Page 1

®

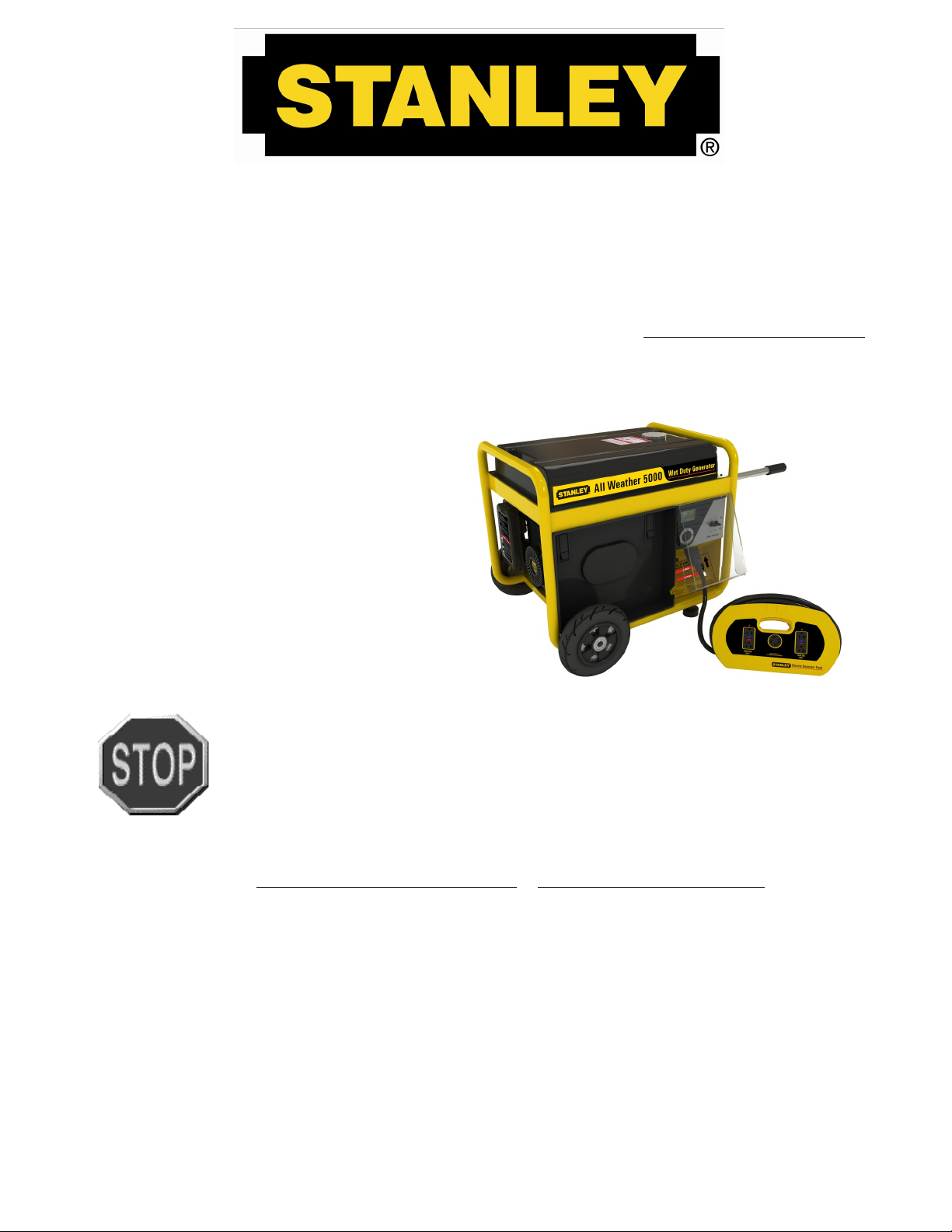

Owner’s Manual

This manual contains important safety instructions for gasoline generator models: G5000S, G8000S

that should be followed during installation and maintenance of the generator and batteries.

READ SAFETY WARNINGS AND OPERATING INSTRUCTIONS CAREFULLY, SAVE THESE INSTRUCTIONS.

Contents:

2-3 STANLEY Product Lines

3 Missing Parts Request Form

4 Warnings

5 Warnings and Specifications

6-7 Component Identification

8 Wheel Kit Installation & Battery Commissioning

9 Controls

10-11 Operating the Generator

12 Maintenance

13 Maintenance, Transporting and Storage

14-15 Troubleshooting

16 Warranty and Service

DO NOT RETURN THIS GENERATOR

TO THE STORE

HAVE QUESTIONS OR NEED HELP?

call our help-line: [1] 919-550-3259

or go to www.portablegenerator911.com or www.GXiOutdoorPower.com

Have the following information ready when you call us:

Date of Purchase: _______________________

Location of Purchase: _______________________

Serial #: _______________________

STANLEY is a registered trademark of The Stanley Works or its affiliates and are used under license by GXi Outdoor Power LLC.

No part of this publication can be printed or copied without written permission.

1 of 16 Rev. 5/2010

Page 2

STANLEY Product Lines

Models: G5000S & G8000S

For more information or where to purchase STANLEY outdoor power equipment, visit

us at: www.GXiOutdoorPower.com

Walk Behind Turf and Brush Mowers

• 36” Brush Mower

• HONDA GXV 530 V-twin engine

• Hydro Drive

• Convertible deck— easily converts to a finish mower.

Zero-Turn Commercial Mowers

• 54” and 62”

• HONDA GXV 530 V-twin engine

• Hydro Drive

Commercial Walk Behind Mowers

• 36” and 54” deck

• HONDA GXV 530 V-twin engine

• Belt drive or Hydro Drive

100” Tow Behind Mower

Model: 100TS

• Commercial duty STANLEY tow behind mower

• HONDA GXV 530 V-twin engine cuts up to 100 inches.

• 52 in. brush cut or a 52 in. finish cut mower with wings up.

STANLEY is a registered trademark of The Stanley Works or its affiliates and are used under license by GXi Outdoor Power LLC.

No part of this publication can be printed or copied without written permission.

