Page 1

OPERATION and MAINTENANCE MANUAL

MANUAL DE OPERACIÓN Y DE MANTENIMIENTO

MANUEL D’INSTRUCTIONS ET D’ENTRETIEN

C SERIES

LIGHT WEIGHT CLINCHING TOOL

HERRAMIENTA REMACHADORA LIVIANA

OUTIL DE SERTISSAGE LÉGER

142013 REVB 09/04

BEFORE OPERATING THIS TOOL, ALL OPERATORS SHOULD STUDY THIS MANUAL TO

UNDERSTAND AND FOLLOW THE SAFETY WARNINGS AND INSTRUCTIONS. KEEP THESE

INSTRUCTIONS WITH THE TOOL FOR FUTURE REFERENCE. IF YOU HAVE ANY QUESTIONS,

CONTACT YOUR BOSTITCH REPRESENTATIVE OR DISTRIBUTOR.

ANTES DE OPERAR ESTAHERRAMIENTA, TODOS LOS OPERADORES DEBERÁN ESTUDIAR

ESTE MANUAL PARA PODER COMPRENDER Y SEGUIR LAS ADVERTENCIAS SOBRE

SEGURIDAD Y LAS INSTRUCCIONES. MANTENGA ESTAS INSTRUCCIONES CON LA

HERRAMIENTA PARA FUTURA REFERENCIA, SI TIENE ALGUNA DUDA, COMUNÍQUESE CON

SU REPRESENTANTE DE BOSTITCH O CON SU DISTRIBUIDOR.

LIRE ATTENTIVEMENT LE PRÉSENT MANUEL AVANT D’UTILISER L’APPAREIL. PRÉTER UNE

ATTENTION TOUTE PARTICULIÈRE AUX CONSIGNES DE SÉCURITÉ ET AUX AVERTISSEMENTS.

GARDER CE MANUEL AVEC L’OUTIL POUR FUTUR RÉFÉRENCE. SI VOUS AVEZ DES

QUESTIONS, CONT ACTEZ VOTRE REPRÉSENTANT OU VOTRE CONCESSIONNAIRE BOSTITCH.

STANLEY FASTENING SYSTEMS

STANLEY FASTENING SYSTEMS

Page 2

-2-

INTRODUCTION

The HARTCO C series are precision-built tools, designed for high speed, high volume fastening. These tools

will deliver efficient, dependable service when used correctly and with care. As with any fine power tool, for

best performance the manufacturer’s instructions must be followed. Please study this manual before operating

the tool and understand the safety warnings and cautions. The instructions on installation, operation and

maintenance should be read carefully, and the manuals kept for reference. NOTE: Additional safety measures

may be required because of your particular application of the tool. Contact your STANLEY HARTCO

representative or distributor with any questions concerning the tool and its use.

INDEX

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Tool Specifications, Tool Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Air Supply: Fittings, Hoses, Filters, Air Consumption, Regulators,

Operating Pressure, Setting Correct Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Loading the Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Maintaining the Pneumatic Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Trouble Shooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

NOTE:

HARTCO tools have been engineered to provide excellent customer satisfaction and are designed to achieve

maximum performance when used with precision HARTCO fasteners engineered to the same exacting standards.

HARTCO cannot assume responsibility for product performance if our tools are used with fasteners or

accessories not meeting the specific requirements established for genuine HARTCO fasteners and accessories.

LIMITED WARRANTY

HARTCO, warrants to the original retail purchaser that this product is free from defects in material and

workmanship, and agrees to repair or replace, at HARTCO’S option, any defective product within 180 days

from the date of purchase. This warranty is not transferable. It only covers damage resulting from defects in

material or workmanship, and it does not cover conditions or malfunctions resulting from normal wear, neglect,

abuse, accidents or repairs attempted or made by other than our regional repair center or authorized warranty

service center. Driver blades and o-rings are considered normally wearing parts.

THIS WARRANTY IS IN LIEU OF ALL OTHER EXPRESS WARRANTIES. ANY WARRANTY OF

MERCHANT ABILITYOR FITNESS FOR APARTICULAR PURPOSE IS LIMITED TO THE DURATION OF THIS

WARRANTY. HARTCO SHALL NOT BE LIABLE FOR ANY INCIDENTALOR CONSEQUENTIAL DAMAGES.

This warranty is limited to sales in the United States and Canada. Some states do not allow limitations on how

long an implied warranty lasts, or the exclusion or limitation of incidental or consequential damages, so the

above limitations or exclusions may not apply to you. This warranty gives you specific legal rights, and you may

also have other rights which vary from state to state.

To obtain warranty service, return the product at your expense together with proof of purchase to a HARTCO

regional or authorized warranty repair center. You may also contact us at 1-800-556-6696 or on the web at

www.bostitch.com for the location of authorized warranty service centers in your area.

Page 3

-3-

SAFETY INSTRUCTIONS

EYE PROTECTION which conforms to ANSI specifications and provides protection against

flying particles both from the FRONT and SIDE should AL W AYS be worn by the operator and

others in the work area when connecting to air supply, loading, operating or servicing this

tool. Eye protection is required to guard against flying fasteners and debris, which could

cause severe eye injury.

The employer and/or user must ensure that proper eye protection is worn. Eye protection

equipment must conform to the requirements of the American National Standards Institute,

ANSI Z87.1 and provide both frontal and side protection. NOTE: Non-side shielded

spectacles and face shields alone do not provide adequate protection.

CAUTION:

Additional Safety Protection will be required in some environments. For

example, the working area may include exposure to noise level which can lead to hearing

damage. The employer and user must ensure that any necessary hearing protection is

provided and used by the operator and others in the work area. Some environments will

require the use of head protection equipment. When required, the employer and user must

ensure that head protection conforming to ANSI Z89.1 is used.

AIR SUPPLY AND CONNECTIONS

Do not use oxygen, combustible gases, or bottled gases as a power source for this tool as

tool may explode, possibly causing injury.

Do not use supply sources which can potentially exceed 90 P.S.I.G. as tool may burst,

possibly causing injury.

The connector on the tool must not hold pressure when air supply is disconnected. If a

wrong fitting is used, the tool can remain charged with air after disconnecting and thus will

be able to drive a fastener into the anvil even after the air line is disconnected possibly

causing injury.

Do not pull trigger while connecting to the air supply as the tool may cycle, possibly

causing injury.

Always disconnect air supply: 1.) Before making adjustments; 2.) When servicing the tool;

3.) When clearing a jam; 4.) When tool is not in use; 5.) When moving to a different work

area, as accidental actuation may occur, possibly causing injury.

LOADING TOOL

When loading tool: 1.) Never place a hand or any part of body in anvil area of tool; 2.) Never

point tool at anyone; 3.) Do not pull the trigger as accidental actuation may occur, possibly

causing injury.

If clips are loaded backward into the magazine with double ears forward, they will not be

wrapped and jamming will occur. The first check of jammed tool should be to see that clips

are properly loaded in magazine.

OPERATION

Always handle the tool with care: 1.) Never engage in horseplay; 2.) Never pull the trigger

unless nose is directed toward the work; 3.) Keep others a safe distance from the tool while

tool is in operation as accidental actuation may occur, possibly causing injury.

Keep hands and body away from the anvil area of the tool.

Do not crimp fasteners on top of other fasteners as this may cause the tool to jam and will

decrease the life of the tool.

MAINTAINING THE TOOL

When working on air tools note the warnings in this manual and use extra care when

evaluating problem tools.

Page 4

-4-

TOOL SPECIFICATIONS

All screws and nuts are American National Standard.

FASTENER SPECIFICATIONS:

See product illustration #IP1200-1 or BOSTITCH Industrial Tool and Fastener Catalog.

TOOL AIR FITTING:

This tool uses a free-flow connector plug, 1/4” N.P.T. The minimum inside diameter should be .200” (5mm).

The fitting must be capable of discharging tool air pressure when disconnected from the air supply.

OPERATING PRESSURE:

70 to 90 p.s.i. ( 4.9 to 6.2 kg/cm2). Select the operating pressure within this range for best fastener

performance. DO NOT EXCEED THIS RECOMMENDED OPERATING PRESSURE OF 90 P.S.I.

AIR CONSUMPTION:

The HARTCO C SERIES tools require 2.6 cubic feet per minute ( .07 cubic meters ) of free air to operate at

the rate of 100 clips per minute, at 90 p.s.i. ( 6.2 kg/cm

2

). Take the actual rate at which the tool will be run to

determine the amount of air required. For instance, if your fastener usage averages 50 clips per minute, you

need 50% of the tool's c.f.m. of free air which is required for running at 100 clips per minute.

TOOL OPERATION

EYE PROTECTION

which conforms to ANSI specifications and provides protection against

flying particles both from the FRONT and SIDE should AL W AYS be worn by the operator and

others in the work area when connecting to air supply, loading, operating or servicing this

tool. Eye protection is required to guard against flying fasteners and debris, which could

cause severe eye injury.

The employer and/or user must ensure that proper eye protection is worn. Eye protection

equipment must conform to the requirements of the American National Standards Institute,

ANSI Z87.1 and provide both frontal and side protection. NOTE: Non-side shielded

spectacles and face shields alone do not provide adequate protection.

BEFORE HANDLING OR OPERATING THIS TOOL:

I. READ AND UNDERSTAND THE WARNINGS CONTAINED IN THIS MANUAL.

II. REFER TO “TOOL SPECIFICATIONS” IN THIS MANUAL TO IDENTIFY THE

OPERATING SYSTEM ON YOUR TOOL.

MODEL LENGTH HEIGHT WIDTH WEIGHT

C Series Tool 18.5” (470mm) 8” (203mm) 3.75” (95mm) 5.20 lbs (2.50 kg)

Page 5

-5-

AIR SUPPLY AND CONNECTIONS

Do not use oxygen, combustible gases, or bottled gases as a power source for this tool as

tool may explode, possibly causing injury.

FITTINGS:

Install a male plug on the tool which is free flowing and which will release air pressure from the tool when

disconnected from the supply source.

HOSES:

Air hoses should have a minimum of 150 p.s.i. (10.6 kg/cm2) working pressure rating or 150 percent of the

maximum pressure that could be produced in the air system. The supply hose should contain a fitting that will

provide “quick disconnecting” from the male plug on the tool.

