Page 1

GPV13

V SERIES

HYDRAULIC POWER UNIT

USER MANUAL

Safety, Operation and Maintenance

73417 1/2014 Ver. 1

Page 2

2 ► GPV13 User Manual

Page 3

TABLE OF CONTENTS

WARNING

IMPORTANT

SAFETY SYMBOLS ..................................................................................................................................................4

SAFETY PRECAUTIONS .......................................................................................................................................... 5

TOOL STICKERS & TAGS ........................................................................................................................................6

HOSE TYPES ............................................................................................................................................................ 7

HOSE RECOMMENDATIONS ..................................................................................................................................8

FIGURE 1. TYPICAL HOSE CONNECTIONS .......................................................................................................8

HTMA REQUIREMENTS ...........................................................................................................................................9

OPERATION ............................................................................................................................................................10

FIGURE 2. PANEL CONTROL VALVE .................................................................................................................10

FIGURE 3. HYDRAULIC CONNECTIONS .......................................................................................................... 11

FIGURE 4. THROTTLE CONTROL LEVER ........................................................................................................11

FIGURE 5. ENGINE COMPONENTS .................................................................................................................. 12

FIGURE 6. CHOKE LEVER ................................................................................................................................. 13

FIGURE 7. FUEL LEVER .....................................................................................................................................13

FIGURE 8. ON-OFF SWITCH .............................................................................................................................. 13

MAINTENANCE ..............................................................................................................................................14 & 17

TESTING & TROUBLESHOOTING ........................................................................................................................15

TROUBLESHOOTING ............................................................................................................................................16

SPECIFICATIONS ................................................................................................................................................... 17

To ll out a Product Warranty Recording form, and for information on your warranty,

visit Stanleyhydraulic.com and select the Warranty tab.

(NOTE: The warranty recording form must be submitted to validate the warranty).

SERVICING: This manual contains safety, operation, and routine maintenance instructions. Stanley Hydraulic Tools

recommends that servicing of hydraulic tools, other than routine maintenance, must be performed by an authorized

and certied dealer. Please read the following warning.

SERIOUS INJURY OR DEATH COULD RESULT FROM THE IMPROPER REPAIR OR SERVICE OF THIS

TOOL.

REPAIRS AND / OR SERVICE TO THIS TOOL MUST ONLY BE DONE BY AN AUTHORIZED AND

CERTIFIED DEALER.

For the nearest authorized and certied dealer, call Stanley Hydraulic Tools at (503-659-5660) and ask for a Customer Service Representative.

