Page 1

INSTALLATION AND OPERATING INSTRUCTIONS

GRAINNE

Boiler & Non Boiler

Solid Fuel Stove

This appliance is hot while in operation and retains its heat for a long period of time after use. Children, aged

or infirm persons should be supervised at all times and should not be allowed to touch the hot working surfaces

while in use or until the appliance has thoroughly cooled.

PLEASE READ THESE INSTRUCTIONS CAREFULLY BEFORE INSTALLATION. These instructions cover

the basic principles to ensure the satisfactory installation of the stove, although detail may need slight

modification to suit particular local site conditions.

Page 2

1

TABLE OF CONTENTS

PAGE NO.

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. Health & Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Fire Cement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Asbestos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Metal Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3. Pre Installation Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4. Flues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

5. Flue Pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

6. Chimney . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

7. Down Draughts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

8. Ventilation & Combustion Air Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

9. Permanent Air Vent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Extractor Fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

10. Commissioning & Handover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

11. Flue Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

12. Top Flue Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Boiler Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Non-Boiler Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

13. Rear Flue Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Boiler Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

14. Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

15. Installation Clearances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

16. Floor Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

17. Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

18. Specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Non Boiler Model. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Boiler Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

19. Plumbing (Boiler Model Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Gravity Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Injector Tee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Water Circuit Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Pipe Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

20. Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

21. Low/Slumber Burn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

22. Primary Air Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

23. Recommended Fuels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

24. Opening Stove Door. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

25. Important Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

26. Lighting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Page 3

2

PAGE NO.

27. De-Ashing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

28. Disposal of Ashes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

29. To Clean Chimney Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Boiler Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Non Boiler Model. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

30. To Replace Damaged Grate or Grate Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Boiler Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Non Boiler Model. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

31. Periods of Prolonged Non-Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

32. Fire Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

33. In Case of Fire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

34. Vitreous Enamel Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

35. Glass Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

36. Glass Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

37. CO Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

38. Exploded View - Boiler Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

39. Exploded View - Non Boiler Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

40. Installation Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Page 4

GRAINNE SOLID FUEL STOVE INSTALLATION & OPERATING INSTRUCTIONS

PRE INSTALLATION ASSEMBLY

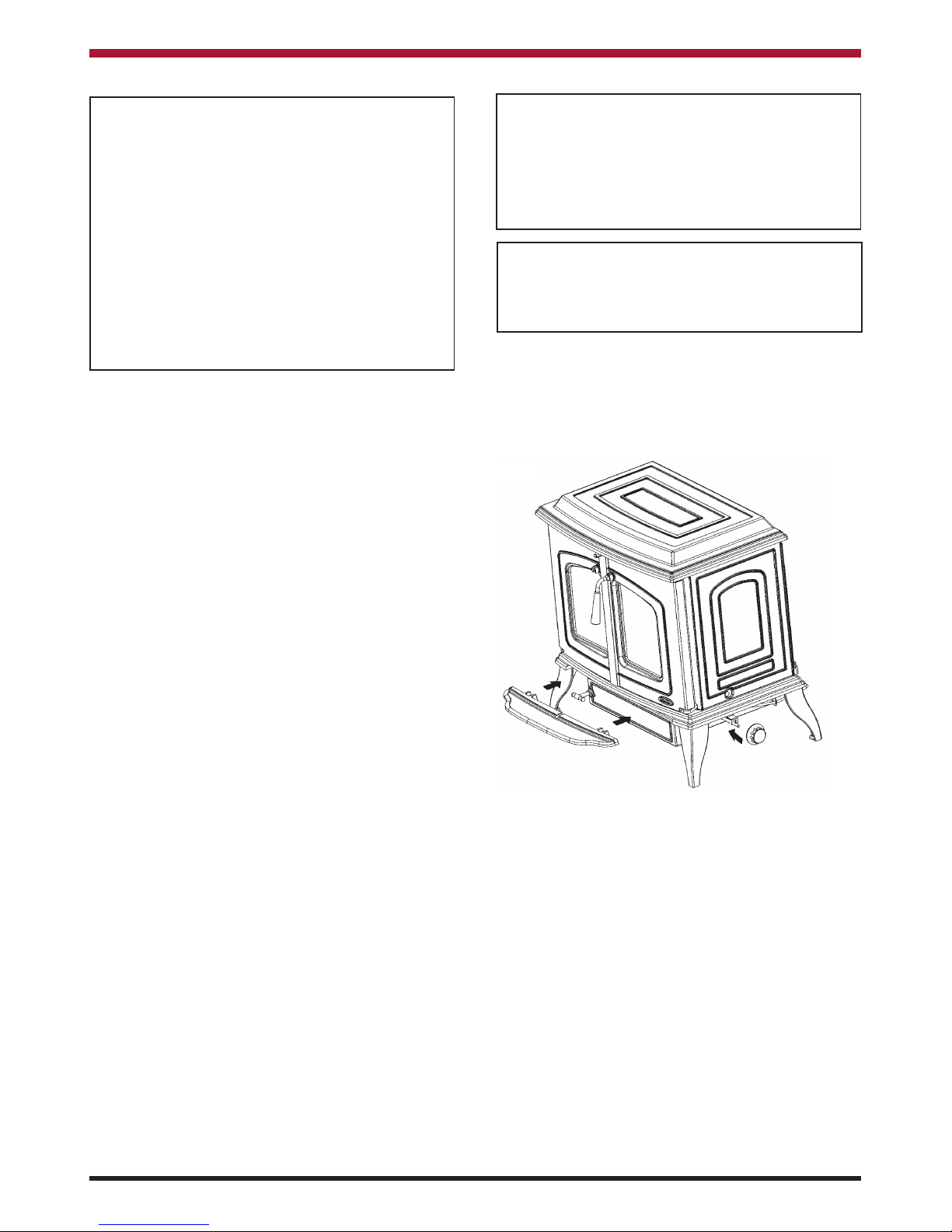

1. Remove the flue spigot (Non boiler only) and put

in the orientation required. (See Flue

Connections)

2. Remove the stove from the wooden pallet.

3. Unscrew the two

1

/4” x 1/2” round head screws

from the base and fit the front ash tray using the

two screws.

4. Fit the primary air control knob to the flexible

drive (see Fig.1).

