Page 1

Catalog Number

FME700

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA DE GARANTÍA.

ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

SAVE THIS INSTRUCTION MANUAL FOR FUTURE REFERENCE.

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

INSTRUCTION MANUAL

14 Inch (355mm)

Chop Saw

Scie fendeuse de

355 mm (14 po)

Serra Multi-Corte de

Metais de 14 pulg.

(355mm)

Page 2

2

GENERAL SAFETY RULES

WARNING: Read all safety warnings and all instructions. Failure to follow the warnings

and instructions may result in electric shock, fire and/or serious injury.

SAVEALLWARNINGSAND INSTRUCTIONS FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

1)WORKAREA SAFETY

• Keep work areaclean and well lit.Cluttered or dark areas invite accidents.

• Donotoperatepowertoolsinexplosiveatmospheres,suchasinthepresenceofflammableliquids,

gasesordust.Power tools create sparks which may ignite the dust or fumes.

• Keep children and bystanders away while operating a power tool. Distractions can cause

you to lose control.

2)ELECTRICAL SAFETY

a)Power tool plugs must matchthe outlet. Never modifythe plugin any way. Donot use

any adapter plugs with earthed (grounded)power tools. Unmodified plugs and matching

outlets will reduce risk of electric shock.

b)Avoidbodycontact with earthedorgrounded surfaces suchaspipes,radiators,ranges and

refrigerators.There isan increased risk of electricshockifyour bodyisearthedorgrounded.

c)Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

d)Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the

power tool. Keep cord away from heat,oil,sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock.

e)When operating a power tool outdoors, use an extension cord suitable for outdoor use.

Useofa cord suitable foroutdoor use reduces the risk of electric shock.

f)If operating a power tool in a damp location is unavoidable, use a groundfault circuit

interrupter (GFCI)protected supply. Use of a GFCI reduces the risk of electric shock.

3)PERSONAL SAFETY

a)Stay alert, watch what you are doing and use common sense when operating a power

tool. Donot use a power toolwhile you are tired or under the influence of drugs,alcohol

ormedication. A moment of inattention while operating power tools may result in serious

personal injury.

b)Use personal protective equipment. Always wear eye protection. Protective equipment

such as dust mask, nonskid safety shoes, hard hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

c)Prevent unintentional starting. Ensurethe switchisin the offpositionbefore connecting to

powersource and/orbatterypack,picking up or carryingthe tool. Carrying power tools withyour

fingeronthe switch orenergizing power tools that have the switchoninvitesaccidents.

d)Remove any adjusting key or wrench before turning the power tool on. A wrenchora key

left attached to arotatingpart of thepower tool may resultinpersonalinjury.

e)Do not overreach.Keep proper footing and balance at all times.This enables better

control of the power tool in unexpected situations.

f)Dress properly. Do notwear loose clothing or jewelry. Keep your hair, clothingand

SAFETY GUIDELINES - DEFINITIONS

It is important for you to read and understand this manual. The information it

contains relates to protecting YOUR SAFETY and PREVENTING PROBLEMS. The

symbols below are used to help you recognize this information.

DANGER: Indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

NOTICE: Used without the safety alert symbol indicates potentially hazardous

situation which, if not avoided, may result in property damage.

Page 3

3

glovesaway from moving parts.Loose clothes, jewelry or longhair can be caught in movingparts.

g)If devices are providedfor the connection of dust extraction and collection facilities,

ensure these are connected andproperly used. Use of dust collection can reduce dust-

related hazards.

4)POWERTOOL USE AND CARE

a)Do not force thepower tool. Usethe correct power tool for your application. The correct

powertoolwill do the job better and safer at the rateforwhichitwas designed.

b)Do not use the power tool if the switch does not turn it on and off. Any power tool that

cannot be controlled with the switch is dangerous and must be repaired.

c)Disconnect the plug from the power source and/or the battery pack fromthe power

tool before making any adjustments,changing accessories, or storing power tools.Such

preventive safety measures reduce the risk of starting the power tool accidentally.

d)Store idle power tools out of the reach of children and do not allow persons unfamiliar

with the power tool or these instructions to operate the powertool. Power tools are

dangerous in the hands of untrained users.

e)Maintainpower tools.Checkfor misalignment or binding ofmoving parts,breakageof parts

andanyother condition thatmayaffect thepower tool’s operation. Ifdamaged,have the

power toolrepairedbeforeuse. Many accidents arecaused by poorly maintained power tools.

f)Keep cutting tools sharp and clean.Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control.

g)Use thepowertool,accessories andtoolbits,etc.inaccordancewith theseinstructions,

takinginto account the working conditionsandthe work to be performed. Useofthe power tool

for operationsdifferent fromthoseintended could result in a hazardous situation.

5)SERVICE

a)Haveyourpower tool serviced by a qualified repair personusingonly identicalreplacement

parts.This will ensure that the safety ofthe powertoolismaintained.

Additional Safety Rules for Chop Saws

• Always wear proper eye and respiratory protection.

• Before using, inspect the cutting wheel for cracks or flaws. If such a crack or

flaw is evident, discard the wheel. The wheel should also be inspected whenever

you think the tool may have been dropped. Flaws may cause wheel breakage.

• When starting the tool with a new or replacement wheel or if you are unsure of

the condition of the wheel, hold the tool in a well protected area and let it run for

one minute. If the wheel has an undetected crack or flaw, it should burst in less than one

minute. Never start the tool with a person in line with the wheel. This includes the operator.

• In operation, avoid bouncing the wheel or giving it rough treatment. If this occurs,

stop the tool and inspect the wheel for cracks or flaws.

• Clean your chop saw periodically following the procedure in this manual.

• Do not remove wheel guards or base.

• ALWAYS USE THE VISE OR SPECIAL FIXTURE TO CLAMP WORK SECURELY.

Other aids such as spring, bar, or C-clamps may be appropriate for certain sizes and

shapes of workpiece. Use care in selecting and placing these clamps and make a dry

run before making a cut.

• Use only 14 in. (355mm) type 1 wheels rated at 4300 rpm or higher.

• Allow cut off parts to cool before handling.

• Do not attempt to cut wood or plastic with this tool.

• NEVER CUT MAGNESIUM WITH THIS TOOL.

• Use chop saw in a well-ventilated area.

• Turn chop saw off before removing any pieces from the base.

• DO NOT CUT ELECTRICALLY LIVE MATERIAL.

• Do not use circular saw blades or any other toothed blades with this tool.

Serious injury may result.

• DO NOT OPERATE THIS TOOL NEAR FLAMMABLE

LIQUIDS, GASES OR DUST. Sparks or hot chips from cutting or arcing motor

brushes may ignite combustible materials.

• Do not use the side of the abrasive wheel as a deburring grinder. This will substantially

weaken the wheel creating an unsafe condition. The wheel may come apart.

Page 4

4

CAUTION: Wear appropriate hearing protection during use. Under some

conditions and duration of use, noise from this product may contribute to hearing loss.

CAUTION: Spark deflector will get hot.Avoid touching or adjusting while hot. Keep

cordset and materials away from spark deflector.

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contains chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work.

To reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding,

drilling, and other construction activities. Wear protective clothing and wash

exposed areas with soap and water. Allowing dust to get into your mouth, eyes, or

lay on the skin may promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust, which may cause

serious and permanent respiratory or other injury. Always use NIOSH/OSHA approved

respiratory protection appropriate for the dust exposure. Direct particles away from face

and body.

WARNING: Always use NIOSH/OSHA approved respiratory protection appropriate for

the dust exposure. Direct particles away from face and body.

For your convenience and safety, the following warnings are on your Heavy-Duty 14 inch

(355mm) Chop Saw:

WARNING: FOR SAFE OPERATION READ THE INSTRUCTION MANUAL.

• DO NOT USE TOOTHED BLADES.

• USE ONLY REINFORCED WHEELS RATED 4300 RPM OR HIGHER.

• WHEN SERVICING USE ONLY IDENTICAL REPLACEMENT PARTS.

• ALWAYS: WEAR EYE PROTECTION, USE GUARDS, CLAMP WORK IN VISE, USE

PROPER RESPIRATORY PROTECTION.

• DO NOT EXPOSE TO RAIN OR USE IN DAMP LOCATIONS.

• An extension cord must have adequate wire size (AWG or American Wire Gauge)

for safety. The smaller the gauge number of the wire, the greater the capacity of the

cable, that is 16 gauge has more capacity than 18 gauge. An undersized cord will cause

a drop in line voltage resulting in loss of power and overheating. When using more than

one extension to make up the total length, be sure each individual extension contains at

least the minimum wire size. The following table shows the correct size to use

depending on cord length and nameplate ampere rating. If in doubt, use the next

heavier gauge. The smaller the gauge number, the heavier the cord.

Minimum Gauge for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

(0-7,6m) (7,6-15,2m) (15,2-30,4m) (30,4-45,7m)

240V 0-50 51-100 101-200 201-300

(0-15,2m) (15,2-30,4m)(30,4-60,9m) (60,9-91,4m)

Ampere Rating

More Not more American Wire Gage

Than Than

0-6 18 16 16 14

6-10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended

Page 5

The label on your tool may include the following symbols. The symbols and their

definitions are as follows:

V..................volts A ..................amperes

Hz................hertz W..................watts

min ..............minutes ................alternating current

..........direct current

n

o ................no load speed

................Class I Construction ..................earthing terminal

(grounded) ................safety alert symbol

................Class II Construction .../min or rpm..revolutions or reciprocation

(double insulated) per minute

POWER SUPPLY

Be sure your power supply agrees with the nameplate marking. A voltage decrease

of more than 10% will cause a loss of power and overheating.

CUTTING CAPACITY

The wide vise opening and high pivot point provide cutting capacity for many large pieces.

Use the cutting capacity chart to determine total maximum size of cuts that can be made

with a new wheel.

CAUTION: CERTAIN LARGE, CIRCULAR OR IRREGULARLY SHAPED

OBJECTS MAY REQUIRE ADDITIONAL HOLDING MEANS IF THEY CANNOT BE

HELD SECURELY IN VISE.

CAUTION: DO NOT CUT MAGNESIUM WITH THIS TOOL.