GPV13 User Manual ◄ 3

Page 4

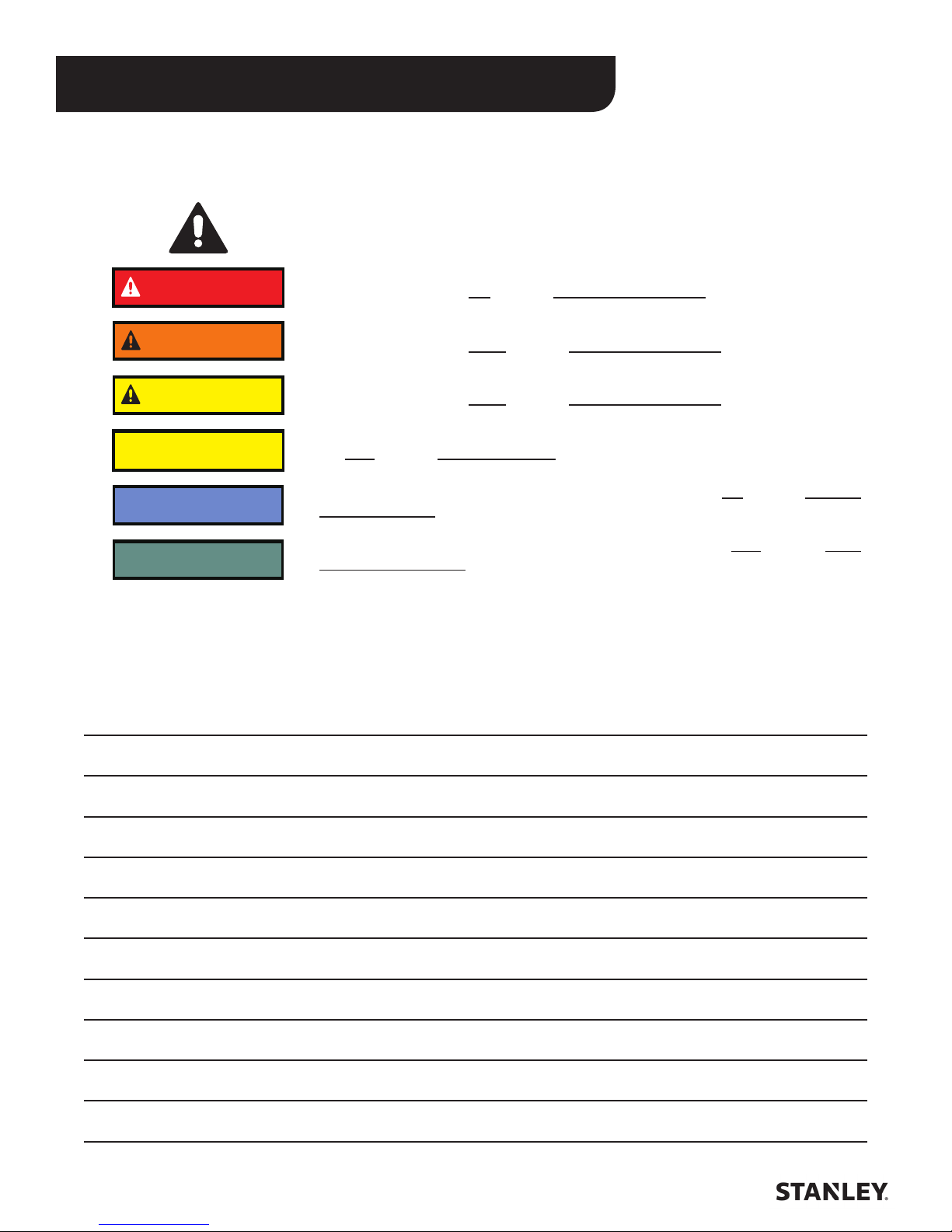

SAFETY SYMBOLS

DANGER

WARNING

CAUTION

CAUTION

NOTICE

IMPORTANT

Safety symbols and signal words, as shown below, are used to emphasize all operator, maintenance and repair actions which, if not strictly followed, could result in a life-threatening situation, bodily injury or damage to equipment.

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid possible

injury or death.

This safety alert and signal word indicate an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

This safety alert and signal word indicate a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

This safety alert and signal word indicate a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

This signal word indicates a potentially hazardous situation which, if not avoid-

ed, may result in property damage.

This signal word indicates a situation which, if not avoided, will result in damage

to the equipment.

This signal word indicates a situation which, if not avoided, may result in damage to the equipment.

Always observe safety symbols. They are included for your safety and for the protection of the tool.

LOCAL SAFETY REGULATIONS

Enter any local safety regulations here. Keep these instructions in an area accessible to the operator and mainte-

nance personnel.

4 ► GPV13 User Manual

Page 5

SAFETY PRECAUTIONS

Tool operators and maintenance personnel must always

comply with the safety precautions given in this manual

and on the stickers and tags attached to the equipment.

These safety precautions are given for your safety. Review them carefully before operating the tool and before

performing general maintenance or repairs.

Supervising personnel should develop additional pre-

cautions relating to the specic work area and local

safety regulations. If so, place the added precautions in

the space provided in this manual.

In addition to this manual, read and understand safety

and operating instructions in the Engine Operation Manual furnished with the power unit.

The GPV13 Hydraulic Power Unit will provide safe and

dependable service if operated in accordance with the

instructions given in this manual. Read and understand

this manual and any stickers and tags attached to the

Power Unit. Failure to do so could result in personal injury or equipment damage.

• Operator must start in a work area without bystand-

ers. The operator must be familiar with all prohibited

work areas such as excessive slopes and danger-

ous terrain conditions.

• Establish a training program for all operators to en-

sure safe operation.

• Do not operate the power unit unless thoroughly

trained or under the supervision of an instructor.

• Always wear safety equipment such as goggles,

ear, head protection, and safety shoes at all times

when operating the power unit and a hydraulic tool.

• Do not inspect or clean the power unit while it is run-

ning. Accidental engagement of the unit can cause

serious injury.

• Always use hoses and ttings rated at 2500 psi/172

bar with a 4 to 1 safety factor. Be sure all hose con-

nections are tight.

• Be sure all hoses are connected for correct ow di-

rection to and from the tool being used.

• Do not inspect hoses and ttings for leaks by using

bare hands. “Pin-hole” leaks can penetrate the skin.

• NEVER OPERATE THE POWER UNIT IN A

CLOSED SPACE. Inhalation of engine exhaust can

be fatal.

• Do not operate a damaged, improperly adjusted

power unit.

• Never wear loose clothing that can get entangled in

the working parts of the power unit.

• Keep all parts of your body away from the working

parts of the power unit.

• Keep clear of hot engine exhaust.

• Do not add fuel to the power unit while the power

unit is running or is still hot.

• Do not operate the power unit if gasoline odor is

present.

• Do not use ammable solvents around the power

unit engine.

• Do not operate the power unit within 3.3 ft/1 m of

buildings, obstructions or ammable objects.

• Do not reverse tool rotation direction by changing

uid ow direction.

• Allow power unit engine to cool before storing in an

enclosed space.

• Always keep critical tool markings, such as labels

and warning stickers legible.

• To avoid personal injury or equipment damage, all

tool repair, maintenance and service must only be

performed by authorized and properly trained personnel.

• Warning: Use of this tool on certain materials during

demolition could generate dust potentially containing a variety of hazardous substances such as as-

bestos, silica or lead. Inhalation of dust containing

these or other hazardous substances could result

in serious injury, cancer or death. Protect yourself

and those around you. Research and understand

the materials you are cutting. Follow correct safety

procedures and comply with all applicable national,

state or provisional health and safety regulations

relating to them, including, if appropriate arranging

for the safe disposal of the materials by a qualied

person.