FLUES

Flues should be vertical wherever possible and

where a bend is necessary, it should not make an

angle of more than 45

o

with the vertical. Horizontal

flue runs should be avoided except in the case of a

back outlet from the appliance, when the length of

the horizontal section should not exceed 150mm. In

order to minimise flue resistance and to make

sweeping easier it is recommended to use 2 x 45

o

bends rather than a 90obend. The flue termination

point must be located to minimise any wind effects.

Wind effects of suction, pressure zones and turbulence can be created by the roof and adjacent

3

The installation must be completed in accordance

with current National and European Standards and

Local Codes. It should be noted that the requirements and these publications may be superseded

during the life of this manual.

Fig.1

In all cases the installation must comply with current Building Regulations, Local Authority Bylaws

and other specifications or regulations as they

affect the installation of the stove.

NOTE: Please note that it is a legal requirement

under England and Wales Building Regulations

that the installation of the stove is either carried out

under Local Authority Building Control approval or

is installed by a Competent Person registered with

a Government approved Competent Persons

Scheme. HETAS Ltd operate such a Scheme and

a listing of their Registered Competent Persons

can be found on their website at www.hetas.co.uk.

GENERAL

When installing, operating and maintaining your

Grainne Stove respect basic standards of fire safety.

Read these instructions carefully before commencing the installation. Failure to do so may result in

damage to persons and property. Consult your local

Municipal office and your insurance representative

to determine what regulations are in force. Save

these instructions for future reference.

HEALTH AND SAFETY PRECAUTIONS

Special care must be taken when installing the stove

such that the requirements of the Health and Safety

at Work Act are met.

Handling

Adequate facilities must be available for loading,

unloading and site handling.

Fire Cement

Some types of fire cement are caustic and should

not be allowed to come into contact with the skin. In

case of contact wash immediately with plenty of

water.

Asbestos

This stove contains no asbestos. If there is a possibility of disturbing any asbestos in the course of

installation then please seek specialist guidance and

use appropriate protective equipment.

Metal Parts

When installing or servicing this stove care should

be taken to avoid the possibility of personal injury.

IMPORTANT WARNING

This stove must not be installed into a chimney that

serves any other heating appliance. There must not

be an extractor fan fitted in the same room as the

stove as this can cause the stove to emit fumes into

the room.

Page 5

objects. Wind effects can also be created by natural land contours.

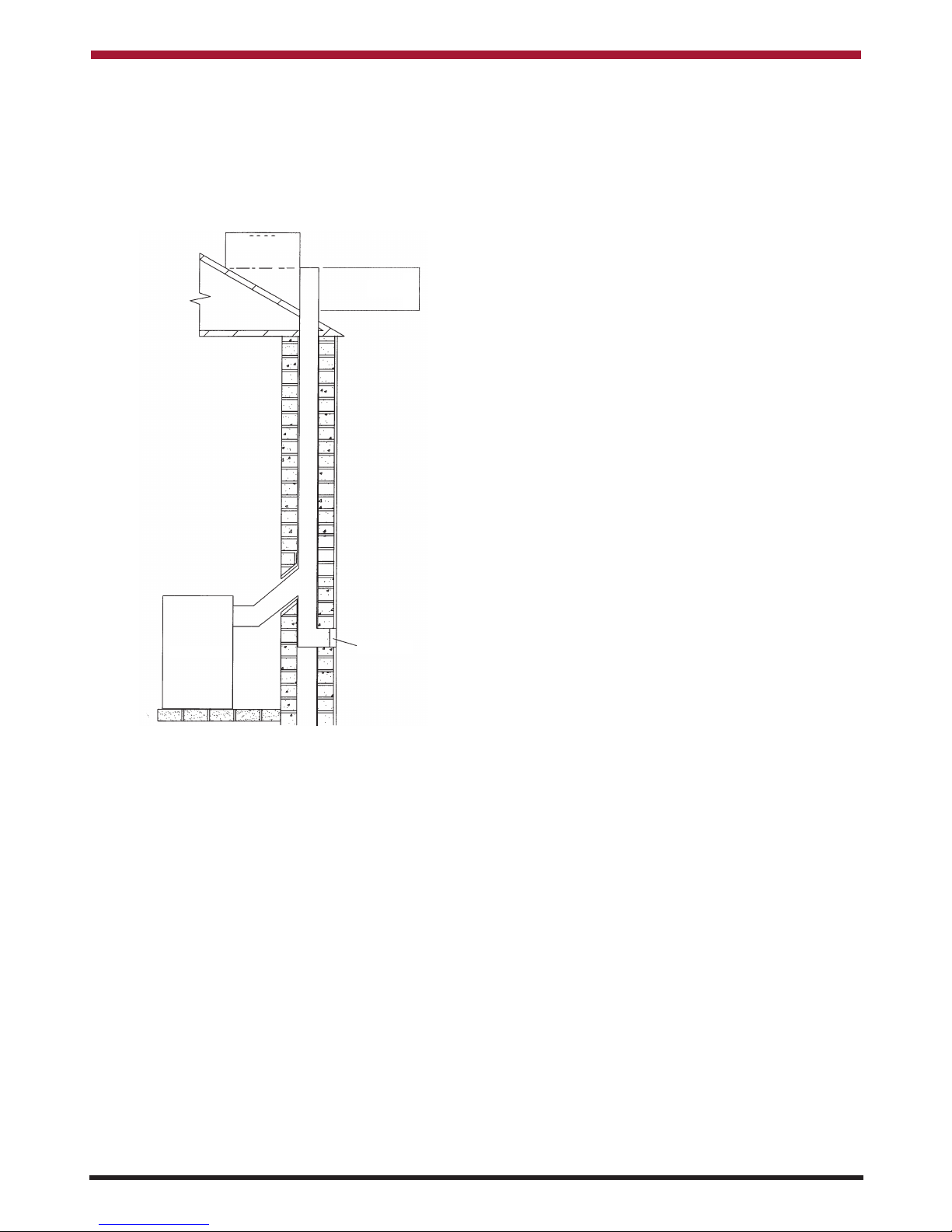

To minimise the wind effects, the flue termination

point should be located a minimum of 1000mm from

the roof measured vertically and 2300mm measured

horizontally. Where this termination point does not

suffice it may be necessary to extend the flue pipe

so that the termination point is above the apex.

FLUE PIPES

A flue pipe should only be used to connect an appliance to a chimney and should not pass through any

roof space.