SUPPLY

SOURCE:

Use only clean regulated compressed air as a power source for this tool. NEVER USE OXYGEN, COMBUSTIBLE

GASES, OR BOTTLED GASES, AS A POWER SOURCE FOR THIS TOOLAS TOOL MAYEXPLODE.

REGULATOR:

A pressure regulator with an operating pressure of 0 - 125 p.s.i. (0 - 8.79 kg/cm2) is required to control the

operating pressure for safe operation of this tool. Do not connect this tool to air pressure which can potentially

exceed 200 p.s.i. (14 kg/cm

2

) as tool may fracture or burst, possibly causing injury.

OPERATING PRESSURE:

Do not exceed recommended maximum operating pressure of 90 p.s.i. as tool wear will be greatly increased.

The air supply must be capable of maintaining the operating pressure at the tool. Pressure drops in the air

supply can reduce the tool’s driving power.

FILTER:

Dirt and water in the air supply are major causes of wear in pneumatic tools. A filter will help to get the best

performance and minimum wear from the tool. The filter must have adequate flow capacity for the specific

installation. The filter has to be kept clean to be effective in providing clean compressed air to the tool. Consult

the manufacturer’s instructions on proper maintenance of your filter. A dirty and clogged filter will cause a

pressure drop which will reduce the tool’s performance.

LUBRICATION

Frequent, but not excessive, lubrication is required for best performance. Oil added through the air line

connection will lubricate the internal parts. Use BOSTITCH Air Tool Lubricant, Mobil Velocite #10, or equivalent.

Do not use detergent oil or additives as these lubricants will cause accelerated wear to the seals in the tool,

resulting in poor tool performance and frequent tool maintenance.

If no airline lubricator is used, add oil during use into the air fitting on the tool once or twice a day. Only a few

drops of oil at a time is necessary. Too much oil will only collect inside the tool and will be noticeable in the

exhaust cycle.

COLD WEATHER OPERATION:

For cold weather operation, near and below freezing, the moisture in the air line may freeze and prevent tool

operation. We recommend the use of BOSTITCH WINTER FORMULA air tool lubricant or permanent

antifreeze (ethylene glycol) as a cold weather lubricant.

CAUTION: Do not store tools in a cold weather environment to prevent frost or ice formation on the

tool’s operating valves and mechanisms that could cause tool failure.

NOTE:Some commercial air line drying liquids are harmful to “O”-rings and seals – do not use these

low temperature air dryers without checking compatibility.

Page 6

-6-

LOADING A C SERIES CLINCHING TOOL

EYE PROTECTION

which conforms to ANSI specifications and provides protection against

flying particles both from the FRONT and SIDE should AL W AYS be worn by the operator and

others in the work area when connecting to air supply, loading, operating or servicing this

tool. Eye protection is required to guard against flying fasteners and debris, which could

cause severe eye injury.

The employer and/or user must ensure that proper eye protection is worn. Eye protection

equipment must conform to the requirements of the American National Standards Institute,

ANSI Z87.1 and provide both frontal and side protection. NOTE: Non-side shielded

spectacles and face shields alone do not provide adequate protection.

TO PREVENT ACCIDENTAL INJURIES:

•Never place a hand or any other part of the body in anvil area of tool while the air supply

is connected.

• Never point the tool at anyone else.

• Never engage in horseplay.

• Never pull the trigger unless nose is directed at the work.

•Always handle the tool with care.

• Do not pull the trigger while loading the tool.

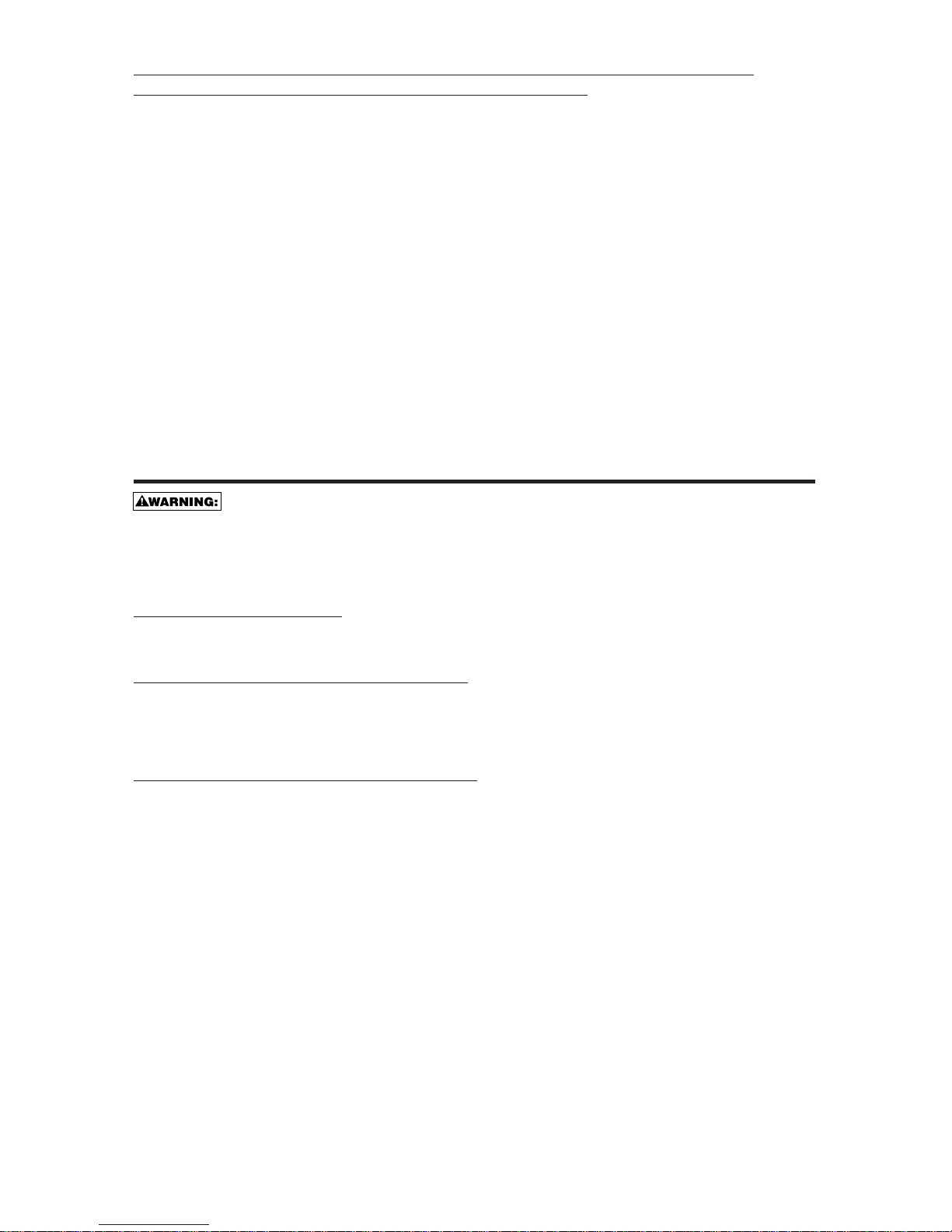

1. STAGING FOLLOWER: Pull the follower to the end of the magazine and hook the follower over the back

edge of the magazine.

2. LOADING CLIPS: Clips are loaded with the single ear forward. If clips are loaded backward into the

magazine, double ears forward, they will not wrap and jamming will occur. The first check of jamming

should be to see that the clips are properly loaded in the magazine.

3. CHECK ADJUSTMENT: Loosen the two screws holding the magazine cover. Place the cover

approximately .04” (1mm) from the top of the clips in the magazine.

4. RELEASE FOLLOWER: Rock the follower forward which will release the hook off the back edge of

the magazine.

REMOVE JAMS: Disconnect the air supply. Pull the follower to the end of the magazine and hook the

follower over the back edge of the magazine. This will remove the force on the strip of the clips ( remove

clips if necessary ) and the clip should drop out. If tool is still jammed, remove clip manually.

NOTE: Use only fasteners recommended by HARTCO for the C Series tool or fasteners which

meet HARTCO specifications.

1.

2.

3.

4.

Page 7

-7-

IN

ADDITION TO THE OTHER WARNINGS CONTAINED IN THIS MANUAL

OBSERVE THE FOLLOWING FOR SAFE OPERATION

• Use the HARTCO pneumatic tool only for the purpose for which it was designed.

• Never use this tool in a manner that could cause a fastener to be directed toward the user

or others in the work area.

• Do not use the tool as a hammer.

• Always carry the tool by the handle. Never carry the tool by the air hose.

• Do not alter or modify this tool from the original design or function without approval from

HARTCO, INC.

• Always be aware that misuse and improper handling of this tool can cause injury to

yourself and others.

• Never clamp or tape the trigger in an actuated position.

• Never leave a tool unattended with the air hose attached.

• Do not operate this tool if it does not contain a legible WARNING LABEL.

•Do not continue to use a tool that leaks air or does not function properly. Notify your

nearest HARTCO representative if your tool continues to experience functional problems.

MAINTAINING THE PNEUMATIC TOOL

When working on air tools, note the warnings in this manual and use extra care when

evaluating problem tools.

Caution must be used for maintaining the follower spring assembly. The spring is not attached to the

roller, and if extended beyond the roller length it will slip off and roll up rapidly. The edges of the spring

are very thin and care should be taken to avoid being cut. Care must also be taken to ensure that no

permanent kinks are put into the spring as this can reduce the spring’s applied force.

REPLACEMENT P

ARTS:

HARTCO replacement parts are recommended. Do not use modified parts or parts which will not give

equivalent performance to the original equipment.

ASSEMBLY PROCEDURE FOR SEALS:

When repairing a tool, make sure the internal parts are clean and lubricated. Use Parker “O”-LUBE or

equivalent on all “O”-rings. Coat each “O”-ring with “O”-LUBE before assembling. Use a small amount of oil

on all moving surfaces and pivots. After reassembly add a few drops of BOSTITCH Air Tool Lubricant through

the air line fitting before testing.