GPV13 User Manual ◄ 5

Page 6

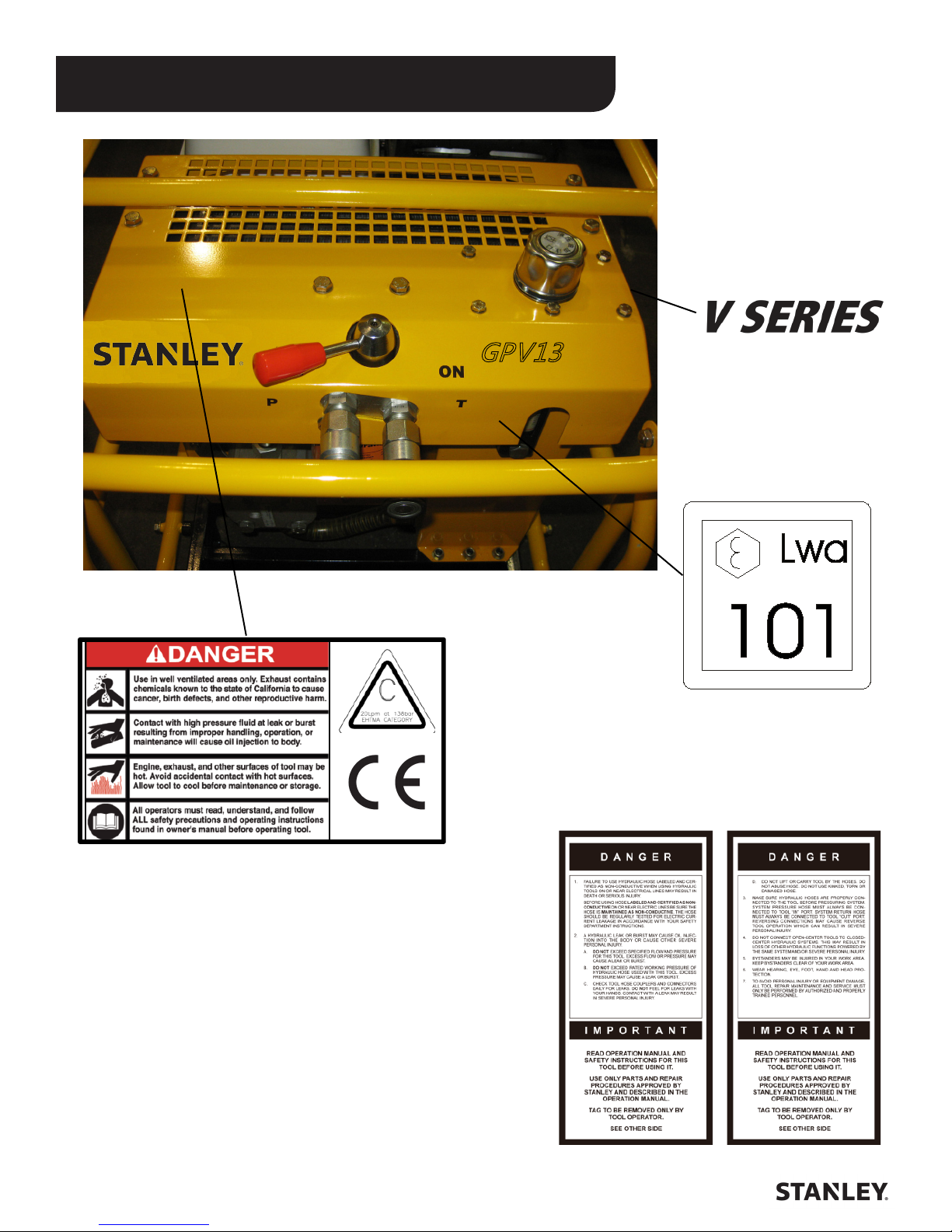

TOOL STICKERS & TAGS

GPV13

Hydraulic

Power Pack

6 ► GPV13 User Manual

Safety Tag wire tied to power unit

Page 7

HOSE TYPES

The rated working pressure of the hydraulic hose must be equal to or higher than the relief valve setting on the hydraulic system. There are three types of hydraulic hose that meet this requirement and are authorized for use with

Stanley Hydraulic Tools. They are:

Certied non-conductive — constructed of thermoplastic or synthetic rubber inner tube, synthetic ber braid

reinforcement, and weather resistant thermoplastic or synthetic rubber cover. Hose labeled certied non-

conductive is the only hose authorized for use near electrical conductors.

Wire-braided (conductive) — constructed of synthetic rubber inner tube, single or double wire braid reinforcement, and weather resistant synthetic rubber cover. This hose is conductive and must never be used near

electrical conductors.

Fabric-braided (not certied or labeled non-conductive) — constructed of thermoplastic or synthetic rubber inner tube, synthetic ber braid reinforcement, and weather resistant thermoplastic or synthetic rubber cover. This

hose is not certied non-conductive and must never be used near electrical conductors.

HOSE SAFETY TAGS

To help ensure your safety, the following DANGER tags are attached to all hose purchased from Stanley Hydraulic

tools. DO NOT REMOVE THESE TAGS.

If the information on a tag is illegible because of wear or damage, replace the tag immediately. A new tag may be

obtained from your Stanley Distributor.

THE TAG SHOWN BELOW IS ATTACHED TO “CERTIFIED NON-CONDUCTIVE” HOSE

DANGER

1. FAILURE TO USE HYDRAULIC HOSE LABELED AND CERTIFIED AS NON-CONDUCTIVE

WHEN USING HYDRAULIC TOOLS ON OR NEAR ELECTRIC LINES MAY RESULT IN

DEATH OR SERIOUS INJURY.

FOR PROPER AND SAFE OPERATION MAKE SURE THAT YOU HAVE BEEN PROPERLY TRAINED IN CORRECT PROCEDURES REQUIRED FOR WORK ON OR AROUND

ELECTRIC LINES.

2. BEFORE USING HYDRAULIC HOSE LABELED AND CERTIFIED AS NON-CONDUCTIVE

ON OR NEAR ELECTRIC LINES. WIPE THE ENTIRE LENGTH OF THE HOSE AND FITTING WITH A CLEAN DRY ABSORBENT CLOTH TO REMOVE DIRT AND MOISTURE AND

TEST HOSE FOR MAXIMUM ALLOWABLE CURRENT LEAKAGE IN ACCORDANCE WITH

SAFETY DEPARTMENT INSTRUCTIONS.

