Page 1

EP30

ELECTRONIC

PIN BRAZING UNIT

EP30200

EP30250

Safety, OperatiOn and Maintenance

USer ManUaL

© 2013 Stanley Black & Decker, Inc.

New Britain, CT 06053

U.S.A.

69924 6-2014 Ver-7

Page 2

Weisbeck, Andy

Directive/Standards

No.

Approved body

SS-EN

60974-10

Self

DECLARATION OF CONFORMITY

DECLARATION OF CONFORMITY

ÜBEREINSTIMMUNGS-ERKLARUNG

DECLARATION DE CONFORMITE CEE

DECLARACION DE CONFORMIDAD

DICHIARAZIONE DI CONFORMITA

______________________________________________________________________

I, the undersigned:

Ich, der Unterzeichnende:

Je soussigné:

El abajo firmante:

lo sottoscritto:

hereby declare that the equipment specified hereunder:

bestätige hiermit, daß erklaren Produkt genannten Werk oder Gerät:

déclare que l’équipement visé ci-dessous:

Por la presente declaro que el equipo se especifica a continuación:

Dichiaro che le apparecchiature specificate di seguito:

Surname and First names/Familiennname und Vornamen/Nom et prénom/ Nom bre y apellido/Cognome e nome

Hydraulic Tools

1. Category:

Kategorie:

Catégorie:

Categoria:

Categoria:

2. Make/Marke/Marque/Marca/Marca

3. Type/Typ/Type/Tipo/Tipo: EP30 / EP60

4. Serial number of equipment:

Seriennummer des Geräts:

Numéro de série de l’équipement:

Numero de serie del equipo:

Matricola dell´attrezzatura:

Has been manufactured in conformity with

Wurde hergestellt in Übereinstimmung mit

Est fabriqué conformément

Ha sido fabricado de acuerdo con

E’ stata costruita in conformitá con

Richtlinie/Standards

Directives/Normes

Directriz/Los Normas

Direttiva/Norme

EMC Directive

5. Special Provisions: None

Spezielle Bestimmungen:

Dispositions particulières:

Provisiones especiales:

Disposizioni speciali:

6. Representative in the Union: Patrick Vervier, Stanley Dubuis 17-19, rue Jules Berthonneau-BP 3406 41034 Blois Cedex, France.

Vertreter in der Union/Représentant dans l’union/Representante en la Union/Rappresentante presso l’Unione

Done at/Ort/Fait à/Dado en/Fatto a Stanley Hydraulic Tools, Milwaukie, Oregon USA

Signature/Unterschrift/Signature/Firma/Firma

Position/Position/Fonction/Cargo/Posizione Engineering Manager

Nr

Numéro

No

n.

2004/108/EC

Pin Braze / Safebond Unit (Product Group-Railroad)

Stanley Hydraulic Tools

All

Prüfung durch

Organisme agréé

Aprobado

Collaudato

Self

Date/Datum/le/Fecha/Data 1-10-11

2 ► EP30200 / EP30250 User Manual

Page 3

TABLE OF CONTENTS

DECLARATION OF CONFORMITY ................................................................................................................................... 2

WARRANTY .......................................................................................................................................................................3

SAFETY SYMBOLS ...........................................................................................................................................................4

SAFETY PRECAUTIONS ................................................................................................................................................... 5

OPERATION EP30200 ......................................................................................................................................... 6 THRU 9

OPERATION EP30250 ..................................................................................................................................... 10 THRU 13

TROUBLESHOOTING .....................................................................................................................................................14

EQUIPMENT MAINTENANCE & CARE ........................................................................................................................... 15

SPECIFICATIONS ............................................................................................................................................................ 16

ACCESSORIES.................................................................................................................................................16 THRU 21

EP30200 PARTS ILLUSTRATION....................................................................................................................................22

EP30200 PARTS LIST......................................................................................................................................................23

IMPORTANT

To ll out a Product Warranty Validation form, and for information on your warranty,

visit Stanleyhydraulics.com and select the Company tab, Warranty.

(NOTE: The warranty Validation record must be submitted to validate the warranty).

SERVICING: This manual contains safety, operation, and routine maintenance instructions. Stanley Hydraulic Tools

recommends that servicing of the unit, other than routine maintenance, must be performed by an authorized and

certied dealer. Please read the following warning.

WARNING

SERIOUS INJURY OR DEATH COULD RESULT FROM THE IMPROPER REPAIR OR

SERVICE OF THIS TOOL.

REPAIRS AND / OR SERVICE TO THIS TOOL MUST ONLY BE DONE BY AN

AUTHORIZED AND CERTIFIED DEALER.

For the nearest authorized and certied dealer, call Stanley Hydraulic Tools at the number listed on the back of this

manual and ask for a Customer Service Representative.

