Page 1

Infrastructure

Safety, Operation & Maintenance

DECLARATION OF CONFORMITY

ÜBEREINSTIMMUNGS-ERKLARUNG

DECLARATION DE CONFORMITE CEE

DECLARACION DE CONFORMIDAD

DICHIARAZIONE DI CONFORMITA

______________________________________________________________________

I, the undersigned:

Ich, der Unterzeichnende:

Je soussigné:

El abajo firmante:

lo sottoscritto:

Nuerenberg, David

Surname and First names/Familiennname und Vornamen/Nom et prénom/Nom bre y apellido/Cognome e nome

hereby declare that the equipment specified hereunder:

bestätige hiermit, daß erklaren Produkt genannten Werk oder Gerät:

déclare que l’équipement visé ci-dessous:

Por la presente declaro que el equipo se especifica a continuación:

Dichiaro che le apparecchiature specificate di seguito:

1. Category:

Hydraverter

Kategorie:

Catégorie:

Categoria:

Categoria:

2. Make/Marke/Marque/Marca/Marca

STANLEY

3. Type/Typ/Type/Tipo/Tipo:

HV18300 / HV18301

4. Serial number of equipment:

Seriennummer des Geräts:

Numéro de série de l’équipement:

Numero de serie del equipo:

Matricola dell´attrezzatura:

All

Has been manufactured in conformity with

Wurde hergestellt in Übereinstimmung mit

Est fabriqué conformément

Ha sido fabricado de acuerdo con

E’ stata costruita in conformitá con

Directive/Standards

Richtlinie/Standards

Directives/Normes

Directriz/Los Normas

Direttiva/Norme

No.

Nr

Numéro

No

n.

Approved body

Prüfung durch

Organisme agréé

Aprobado

Collaudato

EN ISO

EN ISO

3744

13732-1

Self

Self

5. Special Provisions: None

Spezielle Bestimmungen:

Dispositions particulières:

Provisiones especiales:

Disposizioni speciali:

6. Representative in the Union: Patrick Vervier, Stanley Dubuis 17-19, rue Jules Berthonneau-BP 3406 41034 Blois Cedex, France.

Vertreter in der Union/Représentant dans l’union/Representante en la Union/Rappresentante presso l’Unione

Done at/Ort/Fait à/Dado en/Fatto a STANLEY Infrastructure, Milwaukie, Oregon USA Date/Datum/le/Fecha/Data 4-28-2018

Signature/Unterschrift/Signature/Firma/Firma

Position/Position/Fonction/Cargo/Posizione North America Quality Manager

HV18 Hydraulic Power Unit

40404 User Manual 5/2019 Ver. 12

Page 2

Safety Precautions

Protection

Protection

Wear a Mask

The Safety Alert Symbol alerts you to potential

personal injury hazards. Obey all safety messages

that follow to avoid possible injury or death.

Indicates an imminently hazardous situation which

will result in death or serious injury.

Indicates a potentially hazardous situation which

could result in death or serious injury.

Indicates a potentially hazardous situation which

could result in property damage.

Always observe safety symbols. They are included for your safety and for the

protection of the tool.

WARNING: Read all safety warnings and instructions. Failure

to follow warnings and instructions may result in tool damage

and/or serious injury.

WARNING: To reduce the risk of injury, read the instruction

manual.

General

• Do not discard safety instructions. Give to the operator.

• This tool will provide dependable service if operated in accordance

with the instructions given in this manual. Read and understand this

manual and any stickers and tags attached to the tool and hoses before

operation. Failure to do so could result in personal injury or equipment

damage.

• Inspect the tool before each use and ensure all decals are legible.

Contact STANLEY if replacements are needed.

• Establish a training program for all operators to ensure safe operation.

Do not operate the tool unless thoroughly trained or under the

supervision of an instructor. Keep out of the reach of children.

• Operators and maintenance personnel shall be able to physically handle

the bulk, weight and power of the tool.

