Page 1

Operating & Installation Manual

FUSION PELLET STOVE

Page 2

1

TABLE OF CONTENTS

PAGE

NO.

1. Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2. Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3. General Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

4. Assembly & Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

5. Hearth Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

6. Stove Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

7. Safety Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

8. Flue - Vertical External or Internal Chimney . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

9. Combustion Air. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

10. Safety & Correct use of the Appliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

11. In Case Of Chimney Fire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

12. Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

13. Pellet Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

14. Notes on Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

15. Operating Sequence & Switching Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

16. Controlling Timer Thermostat. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

17. Electronic Contol Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

18. Remote Control Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

19. Circuit Board Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

20. Managing Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

21. Switching Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

22. Safety Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

23. Cleaning Of The Stove. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

24. Ashpan & Burn Pot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

25. Cleaning The Ashpan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

26. Glass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

27. Periodic Cleaning Of Stove & Heat Exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

28. Cleaning The Flue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

29. End of Season . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

30. Problems / Causes / Solutions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

31. Technical Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

32. Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Page 3

STANDARDS

N.B.: The information in this manual is given only as a general guide, and local, national or EC regulations

must also be complied with.

RECOMMENDATIONS:

Before using this appliance, please read all parts of this instruction manual carefully, as the information it

contains, is essential in order to use the appliance correctly.

Read this manual prior to installation, maintenance & operation of this appliance.

The manufacturer will not be responsible for any modifications made to this appliance by or on behalf of the

user. The manufacturer will not be responsible for any eventual damage or loss as a result of unauthorised

modifications. In the event that parts need to be replaced, only use parts recommended by Waterford

Stanley.

The user is responsible for all work involved in the initial installation of the appliance and for keeping it

working efficiently thereafter.

Incorrect installation may result in damage to property, or injuries to persons or animals. The manufacturer

will not be liable for any damage resulting from incorrect installation, or failure to follow the instructions that

accompany this appliance.

GENERAL NOTICE

Important: The appliance MUST be earthed.

Before installing the appliance, the power supply system must be checked to ensure it has an effective

earth circuit.

Important: the power supply cable must be of sufficient cross-section for the power requirement of the

appliance.

The supply voltage required for the stove is 220-240 V at 50 Hz. Voltage variations greater than 10% of the

rated value may cause irregular operation, or damage to the electrical system. The appliance must be positioned so that the domestic power supply plug remains accessible.

If the power supply cable becomes damaged, switch off the power and have it repaired by an authorised

Stanley service agent.

2

Page 4

ASSEMBLY AND INSTALLATION

INSTRUCTIONS

N.B. To install the stove, use only authorised and

trained personnel, or contact the dealer.

1. Check that the floor can support the total weight

of the stove (140kgs).

2. Refer to the figure that shows the dimensions

of the flue pipe, and allowing for the thickness

of the floor-protection base (if applicable), make

a hole in the chimney to accommodate the

smoke outlet pipe (diameter 80 mm).

3. Connect the stove to the chimney with a certified steel pipe suitable for this use and seal it.

This appliance must not be connected to a

shared flue.

4. Leave adequate clearance around the stove for

cleaning and servicing. If the appliance is to be

installed in an alcove a minimum of 400mm

clearnace is required all round to allow access

for cleaning and servicing.

HEARTH DIMENSIONS

The hearth should extend 15cm to the rear of the

stove and 14cm to both sides and 30cm to the front.

STOVE DIMENSIONS (MM)