EP30200 / EP30250 User Manual ◄ 3

Page 4

DANGER

WARNING

CAUTION

NOTICE

IMPORTANT

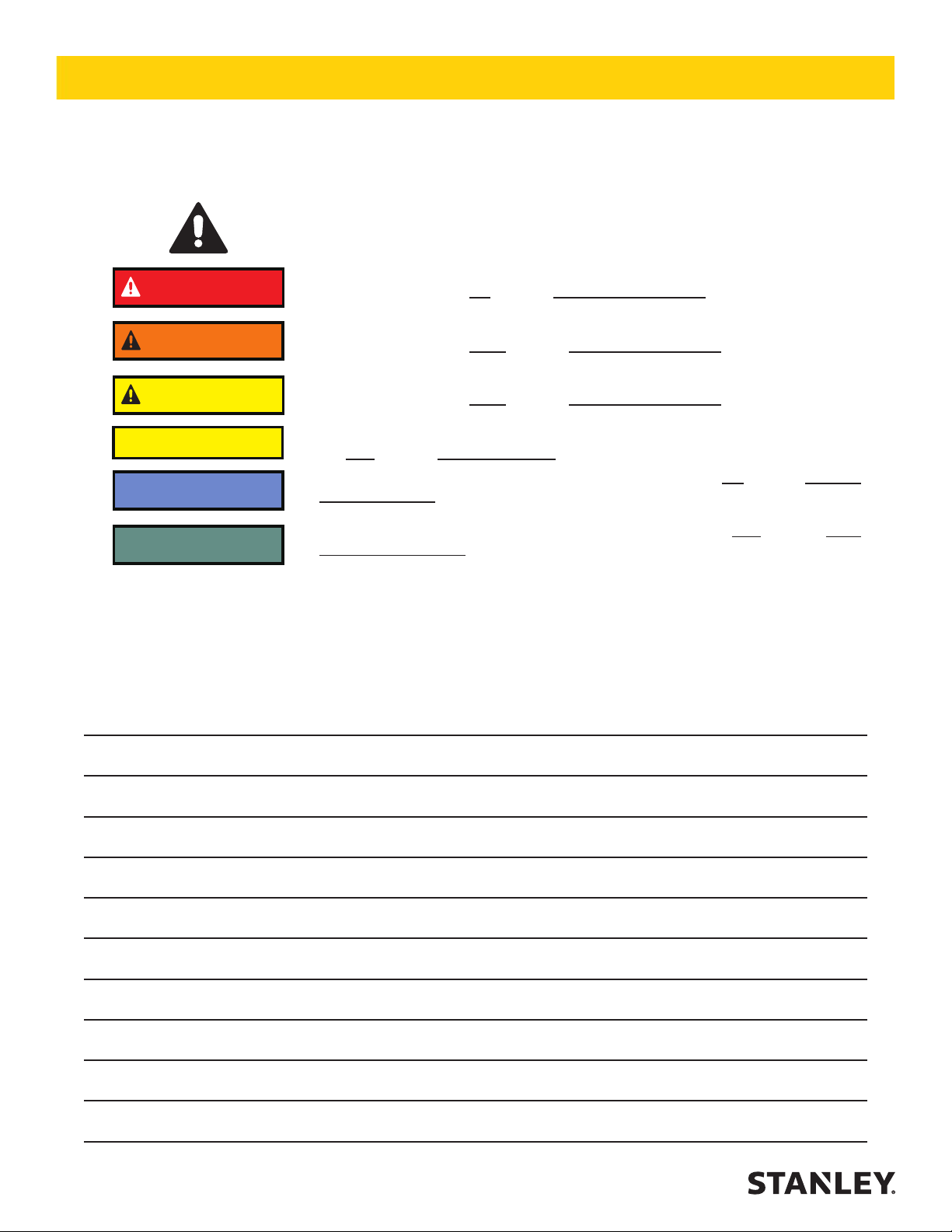

SAFETY SYMBOLS

Safety symbols and signal words, as shown below, are used to emphasize all operator, maintenance and repair actions which, if not strictly followed, could result in a life-threatening situation, bodily injury or damage to equipment.

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid possible

injury or death.

This safety alert and signal word indicate an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

This safety alert and signal word indicate a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

This safety alert and signal word indicate a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION

Always observe safety symbols. They are included for your safety and for the protection of the tool.

This signal word indicates a potentially hazardous situation which, if not avoided, may result in property damage.

This signal word indicates a situation which, if not avoided, will result in damage

to the equipment.

This signal word indicates a situation which, if not avoided, may result in damage to the equipment.

LOCAL SAFETY REGULATIONS

Enter any local safety regulations here. Keep these instructions in an area accessible to the operator and maintenance personnel.

4 ► EP30200 / EP30250User Manual

Page 5

SAFETY PRECAUTIONS

Tool operators and maintenance personnel must always

comply with the safety precautions given in this manual

and on the stickers and tags attached to the tool and

hose.

These safety precautions are given for your safety. Review them carefully before operating the tool and before

performing general maintenance or repairs.

Supervising personnel should develop additional pre-

cautions relating to the specic work area and local

safety regulations. If so, place the added precautions in

the space provided in this manual.

This tool will provide safe and dependable service if

operated in accordance with the instructions given in

this manual. Read and understand this manual and any

stickers and tags attached to the tool before operation.

Failure to do so could result in personal injury or equipment damage.

• Do not operate a damaged, improperly adjusted, or incompletely assembled tools.

• To avoid personal injury or equipment damage, all tool

repair, maintenance and service must only be performed

by authorized and properly trained personnel.

• Do not exceed the rated limits of the tool or use the tool

for applications beyond its design capacity.

• Always keep critical tool markings, such as labels and

warning stickers legible.

• Always replace parts with replacement parts recommended by Stanley Hydraulic Tools.

• Operator must start in a work area without bystanders.

The operator must be familiar with all prohibited work

areas such as excessive slopes, dangerous terrain con-

ditions, and rail trafc.

• Establish a training program for all operators to ensure

safe operation.

• Do not operate the tool unless thoroughly trained or

under the supervision of an instructor.

• Always wear safety equipment such as goggles, ear,

head protection, and respiratory protection at all times

when operating the tool.

• Do not inspect or clean the tool while the battery power

source is connected. Accidental arcing can cause serious injury.

• Do not load brazing pins or ceramic rings while the battery power source is connected. Accidental arcing can

cause serious injury.

• Do not use the tool while it is connected to a battery

charger.

• Ensure battery charging is only done in a dry environment. Charging batteries in the rain or near standing

water presents an electrocution hazard. Read the safety and operation instructions provided with the battery

charger before using the battery charger.

EP30200 / EP30250 User Manual ◄ 5

Page 6

EP30200 OPERATION

GENERAL PROTECTION

Store the Electronic Pin Brazing Unit in a place where it is

protected from the elements, abrasive dust, and damage.

Use only recommended repair and replacement parts and

materials specied in the Parts List section of this manual.

Use only recommended accessories also specied in the

Parts List section of this manual.

Do not use the Electronic Pin Brazers for applications it was

not designed for.