• Do not operate a damaged, improperly adjusted, modified or

incompletely assembled tool.

• Do not operate the tool in explosive atmospheres, such as in the

presence of flammable liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

• Provide adequate ventilation in closed areas when operating a gas or

diesel hydraulic power source.

• Do not inspect, carry, clean, change accessories or perform

maintenance on the tool while the power source is connected.

Accidental engagement of the tool can cause serious injury.

• Stay alert, watch what you are doing and use common sense when

operating a hydraulic tool. Do not operate this tool if you are tired or

under the influence of drugs or alcohol. A moment of inattention while

operating hydraulic tools may result in serious injury.

• Assess risks to others around you before operating the tool.

• During operation, do not contact mechanisms, accessories or hardware

as they can become very hot; use your Personal Protection Equipment

(PPE).

• Use and maintain the tool as stated in this manual. Misuse of this tool

is forbidden. Misuse of the tool can cause serious injury. Do not modify

the tool in any way.

• Supervising personnel should develop additional precautions relating to

the specific work area and local safety regulations.

• Do not overreach. Maintain proper footing and balance at all times

when using the tool.

• Slips, trips and falls are major causes of workplace injury. Be observant

of hoses lying about the work area, as they can be a tripping hazard.

• Operator must start in a work area without bystanders and must assess

the risk to bystanders, including the risk of serious injury or death

caused by the tool or accessories dropped from an elevated height.

• Operators must be familiar with all prohibited work areas such as

excessive slopes and dangerous terrain conditions.

• Only use clean hydraulic fluid and lubricants that have been

recommended by STANLEY.

• Ensure tools are working properly and safely by performing preventative

maintenance (PM) procedures.

• Repair and service of this tool must only be performed by an authorized

and certified dealer.

• Use only replacement parts recommended by STANLEY.

• Check fastener tightness daily and before each use.

• Never operate the tool if you cannot be sure that underground utilities

are not present, such as electrical cables, gas pipes, etc. These can

cause a hazard if damaged with the tool.

• The tool is not insulated against coming into contact with electric

power. Use hose certified as non-conductive.

• Use only hoses and hose couplings that are rated for a minimum

working pressure of 2500 PSI (172 BAR).

• Keep the work area well lit.

• Prevent unintentional starting. Ensure the tool is in the off position

before connecting to power source, picking up or carrying the tool.

• In spite of the application of relevant safety regulations and the

implementation of safety devices, certain residual risks cannot be

avoided. These risks are: pinching risk when operating the tool control

valve.

Dust and Fumes

• WARNING: Use of this tool on certain materials could generate dust

potentially containing a variety of hazardous substances such as

asbestos, silica or lead. Inhalation of dust containing these or other

hazardous substances could result in serious injury, cancer or death.

Protect yourself and those around you. Research and understand the

materials you are cutting. Follow correct safety procedures and comply

with all applicable national, state or provisional health and safety

regulations relating to them, including, if appropriate arranging for the

safe disposal of the materials by a qualified person.

• When dust or fumes are created, control them at the point of emission.

Direct tool exhaust to minimize disturbance of dust.

• Operate and maintain the tool as recommended in this manual to

minimize dust.

• Use respiratory protection in accordance with employers instruction or

as required by occupational health and safety regulations.

• Avoid prolonged contact with dust. Allowing dust to get into your

mouth, eyes or lay on the skin may promote absorption of harmful

chemicals.

PPE

• Always wear safety equipment such as impact resistant goggles, ear

protection, head protection, breathing protection and safety shoes at all

times when operating the tool.

• Hands may be exposed to hazards, impacts, cuts, abrasions and heat.

Wear gloves.

• Use PPE that conforms to standards ANSI Z87.1 (Eye and Face

Protection), ANSI Z89.1 (Head Protection), ANSI Z41.1 (Foot Protection)

and ANSI S12.6 (S3.19) (Hearing Protection).

• Do not wear loose fitting clothing when operating the tool. Loose

fitting clothing can get entangled with the tool and cause serious injury.