AIR SUPPL

Y-PRESSURE AND VOLUME:

Air volume is as important as air pressure. The air volume supplied to the tool may be inadequate because of

undersize fittings and hoses, or from the effects of dirt and water in the system. Restricted air flow will prevent

the tool from receiving an adequate volume of air, even though the pressure reading is high. The results will

be slow operation, misfeeds or reduced driving power. Before evaluating tool problems for these symptoms,

trace the air supply from the tool to the supply source for restrictive connectors, swivel fittings, low points

containing water and anything else that would prevent full volume flow of air to the tool.

Page 8

-8-

TROUBLE SHOOTING

PROBLEM CAUSE CORRECTION

Trigger valve housing leaks air O-ring cut or cracked . . . . . . . . . . . . . . . . . . . .Replace O-ring

Trigger valve stem leaks air O-ring/seals cut or cracked . . . . . . . . . . . . . . . .Replace trigger valve assembly

Frame/cap leaks air Damaged gasket or seal . . . . . . . . . . . . . . . . . .Replace gasket or seal

Loose cap screws . . . . . . . . . . . . . . . . . . . . . .Tighten and recheck

Failure to cycle Air supply restriction . . . . . . . . . . . . . . . . . . . . .Check air supply equipment

Tool dry, lack of lubrication . . . . . . . . . . . . . . . .Use BOSTITCH Air Tool Lubricant

Worn piston O-rings . . . . . . . . . . . . . . . . . . . . .Replace O-rings

Broken piston return springs . . . . . . . . . . . . . . .Replace piston return springs

Lack of power; slow to cycle Tool dry, lacks lubrication . . . . . . . . . . . . . . . . .Use BOSTITCH Air Tool Lubricant

O-rings/seals cut or cracked . . . . . . . . . . . . . . .Replace O-rings/seals

Exhaust blocked . . . . . . . . . . . . . . . . . . . . . . .Check valve O-rings

Trigger assembly worn/leaks . . . . . . . . . . . . . .Replace trigger assembly

Dirt build up on blade . . . . . . . . . . . . . . . . . . . .Disassemble to clean

Valve dry . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Disassemble/lubricate

Air pressure too low . . . . . . . . . . . . . . . . . . . . .Check air supply equipment

Skipping fasteners; intermittent feed Dirt in blade area . . . . . . . . . . . . . . . . . . . . . . .Disassemble and clean tool

Air restriction/inadequate air flow through

quick disconnect socket and plug . . . . . . . . . . .Replace quick disconnect fittings

Worn piston O-ring . . . . . . . . . . . . . . . . . . . . . .Replace O-ring, check driver

Tool dry, lacks lubrication . . . . . . . . . . . . . . . . .Use BOSTITCH Air Tool Lubricant

Damaged follower spring . . . . . . . . . . . . . . . . .Replace spring

Low air pressure . . . . . . . . . . . . . . . . . . . . . . . .Check air supply system to tool

Loose screws . . . . . . . . . . . . . . . . . . . . . . . . . .Tighten all screws

Fasteners too short for tool . . . . . . . . . . . . . . . .Use only recommended fasteners

Bent fasteners . . . . . . . . . . . . . . . . . . . . . . . . .Discontinue using these fasteners

Wrong size fasteners . . . . . . . . . . . . . . . . . . . .Use only recommended fasteners

Leaking head cap gasket . . . . . . . . . . . . . . . . .Tighten screws/replace gasket

Trigger valve O-ring cut/worn . . . . . . . . . . . . . .Replace O-ring

Broken/chipped blade . . . . . . . . . . . . . . . . . . . .Replace blade (check piston O-ring)

Dirty magazine . . . . . . . . . . . . . . . . . . . . . . . . .Clean/lubricate use BOSTITCH Air Tool Lubricant

Worn magazine . . . . . . . . . . . . . . . . . . . . . . . .Replace magazine

Fasteners jam in tool Clips loaded backwards . . . . . . . . . . . . . . . . . .Turn clips around

Wrong size fasteners . . . . . . . . . . . . . . . . . . . .Use only recommended fasteners

Bent fasteners . . . . . . . . . . . . . . . . . . . . . . . . .Discontinue using these fasteners

Loose screws . . . . . . . . . . . . . . . . . . . . . . . . . .Tighten all screws

Broken/chipped blade . . . . . . . . . . . . . . . . . . . .Replace blade

ACCESSORIES AVAILABLE

BC601 4 oz. Bostitch Air-Tool Lubricant.

BC602 1 pint Bostitch Air Tool Lubricant.

BC603 1 pint Bostitch “Winter-Formula” Air-Tool Lubricant.

BC604 1 quart Bostitch Air-Tool Lubricant

851325 Loctite Grade 271 (.02 oz.)

851385 Loctite Grade 242 (.02 oz.)

100679 Lube (1lb. can)

134521 CL, Tool Hanger

HR-55996 Clinch Clip Removal Pliers

Page 9

-9-

INTRODUCCIÓN

Las herramientas HARTCO de la serie C son fabricadas a precisión, diseñadas para funcionar a alta velocidad y con alto

volumen. Estas herramientas entregan un servicio eficiente y fiable cuando se usan correctamente y con cuidado. Al igual que

con toda herramienta automática de calidad, deben seguirse las instrucciones del fabricante para obtener el óptimo rendimiento.

Estudie este manual antes de operar la herramienta y tome nota de las advertencias y precauciones de seguridad. Deben leerse

en detalle las instrucciones sobre la instalación, operación y mantenimiento, y deben conservarse los manuales para referencia.

NOTA: Pueden necesitarse medidas adicionales de seguridad según la aplicación particular de la herramienta. Diríjase al

representante o distribuidor de STANLEY HARTCO si tiene alguna pregunta referente a la herramienta y su uso.

ÍNDICE

Instrucciones de seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Especificaciones de la herramienta, funcionamiento . . . . . . . . . . . . . . . . . . . . . . . 11

Suministro de aire: Accesorios, mangueras, filtros, consumo de aire,

reguladores, presión operativa, cómo establecer la presión correcta . . . . . . . . . . . 12

Lubricación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Carga de la herramienta . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Mantenimiento de la herramienta neumática . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Solución de problemas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Accesorios. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

NOTA:

Las herramientas HARTCO se han diseñado para brindar una satisfacción excelente al cliente y lograr máximo rendimiento al

utilizarse con fijaciones de precisión HARTCO diseñadas con las mismas normas estrictas. HARTCO no puede asumir

responsabilidad alguna por el rendimiento del producto si se utilizan nuestras herramientas con fijaciones o accesorios que no

reúnen los requisitos específicos establecidos para las fijaciones y accesorios genuinos de HARTCO.

GARANTÍA LIMITADA

HARTCO garantiza al comprador original al por menor que este producto está exento de defectos de material y fabricación,

además se compromete a reparar o cambiar, a opción de HARTCO, cualquier producto defectuoso dentro de 180 días de la

fecha de compra. Esta garantía no es transferible. Solamente cubre daños resultantes de defectos en material o fabricación, y

no cubre condiciones o desperfectos resultantes del desgaste normal, negligencia, abuso, accidentes o reparaciones intentadas

o efectuadas por terceros ajenos a nuestro centro regional de reparaciones o al centro de servicio bajo garantía. Las aspas del

impulsor y las juntas tóricas se consideran componentes de desgaste normal.

ESTA GARANTÍA REEMPLAZA TODAS LAS DEMÁS GARANTÍAS EXPRESAS. TODA GARANTÍA DE COMERCIABILIDAD O

IDONEIDAD PARA UN FIN PARTICULAR SE LIMITA A LA DURACIÓN DE ESTA GARANTÍA. HARTCO NO SERÁ

RESPONSABLE DE DAÑOS FORTUITOS NI CONSECUENCIALES.

Esta garantía se limita a ventas dentro de los Estados Unidos y Canadá. Algunos estados no permiten limitaciones a la duración

de una garantía implícita ni la exclusión o limitación de daños fortuitos o consecuenciales, de modo que las limitaciones o

exclusiones anteriores pueden no corresponder a su caso. Esta garantía le concede derechos legales específicos, y usted puede

tener también otros derechos que varían de un estado a otro.

Para obtener servicio bajo la garantía, devuelva el producto con cargo a nosotros junto con su comprobante de compra dirigido

al centro regional o al centro de reparaciones bajo garantía de HARTCO. Puede llamarnos también al 1-800-556-6696 o visitar

la página web www.bostitch.com para obtener la dirección de los centros autorizados de servicio bajo garantía en su área.

Page 10

-10-

INSTRUCCIONES DE SEGURIDAD

Al cargar, operar o dar servicio a esta herramienta, el operador y los demás presentes en el área de

trabajo deben usar SIEMPRE PROTECCIÓN DE LOS OJOS

en conformidad con las especificaciones

ANSI y que proteja contra partículas que vuelen por DELANTE y por el LADO, cuando se haga la

conexión al suministro de aire. Se exige protegerse la vista para resguardarse contra fijaciones o

residuos que vuelen, lo cual puede causar lesiones graves a los ojos.

El empleador o el usuario deben asegurar que se protejan debidamente los ojos. El equipo de

protección ocular debe estar en conformidad con los requisitos del Instituto Nacional Americano de

Normas (American National Standards Institute), ANSI Z87.1 y proteger por delante y por el costado.

NOTA: Los anteojos o máscaras sin protección lateral por sí solos no dan una protección adecuada.

PRECAUCIÓN:

En algunos ambientes se necesitará protección adicional de seguridad. Por ejemplo,

el área de trabajo puede exponer a un nivel de ruido que lesione el oído. El empleador y el usuario

deben comprobar que se cuente con la protección necesaria del oído y que el operador y los demás

presentes en el área la usen. Algunos ambientes exigirán el uso de casco protector. Cuando sea

necesario, el empleado y el usuario deben verificar que se proteja la cabeza en conformidad con la

norma ANSI Z89.1.

SUMINISTRO DE AIRE Y CONEXIONES

No use oxígeno, gases combustibles ni gases envasados en cilindros para operar esta herramienta

porque puede explotar, causando posibles lesiones.

No use fuentes de suministro que tengan el potencial de superar 90 P.S.I.G. dado que la herramienta

puede explotar, causando posibles lesiones.

El conector de la herramienta no debe contener presión cuando se desconecte el suministro de aire.

