Page 1

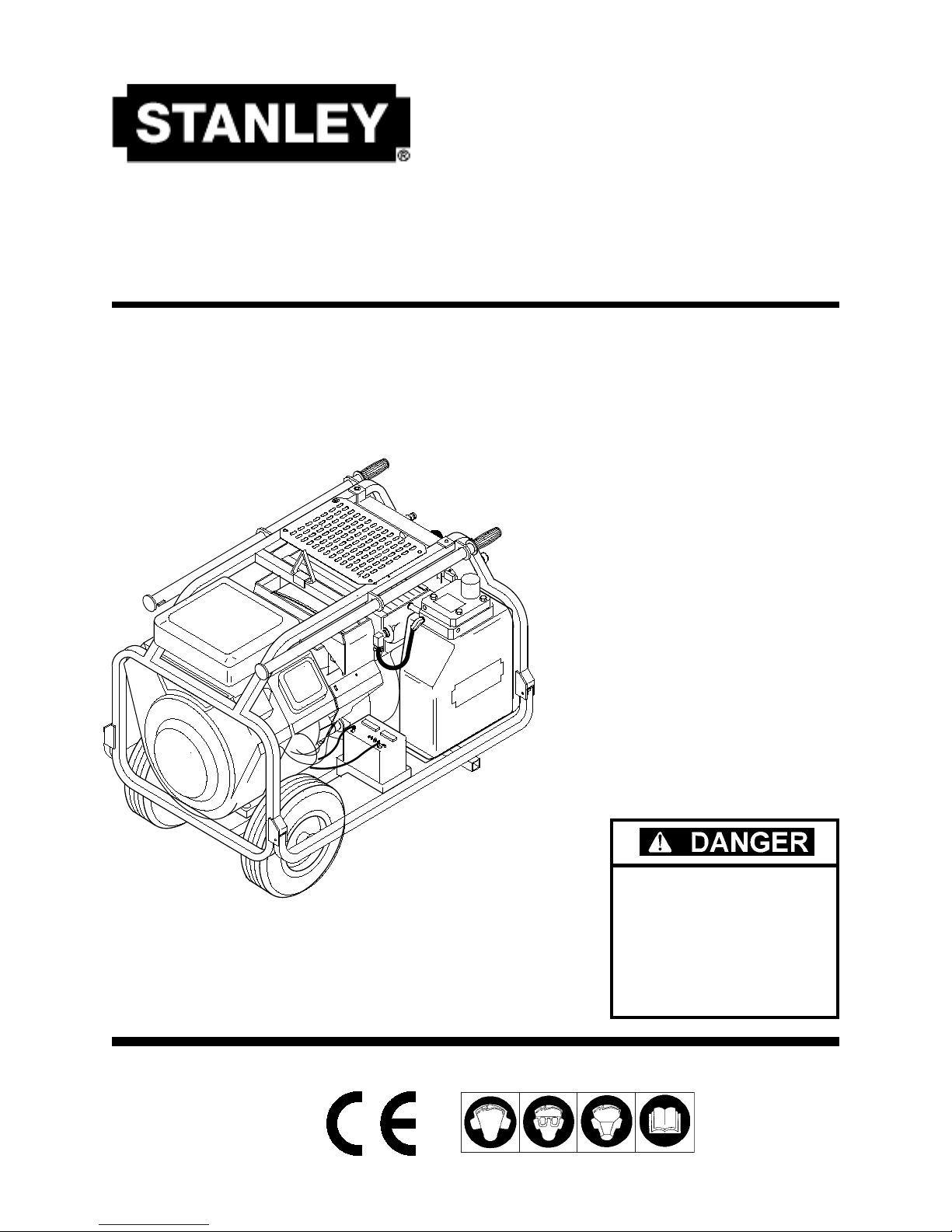

HP1

COMPACT POWER UNIT

Safety, Operation

and

Maintenance

Manual

Copyright © 1998

The Stanley Works

All rights reserved

OPS/MAINT USA & CE VERSION

Printed in U.S.A.