M003

Wear Ear

M004

Wear Eye

M016

Sound

• Exposure to high noise levels can cause permanent, disabling hearing

loss and other problems, such as tinnitus (ringing, buzzing, whistling

or humming in the ears). Use hearing protection in accordance with

employer’s instructions and as required by occupational health and

safety regulations. Appropriate controls to reduce the risk can include

actions such as damping materials to prevent work pieces from

“ringing”.

• Use and maintain as recommended in the manual to prevent an

unnecessary increase in noise levels.

Vibration

• If you experience numbness, tingling, pain or whitening of the skin

in your fingers or hands, stop using the tool. Tell your employer and

2 | HV18 User Manual

Page 3

consult a physician.

• Wear warm clothing when working in cold conditions and keep your

hands warm and dry.

• Exposure to vibration can cause disabling damage to the nerves and

blood supply of the hands and arms.

• Use and maintain as recommended in the manual to prevent an

unnecessary increase in vibration.

• Check the vibration level after each service. If higher than normal,

contact your STANLEY dealer.

Hydraulic

• Warning: Hydraulic fluid under pressure could cause skin injection

injury. Do not check for leaks with your hands. If you are injured by

hydraulic fluid, get medical attention immediately.

• Do not let hydraulic oil get on the skin. Hydraulic oil is hot. Wear

Personal Protection Equipment (PPE) at all times.

• If exposed to hydraulic fluid, wash hands immediately.

• Do not exceed the maximum relief valve setting stated on the tool.

• Inspect and clean couplers before use, daily. Replace damaged couplers

immediately.

• Hydraulic circuit control valve must be OFF before coupling or

uncoupling tools. Failure to do so may damage the couplers and cause

overheating of the hydraulic system.

• Ensure the couplers are properly connected and are tight.

• Do not operate the tool at fluid temperatures above 140°F (60°C).

Higher temperatures can cause operator discomfort and damage to the

tool.

• Do not exceed the rated flow and pressure as stated on the tool. Rapid

failure of the internal seals may result.