Si se usa el conector indebido, la herramienta puede mantenerse cargada con aire después de

desconectarla y podría impulsar una fijación en el yunque, incluso después de desconectar la línea

de aire, causando posibles lesiones.

No accione el gatillo al hacer la conexión al suministro de aire porque la herramienta puede hacer un

ciclo, posiblemente causando lesiones.

Siempre desconecte el suministro de aire: 1.) Antes de hacer ajustes; 2.) Al dar servicio a la

herramienta; 3.) Al eliminar un atasco; 4.) Cuando no esté en uso la herramienta; 5.) Al trasladarse a

un área de trabajo diferente, porque puede activarse la unidad casualmente, causando posibles

lesiones.

CARGA DE LA HERRAMIENTA

Al cargar la herramienta: 1.) Nunca ponga la mano ni ninguna parte del cuerpo en el área del yunque

de la herramienta; 2.) Nunca apunte la herramienta hacia nadie; 3.) No accione el gatillo ya que puede

activarse la unidad accidentalmente, causando posibles lesiones.

Si se cargan los clips al revés dentro del depósito con las orejas dobles hacia adelante, no se

doblarán y se producirán atascos. Lo primero que se revise en la herramienta atascada debe ser que

los clips estén colocados correctamente en el depósito.

FUNCIONAMIENTO

Siempre maneje la herramienta con cuidado: 1.) Nunca participe en juegos rudos; 2.) Nunca accione el

gatillo a menos que la punta esté dirigida hacia el trabajo; 3.) Mantenga a los demás a una distancia

segura de la herramienta mientras esté en funcionamiento porque puede activarse accidentalmente,

causando posibles lesiones.

Mantenga las manos y el cuerpo alejados del área del yunque de la herramienta.

No engarce las fijaciones unas sobre otras porque esto puede hacer que se atasque la herramienta,

disminuyendo su vida útil.

MANTENIMIENTO DE LA HERRAMIENTA

Al trabajar con herramientas neumáticas, observe las advertencias de este manual y tenga sumo

cuidado al evaluar herramientas con problemas.

Page 11

-11-

ESPECIFICACIONES DE LA HERRAMIENTA

Todos los tornillos y tuercas son de la norma nacional americana.

ESPECIFICACIONES DE LAS FIJACIONES:

Vea la ilustración del producto #IP1200-1 o el Catálogo de fijaciones y herramientas industriales de BOSTITCH.

CONECTOR DE AIRE DE LA HERRAMIENTA:

Esta herramienta usa un enchufe conector de flujo libre, de 1/4 pulg. N.P.T. El diámetro mínimo interior debe ser de

5 mm (0.200 pulg.). El conector debe ser capaz de descargar la presión de aire de la herramienta al desconectarse del

suministro de aire.

PRESIÓN OPERATIVA:

70 a 90 p.s.i. ( 4.9 a 6.2 kg/cm2). Seleccione la presión operativa dentro de esta gama para lograr el óptimo rendimiento. NO

SUPERE ESTAPRESIÓN OPERATIVA RECOMENDADA DE 90 P.S.I.

CONSUMO DE AIRE:

Las herramientas HARTCO SERIE C necesitan 0.07 metros cúbicos (2.6 pies cúbicos por minuto) de aire libre para funcionar a

razón de 100 clips por minuto, a 6.2 kg/cm

2

(90 p.s.i.). Tome la velocidad real con la cual operará la herramienta para determinar

la cantidad de aire necesaria. Por ejemplo, si el uso de fijaciones promedia 50 clips por minuto, necesita el 50% de los pies

cúbicos por minuto de la herramienta para funcionar a razón de 100 clips por minuto.

FUNCIONAMIENTO DE LA HERRAMIENTA

Al cargar, operar o dar servicio a esta herramienta, el operador y los demás presentes en el área de

trabajo deben usar SIEMPRE PROTECCIÓN DE LOS OJOS

en conformidad con las especificaciones

ANSI y que proteja contra partículas que vuelen por DELANTE y por el LADO, cuando se haga la

conexión al suministro de aire. Se exige protegerse la vista para resguardarse contra fijaciones o

residuos que vuelen, lo cual puede causar lesiones graves a los ojos.

El empleador o el usuario deben asegurar que se protejan debidamente los ojos. El equipo de

protección ocular debe estar en conformidad con los requisitos del Instituto Nacional Americano de

Normas (American National Standards Institute), ANSI Z87.1 y proteger por delante y por el costado.

NOTA: Las gafas o caretas sin protección lateral por sí solas no dan una protección adecuada.

ANTES DE MANIPULAR U OPERAR ESTA HERRAMIENTA:

I. LEA DETALLADAMENTE LAS ADVERTENCIAS CONTENIDAS EN ESTE MANUAL.

II. CONSULTE LAS “ESPECIFICACIONES DE LA HERRAMIENTA” EN ESTE MANUAL PARA

IDENTIFICAR EL SISTEMA OPERATIVO DE LA HERRAMIENTA.

MODELO LARGO ALTURA ANCHO PESO

Herramienta 470 mm (18.5”) 203 mm (8”) 95 mm (3.75”) 2.50 kg (5.20 lbs)

Serie C

Page 12

-12-

SUMINISTRO DE AIRE Y CONEXIONES

No use oxígeno, gases combustibles ni gases envasados en cilindros para operar esta herramienta

porque puede explotar, causando posibles lesiones.

CONECTORES:

Instale un enchufe macho en la herramienta que está fluyendo libremente y que liberará presión de aire de la herramienta al

desconectarse de la fuente de alimentación.

MANGUERAS:

Las mangueras de aire deben tener un mínimo de 10.6 kg/cm2(150 p.s.i.) de capacidad nominal de presión de trabajo o un 150

por ciento de la presión máxima que podría producirse en el sistema de aire. La manguera de suministro debe contar con un

conector de “desconexión rápida” del enchufe macho en la herramienta.

FUENTE DE SUMINISTRO:

Use solamente aire comprimido regulado limpio como fuente de energía para esta herramienta. NUNCA USE OXÍGENO, GASES

COMBUSTIBLES O GASES ENVASADOS EN CILINDROS COMO FUENTE DE ENERGÍAPARA ESTAHERRAMIENTA, PUES LA

HERRAMIENTAPUEDE EXPLOTAR.

REGULADOR:

Se necesita un regulador de presión con una presión operativa de 0 - 8.79 kg/cm2(0 - 125 p.s.i.) para controlar la presión

operativa con el fin de que la herramienta funcione en forma segura. No conecte esta herramienta a la presión de aire que

potencialmente pueda superar 14 kg/cm

2

(200 p.s.i.) pues la herramienta puede fracturarse o explotar, causando posibles

lesiones.

PRESIÓN OPERATIVA:

No supere la presión operativa máxima recomendada de 90 p.s.i. porque aumentará considerablemente el desgaste de la

herramienta. El suministro de aire debe ser capaz de mantener la presión operativa de la herramienta. Las caídas de presión en

el suministro de aire pueden reducir la energía impulsora de la herramienta.

FIL

TRO:

La suciedad y el agua en el suministro de aire son las causas principales de desgaste en las herramientas neumáticas. Resultará

útil un filtro para obtener el mejor rendimiento y minimizar el desgaste de la herramienta. El filtro debe tener una capacidad de

flujo adecuada para la instalación específica. El filtro debe mantenerse limpio para ser eficaz en el suministro de aire comprimido

limpio a la herramienta. Consulte las instrucciones del fabricante para ver el mantenimiento adecuado del filtro. Si el filtro está

sucio y obstruido ocasionará una caída de presión que a su vez reduce el rendimiento de la herramienta.

LUBRICACIÓN

Se necesita una lubricación frecuente, pero no excesiva, para obtener el óptimo rendimiento. El aceite colocado a través de la

conexión de la línea de aire lubricará las piezas internas. Use el Lubricante para herramientas neumáticas BOSTITCH, Mobil

Velocite #10 u otro equivalente. No use aceite ni aditivos detergentes porque estos lubricantes causarán un desgaste acelerado

a los sellos de la herramienta, ocasionando un rendimiento deficiente y mantenimiento frecuente de la herramienta. Si no se usa

un lubricante de línea de aire, coloque aceite durante el uso en la grasera de aire de la herramienta una o dos veces al día.

Solamente se necesitan unas pocas gotas de aceite a la vez. El exceso de aceite se acumulará dentro de la herramienta y se

notará en el ciclo de escape.

FUNCIONAMIENTO EN CLIMA FRÍO:

Para el funcionamiento en clima frío, cerca o bajo cero grados centígrados, la humedad de la línea de aire puede congelarse e

impedir el funcionamiento de la herramienta. Recomendamos el uso del lubricante invernal para herramientas neumáticas

BOSTITCH WINTER FORMULA o anticongelante permanente (etilenglicol) como lubricante en clima frío.

PRECAUCIÓN: No guarde herramientas en un ambiente de clima frío para evitar la formación de escarcha o hielo en

las válvulas y mecanismos de funcionamiento de las herramientas que pudieran ocasionarles fallas.

NOTA: Algunos líquidos comerciales secantes de línea de aire son dañinos para las juntas tóricas y sellos – no use

estos secadores de aire de baja temperatura sin revisar la compatibilidad.

Page 13

-13-

CÓMO CARGAR UNA HERRAMIENTA REMACHADORA SERIE C

Al cargar, operar o dar servicio a esta herramienta, el operador y los demás presentes en el área de

trabajo deben usar SIEMPRE PROTECCIÓN DE LOS OJOS

en conformidad con las especificaciones

ANSI y que proteja contra partículas que vuelen por DELANTE y por el LADO, cuando se haga la

conexión al suministro de aire. Se exige protegerse la vista para resguardarse contra fijaciones o

residuos que vuelen, lo cual puede causar lesiones graves a los ojos.

El empleador o el usuario deben asegurar que se protejan debidamente los ojos. El equipo de

protección ocular debe estar en conformidad con los requisitos del Instituto Nacional Americano de

Normas (American National Standards Institute), ANSI Z87.1 y proteger por delante y por el costado.

NOTA: Las gafas o caretas sin protección lateral por sí solas no dan una protección adecuada.