WARNING

Make sure battery charging is only accomplished in a

well ventilated room. DO NOT PLACE THE CONTROL

BOX ON TOP OF THE BATTERIES. REMOVE THE

BATTERY BOX COVER. Battery charging produces

explosive gases. A battery explosion can cause serious

injuries. Avoid battery explosions by keeping cigarettes,

sparks, and ames away from batteries being charged.

Always wear safety glasses when working with

batteries.

Use the carrying handle to transport the unit from location

to location.

CLEANING

Establish a routine to keep the unit as free from dirt as possible – daily, or at each shift change, for example.

Pin Brazers exposed to rain, sand, or grit-laden air should be

cleaned prior to each use.

Keep tool labels and stickers legible.

PREOPERATION PROCEDURES

Before putting a new Pin Brazer into initial service, or after an

extended period of being unused, perform a visual inspection

for bent, broken, cracked, missing or worn components.

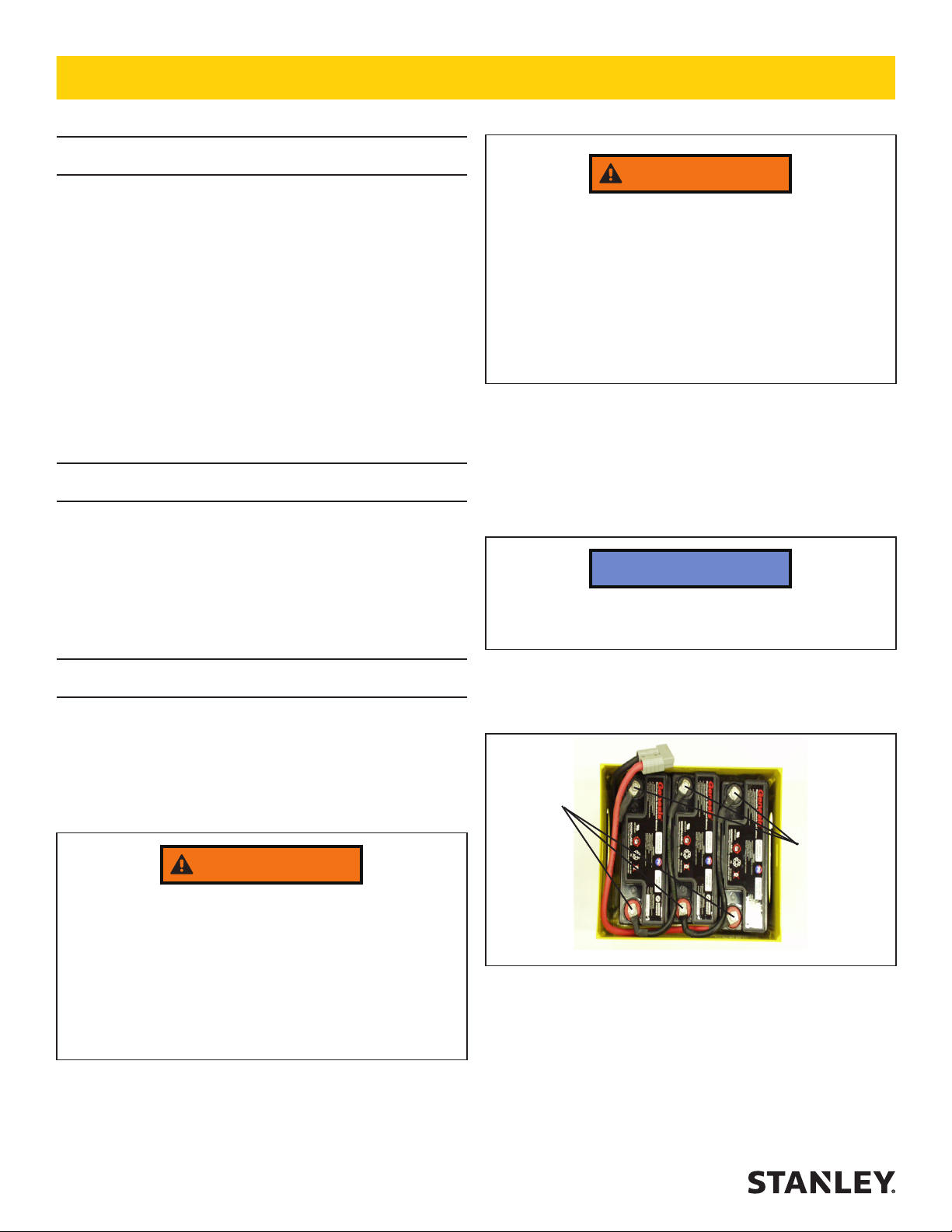

INITIAL SETUP AND BATTERY CHARGING

WARNING

1. The three batteries furnished are sealed, maintenance

free batteries.

Sealed, maintenance free batteries do not contain cell caps

and are already lled with battery acid. They will require

charging before use.

NOTICE

Use only battery charger specially made for pin brazing

units (36V dc) approved by Stanley.

2. Locate the four battery cables and connect them to the

terminals on the batteries and the battery box as shown in

gure 1. Do not replace the lid on the battery box at this time.

+Pos.

-Neg.

Failure to follow the instructions in the battery charger

operation manual can result in battery explosion and

serious bodily injury. To reduce the risk of battery explosion, read and understand the safety and operation

instructions in the battery charger operation manual,

the instructions published by the battery manufacturer,

and the instructions in this manual before attempting to

charge the batteries.

6 ► EP30200 / EP30250 User Manual

Figure 1. Battery cable and terminals

3. Insert the enclosed foam-rubber spacers between each

battery and at both ends between the battery and the unit.

4. Connect the battery charger to the grinder outlet on the

unit, then to the mains. When removing the charger remove

the main rst, the remove the plug from the unit.

Page 7

EP30200 OPERATION

5. Charging is ready in approximately 3-5 hours. Follow the

instructions in the battery charger manual to complete the

charging process.

6. Plug the two cable leads from the adapter box into the

battery box.

7. Insert the plug from the battery charger into the grinder

outlet on the adapter box.