3

Fig.1

Fig.2

Fig.3

Fig.4

Fig.5

1032

566

637

Min 140mm

Min 150mm

Min 300mm

Min 140mm

177.8

182

Flue Outlet

Air Intake

Page 5

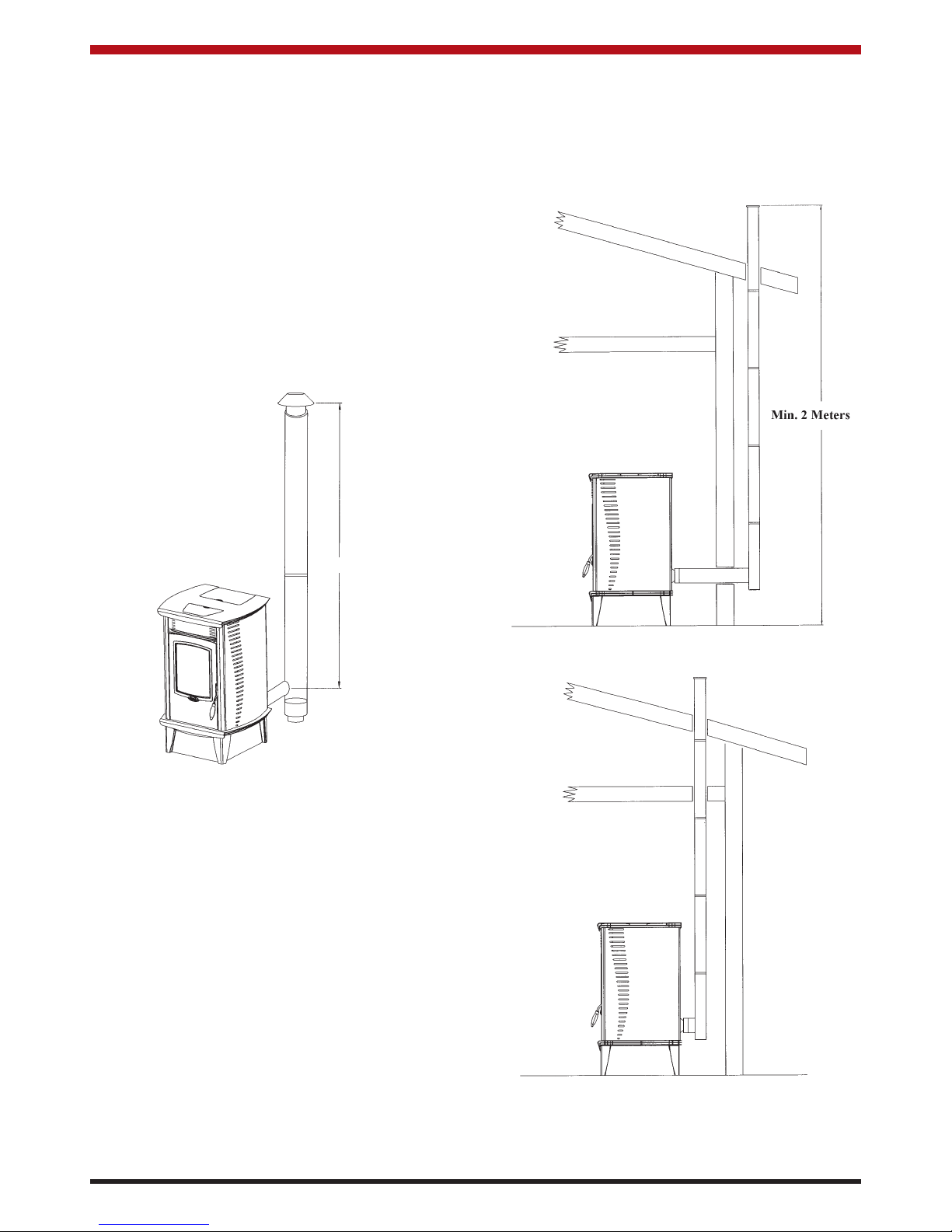

FLUE - VERTICAL EXTERNAL OR INTERNAL

CHIMNEY

The flue arrangement shown is the best solution for

evacuating smoke, even when the ventilator is off

(no power supply, or lock out flame). Any installation

must comply with current building regulations.

The minimum 2.00 metre level difference between

the roof outlet and the T fitting inside or outside the

building, ensures a minimum vacuum inside the

stove, thus preventing smoke issue into the room.

External flues must be insulated: for example by

using double-wall flue pipes.

The figure shows the recommended arrangement

for flue outlets above roof level. In all cases, there

must be a T fitting with inspection plug. The flue

duct must be suitably fastened and fitted with a

chimney pot for rain protection.

SAFETY WARNINGS

This appliance is not suitable for connection to a

shared flue.

The stove must be placed on a non combustible

hearth. If it is to be supported on a combustible floor

surface, it must be supported on a floor-protection

plate of at least the size shown in 3.1. It must be at

least 8mm thick.

The appliance must be connected to a chimney

suitable for solid fuels with a minimum diameter of

80 mm, and with a minimum height of 2.00 m from

the appliance flue outlet.

For insulating and sealing the pipes, use only heatresistant materials (250° C).

The through-holes in walls or floors must always

have an insulated tube or ventilation passage, so

that it is always possible to disassemble the chimney components for cleaning and inspection, and to

prevent contact between these components and

wall masonry or inflammable surfaces.

It is useful to have planned inspections of the pipe

bends for periodic maintenance of the flue duct.

The smoke outlet pipe must be protected against

rainwater ingress.