DO NOT REMOVE THIS TAG

SEE OTHER SIDE

SIDE 1

3. DO NOT EXCEED HOSE WORKING PRESSURE OR ABUSE HOSE. IMPROPER USE

OR HANDLING OF HOSE COULD RESULT IN BURST OR OTHER HOSE FAILURE.

KEEP HOSE AS FAR AWAY AS POSSIBLE FROM BODY AND DO NOT PERMIT DIRECT

CONTACT DURING USE. CONTACT AT THE BURST CAN CAUSE BODILY INJECTION

AND SEVERE PERSONAL INJURY.

4. HANDLE AND ROUTE HOSE CAREFULLY TO AVOID KINKING, ABRASION, CUTTING, OR

CONTACT WITH HIGH TEMPERATURE SURFACES. DO NOT USE IF KINKED. DO NOT

USE HOSE TO PULL OR LIFT TOOLS, POWER UNITS, ETC.

5. CHECK ENTIRE HOSE FOR CUTS CRACKS LEAKS ABRASIONS, BULGES, OR DAMAGE TO COUPLINGS IF ANY OF THESE CONDITIONS EXIST, REPLACE THE HOSE

IMMEDIATELY. NEVER USE TAPE OR ANY DEVICE TO ATTEMPT TO MEND THE HOSE.

6. AFTER EACH USE STORE IN A CLEAN DRY AREA.

(Shown smaller than actual size)

DANGER

DANGER

SEE OTHER SIDE

SIDE 2

THE TAG SHOWN BELOW IS ATTACHED TO “CONDUCTIVE” HOSE.

DANGER

DANGER

1. DO NOT USE THIS HYDRAULIC HOSE ON OR NEAR ELECTRIC LINES. THIS HOSE IS

NOT LABELED OR CERTIFIED AS NON-CONDUCTIVE. USING THIS HOSE ON OR NEAR

ELECTRICAL LINES MAY RESULT IN DEATH OR SERIOUS INJURY.

2. FOR PROPER AND SAFE OPERATION MAKE SURE THAT YOU HAVE BEEN PROPERLY

TRAINED IN CORRECT PROCEDURES REQUIRED FOR WORK ON OR AROUND ELECTRIC LINES.

3. DO NOT EXCEED HOSE WORKING PRESSURE OR ABUSE HOSE. IMPROPER USE OR

HANDLING OF HOSE COULD RESULT IN BURST OR OTHER HOSE FAILURE. KEEP HOSE

AS FAR AWAY AS POSSIBLE FROM BODY AND DO NOT PERMIT DIRECT CONTACT

DURING USE. CONTACT AT THE BURST CAN CAUSE BODILY INJECTION AND SEVERE

PERSONAL INJURY.

4. HANDLE AND ROUTE HOSE CAREFULLY TO AVOID KINKING, CUTTING, OR CONTACT

WITH HIGH TEMPERATURE SURFACES. DO NOT USE IF KINKED. DO NOT USE HOSE TO

PULL OR LIFT TOOLS, POWER UNITS, ETC.

DO NOT REMOVE THIS TAG

SEE OTHER SIDE

SIDE 1

5. CHECK ENTIRE HOSE FOR CUTS CRACKS LEAKS ABRASIONS, BULGES, OR DAMAGE TO

COUPLINGS IF ANY OF THESE CONDITIONS EXIST, REPLACE THE HOSE IMMEDIATELY.

NEVER USE TAPE OR ANY DEVICE TO ATTEMPT TO MEND THE HOSE.

6. AFTER EACH USE STORE IN A CLEAN DRY AREA.

(Shown smaller than actual size)

DANGER

SEE OTHER SIDE

SIDE 2

DO NOT REMOVE THIS TAG

DO NOT REMOVE THIS TAG

GPV13 User Manual ◄ 7

Page 8

HOSE RECOMMENDATIONS

Min. Working Pressure

USE

(Press/Return)

Certied Non-Conductive Hose - Fiber Braid - for Utility Bucket Trucks

Oil Flow Hose Lengths Inside Diameter

GPM LPM FEET METERS INCH MM PSI BAR

4-9 15-34 up to 10 up to 3 3/8 10 Both 2250 155

Conductive Hose - Wire Braid or Fiber Braid -DO NOT USE NEAR ELECTRICAL CONDUCTORS

4-6 15-23 up to 25 up to 7.5 3/8 10 Both 2500 175

4-6 15-23 26-100 7.5-30 1/2 13 Both 2500 175

5-10.5 19-40 up to 50 up to 15 1/2 13 Both 2500 175

5-10.5 19-40 51-100 15-30 5/8 16 Both 2500 175

5/8 16 Pressure 2500 175

3/4 19 Return 2500 175

5-10.5 19-40 100-300 30-90

10-13 38-49 up to 50 up to 15 5/8 16 Both 2500 175

5/8 16 Pressure 2500 175

3/4 19 Return 2500 175

10-13 38-49 51-100 15-30

3/4 19 Pressure 2500 175

1 25.4 Return 2500 175

10-13 38-49 100-200 30-60

5/8 16 Pressure 2500 175

3/4 19 Return 2500 175

13-16 49-60 up to 25 up to 8

3/4 19 Pressure 2500 175

1 25.4 Return 2500 175

13-16 49-60 26-100 8-30

PRESSURE

<<< FLOW

RETURN

FLOW >>>

Figure 1. Typical Hose Connections

Tool to Hydraulic Circuit Hose

Recommendations

The chart to the right shows recommended

minimum hose diameters for various hose

lengths based on gallons per minute (gpm)/

liters per minute (lpm). These recommenda-

tions are intended to keep return line pressure

(back pressure) to a minimum acceptable lev-

el to ensure maximum tool performance.