8. Plug the battery charger into a standard 110 volt AC

outlet.

9. Follow the instructions in the battery charger manual to

complete the charging process.

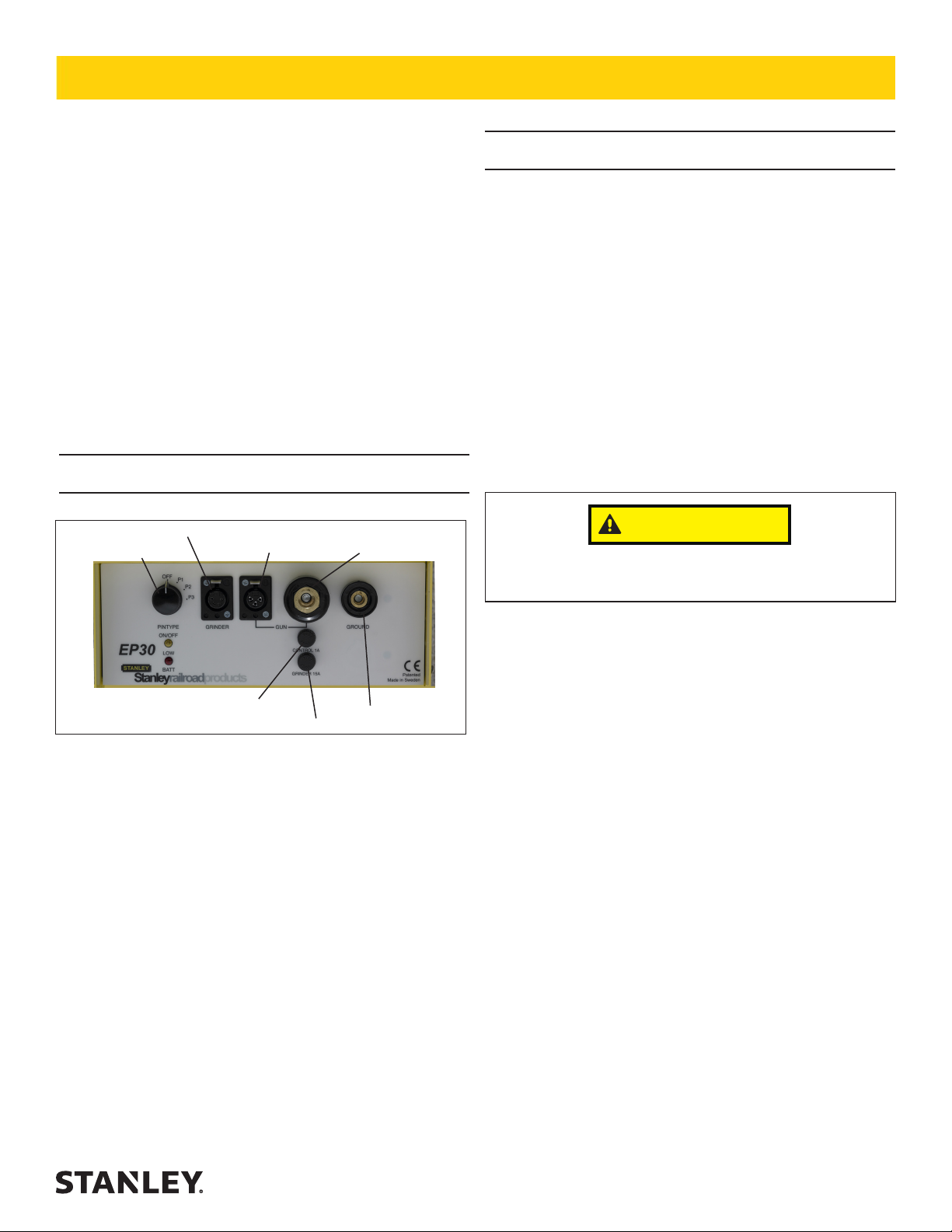

CONNECTIONS

Grinder Receptacle

Pin Size Switch

Control Cable

Female Socket

Gun Power Supply

Receptacle

OPERATION

PREPARE THE RAIL SURFACE

Select the type and length of bonding cable to use for the

bond and use it as a guide to determine where brazing points

on the rail will be required.

Before brazing, the rail must be cleaned of rust, corrosion,

paint, pits, or other contamination at the points where the brazing is going to be done and on an area close to the brazing for

placement of the grounding cable. Cleaning is accomplished

with a grinder to ensure clean, bare metal.

NOTE:

Use only grinding wheels furnished by Stanley. Other

wheels have shown to leave residues which cause faulty

brazing.

CAUTION

Always use eye protection when grinding and brazing.

1 A Fuse

15 A Fuse

Figure 2. EP30 Connections

1. Connect the brazing gun, power and trigger cables to the

unit.

2. Connect the ground cable .

3. Connect the grinder.

Ground Receptacle

1. Grind the surface of the rail where brazing is going to be

done, until the surface shows shiny metal, free of rust, corrosion, pits, or other contamination. When grinding, use the

edge of the grinding wheel - not the face of the wheel.

2. Grind the surface of the rail where the grounding cable

will be placed to ensure a good ground. The grounding cable

should be placed in close proximity to the brazing area.

PLACING THE GROUNDING CABLE

3. When nished grinding the rail for placement of the grounding cable, place the grounding cable on the cleaned surface

and then insert the other end into the twist lock receptacle

in the control box marked "GROUND" or "EARTHING" and

twist to lock.

SELECT PINS AND RINGS

4. Select brazing pins and ceramic rings to match the speci-

cations of the bonding cable you selected.

CHANGING PIN AND RING HOLDER

5. Check that the pin holder and ring holder on the gun are

the correct sizes for the brazing pins and ceramic rings you

selected. If the sizes are incorrect, the pin holder and ring

holder can be changed as follows:

EP30200 / EP30250 User Manual ◄ 7

Page 8

EP30200 OPERATION

a. The ring holder is a "push t" to the gun. To remove it from

the gun, simply pull it away from the gun.

b. The pin holder is threaded onto a threaded shaft in the gun

and locked in place with a nut. Place an open end wrench

over the nut and an open end wrench over the ats on the

pin holder. While holding the nut in place, unscrew the pin

holder counter clockwise.