24280 06/97 Ver 3

SERIOUS INJURY OR DEASERIOUS INJURY OR DEA

SERIOUS INJURY OR DEA

SERIOUS INJURY OR DEASERIOUS INJURY OR DEA

COULD RESULCOULD RESUL

COULD RESUL

COULD RESULCOULD RESUL

IMPROPER REPIMPROPER REP

IMPROPER REP

IMPROPER REPIMPROPER REP

OF THIS TOOLOF THIS TOOL

OF THIS TOOL

OF THIS TOOLOF THIS TOOL

REPREP

AIRS AND / OR SERVICE TOAIRS AND / OR SERVICE TO

REP

AIRS AND / OR SERVICE TO

REPREP

AIRS AND / OR SERVICE TOAIRS AND / OR SERVICE TO

THIS TOOL MUST ONLTHIS TOOL MUST ONL

THIS TOOL MUST ONL

THIS TOOL MUST ONLTHIS TOOL MUST ONL

DONE BDONE B

DONE B

DONE BDONE B

CERTIFIED DEALERCERTIFIED DEALER

CERTIFIED DEALER

CERTIFIED DEALERCERTIFIED DEALER

T FROM THET FROM THE

T FROM THE

T FROM THET FROM THE

AIR OR SERVICEAIR OR SERVICE

AIR OR SERVICE

AIR OR SERVICEAIR OR SERVICE

..

.

..

Y AN AY AN A

UTHORIZED ANDUTHORIZED AND

Y AN A

UTHORIZED AND

Y AN AY AN A

UTHORIZED ANDUTHORIZED AND

..

.

..

Y BEY BE

Y BE

Y BEY BE

THTH

TH

THTH

Page 2

INDEX

Index (this page) ...................................................................................... 1

Hydraulic Hose Requirements ................................................................. 6

Operation ......................................................................................... 7 - 10

Preparation for Use ........................................................................... 7

Hydraulic Connections ................................................................ 7 - 8

Startup ...................................................................................... 9 - 10

Cold Weather Startup ..................................................................... 10

Tool Operation .................................................................................10

Optional Equipment ............................................................................... 28

Parts Lists ...................................................................................... 19 - 20

Parts Drawings .............................................................................. 21 - 27

Engine Assembly (Fig. 1) ................................................................ 21

Frame Assemblies (Fig. 2) .............................................................. 22

Choke Cable Assembly (Fig. 3) ...................................................... 23

Actuator Assembly (Fig. 4) .............................................................. 23

Dash Panel & Valve Assembly (Fig. 5) ........................................... 24

Hydraulic Tank & Filter Assembly (Fig. 6) ....................................... 25

Hose & Fitting Connections (Fig. 7) ................................................26

Wiring Diagram (Fig. 8) .................................................................. 27

Routine Maintenance ............................................................................. 11

Engine ............................................................................................. 11

Hydraulic System ............................................................................ 11

Storage............................................................................................ 11

Safety Precautions ............................................................................ 2 - 5

Local Safety Regulation .................................................................... 4

Safety Stickers & Tags ......................................................................5

Sales & Service ......................................................................... Last Page

Service Instructions ....................................................................... 12 - 14

Specification & Capacities ..................................................................... 18

Testing & Troubleshooting ............................................................. 15 - 16

Troubleshooting Chart ........................................................................... 17

Warranty ................................................................................................ 29

SERIOUS INJURY OR DEASERIOUS INJURY OR DEA

SERIOUS INJURY OR DEA

SERIOUS INJURY OR DEASERIOUS INJURY OR DEA

IMPROPER REPIMPROPER REP

IMPROPER REP

IMPROPER REPIMPROPER REP

REPREP

AIRS AND / OR SERVICE TO THIS EQUIPMENT MUSTAIRS AND / OR SERVICE TO THIS EQUIPMENT MUST

REP

AIRS AND / OR SERVICE TO THIS EQUIPMENT MUST

REPREP

AIRS AND / OR SERVICE TO THIS EQUIPMENT MUSTAIRS AND / OR SERVICE TO THIS EQUIPMENT MUST

ONLONL

Y BE DONE BY BE DONE B

ONL

Y BE DONE B

ONLONL

Y BE DONE BY BE DONE B

DEALERDEALER

DEALER

DEALERDEALER

For the nearest authorized and certified dealer, call Stanley Hydraulic Tools at one of the locations listed on the back of this manual.

..

.

..

TH COULD RESULTH COULD RESUL

TH COULD RESUL

TH COULD RESULTH COULD RESUL

AIR OR SERVICE OF THIS EQUIPMENTAIR OR SERVICE OF THIS EQUIPMENT

AIR OR SERVICE OF THIS EQUIPMENT

AIR OR SERVICE OF THIS EQUIPMENTAIR OR SERVICE OF THIS EQUIPMENT

Y AN AY AN A

Y AN A

Y AN AY AN A

UTHORIZED AND CERTIFIEDUTHORIZED AND CERTIFIED

UTHORIZED AND CERTIFIED

UTHORIZED AND CERTIFIEDUTHORIZED AND CERTIFIED

T FROM THET FROM THE

T FROM THE

T FROM THET FROM THE

..