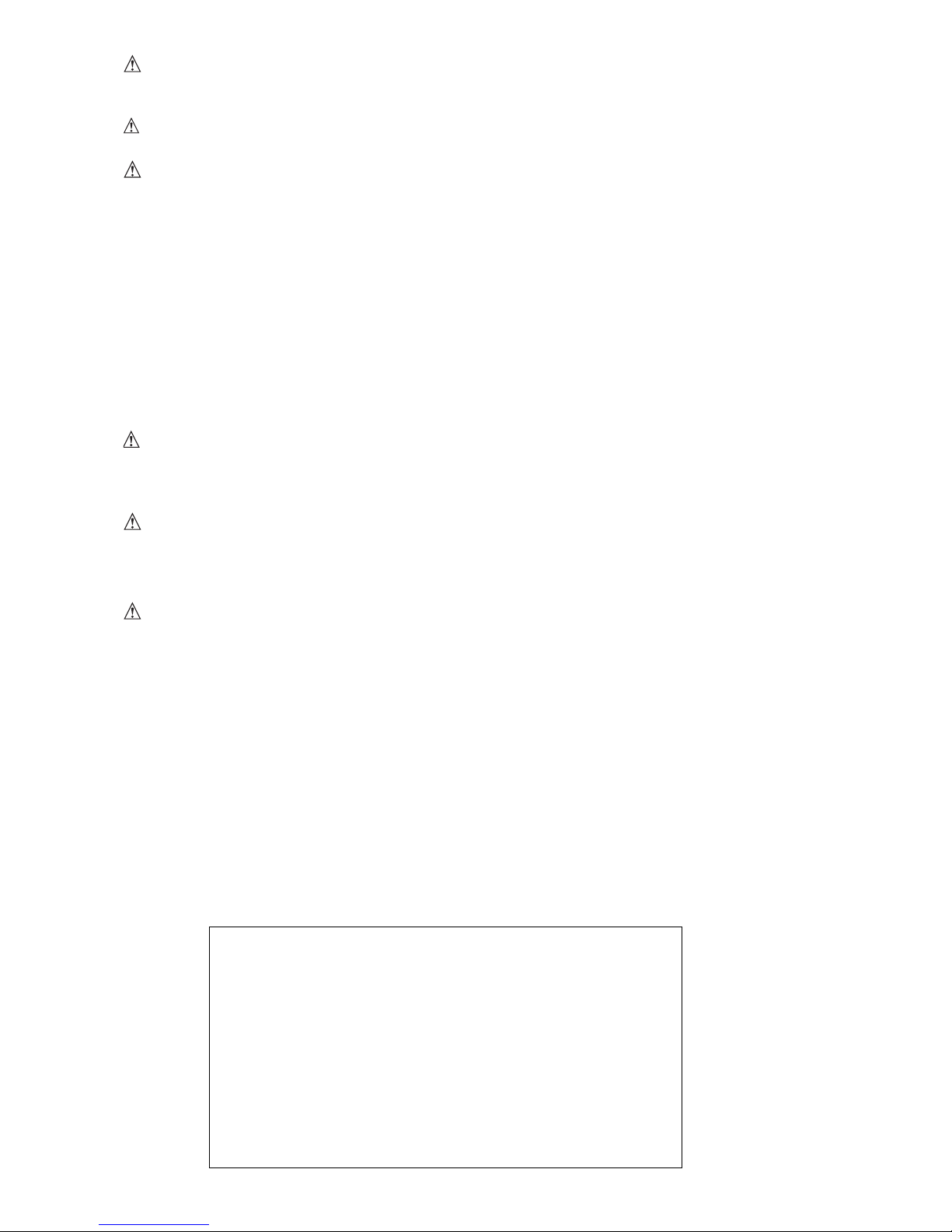

FEATURES

(FIGURES 1, 4)

A. Lock Chain

B. Spark deflector screw

C. Spark deflector

D. Base

E. Fence

F. Vise

G. Flat Wrench

H. Crank

I. Vise Lever

J. Wheel

K. Guard

L. Spindle Lock

M. Depth Stop Bolt and

Jam Nut

N. Trigger Switch

O. Padlock Hole

P. Fence Bolts

Q. Chain Hook

5

2.8

3

55

MAX. mm

Fig. 1

D

E

F

G

H

B

L

K

I

A

N

M

C

O

J

P

Q

Page 6

6

MAXIMUM CUTTING CAPACITY

NOTE: Capacity shown on chart assumes no wheel wear and optimum fence position.

Workpiece Shape:

A X B

90° CuttingAngle A= 4-7/8 in A= 4-1/2 in 4 1/2 in x 51/8in A= 4 1/2in x 5 3/8 in

(125mm) (115mm) (115mm x 130mm) (115mmx 137mm)

4 in x 7-5/8 in

(102mm x 188mm)

3 in x 7-3/8 in

(76mm x 229mm)

45° CuttingAngle A= 4-1/2 in A = 3-13/16 in 4 1/2 in x 313/16 in A= 3-13/16 in

(115mm) (98mm) 4 1/8 in x 33/4in 3-3/4 in

( 105mm x 95mm) (95mm)

STANDARD EQUIPMENT

1 14 inch (355mm) Metal Cutting Abrasive Wheel

1 Wheel Wrench

1 Instruction manual

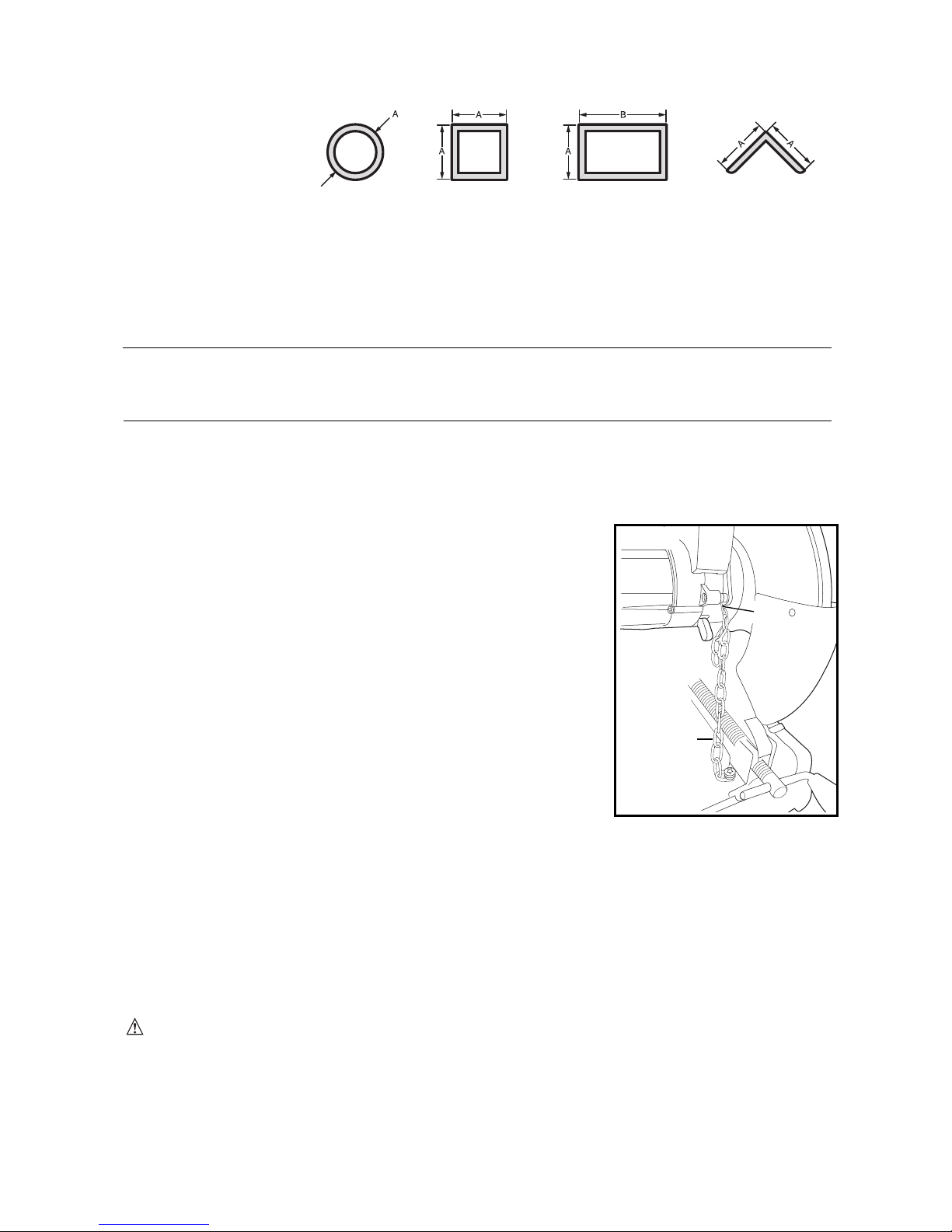

TO CARRY (FIG. 1a)

Fold down unit to position where you can carry the saw. Hook

lock chain (A) to chain hook (Q).

UNLOCKING (FIG. 1a)

To unlock tool and raise head, depress motor arm slightly and

unhook lock chain (A) from chain hook (Q). Motor arm will

then pivot upward.

SPARK DEFLECTOR ADJUSTMENT (FIG. 1)

To best deflect sparks away from surrounding persons and materials, loosen the screw (B),

adjust the spark deflector (C) and then retighten screw. Do not allow cordset to come into

contact with deflector or sparks as damage to cordset may occur.

DEPTH STOP (FIG. 1)

Depth stop is set at the factory for a new 14 inch (355mm) wheel to prevent wheel from

cutting into the supporting surface. To allow more depth of cut, use the flat wrench provided

(G) to loosen the depth stop bolt (M) and lower bolt to desired height and then turn jam nut

(M)clockwise until seated firmly on the casting. Securely tighten the depth stopbolt beforeuse.

CAUTION: When changing to a new wheel, readjust depth stop to original position to

prevent cutting into supporting surface.

TRIGGER SWITCH (FIG. 1)

To start the tool, depress the trigger switch (N). To turn the tool off, release the trigger

switch. Keep hands and material from wheel until it has coasted to a stop.

To prevent unauthorized use of tool, install a standard padlock (not included) into the

padlock hole (O) located in the trigger.

Fig. 1a

A

Q

Page 7

7

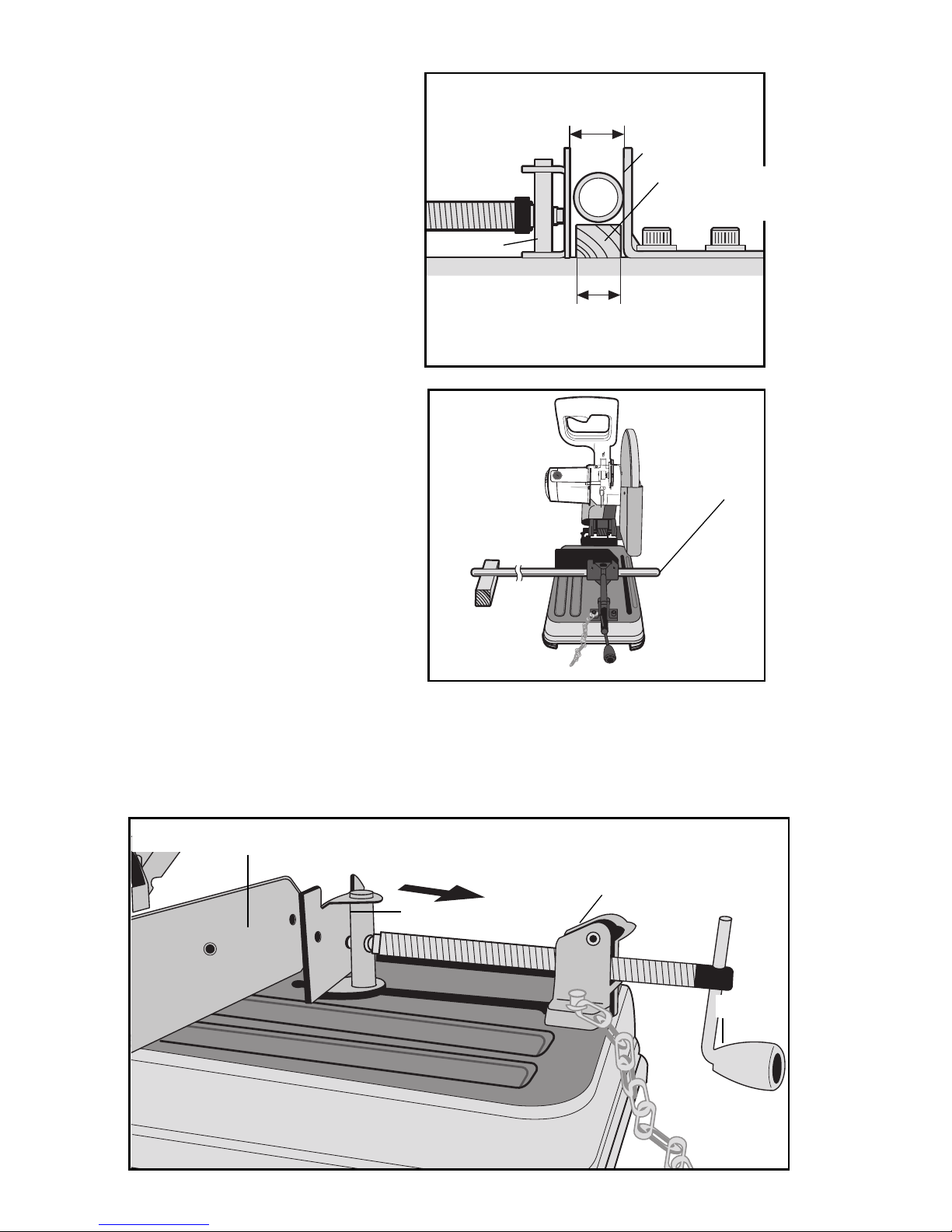

MATERIAL CLAMPING AND SUPPORTING (FIG. 2, 3)

• Angled material is best clamped and

cut with both legs resting against

base.

