished to get back to the

normal display

The display will then switch between the normal screen and a screen similar to above

showing the current time and the sleep time at

which the stove will switch off.

13

Page 14

14

Setting the Programmer.

The unit is equipped with a timer that allows

the unit to be turned on or off at specified

times.

This can be set up by loading one of 10 preset

profiles in the software P01- P10.

Alternatively the unit can be programmed manually with up to 6 on/ off times per day.

To enable the timer press “set”. The “enable”

menu is displayed. The timer may only be activated after setting the configurations, as shown

in the following paragraph..

When the unit is set to switch on and off using

the programmer the display will flash between

the on/ off screen and a screen similar to

above.

To activate the Timer mode, press “Set” the

display starts to flash. Press the “+” or “-" key

to select “On” or “Off” and then “Ok” to confirm.

Press the "+" key to scroll to the "Load profile"

menu.

Press “set”; the display starts to flash. Press

the “+” or “-“ key to select the desired programme and then press “ok” to confirm. Press

the "+" key to go to menu "Reset".

Press the "+" key to go to menu "Reset".This

menu allows you to delete any programme settings. To do this, press "set". The "Confirm"

appears. Press "set" again to confirm that you

want to delete the settings or "esc" to exit.

Alternatively the unit's programmer lets you

choose from 6 different programmes for each

day of the week.

To set up programmes “P1” to “P6”, select the

desired programme using the “-” and “+” keys,

and press “set” to select. The "P1 Enable"

menu appears.

To run a user set program P1 the timer/ chrono

must be enabled and also the program must

be enabled

Press "Set" again and when the display starts

to flash, press the "+" or "-" keys to select "On"

or "Off". Press "ok" to confirm the selection.

Press the "+" key to go to the "start” time.

There are 10 weekly programmes available on

the Timer see “ fixed timer schedules at the

back of the manual . The selected programme

runs from Monday to Friday and from Saturday

to Sunday.

Page 15

15

To set the starting time for Programme P1,

press “set”. The display starts to flash. Press

the “+” or “-“ key to select the time and then

press “ok” to confirm. Press the "+" key to go

to the P1 .” Stop" menu.

To set the stopping time for Programme P1,

press “set”. The display starts to flash. Press

the “+” or “-“ key to select the time and then

press “ok” to confirm. Press the "+" key to go

to the "Air Temperature ”menu.

To set the set point temperature for

Programme P1, press “Set”. The display starts

to flash. Press the “+” or “-" key to select the

desired temperature, followed by “Ok” to confirm.

To set the operating power level (1 to 5) of

Programme P1, press “Set”. The display starts

to flash. Press the “+” or “-" key to select the

desired power level (1 to 5), and then “Ok” to

confirm. Press the "+" key to go to the "Days"

menu.

To select the days of the week that you want

P1 Programme to run, press "set" and then

select the day of the week using the “-” and “+”

keys. Press “set”. The display starts to flash.

Select "On" or "Off" using the "-" and "+" keys.

Press "ok" to confirm the selection. Press the

"esc" key to go to the "Days" menu. Press the

"esc" key again to go to the "program " menu.

Press the “+” key to move on to the next

menu.

Repeat the steps to set up Programs P2 to P6

or as many as are required.

Once the programs are set remember to

Page 16

16

User Information

To access the user information.

press “set” twice and then press “+” until

“ User Info is displayed”

press set to acess the “User info” then scroll

through the following list of parameters using

the “+” and “-”.

Control board code.

Security code

Display code

Parameters

Functioning time/ run hours

Service time/ time since last service

Service time/ time to next service

Carrying out/ current status

Exhaust Fan -Rpm

Consumption pellets- kg/hr

Fumes/ Flue gas temperature

Pellet feed time

Ignitions number

Setting menu,

To access the “settings”

press “set” twice and then press “+” until “settings” is displayed.

press “set” to acess the “settings” then scroll

through the following list of parameters using

the “+” and “-”.

Language

Eco mode

Back light

Remote control

ºC/ºF

Combustion recipe

Language

To select the language, press “set”.

Using the “+” or “-” keys, select the language.

En – English

Eco mode

When the “ECO” mode is enabled at the

same time as the Thermostat feature, the unit

will operate at maximum power until the thermostat opens contact (NO). The unit then will

operate at minimum power for a pre-set period

of time (Shutdown delay time: factory setting:

20 minutes).