.

..

1

Page 3

SAFETY PRECAUTIONS

Do not operate this equipment or associated

equipment until the following safety instructions have been thoroughly read and understood! Read this manual before installing,

operating or maintaining this equipment.

Tool operators and maintenance personnel must always comply with the safety precautions given in this

manual and on the stickers and tags attached to the equipment.

These safety precautions are given for your safety. Review them carefully before operating the tool and

before performing general maintenance or repairs.

Supervising personnel should develop additional precautions relating to the specific work area and local

safety regulations. If so, place the added precautions in the space provided on page 5.

In addition to this manual, read and understand safety and operating instructions in the Engine

Operation Manual furnished with the power unit.

GENERAL SAFETY PRECAUTIONS

The HP1 Compact Hydraulic Power Unit will provide safe and dependable service if operated in accordance with the instructions given in this manual. Read and understand this manual and any stickers and

tags attached to the Power Unit. Failure to do so could result in personal injury or equipment damage.

• Operators must start in a work area without bystanders. The operator must be familiar with all prohibited work areas such as excessive slopes and dangerous terrain conditions.

• Establish a training program for all operators to ensure safe operation.

• Do not operate the power unit unless thoroughly trained or under the supervision of an instructor.

• Always wear safety equipment such as goggles, ear and head protection, and safety shoes at all times

when operating the power unit and a hydraulic tool.

• Do not inspect or clean the power unit while the unit is running.

• Always use hoses and fittings rated at 2500 psi/172 bar with a 4 to 1 safety factor. Be sure all hose

connections are tight.

• Make sure all hoses are connected for correct flow direction to and from the tool being used.

• Do not inspect hoses and fittings for leaks by using bare hands. "Pin-hole" leaks can penetrate the

skin.

• Never operate the power unit in a closed space. Inhalation of engine exhaust can be fatal.

• Do not operate a damaged or improperly adjusted power unit.

• Never wear loose clothing that can get entangled in the working parts of the power unit.

• Keep all parts of your body away from the working parts of the power unit.

2

Page 4

• Always wear appropriate safety equipment such as goggles, ear protection, and toe guards. Certain

tools used in conjunction with the power unit may require other safety equipment such as breathing

filters.

• Keep clear of hot engine exhaust.

• Do not add fuel to the power unit while the power unit is running or is still hot.

• Do not operate the power unit if gasoline odor is present.

• Do not use flammable solvents around the power unit engine.

• Do not operate the power unit within 3.3 ft/1 m of buildings, obstructions, or flammable objects.

• Do not reverse grinding wheel rotation direction by changing fluid flow direction.

• Allow the engine to cool before storing the power unit in an enclosure.

• To avoid personal injury or equipment damage, all tool repair, maintenance and service must only be

performed by authorized and properly trained personnel.

SAFETY SYMBOLS

Safety symbols are used to emphasize all operator, maintenance and repair actions which, if not strictly

followed, could result in a life-threatening situation, bodily injury or damage to equipment.

DANGER

This safety symbol may appear

on the tool. It is used to alert

the operator of an action that

could place him/her or others in

a life threatening situation.

This safety symbol appears in

these instructions to identify

an action that could cause

bodily injury to the operator or

other personnel.

IMPORTANT

This safety symbol appears in

these instructions to identify an

action or condition that could

result in damage to the tool or

other equipment.

Always observe safety symbols. They are included for your safety and for the protection of the tool.

3

Page 5

LOCAL SAFETY REGULATIONS

Enter any local safety regulations here. Keep these instructions in an area accessible to the operator and

maintenance personnel.

4

Page 6

SAFETY STICKERS & TAGS

0110

L

WA

L

WA

CHOKE PULL DECAL

EXHAUST FUMES STICKER

EXHAUST STICKER

WEIGHT STICKER

DO NOT OPERATE THE PUMP WITHOUT WATER. OPERATING THE PUMP

WITHOUT WATER WILL SEVERLY DAMAGE THE PUMP.