• A spacer block slightly narrower than

the workpiece can be used to

increase wheel utilization (Fig. 2).

• Long workpieces must be supported

by a block so it will be level with top

of base (Fig. 3). The cut off end

should be free to fall downward to

avoid wheel binding.

VISE OPERATION (FIG. 4)

The vise (F) has a quick-travel feature. To release the vise when it is clamped tightly, turn

the crank (H) counterclockwise one or two times to remove clamping pressure. Lift vise

lever (I) up. Pull crank assembly out as far as desired. Vise may be pushed forward into

work without cranking. Lower vise lever (I) then tighten vise (F) on work by using crank (H).

Fig. 2

WIDTH OF SPACER BLOCK

LARGEUR DE LA CALE DʼÉCARTEMENT

ANCHO DEL BLOQUE ESPACIADOR

DIAMETER OF WORKPIECE

DIAMÈTRE DE LA PIÈCE DE TRAVAIL

DIÁMETRO DE LA PIEZA DE TRABAJO

F

E

SPACER BLOCK

CALE DʼÉCARTEMENT

BLOQUE ESPACIADOR

Fig. 3

CUT-OFF END

EXTRÉMITÉ

COUPÉE

EXTREMO A

CORTAR

BLOCK

BLOC

BLOQUE

Fig. 4

H

I

F

E

FORWARD

MARCHE AVANT

HACIA ADELANTE

Page 8

8

FENCE OPERATION (FIG. 5, 6)

CAUTION: To reduce the risk of injury,

turn unit off and disconnect machine from

power source before installing and removing

accessories, before adjusting or changing

set-ups or when making repairs. Be sure the

trigger switch is in the OFF position. An

accidental start-up can cause injury.

The fence (E) can be adjusted two ways: to

change desired cutting angle and to change

spacing between the fence and vise.

TO CHANGE THE DESIRED CUTTING

ANGLE

Use the wrench provided to loosen (do not

remove) the two fence bolts (P). Align the

desired angle indicator line with the slot line

(Q) in the base (D). Securely tighten both

fence bolts before use. For more accurate

square cuts, disconnect the power supply,

loosen the two fence bolts, push arm down

until wheel extends into base. Place a square

against the wheel and adjust fence against

the square. Securely tighten both fence bolts

before use. When making a miter cut, the

vise (F) may not clamp securely, depending

on the thickness of the workpiece and the

miter angle. Other aids (such as spring, bar

or C-clamps) will be necessary to secure the

workpiece to the fence when making these

cuts.

TO CHANGE SPACING BETWEEN THE FENCE AND VISE

Using the wrench provided, loosen and remove the two fence bolts (P). Adjust the fence

(E) to desired locations. Insert both fence bolts in provided locations. Securely tighten both

fence bolts before use.

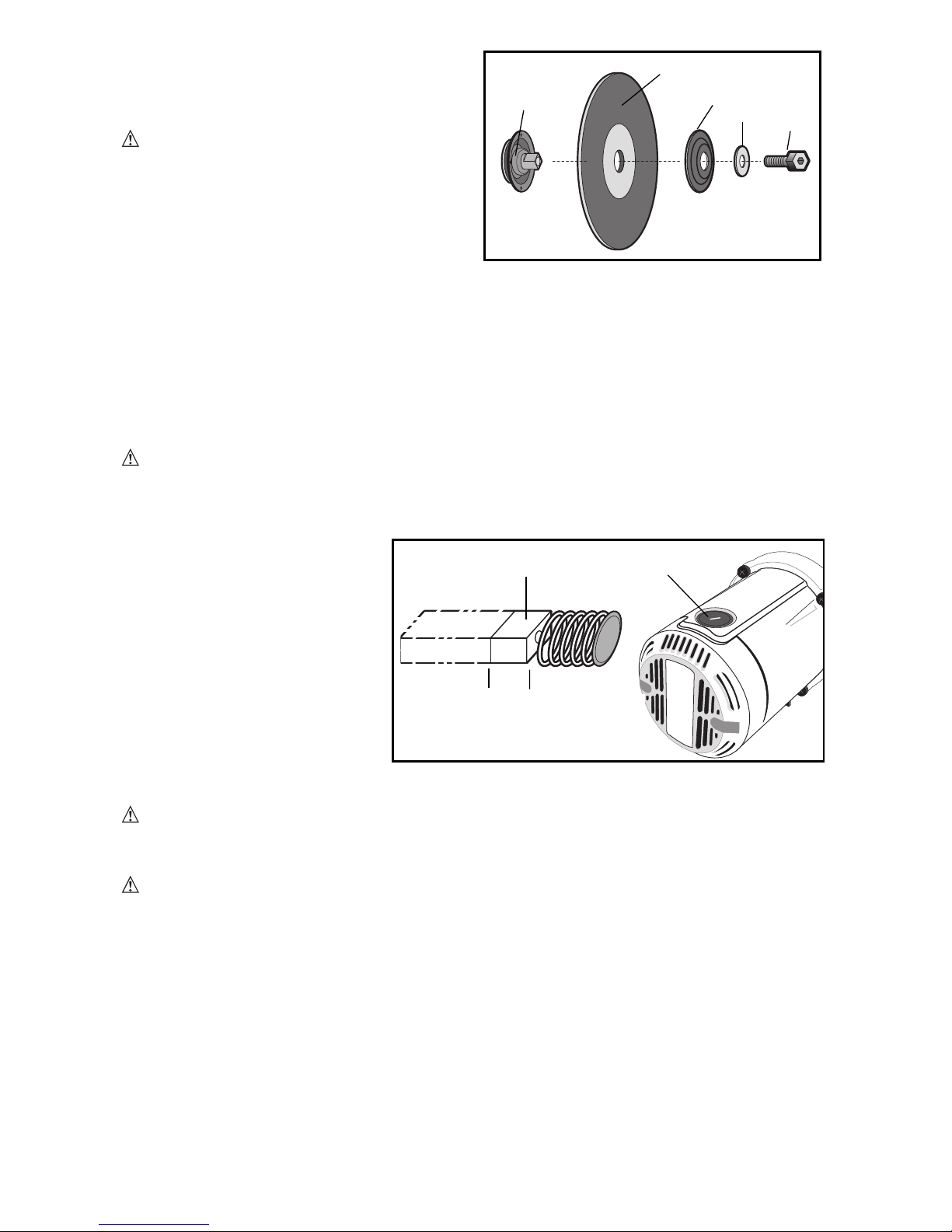

REMOVAL AND INSTALLATION OF WHEELS (FIG. 7, 8)

CAUTION: Turn off and unplug the tool

before making any adjustments or removing

or installing attachments or accessories. Be

sure the trigger switch is in the OFF

position. Do not make any adjustment while

the wheel is in motion.

Do not make any adjustment while chop saw is

plugged into power supply.

1. Push in wheel lock lever (L) and rotate

wheel (J) by hand until wheel lock lever

engages slot in inside flange (R) to lock

wheel. Loosen the bolt (S) counterclockwise

in the center of the abrasive wheel with the

included flat wrench (G). Bolt has right-hand

thread.

2. Remove the bolt (S), washer (T), outside

flange (U) and old wheel (J).

Fig. 6

Fig. 5

P

F

E

Q

D

Q

E

P

Fig. 7

L

Page 9

9

3. Make sure flange surfaces are clean and

flat. Install the new abrasive wheel by

reversing the above steps.

4. Do not overtighten bolt.

WARNING: Risk of personal injury.

Check the work surface that the chop saw

rests on when replacing with a new abrasive

wheel. It is possible that the wheel may

contact ANY ITEMS OR STRUCTURE THAT

EXTENDS ABOVE work surface (under the

base) when the arm is fully lowered.

OPERATION TIPS FOR MORE ACCURATE CUTS

• Allow the wheel to do the cutting. Excessive force will cause the wheel to glaze reducing

cutting efficiency and/or to deflect causing inaccurate cuts.

• Properly adjust fence angle.

• Make sure material is laying flat across base.

• Properly clamp material to avoid movement and vibration.

MAINTENANCE

MOTOR BRUSH INSPECTION AND REPLACEMENT (FIG. 9)

WARNING: To reduce the risk of injury, turn unit off and disconnect machine

from power source before installing and removing accessories, before adjusting or

changing set-ups or when making repairs. Be sure the trigger switch is in the OFF

position. An accidental start-up can cause injury.

Brushes should be regularly

inspected for wear. To inspect

brushes, remove brush cap (W).

Brushes (V) should slide freely in

brush box. If brushes are worn

down to .3 inch (8mm) as

shown in Figure 9 they should be

replaced. To reinstall, push new

brush back into brush

box. If replacing existing brush,

maintain same orientation as

when removed. Replace the

brush cap (do not overtighten).

CLEANING

WARNING: Blow dirt and dust out of the main housing with dry air as often as dirt

is seen collecting in and around the air vents. WearANSI Z87.1 (CAN/CSAZ94.3)

approved eye protection when performing this procedure.

CAUTION: When cleaning, use only mild soap and a damp cloth on plastic parts.

Many household cleaners contain chemicals which could seriously damage plastic. Also,

do not use gasoline, turpentine, lacquer or paint thinner, dry cleaning fluids or similar

products which may seriously damage plastic parts. Never let any liquid get inside the

tool; never immerse any part of the tool into a liquid.

REPAIRS

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment

should be performed by authorized service centers or other qualified service organizations,

always using identical replacement parts.

LUBRICATION

Closed-type, grease-sealed ball bearings are used throughout. These bearings have

sufficient lubrication packed in them at the factory to last the life of the chop saw.

F

ig. 8

R

J

U

T

S

Fig. 9

V

.3in (8mm)

8mm (3 po)

8mm (3 pulg)

w

Page 10

10

REPLACEMENT PARTS

Use only identical replacement parts. For a parts list or toorder parts, visit our service website at

www.stanleytools.com. You canalso order parts from your nearest Stanley FatMax Factory

Service Center or Stanley FatMax AuthorizedWarranty Service Center. Or, you cancall our

Customer Care Center at (800) 262 2161.