2 of 16 Rev. 5/2010

Page 3

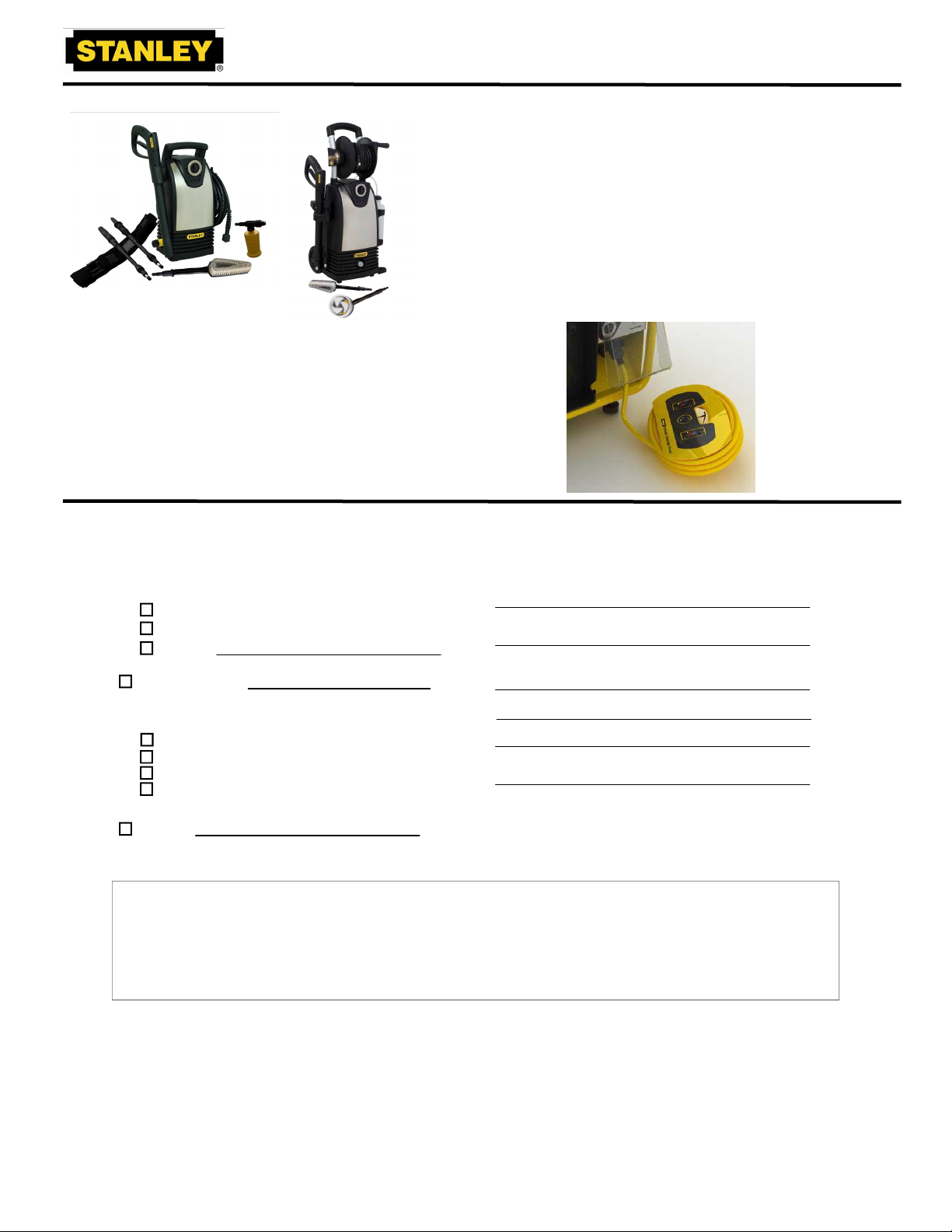

STANLEY Product Lines

Electric Pressure Washer

• 1450 psi to 1800 psi electric pressure washers

• 20 ft of high pressure hose and 35 ft. cord with GFCI protection

• Sleek and unique, high quality, stainless steel finish

• 13 Amps, 120V

• Auto-stop shut off system prolongs pump life

Generator Cord Accessories

240V, 10/4, heavy duty extension cords with L14-30 connectors at each end.

This cord reduces harmful voltage drops experienced when using most

120V extension cords

reach the desired length.

. Available in 15’ and 25’ lengths and can be combined to

Models: G5000S & G8000S

Missing Parts Request Form

Please indicate the part that you are missing:

Hardware bag

Wheel Kit

Other

Date of purchase

Model #:

5000

6500

6500EL

8000

Serial #:

Comments:

Name

Address

Phone

Email

IMPORTANT: Please include a copy your receipt. Without a receipt, your order will be

delayed.

E-mail : customerservice@gxioutdoorpower.com

Fax: 1-919-550-3277

Please scan and attach your proof of purchase to your e-mail.

STANLEY is a registered trademark of The Stanley Works or its affiliates and are used under license by GXi Outdoor Power LLC.

No part of this publication can be printed or copied without written permission.

3 of 16 Rev. 5/2010

Page 4

WARNINGS

Models: G5000S & G8000S

This owner’s manual is considered a permanent part of the generator

and should remain with the generator if resold. The information and

specifications included in this publication were in effect at the time of

approval for printing.

GXi Outdoor Power, LLC, reserves the right to discontinue or change

specifications or design at any time without notice and without incurring any obligation whatever. No part of this publication may be reproduced without written permission.

EMISSION CONTROL SYSTEM INFORMATION

The U.S. and California Clean Air Acts

EPA and California regulations require all manufacturers to furnish

written instructions describing the operation and maintenance of emission control systems. The following instructions and procedures must

be followed in order to keep the emissions from your STANLEY engine

within the emission standards. Maintenance, replacement, or repair of

the emission control devices and systems may be performed by any

engine repair establishment or individual, using parts that are

‘‘certified’’ to EPA standards.

SAFETY LABEL LOCATIONS

These labels warn you of potential hazards that can cause serious

injury. Read them carefully. If a label comes off or becomes hard to

read, contact your STANLEY generator dealer for a replacement.

SAFETY INFORMATION

STANLEY generators are designed to give safe and dependable

service if operated according to instructions. Read and understand this owner’s manual before operating your generator.

OPERATOR RESPONSIBILITY

Know how to stop the generator quickly in case of emergency. Understand the use of all generator controls, output receptacles, and connections. Be sure that anyone who operates the generator receives

proper instruction. Do not let children operate the generator.

WARNING

The engine exhaust from this product contains chemicals known to

the State of California to cause cancer, birth defects or other reproductive harm.

DANGER

CARBON MONOXIDE GAS

Exhaust contains poisonous carbon monoxide, a colorless and

odorless gas. Breathing exhaust can cause loss of consciousness

and may lead to death. To keep exhaust gas from accumulating,

use in an area with adequate ventilation. DO NOT use this generator in a garage, basement, crawlspace, enclosed shed, or any

other area that does not have adequate ventilation. DO NOT use

this generator near ventilation ducts or open windows that may

allow exhaust

gasses to enter your home or business. ONLY

operate this generator outdoors.

DANGER

Fire and Burn Hazards

The exhaust system gets hot enough to ignite some materials.

• Keep the generator at least 3 feet (1 meter) away from buildings

and other equipment during operation.

• Do not enclose the generator in any structure.

• Do not smoke when refueling.

• Keep flammable materials away from the generator.

• The muffler becomes very hot during operation and remains hot for

a while after stopping the engine. Be careful not to touch the muffler while it is hot.

• Let the engine cool before storing the generator indoors.

• Refuel in a well ventilated area with the engine stopped.

• Fuel vapors are extremely flammable and may ignite after the en-

gine has started. Make sure that any spilled fuel has been wiped

up before starting

the generator.

DANGER

Electocution hazard - Electricity can cause DEATH or SERIOUS

INJURY.

• Do not operate the generator in standing water.

• This product is not safe to operate when partially or totally sub-

merged in water.

• Ensure proper drainage in the region surrounding this generator.

• Properly ground the generator and verify ground is in place be-

fore each use. Grounding regulations vary by location, consult a

qualified local electrician for proper grounding instructions.

• Power cords and electrical equipment pose a risk of shock and

electrocution, especially if they are operated in wet conditions.