4

Fig.6

Fig.7

Fig.8

Min. 2 meters

Page 6

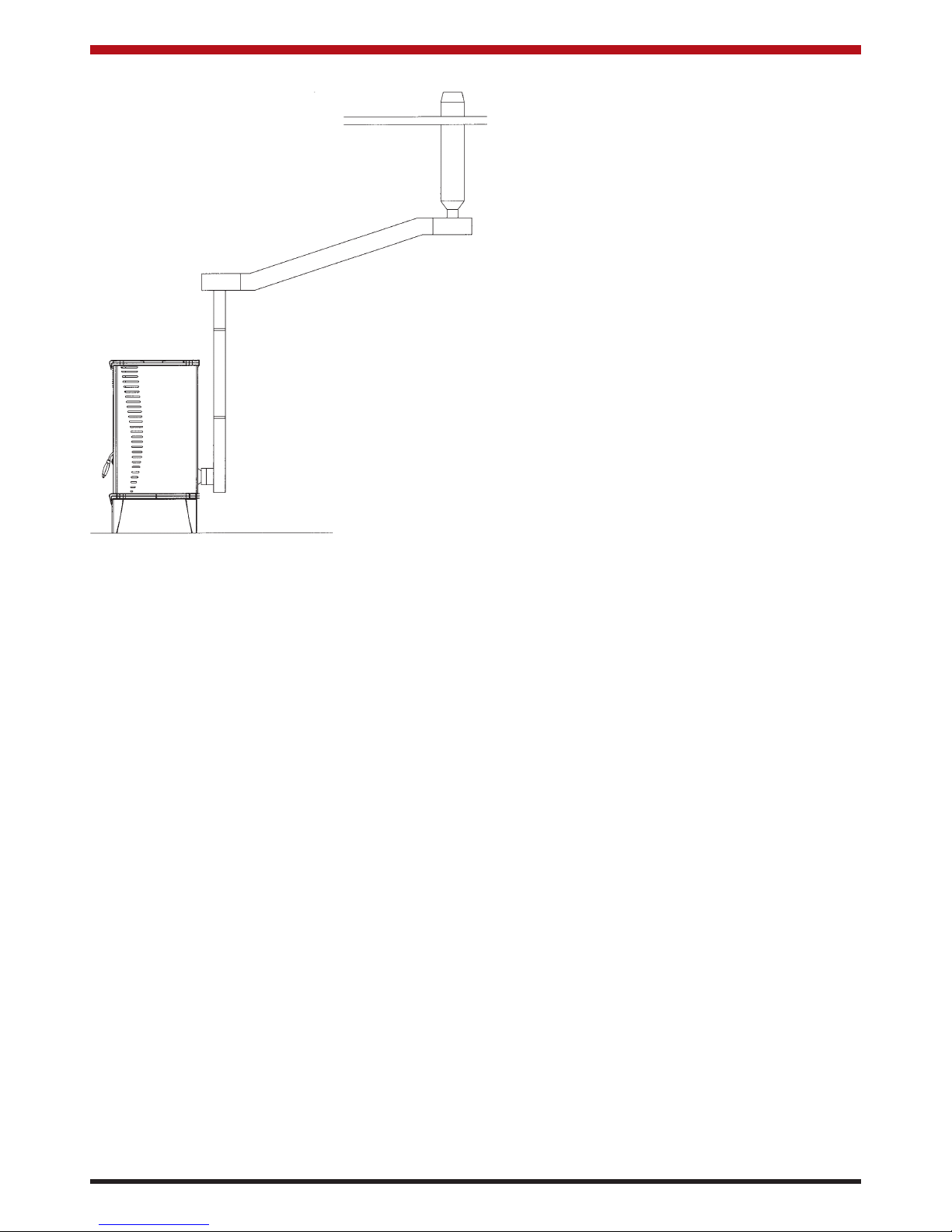

Where it is necessary to have a horizontal length of

pipe, there must be a minimum positive gradient of

3% along its length.

It is forbidden to run flue pipe in a horizontal plain

or in a reverse gradient.

It is forbidden to install the smoke outlet at pavement level, on public streets, car-parks or anywhere

that might cause annoyance to people and/or animals.

The flue must be installed with the outlet above roof

level.

IMPORTANT: All sections of the flue pipe must be

accessible for inspection, and allow for internal

cleaning, removal or substitution.

Do not place nets or grilles over the flue outlet.

When they become dirty they will obstruct the outlet and cause poor combustion, and the stove may

be blocked with soot.

COMBUSTION AIR

The process of combustion requires oxygen, and

therefore air. When in operation, the stove draws

air from the room in which it is installed; poor combustion may therefore result if the room is insufficiently ventilated.

To resolve this problem, a suitable vent hole must

be provided to allow a permanent supply of fresh air

from the outside. The cross-section of the vent

must be 6 cm² for each kW of energy consumed at

maximum input 67cm

2

for the Fusion stove.