SERVICE AND REPAIRS

All quality tools will eventually require servicing and/or replacement of parts. For

information about Stanley FatMax, its factory service centers or authorized warranty

service centers, visit our website at www.stanleytools.com or call our Customer Care

Center at (800) 262 2161. All repairs made by our service centers are fully guaranteed

against defective material and workmanship. We cannot guarantee repairs made or

attempted by others.

You can also write to us for information at Stanley Tools, 701 E. Joppa Road, Towson,

Maryland 21286 - Attention: Product Service. Be sure to include all of the information

shown on the nameplate of your tool (model number, type, serial number, etc.).

ACCESSORIES

WARNING: Since accessories, other than those offered by Stanley FatMax have

not been tested with this product, use of such accessories with this tool could be

hazardous. To reduce the risk of injury, only Stanley FatMax recommended accessories

should be used with this product.

A complete line of accessories is available from your Stanley FatMax Factory Service

Center or a Stanley FatMax Authorized Warranty Service Center. Please visit our Web

Site www.stanleytools.com for a catalog or for the name of your nearest supplier.

THREE YEAR LIMITED WARRANTY

Stanley FatMax will repair or replace, without charge, any defects due to faulty materials or

workmanship for three years from the date of purchase for tools (two years for batteries). This

warranty does not cover part failure due to normal wear or tool abuse. For further detail

of warranty coverage and warranty repair information, visit www.stanleytools.com or

call (800) 262-2161. This warranty does not apply to accessories or damage caused

where repairs have been made or attempted by others. This warranty gives you specific

legal rights and you may have other rights which vary in certain states or provinces.

In addition to the warranty, Stanley FatMax tools are covered by our:

1 YEAR FREE SERVICE: Stanley FatMax will maintain the tool and replace worn parts

caused by normal use, for free, any time during the first year after purchase.

90 DAY MONEY BACK GUARANTEE: If you are not completely satisfied with the

performance of your Stanley FatMax Power Tool for any reason, you can return it within

90 days from the date of purchase with a receipt for a full refund – no questions asked.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For

products sold in Latin America, see country specific warranty information contained in

the packaging, call the local company or see website for warranty information.

To register your tool for warranty service visit our website at www.stanleytools.com

WARNING LABEL REPLACEMENT

If your warning labels become illegible or are missing, call (800) 262-2161 for a free

replacement.

Imported by

Stanley Tools

701 E. Joppa Road

Towson, Maryland 21286

Page 11

11

Troubleshooting Guide

TROUBLE! TOOL WILL NOT START

WHATʼS WRONG? WHAT TO DO…

1. Tool not plugged in. 1. Plug in saw.

2. Fuse blown or circuit breaker tripped. 2. Replace fuse or reset circuit breaker.

3. Cord damaged. 3. Have cord replaced by authorized

service center.

4. Brushes worn out. 4. Replace brushes.

TROUBLE! TOOL MAKES UNSATISFACTORY CUTS

WHATʼS WRONG? WHAT TO DO…

1. Glazed wheel. 1. Dress the wheel or replace with a

new one.

2. Workpiece incorrectly placed or clamped. 2. Firmly clamp and support workpiece.

TROUBLE! BLADE DOES NOT COME UP TO SPEED

WHATʼS WRONG? WHAT TO DO…

1. Extension cord too light or too long. 1. Replace with adequate size cord.

See chart on page 2.

2. Low voltage. 2. Contact your electric company.

3. Low generator voltage. 3. Check generator output voltage.

Reduce number of tools powered by

the generator.

TROUBLE! TOOL VIBRATES EXCESSIVELY DURING CUT

WHATʼS WRONG? WHAT TO DO…

1. Damaged wheel. 1. Replace wheel.

2. Workpiece not clamped properly. 2. Refer to Material Clamping and

Supporting page 8.

TROUBLE! DOES NOT MAKE ACCURATE CUTS

WHATʼS WRONG? WHAT TO DO…

1. Fence not adjusted correctly. 1. Check and adjust. See Fence

Operation on page 9.

2. Wheel is not square to fence. 2. Check and adjust.

3. Excessive force used to make cut. 3. Reduce cutting force, let the wheel

do the work.

4. Work piece moving. 4. Clamp workpiece securely. See

Material Clamping and

Supporting page 8. Make sure

material is laying flat against the base.

TROUBLE! MATERIAL MOVES DURING CUT

WHATʼS WRONG? WHAT TO DO…

1. Fence slipping or workpiece incorrectly 1. See Material Clamping and

placed or clamped. Supporting page 8.

2. Vise too loose 2. Tighten vise clamping.

3. Excessive cutting force. 3. Reduce cutting force.

For assistance with your product, visit our website at www.stanleytools.com. for a list of

service centers, or call the Stanley FatMax Customer Care Center at (800) 262-2161

Page 12

12

MANUEL D'INSTRUCTIONS

Scie fendeuse de 355 mm (14 po)

CONSERVER CE MANUEL POUR UN USAGE ULTÉRIEUR.

N° DE CATALOGUE

FME700

Page 13

13

Consignes de sécurité importantes

AVERTISSEMENT :

Lire,comprendreetsuivretoutesles directivesprécisées ci-

dessousafindʼéviterles risquesdechocélectrique, dʼincendieoudeblessuregrave.

CONSERVER CES DIRECTIVES

ZONE DE TRAVAIL

• Assurez-vous que votre espace de travail est propre et bien éclairé. Les bancs

encombrés et les endroits sombres sont souvent des causes dʼaccidents.

• Ne faites pas fonctionner d’outils électriques dans une atmosphère

inflammable, soit en présence de liquides inflammables, de gaz ou de

poussière. Les outils électriques produisent des étincelles qui peuvent enflammer la

poussière ou les vapeurs.

• Éloignez les curieux, les enfants et les visiteurs lorsque vous utilisez un outil

électrique. Une distraction pourrait vous en faire perdre la maîtrise.

SÉCURITÉ EN ÉLECTRICITÉ

• Les outils à double isolation sont dotés d’une fiche polarisée (dont une lame de

contact est plus large que l’autre). Cette fiche ne se branche que d’une seule

façon dans une prise de courant polarisée.

Si la fiche ne s’insère pas totalement dans la prise de courant, renversez-la. Si

elle ne s’insère toujours pas dans la prise, demandez à un électricien

compétent d’installer une fiche polarisée. Ne tentez pas de remplacer la fiche.

La double isolation élimine la nécessité dʼutiliser un cordon dʼalimentation muni dʼune

fiche à trois fils avec mise à la terre et un bloc dʼalimentation avec mise à la terre.

• Évitez tout contact physique avec des surfaces mises à la terre tels des tuyaux,

des radiateurs, des cuisinières et des réfrigérateurs. Le risque dʼélectrocution est

plus élevé lorsque votre corps est mis à la terre.

• Ne laissez pas vos outils électriques sous la pluie ou dans un environnement

humide. Une infiltration dʼeau dans un outil électrique augmente le risque

dʼélectrocution.

• Faites attention au cordon électrique. Ne l’utilisez pas pour transporter l’outil.

Ne tirez jamais sur le cordon pour le débrancher de la prise de courant.

Éloignez le cordon électrique de la chaleur, de l’huile, des bords tranchants ou

des pièces mobiles. Remplacez immédiatement tout cordon électrique

endommagé. Un cordon endommagé peut provoquer une électrocution.

• Lorsqu’on utilise un outil électrique à l’extérieur, on ne doit utiliser que des

rallonges conçues pour cet usage, comme celles de type « W-A » ou « W », afin

de réduire les risques de choc électrique.

SÉCURITÉ PERSONNELLE

• Soyez vigilant, faites attention à ce que vous faites et faites preuve de jugement

lorsque vous utilisez un outil électrique. N’utilisez pas un outil lorsque vous

LIGNES DIRECTRICES EN MATIÈRE DE SÉCURITÉ - DÉFINITIONS

Il est important que vous lisiez et compreniez ce mode dʼemploi. Les informations

quʼil contient concernent VOTRE SÉCURITÉ et visent à ÉVITER TOUT PROBLÈME.

Les symboles ci-dessous servent à vous aider à reconnaître cette information.

DANGER : Indique une situation dangereuse imminente qui, si elle nʼest pas évitée,

causera la mort ou des graves blessures.

AVERTISSEMENT : Indique une situation potentiellement dangereuse qui, si elle

nʼest pas évitée, pourrait causer la mort ou de graves blessures.

MISE EN GARDE : Indique une situation potentiellement dangereuse qui, si elle

nʼest pas évitée, pourrait causer des blessures mineures ou modérées.

MISE EN GARDE : Utilisé sansle symbole dʼalerteà la sécurité, indiqueunesituation

potentiellementdangereusequi, sielle nʼestpasévitée, peutrésulteren des dommagesà lapropriété.)

Page 14

14

êtes fatigué ou lorsque vous avez pris de la drogue, de l’alcool ou des

médicaments. Un moment dʼinattention, lorsque vous utilisez un outil électrique, peut

se solder par des blessures sérieuses.

• Habillez-vous en conséquence. Ne portez pas de vêtements amples ni de bijoux

qui pourraient s'enchevêtrer quelque part. Attachez les cheveux longs. Gardez

les cheveux, les vêtements et les gants à l'écart des pièces mobiles. Les

vêtements amples, bijoux ou cheveux longs pourraient s'enchevêtrer dans les pièces

mobiles. Tenez-vous à l'écart des évents, car ils couvrent des pièces mobiles.

• Attention de ne pas mettre l’outil en marche accidentellement. Assurez-vous

que l’interrupteur est en position d’arrêt avant de brancher l’outil. Il est très

dangereux de transporter un outil en gardant le doigt sur lʼinterrupteur ou de le

brancher lorsque lʼinterrupteur est enclenché.

• Retirez les clés de réglage ou les clés à molette avant de mettre l’outil en

marche. Une clé à molette ou une clé de réglage attachée à une partie pivotante peut

causer des blessures.

• Ne tendez pas trop les bras. Conservez votre équilibre en tout temps. Un

équilibre convenable vous permettra de maîtriser lʼoutil en situation inattendue.

• Utilisez de l’équipement de sécurité. Portez toujours des verres protecteurs.

Selon les conditions, portez un masque anti-poussières, des souliers antidérapants,

un casque de sécurité ou des protecteurs dʼoreilles.

UTILISATION ET ENTRETIEN DE L’OUTIL

• Utilisez des attaches ou tout autre système permettant de soutenir et de retenir

la pièce sur laquelle vous travaillez sur une plate-forme stable. En retenant la

pièce avec la main ou contre votre corps, vous risquez de perdre votre emprise.

• Ne forcez pas l’outil. Utilisez le bon outil. Le bon outil effectuera le travail de la

bonne façon et en toute sécurité.

• N’utilisez pas l’outil si l’interrupteur ne fonctionne pas. Tout outil dont

lʼinterrupteur ne fonctionne pas est dangereux et doit être réparé.

• Débranchez la fiche du bloc d’alimentation avant de faire quelque ajustement

que ce soit, de changer d’accessoire ou de ranger l’outil. Une telle mesure de

sécurité préventive réduit le risque de mettre lʼoutil en marche accidentellement.

• Rangez les outilshors de laportée des enfants et des personnes sans expérience. Les

outils deviennent des appareils très dangereux dans des mains inexpérimentées.

