Page 1

INSTALLATION AND OPERATING INSTRUCTIONS

This appliance is hot while in operation and retains its heat for a long period of time after use. Children, aged

or infirm persons should be supervised at all times and should not be allowed to touch the hot working surfaces

while in use or until the appliance has thoroughly cooled.

FIONNSOLID FUEL BURNING STOVE

Page 2

TABLE OF CONTENTS

PAGE NO.

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. Pre Installation Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3. Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4. Floor Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

5. Chimney . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

6. Chimney Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

7. Installation Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

8. Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

9. Back Chimney Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

10. Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

11. Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

12. Gravity Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

13. Injector Tee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

14. Water Circuit Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

15. Pipe Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

16. Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

17. Coal Burning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

18. Lighting The Fire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

19. Use of Back Air Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

20. Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

21. Overnight Burning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

22. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

23. Disposal of Ashes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

24. Glass Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

25. Recommended Fuels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

26. Vitreous Enamel Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

27. CO Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

28. Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

29. Stove Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

30. Installation Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2

Page 3

FIONN SOLID FUEL CENTRAL HEATING STOVE INSTALLATION AND OPERATING INSTRUCTIONS

GENERAL

Before installing your new stove, check that the

chimney is clean and clear of obstructions, cracked

brickwork and leaking joints should be made good.

The chimney should have a cross sectional area of

at least 176 sq.cm. or an inner diameter of 15 to 23

c.m. A similar direct air inlet is required in the room

to support combustion. Do not connect to a chimney

serving another appliance. Always ensure that the

connection is to a chimney of the same size - never

connect to one of smaller dimensions.

PRE-INSTALLATION ASSEMBLY

Step 1: after removing the stove from its pack, open

the fire door and remove the contents from the fire

box. Separate the coal burning parts from the wood

burning parts. See exploded drawing.

Step 2: Lay the stove on its side and fit the 4 legs

(item 1) with the

1

/4

” (6.4mm) hex sets screws provided, tighten screws. Stand the stove upright, taking care not to strain the leg bolts.

Step 3: COAL BURNING. Install the Side Bricks (8)

one at each side of the boiler and press them out to

the sides (7).

Step 4: Install the Coal Grate (19) and push it back

so that the legs rest on the pads of the base (3).

Step 5: Install the Ash Pan (21) between the grate

legs and push it back towards the back of the stove.

Step 6: Close the fire door (6) to ensure that the

grate (19) is installed correctly.

Step 3a: WOOD BURNING. Install the Back Baffle

(25) with the 4 holes at the top.

Step 4a: Install the Side Bricks (8) one at each side

of the boiler and push them back to retain the back

baffle (25).

Step 5a: Install the Hearth Plate (26) with the flat

face upwards.

Step 6a: Install the Fire Fence (24) with the long top

plate facing outwards and the end lugs between the

side bricks (8) and the front frame (17).

INSTALLATION INSTRUCTIONS

FLOOR PROTECTION

When installing this heater on a combustible floor, a

floor protector, consisting of a layer of non-combustible material at least

3

/8

” (9.5mm) thick or

1

/4

”

(6.4mm) thick covered with sheet metal is required

to cover the area under the heater and to extend to

at least 18” (457mm) a the front and 8” (203mm) to

the side and rear and this will provide protection

from sparks and embers which may fall out from the

door when stoking or fuelling.

WARNING: All the above parts must be fitted

to the stove before firing.

The complete installation must be done in accordance with current Standards and Local Codes. It

should be noted that the requirements and these

publications may be superseded during the life of

this manual.

Step 7: Install the Hot Plate (16) into the large

opening of Hob (14). Do not remove the hot plate

when the stove is lighting.