FUEL STICKER

SAFETY TAG

Do not remove until read)

HYDRAULIC OIL

STICKER

BATTERY CHARGE TAG

(Do not remove until read)

COUPLER STICKER

BR87, BR37, CH18

BR87, BR37, CH18

L

L

101

11

WA

WA

SOUND POWER LEVER STICKER

MANUAL STICKER

SERIAL NO. LOCATION

(At top of dash panel)

CAUTION STICKER

(If Equipped with Water Pump Kit)

The safety tag at right is

attached to the power unit

when shipped from the

factory. Read and

understand the safety

instructions listed on this

tag before removal. We

suggest you retain this tag

and attach it to the tool

when not in use.

DANGER

1. FAILURE TO USE HYDRAULIC HOSE LABELED AND CERTIFIED AS NON-CONDUCTIVE WHEN USING HYDRAULIC TOOLS

ON OR NEAR ELECTRICAL LINES MAY RESULT IN DEATH OR

SERIOUS INJURY.

BEFORE USING HOSE LABELED AND CERTIFIED AS NON-

CONDUCTIVE ON OR NEAR ELECTRIC LINES BE SURE THE

HOSE IS MAINTAINED AS NON-CONDUCTIVE. THE HOSE

SHOULD BE REGULARLY TESTED FOR ELECTRIC CURRENT

LEAKAGE IN ACCORDANCE WITH YOUR SAFETY DEPARTMENT

INSTRUCTIONS.

2. A HYDRAULIC LEAK OR BURST MAY CAUSE OIL INJECTION

INTO THE BODY OR CAUSE OTHER SEVERE PERSONAL INJURY.

A DO NOT EXCEED SPECIFIED FLOW AND PRESSURE FOR

THIS TOOL. EXCESS FLOW OR PRESSURE MAY CAUSE A

LEAK OR BURST.

B DO NOT EXCEED RATED WORKING PRESSURE OF HYDRAU

LIC HOSE USED WITH THIS TOOL. EXCESS PRESSURE MAY

CAUSE A LEAK OR BURST.

C CHECK TOOL HOSE COUPLERS AND CONNECTORS DAILY

FOR LEAKS. DO NOT FEEL FOR LEAKS WITH YOUR HANDS.

CONTACT WITH A LEAK MAY RESULT IN SEVERE PERSONAL

INJURY.

IMPORTANT

READ OPERATION MANUAL AND

SAFETY INSTRUCTIONS FOR THIS

TOOL BEFORE USING IT.

USE ONLY PARTS AND REPAIR

PROCEDURES APPROVED BY

STANLEY AND DESCRIBED IN THE

OPERATION MANUAL.

TAG TO BE REMOVED ONLY BY

TOOL OPERATOR.

SEE OTHER SIDE

15875

DANGER

D DO NOT LIFT OR CARRY TOOL BY THE HOSES. DO NOT

ABUSE HOSE. DO NOT USE KINKED, TORN OR DAMAGED

HOSE.

3. MAKE SURE HYDRAULIC HOSES ARE PROPERLY CONNECTED

TO THE TOOL BEFORE PRESSURING SYSTEM. SYSTEM PRESSURE HOSE MUST ALWAYS BE CONNECTED TO TOOL "IN"

PORT. SYSTEM RETURN HOSE MUST ALWAYS BE CONNECTED TO TOOL "OUT" PORT. REVERSING CONNECTIONS

MAY CAUSE REVERSE TOOL OPERATION WHICH CAN RESULT

IN SEVERE PERSONAL INJURY.

4. DO NOT CONNECT OPEN-CENTER TOOLS TO CLOSED-CENTER HYDRAULIC SYSTEMS. THIS MAY RESULT IN LOSS OF

OTHER HYDRAULIC FUNCTIONS POWERED BY THE SAME

SYSTEM AND/OR SEVERE PERSONAL INJURY.

5. BYSTANDERS MAY BE INJURED IN YOUR WORK AREA. KEEP

BYSTANDERS CLEAR OF YOUR WORK AREA.

6. WEAR HEARING, EYE, FOOT, HAND AND HEAD PROTECTION.

7. TO AVOID PERSONAL INJURY OR EQUIPMENT DAMAGE, ALL

TOOL REPAIR MAINTENANCE AND SERVICE MUST ONLY BE

PERFORMED BY AUTHORIZED AND PROPERLY TRAINED PERSONNEL.

IMPORTANT

READ OPERATION MANUAL AND

SAFETY INSTRUCTIONS FOR THIS

TOOL BEFORE USING IT.

USE ONLY PARTS AND REPAIR

PROCEDURES APPROVED BY

STANLEY AND DESCRIBED IN THE

OPERATION MANUAL.

TAG TO BE REMOVED ONLY BY

TOOL OPERATOR.