The ventilation hole must have a cross-sectional

area of 67 cm² if a flue draught stabiliser is fitted.

If no flue draught stabiliser is fitted the ventilation

requirement is 34cm².

If the stove is located in a room containing another

appliance cooker hood or extractor fan, it is essential to provide ventilation equivalent to the sum of

the air requirement for all appliances.

The vent must not be placed directly beside the

appliance in order to avoid drawing in air that is too

cold: at certain times of the year when the appliance is very cold, the stove may be locked out

when you first attempt to light it. If this occurs, the

situation should be considered absolutely normal,

and you can unlock the stove using the switch #4

located on the control panel. Then switch on again.

SAFETY AND CORRECT USE OF THE APPLIANCE

Before switching on for the first time, read the following safety instructions.

1. Some parts of the stove become hot (door,

glass, flue, etc.), and contact with these parts

may cause burns.

2. Do not place combustible or inflammable

materials beside the stove, and never at less

than 1 metre.

3. Do not store bags of pellets close to the stove.

4. Your stove burns pellets only - it is not an incin-

erator. It is forbidden to burn other materials or

household waste as fuel.

5. When loading pellets into the tank, avoid pour

ing sawdust along with them. Failure to follow

this instruction may make the appliance unsafe,

and void all warranties.

5

Fig.9

Page 7

6. Keep children away from this the stove. Do not

open the door when the stove is lit.

7. Do not switch off the electric power supply

while the stove is on. This will cause the smoke

extractor fan to stop, and the burning fuel will

cause smoke to issue into the room if there is

no natural upward draught in the chimney.

8. When the stove is lit for the first time, the varnish may release fumes, and these may emit

an unpleasant odour. The room must therefore

must be ventilated to evacuate these fumes.

The varnish will be fully hardened after several

heating cycles (2-3).

9. Periodically ensure that the gaskets between

stove and flue pipe are gas tight.

10. In case of fire, switch off the stove, move any

flammable materials away, and call the fire

services.

IN CASE OF CHIMNEY FIRE

Switch off appliance and close all openings into the

stove, watch for ignition of adjacent combustibles

from hot embers or sparks from chimney.

FUEL

WHAT ARE PELLETS?

PELLETS consist of sawdust or real wood scraps

ground and pressed into small cylinders about 6

mm in diameter and 20-30 mm in length.

As fuel, pellets are completely environmentally

friendly, as they are made entirely of natural wood,

without glue or other chemical compounds. Pellets

have a high calorific value (4.7 to 5.3 kW/kg), and

low moisture content.

IMPORTANT: Pellets must be stored in a dry place.

Use only good quality pellets, without sawdust.

IMPORTANT NOTICE: The small quantities of

sawdust normally present at the bottom of the bags

should not be emptied into the tank, but should be

held inside the bag while pouring the pellets carefully so that the sawdust remains inside.

If sawdust accumulates in the tank, it should be

removed periodically with a vacuum cleaner (with

the door open and disconnecting the power plug

from the electricity supply), to prevent it entering the

loading system and causing serious malfunctions.

IMPORTANT: If, during a loading operation, or for

any other reason, foreign matter is allowed to enter

the tank and then the pellet loader, it may cause

damage to the internal mechanisms.

Besides causing damage, this would cause the

stove to stop. In this case, the manufacturer cannot

accept any liability.

ONL

Y 6mm DIAMETER PELLET MUST BE USED

DO NOT USE POOR QUALITY PELLETS OR REPROCESSED PELLETS WITH HIGH SAWDUST

CONTENT. THIS TYPE OF PELLET CAN SERIOUSLY IMPAIR THE FUNCTIONS IN YOUR

STOVE, VOID THE WARRANTY AND THEREFORE RELEASE THE MANUFACTURER FROM

ALL LIABILITY.

PELLET LOADING

The pellet tank capacity is 25 Kg.

To load, lift the pellet tank lid, and pour in the pellets, taking care to keep any sawdust inside the

bags.

Close the lid when loading is complete.

IMPORTANT: LOADING MUST BE CARRIED

OUT ONLY WHEN THE STOVE IS OFF AND HAS

COOLED DOWN.

When pellets are used up, the stove cannot work

and is therefore locked out, the display shows

“ALARM NO FIRE”.

6

Fig.10

Page 8

selected thermal power value (set by buttons 5 and

6) and ambient temperature.

In this phase, buttons 5 and 6 can be used to set

the power output of the stove from 1 to 5, provided

that room temperature is below the set value, otherwise power is reduced to minimum value.

If the pellets are not lit within 15 min., the stove displays the message “ALARM NO FIRE”.