Inspect all equipment prior to every use and use only as directed

by the manufacturer.

• Use a cord with GFCI protection when using the power outdoors

or when moisture is present.

• Generators vibrate in normal use. During and after the use of the

generator, inspect the generator as well as extension cords and

power supply cords connected to it for damage resulting from

vibration. Have damaged items repaired or replaced as necessary. Do not use plugs or cords that show signs of damage such

as broken or cracked insulation or damaged blades.

NEVER START OR STOP THE ENGINE WITH DEVICES CONNECTED

TO THE GENERATOR.

STANLEY is a registered trademark of The Stanley Works or its affiliates and are used under license by GXi Outdoor Power LLC.

No part of this publication can be printed or copied without written permission.

WARNING

Generator must be installed by a qualified electrician and connected to transfer equipment as a separately derived system in accordance with the National Electrical Code, NFPA 70. The generator

shall be connected through transfer equipment that switches all

conductors other than the equipment grounding conductor. The

frame of the generator shall be connected to an approved grounding

electrode.

Improper connections to a building electrical system can allow

electrical current from the generator to backfeed into the utility

lines. Such backfeed may electrocute utility company workers or

others who contact the lines during a power outage, and the generator may explode, burn, or cause fires when utility power is restored.

Ground System

STANLEY portable generators have a system ground that connects generator frame components to the ground terminals in the AC output receptacles. The system ground is connected to the AC neutral wire.

Special Requirements

There may be Federal or State Occupational Safety and Health Administration (OSHA) regulations, local codes, or ordinances that apply to the

intended use of the generator. Please consult a qualified electrician,

electrical inspector, or the local agency having jurisdiction.

This generator does not meet US Coast Guard regulation 33 CFR-183

and should not be used on marine applications.

4 of 16 Rev. 5/2010

Page 5

WARNINGS

Models: G5000S & G8000S

DANGER

AC Applications

Before connecting an appliance or power cord to the generator:

1. Make sure that appliances are in good working order.

Faulty appliances or power cords can create a potential for

electrical shock. If an appliance begins to operate abnormally, becomes sluggish or stops suddenly, turn it off immediately.

2. Disconnect the appliance, and determine whether the problem is the appliance, or if the rated load capacity of the

generator has been exceeded.

3. Make sure that the electrical rating of the tool or appliance

does not exceed that of the generator. Never exceed the

maximum power rating of the generator. Power levels between rated and maximum may be used for no more than 30

minutes.

Substantial overloading will open the circuit breaker. Exceeding the time limit for maximum power operation or

slightly overloading the generator may not switch the circuit

breaker or circuit protector OFF, but will shorten the service

life of the generator.

Limit operation requiring maximum power to 30 minutes. For

continuous operation (longer than 30 minutes), do not exceed

80% of the rated power balanced equally on the A&B sides of

the Alternator.

WARNING

Failure to properly follow maintenance instructions and precautions can cause serious injuries or death. Always follow

the inspection and maintenance recommendations and

schedules in this owner’s manual.

Safety Precautions:

Make sure the engine is off before you begin any maintenance

or repairs. This will eliminate several potential hazards:

• Carbon monoxide poisoning from engine exhaust.

Be sure there is adequate ventilation whenever you

operate the engine.

• Burns from hot parts.

Let the engine and exhaust system cool before touching.

• Injury from moving parts.

Do not run the engine unless instructed to do so.

In the State of California a spark arrestor is required by law.

Other states may have similar laws. Federal laws apply on all

federal lands. If you equip the muffler with a spark arrestor, it

must be maintained in effective working order. See page 11.

Rapid retraction of the recoil starter cord can pull the

starter cord back faster than you can let go. When starting

the engine, pull the cord slowly until resistance is felt then

pull rapidly to avoid kickback

.

DANGER

Changing the speed of the generator by adjusting the governor can cause damage to the generator, devices attached to the generator, and may result in bodily injury. Do not adjust or tamper

with the engine speed setting.

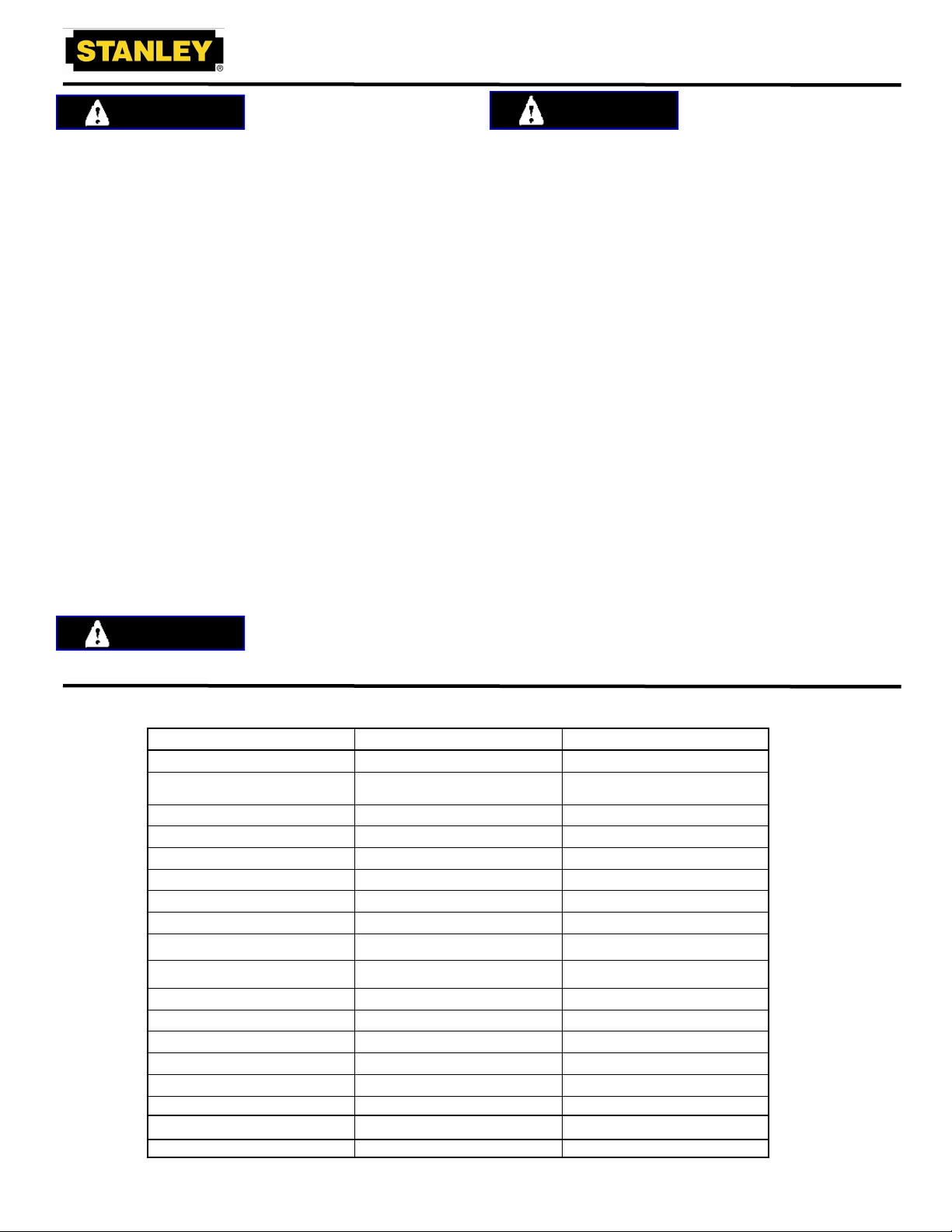

Product Specifications

Generator G5000S G8000S

Rated frequency 60 Hz 60 Hz

Rated voltage 120V / 240V 120V / 240V

Rated output power 5.0 kW (Max.) 8.0 kW (Max)