Once the pre-set time is elapsed, the unit

shuts down. At the start of the Shutdown

phase, another timer for a different pre-set

period of time is triggered (Start-up delay time:

factory setting: 20 minutes), that will make the

unit enter the activation phase, when the thermostat closes contact (NC)

Start-up delay time (Delay time On): The

delay time that elapses between the moment

the thermostat closes (NC) until the unit is activated.

Shutdown delay time (Delay time Off): The

delay time that elapses between the

moment the thermostat opens (OC) until the

unit starts to shutdown.

Note: When using the feature for the first time,

you must press the On/Off button in the display. To enable the eco mode, press “set”. The

display starts to flash. To activate the eco

mode, press "set". The display starts to flash.

Select "On" or "Off" using the "-" and "+" keys.

Press "set" to confirm the selection.

To Select “ back light” , press “set”. The display

starts to flash. Press the "+" or "-" key to select

the time for the screen to light up, or select

"On" to keep the light permanently on. Press

“ok” to confirm.

Remote Control.

This feature enables and disables the remote

control, when the user wants to operate the

unit's thermostat remotely. Press "Set" and use

the "+" and "-" keys to select the "On" or "Off"

mode. Press "Ok" to confirm. Press the “+” key

to go to the “temperature units” menu.

Note: Some TV remote controls share the

same frequency as the unit’s remote control,

possibly influencing the unit's operation. If this

is the case, it is recommended to disable the

remote control feature.

ºC/ºF

To select ºC / ºF, press “set”. The display starts

to flash. Press the “+” or “-” key to select “ºC”,

“ºF” or “Auto”, and then “ok” to confirm.

Page 17

17

Combustion settings.

This allows for adjustment of the “pellet” quantity and the “air flow”

Pellet

This feature allows the user to increase or

decrease by 25% the pellet quantity during the

start-up and power process. Press "set". The

display starts to flash. Press "+" or "-" to

increase or decrease (between -10 to +10), as

required. Each unit must be multiplied by 2.5 to

obtain the correct percentage.

Air

This feature allows the user to increase or

decrease by 25% the rotation speed of the

fume extractor during the start-up and power

stages. Press “set”. The display starts to

flash. Press the "+" or "-" key to increase or

decrease (from -10 to

+10), as required. Each unit must be multiplied

by 2.5 to obtain the correct percentage. Press

“ok” to confirm.

Technical menu,

The technical menu is password protected, the

password is only provided to authorised technicians.

Operation.

Start up.

After loading the pellets into the hopper , press

and hold the ON/OFF button for 3 seconds, to

start the stove. During the lighting phase, the

display will show the message “Ignition” (until

this phase is completed.

The pellets are fed through the supply channel

to the burning pot (combustion chamber),

where they will be ignited using an igniter. This

process may take 5 to 10 minutes, depending

on whether the worm screw used to push

through the pellets has been previously filled or

not. Once the ignition phase is completed, the

message "On" appears on the display. The

heating power can be adjusted at any time by

pressing the power selection button for approximately 1 second. You can select from the five

pre-set power levels that are available. The

selected power is indicated on the display. The

initial power status at each start-up will correspond to the power level set before the last

stop.

Note Before starting the machine check that

the baffle plate is correctly positioned.

Shut down.

To turn off the pellet stove is carried out by

pressing the ON / OFF button for 3 seconds.

The display will show “shut down” until full

completion of this phase. The extractor will

operate until the fume temperature of 64ºC is

reached, to guarantee that all the material has

been burnt.

Note

Do not shut down the appliance by isolating the electrical supply .

Fig. 10

Fig 10 shows the baffle position as viewed

from inside the firebox. Item 1 on the picture

highlights that the tab on the baffle must overlap down over the vermiculite lining at the rear

of the firebox. Item 2 shows the gap to the

front between the baffle and the body of the

appliance, this should be approx 20mm

CO ALARM

The fitting of CO Alarms in the same room as the

appliance is a compulsory requirement under current Building Regulations. For ROI an additional

CO Alarm must be fitted either inside each bedroom or within 5 metres of the bedroom door, refer

to Building Regulations Part J. Further guidance on

the installation of a carbon monoxide alarm is

available in BS EN 50292:2002 and from the alarm

manufacturers instructions.