HV18 User Manual | 3

Page 4

10

A

9

8

11

7

12

13

14

1

2

3

4

5

6

B

1

3

4 | HV18 User Manual

2

Page 5

C

5

8

7

1

D

4

3

7

90 °

8

HV18 User Manual | 5

Page 6

E

1

2

3

19 20

4

5 6 7 9 8 10 11 12

22

13 14

21

15

16

6 | HV18 User Manual

18

17

Page 7

F

1 2 3 4 5 6 7 8 9 10 11

15 16 17

13 14

12

18

19 20

HV18 User Manual | 7

Page 8

G

7

10

9

8

1 2

11

12

4

5

3

H

14

13

12

6

4

3

2

1

5 6

7

8

9

10

8 | HV18 User Manual

11

Page 9

Manifold Parts Illustration - Detail E

ITEM P/N DESCRIPTION

1

350237 Hex Plug

2

18952 Steel Ball

3

40089 Manifold

4

05043 Relief Valve

5

350041 Hex Plug

6

40137 Tool Circuit Control Valve

7

07882 Adapter

8

03976 Male Coupler

9

03975 Female Coupler

10

16800 Plug

11

37301 Flow Regulator

12

350237 Hex Plug

13

27634 Cap Screw

14

04585 Washer

15

40415 Operation Decal - Model HV18300

48842 Operation Decal - Model HV18301

16

35686 Hydraulic Fluid Decal

17

04353 Nylock Nut

18

40413 Elbow Adapter

19

08045 Hose Clamp

20

04306 Hose - 19 Inches Long

21

350104 Straight Thread Connector

22

02773 Adapter

Fan & Oil Cooler Parts Illustration - Detail F

ITEM P/N DESCRIPTION

1

08667 Screw

2

40084 Inlet Ring

3

08669 Gasket

4

27931 Cap Screw

5

08035 Blower Wheel

6

10706 Cap Screw

7

40079 Blower Hub

8

40083 Bushing

9

24142 Hex Flange Bolt

10

40433 Hex Flange Bolt

11

40401 Angle Bracket

12

12787 Flange Nut

13

35782 Spacer

14

40435 Hex Flange Bolt

15

07783 Blower Housing

16

40053 Cooler Mount

17

08668 Screw

18

40433 Screw

19

40078 Cooler

20

40054 Cooler Mount

Motor Parts Illustration - Detail G

ITEM P/N DESCRIPTION

1

40407 Hose Assembly

2

40406 Hose Assembly

3

40414 45° Elbow Hydraulic Adapter

4

08045 Hose Clamp

5

04306 Hose - 16 Inches Long

6

04321 Straight Thread Elbow Adapter

7

40406 Hose Assembly

8

06151 Cap Screw

9

00683 Lock Washer

10

40081 Hydraulic Pump - Model HV18300

48841 Hydraulic Pump - Model HV18301

11

05967 Straight Thread Elbow Adapter

12

04321 Straight Thread Elbow Adapter

Hydraulic Oil Reservoir Parts Illustration - Detail H

ITEM P/N DESCRIPTION

1

40082 Hydraulic Oil Tank

2

40133 Grip Plate

3

43687 Cap Screw

4

40080 Filter Assembly

5

40364 45° Elbow Adapter

6

08045 Hose Clamp

7

04306 Hose - 4 3/4 Inch Long

8

40405 Hose Barb

9

40082 Hydraulic Tank

10

40433 Hex Flange Bolts

11

40075 Frame Weldment

12

11179 Hose Clamp

13

07747 Suction Sleeve

14

07749 Suction Tube

HV18 User Manual | 9

Page 10

What is the HV18 Hydraulic Power Unit?

HV18 is a hydraulic power unit that connects to a carrier, such as a backhoe,

excavator or skidsteer loader, and uses that carriers main hydraulic circuit to

power a self contained 7-9 GPM (27-34 LPM) hydraulic circuit suitable for

running hand-held tools. Model HV18300 uses an input supply of 16-35

GPM (61-133 LPM) and model HV18301 uses an input supply of 13-25 GPM

(49-95 LPM).

Specifications

Hydraulic Supply

Hydraulic Power Source

Flow

Hydraulic Power Source

Supply Relief Pressure

Supply Port Size -12 (3/4) SAE ORB

Hydraulic Output

Output Flow 8 GPM (30 LPM)

Output Relief Pressure 2150 PSI (148 BAR)

Maximum Back Pressure 400 PSI (28 BAR)

Output Couplers 3/8 inch Flush Face

Output Port Size 1/2 inch NPT

Min. Hose Pressure Rating 2500 PSI (175 BAR)

Max. Hydraulic Oil

Temperature

HTMA/EHTMA Category Type II, Category D

Tool Weight 109 lbs.

Tool Size 21 inches x 19 inches x 18 inches

Sound Declaration

Measured A-Weighted sound power

level

Measured A-Weighted Sound Pressure 93.1 dBA

Uncertainty, Kpa, in decibels 1.29 dBA

Values determined according to noise test code given in ISO 3744.

HV18300 - 16-35 GPM (61-132 LPM)

HV18301 - 13-25 GPM (49-95 LPM)

HV18300 - 2000-3000 PSI (138-206 BAR)

HV18301 - 2300-3000 PSI (159-206 BAR)

140°F (60°C)

101.1 dBA

Do not install or perform maintenance while the

a hydraulic power source is connected. Accidental

engagement of the tool can cause serious injury.

Disconnect and depressurize the hydraulic power source

before installing or performing maintenance.