If there is an electrical power failure, when power is

restored, the stove expels the remaining smoke and

resumes the working program from the point at

which it stopped. It can do this only if the electrical

power was lost for a few minutes. If the stove has

cooled down during the power failure, the control

unit puts the stove back into the ignition phase, and

re-starts the program from the beginning.

To change the temperature setting at any time, simply press button 3 and use buttons 2 and 1 to adjust

the temperature shown on the lower display. During

the operating phase, the lower display indicates

ambient temperature.

When the room temperature is reached, the

stove changes from the working program into

ECO mode (pilot flame). When ambient temperature falls by 2°C, the stove goes back into

working mode.

When not in setting mode, button 1 can be pressed

to show the smoke temperature on the lower display.

The stove can be switched off by pressing button 4;

in this case, the word OFF appears on the upper

display, pellet flow is stopped and extractor fan

speed increases. When cooling is complete, the

ventilator (exchanger) is switched off and, after

several minutes, the extractor fan is also switched

off.

N.B.: when the stove has cooled, the extractor is

also switched on for several minutes.

OPERATING SEQUENCE AND SWITCHING OFF

To start the stove, press button 4 on the control

panel.

display for the loading time of 1.5 minutes (pre-ignition phase), then the message

appears for about 4-5 minutes, during which the

burn pot is ignited and stabilised. Finally, the mes

When refilling with pellet at this point it will take a little while for the pellet to come through so the fire

may go to lockout again. This is normal and will light

normally once the pellet has started to feed, probably at the second attempt.

NOTES ON OPERATION

Description of front panel controls

Button 4: ON/OFF and exit programming mode

Button 3: change temperature setting

Buttons 5 and 6: UP/DOWN for thermal power setting

Buttons 2 and 1: UP/DOWN for temperature setting, programming functions and indicators

Upper LED display

Top left: timer program active

Bottom right: pellet auger ON

Top right: (not active)

Bottom left: (not active)

Lower LED display

Top left: heating elements ON

Top right: thermostat ON

Bottom right (flashing): temperature setting

Bottom left: lock out (ALARM)

Operation:

To start the stove, press button 4; after a few

moments, the control unit puts the stove into the

pre-ignition phase, lighting the igniter plug and

showing the message “FAN CAND” on the display;

it also switches the extractor fan on at maximum

power for about 5 seconds, then brings it down to

ignition power.

After this phase (which lasts about 90 seconds), the

message “LOAD WOOD” appears on the display

and the auger loads the pellets at the pre-set

speed.

When the smoke temperature reaches the ignition

value set by the manufacturer, the stove goes into

stabilization phase and shows the message “FIRE

ON” on the display. It then switches off the igniter

plug.

The room air ventilator (exchanger) also starts up

during the stabilisation phase.

When this phase is complete, the control unit goes

into working mode, in which the display shows the

LOAD WOOD

FIRE ON

The message

appears on the

sage appears for about 3 minutes.

FAN CAND

7

Page 9

During this initial phase, the display shows the

working program, which can be modified using buttons 5 and 6 on the control panel. To set the desired

room temperature, press buttons 1 and 2. When the

programming phase is complete, the stove continues working until the selected room temperature is

mode

(small pilot flame remains lit).

When the room temperature falls by 2°C relative to

the temperature selected on the control panel, the

stove resumes the program previously set.

To switch off the stove completely, hold down button

4 on the control panel for about 3 seconds.

CONTROLLING THE TIMER-THERMOSTAT

Press button 3 “SET” to access the timer-thermostat programming function, which starts at parameter UT01.

To select subsequent parameters, press button 3

“SET”.

To increase or decrease a value, press buttons 1

and 2 repeatedly.

UT01: used to set the day on which the program is

being set, for example if it is W

ednesday when you

are programming the timer-thermostat, set parameter UT01 to Day 3

using buttons 1 and 2.

To confirm and continue programming, press button

3 “SET”.

UT02: used to set the current clock time; use but-

tons 1 and 2 again to adjust the time as required.

Press 3 “SET” to confirm and continue.

UT03: used to set the minutes; use buttons 1 and 2

again to adjust as required. Press 3 “SET” to confirm and continue.

UT04: is not used.

Before we go into the programming phase, it is

important to note that the programmer is designed

to switch on and off twice per day, where AM is the

morning program and PM is the

afternoon/evening program.

UT05: used to set the AM switch-on time in steps of

10 minutes.

Press 3 “SET” to confirm and continue.

UT06: used to set the AM switch-off time in steps of

10 minutes.

Press 3 “SET” to confirm and continue.

UT07: this parameter is used to confirm the day on

which to run the AM program set previously with

parameters UT05 and UT06.