Flue pipes may be of any of the following materials:

(a) Cast iron as described in BS 41: 1973 (1981),

or

(b) Mild steel with a wall thickness of at least 3mm,

or

(c) Stainless steel with a wall thickness of at least

1mm and as described in BS EN 10095:

1999 Specification for stainless and

heat resisting steel plate, sheet and strip, for

Grade 316 S11, 316 S13, 316 S16, 316 S31,

316 S33, or the equivalent Euronorm 88-71

designation, or

(d) Vitreous enamelled steel complying with BS

6999: 1989.

Flue pipes with spigot and socket joints should be fitted with the socket uppermost.

Fig.2

2300

Soot Door

Appliance

CHIMNEY

The stove is a radiant room heater and must be connected to a chimney of the proper size and type. The

chimney must have a cross sectional area of at least

19350 square mm (30 square inches) or a diameter

of 150mm (6“). The chimney should be checked for

soundness and draught before installation. The

stove must be connected to a chimney with a minimum continuous draught of 12pa. Poor draught will

result in poor performance. Similarly an excessive

draught will result in the appliance over firing or

being difficult to control. An excessive draught may

require a flue draught stabiliser to be fitted. Do not

connect this appliance to a chimney serving another

appliance. The minimum required chimney height is

4.5 metres from the floor on which the appliance is

installed. An existing masonry chimney should be

inspected and if necessary, repaired by a competent

mason.

If the stove is fitted in place of an open fire then the

chimney should be swept one month after installation to clear any soot falls which may have occurred

due to the difference in combustion between the

stove and the open fire.

DOWN DRAUGHTS

However well designed constructed and positioned,

the satisfactory performance of the flue can be

adversely affected by down draught caused by nearby hills, adjacent tall buildings or trees. These can

deflect wind to blow directly down the flue or create

a zone of low pressure over the terminal. A suitable

anti-down draught terminal or cowl will usually effectively combat direct down blow but no cowl is likely

to prevent down draught due to a low pressure zone.

VENTILATION & COMBUSTION AIR

REQUIREMENTS

This appliance is rated at less than 9kW. It is imperative that there is sufficient air supply to the stove in

order to support correct combustion. The air supply

to this appliance must comply with B.S. 8303: Part 1

and current Building Regulations. The minimum

effective air requirement for this appliance is 22cm2.

If a draught stabiliser is used then this increases to

49cm2.

When calculating combustion air requirement for

this appliance use the following equation: a total free

area of at least 550mm

2

per kW of rated output

above 5kW shall be provided. If there is another air

using appliance fitted in the same or adjacent room,

it will be necessary to calculate additional air supply.

All materials used in the manufacture of air vents

should be such that the vent is dimensionally stable

and corrosion resistant.

4

1000

Page 6

out, before lighting the stove. Once the stove is

under fire check all seals for soundness and that the

boiler and water system are operating correctly.

Ensure that the flue is functioning correctly and that

all products of combustion are vented safely to

atmosphere via the chimney terminal.

On completion of the installation and commissioning

ensure that the operating instructions for the stove

are left with the customer. Ensure to advise the customer on the correct use of the appliance and warn

them to use only the recommended fuels for the

stove.

Advise the user what to do should smoke or fumes

be emitted from the stove. The customer should be

warned to use a fireguard to BS 6539 in the presence of children, aged and/or infirm persons.

FLUE CONNECTION

Flue pipes with spigot and socket joints should be fitted with the socket upper most. Clearance to combustibles must be adhered to when fitting the flue

pipe. The connecting flue pipe must not be less than

the diameter of the stove outlet.

The flue gas mass flow non boiler model is 6.1g/s

(mineral wood logs) and 7.9g/s (mineral fuel), with

respective mean flue gas temperatures of 342

o

C and

294

o

C.

The flue gas mass flow boiler model is 6.1g/s (mineral wood logs) and 5.4g/s (mineral fuel), with

respective mean flue gas temperatures of 220

o

C and

262

o

C.

TOP FLUE EXIT

Boiler Model

For the top outlet configuration, connect bend (not

supplied) into flue outlet socket at the rear of the

stove and cement into place using approved fire

cement ensuring that no cement blocks the flue passageway. (See Fig. 3)

Non Boiler Model

This stove can be connected to either a top flue exit

(see Fig. 5 or a rear flue exit (see Fig.6) by simply

reversing the orientation of the flue spigot on the flue

spigot flange.

5

The effective free area of any vent should be ascertained before installation. The effect of any screen

should be allowed for when determining the effective free area of any vent.

Air vents direct to the outside of the building should

be located so that any air current produced will not

pass through normally occupied areas of the room.

An air vent outside the building should not be located less than the dimensions specified within the

Building Regulations from any part of any flue terminal. These air vents must also be fire proofed as per

Building Regulations.

Air vents traversing cavity walls should include a

continuous duct across the cavity. The duct should

be installed in such a manner as not to impair the

weather resistance of the cavity. Joints between air

vents and outside walls should be sealed to prevent

the ingress of moisture. Existing air vents should be

of the correct size and unobstructed for the appliance in use. If there is an air extraction fan or other

air using appliance fitted in the room or adjacent

rooms where this appliance is fitted, additional air

vents will be required to alleviate the possibility of

spillage of products of combustion from the appliance/flue while the fan is in operation.

Where such an installation exists, a test for spillage

should be made with the fan or fans and other appliances using air in operation at full rate, (i.e. extraction fans, tumble dryers) with all external doors and

windows closed. If spillage occurs following the

above operation, an additional air vent of sufficient

size to prevent this occurrence should be installed.

PERMANENT AIR VENT

The stove requires an adequate air supply in order

for it to operate safely and efficiently. The installer

may have fitted a permanent air supply vent into the

room in which the stove is installed to provide combustion and/or ventilation air. This air vent should

not under any circumstances be shut off or sealed.

Extractor Fan

There must not be an extractor fan fitted in the same

room as the stove as this can cause the stove to

emit smoke and fumes into the room.

COMMISSIONING AND HANDOVER

Ensure all parts are fitted in accordance with the

instructions.