• Prenez soin de vos outils. Assurez-vous que vous outils coupants sont aiguisés

et propres. Lorsque vous les entretenez correctement, vos outils tranchants

accrochent moins et sont plus faciles à maîtriser.

• Vérifiez que les pièces mobiles ne sont pas désalignées, tordues, brisées ou

dans un état qui pourrait affecter l’utilisation de l’outil. Si elles sont

endommagées, faites réparer l’outil avant de l’utiliser. Beaucoup dʼaccidents sont

causés par des outils mal entretenus.

• N’utilisez que les accessoires conseillés par le fabricant pour le modèle de

votre outil. Des accessoires qui conviennent à un outil peuvent devenir dangereux

lorsquʼils sont utilisés avec un autre outil.

RÉPARATION

• La réparation d’outils doit être exécutée uniquement par un personnel de

réparation formé. Toute réparation ou tout entretien réalisé par un personnel non

formé peut causer un risque de blessures.

• Pour réparer un outil, n’utilisez que des pièces de rechange identiques. Suivez

les directives figurant à la section « Entretien » du mode d’emploi. Lʼutilisation

de pièces non autorisées ou le fait de ne pas suivre les directives dʼentretien, peut

entraîner un risque de choc électrique ou de blessure corporelle.

Règles de sécurité additionnelles relativesaux scies fendeuses

• Toujours porter des lunettes de protection et un appareil respiratoire

antipoussières adéquats.

• Avant toute utilisation, vérifier que le disque de tronçonnage ne comporte ni

fissures ni défauts. Dans lʼaffirmative, mettre le disque au rebut. Inspecter aussi

le disque chaque fois que lʼon suspecte que lʼoutil a fait une chute. Tout défaut

pourrait provoquer la casse du disque.

• Avant de redémarrer lʼoutil équipé dʼun disque neuf ou de rechange ou si lʼon

nʼest pas sûr de la condition du disque, faire fonctionner lʼoutil pendant une

minute en sʼassurant dʼen être bien protégé. Si le disque est affecté dʼune fêlure ou

Page 15

15

dʼun défaut caché, il devrait éclater en moins dʼune minute. Ne jamais démarrer lʼoutil

lorsque quelquʼun se tient directement devant le disque. y compris lʼutilisateur,

• Pendant le fonctionnement, protéger le disque contre tout choc ou traitement

brutal. Dans cette éventualité, arrêter lʼoutil et vérifier que le disque de tronçonnage ne

comporte ni fissures ni défauts.

• Nettoyer la scie fendeuse régulièrement en suivant la procédure inclue dans ce manuel.

• Ne jamais retirer les protèges disque ou la base.

• TOUJOURS UTILISER UN ÉTAU OU TOUT AUTRE DISPOSITIF DE FIXATION

POUR ARRIMER SOLIDEMENT LA PIÈCE À DÉCOUPER. Tout autre dispositif, tels

pinces à ressort, serre-joints à coulisse ou étaux en C, peut être approprié selon la

taille ou la forme de la pièce à travailler. Choisir et installer soigneusement ces

dispositifs de fixation puis faire fonctionner lʼoutil à vide avant de commencer à découper.

• Nʼutiliser que des disques de type 1 de 355 mm (14 po) conçus pour un régime

minimal de 4300 r/min.

• Laisser toute pièce découpée refroidir avant toute manipulation.

• Ne pas tenter de découper bois ou plastique avec cet outil.

• NE JAMAIS DÉCOUPER DE MAGNÉSIUM AVEC CET OUTIL.

• Utiliser la scie fendeuse dans un endroit bien ventilé.

• Arrêter la scie fendeuse avant de retirer aucune pièce de sa base.

• NE DÉCOUPER AUCUN MATÉRIAU SOUS TENSION.

• Ne jamais utiliser de lames pour scie circulaire avec cet outil, ni de lames

dentées, afin dʼéviter les risques de blessure grave.

• NE PAS UTILISER CET OUTIL PRÈS DE LIQUIDES, DE GAZ OU DE POUSSIÈRES

INFLAMMABLES. Des étincelles ou copeaux brûlants, ou les balais incandescents du

moteur pourraient enflammer des matériaux combustibles.

• Nepas utiliser le côté du disque abrasif comme une meule à ébarboir. Cela affaiblirait

considérablement le disqueposant ainsi des risques à lʼutilisateur. Le disque pourrait se casser.

MISE EN GARDE : Porter un dispositif de protection personnel anti-bruit

approprié durant lʼutilisation. Sous certaines conditions et selon la durée dʼutilisation, le

bruit émanant de ce produit pourrait contribuer à la perte dʼaudition.

MISE EN GARDE : Le pare-étincelles deviendra chaud. Éviter de toucher ou de

régler l'outil lorsqu'il est chaud. Tenez le cordon amovible et le matériel loin du pare-étincelles.

AVERTISSEMENT : Certains outils électriques, tels que les sableuses, les scies,

les meules, les perceuses ou autres outils de construction peuvent produire des poussières

contenant des produits chimiques reconnus par lʼétat californien pour causer cancers,

malformations congénitales ou être nocifs au système reproductif. Parmi ces produits

chimiques, on retrouve :

• le plomb dans les peintures à base de plomb,

• la silice cristallisée dans les briques et le ciment ou autres articles de maçonnerie, et

• lʼarsenic et le chrome dans le bois ayant subi un traitement chimique (ACC).

Le risque associé à de telles expositions varie selon la fréquence à laquelle on effectue

ces travaux. Pour réduire toute exposition à ces produits : travailler dans un endroit bien

aéré, en utilisant le matériel de sécurité approprié tel un masque antipoussières

spécialement conçu pour filtrer les particules microscopiques.

• Éviter tout contact prolongé avec la poussière soulevée par cet outil ou autres

outils électriques. Porter des vêtements de protection et nettoyer les parties

exposées du corps à lʼeau savonneuse. Sʼassurer de bien se protéger afin dʼéviter

dʼabsorber par la bouche, les yeux ou la peau des produits chimiques nocifs.

AVERTISSEMENT : lʼutilisation decet outilpeutproduire et/oudégagerdes poussières

pouvant causerdes problèmes respiratoiresgravesetpermanents ou dʼautresproblèmes

médicaux. Toujours porterunappareil respiratoire approuvépar laNIOSH/OSHApourseprotéger

delapoussière.Dirigerles particulesloinduvisage etducorps.

Page 16

Lʼétiquette apposée sur votre outil pourrait comprendre les symboles suivants. Les

symboles et leurs définitions sont indiqués ci-après :

V ....................................volts A..........................ampères

Hz ..................................hertz W ........................watts

min..................................minutes ......................courant

alternatif

................................courant continu

n

o ........................sous vide

....................................

construction de classe II

........................borne de terre

..................................symbole d´avertissement .../minorrpm ..........tours ou

courses à la minute

SANS FIL

Sʼassurer que le bloc dʼalimentation est compatible avec lʼinscription de la plaque

signalétique. Une diminution de tension de plus de 10 % provoquera une perte de

puissance et une surchauffe.

CAPACITÉ DE COUPE

La grande ouverture de lʼétau et le point de pivotement élevé permettent de couper

beaucoup de grosses pièces. Consulter le tableau sur la capacité de coupe pour déterminer

la dimension maximale totale des coupes pouvant être réalisées à lʼaide dʼune meule neuve.

MISE EN GARDE : CERTAINS OBJETS QUI SONT GROS, CIRCULAIRESOU DE

FORME IRRÉGULIÈRE, PEUVENT NÉCESSITER DES DISPOSITIFS DE RETENUE

SUPPLÉMENTAIRES S’ILS NE PEUVENT ÊTRE BIEN RETENUS DANSUN ÉTAU.

MISE EN GARDE : NE PAS COUPER DU MAGNÉSIUM AVEC CET OUTIL.

16

AVERTISSEMENT : Toujours utiliser un appareil respiratoire antipoussières

approprié approuvé par le NIOSH ou lʼOSHA. Diriger les particules dans le sens opposé

du visage et du corps. Pour des raisons de commodités et de sécurité, les étiquettes

suivantes sont apposées sur votre scie fendeuse à service intensif de 355mm (14 po.)

AVERTISSEMENT :

POURVOTRESÉCURITÉ, LIRE LEMANUELDELʼUTILISATEUR.

• NE PAS UTILISER DE LAMES DENTÉES.

• NʼUTILISER QUE DES DISQUES RENFORCÉS CONÇUS POUR UN RÉGIME

MINIMAL DE 4300 R/MIN.

• LORSDE LʼENTRETIEN, NʼUTILISER QUE DES PIÈCES DE RECHANGE IDENTIQUES.

• TOUJOURS : PORTER DES LUNETTES DE PROTECTION, UTILISER UN

DISPOSITIF DE PROTECTION, MAINTENIR LA PIÈCE À TRAVAILLER DANS UN

ÉTAU, UTILISER UN APPAREIL RESPIRATOIRE ANTIPOUSSIÈRES ADÉQUAT.

• NEPASEXPOSERLʼOUTILÀ LAPLUIENILʼUTILISER DANSDES ENDROITSHUMIDES.

• En cas dʼutilisation dʼune

rallonge, sʼassurer que les

valeurs nominales de la

rallonge utilisée

correspondent bien à celles

de lʼoutil alimenté. Lʼusage

dʼune rallonge de calibre

insuffisant causera une

chute de tension entraînant

perte de puissance et

surchauffe. Le tableau cidessous illustre les calibres

à utiliser selon la longueur

de rallonge et lʼintensité

nominale indiquée sur la

plaque signalétique. En cas de doutes, utiliser le calibre suivant. Plus le calibre est petit,

plus la rallonge peut supporter de courant.

2.8

355

MAX. mm

Calibre minimal des cordons de rallonge

Tension Longueur totale du cordon en pieds

120V 0-25 26-50 51-100 101-150

(0-7,6m) (7,6-15,2m) (15,2-30,4m) (30,4-45,7m)

240V 0-50 51-100 101-200 201-300

(0-15,2m) (15,2-30,4m)(30,4-60,9m) (60,9-91,4m)

Intensité (A)

Au Au Calibre moyen des fils (AWG)

moins plus

0-6 18 16 16 14

6-10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Non recommandé

Page 17

17

CARACTÉRISTIQUES (FIG. 1, 4)

A. Chaîne de retenue

B. Vis de pare-étincelles

C. Pare-étincelles

D. Base

E. Guide

F. Étau

CAPACITÉ DE COUPE MAXIMALE

REMARQUE : la capacité indiquée dans le tableau ne tient pas compte de lʼusure de la

meule ni de la position optimale du guide.

Forme de la pièce :

A X B

Angle de coupe de 90° A = 125 mm A= 115 mm 115 mm x 130mm A= 115mm x 137 mm

(4 7/8 po) (4 1/2po) (4 1/2 po x 51/8po) (4 1/2 po x 5 3/8 po)

102 mm x 188 mm

(4 po x 7 5/8 po)

76 mm x 229 mm

(3 po x 7 3/8 po)

Angle de coupe de 45° A = 115 mm A = 98 mm 105mm x 95 mm A =95 mm

(4 1/2 po) (3 13/16 po) (4 1/2po x 3 13/16) (3 3/4 po)

(4 1/8 po x 3 3/4 po) (3-13/16 po)

ÉQUIPEMENT STANDARD

1 meule de tronçonnage des métaux de 355 mm (14 po),

1 clé pour meule, 1 mode dʼemploi

POUR TRANSPORTER (FIG. 1a)

Replier en deux lʼappareil à la position vous permettant de transporter la scie. Accrocher la

chaîne de retenue (A) au crochet pour chaîne (Q).