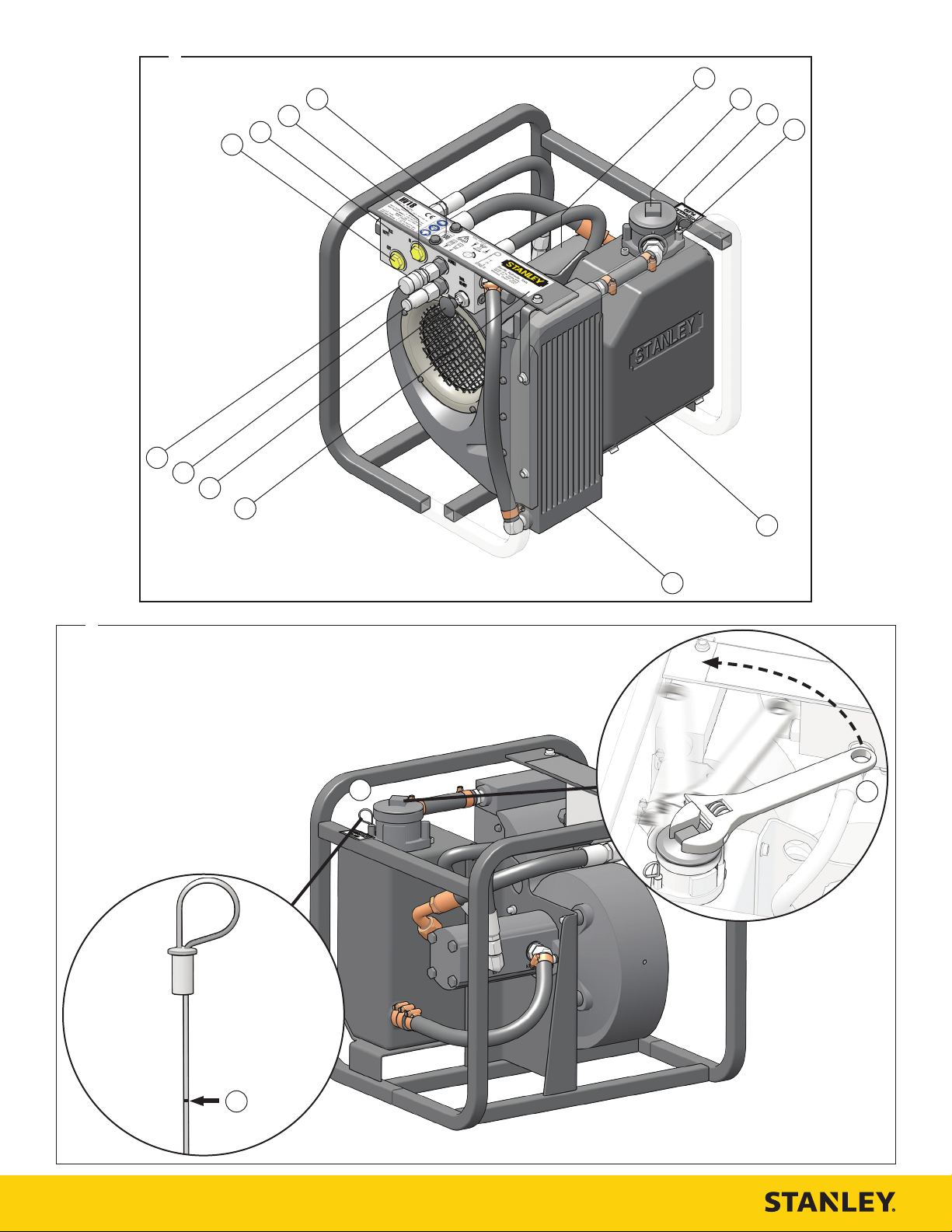

Check and Fill Hydraulic Oil Reservoir - Detail B

1. Remove the dipstick from the hydraulic reservoir.

2. Ensure the hydraulic oil level is between the max fill line and the bottom

of the dipstick.

3. If the hydraulic oil level is low, remove the hydraulic oil reservoir cap

using a crescent wrench.

4. Fill the hydraulic reservoir to the max fill line on the dipstick with an ISO

Grade 32 hydraulic oil.