On completion of the installation allow a suitable

period of time for any fire cement and mortar to dry

Page 7

REAR FLUE EXIT

Boiler Model

For the rear flue outlet configuration, push in the flue

connector pipe (not supplied) into the flue outlet

socket at the rear of the stove and cement into place

using approved fire cement ensuring that no cement

blocks the flue passageway. (See Fig.4)

Fig 3

Fig. 4

Fig. 5

Fig.6

LOCATION

There are several conditions to be considered in

selecting a location for your Grainne Stove.

a. Position in the area to be heated- central

locations are usually best.

b. Allowances for proper clearances to

combustibles.

Note: Sufficient space should be given around

the back and sides of the stove to allow

access to the air control damper.

INSTALLATION CLEARANCES

Maintain at least the following clearances to all

combustible material:

Boiler Model

From the front 910 mm

From the back 150 mm

From the sides 150 mm

From the flue pipe 910 mm

Non Boiler Model

From the front 910 mm

From the back 800 mm

From the sides 800 mm

From the flue pipe 910 mm

It is recommended that this appliance is sited next to

and on a non-combustible surface. A minimum all

round clearance of 100 mm will allow air circulation

and not impede the performance of the stove.

FLOOR PROTECTION

It is recommended that this appliance is installed on

a solid, level, non combustible hearth conforming to

current Building Regulations.

6

Page 8

7

Fig.7

Mean Flue gas temperature directly downstream of

the spigot at nominal output 317°C

The appliance is suitable for continuous operation

on solid mineral fuel and intermittent operation on

wood logs. This appliance has been tested using

seasoned wood logs and manufactured briquettes

smokeless fuel (Ancit) for closed appliances, sized

between 20g and 140g. Other fuels are commercially available. Wood logs up to 400 mm long are suitable. All fuels should be stored under cover and kept

as dry as possible prior to use.

Flue Outlet Diameter: 152mm

Typical refuelling intervals to obtain nominal

outputs:

1.5 hours wood

4 hours solid mineral fuel

Wood Log Size: 400mm

Gross Weight: 167kgs

OUTPUT TO WATER OUTPUT TO ROOM TOTAL OUTPUT

NOMINAL MAX. NOMINAL MAX. NOMINAL MAX.

WOOD LOGS 4.8 3.2 8

SOLID MINERAL FUEL 4.5 9.67 3.4 6.1 7.9 15.8

BOILER MODEL

OUTPUT TO ROOM TOTAL OUTPUT

NOMINAL MAX. NOMINAL MAX.

WOOD LOGS 8.2 8.2

SOLID MINERAL FUEL 8.5 12 8.5 12

NON-BOILER MODEL

TECHNICAL DATA

Page 9

SPECIFICATION - NON BOILER

8

Fig.8

SPECIFICATION - BOILER

Fig. 9

Note: Dimensions stated are in millimetres unless otherwise stated and may be subject to a slight +/-

variation.

Page 10

9

PLUMBING (BOILER MODEL)

REGULATIONS

The plumbing must be in accordance with all

relevant regulations and practices. It must include a

gravity circuit with expansion pipe, open to the

atmosphere. The central heating will be pump-driven as with other types of boilers.

The installation of any electrical services during the

installation of this boiler and the associated heating

system must be carried out by a registered competent electrician and in accordance with the requirements of the latest issue of BS 7671.

The installation of the central heating system should

be in accordance with BS 5449: code of practice for

central heating systems for domestic premises.

GRAVITY CIRCUIT

The gravity circuit consists of the domestic hot water

tank of 135 litres indirect cylinder, fixed in an upright

position, recommended for hot water storage and it

should be connected to the boiler by 28mm diameter flow and return piping. The pipes should not

exceed 7.8 meters (25ft) in length and cylinder and

pipework should be fully lagged. The shorter the run

of pipe work the more effective the water heating.

The domestic hot water cylinder should be to

BS1566:Part1.

There must be no gate valves on this circuit and it

must have an expansion pipe exhausting to atmosphere. Cylinder and pipe work should be lagged to

minimise heat loss.