DÉVERROUILLAGE (FIG. 1a)

Pour déverrouiller lʼoutil et monter la tête, abaisser légèrement le bras du moteur, puis

décrocher la chaîne de retenue (A) du crochet pour chaîne (Q). Le bras du moteur pivotera

ensuite vers le haut.

RÉGLAGE DU PARE-ÉTINCELLES (FIG. 1)

Pour protéger toute personne ou matériel près des étincelles, dévisser la vis (B), régler le

déflecteur dʼétincelles (C) puis resserrer la vis. Ne pas laisser le cordon amovible entrer en

contactavecle pare-étincelles oulesétincelles, car le cordon amovible risque dʼêtre endommagé.

BUTÉE DE PROFONDEUR (FIG. 1)

La butée dʼarrêt est réglée à lʼusine à lʼintention dʼune meule neuve de 355 mm (14 po) pour

éviter que la meule ne coupe la surface portante. Pour augmenter la profondeur de coupe,

utiliser la clé plate fournie (G) pour desserrer le boulon (M) de la butée de profondeur et le

baisser à la hauteur désirée, puis tourner le contre-écrou (M) dans le sens horaire jusquʼà

ce quʼil soit bien serré contre le moulage. Bien serrer le boulon de la butée de profondeur

avant usage.

MISE EN GARDE : Au montage dʼune meule neuve, remettre le blocage de la

profondeur à la position originale pour éviter de couper la surface portante.

DÉTENTE (FIG. 1)

Pour démarrer lʼoutil, presser la détente (N). Pour lʼéteindre, simplement la relâcher. Tenir

G. Clé plate

H. Manivelle

I. Levier dʼétau

J. Meule

K. Garde protecteur

L. Dispositif de verrouillage

de la broche

M. Boulon et écrou de blocage

de la profondeur

N. Détente

O. Orifice pour cadenas

P. Boulons du guide

Q. Crochet pour chaîne

Page 18

18

les mains et les matériaux éloignés de la meule jusquʼà ce que cette dernière se soit

arrêtée complètement. Pour éviter toute utilisation non permise de lʼoutil, poser un

cadenas standard (non inclus) dans lʼorifice pour cadenas (O) situé dans la détente.

SERRAGE ET SOUTIEN DU MATÉRIAU (FIG. 2, 3)

• Il est plus facile de serrer et de couper les pièces angulaires si les deux montants

reposent contre la base.

• On peut utiliser une cale dʼécartement légèrement plus étroite que la pièce pour pouvoir

utiliser davantage la meule (fig. 2).

• Les pièces longues doivent être soutenues par une cale de manière à être alignées avec

le dessus de la base (fig. 3). Lʼextrémité coupée doit être libre de pouvoir tomber afin

dʼéviter tout grippage de la meule.

UTILISATION DE L’ÉTAU (FIG. 4)

Lʼétau (F) comprend une fonction de marche rapide. Pour dégager lʼétau lorsquʼil est

fortement serré, tourner la manivelle (H) une ou deux fois, dans le sens antihoraire, pour

libérer la pression de serrage. Soulever le levier de lʼétau (I). Tirer la manivelle aussi loin

que possible. Lʼétau peut être poussé vers lʼavant contre la pièce sans utiliser la manivelle.

Baisser le levier de lʼétau (I), puis serrer lʼétau (F) sur la pièce à lʼaide de la manivelle (H).

UTILISATION DU GUIDE (FIG. 5, 6)

MISE EN GARDE : Éteindre et débrancher l’outil avant d’effectuer tout

réglage ou d’enlever ou installer tout accessoire. S’assurer que l’interrupteur est en

position d’arrêt. Il est possible dʼajuster le guide (E) de deux façons : pour le mettre à

lʼangle de coupe désiré et pour régler lʼespacement entre le guide et lʼétau.

RÉGLAGE À L’ANGLE DE COUPE DÉSIRÉ

Utiliser la clé fournie pour desserrer les deux boulons du guide (P) (sans les enlever).

Aligner le trait désiré de lʼindicateur dʼangle avec la fente (Q) dans la base (D). Bien serrer

les deux boulons du guide avant usage. Pour accroître la précision des coupes carrées,

couper lʼalimentation, desserrer les deux boulons du guide et abaisser le bras jusquʼà ce

que la meule passe la base. Placer une équerre contre la meule et régler le guide de manière à

être contre lʼéquerre. Bien serrer les deux boulons du guide avant usage. Lors dʼune coupe

à onglet, il se peut que lʼétau (F) serre mal selon lʼépaisseur de la pièce et lʼangle dʼonglet.

Dʼautres accessoires (comme des pinces à ressort, des serres à barre ou des serre-joints

en C) sont nécessaires pour immobiliser la pièce sur le guide lors de telles coupes.

RÉGLAGE DE L’ESPACEMENT ENTRE LE GUIDE ET L’ÉTAU

À lʼaide de la clé fournie, desserrer et retirer les deux boulons du guide (P). Régler le guide

(E) aux emplacements désirés. Insérer les deux boulons du guide aux emplacements

prévus. Bien serrer les deux boulons du guide avant usage.

DÉPOSE ET INSTALLATION DES MEULES (FIG. 7, 8)

MISE EN GARDE : Éteindre et débrancher l’outil avant d’effectuer tout

réglage ou d’enlever ou installer tout accessoire. S’assurer que l’interrupteur est en

position d’arrêt. Ne pas effectuer de réglage tandis que la meule tourne.

Nepas effectuer de réglage tandis que la scie fendeuse estbranchée à la source dʼalimentation.

1. Enfoncer le levier de verrouillage de la meule (L), puis tourner la meule (J)

manuellement de manière à ce que le levier engage la fente, logée dans la bride

intérieure (R), pour verrouiller la meule. Desserrer le boulon (S) dans le sens

antihoraire au centre de la meule abrasive avec la clé plate comprise (G). Le boulon

est pourvu dʼun filetage à droite.

2. Retirer le boulon (S), la rondelle (T), la bride externe (U) et la vieille meule (J).

3. Sʼassurer que la surface de la bride est propre et plate. Installer la nouvelle meule

abrasive en inversant les étapes précédentes.

4. Ne pas serrer le boulon de manière excessive.

AVERTISSEMENT : Vérifier la surface de travail sur laquelle repose la scie

fendeuse au moment de remplacer la meule abrasive par une neuve. Il est possible que

la meule entre en contact avec TOUT OBJET OU STRUCTURE (se trouvant sous la

base) QUI DÉPASSE la surface de travail lorsque le bras est complètement descendu.

CONSEILS D’UTILISATION POUR DES COUPES PLUS PRÉCISES.

• Laisser la meule réaliser la coupe. Toute force excessive exercée sur la meule la rendra

glacée réduisant ainsi le rendement de coupe et/ou la fera dévier, ce qui entraînera des

coupes imprécises.

• Bien régler lʼangle du guide.

Page 19

19

• Sʼassurer que le matériau repose à plat sur la base.

• Bien serrer le matériau pour éviter quʼil ne se déplace ou ne vibre.

ENTRETIEN

INSPECTION ET REMPLACEMENT DES BALAIS DU MOTEUR (FIG. 9)

AVERTISSEMENT : Mettre l’outil hors tension et le débrancher. S’assurer

que l’interrupteur est en position d’arrêt.

Il importe dʼinspecter régulièrement les balais pour en vérifier lʼusure. Pour inspecter les

balais, retirer le capuchon du balai (W). Les balais (V) doivent pouvoir glisser librement

dans la cage à balais. Si les balais sont réduits par lʼusure à 8 mm (0,3 po) comme sur la

figure 9, il faut les remplacer. Pour une réinstallation, remettre les balais neufs dans la cage

à balais. Pour remettre en place le même balai, conserver la même orientation quʼau

moment de lʼenlever. Remettre le capuchon du balai (ne pas trop serrer).

NETTOYAGE

AVERTISSEMENT : nettoyer la saleté et la poussière du boîtier principal à lʼair

sec dès que vous voyez la saleté sʼaccumuler à lʼintérieur des évents et autour de ceux-ci.

Porter un dispositif de protection oculaire conforme à la norme ANSI Z87.1 (CAN/CSA

Z94.3) au moment dʼexécuter cette procédure.

MISE EN GARDE : lors du nettoyage des pièces en plastique, utiliser

uniquement du savon doux et un chiffon humide. Bon nombre de nettoyants domestiques

renferment des produits chimiques pouvant grandement endommager le plastique. En

outre, ne pas utiliser dʼessence, de térébenthine, de diluant à peinture-laque, de liquides

pour nettoyage à sec ou tout autre produit semblable qui pourrait endommager

gravement les composants en plastique. Ne jamais laisser de liquide pénétrer dans lʼoutil

et nʼimmerger aucune partie de lʼoutil dans un liquide.

RÉPARATIONS

Pour garantir la SÉCURITÉ et la FIABILITÉ du produit, les réparations, lʼentretien et le

réglage doivent être réalisés par un centre de réparation autorisé ou tout autre centre de

réparation professionnel, et des pièces de rechange identiques doivent toujours être utilisées.

LUBRIFICATION

Les roulements à billes fermés retenus de graisse sont utilisés dʼun bout à lʼautre de lʼoutil.

Ces roulements ont reçu suffisamment de lubrifiant en usine pour durer toute la vie utile de

la scie fendeuse.

PIÈCES DE RECHANGE

Utiliser seulement des pièces de rechange identiques. Pour obtenir une liste des

pièces ou pour en commander, consulter notre site Web de réparation à lʼadresse

suivante : www.stanleytools.com. Il est également possible de commander des

pièces auprès du centre de réparation en usine Stanley FatMax ou du centre de

réparation sous garantie agréé Stanley FatMax le plus proche. Sinon, appeler notre

service à la clientèle au 800 262-2161.

ENTRETIEN ET RÉPARATION

Tous les outils de qualité finissent par demander un entretien ou un changement de

pièce. Pour de plus amples renseignements à propos de Stanley FatMax, ses centres

de réparation en usine ou ses centres de réparation sous garantie agréés, visiter son site

Web à lʼadresse suivante : www.stanleytools.com ou communiquer avec son centre de

service à la clientèle en composant le 800 262-2161. Toutes les réparations effectuées

dans nos centres de réparation sont entièrement garanties contre les défauts de

matériaux et de main-dʼœuvre. Nous ne pouvons garantir les réparations effectuées en

partie ou totalement par dʼautres.

Vous pouvez aussi nous écrire pour obtenir de lʼinformation à lʼadresse suivante : Stanley

Tools, 701 E. Joppa Road, Towson, Maryland 21286 - Attention: Product Service.

Sʼassurer dʼindiquer toutes les informations figurant sur la plaque signalétique de lʼoutil

(numéro du modèle, type, numéro de série, etc.).

Page 20

20

Guide de depannage

PROBLEME! LʼOUTIL REFUSE DE DEMARRER

RAISONS ACTION

1. Lʼappareil nʼest pas branché. 1. Brancher la scie.

2. Un fusible a sauté ou le circuit a disjoncté. 2. Changer le fusible ou réenclencher

le disjoncteur.