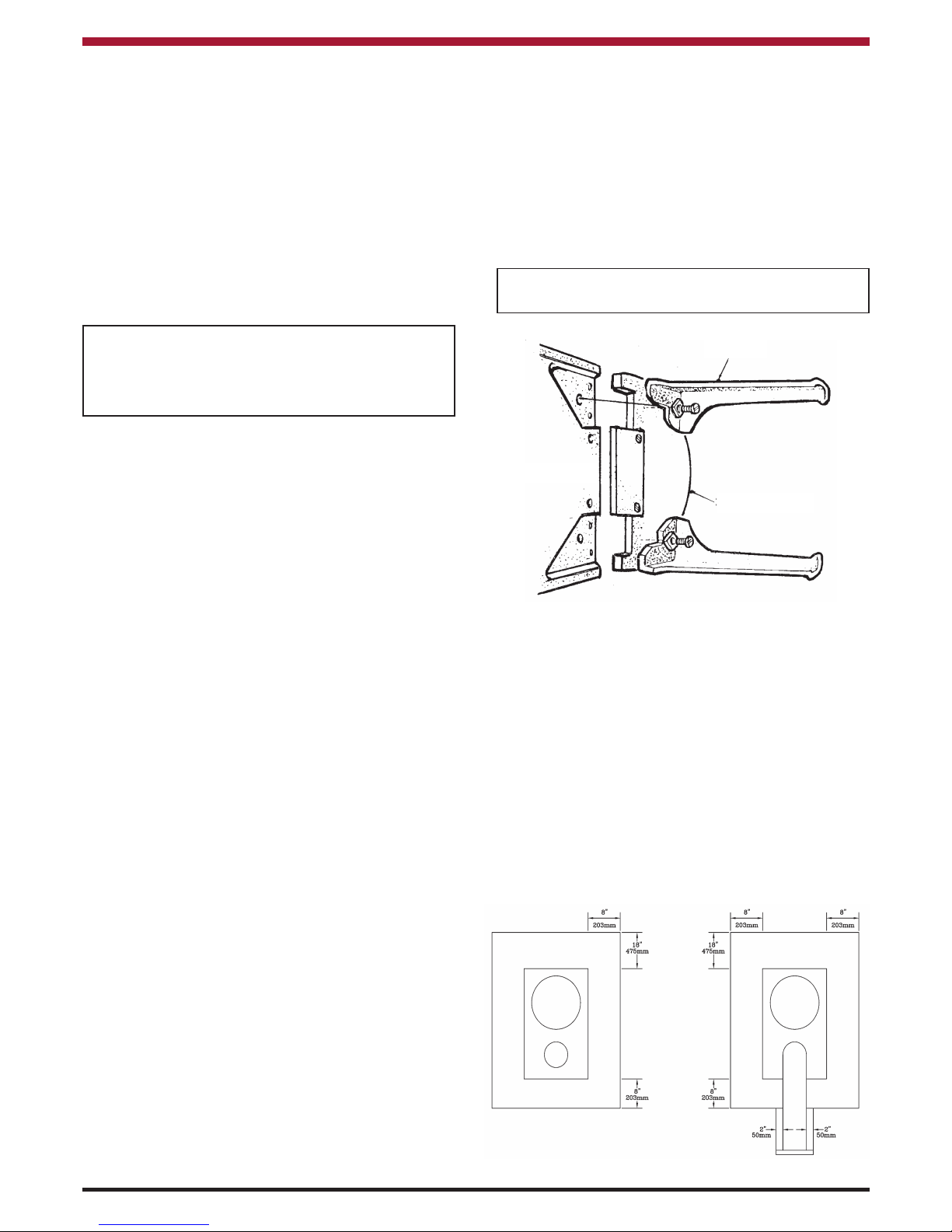

Step 8: Attach the spigot (15) to the back panel (12)

or the hob (14) as required with the

1

/4

” (6.4mm)

countersunk screws provided. Fit the back sealing

plate (18) to whichever opening is not used.

3

1. Leg

3. Base

2. Ashtray

Page 4

CHIMNEY

The Fionn Solid Fuel Stove must be connected to a

chimney of the correct size and type.