Page 18

18

Assembly Instruction for Installing the control panel, side panels , hopper cover and grill.

Installing the Casings on K100.

Before installing the casings you should check

immediately whether the packing is complete

and in perfect condition, possible damages or

parts missing must be reported before proceeding with installation. Following procedure

describes how to install the casings for the

K100 unit.

Equipment required.

Philips Screwdriver, PH2

10mm open ended spanner.

Place the display located inside the pellet hopper on the back of the unit, as shown in Figure

12. To perform this task, slightly unfasten the

screws located in the rear of the unit. When

securing the display it may be necessary to

adjust the height.

Note

When installing the display handle it with care

because there is a cable from the central unit

of the stove connected to it. Disconnecting this

cable will prevent the proper operation of the

equipment.

Fit the lower holes on the side covers (figure

13) to the guides located at the bottom of the

machine (Figure 14).

c) Next, attach the side casing by sliding it

downwards. During the assembly of the casing, make sure the flap on the top side (1) is

placed overlapping the structure and, simultaneously, covering the rear side of the unit on

the outside, as shown in Figure 15 & 16

Required parts

Fig. 11

Fig. 12

Fig. 13

Fig. 14

Page 19

19

d) Repeat the process described above for

the other side panel and secure using four

screws from the kit, two on each side, as

shown in Figure 17

Secure the side panels to the back of the unit

using 10 screws from the kit, as shown in

Figure 18.

The cover is equipped with four guide pins (1)

in the bottom to ensure its proper placement.

These guide pins must be fitted onto the

springs in located in the structure.

Note:

You may need to gently press the guide pins

onto the structure to secure them.

Fig. 15

Fig. 16

Fig. 17

Fig. 18

Fig. 19

Fig. 20

Page 20

20

Installing the Casings on K300.

Before installing the casings you should check

immediately whether the packing is complete

and in perfect condition, possible damages or

parts missing must be reported before proceeding with installation. Following procedure

describes how to install the casings for the

K300 unit.

Equipment required.

Philips Screwdriver, PH2

10mm open ended spanner.

8mm open ended spanner.

Hexagonal / allen key 4mm

Required parts

a) Fit the top plate as shown in figure 21.

To ensure that the top is properly seated, it

contains four pins on the bottom that should fit

the springs in the frame.

Fit the front grille, matching the holes in the

grille to the holes in the appliance (figure 22).

Fig. 21

Fig. 22

Fig. 23

Page 21

21

Fasten the upper part of the grill with two self

tapping screws location C, fixed directly to the

cover previously placed. Then fix with M5x12

screws at locations marked A and fix with

M5x12 screws and M5 nuts at locations

marked B, see figure 24.

When fitting the side covers, first fit the tabs,

(note 1 fig 25) to the slots (note 2 fig 26) and

then the studs 3 (note 3 fig 27) on the side

covers to the spring clips (note 4 fig 28) on the

chassis.

Fig. 24

Fig. 27

Fig. 26

F

i

g

.

2

5

Fig. 28

Fitting Side Covers

Page 22

22

Pellet Reservoir / Hopper

To access the pellet reservoir, open the lid on

the top of the unit by pushing down and sliding

the clip top the left.

The reservoir will hold approx 15 kg on the

K100 with the K300 holding approx 18kg to fill

the hopper carefully cut the corner of the bag

so the pellets can be poured into the hopper

without spilling outside of the rubber seal. Do

not pour dust into the hopper as it can impair

the feed screw mechanism.

T

h

e

s

to

v

e

r

e

q

u

ir

e

s

c

a

r

e

fu

l

m

a

in

te

n

a

n

c

e

s

e

e

la

b

e

l

o

n

th

e

h

o

p

p

e

r

lid

,

it

is

r

e

c

o

m

m

e

n

d

e

d

to

k

e

e

p

a

m

a

in

te

n

e

n

c

e

lo

g

a

s

o

u

tlin

e

d

in

m

a

in

te

-

n

a

n

c

e

lo

g

s

e

c

tio

n

. T

h

e

m

o

s

t

im

p

o

r

ta

n

t

th

in

g

is

to

p

e

r

io

d

ic

a

lly

r

e

m

o

v

e

th

e

a

s

h

e

s

fr

o

m

th

e

p

e

lle

t

b

u

r

n

in

g

c

h

a

m

b

e

r.