This chart is intended to be used for hydraulic

tool applications only based on Stanley Hy-

draulic Tools tool operating requirements and

8 ► GPV13 User Manual

should not be used for any other applications.

All hydraulic hose must have at least a rated

minimum working pressure equal to the maxi-

mum hydraulic system relief valve setting.

All hydraulic hose must meet or exceed

specications as set forth by SAE J517.

Page 9

HTMA / EHTMA REQUIREMENTS

HTMA / EHTMA REQUIREMENTS

HTMA

HYDRAULIC SYSTEM REQUIREMENTS

Flow Range

Nominal Operating Pressure

(at the power supply outlet)

System relief valve setting

(at the power supply outlet)

Maximum back pressure

(at tool end of the return hose)

Measured at a max. uid viscosity of:

(at min. operating temperature)

Temperature: Sufcient heat rejection

capacity to limit max. uid temperature to:

(at max. expected ambient temperature)

Min. cooling capacity at a temperature

difference of between ambient and uid

temps

NOTE:

Do not operate the tool at oil temperatures above 140° F (60° C). Operation at higher temperatures can cause operator

discomfort at the tool.

Filter

Min. full-ow ltration

Sized for ow of at least:

(For cold temp. startup and max.

dirt-holding capacity)

4-6 gpm 7-9 gpm 9-10.5 gpm 11-13 gpm

(15-23 lpm) (26-34 lpm) (34-40 lpm) (42-49 lpm)

1500 psi 1500 psi 1500 psi 1500 psi

(103 bar) (103 bar) (103 bar) (103 bar)

2100-2250 psi 2100-2250 psi 2200-2300 psi 2100-2250 psi

(145-155 bar) (145-155 bar) (152-159 bar) (145-155 bar)

250 psi 250 psi 250 psi 250 psi

(17 bar) (17 bar) (17 bar) (17 bar)

400 ssu* 400 ssu* 400 ssu* 400 ssu*

(82 centistokes) (82 centistokes) (82 centistokes) (82 centistokes)

140° F 140° F 140° F 140° F

(60° C) (60° C) (60° C) (60° C)

3 hp 5 hp 6 hp 7 hp

(2.24 kW) (3.73 kW) (5.22 kW) (4.47 kW)

40° F 40° F 40° F 40° F

(22° C) (22° C) (22° C) (22° C)

25 microns 25 microns 25 microns 25 microns

30 gpm 30 gpm 30 gpm 30 gpm

(114 lpm) (114 lpm) (114 lpm) (114 lpm)

TYPE I TYPE II

TOOL TYPE

TYPE RR

TYPE III

Hydraulic uid Petroleum based

(premium grade, anti-wear, non-conductive)

Viscosity (at min. and max. operating temps)

NOTE:

When choosing hydraulic uid, the expected oil temperature extremes that will be experienced in service determine the

most suitable temperature viscosity characteristics. Hydraulic uids with a viscosity index over 140 will meet the requirements

over a wide range of operating temperatures.

*SSU = Saybolt Seconds Universal

EHTMA

100-400 ssu* 100-400 ssu* 100-400 ssu* 100-400 ssu*

(20-82 centistokes)

CLASSIFICATION

HYDRAULIC SYSTEM

REQUIREMENTS

Flow Range

Nominal Operating Pressure

(at the power supply outlet)

System relief valve setting

(at the power supply outlet)

NOTE: These are general hydraulic system requirements. See tool specication page for tool specic requirements

B

3.5-4.3 gpm 4.7-5.8 gpm 7.1-8.7 gpm 9.5-11.6 gpm 11.8-14.5 gpm

(13.5-16.5 lpm) (18-22 lpm) (27-33 lpm) (36-44 lpm) (45-55 lpm)

1870 psi 1500 psi 1500 psi 1500 psi 1500 psi

(129 bar) (103 bar) (103 bar) (103 bar) (103 bar)

2495 psi 2000 psi 2000 psi 2000 psi 2000 psi

(172 bar) (138 bar) (138 bar) (138 bar) (138 bar)

C

D

GPV13 User Manual ◄ 9

Page 10

OPERATION

Hydraulic

Powe r Pack

GPV13

PREPARATION FOR USE

Do not operate the power unit until you have read the

engine operating and maintenance instructions manual

furnished with the unit.

1. ENGINE CRANKCASE OIL LEVEL

Always check the engine oil level before starting the

engine. Make sure the oil level is at the FULL MARK

on the dipstick. Do not overll. Use 4-stroke motor oil

that meets or exceeds the requirements for API service

classications SJ or later as specied in the engine operating and maintenance manual. Refer to the engine

manual for oil viscosity grade.

2. ENGINE FUEL LEVEL

Check the fuel level. If low, ll with unleaded gasoline

with a minimum of pump octane of 86 or higher. Refer to

the engine manual for details.

3. HYDRAULIC FLUID

Check the sight gauge on the hydraulic uid reservoir for

the proper uid level. Use uids meeting the following

specications.

VISCOSITY (FLUID THICKNESS)

U.S. METRIC

50 °F 450 SSU Maximum 10 °C 95 C.S.

100 °F 130-200 SSU 38 °C 27-42 C.S.