The chimney must have a CROSS-SECTIONAL

AREA of at least 30.sq. inches (176sq.cm) or a

diameter of at least 6” (15.2 cm). It is best to connect to a chimney of the same size, as connection to

a larger size may result in somewhat less draught.

Never connect to a smaller size chimney. Do not

connect to a chimney serving another appliance.

Minimum chimney height 15ft. (5m) from floor on

which stove is installed. An existing masonry chimney should be inspected, and if necessary repaired

by a competent mason. A steady draught condition

of 1.5mm (0.06 ins) WG is required for this stove.

CHIMNEY CONNECTORS

(Not Supplied)

The CHIMNEY CONNECTOR is a smokepipe used

to connect the Fionn Solid Fuel Stove to the chimney

described above. The CHIMNEY CONNECTOR

must be made of CORROSION RESISTANT STEEL

24 gauge of heavier (‘black’ or ‘blued’ or equivalent

treated steel), ENAMELLED CAST IRON or ENAMELLED STEEL of 6” (150mm) diameter.

SINGLE WALL STOVE PIPE MUST NOT PENETRATE COMBUSTIBLE WALLS OR CEILINGS.

INSTALLATION CLEARANCES

Maintain at least the following clearances to all

combustible material:

From the front 48” (1,219mm)

From the back 32” (820mm) straight up

only

From the sides 36” (914mm)

From the flue pipe 32

1

/4

” (812mm) straight up

only

It is recommended that this appliance is sited next to

and on a non-combustible surface. A minimum all

round clearance of 100 mm will allow air circulation

and not impede the performance of the stove.

CYLINDER

A 135 litre (30 Gallon) indirect cylinder with 25mm

(1” bore) flow is suitable and the length of pipes from

the cylinder to the stove should not exceed 7.8

metres (251/2) feet. There must be no gate valves

on this circuit and it must have an expansion pipe

exhausting to atmosphere. Cylinder and pipe work

should be lagged to minimise heat loss.