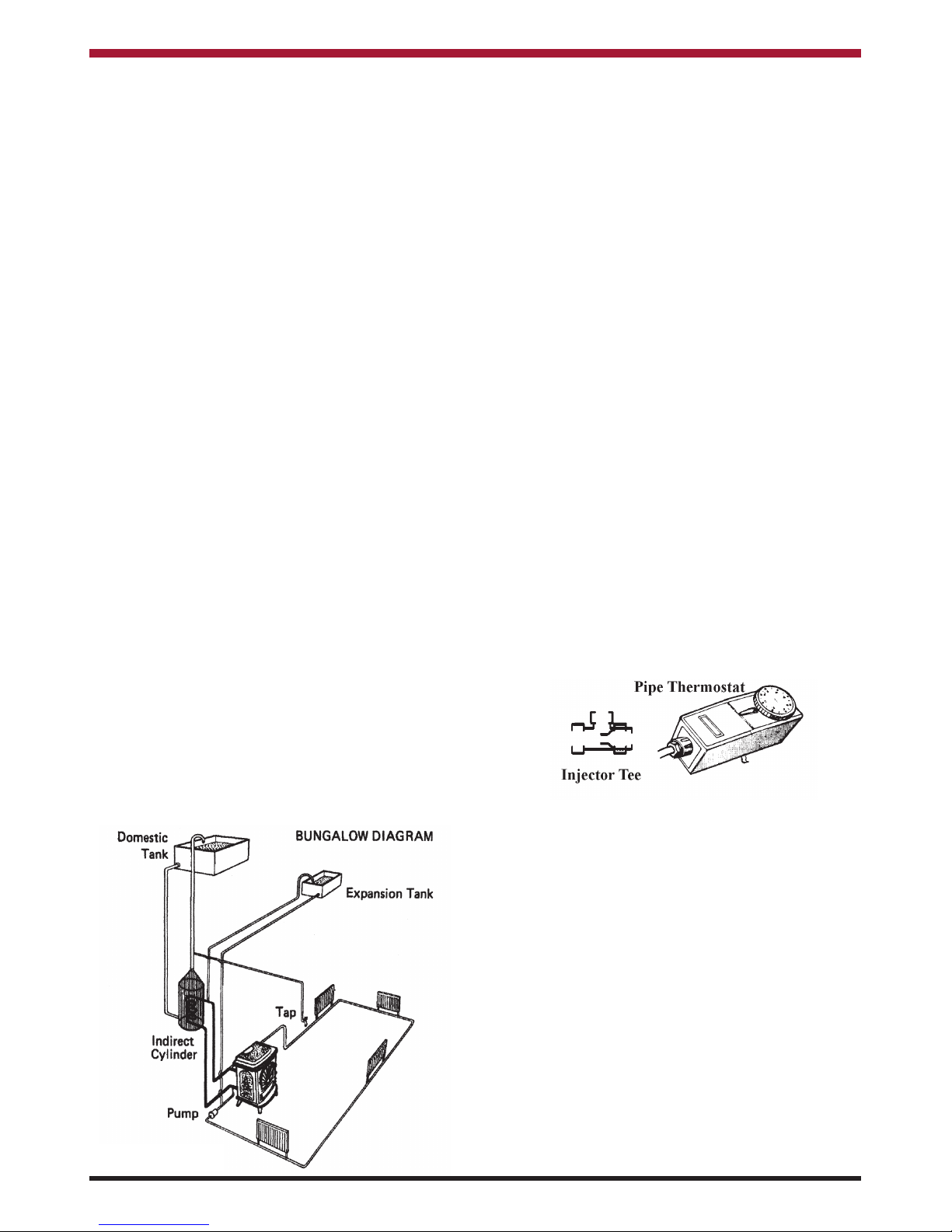

This diagram illustrates the basic principal of water

heating systems and must not be regarded as a

working drawing.

Fig.10

INJECTOR TEE

Where the gravity and central heating circuits join

together to return to the stove we recommend the

use of an injector tee connection, situated as close

to the unit as possible. This type of tee encourages

a stable flow of water through both circuits and helps

to prevent priority being given to the stronger flow,

which is most commonly the pumped central heating

circuit.

WATER CIRCUIT TEMPERATURE

The return water temperature should be maintained

at not less than 40°C so as to avoid condensation on

the boiler and return piping. Fitting a pipe thermostat to the flow pipe of the gravity circuit and wiring it

into the pump control will ensure rapid circulation of

the hot water.

PIPE THERMOSTAT

The fitting of a pipe thermostat to the flow pipe is

essential in order to activate the water circulation

pump when the water reaches the selected

temperature.

When the water temperature falls below the selected temperature the pipe thermostat will cut off the

water circulation pump in order to allow the boiler to

recover.

Fig.11

OPERATING INSTRUCTIONS

COAL, ANTHRACITE, WOOD SYNTHETIC LOGS,

OR OTHER FUELS. “Never use gasoline” gasoline

type lantern fuel, kerosene, charcoal lighter fluid or

similar liquids to start or ‘freshen up’ a fire in this

heater. Keep all such liquid well away from the

heater at all times. Operate stove only with fuelling

door and ashpit doors closed. This heater is hot

whilst in operation. Keep children, clothing and furniture a safe distance away.

Page 11

WARNING Do not attempt to light the stove if there

is a possibility the heating system is frozen (boiler

models only).

Never use an aerosol spray can near the stove

when it is alight as there is a risk of an explosion or

“flare up”.

LOW / SLUMBER BURN

To achieve an overnight or a low burn rate, close the

air wash slider fully by sliding the lever left using the

ashpan tool and turn the primary air control knob to

setting 0.

WARNING NOTE

Properly installed, operated and maintained this

stove will not emit fumes into the dwelling.

Occasional fumes from de ashing and re fuelling

may occur. However, persistent fume emission is

potentially dangerous and must not be tolerated. If

fume emission does persist, then the following

immediate action should be taken:

(a) Open doors and windows to ventilate room

(b) Let the fire out or eject and safely dispose of

fuel from the appliance

(c) Check for flue or chimney blockage and clean if

required

(d) Do not attempt to relight the fire until the cause

of the fume emission has been identified and

corrected. If necessary seek expert advice.

The most common cause of fume emission is flueway or chimney blockage. For your own safety

these must be kept clean at all times.