F

o

r

y

o

u

r

c

o

n

v

e

n

ie

n

c

e

,

y

o

u

m

a

y

u

s

e

a

h

o

u

s

e

h

o

ld

v

a

c

u

u

m

c

le

a

n

e

r.

T

h

e

c

le

a

n

in

g

o

p

e

r

a

tio

n

m

u

s

t

b

e

p

e

r

fo

r

m

e

d

a

fte

r

b

u

r

n

in

g

a

p

p

r

o

x

im

a

te

ly

3

0

k

g

o

f

p

e

lle

t

s

.

Prior to cleaning, the stove must be turned off

and allowed to cool to prevent injury.

The glass can only be cleaned when it is completely cold. It must be cleaned with a suitable

product in accordance with the instructions for

use and care must be taken to prevent the

product from reaching the sealing cord and

painted metal parts - so as not to cause undesired effects. The rope seal is fixed with adhesive so any contact with water or any other liquids must be avoided. If using a glass cleaning

spray, apply the product to a cloth first as

opposed to applying it directly to the glass.

Glass Cleaning

Daily Maintenance/ Ash Removal

Fig. 31 – Incorrect cleaning of the glass

Fig. 31

Fig. 30

Fig. 29

Fig. 33

Fig. 32

Fig.32 & 33 – Correct cleaning of the glass.

Cleaning the glass:

a) moisten a soft cloth with liquid;

b) clean the glass using the cloth

Page 23

23

Weekly Maintenance/Cleaning the flueways.

To perform this maintenance, pull the cleaning

bar from the heat exchanger see fig 34, then

open the door (b), vacuum the ash and clean

the burner (c).

There is a trapdoor hidden under the ashpan

which can be removed for cleaning.

Fig. 35A

Fig. 34

Fig. 38

Fig. 37

Fig. 36

Fig. 35B

Grate removal

Ash pan removal

Page 24

Clean the area under the trap door with a vacuum cleaner , carefully replace the trapdoor in

the correct location. It is critical that this component is returned to the correct location and

seated properly.

Note The frequency of maintenance depends

on the quality of the pellets burned.

Additional cleaning

Additional cleaning should be performed for

every 600-800 kg of pellets burned.

Remove the side covers, to access the side

lids of the combustion chamber. To clean the

interior of the unit, remove the screws

Removal of cleaning access panels K100

Removal of cleaning access panels K300

24

Fig. 39

Fig. 40

F

i

g

.

4

1

Fig. 42

Page 25

25

If you noticed that the flue gas extraction is not

effective, we recommend cleaning the interior

of the extractor with a vacuum cleaner, as

shown in figure 46. This operation should be

performed, on an annual basis at a very minimum, more frequent cleaning may be required.

Following removal of the panels . Using a 2025mm wide 80cm long steel brush,thoroughly

clean the channels and vacuum clean the

residue.

Fig. 43

Fig. 46

Fig. 45

Fig. 44

Page 26

Note

A “service” warning on the display (maintenance due) indicates that the unit has exceeded 2100 operating hours. In this case, the

client must perform the unit's maintenance procedure (following the instruction on the

Technical Manual). Once this procedure is

completed the hour meter may be reset, to

clear the waning message. This message does

not impact the normal operation of the unit. It is

simply a warning.

Note

The errors can be reset only when the error

information is flashing on the display. To reset

the error, press the ”Mode” button once while

displaying the error.

26

Maintenance Plan and Log

To ensure the proper operation of the unit,

maintenance operations must be performed,

as described in sections “Weekly cleaning”

through to “Additional cleaning “of this

Instruction Manual . There are specific maintenance tasks that must be performed by authorised technicians only. Please contact the person responsible for installing the unit. To make

sure the warranty remains valid, the maintenance operations performed on this unit must

comply with the frequency requirement specified in the manual, and the service technician

must fill and sign the maintenance log.