Note: Use clean hydraulic oil and filling equipment. Only use hydraulic oils

recommended by STANLEY. See “STANLEY Recommended Hydraulic Oils” on

page 10.

5. Reinstall the cap before operation.

STANLEY Recommended Hydraulic Oils

Brand Description Biodegradable?

Clarion (CITGO) Green Bio 32 Yes

Exxon Mobil EAL 224H Yes

Chevron Clarity AW32 Yes

Terresolve Envirologic 132 Ye s

Shell Naturelle HF-E-32 Yes

CITGO Hydurance AW32 No

AMS Oil HVH 32 No

Exxon Mobil DTE 10 Excel No

Shell S2 V 32 No

Chevron Rando HDZ 32 No

Conoco Phillips Unax AW-WR-32 No

Exxon Mobile Univis HV126

No

(Recommend for extreme cold)

Parts of a HV18 - Detail A

1

Hydraulic Pump

2

Hydraulic Oil Filter

3

Hydraulic Fluid Decal

4

Hydraulic Oil Level Dipstick

5

Hydraulic Oil Reservoir

6

Hydraulic Oil Cooler

7

Operation Decal (includes CE mark &

EHTMA Circuit Type “D” Decal)

8

Tool Circuit Control Valve

9

Tool Circuit Male Coupler

10

Tool Circuit Female Coupler

11

Hydraulic Power Source“Out” Port

12

Serial Number and Year of Manufacture

13

Hydraulic Power Source “In” Port

14

Sound Power Decal

Tool Setup

Connect to a Hydraulic Power Source - Detail C

1. Ensure the HV18 tool circuit control valve is in the off position.

Note: The off position is when the control valve pegs are in the deepest

groove of the valve, pushed all the way in.

2. Using a calibrated flow and pressure gauge, check the output of the

hydraulic power source. Ensure it matches the flow and pressure in

“Specifications” on page 10. Hydraulic fluid must be 50°F or above.

Preheat if necessary.

3. Ensure that the hydraulic power source is equipped with a relief valve

set to open at the maximum relief pressure. See “Specifications” on

page 10.

4. Power down and depressurize the hydraulic power source.

5. Remove the plugs from the hydraulic power source ports.

6. Wipe the hydraulic power supply hose couplers with a clean, lint free

cloth.

7. Connect the hydraulic power source pressure hose to the supply “IN”

port.

8. Connect the hydraulic power source return hose to the supply “OUT”

port.

9. Ensure the hydraulic power supply couplers are undamaged, properly

connected and are tight.

10. Power up the hydraulic power source.

10 | HV18 User Manual

Page 11

Tool Operation - Detail D

Use the HV18 as stated in this manual. Misuse of this

tool is forbidden. Misuse of the tool can cause serious

injury. Do not modify the tool in any way.

1. Ensure the tool circuit control valve is in the off position.

Note: The off position is when the control valve pegs are in the deepest

groove of the valve, pushed all the way in.

2. Wipe hose couplers with a clean, lint free cloth.

3. Connect the hydraulic tool pressure hose to the male quick coupler

marked “Pressure”.

4. Connect the hydraulic tool return hose to the female quick coupler

marked “Return”.

5. Ensure couplers are undamaged, properly connected and are tight.

6. Ensure the activation trigger for the hydraulic tool being used is set to

the “OFF” position.

Tool Storage & Transport

Storage

Plug open hydraulic ports. Clean the tool and store in a clean, dry space that

is safe from damage.

Transport

Secure the HV18 frame to the transport vehicle. Lift only as high as necessary

to load. NEVER lift or transport over people. Ensure HV18 is secured and will

not move during transport. An unsecured tool could cause personal injury or

damage to the tool.

Tool Disposal

Hydraulic Oil

Hydraulic oil can contaminate the air, ground and water if not properly

recycled. Recycle hydraulic oil in accordance with all State, Federal and local

laws, at your local oil recycling facility.