PARAPREVENIR LESIONES ACCIDENTALES:

• Nunca coloque la mano ni ninguna parte del cuerpo en el área del yunque de la herramienta mientras

esté conectado el suministro de aire.

• Nunca apunte la herramienta hacia una persona.

• Nunca participe en juegos rudos.

• Nunca accione el gatillo a menos que la punta esté dirigida hacia el trabajo.

• Siempre maneje la herramienta con cuidado.

• No accione el gatillo al cargar la herramienta.

1. PREPARACIÓN DEL SEGUIDOR: Lleve el seguidor al extremo del depósito y engánchelo por encima del borde posterior

del depósito.

2. CARGA DE LOS CLIPS: Los clips se cargan con la oreja simple hacia adelante. Si se cargan los clips al revés dentro del

depósito, con las orejas dobles hacia delante, no se envolverán bien y causarán atascos. La primera vez que se revise un

atasco debe comprobarse que los clips estén cargados correctamente en el depósito.

3. REVISE EL AJUSTE: Suelte los dos tornillos que sujetan la tapa del depósito. Ponga la tapa aproximadamente a

1 mm (0.04”) de la parte superior de los clips en el depósito.

4. LIBERACIÓN DEL SEGUIDOR: Oscile el seguidor hacia adelante para liberar el enganche del borde posterior del

depósito.

ELIMINE LOS ATASCOS: Desconecte el suministro de aire. Lleve el seguidor hasta el final del depósito y engánchelo

por encima del borde posterior del depósito. Esto eliminará la fuerza de la tira de clips (retire los clips si es necesario) y el clip

debe salirse. Si la herramienta sigue atascada, retire el clip manualmente.

NOTA: Use solamente fijaciones recomendadas por HARTCO para la herramienta Serie C o fijaciones que

cumplan con las especificaciones de HARTCO.

1.

2.

3.

4.

Page 14

-14-

ADEMÁS DE LAS OTRAS

ADVERTENCIAS CONTENIDAS EN ESTE MANUAL

OBSERVE LO SIGUIENTE PARA LA OPERACIÓN SEGURA

• Use la herramienta neumática HARTCO solamente para el fin que fue diseñada.

• Nunca use esta herramienta en forma que pueda causar la salida de una fijación hacia el usuario

u otros presentes en el área de trabajo.

• No use la herramienta como martillo.

• Siempre lleve la herramienta tomándola por la empuñadura. Nunca lleve la herramienta tomándola por la manguera

de aire.

• No altere ni modifique el diseño o función original de esta herramienta sin la aprobación de

HARTCO, INC.

• Siempre tenga presente que el uso indebido o la manipulación incorrecta de esta herramienta puede causarle

lesiones a usted y a los demás.

• Nunca sujete el gatillo con abrazaderas ni lo pegue con cinta adhesiva en una posición activada.

• Nunca deje una herramienta sin supervisión con la manguera de aire conectada.

• No opere esta herramienta si no cuenta con una ETIQUETADE ADVERTENCIA legible.

• Deje de usar la herramienta si tiene fugas de aire o no funciona bien. Notifique al representante

más cercano de HARTCO si la herramienta sigue presentando problemas funcionales.

MANTENIMIENTO DE LA HERRAMIENTA NEUMÁTICA

Al trabajar con herramientas neumáticas, observe las advertencias de este manual y tenga sumo

cuidado al evaluar herramientas con problemas.

Debe tenerse cuidado al mantener el ensamblaje del resorte del seguidor. El resorte no está conectado al rodillo y, si se

extiende más allá del largo del rodillo, se saldrá y enrollará rápidamente. Los bordes del resorte son muy delgados y debe

tener cuidado para evitar cortarse. Debe tener cuidado para asegurar que no se hagan dobleces permanentes en el

resorte porque esto reducirá la fuerza aplicada del mismo.

PIEZAS DE REPUESTO:

Se recomienda usar repuestos HARTCO. No use piezas modificadas ni componentes que no tengan un rendimiento equivalente

al equipo original.

PROCEDIMIENTO DE ENSAMBLAJE PARA LOS SELLOS:

Al reparar una herramienta, fíjese que las piezas internas estén limpias y lubricadas. Use Parker “O”-LUBE u otro lubricante

equivalente en todas las juntas tóricas. Cubra cada junta tórica con “O”-LUBE antes del ensamblaje. Use un poco de aceite en

todas las superficies y pivotes móviles. Después del reensamblaje añada unas pocas gotas de Lubricante para herramientas

neumáticas BOSTITCH (Air Tool Lubricant) a través de la grasera de la línea de aire antes de probar.

PRESIÓN Y VOLUMEN DEL SUMINISTRO DE AIRE:

El volumen de aire es tan importante como la presión de aire. El volumen de aire suministrado a la herramienta puede ser

inadecuado debido a accesorios y mangueras de tamaño inferior o por los efectos de suciedad y agua en el sistema. El flujo de

aire restringido impedirá que la herramienta reciba un volumen de aire adecuado, aun cuando la lectura de presión sea alta. Los

resultados serán: funcionamiento lento, fijaciones mal dirigidas o menor potencia de impulso. Antes de evaluar los problemas de

las herramientas según estos síntomas, inspeccione el suministro de aire desde la herramienta a la fuente de suministro en

busca de conectores restrictivos, accesorios giratorios, puntos bajos que tengan agua y cualquier otra cosa que impida el flujo

del volumen completo de aire a la herramienta.

Page 15

-15-

SOLUCIÓN DE PROBLEMAS

PROBLEMA CAUSA CORRECCIÓN

El alojamiento de la válvula de disparo

tiene una fuga de aire La junta tórica está cortada o agrietada . . . . . . . . . . . . . . .Cambie la junta tórica

El vástago de la válvula de disparo

tiene fuga de aire La junta tórica o los sellos están cortados o agrietados . . .Cambie el ensamblaje de la válvula de disparo

El armazón o la tapa tienen una fuga de aire La empaquetadura o el sello están dañados . . . . . . . . . . .Cambie la empaquetadura o sello

Los tornillos de casquete están sueltos . . . . . . . . . . . . . . .Apriete y revíselos de nuevo

No hay ciclos El suministro de aire está restringido . . . . . . . . . . . . . . . . .Revise el equipo de suministro de aire

La herramienta está seca, falta de lubricación . . . . . . . . . .Use el Lubricante para herramientas neumáticas BOSTITCH

Las juntas tóricas de los pistones están desgastadas . . . .Cambie las juntas tóricas

Los resortes de retorno del pistón están rotos . . . . . . . . . .Cambie los resortes de retorno del pistón

Falta energía; el ciclo es lento La herramienta está seca, falta lubricación . . . . . . . . . . . .Use el Lubricante para herramientas neumáticas BOSTITCH

Las juntas tóricas o sellos están cortados o agrietados . . .Cambie las juntas tóricas o los sellos

El escape está bloqueado . . . . . . . . . . . . . . . . . . . . . . . .Revise las juntas tóricas de la válvula

El ensamblaje del gatillo está desgastado o tiene fugas . . .Cambie el ensamblaje del gatillo

Hay acumulación de suciedad en la hoja . . . . . . . . . . . . . .Desarme para limpiar

La válvula está seca . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Desármela y lubríquela

La presión de aire está demasiado baja . . . . . . . . . . . . . . .Revise el equipo de suministro de aire

Se saltan fijaciones;

alimentación intermitente Hay suciedad en el área de la hoja . . . . . . . . . . . . . . . . . .Desarme y limpie la herramienta

Hay restricción de aire y flujo de aire inadecuado a

través del enchufe y la toma de desconexión rápida . . . . .Cambie los accesorios de desconexión rápida

Está desgastada la junta tórica del pistón . . . . . . . . . . . . .Cambie la junta tórica y revise el impulsor

La herramienta está seca, falta lubricación . . . . . . . . . . . .Use el Lubricante para herramientas neumáticas BOSTITCH

El resorte del seguidor está dañado . . . . . . . . . . . . . . . . . .Cambie el resorte

Hay baja presión de aire . . . . . . . . . . . . . . . . . . . . . . . . . .Revise el sistema de suministro de aire a la herramienta

Hay tornillos sueltos . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Apriete todos los tornillos

Las fijaciones son demasiado cortas para la herramienta . .Use solamente las fijaciones recomendadas

Hay fijaciones dobladas . . . . . . . . . . . . . . . . . . . . . . . . . . .Deje de usar estas fijaciones

Las fijaciones son del tamaño incorrecto . . . . . . . . . . . . . .Use solamente las fijaciones recomendadas

La empaquetadura de la tapa cabezal tiene fugas . . . . . . .Apriete los tornillos y cambie la empaquetadura

La junta tórica de la válvula de gatillo está cortada

o desgastada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Cambie la junta tórica

La hoja está rota o picada . . . . . . . . . . . . . . . . . . . . . . . . .Cambie la hoja (revise la junta tórica del pistón)

El depósito está sucio . . . . . . . . . . . . . . . . . . . . . . . . . . . .Limpie/lubrique con Lubricante para herramientas neumáticas BOSTITCH

El depósito está desgastado . . . . . . . . . . . . . . . . . . . . . . .Cambie el depósito

Las fijaciones se atascan en la herramienta Los clips están cargados al revés . . . . . . . . . . . . . . . . . . .Cambie los clips de posición

Las fijaciones tienen el tamaño incorrecto . . . . . . . . . . . . .Use solamente las fijaciones recomendadas

Hay fijaciones dobladas . . . . . . . . . . . . . . . . . . . . . . . . . . .Deje de usar estas fijaciones

Hay tornillos sueltos . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Apriete todos los tornillos

La hoja está rota o picada . . . . . . . . . . . . . . . . . . . . . . . . .Cambie la hoja

ACCESORIOS DISPONIBLES

BC601 Lubricante Bostitch Air -Tool de 118 ml (4 oz.) para herramientas neumáticas.

BC602 Lubricante Bostitch Air Tool de 470 ml (1 pinta) para herramientas neumáticas.

BC603 Lubricante Bostitch “Winter-Formula” de 470 ml (1 pinta) para herramientas neumáticas.