SEE OTHER SIDE

15875

SAFETY TAG

(shown smaller then actual size)

5

Page 7

HYDRAULIC HOSE REQUIREMENTS

HOSE TYPES

Hydraulic hose types authorized for use with Stanley Hydraulic Tools are as follows:

1

2

3

Hose listed above is the only hose authorized for use near electrical conductors.

Hoses and listed above are conductive and must never be used near electrical conductors.

Certified non-conductive

Wire-braided (conductive)

Fabric-braided (not certified or labeled non-conductive)

1

32

To help ensure your safety, the following DANGER tags are attached to all hose purchased from Stanley.

DO NOT REMOVE THESE TAGS.

If the information on a tag is illegible because of wear or damage, replace the tag immediately. A new

tag may be obtained at no charge from your Stanley Distributor.

CERTIFIED NON-CONDUCTIVE HOSE

1

This tag is attached to all certified non-conductive hose.

D A N G E R

1 FAILURE TO USE HYDRAULIC HOSE LABELED AND CERTIFIED AS NON-CONDUCTIVE

WHEN USING HYDRAULIC TOOLS ON OR NEAR ELECTRIC LINES MAYRESULT IN DEATH

OR SERIOUS INJURY.

FOR PROPER AND SAFE OPERATION MAKE SURE THAT YOU HAVE BEEN PROPERLY

TRAINED IN CORRECT PROCEDURES REQUIRED FOR WORK ON OR AROUND ELECTRIC

LINES.

2. BEFORE USING HYDRAULIC HOSE LABELED AND CERTIFIED AS NON-CONDUCTIVE ON OR

NEAR ELECTRIC LINES. WIPE THE ENTIRE LENGTH OF THE HOSE AND FITTING WITH A

CLEAN DRY ABSORBENT CLOTH TO REMOVE DIRT AND MOSISTURE AND TEST HOSE FOR

MAXIMUM ALLOWABLE CURRENT LEAKAGE IN ACCORDANCE WITH SAFETY

DEPARTMENT INSTRUCTIONS.

DO NOT REMOVE THIS TAG

SEE OTHER SIDE

D A N G E R

3. DO NOT EXCEED HOSE WORKING PRESSURE OR ABUSE HOSE. IMPROPER USE OR

HANDLING OF HOSE COULD RESULT IN BURST OR OTHER HOSE FAILURE. KEEP HOSE AS

FAR AWAY AS POSSIBLE FROM BODY AND DO NOT PERMIT DIRECT CONTACT DURING

USE. CONTACT AT THE BURST CAN CAUSE BODILY INJECTION AND SEVERE PERSONAL

INJURY.

4. HANDLE AND ROUTE HOSE CAREFULLY TO AVOID KINKING, ABRASION, CUTTING, OR

CONTACT WITH HIGH TEMPERATURE SURFACES. DO NOT USE IF KINKED. DO NOT USE

HOSE TO PULL OR LIFT TOOLS, POWER UNITS, ETC.

5. CHECK ENTIRE HOSE FOR CUTS CRACKS LEAKS ABRASIONS, BULGES, OR DAMAGE TO

COUPLINGS IF ANY OF THESE CONDITIONS EXIST, REPLACE THE HOSE IMMEDIATELY.

NEVER USE TAPE OR ANY DEVICE TO ATTEMPT TO MEND THE HOSE.

6. AFTER EACH USE STORE IN A CLEAN DRY AREA.

SEE OTHER SIDE

DO NOT REMOVE THIS TAG

SIDE 1 SIDE 2

2

AND 1 WIRE-BRAIDED AND FABRIC-BRAIDED (NOT CERTIFIED OR LABELED NON-CON-

3

DUCTIVE) HOSE

This tag is attached to all conductive hose.

D A N G E R

1 DO NOT USE THIS HYDRAULIC HOSE IN OR NEAR ELECTRIC LINES. THIS HOSE IS NOT

LABELED OR CERTIFIED AS NON-CONDUCTIVE. USING THIS HOSE ON OR NEAR

ELECTRICAL LINES MAY RESULT IN DEATH OR SERIOUS INJURY.

2. FOR PROPER AND SAFE OPERATION MAKE SURE THAT YOU HAVE BEEN PROPERLY

TRAINED IN CORRECT PROCEDURES REQUIRED FOR WORK ON OR AROUND ELECTRIC

LINES.