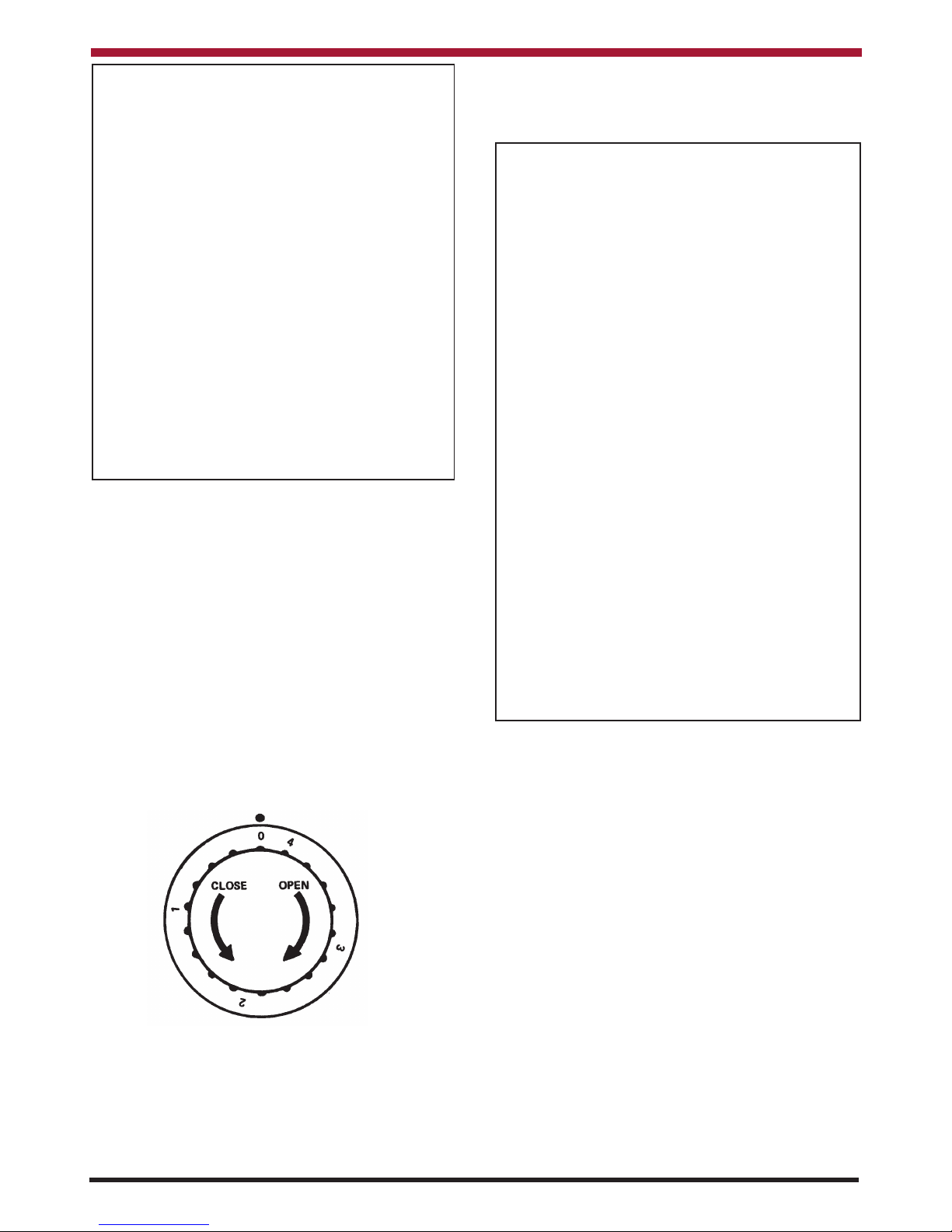

Setting 0: Overnight Burning

Setting 1: Closed

Setting 2: Slow burning

Setting 3: Medium burning

Setting 4: Maximum Heat

Fig.12

PRIMARY AIR CONTROL

10

Rotate the knob to the required setting. These are

a guide only and experience will dictate the required

setting for comfort.

NOTE:-

A boiler model stove will provide heat into the boiler and also to the room in which it is situated. The

heat to room is in a fixed relationship with the heat

to the boiler.

The heat to the boiler is controlled by the air supply

to the stove which is required to have a thermostatic damper for safety reasons. When the temperature of the water in the boiler exceeds 55 ˚C the

thermostatic damper will begin to shut off the air

supply, should the water temperature continue to

rise the thermostatic damper will continue to close

and if the water temperature reaches 85 ˚C the

thermostatic damper closes the primary air supply

fully.

In the event where a stove is fitted to a central heating system which is undersized in relation to the

nominal heat output to boiler then the stove will

operate satisfactorily but will be unable to achieve

the nominal heat output to room as the thermostatic damper will shut off the air supply to prevent an

overheat situation in the boiler.

For example:- Where a stove provides 2kW to the

room and 8kW to the boiler and if the thermostatic

damper shuts down the air supply to provide 4kW to

the boiler, then the heat to room will decrease proportionally to 1kW.

RECOMMENDED FUELS

This appliance has been tested using seasoned

wood logs and manufactured briquetted smokeless

fuel (Ancit) for closed appliances, sized between

20g and 140g. Other fuels are commercially available and may give similar results. Wood logs up to

400mm long are suitable. All fuels should be stored

under cover and kept as dry as possible prior to use.

Do not use fuels with a coke ingredient as this may

cause the grate to overheat, causing damage.

Reduced outputs will result when fuels of lower

calorific values are used. Never use gasoline or

gasoline type lantern fuel, kerosene, charcoal lighter

fluid or similar liquids to start or freshen up a fire in

this heater. Keep all such liquid well away from the

heater at all times. Operate the stove only with the

fuelling door closed except for re-fuelling.

Page 12

11

OPENING STOVE DOOR

The stove is provided with a removable handle. The

door opening mechanism is operated by sliding the

handle onto the door latch shaft located on the right

hand door. Slide the handle up from underneath

into the door latch as shown in Fig.14.

When the handle is fully engaged, rotate the handle

in an anticlockwise direction to open the door see

Figs 15 & 15a.

Reverse the above procedure to lock the door. The

door latch shaft on the left hand door is fixed and

cannot be rotated. If you require to open this door

whilst hot, slide the handle on from top down to the

bottom in a vertical direction and then use the handle to pull the door open. The right hand door must

be open to allow the left hand door to open.

Fig.14

Fig.15

Fig.15a

Fig.13

OPEN When burning coal, timber or peat.

CLOSE When burning anthracite and

smokeless fuels. See Fig.13

WARNING: DO NOT OBSTRUCT PRIMARY

AIR SUPPLY TO THE AIR DUCT AT THE BACK

OF THE STOVE.

WARNING: THE AIR SLIDER IS HOT WHILE

STOVE IS IN USE - USE TOOL TO OPERATE.

Page 13

IMPORTANT NOTES

Now that your Solid Fuel Stove is installed and no doubt you are looking forward to many comforts it will provide, we would like to give you some tips on how to get the best results from your stove.

1. We would like if you could take some time to read the operating instructions/hints, which we are confident,

will be of great benefit to you.

2. Do not burn fuel with a high moisture content, such as a damp or unseasoned timber. This will only result

in a build up of tar in the stove and in the chimney.

3. Clean the flue-ways of the stove weekly and ensure that there are no blockages. Check flueways before

lighting especially after a shut down period. Please refer to manual for instructions.

4. Before loading fresh fuel into the firebox, riddle fully to remove all ashes, this will allow better and cleaner

burning. See Re-Fuelling Section.

5. Never allow a build up of ashes in the ash pan, as this will cause the grate to burn out prematurely. Empty

the ashpan when re–fuelling.

6. Allow adequate air ventilation to ensure plenty of air for combustion.

7. Do not use as an incinerator burning rubbish/household waste.

8. Do not leave ash door open for long periods as this will over heat the unit causing unnecessary damage.

Close the ash door between removing and replacing the ashpan.

9. Clean the chimney at least twice a year.

10. Burning soft fuels such as timber or peat will stain the glass. Regular cleaning will prevent permanent

staining. Clean with soapy water when cool.

11. Keep all combustible materials a safe distance away from unit, please consult manual for clearance to combustibles table.

12. For safety reasons never leave children or the elderly unaccompanied while stove is in use. Use a fire

guard.

13. Avoid contact with the appliance when in use as stove reaches very high operating temperatures.

14. This appliance should be regularly maintained by a competent service engineer.

15. Store the operating tool / door handle on the ash door on the bottom of the stove. DO NOT STORE THIS

HANDLE ON EITHER OF THE FIREBOX DOORS AS THE HANDLE WILL GET EXCESSIVELY HOT

WHILE THE STOVE IS IN OPERATION.