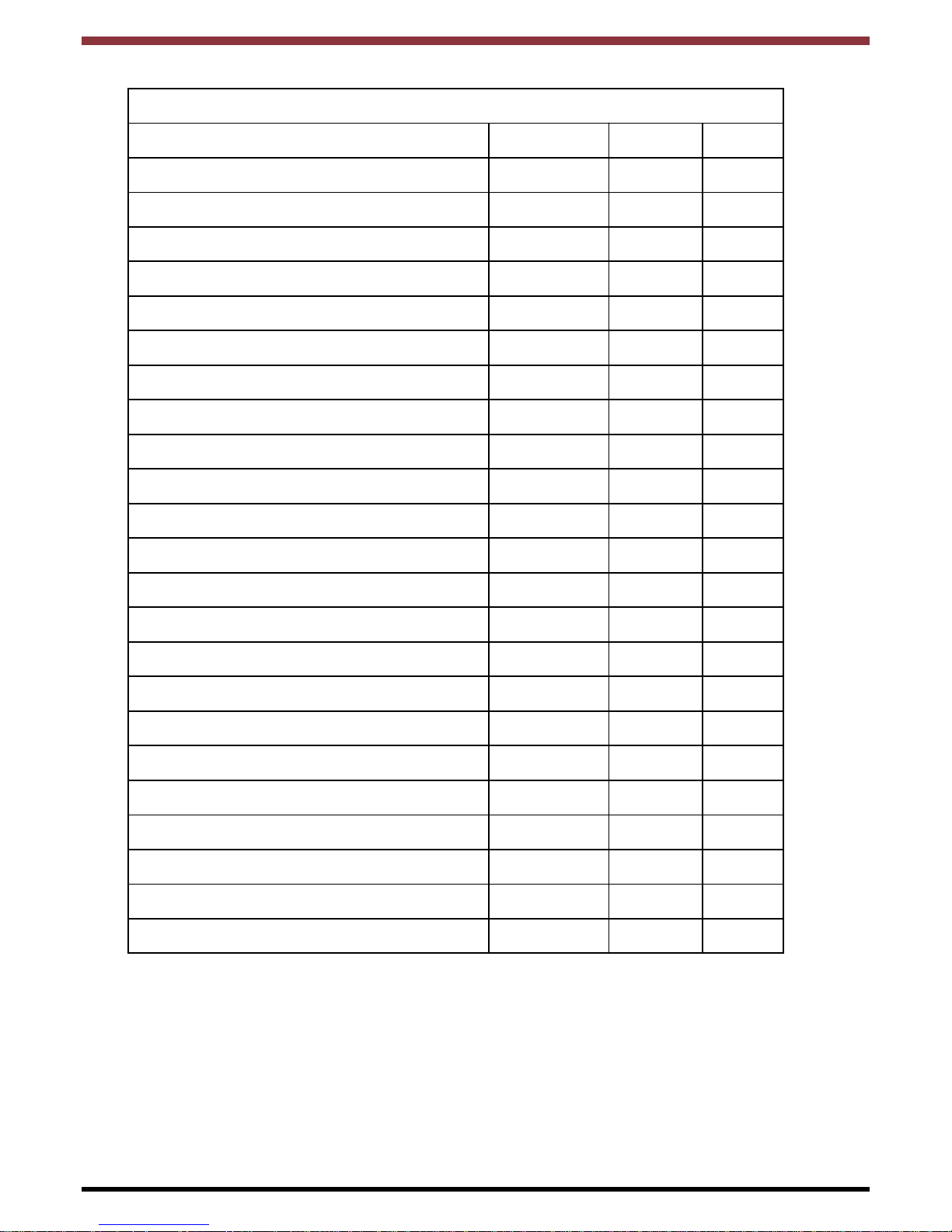

Service / Cleaning schedule

Empty the ashpan after each burning of 30kg

of pellets.

Vacuum the burner and under the trapdoor etc

on a weekly basis.

Brush and vacuum all residue from side channels after each burning of 600-800kg of pellets.

Full service by Technician including all of the

above and cleaning of the flue and flue fan etc

must be carried out on an annual basis, full

details are provided on the label fixed to the

hopper cover.

Page 27

Troubleshooting guide

Note

When triggered, all the alarms below cause the machine to shutdown. The alarm must be reset

and the unit restarted. To reset the unit, press the “On/Off” button for 10 seconds until the alarm

sounds.

27

Page 28

28

Page 29

29

Page 30

30

Electrical diagrams

Page 31

31

Ignition process

Page 32

Manufactured by

Waterford Stanley Ltd.,

Unit 401-403, IDA Industrial Estate, Cork Road,

Waterford, Ireland.

Tel: (051) 302300

Shut down

process

Item No: N00832AXX

NH 181218 Rev 001

32

Fixed timer program schedules

Loading...

Loading...