140 °F 85 SSU Minimum 60 °C 16.5 C.S. Min

Pour Point: -10°F/-23°C Minimum (for cold startup)

Viscosity Index: (ASTM D-2220) 140 Minimum

Demulsibility: (ASTM D-1401) 30 Minutes Maximum

Flash Point: (ASTM D-92) 340°F/171°C Minimum

Rust Inhibition: (ASTM D-665 A & B) Pass

Oxidation: (ASTM D-943) 1000 Hours Minimum

Pump Wear Test: (ASTM D-2882) 60 mg Maximum

The following uids work well over a wide temperature

range, allow moisture to settle out and resist biological growth that may occur in cool operating hydraulic

circuits. These uids are recommended by Stanley Hydraulic Tools. Other uids that meet or exceed the specications of these uids may also be used.

• Chevron AW-MV-32

• Exxon “Univis” J-26

• Mobil D.T.E. 13

• Gulf “Harmony” AW-HVI-150-32

• Shell “Tellus” T-32

• Texaco “Rando” HD-AZ

• Union “Unax” AW-WR-32

• Terresolve EnviroLogic 132

4. HYDRAULIC CONNECTIONS

The recommended hose length is 25 ft/8 m with a 1/2

inch/12.7 mm inside diameter. The hoses must have

a working pressure rating of at least 2500 psi/175 bar.

Each hose end must have male thread ends compatible

with HTMA or EHTMA (HYDRAULIC TOOL MANUFACTURERS ASSOCIATION) quick disconnect ttings (NPT

type threads). (See Figure 3.)

Figure 2. Panel Control Valve

Facing the panel control valve (see Figure 2, the left

male quick disconnect tting is the PRESSURE FLUID

OUT tting, marked with “P”. The right female quick disconnect tting is the RETURN FLUID IN tting, marked

with “T”.

QUICK DISCONNECT COUPLERS

HTMA approved quick disconnect couplings are installed to hydraulic hoses so that the direction of oil ow

is always from the male to the female quick disconnect

as shown in Figure 3. Quick disconnect couplings and

hose ttings are selected so that additional ttings such

as reducer or adapter ttings are not required.

If adapter ttings are used, they must be approved steel

hydraulic ttings meeting a minimum operating pressure

rating of 2500 psi/172 bar. Do not use galvanized pipe

ttings or black pipe ttings.

DO NOT OVERTIGHTEN THE FITTINGS.

10 ► GPV13 User Manual

Page 11

CONTROL PANEL

PRESSURE

HTMA 1/2 INCH FEMALE

QUICK DISCONNECT

COUPLER

HTMA 1/2 INCH MALE

QUICK DISCONNECT

COUPLER

1/2 INCH MALE PIPE HOSE END

1/2 INCH I.D. HOSE, 25 FT

LONG WITH 2500 PSI/

172 BAR RATING AND

4 TO 1 SAFETY FACTOR

RETURN

OPERATION

CONTROLS

The power unit provides one circuit, with an oil ow of

5 gpm/20 lpm up to 2000 psi/140 bar GPV135H02 or 8

gpm/30 lpm up to 2000 psi/140 bar GPV138B02.

One hydraulic tool can be connected to the tool circuit.

The circuit is activated by moving the control lever on

the power unit to the ON position.

THROTTLE CONTROL

The power unit is equipped with a manual throttle (See

below).

PRESSURE

PRESSURE

1/2 INCH MALE PIPE HOSE END

HTMA 1/2 INCH FEMALE

QUICK DISCONNECT

COUPLER

HTMA 1/2 INCH MALE

QUICK DISCONNECT

COUPLER

ADAPTER, 3/8 INCH MALE PIPE

× -8 SAE O-RING

RETURN

TOOL

RETURN

Figure 4. Throttle Control Lever Honda

MANUAL THROTTLE CONTROL HONDA

Engine speed is manually held at full throttle to maintain

5 gpm/20 lpm. When a tool is not being used move the

lever to the idle position.

Manual full throttle control on the Honda engine is set

by positioning the control lever (shown in Figure 4) to

the far left.

MANUAL THROTTLE CONTROL BRIGGS

The Briggs engine speed is manually held at full throttle

to maintain 8 gpm/30 lpm (see below). When a tool is

not being used move the lever to the idle position.

Figure 3. Hydraulic Connections

Briggs Throttle Control Lever

GPV13 User Manual ◄ 11

Page 12

OPERATION

HONDA ENGINE

GPV135H02

Figure 5.

AIR CLEANER

BRIGGS ENGINE

GPV138B02

FUEL VALVE LEVER

THROTTLE LEVER

Shown above (Figure 5) are the Honda and Briggs primary engine components referred to in this section. Become familiar with these components and read and un-

derstand the engine operation and maintenance manual

before starting the engine and operating the power unit

for the rst time.

MUFFLER

CHOKE

ENGINE ON/OFF

SWITCH

RECOIL START

Explosion and re hazard.

Checking the engine fuel level or refueling the

engine when it is hot or running can result in an

explosion and/or re that may result in death or

serious injury.

Do not remove the fuel cap while the engine is

running. Do not add fuel to the tank while the

engine is hot. Do not ll the fuel tank to a point of

overowing.

FUEL TANK

12 ► GPV13 User Manual

Page 13

NOTICE

Before starting the engine, make sure the throttle

control lever is at the far right or idle position.

START-UP

1. Check the engine oil level.

2. Check the hydraulic oil level in power unit.

3. Check that the engine fuel tank is full.

4. Ensure the throttle control lever is at the far right or

idle position.

5. Move the choke lever to the CLOSED position as

shown in Figure 6. Honda pictured below, see gure

5 for Briggs choke location.

OPERATION

Figure 8. ON-OFF Switch Honda

8. Pull the starter grip on the recoil starter until you feel

resistance. Then pull rmly upward. Do not allow the

starter grip to snap back against the engine. Return

it gently.