AC output (Max.) 20.8A 33.3A

Engine type OHV 4-Stroke OHV 4-Stroke

displacement 279 cc 401 cc

Compression ratio 8.2:1 8.0:1

Rated rotation speed 3600 RPM 3600 RPM

Rated power 10 Hp 15 Hp

Starting system Recoil Recoil and electric starter

Rotation direction Counter clockwise Counter clockwise

Fuel type Unleaded gasoline Unleaded gasoline

Low oil shutdown Yes Yes

Fuel tank size 12 gallons 12 gallons

Oil type / Capacity SAE 10W-30 0.9 quarts SAE 10W-30 1.1 quarts

Gross weight 207 lbs (94 kg) 235lbs (107kg)

Battery N/A 12 AH 12 VDC

Integrated voltmeter Yes Yes

STANLEY is a registered trademark of The Stanley Works or its affiliates and are used under license by GXi Outdoor Power LLC.

No part of this publication can be printed or copied without written permission.

5 of 16 Rev. 5/2010

Page 6

Component Identification

Models: G5000S & G8000S

Fuel Tank

Choke Lever

Air Filter

Fuel Valve

Recoil Starter (Assembly)

Digital Meter

On/ Off & Start Switch

(electric start option)

Fuel Cap

Generator models may have

different features and/or options than

shown in these diagrams. STANLEY reserves the right to alter product features

and specifications without notice.

Main Breaker

ON/OFF Switch

Remote Generator Panel

Main Breaker

Pull Out Handle Bars

Ground Lug

L14-30 240V/120V

Twist Lock Connector

Carburetor

Valve Cover

Battery (electric start option only)

Alternator

Muffler Guard

Exhaust Pipe

STANLEY is a registered trademark of The Stanley Works or its affiliates and are used under license by GXi Outdoor Power LLC.

No part of this publication can be printed or copied without written permission.

6 of 16 Rev. 5/2010

Page 7

Access panel latches

Component Identification

Models: G5000S & G8000S

Alternator

Weather Shield

Engine Serial Number stamped

on the engine block

Access Panel

Additional equipment required to safely operate this generator:

1. Gas can.

2. Unleaded gasoline.

3. SAE 10W-30 - 1.1 quarts for STANLEY 11hp, 13hp, 14hp, and 15hp engines, 0.9 quarts required for STANLEY 10 HP.

4. An oil fill funnel.

5. Gasoline fuel stabilizer (for storing your generator).

6. 120V and/or 240V extension cords.

7. An adjustable wrench or a 12mm socket for oil changes.

Note: A spark arrestor was supplied with your generator and must be installed for use within the State of California. See supplemental instructions.

STANLEY is a registered trademark of The Stanley Works or its affiliates and are used under license by GXi Outdoor Power LLC.

No part of this publication can be printed or copied without written permission.

7 of 16 Rev. 5/2010

Page 8

Wheel Kit Assembly

Models: G5000S & G8000S

Approximate assembly time is 5

minutes.

Supplied with your generator:

1. Two(2) foot assemblies with two (2)

13 mm nuts.

2. Two (2) wheel axle assemblies.

Two pre-assembled, retractable, handle bars, one on

each side of the generator frame. Twist to lock /

unlock. Pull or push to extend / retract.

Step

Insert each foot assembly through

1

holes in the frame. Tighten nut with

13mm wrench or socket.

Commissioning the Battery

The battery is an optional feature. The battery is used to start a

generator equipped with an electric starter. Not all generators are

sold with batteries. Please verify with your retailer if you believe

the battery is missing.

Insert each axle and tighten the

Step

2

bolt to secure in place using a 13

mm wrench or socket.

Battery Terminals

Pre-assembled wheel / axle

assembly.

WARNING

Lead acid storage batteries contain sulfuric acid which can cause

serious injuries. The battery also gives off explosive gases. Keep

sparks, flames and cigarettes away. Provide adequate ventilation

when charging or using batteries. Battery posts, terminals and

related accessories contain lead and lead compounds. Avoid spills

of electrolyte and wash hands thoroughly after handling.

Use gloves and safety glasses when handling and installing lead

acid batteries.

If you get electrolyte in your eyes, flush your eyes with clean water for 15 minutes and seek medical attention. Keep out of reach of

children.

FOR YOUR SAFETY AND CONVENIENCE, THE

BATTERY WAS SHIPPED SEALED AND

PRE-CHARGED.

The battery is ready to be connected to the generator.

To connect the battery, use an adjustable wrench or 8 mm socket to

secure the BLACK wire to the negative (-) terminal and the RED

wire to the positive (+) terminal. Do not allow the wrench to con-

tact any other part of the generator when tightening the battery

terminals.

Battery

STANLEY is a registered trademark of The Stanley Works or its affiliates and are used under license by GXi Outdoor Power LLC.

No part of this publication can be printed or copied without written permission.

8 of 16 Rev. 5/2010

Page 9

Controls

Models: G5000S & G8000S

WARNING

The engine was shipped without engine oil. DO NOT START THE

ENGINE WITHOUT FILLING THE ENGINE WITH OIL. Use SAE 10W30 for normal conditions and SAE 5W-30 when the ambient temperature is below 32° F.

Choke Rod

The choke is used to

provide an enriched

fuel mixture when

starting a cold engine.

It can be opened and

closed by operating

the choke rod manually. Pull the rod out

toward CLOSED to

enrich the mixture for

cold starting. Open

once the engine is

running.

Turn clockwise

to turn fuel valve

on.

Fuel Valve Lever

The fuel valve is located between the fuel

tank and carburetor.

When the valve lever is

in the ON position, fuel

is allowed to flow from

ON

F

F

O

the fuel tank to the

carburetor. Be sure to

return the fuel valve

lever to the OFF position after stopping the

engine.

Engine Switch

To start and stop the engine.

Recoil Starter

To start the engine, pull the starter grip lightly until resistance is felt,

then pull briskly.

NOTICE:

Do not allow the starter grip to snap back against the engine. Return it

gently to prevent damage to the starter.

The recoil starter is used to start the engine if the generator is not

equipped with a 12 volt battery to operate the starter motor, or if the

battery does not contain adequate charge to operate the starter motor.

RECOIL STARTER

STARTER GRIP

Oil Alert System

The Oil Alert system is designed to prevent engine damage caused by

an insufficient amount of oil in the crankcase. Before the oil level in the

crankcase can fall below a safe limit, the Oil Alert system will automatically stop the engine (the engine switch will remain in the ON position).