3. Le cordon est endommagé. 3. Faire remplacer le cordon par un

centre de service autorisé.

4. Les balais sont usés. 4. Changer les balais.

PROBLEME! LES COUPESEFFECTUEES PAR LʼOUTIL NE SONT PAS SATISFAISANTES

RAISONS ACTION

1. Disque glacé. 1. Corroyer le disque ou le changer.

2. Pièce disposée ou arrimée incorrectement. 2. Arrimer et supporter fermement la

pièce.

PROBLEME! LE DISQUE NʼARRIVE PAS A PRENDRE SA VITESSE NORMALE

RAISONS ACTION

1. Rallonge de mauvais calibre ou trop longue. 1. Utiliser le cordon au calibre

adéquat. Se reporter à la planche en page 14.

2. Tension trop faible. 2. Contacter votre compagnie

dʼélectricité.

3. Générateur de tension faible. 3. Vérifier le générateur de tension.

Réduire le nombre dʼoutils

utilisés avec le générateur.

PROBLEME! LʼOUTIL VIBRE DE FAÇON EXCESSIVE PENDANT LA COUPE

RAISONS ACTION

1. Le disque est endommagé. 1. Changer le disque.

2. La pièce nʼest pas arrimée correctement. 2. Se reporter à la section Arrimage et

support des matériaux en page 19.

PROBLEME! LES COUPES NE SONT PAS PRECISES

RAISONS ACTION

1. Le guide nʼest pas réglé correctement. 1. Vérifier et ajuster. Se reporter à la

sectionUtilisation du guide en page 19.

2. Le disque nʼest pas dʼéquerre avec le guide. 2. Vérifier et ajustert.

3. Une force excessive est utilisée pour 3. Réduire la force utilisée et laisser le

effectuer la coupe. disque faire le travail.

4. La pièce à travailler bouge. 4. Arrimer la pièce solidement. Se

reporter à la section Arrimage et

support des matériaux en page 19.

Sʼassurer que le matériau est bien à

plat contre la base.

PROBLEME! LE MATERIAU BOUGE PENDANT LA COUPE

RAISONS ACTION

1. Le guide glisse ou la pièce est arrimée 1. Se reporter à la section Arrimage

ou placée incorrectement. et support des matériaux en page 19.

2. Lʼétau est trop lâche. 2. Resserrer lʼétau.

3. La force utilisée est excessive. 3. Réduire la force utilisée.

Pour obtenir de lʼaide relativement au produit, consulter notre site Web à lʼadresse

suivante : www.stanleytools.com pour obtenir une liste des centres de réparation ou

appeler le centre de service à la clientèle de Stanley FatMax au 800 262-2161.

ACCESSOIRES

AVERTISSEMENT : Puisque les accessoires autres que ceux offerts par Stanley

FatMax nʼont pas été testés avec ce produit, lʼutilisation de ceux-ci avec lʼoutil pourrait

sʼavérer dangereuse. Pour réduire le risque de blessures, utiliser exclusivement les

accessoires Stanley FatMax recommandés avec le produit. Les centres de réparation

de lʼusine Stanley FatMax ou les centres de réparation sous garantie autorisés

Stanley FatMax sont en mesure de vous fournir la gamme complète dʼaccessoires.

Consulter le site Web www.stanleytools.com pour obtenir un catalogue ou le nom du

fournisseur local.

Page 21

21

GARANTIE RESTREINTE DE TROIS ANS

Stanley FatMax réparera ou remplacera gratuitement les outils défectueux présentant

des défauts de matériau ou de fabrication pendant trois ans à compter de la date dʼachat

des outils (garantie de deux ans pour les blocs-piles). Cette garantie ne couvre pas des

défaillances de pièce dues à une usure normale ou à une mauvaise utilisation de lʼoutil.

Pour plus de détails relatifs à la couverture de la garantie et aux réparations sous

garantie, visitez le site Web www.stanleytools.com ou composez le 800 262-2161. Cette

garantie ne sʼapplique pas aux accessoires ni aux dommages causés par des réparations

réalisées ou tentées par des tiers. Cette garantie vous accorde des droits légaux

spécifiques et il est possible que vous ayez dʼautres droits qui varient dʼun État ou dʼune

province à lʼautre.

En plus de la garantie, les outils Stanley FatMax sont couverts par notre :

SERVICE DʼENTRETIEN GRATUIT DE 1 AN : Stanley FatMax entretiendra lʼoutil et

remplacera gratuitement les pièces usées par une utilisation normale en tout temps

pendant la première année à compter de la date dʼachat.

GARANTIE DE REMBOURSEMENT DE 90 JOURS : Si vous nʼêtes pas entièrement

satisfait des performances de votre outil électrique Stanley FatMax pour quelque raison

que ce soit, vous pouvez le retourner accompagné dʼun reçu dans les 90 jours suivant

la date dʼachat et nous vous rembourserons entièrement – sans poser de questions.

AMÉRIQUE LATINE : Cette garantie ne sʼapplique pas aux produits vendus en

Amérique latine. Pour les produits vendus en Amérique latine, veuillez consulter les

informations relatives à la garantie propre au pays, présentes dans lʼemballage,

appelez lʼentreprise locale ou consultez le site Web pour connaître les informations

relatives à la garantie.

Pour enregistrer votre outil en vue dʼobtenir un service de garantie, consultez notre

site Web à lʼadresse suivante : www.stanleytools.com.

REMPLACEMENT DES ÉTIQUETTES DʼAVERTISSEMENT

Si les étiquettes dʼavertissement deviennent illisibles ou sont manquantes, composez

le 800 262-2161 pour en obtenir le remplacement gratuit.

Imported by / Importé par

Stanley Tools

701 E. Joppa Road

Towson, Maryland 21286

Page 22

22

CATÁLOGO N°

FME700

MANUAL DE'INSTRUCCIONES

Serra Multi-Corte de Metais de

14 pulg. (355mm)

CONSERVE ESTE MANUAL PARA FUTURAS CONSULTAS.

Page 23

23

Instrucciones de seguridad importantes

ADVERTENCIA: Lea todas las instrucciones hasta comprenderlas. El

incumplimiento con alguna de las instrucciones enumeradas más abajo puede resultar en

descarga eléctrica, incendio y/o lesiones corporales serias.

CONSERVE ESTAS INSTRUCCIONES

• MANTENGA LOS PROTECTORES EN SU SITIO y en buenas condiciones de

funcionamiento.

• QUITE LAS LLAVES DE AJUSTE. Hágase el hábito de comprobar que la herramienta

no tenga ninguna llave de ajuste puesta antes de encenderla.

• MANTENGA LIMPIA EL ÁREA DE TRABAJO. Las áreas y mesas de trabajo

desordenadas aumentan el riesgo de lesiones.

• NO UTILICE LA HERRAMIENTA EN AMBIENTES PELIGROSOS. No utilice máquinas

herramienta en lugares húmedos o mojados ni las exponga a lluvia. Mantenga el área

de trabajo bien iluminada.

• MANTENGA ALEJADOS A NIÑOS. Toda visita debería mantenerse a una distancia

segura del área de trabajo.

• QUE SU TALLER SEA A PRUEBA DE NIÑOS. Para ello utilice candados o

conmutadores maestros o quite las llaves de arranque.

• NO FUERCE LA HERRAMIENTA. La herramienta hace el trabajo mejor y más seguro

a la velocidad para la cual fue diseñada.

• UTILICE LA HERRAMIENTA CORRECTA. No fuerce la herramienta o el accesorio a

que realice una tarea para la cual no fue diseñada.

• USE ROPA ADECUADA. No lleve ropa suelta, guantes, corbatas, anillos,

pulseras u otras joyas que podrían engancharse en las piezas móviles. Se

recomienda el uso de calzado antideslizante. Cúbrase y recójase el pelo si lo

tiene largo. Los orificios de ventilación suelen cubrir piezas en movimiento, por lo

que también se deben evitar.

• USE SIEMPRE GAFAS DE SEGURIDAD que cumplan con los requisitos de ANSI

Z87.1. Utilice además una máscara para la cara o guardapolvo si la operación de corte

genera demasiado polvo. Los anteojos de uso diario sólo tienen lentes resistentes a

golpes, no son gafas de seguridad.

• AFIRME BIEN SU TRABAJO. Utilice abrazaderas o tornillos para sujetar las piezas

en las que trabaja. Es más seguro, y así podrá utilizar ambas manos para operar la

herramienta.

• NO SE SOBREEXTIENDA. Manténgase siempre bien apoyado y equilibrado.

• CUIDE LAS HERRAMIENTAS. Mantenga las herramientas afiladas y limpias para un

funcionamiento mejor y más seguro. Siga las instrucciones para lubricar y cambiar

accesorios.

• DESENCHUFE LAS HERRAMIENTAS antes de reparar o mantenerlas; cuando

cambie accesorios tales como hojas, brocas, mecanismos de corte y otros por el estilo.

• REDUZCA EL RIESGO DE PUESTAS EN MARCHA ACCIDENTALES. Asegúrese

de que el conmutador esté apagado antes de enchufarla.

PAUTAS DE SEGURIDAD/DEFINICIONES

Esimportante que lea ycomprenda este manual. La información que contiene se relaciona con

laprotección de SUSEGURIDAD y la PREVENCIÓN DE PROBLEMAS. Los símbolos que

siguen se utilizan para ayudarlo a reconocer esta información.

PELIGRO: indica una situación de peligro inminente que, si no se evita, provocará

la muerte o lesiones graves.

ADVERTENCIA: indica una situación de peligro potencial que, si no se evita,

provocará la muerte o lesiones graves.

PRECAUCIÓN: indicauna situación de peligro potencial que, si no se evita,

provocará lesiones leves o moderadas.

PRECAUCIÓN: utilizado sin el símbolo de alerta de seguridad indica una situación de

peligro potencialque, si no se evita, puede provocardaños en la propiedad.

Page 24

24

• UTILICE LOS ACCESORIOS RECOMENDADOS. Consulte el manual de

instrucciones para conocer los accesorios recomendados. El uso de accesorios no

debidos puede producir un riesgo de lesiones corporales.

• NUNCA SE PARE SOBRE LA HERRAMIENTA. Podría sufrir graves lesiones si la

herramienta se cae a un lado o si se entra en contacto no intencionado con la

herramienta de corte.

• REVISE LAS PIEZAS DAÑADAS. Antes de continuar usando la herramienta, se

debe revisar cuidadosamente el protector o cualquier otra pieza dañada para

determinar que funcionará correctamente y realizará la función para la que fue

diseñada - verifique que las piezas móviles estén alineadas, que no estén atascadas,

rotas, montadas una sobre otra o de otra forma que pudiera afectar su operación.

Cualquier protector o pieza dañada debe repararse debidamente o cambiarse.

• JAMÁS DEJE SIN SUPERVISIÓN UNA HERRAMIENTA EN FUNCIONAMIENTO.

APAGUE LA HERRAMIENTA. No deje la herramienta hasta que no se haya detenido

completamente.

• REPUESTOS. Cuando realice mantenimiento, use sólo repuestos originales.