9. After the engine starts, allow it to warm up. Gradu-

ally adjust the choke until it is in the open position.

10. Connect hoses and the tool as described on pages

7 and 8.

11. Move the tool circuit control lever to the ON position.

12. When nished operating the tool, move the tool cir-

cuit control lever to the OFF position.

Figure 6. Choke Lever Honda

6. Move the fuel valve lever to the ON position as

shown in Figure 7, see gure 5 for Briggs fuel valve

location.

Figure 7. Fuel Lever Honda

7. Position the engine ON-OFF switch to the ON posi-

tion as shown in Figure 8, see gure 5 for Briggs on/

off switch location.

COLD WEATHER STARTUP

1. Use the procedures described under START-UP

and then follow the procedure below.

2. Hydraulic uids are thicker in cold weather. Therefore, it is recommended that the engine be run at low

idle long enough to bring the uid temperature up to

a minimum of 50 °F/10 °C.

3. If the tools and tool hoses are cold, it is recommended to allow hydraulic uid to circulate through the

tool hoses until warm before using the tool.

SHUTDOWN

1. Ensure the tool circuit control lever is in the OFF

position.

2. Allow the engine to idle for approximately one min-

ute and move the engine switch to the OFF position.

GPV13 User Manual ◄ 13

Page 14

MAINTENANCE

ENGINE MAINTENANCE

Follow the maintenance schedule and general maintenance instructions in the engine maintenance and operation manual furnished with the power unit. Also see

maintenance schedule on pages 15 & 16.

HYDRAULIC SYSTEM

MAINTENANCE

• Check hydraulic uid level daily. Add uid per specications in this manual. (See HYDRAULIC FLUID

under the section titled OPERATION.

• Remove condensed moisture from the hydraulic

uid by pumping the hydraulic uid into a 5 gal/20

l container through the pressure hose. Make sure

the engine is at idle when performing this procedure.

When the hydraulic reservoir is empty turn the en-

gine off immediately.

• Allow the uid to sit long enough for the water to

settle to the bottom of the container. Slowly pour the

uid back into the hydraulic tank, avoiding the water

at the bottom of the container.

• Each day, check hydraulic lines and ttings for

leaks, kinks, etc. Do not use your hand to perform

this check.

• Change the hydraulic lter element every 100 hours

of operation or 6 months which ever comes rst.

Change more often if cold, moist or dusty conditions

exist.

• Check oil cooler for debris. Remove debris with air

pressure.

STORAGE

• Clean the unit thoroughly before storage. Do not use

water pressure.

• Always store the unit in a clean and dry facility.

• If the unit will be stored for a prolonged period (over

30 days), add a fuel additive to the fuel tank to prevent the fuel from gumming. Run engine for a short

period to circulate the additive.

• Replace crankcase oil with new oil.

• Remove the spark plug and pour approximately 1

ounce (30 ml) of engine oil into the cylinder. Replace

the spark plug and crank the engine slowly to distrib-

ute the oil.

• Check hydraulic reservoir for water. If water is found,

change the oil and circulate it through the tool hose

and tool. (See HYDRAULIC SYSTEM MAINTENANCE earlier in this section).

• Disconnect tool hoses.

14 ► GPV13 User Manual

Page 15

HONDA ENGINE MAINTENANCE

MAINTENANCE

MAINTENANCE

Regular Service Period

Perform at every indicated month or

operating hour interval, whichever comes rst.

Engine Oil Check Level

Change

Air Cleaner Check

Clean

Sediment Cup Clean

Spark Plugs Clean-Readjust

EngineHydraulics

Spark Arrester (optional) Clean

Valve Clearance Check-Readjust

Fuel Tank and Strainer Clean

Fuel Line Check (Replace if

Necessary)

Hydraulic Fluid Level Check

Hydraulic Fluid Replace Every 200 hours

Remove Condensed Moisture

Check For Leaks, Kinks, etc.

Hydraulic Fluid Filter Replace

Hyd Fluid Cooler (Inspect & Clean as necessary) Every 50 hours

Maintenance Schedule

Each

Use

First

month

or

20 Hrs

•

• •

•

Every 2 years (2)

•

•

Every

3 months

50 Hrs

or

(1)

•

•

Every

6 months

or

100 Hrs

•

•

•

•

Every

year

or

300 Hrs

(2)

•

(2)

•

NOTE: (1)

For additional maintenance information see the Honda engine operator’s manual that was supplied with the power unit.

Service more frequently when used in dusty areas.

(2)

These items should be serviced by an authorized Honda dealer, unless the owner has the proper

tools and is mechanically procient. See the Honda Shop Manual.

GPV13 User Manual ◄ 15

Page 16

MAINTENANCE

BRIGGS & STRATTON ENGINE MAINTENANCE

Maintenance Schedule

Regular Service Period

Perform at every indicated month or

operating hour interval, whichever comes rst.

Engine Oil Check Level

Change

Air Cleaner Clean

Pre Cleaner Clean

Air Cooling System Clean

Spark Plugs Clean-Readjust

EngineHydraulics

Finger Guard Clean

Mufer & Controls Clean

Hydraulic Fluid Level Check

Hydraulic Fluid Replace Every 200 hours

Remove Condensed Moisture

Check For Leaks, Kinks, etc.

Hydraulic Fluid Filter Replace

Hyd Fluid Cooler (Inspect & Clean as necessary) Every 50 hours

NOTE: (1)

Service more frequently when used in dusty areas.