The Oil Alert system should not take the place of checking the oil level

before each use. If the engine stops and will not restart, check the

engine oil level (see page 14) before troubleshooting in other areas.

Ground Terminal

The generator ground terminal is connected to the

frame of the generator, the metal non-currentcarrying parts of the generator, and the ground

terminals of each receptacle.

WARNING

Before using the ground terminal, consult a qualified electrician,

electrical inspector or local agency having jurisdiction for local

codes or ordinances that apply to the intended use of the generator.

Engine ON / OFF / Start Switch

(electric start shown)

STANLEY is a registered trademark of The Stanley Works or its affiliates and are used under license by GXi Outdoor Power LLC.

NOTE: SYSTEM GROUND IS CONNECTED TO THE AC NEUTRAL ON

THIS GENERATOR. CONSULT AN ELECTRICIAN WHEN CONNECTING THIS GENERATOR TO YOUR HOME OR BUSINESS ELECTRICAL

PANEL TO ENSURE GROUNDING MEETS THE LOCAL ELECTRICAL

CODE

No part of this publication can be printed or copied without written permission.

9 of 16 Rev. 5/2010

Page 10

Operating the Generator

Models: G5000S & G8000S

DANGER

CARBON MONOXIDE GAS

Using a generator indoors CAN KILL YOU IN MINUTES.

Generator exhaust contains carbon monoxide (CO). This is a

poison you cannot see or smell. If you can smell the generator exhaust, you are breathing CO. But even if you cannot

smell the exhaust, you could be breathing CO.

NEVER use a generator inside homes, garages, crawlspaces, or other partly enclosed areas. Deadly levels of

carbon monoxide can build up in these areas. Using a fan or

opening windows and doors does NOT supply enough fresh

air.

ONLY use a generator outside and far away from windows,

doors, and vents. These openings can pull in generator exhaust.

Even when you use a generator correctly, CO may leak into

the home. ALWAYS use a battery-powered or batterybackup CO alarm in the home.

If you start to feel sick, dizzy, or weak after the generator

has been running, move to fresh air RIGHT AWAY. See a

doctor. You could have carbon monoxide poison.

DANGER

Electocution hazard - Electricity can cause DEATH or SERIOUS INJURY.

• Do not operate the generator in standing water.

• This product is not safe to operate when partially or totally submerged

in water.

• Ensure proper drainage in the region surrounding this generator.

• Properly ground the generator and verify ground is in place before

each use. Grounding regulations vary by location, consult a qualified

local electrician for proper grounding instructions.

• Power cords and electrical equipment pose a risk of shock and electrocution, especially if they are operated in wet conditions. Inspect all

equipment prior to every use and use only as directed by the manufacturer.

• Use a cord with GFCI protection when using the power outdoors or

when moisture is present.

• Generators vibrate in normal use. During and after the use of the generator, inspect the generator as well as extension cords and power

supply cords connected to it for damage resulting from vibration. Have

damaged items repaired or replaced as necessary. Do not use plugs

or cords that show signs of damage such as broken or cracked insulation or damaged blades.

NEVER START OR STOP THE ENGINE WITH DEVICES CONNECTED TO

THE GENERATOR.

WARNING

Step 1.

Ensure all electrical loads are removed from the generator. Disconnect

all the extension cords and ensure the main breaker is in the OFF position. Remove all flammable materials and debris from the area. Make

sure the generator is level.

Step 2.

Check the oil level.

• Put the generator on a level surface with the engine stopped.

• Remove the oil filler cap.

• Check the oil level. If the oil level is low, fill it until the oil is over-

flowing. It will take approximately 0.9 - 1.5 quarts of oil depending

on the model of generator.

If additional oil is need, SAE 10W-30 engine oil is recommended for

most general purpose applications. In cold weather climate, use SAE

5W-30.

Step 3.

Make sure there is fuel in the gasoline tank. Look at the fuel level indi-

cated by removing the fuel cap to inspect the contents of the fuel tank.

The fuel filter can also be inspected once the fuel cap is removed.

Ensure the fuel filter is clean of dirt and debris. Tightly secure the fuel

cap after your inspection is complete.

Fuel can damage paint and plastic. Be careful not to spill fuel when

filling your fuel tank. Damage caused by spilling fuel is not covered

under warranty. Use unleaded gasoline with a pump octane rating of

86 or higher. This engine is certified to operate on unleaded gasoline.

Unleaded gasoline produces fewer engine and spark plug deposits and

extends exhaust system life. Never use stale or contaminated gasoline

or an oil/gasoline mixture. Avoid getting dirt or water in the fuel tank.

WARNING

DO NOT overfill the tank. Leave a 1 inch air gap in the tank. Gasoline is highly flammable and explosive. You can be burned or seriously injured when refueling.

• Stop engine and keep heat, sparks, and flame away.

• Refuel only outdoors.

• Wipe up spills immediately.

This portable generator is not for use with gasoline/ethanol blends

with over 15% ethanol.

STANLEY is a registered trademark of The Stanley Works or its affiliates and are used under license by GXi Outdoor Power LLC.

No part of this publication can be printed or copied without written permission.

10 of 16 Rev. 5/2010

Page 11

Operating the Generator

Models: G5000S & G8000S

Step 4.

Set the fuel valve lever to the ON position by rotating it clockwise.

Step 5.

Pull the choke lever to the CLOSED position. See page 7 for a diagram

of the choke lever.

Step 6.

Turn the generator ON/OFF switch to the “ON” position.

Step 7.

Start the engine

1. If you have an electric starter, turn the switch to the START position, hold it there for 5 seconds and let it come to rest in the ON

position once the engine has started.

2. If you are using the recoil starter, pull slightly on the cord until you

feel some pressure. Once you feel the back-pressure building,

rapidly pull the cord.

Step 8.

Once the generator is running, push the choke lever into the OPEN position.

Step 9.

Let the generator warm up for approximately 3 minutes before applying

any electrical loads.

Step 10.

Apply loads to the generator one at a time, allowing the generator to

stabilize after you add each incremental load. Add the loads with the

largest surge power requirement first. This would include refrigerators,

air-conditioners, large motors, and pumps. Add smaller loads once the

generator has stabilized with the larger loads.

ALWAYS UNPLUG APPLIANCES AND REMOVE ALL ELECTRICAL

LOADS BEFORE REFUELING. THEN FOLLOW STEPS 2 - 10.

WARNING

For power outages, permanently installed stationary generators are

better suited for providing backup power to the home. Even a properly

connected portable generator can become overloaded. This may result

in overheating or stressing the generator components, possibly leading

to a generator failure.

To determine maximum load that you may safely connect to this

generator:

1. Calculate the maximum continuous power required by adding up

the running power of each appliance. The total running power of

your appliances cannot exceed the maximum output power of this

generator.

2. Calculate the surge power by:

i) Adding up the running power of each appliance with an * and

in bold below.

ii) Multiplying the total by 1.5.

iii) Adding this to the total running power calculated in step 1

above.

The surge power requirements of your appliances cannot exceed

the surge power rating of this generator.