Pin Holder

Figure 3. Pin and Ring Holder

c. Install the correct pin holder and tighten it securely against

the nut.

Ring Holder

IMPORTANT

Make sure, never twist the axle when mounting the

pin holder.

The BG10100 automatically adjusts the correct distance of

the brazing pin to the surface to be brazed.

NOTE:

The BG10100 may be adjusted manually if necessary

using the dial located on the back of the gun. The settings are as follows:

+ = 2.5 mm distance

0 = 2.0 mm distance (normal position)

- = 1.5 mm distance

Dial

Figure 2. Gun Adjustment Dial

8. Plug the two gun cable into the appropriate outlets on the

control box.

SET CONTROL FOR PIN SIZE

d. Install the correct ring holder by placing it over the pin holder

and into the circular groove in the gun, and nally, pushing

on it to seat it in place.

LOADING PIN AND RING

6. Insert the brazing pin into the pin holder. The rounded tip

should be facing away from the gun.

7. Insert the ceramic ring into the ring holder. The serrated

edge should be facing away from the gun. See gure 4.

Figure 4. Loading pin and ring

ADJUSTING BRAZING PIN DISTANCE TO

BRAZE SURFACE

9. Set the PIN TYPE switch on the control box for the

appropriate pin type being used. See Figure 3 below.

Brazing Pin Setting

8 mm Std P1

8 mm Extra P2

9.5 mm P3

SWITCH

Figure 3. Pin Type Control Switch

10. Turn the POWER switch to 1.

8 ► EP30200 / EP30250 User Manual

Page 9

EP30200 OPERATION

NOTE:

The EP30 does not have a power switch.

11. Position the terminal lug of the bonding cable against the

cleaned surface of the rail. Position the gun against the cable

lug so that the brazing pin is at the top edge of the cable lug

hole. See Figure 4 below.

Figure 4. Gun position

IMPORTANT

Make sure the correct ferrule and brazing pin are used.

The pin braze must be made in the top of the hole when

brazing to a vertical surface.

12. Hold the gun rmly with both hands and pull the trigger

once. The electronics will nish the braze automatically.

13. Hold the gun in place for 3-4 seconds after the brazing is

complete to allow for cooling. Then remove the gun straight

backwards without pulling trigger.

14. After the braze has cooled, knock the shank off the brazing pin using a hammer.

15. Use a new ceramic ring for each new pin braze.

NOTE:

A red light indicates low batteries on the unit. Charge

as soon as possible.

EP30200 / EP30250 User Manual ◄ 9

Page 10

CAUTION

EP30250 OPERATION

The S300 requires a welding machine capable to deliver

250-300 Amp, open circuit voltage of max. 80V.

(Not supplied by Stanley)

1. Check that all parts were received.

EP300 Unit Delivered with:

Gun S15, incl 2,7 m SAFE 91015

Ground device 2,7 m SAFE 8089

1 - Power cord

2 - Power cable 3 m

2. Connect

Connect power cords to mains and power

cables to an welding machine.

(Welding machine not supplied by Stanley).

Make sure positive and negative is correct.

Set welding current on welding

machine to 250 Amp.

(Max 280 Amp)

Open circuit voltage of max. 80V.

Connect brazing gun, power cable and

control cable, to units gun outlets.

Connect ground magnet to ground outlet.

10 ► EP30200 / EP30250 User Manual

Page 11

WARNING

IMPORTANT

EP30250 OPERATION

3. Brazing instruction.

Warning! Always use eye protectors when grinding and brazing!

Note, use only STANLEY´s grinding wheel specially made for brazing, other type of wheels will leave a surface

not suitable for brazings. Keep the grinding wheel clean and free from oil etc.

- Grind the brazing and grounding area until you have an even and clean surface

Move the grinder up and down until you have an

even surface for both the pinbraze and ground

magnet.

- Attach the earth magnet on the same rail/work piece where the pinbrazing should be done. Try to attach the

magnet within 0,5m from brazing area.

- Set pintype:

Pin Setting

8 mm std 1

8 mm Extra 2

9,5 mm 3

- Load the gun with brazing pin and ferrule.

EP30200 / EP30250 User Manual ◄ 11

Page 12

EP30250 OPERATION

- Press carefully the gun with the cable shoe, the ferrule and the

brazing pin to the work piece.

- Note that you always must use a railbond together with the brazing pin and the ferrule to do a pin brazing, except

when brazing a special threaded brazing pin then only a ferrule and M8, M10 or M12 brazing pin is to be used.

- Make sure to braze in the top of the hole

when brazing to a vertical surface.

Brazing.

- Hold the gun rmly with both hands as shown and

pull the trigger just once.

The electronic will by it self nish the brazing process.

- Hold the gun in place for 3-4 sec after the brazing

while the braze freezes.

- Remove the gun straight backwards without

pulling the trigger!

Knock off the shank of the brazing pin.

The brazing is completed.

ACCESSORIES EP300

SEE PAGE 17

Pin holder 8-9,5 mm (A)

Pin holder M8 (B)

Pin holder M10 (C)

Pin holder M12 (D)

Ring holder 8-9,5 mm

Ring holder M8/M10/M12

12 ► EP30200 / EP30250 User Manual

Page 13

WARNING

EP30250 MAINTENANCE

PIN HOLDERS

Squeeze the ngers on the pin holder together each time you feel that the brazing pin goes in too easy when

mounting them into the pin holder. This is important since all the current goes thru the pin holder to the

brazing pin. If the ngers are too loose the pin holder will be damaged and must be replaced.

CHANGE PIN HOLDER

-Separate the ring holder from the gun with your hands.

-Hold the nut closest to the pin holder with a 10mm key.

-Screw the pin holder off.