BC604 Lubricante Bostitch Air -Tool de 940 ml (1 cuarto de galón) para herramientas neumáticas

851325 Loctite Grade 271 (59 ml [0.02 oz.])

851385 Loctite Grade 242 (59 ml [0.02 oz.])

100679 Lubricante (lata de 454 g [1 lb.])

134521 CL, Colgador de herramienta

HR-55996 Alicates sacaclips de remache

Page 16

-16-

INTRODUCTION

Les appareils de la série C de HARTCO sont des outils de précision conçus pour fonctionner à haute vitesse et fournir un haut

rendement. Ils offrent un service efficace et fiable lorsque utilisés correctement et avec soin. Comme pour tout outil sophistiqué,

il est nécessaire de suivre les instructions du fabricant pour obtenir de meilleures performances. Veuillez étudier ce manuel avant

la mise en fonction de l’outil, et vous assurer d’avoir compris les avertissements et consignes de sécurité inclus. Lisez avec

précaution les instructions d’installation, de fonctionnement et de maintenance; conservez les manuels pour référence ultérieure.

REMARQUE : Des mesures de sécurité supplémentaires peuvent être requises en fonction de votre utilisation particulière de

l’outil. Pour toute question concernant l’outil et son utilisation, contactez votre représentant ou distributeur STANLEY HARTCO.

INDEX

Instructions de sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Spécifications de l’outil, utilisation de l’outil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Source d’alimentation en air : Garnitures, conduits, filtres, consommation d’air,

régulateurs, pression de fonctionnement, réglage de la pression correcte . . . . . . . 19

Lubrification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Chargement de l’outil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Maintenance de l’outil pneumatique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Dépannage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Accessoires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

REMARQUE :

Les outils HARTCO ont été conçus pour répondre aux attentes des consommateurs et offrent des performances optimales, lorsqu’ils

sont utilisés en conjonction avec les dispositifs de fixation HARTCO obéissant au même standard. HARTCO ne garantit pas les

performances de vos outils s’ils sont utilisés avec des dispositifs de fixation ou accessoires ne répondant pas strictement aux

exigences établies pour les attaches et accessoires originaux HARTCO.

GARANTIE LIMITÉE

HARTCO garantit à l’utilisateur final que ce produit est exempt de tout défaut de matériaux et de fabrication, et accepte le cas

échéant de réparer ou remplacer, à la discrétion de Hartco, tout produit défectueux pendant une période de 180 jours à partir de

la date d’achat. Cette garantie n’est pas cessible. Elle couvre uniquement les dommages résultant de défaut de matériaux et de

fabrication, et ne couvre pas les conditions ou défauts de fonctionnement résultant d’une usure normale, d’une négligence, d’un

usage abusif, d’un accident ou de tentatives de réparation par une entité autre que notre Centre de réparation local ou un Centre

de service de garantie autorisé. Les lames du chargeur et les joints toriques sont considérés comme des pièces normales

d’usure.

CETTE GARANTIE REMPLACE TOUTE AUTRE GARANTIE EXPRESSE. TOUTE GARANTIE DE VALEUR MARCHANDE, DE

QUALITÉ COMMERCIALE OU D’ADÉQUATION À UN USAGE PARTICULIER SE LIMITE À LA DURÉE DE CETTE GARANTIE.

HARTCO NE SERA PAS TENUE RESPONSABLE DES DOMMAGES INDIRECTS OU ACCESSOIRES.

Cette garantie se limite aux ventes effectuées aux États-Unis et au Canada. Les limitations imposées par la durée d’une garantie

implicite ou l’exclusion des dommages accessoires ou indirects n’étant pas reconnue dans certains États, les limitations ou

exclusions précitées peuvent ne pas vous être adressées. Cette garantie vous confère des droits juridiques spécifiques qui

s’ajoutent aux autres droits éventuels qui peuvent varier d’une province ou d’une juridiction à l’autre.

Pour obtenir des services liés à la garantie, retournez le produit à vos frais accompagné de la preuve d’achat à votre Centre de

réparation local ou à un Centre de service de garantie autorisé HARTCO. Pour obtenir l’adresse d’un centre de service de

garantie autorisé dans votre localité, composez le 1-800-556-6696 ou consultez notre site Web : www.bostitch.com.

Page 17

-17-

INSTRUCTIONS DE SÉCURITÉ

UNE PROTECTION DES YEUX, conforme aux normes ANSI et fournissant une protection contre les

projectiles en provenance de l’AVANT et des CÔTÉS, doit TOUJOURS être portée par l’opérateur et les

personnes présentes dans la zone de travail, lors du raccordement à une source d’air, du chargement,

du fonctionnement et de la maintenance de l’outil. Une telle protection est indispensable pour vous

protéger contre les attaches et débris projetés, susceptibles d’entraîner des blessures sérieuses.

L’employeur et/ou l’utilisateur doivent s’assurer de porter une protection oculaire. L’équipement de

protection doit être conforme à la norme ANSI Z87.1 et doit fournir une protection frontale et latérale.

REMARQUE : Des lunettes sans protection latérale et des masques faciaux ne fournissent pas la

protection nécessaire.

MISE EN GARDE

: Des mesures de sécurité supplémentaire sont requises dans certains

environnements. Par exemple, la zone de travail peut favoriser l’exposition à un niveau de bruit

susceptible d’entraîner une surdité. L’employeur et l’utilisateur doivent s’assurer qu’une protection de

l’ouïe sera utilisée par l’opérateur et les personnes présentes dans la zone de travail. Certains

environnements exigeront l’utilisation d’un équipement de protection de la tête. Lorsque cela s’avère

nécessaire, l’employeur et l’utilisateur doivent s’assurer que la protection de la tête est conforme à la

norme ANSI Z89.1.

ALIMENTATION D’AIR ET CONNEXIONS

N’utilisez jamais de l’oxygène, des gaz combustibles ou des bouteilles de gaz comme source

d’alimentation pour cet outil; il pourrait exploser et causer des blessures.

Ne pas utiliser de sources d’alimentation pouvant excéder 6,3 kg/cm (90 lb/po) de pression

manométrique; l’outil pourrait exploser et causer des blessures.

Le connecteur de l’outil ne doit pas être sous pression après avoir été déconnecté de l’alimentation

d’air. Si un raccord incorrect est utilisé, l’outil peut rester sous pression après déconnexion et être

capable de fixer un dispositif dans l’enclume même si la conduite d’air est déconnectée, occasionnant

le cas échéant des blessures.

Ne pas appuyer sur la gâchette lorsque vous vous connectez à l’alimentation d’air; l’outil pourrait

effectuer un cycle et causer des blessures.

Veillez à toujours déconnecter l’alimentation d’air : 1.) Avant d’effectuer tout réglage; 2.) Lors de la

maintenance de l’outil; 3.) Au moment de déloger une obstruction; 4.) Lorsque l’outil n’est pas utilisé;

5.) Lors du transport de l’outil dans une autre zone de travail — une mise en marche accidentelle

pourrait causer des blessures.

CHARGEMENT DE L’OUTIL

Lors du chargement de l’outil : 1.) Ne placez jamais une main ou une partie quelconque du corps

dans la zone de l’enclume de l’outil; 2.) Ne pointez jamais l’outil vers une autre personne; 3.)

N’appuyez jamais sur la gâchette — une mise en marche accidentelle pourrait se produire et causer

des blessures.

Si les attaches sont chargées à l’envers dans le magasin, les oreilles doubles vers l’avant, elles ne

s’enrouleront pas, et un blocage se produira. La première vérification en cas d’outil coincé devrait

être de s’assurer du bon chargement des attaches dans le magasin.

FONCTIONNEMENT

Veillez à toujours manipuler l’outil avec précaution : 1.) Ne chahutez pas; 2.) N’appuyez pas sur la

gâchette à moins que le nez de pose de l’outil soit dirigé vers l’ouvrage; 3.) Conservez une distance de

sécurité avec l’outil lorsqu’il est en fonctionnement, car un déclenchement accidentel est possible, et

peut occasionner des blessures.

Gardez les mains et le corps à l’écart de l’enclume de l’outil.

Ne sertissez pas d’attaches au-dessus d’autres attaches — cela pourrait causer le coinçage de l’outil

et réduire la durée de vie de l’outil.

MAINTENANCE DE L’OUTIL

Lorsque vous travaillez avec des outils pneumatiques, veuillez observer les avertissements contenus

dans ce manuel et prêter une attention redoublée en cas de problème.

Page 18

-18-

CARACTÉRISTIQUES TECHNIQUES DE L’OUTIL

Toutes les dimensions de vis et d’écrous sont exprimées selon l’American National Standard.

SPÉCIFICA

TIONS DES DISPOSITIFS DE FIXATION :

Voir l’illustration de produit IP1200-1 ou consultez le catalogue des outils et attaches industriels BOSTITCH.

RACCORD PNEUMATIQUE :

Cet outil utilise une fiche de débit continu, 1/4 po NPT, dont le diamètre intérieur doit mesurer au moins 0,200 po (5 mm). La

garniture doit être en mesure d’évacuer la pression pneumatique lorsque l’outil est déconnecté de l’alimentation d’air.

PRESSION DE FONCTIONNEMENT :

4,9 à 6,3 kg/cm2(70 à 90 lb/po) de pression manométrique. Sélectionnez la pression de fonctionnement pour les meilleures

performances. NE PAS EXCÉDER LAPRESSION DE FONCTIONNEMENT RECOMMANDÉE DE 6,3 kg/cm (90 lb/po).

CONSOMMATION D’AIR :

Les outils de la série C de HARTCO exigent 0,07 m/min (2,6 pi/min) pour fonctionner à la cadence de 100 clous par minute à

une pression de 6,3 kg/cm2(90 lb/po). Considérez le régime de fonctionnement de votre outil afin de déterminer le montant d’air

requis. Ainsi, pour un débit de 50 attaches par minute, vous aurez besoin de 50 % du volume d’air libre par minute requis pour

faire fonctionner l’outil avec un débit de 100 attaches par minute.

FONCTIONNEMENT DE L’OUTIL

UNE PROTECTION DES YEUX, conforme aux normes ANSI et fournissant une protection contre les

projectiles en provenance de l’AVANT et des CÔTÉS, doit TOUJOURS être portée par l’opérateur et les

personnes présentes dans la zone de travail, lors du raccordement à une source d’air, du chargement,

du fonctionnement et de la maintenance de l’outil. Une telle protection est indispensable pour vous

protéger contre les attaches et débris projetés, susceptibles d’entraîner des blessures sérieuses.