Typical Residential Loads

Appliance Running Power

Light bulbs (each) 75 Watts

Stove element (each) 1000 Watts

Microwave 1500 Watts

Coffee maker 700 Watts

Television 750 Watts

VCR 250 Watts

Computer & monitor 800 Watts

Space heater 1500 Watts

Washing machine 1000 Watts

NG clothes dryer 750 Watts

Electric clothes dryer 5500 Watts

Dishwasher 1850 Watts

Water heater 5000 Watts

Electric furnace 5000 Watts

Toaster 1200 Watts

Box fan* 750 Watts

Window A/C - 8000 BTU* 2400 Watts

Central A/C (per ton)* 2800 Watts

Furnace blower* 850 Watts

2 hp well pump* 2000 Watts

Refrigerator* 1000 Watts

Freezer* 1000 Watts

WARNING

Connecting a load larger than this generator’s power rating may damage the circuit breakers, alternator and sensitive appliances.

Continuously loading this generator above 80% of its maximum output

power will shorten the life of the generator.

Balance the load evenly between the A and B outlets to maximize the

output power.

Appliances with electric motors require an

additional

150%

power when they are starting up (indicated by an * and in bold in

the following chart ).

STANLEY is a registered trademark of The Stanley Works or its affiliates and are used under license by GXi Outdoor Power LLC.

No part of this publication can be printed or copied without written permission.

STOPPING THE GENERATOR

In an emergency:

To stop the engine in an emergency, move the engine switch to the

OFF position and turn the fuel valve OFF.

In normal use:

1. Turn the AC circuit breaker to the OFF position (if applicable).

2. Disconnect all loads and extension cords.

3. Allow the engine to run with no load for 3 minutes.

4. Turn the engine switch to the OFF position.

5. Turn the fuel valve lever to the OFF position.

6. Allow the generator to cool off before touching any engine or alternator components. It may take as long as 30 minutes before the

generator is cool enough to touch safely.

11 of 16 Rev. 5/2010

Page 12

Maintenance

Models: G5000S & G8000S

MAINTENANCE

The Importance of Maintenance

Good maintenance is essential for safe, economical, and trouble-free

operation. It will also help reduce air pollution.

To help you properly care for your generator, the following pages

include a maintenance schedule, routine inspection procedures, and

simple maintenance procedures using basic hand tools. Other service tasks that are more difficult, or require special tools, are best

handled by professionals and are normally performed by a STANLEY

technician or other qualified mechanic.

The maintenance schedule applies to normal operating conditions. If

you operate your generator under severe conditions, such as sustained high-load or high-temperature operation, or use it in unusually

wet or dusty conditions, consult your servicing dealer for recommendations applicable to your individual needs and use.

Maintenance, replacement, or repair of the emission control

devices and systems may be performed by any engine repair

establishment or individual, using parts that are ‘‘certified’’ to

EPA standards.

Maintenance Schedule

Item Before each

Engine oil (Check) X

Engine Oil (Change) X

Air Cleaner (Check) X

Air Cleaner Wash X

Fuel filter Cup (Clean) X

Spark Plug (Clean) X

Spark Plug (Change) X

Optional Spark Arrestor (Clean) X

Valve Clearance (Adjust) X*

Fuel Tank and Filter (Clean) X*

Fuel Tube (Check)

Combustion Chamber (Clean)

* Should be performed by an authorized STANLEY service center.

20hrs or

use

every 3

Every 2 yrs (replace if necessary)*

After every 250 hrs*

month

50 hrs or

every 3

months

100 hrs or

every 6

months

300 hrs or

every 1

year

Replacement Parts

The emission control systems on your STANLEY engine were designed,

built, and certified to conform with EPA and California emission regulations. We recommend the use of genuine STANLEY parts whenever

you have maintenance done. These original-design replacement parts

are manufactured to the same standards as the original parts, so you

can be confident of their performance. The use of replacement parts

that are not of the original design and quality may impair the effectiveness of your emission control system.

A manufacturer of an aftermarket part assumes the responsibility that

the part will not adversely affect emission performance. The manufacturer or rebuilder of the part must certify that use of the part will not

result in a failure of the engine to comply with emission regulations.

Engine Oil Change

Drain the oil while the engine is warm to assure rapid and complete

draining.

1. Remove the drain plug and sealing washer, remove the oil filler

cap, and drain the oil.

2. Reinstall the drain plug and sealing washer. Tighten the plug securely.

3. Refill with the recommended oil (SAE 10W-30 ) and check the oil

level.

Dispose of used motor oil in a manner that is compatible with the environment. Do not throw it in the trash, pour it on the ground, or down a

drain.

Air Cleaner Service

A dirty air cleaner will restrict air flow to the carburetor. To prevent

carburetor malfunction, service the air cleaner regularly. Service more

frequently when operating the generator in extremely dusty areas.

NOTICE:

Never run the generator without the air filter. Rapid engine wear will

result.

1. Unsnap the air cleaner cover clips, remove the air cleaner

cover, and remove the element.

2. Wash the air cleaner element in a solution of household detergent and warm water, then rinse thoroughly, or wash in

nonflammable or high flashpoint solvent. Allow the air cleaner

element to dry thoroughly.

3. Soak the air cleaner element in clean engine oil and squeeze

out the excess oil. The engine will smoke during initial startup

if too much oil is left in the air cleaner element.

4. Reinstall the air cleaner element and the cover.

Fuel Filter Cleaning

The fuel filter cup / screen prevents dirt which may be in the fuel

from entering the carburetor. The fuel filter should be inspected

and cleaned on a regular basis. For best results, clean the filter

with gasoline and a toothbrush or blow the debris out of the filter

with air pressure.

Spark Plug Service

In order to service the spark plug, you will need a spark plug

wrench. Recommended spark plugs: BPR5ES (NGK) and W16EPRU (DENSO). To ensure proper engine operation, the spark plug

must be properly gapped and free of deposits.

If the engine has been running, the muffler will be very hot. Be

careful not to touch the muffler.

1. Remove the spark plug cap.

2. Clean any dirt from around the spark plug base.

3. Use a spark plug wrench to remove the spark plug.

STANLEY is a registered trademark of The Stanley Works or its affiliates and are used under license by GXi Outdoor Power LLC.

No part of this publication can be printed or copied without written permission.

12 of 16 Rev. 5/2010

Page 13

4. Visually inspect the spark plug. Discard

it if the insulator is cracked, chipped or

fouled.

5. Measure the plug gap with a feeler

gauge. Correct as necessary by carefully bending the side electrode. The

gap should be: 0.028 to 0.031 in (0.70 to

0.80 mm)

Maintenance

TRANSPORTING

When transporting the generator, turn the engine switch and the fuel

valve OFF. Keep the generator level to prevent fuel spillage. Fuel vapor

or spilled fuel may ignite.

Take care not to drop or strike the generator when transporting. Do not

place heavy objects on the generator. When transporting the generator

by loading it on to a vehicle, secure to the generator frame as shown.

Models: G5000S & G8000S

6. Check that the spark plug washer is in good condition, and thread

the spark plug in by hand to prevent cross-threading.

7. After the spark plug is seated, tighten with a spark plug wrench to

compress the washer.