3. DO NOT EXCEED HOSE WORKING PRESSURE OR ABUSE HOSE. IMPROPER USE OR

HANDLING OF HOSE COULD RESULT IN BURST OR OTHER HOSE FAILURE. KEEP HOSE

AS FAR AWAY AS POSSIBLE FROM BODY AND DO NOT PERMIT DIRECT CONTACT

DURING USE. CONTACT AT THE BURST CAN CAUSE BODILY INJECTION AND SEVERE

PERSONAL INJURY.

4. HANDLE AND ROUTE HOSE CAREFULLY TO AVOID KINKING, CUTTING, OR CONTACT WITH

HIGH TEMPERATURE SURFACES. DO NOT USE IF KINKED. DO NOT USE HOSE TO PULL

OR LIFT TOOLS, POWER UNITS, ETC.

DO NOT REMOVE THIS TAG

SEE OTHER SIDE

SIDE 1 SIDE 2

HOSE PRESSURE RATING

The rated working pressure of the hydraulic hose must be equal or higher than the relief valve setting on

the hydraulic system.

6

(shown smaller then actual size)

5. CHECK ENTIRE HOSE FOR CUTS CRACKS LEAKS ABRASIONS, BULGES, OR DAMAGE TO

COUPLINGS IF ANY OF THESE CONDITIONS EXIST, REPLACE THE HOSE IMMEDIATELY.

NEVER USE TAPE OR ANY DEVICE TO ATTEMPT TO MEND THE HOSE.

6. AFTER EACH USE STORE IN A CLEAN DRY AREA.

(shown smaller then actual size)

D A N G E R

SEE OTHER SIDE

DO NOT REMOVE THIS TAG

Page 8

OPERATING INSTRUCTIONS

PREPARATION FOR USE

Do not operate the power unit until you have

read the engine operating and maintenance

instructions manual furnished with the unit.

1. ENGINE CRANKCASE OIL LEVEL

IMPORTANT

Do not start the Engine with the

Always check the oil level before starting tne

engine. Make sure the oil level is at the FULL

MARK on the dipstick. Do not overfill. Use detergent oil classified "For Service SE, SF, SG" as

specified in the engine operating and maintenance

manual.

trottle control set at 5 or 8 gpm/

19 or 30 lpm.

Flash Point (ASTM D-92) 340°F/171°C Minimum

Rust Inhibition (ASTM D-665 A & B) Pass

Oxidation (ASTM D-943) 1000 Hours Minimum

Pump Wear Test (ASTM D-2882) 60 mg Maximum

The following fluids work well over a wide temperature range, allow moisture to settle out and resist

biological growth that may occur in cool operating

hydraulic circuits. These fluids are recommended

by Stanley. Other fluids that meet or exceed the

specifications of these fluids may also be used.

Chevron AW-MV-32

Exxon "Univis" J-26

Mobil D.T.E. 13

Gulf "Harmony" AW-HVI-150-32

Shell "Tellus" T-32

Texaco "Rando" HD-AZ

Union "Unax" AW-WR-32

2. ENGINE FUEL LEVEL

Check the fuel level. If low, fill with un-leaded

gasoline with a minimum of 85 octane.

3. HYDRAULIC FLUID

Check the sight pipe in the hydraulic fluid reservoir

for the proper fiuid level. Proper fluid level is

indicated when the center section of the sight pipe

is dark. If the center section of the sight pipe is not

dark, add hydraulic fluid. Use fluids meeting the

following specifications.

Viscosity (Fluid Thickness)

U.S. METRIC

50°F 450 SSU Maximum 10°C 95 Centistokes

100°F 130-200 SSU 38°C 27-42 C.S.

140°F 85 SSU Minimum 60°C 16.5 C.S. Minimum

PourPoint -10°F/-23°C Minimum (for cold startup)

Viscosity Index (ASTM D-2220) 140 Minimum

4. HYDRAULIC CONNECTIONS

Facing the panel control valve, the far right-hand

male quick disconnect fitting is the pressure

(FLUID OUT) fitting. The left-hand female quick

disconnect fitting is the return (FLUID IN) fitting.

The recommended hose length is 25 ft/8 m with a

1/2 inch/12.7 mm inside diameter. The hoses

must have a working pressure rating of at least

2500 psi/175 bar. Each hose end must have male

thread ends compatible with H.T.M.A. (HYDRAULIC TOOL MANUFACTURERS ASSOCIATION)

5. BATTERY

The supplied 12 Volt DC battery has been partially

dry charged. Before using, it must first be filled

with battery electrolyte at a specific density of

1.240 to 1.260. Fill each cell to its upper level

indicator and then charge at a 2 Amp rate for at

least 12 to 15 hours. After charging, check the

electrolyte level and fill as required.