-When replacing the new pinholder, hold the nut, closest to the pinholder even now.

WARNING! Never rotate the shaft! The internal cables may be damaged!

EQUIPMENT

-Check the cables from time to time, to make sure they are not damaged.

-Check the contact surface on the ground magnet from time to time and use a le to even or clean the surface.

BRAZING PINS AND FERRULES

-Keep them dry.

RAILBONDS AND CABLE LUGS

-Keep them free from oxidation.

-Keep them free from contamination like: Grease, oil, dirt, paint, glue etc.

-Make sure that they are not damaged.

EP30200 / EP30250 User Manual ◄ 13

Page 14

TROUBLESHOOTING

EP30250

In order to perform this trouble shooting you will need: voltmeter, 8 mm and 10 mm spanners, hexagon spanner

3 mm, 4mm and 5 mm, control instrument to check lift height for S15 pistol.

Working material Are the bonds in good condition - no breaks, clean ?

Are the pins of the correct type ?

Grinding wheeel Is the grinding wheel the approved type ?

The Tyrolit is a silicon free wheel.

You can use a steel carbide wheel.

No other wheels are allowed.

Brazing gun

S 15 Check cables, plugs.

Does axle move easily with pin and ring installed ?

Are the pin and ring holders bent ?

Unscrew the front of the gun and open carefully. Smell if there is burning, otherwise

clean and replace.

Check the lifting height with the control instrument.

Ground magnet Is the magnet broken ( between the plates) ?

Is the plug well screwed in ?

Make sure the contact surfaces are even.

Electronic units Check cables and connections for play.

Are the contact on the cables damaged ?

Are the knobs loose ?

Are the fuses whole ?

Open the panel, check for a burnt smell, ( the breaker can have burnt out )

Check that cables are attached correctly.

Make a full optical control.

EP30200

PROBLEM CAUSE SOLUTION

Brazing pin does not ignite

or does not ignite long

enough.

Braze is faulty. Batteries not charged or are defective.

Batteries not charged or are defective.

Blown fuse. Check fuses.

Magnetic ground faulty.

Faulty cables. Check gun cables and plugs for damage.

Bonding surface contaminated. Check that the brazing surface is ground clean.

Incorrect PIN TYPE setting. Check PIN TYPE setting on the control box.

Magnetic ground faulty.

Bonding surface contaminated. Check that the brazing surface is ground clean.

Incorrect grinding wheel is used. Use only Tyrolit grinding wheels or carbide burr.

Ceramic ring was not positioned

square to the lug.

Brazing pin not positioned correctly in

lug hole.

Test batteries for proper charge. Replace and/or

charge as necessary.

Check that surface magnetic ground is applied to

is ground clean. Check magnetic ground cable

and plug for damage.

Test batteries for proper charge. Replace and/or

charge as necessary.

Check that surface magnetic ground is applied to

is ground clean. Check magnetic ground cable

and plug for damage.

Ensure ring is positioned correctly.

Ensure pin is positioned correctly.

14 ► EP30200 / EP30250 User Manual

Page 15

NOTICE

EQUIPMENT MAINTENANCE & CARE

In addition to the Safety

Precautions in this manual,

observe the following for

equipment protection and

care.

• Check that the pin holder is not burnt or not holding the pin tightly. If not, remove the ring holder, clean all the

parts and squeeze the ngers of the pin holder together.

• Check the cables on the gun from time to time for damage. Replace as required.

• Check that the lift level is correct with lift level tool.

• Always store the tool in a clean dry space, safe from damage or pilferage.

• Always keep critical equipment markings, such as warning stickers and tags legible.

• Equipment repair should be performed by experienced personnel only.

• Do not use the equipment for applications for which it was not intended.

EP30200 / EP30250 User Manual ◄ 15

Page 16

SPECIFICATIONS

EP30200

Voltage...............................................................................................................................................................................................36V dc

Approximate Number of Brazings per Battery Charge ........................................................................................................................ 40-60

Weight .....................................................................................................................................................................................44 lbs / 20 kg

Overall Length .................................................................................................................................................................. 12.5 in. / 315 mm

Overall Width .................................................................................................................................................................... 8.75 in. / 220 mm

Overall Height ...................................................................................................................................................................... 16 in. / 400 mm

EP30250 ............................................................................................................................................................................... - This unit

does not have on-board batteries but is powered by an external welding machine (not included) capable of 250-300 amps at 80

volts. Otherwise this has the same functionality and uses the same accessories as our other EP30 units.

ACCESSORIES

35812...............................................................................................................................................................Carrying Case

58867.................................................................................................................................Transport Wagon, EPX 31, EP30

EP30010 (Includes Items Below)..................................................................................................... Pin Brazing Kit 110VAC

35866..............................................................................................................................................Battery Charger

40409.....................................................................................................................Battery, Genesis 16amp 12V (3)

72776..............................................................................................................................Nonspillable Battery Label

73358..........................................................................................................................................Carbide Burr SF-5

EP30200..........................................................................................................Medium Duty Elec. Pin Brazing Unit

BG10100.........................................................................................................................................Pin Brazing Gun

HGE12151......................Grinder, Elec. Cordless Kit (Includes: Grinder, Charger 120V & Battery Lithium-Ion 18V

EP30020 (Includes Items Blelow)..............................................................................................Pin Brazing Kit 110V/12VDC

73358...........................................................................................................................Carbide Burr (1/4 in. Shank)

35812.................................................................................................................................................Carrying Case

35818.........................................................................................................................Extension Cable for S4 Pistol

35819........................................................................................................................Extension Cable for Earth 5m

35866..............................................................................................................................................Battery Charger

40409................................................................................................................... Battery, Genesis 16amp 12V (3)

47320.............................................................................................................................Inverter 12VDC to 110VAC

72776............................................................................................................................. Nonspillable Battery Label

EP30200..........................................................................................................Medium Duty Elec. Pin Brazing Unit

BG10100.........................................................................................................................................Pin Brazing Gun