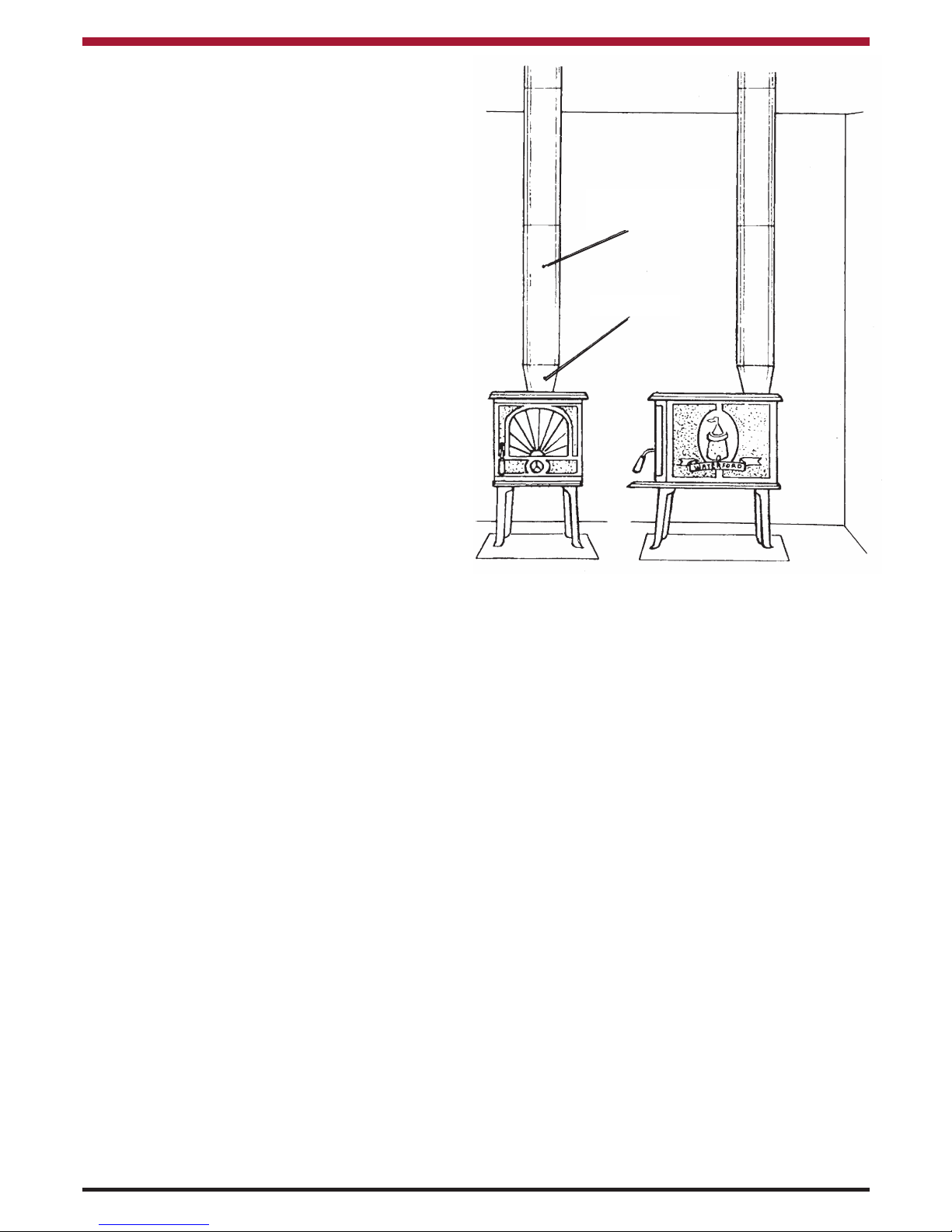

BACK CHIMNEY CONNECTORS

The stove may be installed at zero clearance to a

tiled fireplace or masonry wall

PLUMBING

(Boiler Model)

REGULATIONS

The Plumbing must be in accordance with all relevant regulations and practices. It must include a

gravity circuit with expansion pipe, open to the

atmosphere. The central heating will normally be

pump-driven as with other types of boilers.

GRAVITY CIRCUIT

The gravity circuit consists of the domestic hot water

tank o f 135 litres indirect cylinder, fixed in an upright

position, recommended for hot water storage and it

should be connected to the boiler by 25mm (1”)

diameter and return piping. The pipes should not

exceed flow 3.7m in length and anything in excess

of 2.0m must be fully lagged. The shorter the run of

pipe work the more effective the water heating. The

cylinder should be fully lagged.

Do not have any gate valves on this circuit.

4

6” (150mm)

Connector Pipe

Increaser

Page 5

Back chimney connection

into existing fireplace or

solid masonry wall.

Height to centre of back

outlet 530mm (20

7

/8)

5

mostat to the flow pipe of the gravity circuit and

wiring it into the pump control will ensure rapid circulation of the hot water.

PIPE THERMOSTAT

The fitting of a pipe thermostat to the flow pipe is

essential in order to activate the water circulation

pump when the water reaches the selected temperature.

When the water temperature falls below the selected temperature the pipe thermostat will cut off the

water circulation pump in order to allow the boiler to

recover.

OPERATING INSTRUCTIONS

COAL BURNING

LIGHTING THE FIRE

Thoroughly check all pipe work for leaks, especially

the pipe connections to the boiler before lighting.

Allow the stove to build up heat slowly at first.

Check that all dampers and catches are operating

correctly and ensure that all flue connections are

thoroughly sealed.

Fully open the Spin Valve and Back Air Valve and

kindle with paper and sticks in the usual way and

ignite by using a taper or rolled wad of paper. Under

no circumstances should any inflammable liquid i.e.

petrol, paraffin etc. be used to light the fire. When

the fire is well established adjust the spin valve and

back air valve. Add fuel to the firebox as required

and adjust the air valves to suit current requirements.