Demulsibility (ASTM D-1401) 30 Minutes Maximum

Also, make sure the battery cables are tight and

charging circuit functions are operating properly.

7

Page 9

quick disconnect fittings (NPT type threads).

(See Figure 1.)

CONTROL PANEL

PRESSURE

RETURN

H.T.M.A. 1/2 INCH

FEMALE QUICK

DISCONNECT COUPLER

H.T.M.A. 1/2 INCH MALE

QUICK DISCONNECT

COUPLER

1/2 INCH MALE PIPE

HOSE END

1/2 INCH I.D. HOSE, 25 FT

LONG WITH 2500 PSI/

172 BAR RATING AND

4 TO 1 SAFETY FACTOR

Longer hoses may be used when necessary,

but can effect the operation of the engine

automatic throttle due to fluid resistance in the

hose. If small diameter or long hoses are

used, or if restrictive fittings are connected to

the supply and return ports, the pressure

required to push the fluid through the system

and back to the hydraulic tank will be higher.

If the pressure is too high, this will cause the

engine RPM to remain at full load if "AUTO" is

selected on the automatic throttle. Also see

"HYDRAULIC HOSE REQUIREMENTS"

earlier in this manual.

QUICK DISCONNECT COUPLERS

H.T.M.A. approved quick disconnect couplings

are installed to hydraulic hoses so that the

direction of oil flow is always from the male to

the female quick disconnect as shown in figure

1. Quick disconnect couplings and hose

fittings are selected so that additional fittings

such as reducer or adapter fittings are not

required.

1/2 INCH MALE PIPE

HOSE END

H.T.M.A. 1/2 INCH

FEMALE QUICK

DISCONNECT COUPLER

H.T.M.A. 1/2 INCH MALE

QUICK DISCONNECT

COUPLER

ADAPTER, 3/8 INCH MALE

PIPE x -8 SAE O-RING

RETURN

PRESSURE

If adapter fittings are used, they must be

PRESSURERETURN

approved steel hydraulic fittings meeting a

minimum operating pressure rating of 2500

psi/172 bar. Do not use galvanized pipe

fittings or black pipe fittings.

Use thread tape or pipe joint compound when

installing quick disconnect couplings to hose or

tool fittings. Follow the instructions furnished

with the selected thread sealant. DO NOT

OVERTIGHTEN THE FITTINGS.

TOOL

Figure 1. Hydraulic Connections

8

Page 10

Do not charge the battery with a

standard automotive battery

charger. This type of charger

produces a charging amperage

higher than 2 amps. Charging the

battery with amperage higher than

2 amps will damage the battery.

6. THROTTLE CONTROL (See Figure 2)

The throttle control permits the operator to select

one of 3 operating modes after the engine has

warmed up. For startup, the throttle control should

be set on "AUTO".

a. AUTO - Engine speed varies with hydraulic

circuit pressure to maintain a constant 8.5 gpm/32

lpm. When a tool is not being used the engine will

return to idle automatically.

b. 5 - Engine speed is held at part throttle to

maintain 5 gpm/19 lpm. When a tool is not being

used the engine will not return to idle until the

faspin is removed.

CYLINDER

LEVER

FASPIN

AUTO

HOLD 5 GPM

BASE

GOVERNOR

LEVER

c. 8 - Engine speed is held at full throttle to

maintain 8.5 gpm/32 lpm. When a tool is not

being used the engine will not return to idle until

the faspin is removed.

Typical conditions requiring the "8" position are:

• When operating an alternator, fluid flow must be

constant to produce the required voltage and

frequency, even when load requirements are light.

• When operating drills or grinders or diamond

saws, tool rpm must be maintained even when

load requirements are light.

HOLD 8 GPM

Figure 2. Throttle Control Settings

STARTUP - See "PANEL CON-

TROLS" - Figure 3

1. Assure the circuit control lever is in the "OFF"

position.

2. Select the "AUTO" throttle operating mode by

positioning the governor lever to the cylinder lever

and inserting the faspin as shown in figure 2.

9

Page 11

ON/OFF

SWITCH

ON

OFF

ENGINE

TOOL

RETURN

HOSE

OFF

Stanley Hydraulic Tools

MILWAUKIE, OREGON

TOOL

ON

PRESSURE

HOSE

HP1 COMPACT POWER UNIT

3. If the tools and tool hoses are cold, it is

recommended to allow hydraulic fluid to

circulate through the tool hoses until warm

before using the tool.