Example: if you want the stove to run the program

on Monday, the lower display must be set to on1.

If you want the stove not to run the AM program on

Monday, the lower display must be set to off1. To

change the setting on the lower display, use buttons

1 and 2. Use button 1 to scroll through the program

days, and button 2 to select ON or OFF.

To go on to the next parameter, press button 3

“SET”.

UT08: used to set the PM switch-on time in steps of

10 minutes.

Press 3 “SET” to confirm and continue.

UT09: used to set the PM switch-off time in steps of

10 minutes.

Press 3 “SET” to confirm and continue.

UT10: this parameter is used to confirm the day on

which to run the PM program set previously with

parameters UT08 and UT09. The rest of the programming is the same as for parameter UT07.

Press 3 “SET” to confirm and continue.

As an example, if you want to set only one daily program, to run continuously over a period from 8:00 in

the morning to 20:00 in the evening, just set parameters UT05, UT06 and UT07, with parameter UT05

set to 8:00 and UT06 set to 20:00; then use UT07

to select the day on which this program is to run.

If you do not want to have the stove switch on automatically at all, simply set parameter UT01 to off,

using buttons 1 and

2 again.

In this case, the stove ignores all the other programmed values, and is only switched on manually.

N.B. you can exit programming mode at any

time by lightly pressing button 4 (ON-OFF).

ECO

reached, then the stove goes into

8

Page 10

ELECTRONIC CONTROL PANEL

REMOTE CONTROL FUNCTIONS (optional)

9

Access to timer-thermostat

and clock programmer

Power increase

from 1 to 5

Room temperature setting

The display shows the

stove operating phases

Power decreases from 5

to 1

Stove On/Off control

The stove is switched on/off by

pressing buttons 1 and 6 at the

same time.

Program selection

buttons:

6: Increase power

5: Decrease power

Page 11

CIRCUIT BOARD WIRING DIAGRAM

10

Page 12

MANAGING ALARMS

An alarm indication may appear in one of the following cases (the alarm can be cleared by pressing

button 4 “ON OFF”:

- Flue gas temperature probe alarm

If there is a fault in the flue gas temperature probe,

the message “ALARM SOND FUMI” appears and

the ventilator and extractor fan are switched on at

maximum speed.

- Flue gas over-temperature alarm

If the flue gas temperature rises above 280° C, the

message “ALARM HOT TEMP” appears and ventilator and extractor fan remain lit until the decrease

of flue temperature.

- Ignition failure alarm

- Extractor alarm (if this option is available)

This appears if the initial attempt to ignite has failed,

or if stove temperature is too low for operation,

even after the full ignition period has elapsed. The

message “ALARM NO FIRE” is displayed and the

extractor fan remains lit for a pre-set time until the

stove is completely switched off.

- Pressostat alarm

Incase the exchanger gets dirty or the chimney is

obstructed, the safety pressostat switches the

motor auger off (stops the fuel).

In special weather conditions, the pressostat

switch can operate even if there is no bad functioning of the stove. This can be caused by the

lower draught of the chimney. Please consider

this event as a normal one, it does not depent

on the stove.

- Safety thermostat alarm

In case of irregular stove temperature, the safety

thermostat operates and shows on the display the

following notice: “ALARM TERM SICC”. To restart

the stove, wait until cool and unblock it as shown in

Fig.

HOT TEMP

NO FIRE

SOND FUMI

ALARM

ALARM

DEP FAIL

ALARM

SIC FAIL

ALARM

ALARM

ATTENTION: the thermostat has to be reset by

cooled stove.

The control panel is situated in the lower rear

part of the stove.

N.B. the thermostat does not unblock until the

stove has cooled completely.

If the thermostat reset has been successful, a click

cna be heard when you press the button. Before

every new ignition, verifty that the burn pot is completely empty; if not, clean it immediately.

The alarm signals can be cancelled by switching off and on the stove with button No.4 situated in the frontal panel of the stove.

Ensure Air Inlet and flue gas outlet are clear

from obstructions.

If the flue gas temperature rises above 260°C, the

stove goes into Economy mode and the message

appears on the display.

ted room temperature has been reached.

SWITCHING OFF

The stove can be switched off in different ways:

1. Manually (putting the On/Off switch on the back

of the stove in the Off position).

2. By actuation of a room thermostat, if this is connected.

3. By a timer program.

4. Using the remote control (if this option is available).

ECO

ECO

The message

also appears when the selec-

11

1. Unscrew the cap

anticlockwise

2. Push The Button

Fig.11

Page 13

N.B.: Method 1 is used to carry out maintenance or

to switch off the stove permanently at the end of the

cold season. Never switch off the stove while it is in

operation, either by cutting off the current at the

plug or at the switch located on the back of the

stove.