When refuelling open the spin valve before opening

the door as this will help to eliminate smoking, afterwards be sure to reset the spin valve and back air

valve to get maximum output from the boiler. Never

pack fuel tightly or fill the firebox to capacity. A low

INJECTOR TEE

Where the gravity and central heating circuits join

together to return the stove we recommended the

use of an injector tee connection, situation as close

to the unit as possible. This type of tee encourages

a stable flow of hot water through both circuits and

helps to prevent priority being given to the stronger

flow, which is most commonly the pumped central

heating circuit. This way, there will be no shortage

of hot water to the taps when the heating is on.

WATER CIRCUIT TEMPERATURE

The return water temperature should be maintained

at not less than 40oC so as to avoid condensation

on the boiler and return piping. Fitting a pipe ther-

Injector Tee

Pipe Thermostat

Indirect

Cylinder

Header

Tank

1” Bore

Flow &

Return

Radiator

6” (150mm)

Connector Pipe

Combustible

Material

Increaser

Pump

Expansion

Pipe

Boiler

Function Diagram

Back Air

Valve

Window Air Wash

Secondary Air

Ashpan

Control

Handle

Spin

Valve

Page 6

level fire is more effective, particularly in regard to

water heating efficiency. The maximum fuel level is

up to the front lip of the coal grate and angled backwards at approximately 150o.

It is not unusual for some condensation to form on

the boiler when the unit is first lit. Do not use the circulating pump until the water in the boiler has heated up. If, when the pump comes on, the return water

temperature is too low, condensation may persist.

In this case, allow the system to warm up gradually

by turning on the radiators in the central heating circuit one by one. Always be prepared for condensation when lighting from cold. To dry out condensation run the appliance for a time with the spin valve

and back air valve open, then reset them.

Attention should be paid to the amount of ash

that is allowed to build up in the firebox.

The ash should be removed from a high burning

coal fire after 6 hours, to prevent damaging or

burning out of the grate.

USE OF BACK AIR VALVE

This air inlet is situated on the back of the stove to

supply primary air through the back insulating plate

to the fire. Its purpose is to assist the combustion

activity at the back of the fire chamber.

The Back Air Valve has four settings: fully closed

1

/4

”

(6.4mm),

1

/2

” (12.7mm), and fully opened. These

settings are used in conjunction with spin valve settings of similar magnitude to give low, medium or

high burning rates. A little practice will familiarise

you with the best settings for your needs.

6

WOODBURNING

To burn wood, peat briquettes, bog peat or synthetic wood, burn directly on hearth, do not use a grate

or elevate fire. “Never use gasoline, gasoline type

lantern fuel, kerosene, charcoal lighter fluid or similar liquids to start or ‘freshen up’ a fire in this heater.

Keep all liquids well away from the heater while it is

in use.” Operate stove only with fuelling door

closed.

LIGHTING

Lay a few crumbled sheets of paper on the hearth,

then a few small sticks on the kindling to get the fire

started. Close the door, and close the Back Air

Valve and open the Spin Valve control ALL THE

WAY.

The fire will catch the kindling quickly, after which the

full size logs may be placed on top. After the logs

have caught fire adjust the Air controls front and

back to suit the heat requirements.

The logs will burn slowly towards the rear of the fire

chamber and the rate of burning is adjustable at all

times by means of the Air controls. The more air

(wider opening) the faster the burning. Do not overfire the stove.

Once they are well lighted, the logs need little attention. It is recommended that the draught be reduced

(smaller opening) after the logs are well lighted as

they will require little draught to maintain combustion.

When the fire is reduced to embers, open the door

and carefully rake the embers towards the front of

the fire chamber and reload with logs.

OVERNIGHT BURNING

Overnight burning is controlled by closing the front

spin valve fully or leaving it about half a turn open

depending on draught conditions. The Back Air

Valve is fully closed by pushing the control rod

underneath the ash tray fully home.