L’employeur et/ou l’utilisateur doivent s’assurer de porter une bonne protection oculaire.

L’équipement de protection doit être conforme à la norme ANSI Z87.1 et doit fournir une protection

frontale et latérale. REMARQUE : Les lunettes sans coques latérales et les masques faciaux ne

fournissent pas la protection nécessaire.

PRÉALABLEMENT À LA MANIPULATION OU À L’UTILISATION DE CET OUTIL :

I. VEILLEZ À LIRE ET COMPRENDRE LES AVERTISSEMENTS CONTENUS DANS CE MANUEL.

II. REPORTEZ-VOUS AUX « CARACTÉRISTIQUES TECHNIQUES DE L’OUTIL » DANS CE MANUEL

POUR IDENTIFIER LE PRINCIPE DE FONCTIONNEMENT DE VOTRE OUTIL.

MODÈLE LONGUEUR HAUTEUR LARGEUR POIDS

Outil de la série C 470 mm (18,5 po) 203 mm (8 po) 95 mm (3,75 po) 2,5 kg (5,2 lb)

Page 19

-19-

ALIMENTATION D’AIR ET CONNEXIONS

N’utilisez jamais de l’oxygène, des gaz combustibles ou des bouteilles de gaz pour alimenter cet outil;

il pourrait exploser et causer des blessures.

RACCORDS :

Installez une fiche mâle sur l’outil capable de délivrer un débit d’air continu et de libérer la pression d’air de l’outil lorsqu’il est

déconnecté de la source d’alimentation.

CONDUITS :

Les conduits d’air doivent être soumis à un minimum de 10,6 kg/cm (150 lb/po) de pression nominale de fonctionnement, ou 150

pour cent de la pression maximum qui peut être produite par le système d’alimentation d’air. Le conduit d’alimentation doit

contenir une garniture permettant une « déconnexion rapide » de la fiche mâle de l’outil.

ALIMENTATION :

Veillez à n’utiliser qu’une source d’air comprimé régulée et propre pour alimenter cet outil. N’UTILISEZ JAMAIS D’OXYGÈNE, DE GAZ

COMBUSTIBLES NI DE BOUTEILLES DE GAZ POUR ALIMENTER CETOUTIL, CAR IL POURRAIT EXPLOSER.

RÉGULATEUR :

Un régulateur de pression capable de maintenir une pression de fonctionnement de 0 à 8,79 kg/cm2(0 à 125 lb/po) est requis

pour garantir la sécurité d’utilisation de cet outil. Ne connectez pas cet outil si la pression d’air est susceptible de dépasser 14

kg/cm2(200 lb/po), car l’outil pourrait exploser et occasionner des blessures.

PRESSION DE FONCTIONNEMENT :

Ne dépassez pas la pression de fonctionnement recommandée (6,3 kg/m, ou 90 lb/po), car l’usure de l’outil augmenterait de

façon considérable. L’alimentation d’air doit être en mesure de maintenir la pression de fonctionnement de l’outil. Une baisse de

pression subite de l’alimentation d’air est susceptible de réduire la puissance motrice de l’outil.

FILTRE :

La poussière et la vapeur d’eau dans l’air constituent des causes majeures de l’usure des outils pneumatiques. L’utilisation d’un

filtre permettra d’obtenir de meilleures performances ainsi qu’une usure minimum de l’outil. Le filtre doit permettre un débit d’air

suffisant pour une installation donnée. Il doit aussi demeurer propre afin de fournir une source d’air comprimé optimale à l’outil.

Consultez les instructions du fabricant pour assurer une maintenance correcte de votre filtre. Un filtre sale et bouché a pour effet

une baisse de pression susceptible de réduire les performances de l’outil.

LUBRIFICATION

Une lubrification fréquente mais sans excès est nécessaire pour assurer un fonctionnement optimal. Les pièces internes sont

lubrifiées par l’ajout d’huile via la conduite d’air. Utilisez le lubrifiant pour outil pneumatique BOSTITCH, Mobil Velocite n° 10, ou

un équivalent. N’utilisez pas d’huile détergente ni d’additifs. Ces lubrifiants accélèrent l’usure des joints de l’outil, ce qui a un effet

négatif sur les performances et la fréquence d’entretien.

Si aucun lubrifiant de conduite d’air n’est utilisé, ajoutez de l’huile dans le raccord d’air de l’outil une ou deux fois par jour.

Quelques gouttes suffisent. Tout excès s’accumule dans l’outil et apparaîtra lors du cycle d’échappement.

FONCTIONNEMENT À BASSE TEMPÉRA

TURE :

Pour un fonctionnement par temps froid (une température proche ou inférieure à 0 °C), la conduite d’air peut geler et empêcher

le fonctionnement de l’outil. Nous vous recommandons d’utiliser la formule hivernale du lubrifiant pour outil pneumatique

BOSTITCH ou, à défaut, un antigel permanent (éthylène-glycol).

MISE EN GARDE : Ne pas stocker les outils à basse température afin d’éviter la formation de gel ou de glace dans les

soupapes et mécanismes. Cela pourrait causer un mauvais fonctionnement de l’outil.

REMARQUE : Certains liquides commerciaux de séchage de conduite d’air ne conviennent pas aux joints toriques.

Évitez d’utiliser de tels liquides avant de vous être assuré qu’ils sont compatibles.

Page 20

-20-

CHARGEMENT D’UN OUTIL DE SERTISSAGE DE LA SÉRIE C

UNE PROTECTION DES YEUX, conforme aux normes ANSI et fournissant une protection contre les

projectiles en provenance de l’AVANT et des CÔTÉS, doit TOUJOURS être portée par l’opérateur et les

personnes présentes dans la zone de travail, lors du raccordement à une source d’air, du chargement,

du fonctionnement et de la maintenance de l’outil. Une telle protection est indispensable pour vous

protéger contre les attaches et débris projetés, susceptibles d’entraîner des blessures sérieuses.

L’employeur et/ou l’utilisateur doivent s’assurer de porter une bonne protection oculaire.

L’équipement de protection doit être conforme à la norme ANSI Z87.1 et doit fournir une protection

frontale et latérale. REMARQUE : Les lunettes sans coques latérales et les masques faciaux ne

fournissent pas la protection nécessaire.

POUR PRÉVENIR TOUT ACCIDENT :

• Ne placez jamais une main ou une partie quelconque du corps dans la zone de l’enclume de l’outil

lorsque la source d’alimentation est connectée.

• Ne pointez jamais l’outil vers une autre personne.

• Ne chahutez jamais.

• N’appuyez sur la gâchette que lorsque le nez de pose de l’outil est dirigé vers l’ouvrage.

•Veillez à toujours manipuler l’outil avec précaution.

•N’appuyez jamais sur la gâchettes en chargeant l’outil.

1. MISE EN PLACE DU PROLONGATEUR : Tirez le prolongateur vers l’extrémité du magasin puis accrochez-le sur le rebord

arrière du magasin.

2. CHARGEMENT DES ATTACHES : Les attaches doivent être chargées l’oreille unique orientée vers l’avant. Si elles sont

chargées à l’envers dans le magasin, les oreilles doubles vers l’avant, elles ne s’enrouleront pas, et un blocage se produira.

La première vérification en cas d’outil coincé devrait être de s’assurer du bon chargement des attaches dans le magasin.

3. VÉRIFICATION DU RÉGLAGE : Desserrez les deux vis gardant le couvercle du magasin en place. Placez le couvercle à

environ 1 mm (0,04 po) du dessus des attaches dans le magasin.

4. DÉGAGEMENT DU PROLONGATEUR : Basculez le prolongateur vers l’avant pour débloquer le crochet du rebord arrière

du magasin.

DÉBLOCAGE : Déconnectez l’alimentation d’air. Tirez le prolongateur vers l’extrémité du magasin puis accrochez-le

sur le rebord arrière du magasin. Cela enlèvera la force appliquée sur la bande des attaches (retirez ces dernières, si

nécessaire), et l’attache devrait tomber d’elle-même. Si l’outil est toujours coincé, retirez l’attache à la main.

REMARQUE : N’utilisez que les attaches recommandées par HARTCO pour l’outil de la série C ou des attaches

répondant aux spécifications de HARTCO.

1.

2.

3.

4.

Page 21

-21-

EN PLUS DES AUTRES

AVERTISSEMENTS CONTENUS DANS CE MANUEL,

VEILLEZ À OBSERVER LES PRÉCAUTIONS SUIVANTES :

• N’utilisez jamais l’outil pneumatique HARTCO dans un but autre que celui pour lequel il a été

conçu.

• N’orientez jamais l’outil de façon à ce qu’il puisse éjecter une attache en direction de l’utilisateur

ou d’autres personnes dans la zone de travail.

• N’utilisez jamais l’outil comme un marteau.

•Veillez à toujours transporter l’outil à l’aide de la poignée. Ne transportez jamais l’outil par le

conduit d’air.

• Ne modifiez pas la conception ou la fonction originale de l’outil sans avoir obtenu l’accord de

HARTCO, INC.

• Gardez toujours présent à l’esprit qu’une utilisation ou une manipulation incorrecte de cet outil est

susceptible d’occasionner des blessures à vous-même et à d’autres personnes.

• Ne bloquez jamais la gâchette en position enclenchée.

• Ne laissez jamais un outil sans surveillance avec le conduit d’air attaché.

• Ne faites pas fonctionner l’outil s’il ne comporte pas une ÉTIQUETTE D’AVERTISSEMENT lisible.

• Cessez d’utiliser l’outil en cas de fuite d’air ou s’il ne fonctionne pas correctement. Si le problème

persiste, communiquez avec le représentant HARTCO le plus proche.

MAINTENANCE DE L’OUTIL PNEUMATIQUE

Lorsque vous travaillez avec des outils pneumatiques, veuillez observer les avertissements contenus

dans ce manuel et prêter une attention redoublée en cas de problème.