HGE12151......................Grinder, Elec. Cordless Kit (Includes: Grinder, Charger 120V & Battery Lithium-Ion 18V

16 ► EP30200 / EP30250 User Manual

Page 17

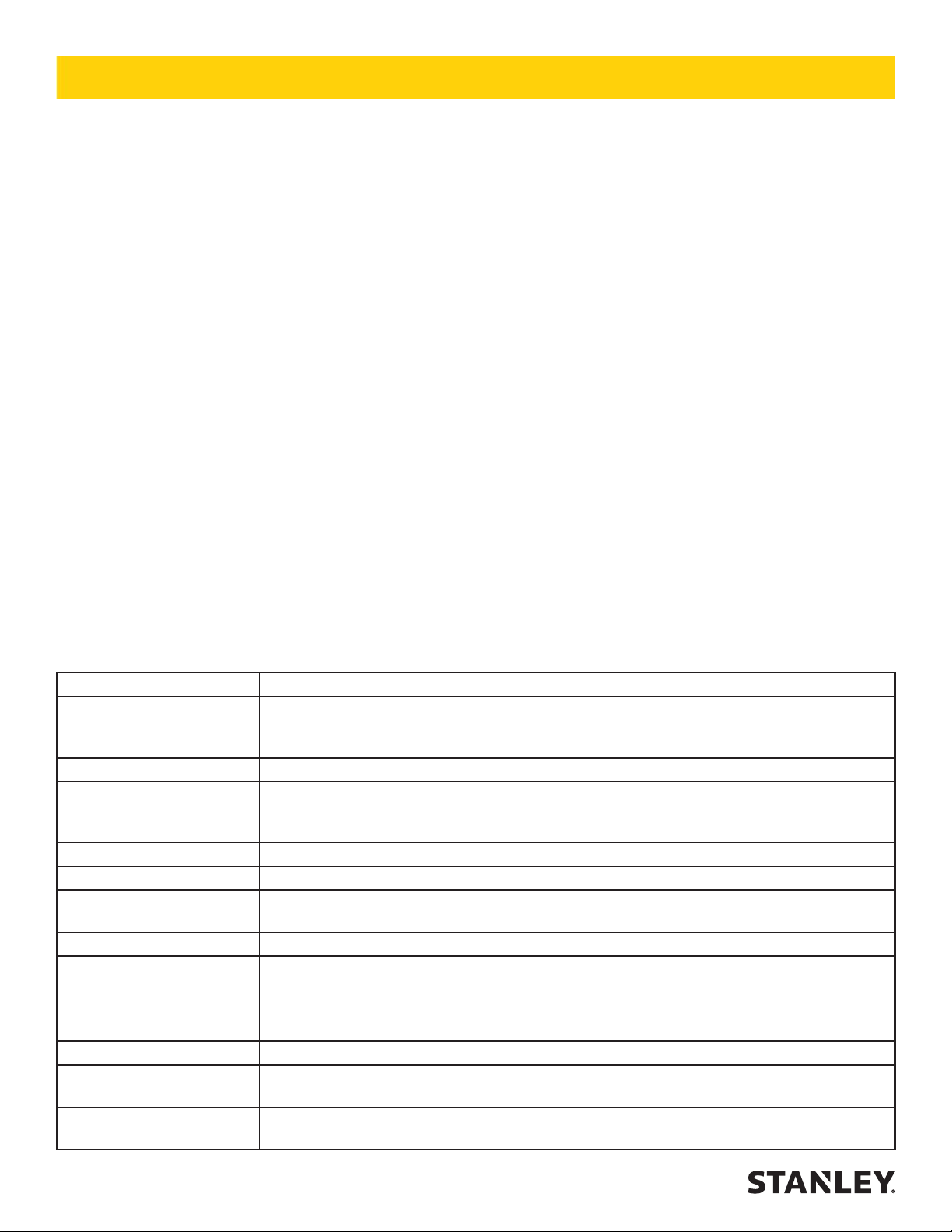

ACCESSORIES

BRAZING PINS & CERAMIC RINGS

STANDARD BRAZING PINS

Part No. Description Ceramic Ring Reqd

35835 8 mm 35832

35836 8 mm w/ extra silver 35832

35837 9.5 mm 35833

35840 M8/12 Threaded 35834

35841 M10 Threaded 35834

35839 M12 Threaded 35834

CERAMIC RINGS

Part No. Description

35832 8 mm

35833 9.5 mm

35834 12 mm

PIN & RING HOLDERS

Part No. Description

Brazing Pins are for

use on Rail Only

35826 Pin Holder for Pinbrazing, 8-9,5 mm brazing pins.

35827 Pin Holder for Pinbrazing, M8 Threaded pins.

35828 Pin Holder for Pinbrazing, M10 Threaded pins.

35829 Pin Holder for Pinbrazing, M12 Threaded pins.

35825 Extended pin and ring holder set for 8-9,5 mm brazing pins.

37945 Ring Holder, 8 mm pin & ringholder Set

35830 Ring Holder, 8-9,5 mm ceramic rings.

35831 Ring Holder, M8/M10/M12 mm ceramic rings.

35827 Pictured

35831 Pictured

CABLE LUGS (for Pin Brazing to rail)

Part No. Description Brazing Pin Reqd

47523 Braze Lug for 25 mm Cable 35836

47524 Braze Lug for 35 mm Cable 35836

47525 Braze Lug for 50 mm Cable 35836

39241 Cable Shoe #6 2 x 35836

35847 Cable Shoe 10 mm 35835

35855 Cable Shoe D=8 mm 35836

47526 Cable Lug for 16 mm Cable 35835

47527 Cable Lug for 25 mm Cable 35836

47528 Cable Lug for 35 mm Cable 35836

47529 Cable Lug for 50 mm Cable 35836

47522 Cable Lug 5/8" ground rod to #2 cable 2 x 35836

47521 Braze Sleeve #6 to #6 35836

41625 Multi-Wire Track Connection 2 x 35836

47523 Pictured

39241 Pictured

47527 Pictured

47521 Pictured

41625 Pictured

35865 Clip for 18x5mm 35835

67122 Brazing Clip 35835

(Secures Wire to Rail)