Use only replacement parts recommended by Waterford Stanley. Making unauthorised modifications, or using

unauthorised parts will invalidate your guarantee and may cause damage or injury.

FUEL CALORIFIC VALUES - SOLID FUELS

Anthracite 25-50mm C.V.: 8.2kW/Kg 14,000 BTUs/lb

House Coal 25-75mm C.V.: 7.2kW/Kg 12,000 BTUs/lb

Timber - Firebox size C.V.: 5.0kW/Kg 8,600 BTUs/lb

Peat Briquettes C.V.: 4.8kW/Kg 8,300 BTUs/lb

12

Page 14

LIGHTING

1. Before lighting the stove, ensure that any build up of ashes in the

fire box has been removed and that the ashpan has been emptied.

2. Open the firebox and cover the grate with crumpled pieces of paper.

3. Lay pieces of kindling on top of the paper towards the back of the

fire box.

4. Open the primary air inlet by turning the control knob to setting 4.

5. Open the secondary air control by sliding the control lever located

over the top of the fire door to the right. (See Fig.13).

6. Ignite the paper and close the firedoor.

7. When the kindling is well alight, open the fire door and add more

kindling of a larger size to sustain the fire. Close the firedoor. Do

not operate this appliance with the firedoor open.

8. Never use inflammable liquid i.e. gasoline, petrol paraffin etc. to

start or freshen up a fire in this heater.

9. When a hot bed of fuel is established, add the normal fuel load and

adjust the air controls to the required setting.

10. When re-fuelling open the firedoor and reload, close the firedoor.

11. To shut the fire down, do not add fuel, make sure that the firedoor

is properly closed and that the primary and secondary air controls

are all in the closed position. Cutting off the air supply will reduce

the heat output.

This appliance is hot whilst in operation.

Keep children, clothing and furniture a safe distance away.

13

Page 15

14

Fig.16

DISPOSAL OF ASHES

The stove is provided with a steel ashpan. This ashpan must be emptied every day.

If ashes are allowed to build up to grate level the firebars could be damaged by overheating. We recommend that you remove ashes after you have riddled

the fire following an overnight burn.

Note: The stove should never be operated with the

ashpit door open.

Ashes should be placed in a metal or other noncombustible container with a tight fitting lid. The

closed container of ashes should be placed on a

non-combustible material, pending final disposal. If

ashes are buried in soil, or otherwise dumped they

should be retained in the closed container until they

are thoroughly cooled.

DE-ASHING

When ash build-up becomes excessive in the fire

chamber shake the firebars by inserting the operating tool/door handle into the round slot on the right

side of the stove, twisting clockwise and anti-clockwise. A poker is also provided for de-ashing.

Fig.17

TO CLEAN CHIMNEY OUTLET

Boiler Model

Remove baffle underneath the boiler cross flow

chamber by lifting it upwards and pulling it outwards

and insert cleaning brush. Replace baffle before

lighting fire.

Fig.18

NON BOILER MODEL

Remove hob and place to one side, taking care not

to damage the enamel finish. Remove the hotplate

and inner top by unscrewing the four 1/4” hex head

bolts and insert the cleaning brush. Replace the

hotplate and inner-top, ensuring that the rope on the

bottom of the inner-top has not moved out of position or been damaged. Replace the hob before

relighting the fire.

TO REPLACE DAMAGED GRATE OR GRATE

BAR

BOILER MODEL

Remove the two sets of side firebricks and the front

firebrick from the stove, taking care not to damage

or break the bricks in the process. Tilt the grate

assembly up on the left hand side, and pull towards

the left hand side of the stove, until the front bar is

clear of the right hand side of the stove (See Fig.

19). Remove the grate bars from the firebox and

then remove the grate frame, replace the damaged

part and reassemble the grate system by firstly

replacing the grate frame, and the grate bars, and

replacing finally the firebricks.

NON - BOILER MODEL

Remove the front brick, the back brick, all the left

hand side bricks and both small right side bricks

from the stove, taking care not to damage or break

any of the bricks in the process. Tilt the grate

assembly up on the left hand side of the stove and

pull towards the left side of the stove until the driven

Page 16

rocker bar is clear of the right hand firebricks.

Remove the grate assembly from the firebox,

replace the damaged part and reassemble the firebox by re-positioning the grate assembly and then

reposition all the firebricks.

Ensure the riddling mechanism works properly from

outside the stove before replacing the firebricks.

PERIODS OF PROLONGED NON-USE

If the stove is to be left unused for a prolonged period of time then it should be given a thorough clean

to remove ash and unburned fuel residues. To

enable a good flow of air through the appliance to

reduce condensation and subsequent corrosion

damage, leave the air controls in the fully open position.

FIRE SAFETY

To provide reasonable fire safety, the following

should be given serious consideration.

1. DO NOT OVER FIRE THE STOVE.

2. OVER-FIRING WILL ALSO DAMAGE

PAINTED OR ENAMEL FINISH.

3. Install a smoke detector in the room.

4. A conveniently located class A fire extinguisher

to contend with small fires resulting from burning

embers.

5. A practical evacuation plan.

6. A plan to deal with a chimney fire as follows:-

(a) Notify the fire department.

(b) Prepare occupants for immediate

evacuation.

Fig.19

Fig.20

STAINLESS STEEL DOOR AXLES MAY TARNISH

PARTICULARLY IF STOVE IS OVERFIRED

IN CASE OF FIRE

Close all openings into the stove and watch for ignition of adjacent combustibles from over heated

stove, or hot embers or sparks from chimney.

VITREOUS ENAMEL CLEANING

General cleaning must be carried out when the

stove is thoroughly cool.

If this stove is finished in a high gloss vitreous

enamel, to keep the enamel in the best condition

observe the following tips:

1. Wipe over daily with a soapy damp cloth,

followed by a polish with a clean dry duster.

2. For stubborn deposits a soap impregnated pad

can be carefully used on the vitreous enamel.

3. Use only products recommended by the

Vitreous Enamel Association, these products

carry the Vitramel label.

4. DO NOT USE ABRASIVE PADS OR OVEN

CLEANSERS CONTAINING CITRIC ACID

ON ENAMELLED SURFACES. ENSURE

THAT THE CLEANSER MANUFACTURERS INSTRUCTIONS ARE ADHERED TO.

15

(c) Close all openings into the stove.