Soyez vigilant lorsque vous utilisez le ressort du prolongateur. Ce ressort n’est pas fixé au rouleau, et s’il est tendu audelà de ce dernier, il glissera et roulera rapidement vers le haut. Notez aussi que les bords du ressort sont très minces;

faites attention de ne pas vous couper. Vérifiez que le ressort ne comporte aucune torsion indésirable, afin qu’il puisse

exercer la force prescrite.

PIÈCES DE RECHANGE :

Nous recommandons les pièces de rechange HARTCO. N’utilisez pas de pièces modifiées ou ne fournissant pas une

performance équivalente à celle de l’équipement d’origine.

PROCÉDURE DE MONTAGE DES JOINTS

:

Lors de la réparation d’un outil, assurez-vous que les pièces internes sont propres et lubrifiées. Utilisez le produit « O »-LUBE

de Parker ou un équivalent sur tous les joints toriques. Avant l’assemblage, recouvrez chaque joint torique de lubrifiant. Utilisez

un peu d’huile sur les surfaces mobiles et les axes. Après le réassemblage et avant de procéder au test, ajoutez quelques

gouttes de lubrifiant pour outil pneumatique BOSTITCH dans la garniture de conduite d’air.

PRESSION ET VOLUME DE L’ALIMENTATION D’AIR :

Le volume d’air est aussi important que la pression. Le volume d’air fourni à l’outil peut être inadéquat en raison de garnitures et

conduits trop justes, ou en raison de la présence de poussière ou d’eau dans le système. Un débit d’air restreint empêchera que

l’outil reçoive suffisamment d’air, même si la pression est haute. Il en résulte un fonctionnement ralenti, un défaut d’alimentation

ou une force motrice réduite. Avant de rechercher l’existence éventuelle de ces problèmes, retracez le parcours de l’alimentation

d’air de l’outil à la source. Notez l’existence possible de tout élément susceptible de diminuer la circulation de l’air vers l’outil,

comme un conduit ou une garniture à rotule obstrués, ou un point inférieur contenant de l’eau.

Page 22

-22-

DÉPANNAGE

PROBLÈME CAUSE SOLUTION

Le logement de soupape de la

gâchette laisse fuir de l’air Le joint torique est coupé ou craquelé . . . . . . . . . . . . . . .Remplacez le joint torique

La tige de soupape de la gâchette

laisse fuir de l’air Le joint torique est coupé ou craquelé . . . . . . . . . . . . . . .Remplacez la soupape de la gâchette

Le cadre ou chapeau de l’outil

laisse fuir de l’air Le joint torique ou statique est endommagé . . . . . . . . . . .Remplacez le joint Vis desserrées

Resserrez et vérifiez de nouveau

Échec d’approvisionnement Alimentation d’air restreinte . . . . . . . . . . . . . . . . . . . . . . .Vérifiez l’équipement d’alimentation d’air L’outil manque de lubrification

Utilisez le lubrifiant pour outil pneumatique BOSTITCH . . .Joints toriques du piston usés

Remplacez les joints toriques Ressorts de

retour du piston cassés . . . . . . . . . . . . . . . . . . . . . . . . . .Remplacez les ressorts de retour du piston

Manque de puissance, lenteur du cycle L’outil manque de lubrification . . . . . . . . . . . . . . . . . . . . . .Utilisez le lubrifiant pour outil pneumatique BOSTITCH

Les joints toriques/joints sont coupés ou craquelés . . . . . .Remplacez les joints toriques/joints

Échappement bloqué . . . . . . . . . . . . . . . . . . . . . . . . . . .Vérifiez les joints toriques de la soupape

Assemblage de gâchette trop usé ou qui fuit . . . . . . . . . .Remplacez l’assemblage de gâchette

Accumulation de saleté sur la lame . . . . . . . . . . . . . . . . .Démontez pour nettoyer

Soupape mal lubrifiée . . . . . . . . . . . . . . . . . . . . . . . . . . . .Démontez/lubrifiez

Pression d’air trop basse . . . . . . . . . . . . . . . . . . . . . . . . .Vérifiez l’équipement d’alimentation d’air

Saut de dispositifs de fixation,

alimentation intermittente Accumulation de saleté sur la lame . . . . . . . . . . . . . . . . .Démontez et nettoyez l’outil

Alimentation d’air restreinte ou débit d’air inadéquat dans

la douille de débranchement rapide et la fiche . . . . . . . . .Remplacez les raccords de débranchement rapide

Joint torique du piston trop usé . . . . . . . . . . . . . . . . . . . . .Remplacez le joint torique, vérifiez le mandrin

Outil manquant de lubrification . . . . . . . . . . . . . . . . . . . . .Utilisez le lubrifiant pour outil pneumatique BOSTITCH

Ressort du prolongateur endommagé . . . . . . . . . . . . . . . .Remplacez le ressort Pression d’air basse

Vérifiez le système d’alimentation d’air vers

l’outil Vis desserrées . . . . . . . . . . . . . . . . . . . . . . . . . . . .Serrez toutes les vis Dispositifs de fixation trop courts pour l’outil

N’utilisez que les attaches recommandées

Pliez les attaches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Cessez d’utiliser ce type de dispositif

Taille incorrecte des attaches . . . . . . . . . . . . . . . . . . . . . .N’utilisez que les attaches recommandées

Joint statique qui fuit . . . . . . . . . . . . . . . . . . . . . . . . . . . .Serrez les vis/remplacez le joint

Joint torique de la soupape de déclenchement

coupé ou trop usé . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Remplacez le joint torique

Lame cassée/ébréchée . . . . . . . . . . . . . . . . . . . . . . . . . .Remplacez la lame (vérifiez le joint torique du piston)

Magasin sale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Nettoyez/lubrifiez; utilisez le lubrifiant pour outil pneumatique BOSTITCH

Magasin usé . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Retournez les attaches

Attaches coincées dans l’outil. Attache chargée à l’envers. . . . . . . . . . . . . . . . . . . . . . . .Remplacez le magasin

Attaches du mauvais format . . . . . . . . . . . . . . . . . . . . . . .N’utilisez que les attaches recommandées

Vis desserrées . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Cessez d’utiliser ce type d’attaches

Pliez les attaches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Serrez les vis

Serrez toutes les vis Lame cassée/ébréchée . . . . . . . . . .Remplacez la lame

ACCESSOIRES DISPONIBLES

BC601 Lubrifiant pour outil pneumatique Bostitch, 4 oz (124 g)

BC602 Lubrifiant pour outil pneumatique Bostitch, 1 chopine (473 ml)

BC603 Lubrifiant pour outil pneumatique (formule hivernale) Bostitch, 1 chopine (473 ml)

BC604 Lubrifiant pour outil pneumatique Bostitch, 1 pinte (946 ml)

851325 Loctite Grade 271 0,57 g (0,02 oz)

851385 Loctite Grade 242 0,57 g (0,02 oz)

100679 Lubrifiant 454 g (1 lb)

134521 CL, support à outil

HR-55996 Pinces de démontage d’attaches de sertissage

Page 23

IP1200-1 REVB 9/04

STANLEY FASTENING SYSTEMS

C SERIES

LIGHT WEIGHT CLINCHING TOOL

HERRAMIENTA REMACHADORA LIVIANA

OUTIL DE SERTISSAGE LÉGER

TOOL PARTS ILLUSTRATION

ILUSTRACIÓN DE LAS PIEZAS DE LA HERRAMIENTA

ILLUSTRATION DES PIÈCES D'OUTILLAGE

BEFORE PERFORMING REPAIRS ON THIS TOOL, ALL OPERATORS SHOULD STUDY

THIS ILLUSTRATION, AS WELL AS THE PARTS LIST AND OPERATION AND

MAINTENANCE MANUAL. OPERATORS SHOULD UNDERSTAND AND FOLLOW ALL

SAFETY WARNINGS AND INSTRUCTIONS. KEEP THIS ILLUSTRATION WITH THE

TOOL FOR FUTURE REFERENCE. IF YOU HAVE ANY QUESTIONS, CONTACT YOUR

BOSTITCH REPRESENTATIVE DISTRIBUTOR.

ANTES DE LLEVAR A CABO CUALQUIER REPARACIÓN EN LA HERRAMIENTA, TODOS

LOS OPERARIOS DEBERÁN ESTUDIAR ESTA ILUSTRACIÓN, ASÍ COMO LA LISTA DE

PIEZAS Y EL MANUAL DE OPERACIÓN Y MANTENIMIENTO. LOS OPERARIOS

DEBERÁN ENTENDER Y SEGUIR TODAS LAS ADVERTENCIAS E INSTRUCCIONES DE

SEGURIDAD. CONSERVE ESTA ILUSTRACIÓN CON LA HERRAMIENTA PARA PODER

CONSULTARLA EN LO FUTURO. SI TUVIERA ALGUNA PREGUNTA, PÓNGASE EN

CONTACTO CON SU REPRESENTANTE O DISTRIBUIDOR DE BOSTITCH.

AVANT DE PROCÉDER À LA RÉPARATION DE CET OUTIL, LES OPÉRATEURS

DOIVENT ÉTUDIER LA PRÉSENTE ILLUSTRATION AINSI QUE LA LISTE DE PIÈCES ET

LE MANUEL D’INSTRUCTIONS ET D'ENTRETIEN ; ILS DOIVENT ÉGALEMENT

COMPRENDRE ET OBSERVER LES CONSIGNES DE SÉCURITÉ ET LES

INSTRUCTIONS. CONSERVER CETTE ILLUSTRATION AVEC L'OUTIL POUR

RÉFÉRENCE FUTURE. SI VOUS AVEZ DES QUESTIONS, COMMUNIQUEZ AVEC

VOTRE REPRÉSENTANT OU VOTRE DISTRIBUTEUR DE BOSTITCH.

Stanley Fastening Systems

Declaration of Conformity

The manufacture of the pneumatic fastening tools, declares under sole responsibility

that this product conforms to the following standards. EN 292 – part 1 and 2 and to

the directive 89/392/EEC and the revisions.

Declaración de Conformidad

El fabricante de las herramientas instaladoras neumáticas, declara bajo su exclusiva

responsabilidad que este producto está conforme a las normas siguientes.

EN 292 – apartado 1 y 2 además de la directriz 89/392/EEC y las revisiones.

Déclaration de conformité

Le fabricant des outils d’assemblage pneumatiques déclare, sous son unique