If installing a new spark plug, tighten 1/2 turn after the spark plug seats

to compress the washer. If reinstalling a used spark plug, tighten 1/8 to

1/4 turn after the spark plug seats to compress the washer.

NOTICE:

The spark plug must be securely tightened. An improperly tightened

spark plug can become very hot and could damage the engine. Use

only the recommended spark plugs or equivalent.

Optional Spark Arrestor Maintenance

If the generator has been running, the muffler will be very hot. Allow it

to cool before proceeding.

The spark arrester must be serviced

every 50 hours to keep it functioning as designed.

Clean the spark arrester as follows:

1. Loosen the screw by the exhaust port of the muffler and remove

the spark arrester.

2. Use a brush to remove carbon deposits from the spark arrester

screen. Inspect the screen for breaks or tears and replace it if

necessary.

3. Install the spark arrester in the reverse order of removal.

SCREW

DANGER

Contact with a hot engine or

exhaust system can cause

serious burns or fires. Let the

engine cool before transporting or storing the generator.

STORING

Before storing the unit for an extended period:

1. Be sure the storage area is free of excessive humidity and dust.

2. Service according to the table below:

STORAGE TIME Recommended Service Procedure to prevent hard s tarting:

1 to 2 months Fill with fresh gasoline and add gasoline stabilizer*.

2 months to 1 year Fill with fresh gasoline and add gasoline stabilizer*.

Drain the carburetor float bowl.

1 year or longer

* Use gasoline stabilizers that are formulated to extend storage life. Contact your authorized STANLEY generator dealer

for conditioner recommendations.

Fill with fresh gasoline and add gasoline stabilizer*.

Drain the carburetor float bowl.

Remove the spark plug. Put a tablespoon of engine oil into the cylinder. Turn the engine

slowly with the recoil starter to distribute the oil. Reinstall the spark plug.

Change the engine oil.

After removal from storage, drain the stored gasoline into a suitable container, and fill with

fresh gasoline before starting.

SPARK ARRESTOR

Optional Starter Motor Fuse Replacement

If the fuse is blown, the starter motor won’t operate. Turn the engine

switch to the OFF position. Remove the fuse holder cover and replace

the fuse. The specified fuse is 10A.

NOTICE:

Never use a fuse with a

different rating from that

specified. Serious damage

to the electrical system or

fire may result.

STANLEY is a registered trademark of The Stanley Works or its affiliates and are used under license by GXi Outdoor Power LLC.

No part of this publication can be printed or copied without written permission.

Storage Preparation

1. Drain the carburetor by loosening the drain screw. Drain the gasoline into a suitable container. Place 4 ounces of fuel stabilizer in

the fuel tank.

2. Change the engine oil (page 10 ).

3. Remove the spark plug, and pour about a tablespoon of clean

engine oil into the cylinder. Turn the engine several revolutions

slowly with the recoil starter to distribute the oil, then reinstall the

spark plug.

4. Slowly pull the starter grip until resistance is felt. At this point, the

piston is coming up on its compression stroke and both the intake

and exhaust valves are closed. Storing the engine in this position

will help to protect it from internal corrosion.

WARNING

Gasoline is extremely flammable and is explosive under certain

conditions. Perform this task in a well-ventilated area with the

engine stopped. Do not smoke or allow flames or sparks in the

area during this procedure.

13 of 16 Rev. 5/2010

Page 14

Troubleshooting

Models: G5000S & G8000S

Symptom: Potential Causes Solution

Engine won't start Fuel valve off/out of fuel Fill tank with fuel and turn fuel valve on

Engine Switch in off position Turn engine switch to on position

Spark arrestor clogged Remove spark arrestor, clean and replace.

Choke is open

Close choke by pulling choke handle out.

Open choke after starting.

Oil level too low

Fill oil to top of opening with recommended

grade of oil.

Oil float stuck in shipment

Fill oil to top of opening, disconnect the yellow wire from the low oil level switch. The

switch is located on the engine above the

oil drain plug. It is a small gold colored box

with a yellow and a black wire.

Start the unit and run it for one hour minimum - this will get enough movement of hot

oil to free the float if this is the cause.

Re-attach the yellow wire and run the unit.

Fuel filter is dirty

Check for fuel flow to carburetor by removing drain screw. Clean or replace fuel filter.

Fuel is contaminated

Drain fuel tank and carburetor. Replace or

clean filter and carburetor float bowl. Fill

tank with clean fuel.

Spark plug boot off/loose Press spark plug boot firmly on spark plug.

Spark plug fouled or failed Remove spark plug, clean or replace

Carburetor clogged

Remove float bowl and clean components

and jets. Replace carburetor if varnish or

gum has accumulated from improper stor-

age.

Recoil is hard to pull Spark arrestor clogged Remove, clean and replace.

Engine flooded with fuel after storage with fuel

valve in on position

Remove spark plug and slowly pull recoil to

discharge excess fuel. Clean and re-install

spark plug.

Valve clearance too large

Rest exhaust valve clearance to .008", call

customer help line.

Engine starts, but then shuts off

Remove/Clean spark arrestor Remove, clean and replace.

after running for short time

Oil level too low

Fill oil to top of opening with recommended

grade of oil.

Engine runs: rough/vibrating/

Fuel valve off/out of fuel Fill tank with fuel and turn fuel valve on

Spark plug fouled or failed Remove spark plug, clean or replace

Remove/Clean spark arrestor Remove, clean and replace.

oscillating

The choke is not open Push choke lever in.

Over loading generator Disconnect some appliances

Air filter is dirty Clean air filter

Fuel filter is dirty

Check for fuel flow to carburetor by remov-

ing drain screw. Clean or replace fuel filter.

Fuel is contaminated

Drain fuel tank and carburetor. Replace or

clean filter and carburetor float bowl. Fill

tank with clean fuel.

STANLEY is a registered trademark of The Stanley Works or its affiliates and are used under license by GXi Outdoor Power LLC.

No part of this publication can be printed or copied without written permission.

14 of 16 Rev. 5/2010

Page 15

Troubleshooting

Models: G5000S & G8000S

Symptom: Potential Causes Solution

Engine runs, low speed, bogs

Remove/Clean spark arrestor Remove, clean and replace.

down under load or does not

maintain 60Hz

Choke is not open Push choke lever in

Over loading generator Disconnect some appliances / devices

Air filter is dirty Clean air filter

Fuel filter is clogged

Fuel filter is dirty

Fuel is contaminated

Engine oil leak Oil fill cap loose or cross threaded

Oil drain plug loose tighten both drain plugs

Debris under oil drain plug gasket

Loose crankcase bolt(s) Tighten crankcase bolts

Valve cover bolt loose Tighten bolt

Contaminates will clog filter, not allowing

fuel to get to engine

Check for fuel flow to carburetor by removing drain screw. Clean or replace fuel filter.

Drain fuel tank and carburetor. Replace or

clean filter and carburetor float bowl. Fill

tank with clean fuel.

Wipe all oil off unit, remove both oil fill caps,

inspect and replace. Tighten securely.

Remove drain plug and debris. Inspect gasket for damage and replace if damaged.