This will cause the smoke extractor fan to stop

immediately, causing smoke to issue into the room

if there is no natural upward draught in the chimney.

After switching off the stove on the front panel, or

using the remote control (if this option is present),

wait for 15 minutes cooling time to elapse before

attempting to start again. The stove may not re-light

if it has not cooled sufficiently.

During the switch-off phase, the smoke extraction

motor continues to run until the stove is cooled,

then switches off automatically. Similarly, the room

air ventilator continues running until the stove has

cooled (the ventilator may switch off and then on

again if there is still some heat in the stove).

SAFETY DEVICES

1. Flue Gas Extraction Motor Failure

If the flue gas extractor stops, a pressure switch

immediately stops the pellet supply.

2. Flue Gas Outlet Safety Device

If the flue gas outlet is obstructed, the pressure

switch prevents fuel from entering the burn pot.

3. Pellet Loading Gear Motor Failure Or

Blockage

If the gear motor stops, the stove continues to operate until it stops to cool down. The system will

attempt to start up the stove, and if the fault persists

the stove will stop completely and remain lock out.

4. Hot Air Distribution Ventilator Failure

When the temperature at the end of the loader

reaches 105°C, a safety thermostat stops the gear

motor, causing the stove to switch off.

If the thermostat is activated, it must be reset using

the special control (protected by a screw plug) on

the back of the stove under the main switch and

protection fuse.

If the thermostat is actuated again and causes

the stove to stop, contact the technical support

service immediately.

5. Temporary Electircal Power Failure

If there is a temporary power failure while the stove

is in operation, the appliance will come on again

automatically. If the power failure is longer lasting,

the smoke extractor stops running and the stove

may therefore emit smoke into the room.

6. Electrical Safety

The stove is protected by a main fuse located on

the rear panel.

CLEANING OF THE STOVE

IMPORTANT: before starting to clean the stove,

check that it is switched off and completely cooled

and that the electrical power supply is disconnected.

ASHPAN AND BURN POT

The burn pot must be cleaned everyday. Pull it out

manually by lifting, and empty the accumulated ash.

When re-inserting the burn pot, check that it is the

right way around, with the hole for the igniter plug

facing towards the inside of the stove.

Every two or three days, lift the grid at the bottom of

the combustion chamber, take out the drawer,

empty it and re-insert in the correct position. Finish

off cleaning the inside of the chamber using a vacuum cleaner. We recommend emptying the lower

ashpan periodically, as described in the following

paragraphs.

IMPORTANT: All cleaning and maintenance operations must be carried out when the stove is cold.

These cleaning operations ensure that the appliance continues to work efficiently and correctly.

The required frequency of cleaning operations

depends very much on the quality of the pellets

used. We recommend using only tested, good-quality pellets.

After the cold season has ended, the exchanger

must be cleaned. This operation may be required

more often, depending on the pellet quality, but this

should not be considered a sign that the stove is not

functioning correctly.

CLEANING THE ASHPAN

Open the panel, remove the ashpan, empty it and

re-insert correctly. This operation is usually carried

out once per week, and more often if required.

12

Page 14

END OF SEASON

We advise using up all pellets remaining in the tank

in order to prevent condensates from forming and

thus clogging and blocking the feeder motor.

Pellets and sawdust remaining at the bottom of the

tank should be removed using a vacuum cleaner.

If there are substantial amounts of sawdust, we recommend checking the quality of the pellets used to

fuel the stove.

This operation is carried out with the stove off and

cool, and the power supply plug disconnected.

CAUTION: Do not vacuum hot cinders as they

may cause a fire in the vacuum cleaner.

GLASS

The glass will self clean when there is sufficient

heat generated by the burning fuel. If a build-up of

deposits occur on the glass it may be due to draft

conditions, poor quality fuel or very low burning for

a long time. It is best to clean the glass when it is

thoroughly cooled.

PERIODIC CLEANING OF THE STOVE AND

HEAT EXCHANGER

The stove and heat exchanger must be cleaned

periodically, and exclusively by authorised personnel. You should therefore call the technical support

service.

We suggest you to carry out this operation after the

cold season has finished.

CLEANING THE FLUE

Whenever this is found to be necessary (and at

least once a year) vacuum and clean all flue ducts

to prevent the build up of particulate matter. It is

important not to obstruct the passage of the flue

gasses.

IMPORTANT: Ensure that the flue pipe gaskets are

gas tight. Where they are not in good condition

replace them immediately.