First 5

Hours

•

Every 8

Hours

or Daily

•

•

•

•

•

Every 25

Hours or

Annually

(1)

•

(1)

•

Every 50

Hours or

Annually

•

Every 100

Hours or

Annually

•

•

Annually

Replace

•

•

(1)

•

•

For additional maintenance information see the Briggs & Stratton engine operator’s manual that was supplied with

the power unit.

16 ► GPV13 User Manual

Page 17

TESTING & TROUBLESHOOTING

GENERAL

Tests and adjustments should be performed periodically

to ensure the power unit is operating at maximum efciency. Stanley Circuit Tester (Part Number 04182) is

recommended. This tester can be used to isolate problems in both the engine and hydraulic system prior to

any power unit disassembly.

TESTING THE HYDRAULIC CIRCUIT

The following tests can be performed to ensure that the

hydraulic pump is supplying the correct ow and pres-

sure and that the system relief valve is operating properly.

During these tests, make sure the engine is warm and

operating smoothly. If test results are not as specied,

refer to the troubleshooting table in this section for possible causes.

TESTING THE 5 GPM HTMA TYPE 1 OR 8

GPM HTMA TYPE II CIRCUIT

To test the circuit, proceed as follows:

1. Set the throttle control lever to the far left or full throttle position.

2. Connect the Stanley Circuit Tester across the hose

ends (where the tool would normally be connected).

3. Fully open the tester restrictor valve (counterclockwise).

4. Start the engine and allow it to run until warm.

5. With the engine at full operating speed, the test

ow gauge should read 4–6 gpm/15–23 lpm on

GPV135H02 or 7-9 gpm/26-34 lpm on GPV138B02.

6. Slowly turn the restrictor valve clockwise while watching the pressure gauge. The ow rate should stay at

4–6 gpm/15–23 lpm as the pressure gauge reaches

1900–2000 psi/131–138 bar on GPV135H02 or 7–9

gpm/26–34 lpm as the pressure gauge reaches

1900–2000 psi/131–138 bar on GPV138B02.

7. At 1900–2000 psi/131–138 bar, the relief valve

should begin to open. The pressure at which the relief valve just begins to open is commonly referred

to as the “cracking pressure”. At the “cracking pressure,” the ow rate should start to drop because the

relief valve is allowing uid to bypass to the hydraulic reservoir. The “cracking pressure” is preset at the

factory and if it is not within the above range, the

relief valve must be re-set as follows:

a. The relief valve is located behind the dash pan-

el in the valve manifold assembly. Use an open

end or box end wrench to loosen the nut on the

relief valve.

b. Use an Allen wrench to adjust the relief valve.

Turn clockwise to raise the pressure and counterclockwise to reduce the pressure.

c. Tighten the nut and retest.

GPV13 User Manual ◄ 17

Page 18

TROUBLESHOOTING

Problem Cause Solution

Engine will not start. No fuel. Add fuel.

Defective spark plug. Remove plug, check gap, clean or replace.

Fluid blowing out of uid

reservoir vent.

Hydraulic tool won’t operate. Incorrect hose connection to

Hydraulic tank overlled. Correct the uid level.

Pump suction leak. Check suction connections. Tighten if

necessary.

Make sure the tool hose circuit goes from left

tool.

Quick disconnect ttings

defective.

Hydraulic uid level low. Check for correct uid level. Fill using the

Pump coupling defective. With the engine not running, check the

Relief valve stuck open. Adjust or replace valve.

Suction hose kinked. Make sure suction hose from uid reservoir

Tool is defective. Refer to tool manual.

(pressure) tting to tool and back to the right

tting (return). Fluid always ows from the

male to female ttings.

Detach from hose, connect set together and

check for free ow.

recommended uid.

coupling between the pump and engine that

it is engaged and is not damaged. Caution:

Keep hands clear of rotating objects.

to pump inlet has a smooth curve.

18 ► GPV13 User Manual

Page 19

SPECIFICATIONS

Engine: ............................................................ GPV135H02 Honda 13hp, GPV138B02 Briggs and Stratton 13.5HP

Capacity (GPV135H02) Honda ..........................................................................................15-24 lpm/4-6 gpm Circuit

Capacity (GPV138B02) Briggs ...........................................................................................26-34 lpm/7-9 gpm Circuit

Pressure Range: (GPV135H02 and GPV138B02) ........................................................... 1015~2000 psi/70~140 bar

Length: (GPV135H02 and GPV138B02) ........................................................................................... 780 mm/30.7 in.

Width: (GPV135H02 and GPV138B02) ............................................................................................. 510 mm/20.1 in.

Height: (GPV135H02 and GPV138B02)............................................................................................ 600 mm/23.6 in.

Weight: (GPV135H02 and GPV138B02) ................................................................................................ 75 kg/166 lb

HTMA/EHTMA

Category (GPV135H02) ....................................................................................................... Type 1, EHTMA Class C

Category (GPV138B02)........................................................................................................ Type II, EHTMA Class D

Flow Rate ................................................................................................................ 20 lpm/5 gpm or 30 lpm/8 gpm

Nominal Pressure .......................................................................................................................... 103 bar/1500 psi

Max Pressure ................................................................................................................................ 155 bar/2250 psi

Sound Power Level ....................................................................................................................................... 101 Lwa

Vibration Level ....................................................................................................................................................... N/A

GPV13 User Manual ◄ 19

Page 20

Hefei INTACA Science-Technology Development Co.,Ltd.

Add: A-7 Building Gongtou-Liheng Industry Square, Western Section

Fanhua Street(the Cross Wenshan Road),Hefei,Anhui,China

Tel:0551-63498781/2/3 Fax:0551-63498780

P.C.:230601

http: //www.intaca.cn

Loading...

Loading...