(d) While awaiting the fire department watch for

ignition to adjacent combustibles from over

heated flue pipe or from embers or sparks

from the chimney.

Page 17

16

Fig.21

GLASS CLEANING

The glass will self clean when there is sufficient heat

generated by the burning fuel. If a build-up of creosote occurs on the glass it may be due to draft conditions, poor quality fuel or very low burning for a

long time. It is best to clean the glass when it is

thoroughly cooled.

GLASS REPLACEMENT

(a) Open the firedoor fully.

(b) Remove the screws and the four segments of

the window frame and carefully remove the broken glass.

(c) Clean the glass recess in the door.

(d) Attach adhesive thermal tape to the perimeter of

the replacement glass.

(e) Place the thermal tape side of the glass into

the door recess and replace the four segments

of the window frame.

(f) Tighten screws.

(g) Replace glass only with ceramic glass 5mm

thick. (See Fig.21)

CO ALARM

Waterford Stanley recommend the fitting of a CO

Alarm in the same room as the appliance, this is a

requirement under UK Building Regulations.

Further guidance on the installation of a carbon

monoxide alarm is available in BS EN 50292:2002

and from the alarm manufacturers instructions.

Provision of an alarm must not be considered a

substitute for either installing the appliance

correctly or ensuring regular servicing and

maintenance of the appliance and chimney

system.

WARNING:-

If the CO Alarm sounds unexpectedly:-

1. Open Doors and windows to ventilate the

room and then leave the premises.

2. Let the fire go out.

Page 18

GRAINNE SOLID FUEL- HPB MODEL EXPLODED VIEW

17

1. HANDLE 16. HINGE PIN 31. 25MM SPACER

2. OPERATING TOOL 17. ASH COMPARTMENT 32. BOILER PLUG

3. LEG 18. FLEXIBLE DRIVE 33. DOOR HANDLE SPACER

4. ASHTRAY FRONT 19. FRONT BRICK 34. FIRE FENCE

5. BASE PANEL 20. SIDE BRICK NO.1 35. BOILER CLEANING DOOR

6. FRONT 21. SIDE BRICK NO.2 36. DOOR LATCH

7. HOB 22. THERMOSTAT ASSEMBLY 37. ASHPIT DOOR HANDLE

8. INNER TOP 23. GRATE ASSEMBLY 38. HINGE

9. LH SIDE 24. LH FIRE DOOR 39. DOOR AXLE

10. RH SIDE 25. RH FIRE DOOR 40. BADGE

11. RIDDLING HANDLE 26. ASH DOOR 41. GLASS

12. BOILER 27. SERIAL NUMBER PLATE 42. WINDOW CLIP

13. AIR SLIDE SUB ASSEMBLY 28. BOX AIR WASH

14. ASHPAN 29. AIR WASH CASTING

15. DOOR STOP 30. AIR CONTROL KNOB

Page 19

GRAINNE SOLID FUEL- NON BOILER MODEL EXPLODED VIEW

18

1. HANDLE 18. ASH COMPARTMENT ASSEMBLY 35. FIRE FENCE SUPPORT

2. LEG 19. DOOR STOP 36. BACK PANEL

3. OUTER BACK 20. HINGE PIN 37. EXTERNAL AIR WASH

CASTING

4. ASHTRAY FRONT 21. FLEXIBLE DRIVE 38. AIR WASH CASTING

5. BASE PANEL 22. QWX THERMOSTAT 39. INNER TOP

6. LH SIDE 23. FRONT BRICK 40. AIR CONTROL KNOB

7. RH SIDE 24. BACK BRICK 41. ROCKER BAR (DRIVEN)

8. FRONT 25. SIDE BACK BRICK 42. ROCKER BAR (IDLE)

9. HOB 26. LEFT FRONT BRICK 43. GRATE

10. TOP AIR DUCT WINGS 27. RIGHT FRONT BRICK 44. FIRE FENCE

11. AIR CONTROL STAT PLATE 28. SIDE BRICK NO.1 45. HINGE

12. TOP AIR DUCT ASSEMBLY 29. SIDE BRICK NO.2 46. DOOR LATCH

13. FLEXIBLE DRIVE REST.

BRACKET

30. LH FRONT BRICK NO.2 47. ASH DOOR HANDLE

14. FLEXIBLE DRIVE BRACKET 31. LH FIRE DOOR 48. BADGE

15. SHAKER BAR SLEEVE 32. RH FIRE DOOR 49. DOOR AXLE

16. AIR SLIDE SUB ASSEMBLY 33. ASH DOOR 50. WINDOW CLIP

17. ASHPAN 34. SERIAL NUMBER PLATE 51. GLASS

Page 20

INSTALLATION CHECK LIST

Flue System

1. Minimum Flue Height of 4.6 metres (15 feet).

2. Appliance should be connected to a minimum of 1.8 metres (6 feet) of 150mm (6”)

flue pipe with a horizontal run not exceeding 150mm (6”).

3. Appliance should be connected to a chimney of less than 200mm (8”) in diameter

(otherwise the chimney must be lined with a 6” flue liner).

4. The chimney venting position must be above the main ridge of the roof or adjacent

outside obstructions.

5. The chimney serving this appliance should not serve any other appliance.

6. Access should be provided to the chimney serving the appliance to allow for cleaning.

Location

7. Clearance to combustible materials must be adhered to as described in the Clearance

to Combustible section.

8. The stove must be installed on a floor protector that covers the area under the stove

and extends 18” to the front & 8” to the sides and back.

Plumbing (Boiler Model Only)

9. Appliance must be connected to a gravity circuit using 1” ID flow & return piping.

10. The length of pipes from the cylinder to the cooker should not exceed 7.8 metres

(25

1

/2

feet).

11. A circulation pump should be fitted to the return pipe of the radiator circuit and controlled by

a pipe stat fitted to the flow pipe of the gravity circuit to the cylinder.

Ventilation & Combustion Air Requirements

12. The room in which the appliance is located should have an air vent of adequate

size to support correct combustion (see Ventilation & Combustion Air Requirement

Section for specific details).

Tick

19

Rev: 10 DP130903

N00428AXX

Manufactured by

Waterford Stanley Ltd.,

Unit 401-403, IDA Industrial Estate, Cork Road,

Waterford, Ireland.

Tel: (051) 302300 Fax (051) 302315

Website: www.waterfordstanley.com

Loading...

Loading...