MAINTENANCE

Inspect the chimney flue weekly until a safe frequency is established. The burning of wood, particularly if it is not seasoned, may cause build up of

creosote. If creosote has accumulated it should be

removed to reduce the risk of a chimney fire. Should

this creosote become ignited an extremely hot chimney fire can result.

DISPOSAL OF ASHES

Remove ashes carefully.

Ashes should be placed in a metal container with a

tight-fitting lid. The closed container of ashes should

be placed on a non-combustible floor or on the

ground, well away from all combustible materials,

Back Baffle

Function Diagram

Back Air

Valve

Window Air Wash

Secondary Air

Control

Handle

Spin

Valve

Boiler

Page 7

pending final disposal. If the ashes are disposed of

by burial in soil or otherwise locally dispersed , they

should be retained in the closed container until all

cinders have thoroughly cooled.

GLASS WINDOW

The glass will clean itself when there is sufficient

heat generated by burning fuel. The Air Way system

provides preheated air which keeps the glass clean

even at low heat conditions.

RECOMMENDED FUELS

The stove output levels are assessed on standard

House Coals of good quality. Reduced outputs will

result when fuels of lower calorific values are used.

Wood logs up to 36 cm long are suitable.

All fuels should be stored under cover and kept as

dry as possible prior to use.

House Coal 25 - 75mm Calorific Value 7.2 kW/KG = 12,300 BTUS/LB

Timber - Firebox Size Calorific Value 5.0 kW/KG = 8,600 BTUS/LB

Peat Briquettes - Calorific Value 4.8 kW/KG = 8,300 BTUS/LB

Bog Peat - Calorific Value 3.4 kW/KG = 6,000 BTUS/LB

VITREOUS ENAMEL CLEANING

General cleaning must be carried out when the

stove is cool.

If this stove is finished in a high gloss vitreous

enamel, to keep the enamel in the best condition

observe the following tips:

1. Wipe over daily with a soapy damp cloth,

followed by a polish with a clean dry duster.

2. For stubborn deposits a soap impregnated

pad can be carefully used on the vitreous

enamel.

3. Use only products recommended by the

Vitreous Enamel Association, these products

carry the Vitramel label.

4. DO NOT USE ABRASIVE PADS OR OVEN

CLEANSERS CONTAINING CITRIC ACID

ON ENAMELLED SURFACES. ENSURE

THAT THE CLEANSER MANUFACTURERS INSTRUCTIONS ARE ADHERED TO.

7

CO ALARM

Waterford Stanley recommend the fitting of a CO

Alarm in the same room as the appliance, this is a

requirement under UK Building Regulations. Further guidance on the installation of a carbon monoxide alarm is available in BS EN 50292:2002 and

from the alarm manufacturers instructions.

Provision of an alarm must not be considered a

substitute for either installing the appliance

correctly or ensuring regular servicing and

maintenance of the appliance and chimney

system.

WARNING:-

If the CO Alarm sounds unexpectedly:-

1. Open Doors and windows to ventilate the

room and then leave the premises.

2. Let the fire go out.

Page 8

8

1. LEG

2. ASH TRAY

3. BASE

4. BASE BAFFLE

5. SPIN VALVE

6. FIRE DOOR

7. SIDE

8. SIDE BRICK

9. INSIDE FIRE DOOR

10. DOOR LATCH

11. ASH PAN LIFTING TOOL

12. BACK PANEL

13. BOILER (INDIRECT

CYLINDER)

14. HOB

15. SPIGOT

16. HOTPLATE

17. FRONT FRAME

18. BACK SEALING PLATE

19. COAL GRATE (COAL

BURNING)

20. DOOR CATCH

21. ASHPAN (COAL BURNING)

22. WINDOW INSULATION

23. WINDOW GLASS

24. FIRE FENCE (WOOD

BURNING)