FAILURE TO CLEAN THE FLUE MAY AFFECT

THE SAFE OPERATION OF THE STOVE.

13

Fig.12

Page 15

PROBLEM / CAUSE SOLUTION

Problem Pellets not delivered into burn pot

Causes * Tank is empty

* Flue gas extractor fan is not working

* Auger blocked by foreign objects

* No electrical power to control panel

* Flue obstructed causing differential pressure switch lock out

Solutions * Re-fill the tank

* Call technical support service

* Call technical support service

* Check that the power plug s correctly inserted and that the fuse is good

* Clean all the smoke outlet pipe and flue

Problem When switched on, the stove functions for a few minutes then is switched off by a

safety device.

Cause The outlet fumes are not reaching the minimum temperature required to switch off

the igniter.

Solution Check that the burn pot is clean

Problem Flame is too smoky

Causes * Insufficient combustion air as the air holes in the burn pot are obstructed

* Flue obstructed or clogged.

* Stove and exchanger dirty

* Pellets are poor quality or contain too much moisture.

Solutions * Clean the burn pot

* Clean the flue gas outlet pipe and flue

* Clean the exchanger

* Replace the pellets

Problem Flame does not ignite

Causes * Air inlet clogged

* Ash present in the burn pot

* Pellets used up

* Differential pressure switch activated

Solutions * Check that the air inlet is clean and not obstructed

* Clean the burn pot

* Re-fill the tank

* Clean the flue gas outlet pipe and flue or close main door

PROBLEMS - CAUSES - SOLUTIONS

14

Page 16

PROBLEM / CAUSE SOLUTION

Problem Pellet loader blocked

Causes Poor quality pellets, sawdust inclued accidentally or pellet stuck and obstructing the

feeder slide to the burner, possibly causing the loading auger to become blocked.

Solutions The problem can often be resolved without calling technical support, simply by insert-

ing a flexible steel rod inside the pellet loading tube once the stove is off and has

cooled. In this way, the blocked pellet can be made to fall into the burn pot, thus

unblocking the auger. This operation is carried out with the stove off and the power

supply plug disconnected.

Problem While the stove is in operation, the pellet loading indicator light comes on, but no pel-

lets fall into the burn pot.

Cause * Air exchanger ventilator dirty

* Air exchanger ventilator broken

* Stove overheating and safety thermostat was activated

* Flue obstructed or draught diverter grill clogged

Solution * Call technical support service

* Call technical support service

* Call technical support service

* Clean the whole flue - remove draught diverter and grill

If the problem cannot be resolved, please contact the Stanley Service Department.

15

Page 17

FUSION PELLET STOVE TECHNICAL DETAILS

Max. fuel consumption per hour kg/h 1.85

Maximum input kW 11.2

Minimum input kW 4.2

Maximum output kW 9.0

Minimum output kW 3.3

Efficiency % >81

Minimum air requirement for combustion m3/h 30

Flue gas mass flow rate gr/s 11

Flue gas temperature maximum power

o

C 190

minimum power

o

C 125

Minimum draught of fireplace mbar 0.1

pascal 10

Elect. power consumption during ignition* W 260

Elect. power consumption during operation W 91

Power Supply V/Hz 230/50

Width mm 490

Height mm 1050

Depth mm 540

Net weight kg 115

Pellet tank capacity kg 25

Total Weight kg 140

Diameter of flue gas outlet mm 80

Diameter of combustion air inlet pipe mm 30

Features

Flue outlet pressure switch

Ashpan

Self-cleaning glass

Forced ventilation

Adjustable feet

Pre-equipped for connectionn to room thermostat

* Power consumption during first 10 minutes of operation

16

Page 18

We undertake to repair or replace, free of charge to you any part found to be faulty within the 1 year

period from the date of purchase provided that:-

* The fault is, in our opinion, caused by defective workmanship, or material and not by accident,

misuse, neglect or normal wear and tear.

* Any manufacturing defect is reported to the stockist from whom you bought the appliance or

directly to Waterford Stanley Service Department within 1 year of the date of purchase.

* The Waterford appliance is installed to the Manufacturer’s recommendations and by a suitably

qualified person.

* The guarantee registration form is completed fully and returned to us within 30 days of the

purchase date, or proof of purchase is provided detailing the date of purchase.

IMPORTANT NOTICE: Any alteration to this appliance that is not approved in writing by Waterford

Stanley will render the guarantee void.

WARRANTY

Rev:00 1 DP 071109

Manufactured by

Waterford Stanley Ltd.,

Unit 210, IDA Industrial Estate, Cork Road, Waterford,

Ireland.

Tel: (051) 302300 Fax (051) 302315

17

Loading...

Loading...