TOOL OPERATION

1. With the engine running smoothly,

move the control lever to the "ON" position.

2. Activate the tool. The automatic throttle

will increase engine speed to permit proper

tool operation. When the tool is deactivated, the automatic throttle allows the

engine to return to idle.

3. If automatic throttle operation is not

desired, change the throttle control to "5 or

8".

RETURN QUICK

DISCONNECT

PRESSURE QUICK

DISCONNECT

Figure 3. Control Panel

3. Position the ON/OFF switch to the "ON"

position.

4. Pull the choke lever out.

5. Push the circuit control lever to the "START"

position.

6. After the engine starts, allow the engine to

warm up until it runs smoothly with the choke

released.

IMPORTANT

Do not start the Engine with the

trottle control set at 5 or 8 gpm/

19 or 30 lpm.

SHUTDOWN

1. Place the circuit control lever in the

"OFF" position.

2. If the throttle control is in the "5" or "8" position,

change it to the "AUTO" position.

3. Allow the engine to idle for approximately one

minute and then switch the ON/OFF switch to the

"OFF" position.

OPTIONAL WATER

PUMP KIT

DO NOT OPERATE THE PUMP WITHOUT WATER. OPERATING THE PUMP

WITHOUT WATER WILL SEVERLY DAMAGE THE PUMP.

COLD WEATHER

STARTUP

1. Use the procedures described under

"STARTUP" and then follow the procedure below.

2. Hydraulic fluids are thicker in cold weather,

therefore, it is recommended that the engine be

run at low idle long enough to bring the fluid

temperature up to a minimum of 50°F/10°C or

until the top of the hydraulic filter feels warm.

10

If the power unit will be operated without need of

the water pump, unpin the water pump and

remove it.

Page 12

ROUTINE MAINTENANCE

ENGINE MAINTENANCE

Follow the maintenance schedule and general

maintenance instructions in the engine maintenance and operation manual furnished with the

power unit. Normal maintenance includes:

• Service foam air pre-cleaner every 25 hours of

operation.

• Service air paper cartridge every 100 hours of

operation.

• Replace in-line fuel filter every 100-300 hours or

sooner if required.

• Replace spark plugs every 100 hours of operation.

• Change engine oil after first 5 hours of operation, then after every 50 hours of operation. If

engine has been operating under heavy load or

in high ambient temperature, change the oil

every 25 hours of operation.

• Change oil filter when engine oil is changed.

• Check oil level daily.

• Remove dirt and debris from engine with a cloth

or brush daily. Do not use water spray.

• Clean air cooling system every 100 hours of

operation.

avoiding the water at the bottom of the container.

• Each day, check hydraulic lines and fittings for

leaks, kinks, etc. Do not use your hand to

perform this check.

• Change the hydraulic filter element every 200

hours of operation. Change more often if cold,

moist or dusty conditions exist.

• Check oil cooler for debris. Remove debris with

air pressure.

STORAGE

• Clean the unit thoroughly before storage. Do

not use water pressure.

• Always store the unit in a clean and dry facility.

• If the unit will be stored for a prolonged period

(over 30 days), add a fuel additive to the fuel

tank to prevent the fuel from gumming. Run

engine for a short period to circulate the additive.

• Replace crankcase oil with new oil.

• Remove spark plugs and pour approximately 1

ounce (30 ml) of engine oil into each cylinder.

Replace spark plugs and crank the engine

slowly to distribute the oil.

HYDRAULIC SYSTEM MAINTENANCE

• Check hydraulic fluid level daily. The center of

the sight pipe on the reservoir must be dark. If

it is not dark, fluid must be added. Add fluid per

specifications in this manual. (See "HYDRAULIC FLUID" under the section titled "OPERATING INSTRUCTIONS".

• Remove condensed moisture from the hydraulic

fluid by pumping the hydraulic fluid into a 5 gal/20

ltr container through the pressure hose. Make

sure the engine is at idle when performing this

procedure. When the hydraulic reservoir is empty

turn the engine off immediately.

• Allow the fluid to sit long enough for the water to

settle to the bottom of the container. Slowly

pour the fluid back into the hydraulic tank,

• Check hydraulic reservoir for water. If water is

found, change the oil and circulate it through the

tool hose and tool. (See "HYDRAULIC SYSTEM MAINTENANCE" earlier in this section).

• Disconnect tool hoses.

11

Loading...

Loading...