Fuel leak at tank shut-off Shut-off valve loose

Oil leaking from shaft Oil seals failed, call customer help line

Tighten nut on shut-off valve/replace shutoff valve

Fuel leaking out of carburetor Fuel drain screw loose Tighten fuel drain screw

Engine runs, Volt meter shows 0

Volts, no power to outlets

Engine runs and volt meter

Carburetor float seat not seating Flush with clean fuel

Breaker tripped

Disconnect all loads and turn breaker to off

and back to on to reset.

Disconnected or damaged wiring inside unit Call customer helpline

Faulty extension cord/power strip Use different power strip or extension cord

shows 240VAC but no power

goes to connected devices

Voltage too high/low Engine speed low or high

Breaker or GFCI trippedon extension cord or

power strip

Rest breaker and remove loads from power

strip

Verify frequency reading is 58Hz to 62Hz on

meter. Call customer helpline if frequency is

above 58Hz. See engine speed troubleshooting if engine speed is below 58Hz.

Alternator damaged Call customer helpline

Speed screw damaged or bent Call customer helpline

Voltage is 120 VAC on 1 phase

but too high/low on other phase

STANLEY is a registered trademark of The Stanley Works or its affiliates and are used under license by GXi Outdoor Power LLC.

Alternator phase is damaged Call customer helpline

No part of this publication can be printed or copied without written permission.

15 of 16 Rev. 5/2010

Page 16

Limited Warranty & Service

Models: G5000S & G8000S

PRODUCTS COVERED BY THIS WARRANTY:

Engine 24 months / 200 hours 6 months / 200 hours 3 months / 200 hours

Battery 3 months 3 months 3 months

Alternator 24 months / 200 hours 6 months / 200 hours 3 months / 200 hours

Electrical and Frame Components 24 months / 200 hours 6 months /200 hours 3 months / 200 hours

Emission Controls 24 months 24 months 24 months

NONCOMMERCIAL/

NONRENTAL

(FROM THE DATE OF ORIGINAL RETAIL PURCHASE)

LENGTH OF WARRANTY:*

COMMERCIAL RENTAL

*LENGTH OF WARRANTY: All warranty coverage except emission controls expires when the operating hours exceed 200 hours.

TO QUALIFY FOR THIS WARRANTY:

The product must be purchased in the United States from a dealer authorized by GXi Outdoor Power, LLC to sell those products. This warranty applies to first retail

purchaser / owner during the applicable warranty time period. SAVE YOUR PROOF OF PURCHASE RECEIPT.

WHAT STANLEY POWER EQUIPMENT WILL REPAIR OR REPLACE UNDER WARRANTY:

STANLEY will repair or replace, at its option, any part that is proven to be defective in material or workmanship

under normal use during the applicable warranty

time period subject to the exclusions stated herein. This warranty is void if the owner fails to follow the prescribed maintenance and operating procedures described in this manual. This specifically refers to ensuring routine oil changes are made, that fuel stabilizer is used for long-term storage, that the generator is not

overloaded, and that the generator loads are distributed evenly between the A and B outlets. Dirty carburetors, spark plugs, air filters, fuel filters, and freight or

handling damage are not covered under warranty.

STANLEY has the right to recover warranty administration costs from the owner if the root cause of the malfunction was found to be other than defective material or

workmanship. In particular, this warranty does not cover: contaminants in the fuel or oil; damage caused by not following the prescribed warnings and operating

practices; failure to follow proper maintenance and storage procedures; and physical damage due to shipping or handling or storage. Damage to the generator that

occurs as a result of connecting a STANLEY generator to household wiring without the use of a UL approved transfer switch device that is connected to the home or

business and grounded as per applicable local electrical codes, is not covered by this warranty.

Warranty repairs will be made without charge for parts and labor for the first year. After the first year, this limited warranty covers the costs of replacement parts

only.

TO OBTAIN WARRANTY SERVICE:

You must take the STANLEY Power Equipment product, accessory, replacement part, apparel or the power equipment on which the accessory or replacement part is

installed, and proof of purchase, at your expense, to any STANLEY Power Equipment service location in the United States, who is authorized to service that product,

during the service location’s normal business hours. If you are unable to obtain warranty service, or are dissatisfied with the warranty service you receive, take the

following steps: First, contact the manager of the service center involved; normally this will resolve the problem. However, if you should require further assistance,

EXCLUSIONS:

THIS WARRANTY DOES NOT EXTEND TO PARTS AFFECTED OR DAMAGED BY ACCIDENT AND/OR COLLISION, NORMAL WEAR, FUEL CONTAMINATION, USE IN AN

APPLICATION FOR WHICH THE PRODUCT WAS NOT DESIGNED OR ANY OTHER MISUSE, NEGLECT, INCORPORATION OR USE OF UNSUITABLE ATTACHMENTS OR

PARTS, UNAUTHORIZED ALTERATION, OR ANY CAUSES OTHER THAN DEFECTS IN MATERIAL OR WORKMANSHIP OF THE PRODUCT. Consumable parts such as oil,

spark plugs, filters, carburetors, are not covered by this warranty.

DISCLAIMER OF CONSEQUENTIAL DAMAGE AND LIMITATION OF IMPLIED WARRANTIES:

STANLEY DISCLAIMS ANY RESPONSIBILITY FOR LOSS OF TIME OR USE OF THE PRODUCT, TRANSPORTATION, COMMERCIAL LOSS, OR ANY OTHER INCIDENTAL

OR CONSEQUENTIAL DAMAGE. ANY IMPLIED WARRANTIES ARE LIMITED TO THE DURATION OF THIS WRITTEN LIMITED WARRANTY.

This warranty is void if the manufacturing date and the serial number on the equipment has been removed or the equipment has been modified.

EMISSION CONTROL SYSTEM INFORMATION

The U.S. and California Clean Air Acts

EPA and California regulations require all manufacturers to furnish written instructions describing the operation and maintenance of emission control systems. The

following instructions and procedures must be followed in order to keep the emissions from your STANLEY engine within the emission standards. Maintenance,

replacement, or repair of the emission control devices and systems may be performed by any engine repair establishment or individual, using parts that are

‘‘certified’’ to EPA standards.

The emission control systems on your STANLEY engine were designed, built, and certified to conform with EPA regulations. We recommend the use of genuine

STANLEY parts whenever you have maintenance done. These original-design replacement parts are manufactured to the same standards as the original parts, so

you can be confident of their performance. The use of replacement parts that are not of the original design and quality may impair the effectiveness of your emission

control system. A manufacturer of an aftermarket part assumes the responsibility that the part will not adversely affect emission performance. The manufacturer or

re-builder of the part must certify that use of the part will not result in a failure of the engine to comply with emission regulations.

Emission controls are covered by this warranty for all uses for a period of 2 years from original retail purchase date, this coverage extends to subsequent owners of

the product with proof of original purchase. For emissions warranty service call 1-800-393-0668 or e-mail customerservice@gxioutdoorpower.com .

STANLEY is a registered trademark of The Stanley Works or its affiliates and are used under license by GXi Outdoor Power LLC.

No part of this publication can be printed or copied without written permission.

16 of 16 Rev. 5/2010

Loading...

Loading...