26. HEARTH PLATE (WOOD

BURNING)

27. BACK AIR VALVE HOUSING

28. BACK AIR VALVE

29. SEAL TO AIR VALVE

30. CONNECTING ROD TO

BACK AIR VALVE

31. GUIDE BRACKET TO BACK

AIR VALVE

32. NUT TO BOILER

33. DOOR SEALING ROPE

35. TOP BAFFLE (NON-BOILER)

36. BACK BAFFLE (NON-

BOILER)

EXPLODED VIEW

SECTION SHOWING INTERIOR OF STOVE

Page 9

FIONN SOLID FUEL STOVE SPECIFICATION

Height ................................................................................ 650mm 24

3

/4

ins.

Width.................................................................................. 370mm 14

1

/2

ins.

Depth.................................................................................. 630mm 24

3

/4

ins.

Flue Size............................................................................ 150mm dia. 6 ins. dia.

Height to centre of back of Flue Outlet............................. 530mm 20

7

/8

Fire Door Size................................................................... 264mm W x 280mm H 10

3

/8 ins. W x 11 ins. H

Log Size............................................................................ 360mm Long 14 ins. Long

Burning Rate (Coal).......................................................... 2.4 Kg/Hr 5.3 Lbs/Hr

Gross Output.................................................................... 19.0 kW/Hr 65,000 Btus/Hr

Radiation to Room........................................................... 7.3 kW/Hr 25,000 Btus/Hr

Max. Heat to Water.......................................................... 4.7 kW/Hr 16,000 Btus/Hr

Radiation Surface

Heating Surface Only....................................................... 8.6 sq. meters 92 sq. feet.

Heating Plus Domestic Hot Water................................... 3.7 sq. meters 40 sq. feet.

Gross Weight................................................................... 107 Kg 235 Lbs

It is of the utmost importance to keep the flue pipe and chimney clear of deposits by regular sweeping of the chimney. All

fuels give rise to soot or ash deposits and regular cleaning is essential for safe operation.

Blocked or partially obstructed flueways will cause dangerous fumes to be emitted into the room, these may well be

invisible if a smokeless fuel is burned.

Coal Burning

Wood Burning

9

Page 10

INSTALLATION CHECK LIST

Flue System

1. Minimum Flue Height of 4.6 metres (15 feet).

2. Appliance should be connected to a minimum of 1.8 metres (6 feet) of 150mm (6”)

flue pipe with a horizontal run not exceeding 150mm (6”).

3. Appliance should be connected to a chimney of less than 200mm (8”) in diameter

(otherwise the chimney must be lined with a 6” flue liner).

4. The chimney venting position must be above the main ridge of the roof or adjacent

outside obstructions.

5. The chimney serving this appliance should not serve any other appliance.

6. Access should be provided to the chimney serving the appliance to allow for cleaning.

Location

7. Clearance to combustible materials must be adhered to as described in the Clearance

to Combustible section.

8. The stove must be installed on a floor protector that covers the area under the stove

and extends 18” to the front & 8” to the sides and back.

Plumbing

9. Appliance must be connected to a gravity circuit using 1” ID flow & return piping.

10. The length of pipes from the cylinder to the cooker should not exceed 7.8 metres

(25

1

/2

feet).

11. A circulation pump should be fitted to the return pipe of the radiator circuit and controlled by

a pipe stat fitted to the flow pipe of the gravity circuit to the cylinder.

Ventilation & Combustion Air Requirements

12. The room in which the appliance is located should have an air vent of adequate

size to support correct combustion (see Ventilation & Combustion Air Requirement

Section for specific details).

Tick

10

Page 11

11

NOTES

Page 12

N00044AXX DP130903

Manufactured by

Waterford Stanley Ltd.,

Unit 401-403, IDA Industrial Estate, Cork Road,

Waterford, Ireland.

Tel: (051) 302300 Fax (051) 302315

12

Loading...

Loading...