Hydraulic Hoses

Hang hydraulic hoses to drain. Collect the oil for recycling. Contact your local

municipal recycling authorities for an approved hydraulic hose recycling site.

Beware of unintentional starting. Serious injury can

result. Ensure the tool is in the off position before

connecting to power source, picking up or carrying the

tool to prevent unintentional starting.

7. Pull the tool circuit control valve out. Turn the knob 90°.

8. Set the valve pegs into the shallow groove of the valve.

9. Use the hydraulic tool.

10. When finished using the tool, pull the tool circuit control valve out, turn

the knob 90° and set the valve pegs into the deepest groove on the

valve.

Note: If you encounter a breakdown or the HV18 stops for any reason,

set the tool circuit control valve to the “OFF” position, power down and

depressurize the hydraulic power source. Disconnect HV18 from the

hydraulic power source and plug the supply ports before performing

maintenance.

Tool Maintenance

Daily Maintenance

1. Maintain the tool in an area that is clean, free of dirt and debris and is

well lit.

2. Remove hydraulic power from the tool.

3. Throughly clean the fan screen and around the oil cooler.

4. Check all hydraulic connections and hoses for damage. Replace

damaged parts before operating the tool.

5. Using the dipstick, check the hydraulic oil reservoir fill level. Fill if

necessary (see “Check and Fill Hydraulic Oil Reservoir - Detail B” on

page 10.

6. Inspect tool to ensure all decals are legible. Contact STANLEY if

replacements are needed.

7. Using a calibrated flow and pressure gauge, check the output of the

hydraulic power source. Ensure it matches the flow and pressure in

“Specifications” on page 10.

Replace the Hydraulic Oil Filter

The hydraulic oil filter must be changed every 200 hours. Change the filter

more often if HV18 is operating in a cold, moist or dusty environment.

1. Remove hydraulic power from the tool.

2. Remove the hydraulic oil reservoir cap using a crescent wrench.

3. Pull the filter out of the filter assembly.

4. Replace the filter element (part number 40408).

Note: Push the filter down into the filter assembly until you feel it click into

place.

5. Install the cap and lightly tighten with a crescent wrench.

Tool Body

Drain hydraulic oil from the tool, making sure to collect the oil for recycling.

Disassemble the tool and dispose of all non-metal parts. Recycle the metal

components. Contact your local municipal recycling authorities for recycling

instructions.

Accessories

HV18 Accessories

Description Part Number

Supply Hose Kit 51290

Filter Service Kit 43592

Filter Element 40408

Troubleshooting

Problem Possible Cause Solution

Ensure the power source

is delivering proper

flow and pressure.

See “Specifications”

on page 10. Check

regularly. Ensure supply

hoses are properly

connected. See

“Connect to a Hydraulic

Power Source - Detail

C” on page 10.

Ensure the hydraulic

power supply relief

valve is set properly.

See “Specifications” on

page 10.

Contact your STANLEY

dealer for service.

Ensure the power source

is delivering proper

flow and pressure.

See “Specifications”

on page 10. Check

regularly. Ensure supply

hoses are properly

connected. See

“Connect to a Hydraulic

Power Source - Detail

C” on page 10.

HV18 pump does not

run with the hydraulic

supply circuit on.

HV18 tool hydraulic

circuit does not

operate tools properly.

Supply hoses not

connected, are

obstructed or

hydraulic power

source is not

providing adequate

flow and pressure.

Hydraulic power

supply relief set too

low.

HV18 pump has

failed.

Supply hoses not

connected, are

obstructed or

hydraulic power

source is not

providing adequate

flow and pressure.

HV18 User Manual | 11

Page 12

STANLEY Infrastructure

6430 SE Lake Road, Portland, Oregon 97222 USA

(503) 659-5660 / Fax (503) 652-1780

www.stanleyinfrastructure.com

© 2014 Stanley Black&Decker, Inc.

New Britain, CT 06053 USA

Loading...

Loading...