• PARA REDUCIR EL RIESGO DE DESCARGA ELÉCTRICA:

a. Puede que este equipo tenga un enchufe polarizado (con una para más ancha que

la otra.) Este enchufe sólo puede ser insertado en una toma de corriente

polarizada de una manera. Si el enchufe no entra, comuníquese con un electricista

calificado para que instale la toma de corriente apropiada.

b. Puede que la herramienta venga equipada con un enchufe con conexión a tierra

de tres patas. Este enchufe sólo puede ser utilizado en una toma de corriente con

conexión a tierra. Si el enchufe no entra, comuníquese con un electricista

calificado para que instale la toma de corriente apropiada.

c. No altere el enchufe de ninguna forma.

Reglas de seguridad adicionales para tronzadoras de metal

• Use siempre protección ocular y respiratoria apropiada.

• Antes de usarla, revise el disco de corte para verificar que no esté trizado o

tenga fallas. Si tuviera alguna trizadura o falla, descarte el disco. También se

debe inspeccionar el disco siempre que piense que la herramienta pudiera

haber caído. Las fallas pueden provocar la rotura del disco.

• Cuando arranque la herramienta con un disco nuevo o de repuesto o si no está

seguro de la condición del disco, sostenga la herramienta en un lugar bien

protegido y déjela andar por un minuto. Si el disco tiene una trizadura

o falla que haya pasado inadvertida, se debería romper en pedazos en menos de un

minuto. Nunca encienda la herramienta cuando haya una persona alineada con el

disco. Esto incluye al operador.

• Durante la operación, evite hacer rebotar el disco o tratarlo bruscamente. Si ello

sucediera, detenga la herramienta y revise que el disco no tenga trizaduras o fallas.

• Limpie su sierra circular estacionaria periódicamente, siguiendo el procedimiento de

este manual.

• No quite los protectores del disco o la base.

• SIEMPRE USE EL TORNO O DISPOSITIVO DE FIJACIÓN ESPECIAL PARA

SOSTENER BIEN LA PIEZA DE TRABAJO. Otros dispositivos tales como

abrazaderas de resorte, de barra o en C pueden ser apropiadas para piezas de

trabajo de diferentes tamaños y formas. Tenga cuidado al seleccionar y colocar estas

abrazaderas y haga un movimiento de práctica antes de hacer un corte.

• Use sólo discos tipo 1 de 355 mm (14 pulg.) para 4300 rpm o superiores.

• Deje que las piezas cortadas se enfríen antes de cogerlas.

• No intente cortar madera o plástico con esta herramienta.

• NUNCA CORTE MAGNESIO CON ESTA HERRAMIENTA.

• Use la sierra circular estacionaria en un lugar bien ventilado.

• Apague la sierra circular estacionaria antes de quitar cualquier pieza de su base.

• NO CORTE MATERIALES CARGADOS DE ELECTRICIDAD.

• No use hojas para sierras circulares ni ninguna otra hoja dentada con esta

herramienta. Pueden producirse lesiones graves.

Page 25

25

• NO OPERE ESTA HERRAMIENTA CERCA DE LÍQUIDOS, GASES O POLVOS

INFLAMABLES. Las chispas o partículas calientes generadas del corte o las escobillas

del motor podrían encender materiales combustibles.

• No use el lado del disco abrasivo como pulidor de rebabas. Esto debilitará

significativamente el disco y creará una condición poco segura. El disco podría desarmarse.

PRECAUCIÓN: Use protección auditiva apropiada durante el uso de esta

herramienta. Bajo algunas condiciones y duraciones de uso, el ruido producido por este

producto puede contribuir a la pérdida auditiva.

PRECAUCIÓN: El deflector de chispas se calienta. Evite tocarlo o ajustarlo

mientras está caliente. Mantenga cables y materiales alejados del deflector de chispas.

ADVERTENCIA: Algunos tipos de polvo, como aquellos generados por el lijado,

serruchado, pulido y taladrado eléctrico y otras actividades de construcción, contienen

químicos que el estado de California sabe causan cáncer, defectos de nacimiento y otros

daños reproductivos.Algunos ejemplos de estos químicos son:

• plomo procedente de pinturas con base de plomo,

• óxido de silicio procedente de ladrillos, cemento y otros productos de mampostería,

y

• arsénico y cromo provenientes de maderas tratadas con químicos (arseniato de

cobre cromado).

El peligro derivado de la exposición a estos materiales varía en función de la frecuencia

con que se realice este tipo de trabajo. Para reducir su exposición a estos químicos:

trabaje en una zona bien ventilada y llevando equipos de seguridad aprobados, como

mascarillas antipolvo especialmente diseñadas para filtrar partículas microscópicas.

• Evite el contacto prolongado con polvo generado por el

lijado, serruchado, pulido y taladrado eléctricos y otras actividades de

construcción. Vista ropa protectora y lave las áreas de la piel expuestas con agua

y jabón. Si permite que el polvo se introduzca en su boca o sus ojos, o que quede sobre

la piel, puede favorecer la absorción de químicos peligrosos.

ADVERTENCIA: El uso de esta herramienta puede generar o dispersar partículas

de polvo, que pueden causar lesiones respiratorias permanentes y graves u otras

lesiones. Use siempre protección respiratoria apropiada para la exposición al polvo

aprobada por el Instituto Nacional de Salud y Seguridad Ocupacional de EE.UU. y la

Administración de Salud y Seguridad Ocupacional de EE.UU. (NIOSH y OSHA

respectivamente, por sus siglas en inglés). Aleje la cara y el cuerpo del contacto con las

partículas.

ADVERTENCIA: Siempre use protección respiratoria aprobada por NIOSH

(Instituto Nacional de Seguridad y Salud en el Trabajo) u OSHA (Administración de

Seguridad y Salud en el Trabajo) apropiada para la exposición al polvo. Dirija las partículas

en dirección contraria a la cara y el cuerpo.

Para su conveniencia y seguridad, su tronzadora de metales de 14 pulg. (355 mm) tiene

las siguientes advertencias:

ADVERTENCIA: PARA OPERARLA DE UNA MANERA SEGURA, LEA EL

MANUAL DE INSTRUCCIONES.

• NO UTILICE HOJAS DENTADAS.

• UTILICE SÓLO DISCOS REFORZADOSCALIFICADOS PARA4300 RPMO SUPERIORES.

• CUANDO REALICE MANTENIMIENTO, USE SÓLO REPUESTOS ORIGINALES.

• SIEMPRE: UTILICE PROTECCIÓN OCULAR; USE LOS PROTECTORES DE

HOJA; SUJETE LA PIEZA DE TRABAJO CON EL TORNO; UTILICE LA

PROTECCIÓN RESPIRATORIA APROPIADA.

• NO EXPONGA A LLUVIA NI USE EN LUGARES HÚMEDOS.

Page 26

26

•

USE EL ALARGADOR INDICADO. Cerciórese de que su alargador esté en buenas

condiciones. Cuando use un alargador, asegúrese de que sea lo bastante resistente

como para llevar la corriente que su producto requerirá. Un alargador de menor calibre

causará una caída en el voltaje de la línea lo que resultará en pérdida de potencia y

sobrecalentamiento. El siguiente cuadro muestra el tamaño correcto a utilizar,

dependiendo del largo del cable y del amperaje nominal. En caso de tener dudas,

utilice el de mayor calibre. Mientras menor sea el número del calibre, mayor la

capacidad del cable.

La etiqueta de su herramienta puede incluir los siguientes símbolos. Los símbolos y sus

definiciones son los siguientes:

V ..............voltios A ............amperios

Hz ............hertz W ............vatios

min............minutos ..........corriente alterna

........corriente continua

n

o............no velocidad sin carga

............Construcción Clase I

(con conexión a tierra)

............

Construcción de clase II

........

terminal a tierra

..........símbolo de alerta de ../minorpm ..revoluciones o reciprocidad por minuto

seguridad

PAUTAS DE SEGURIDAD/DEFINICIONES

Es importante que lea y comprenda este manual. La información que contiene se

relaciona con la protección de SU SEGURIDAD y la PREVENCIÓN DE PROBLEMAS.

Los símbolos que siguen se utilizan para ayudarlo a reconocer esta información.

PELIGRO: indica una situación de peligro inminente que, si no se evita, provocará la

muerte o lesiones graves.

ADVERTENCIA: indica una situación de peligro potencial que, si no se evita,

provocará la muerte o lesiones graves.

PRECAUCIÓN: indicauna situación de peligro potencial que, si no se evita,

provocará lesiones leves o moderadas.

PRECAUCIÓN: utilizado sin el símbolo de alerta de seguridad indica una situación de

peligro potencialque, si no se evita, puede provocardaños en la propiedad.

Calibre mínimo para cables de extensión

Volts Longitud total del cable en pies

120V 0-25 26-50 51-100 101-150

(0-7,6m) (7,6-15,2m) (15,2-30,4m) (30,4-45,7m)

240V 0-50 51-100 101-200 201-300

(0-15,2m) (15,2-30,4m)(30,4-60,9m) (60,9-91,4m)

Amperaje

Más de No más de American Wire Gage

0-6 18 16 16 14

6-10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 No se recomienda

CARACTERÍSTICAS

(FIG. 1, 4)

A.Cadena de fijación

B.Tornillopara ajuste de

deflector de chispas

C.Deflector de chispas

D.Base

E.Guía

F. Prensa

G.Llave para discoy

pernos

H.Manivela

I. Palanca de bloqueo de

prensa

J.Disco

K.Guarda retráctil

L.Botón de bloqueode eje

M.Tope de profundidad y

tuerca de obstrucción

N.Interruptor

O.Orificio para insertar

candado

P. Pernos de ajuste deguía

Q.Gancho para cadena

Page 27

27

ALIMENTACIÓN ELÉCTRICA

Compruebe que su suministro eléctrico concuerde con el indicado en la placa nominal.

Una reducción de voltaje superior al 10% provocará pérdida de potencia y

sobrecalentamiento.

CAPACIDAD DE CORTE

La amplitud de apertura de la prensa y la altura del punto de pivote proporcionan

capacidad de corte para varias piezas grandes. Use la tabla de capacidad de corte

para determinar el tamaño máximo total de los cortes que se pueden realizar con un

disco nuevo.

PRECAUCIÓN: PUEDE QUE CIERTOS OBJETOS GRANDES, CIRCULARES

O DE FORMAS IRREGULARES REQUIERAN DE SOPORTE ADICIONAL SI NO

PUEDEN SER SUJETOS FIRMEMENTE EN LA PRENSA.

PRECAUCIÓN: NO CORTE MAGNESIO CON ESTA HERRAMIENTA.

CAPACIDAD MÁXIMA DE CORTE

NOTA: La capacidad indicada en la tabla supone que el disco no está desgastado y

que la guía está en la posición óptima.

Forma de la pieza

de trabajo:

A X B

Ángulo de corte

de 90°

Ángulo de corte

de 45°

EQUIPO ESTÁNDAR

1 Disco abrasivo de 355 mm (14 pulg.) para cortar metales

1 Llave para el disco

1 Manual de instrucciones

PARA TRANSPORTE (FIG. 1a)

Pliegue la unidad a una posición en la que pueda transportar la sierra. Enganche la

cadena de bloqueo (A) en el gancho para cadena (Q).

DESBLOQUEO (FIG. 1a)

Para desbloquear la herramienta y levantar el cabezal, aplique una presión leve sobre el

brazo del motor y desenganche la cadena de bloqueo (A) del gancho para cadena (Q). El

brazo del motor girará hacia arriba.

AJUSTE DEL DEFLECTOR DE CHISPAS (FIG. 1)

Para deflectar mejor las chispas de las personas y los materiales circundantes, afloje el