67122 Pictured

EP30200 / EP30250 User Manual ◄ 17

Page 18

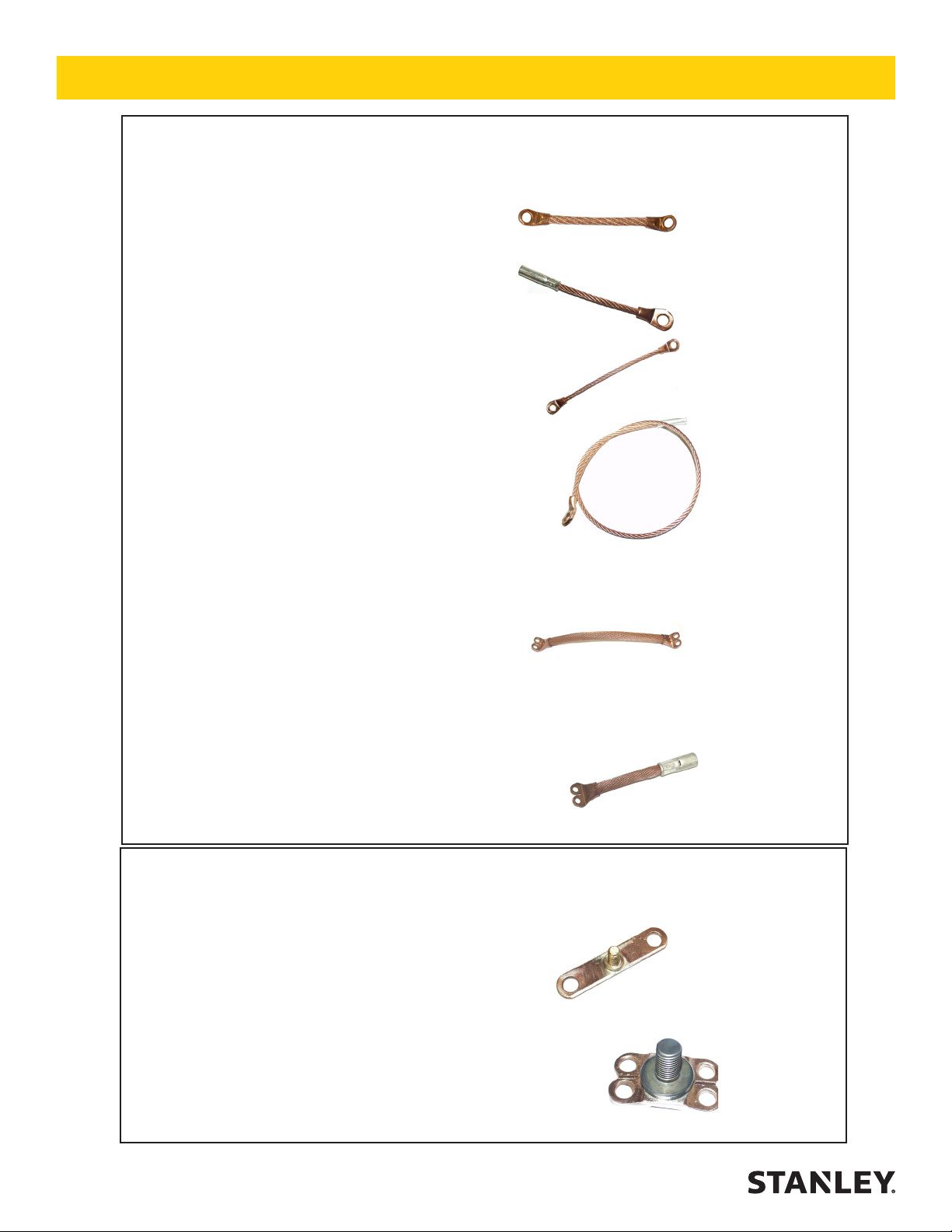

ACCESSORIES

BONDING CABLE WITH LUGS (for Pin Brazing)

Part No. Description Brazing Pin Reqd

35845 1 AWG / 50 mm², 185 mm long, copper 35837

35844 4 AWG / 25 mm², 145 mm long, copper 35835

39243 3/16 Bond, 300 mm long 35835

39244 25 mm², 200 mm long 35835

37944 50 mm², 185 mm long 35836

39705 Bond Wire 16" OAL x 25 mm 35835

39706 Bond Wire 24" OAL x 25 mm 35835

39707 Bond Wire 36" OAL x 25 mm 35835

39242 3/16 Bond Crimpable Sleev 35835

40366 Signal Extension Bond 3/16" (170 mm) 35835

40091 Signal Extension Bond 150 mm L=430 35837

40090 Signal Extension Bond 2 x 35 mm - 2 x L=170 35836

41635 3/16 Signal Bond Wire W/Eye & Crimpable sleeve 35835

24 inch long

58563 3/16 x 7”/180 mm Long with Electrode & Ferrule

41815 3/16 Bond 12’ Long Eyelet one end, AL block for 35835

Tig Weld Other End

43686 Extension Bond CU, 25 mm², x 330 mm Long 35835

43519 3/16 Extension Bond 12" 35835

41225 Bond Wire 34" Long C/L-C/L W/9 mm eyelets on 35835

both ends

41226 Bond Wire 46" Long C/L-C/L W/9 mm eyelets on 35835

both ends.

66579 25mm2 x 500mm Extension Bond 35835

66580 25mm2 x 900mm Extension Bond 35835

66269 Signal Bond 3/16" x 6' Braze Lug Both Ends 35835

35844 Pictured

39242 Pictured

40366 Pictured

41635 Pictured

67634 Railbond 300 mcm L=330 mm Uninsulated 35837

(4) 9.5 Pins Required

73652 Railbond 300 mcm L=430 mm Use with 4X Pins

73016 Railbond 300 MCM

72988 Railbond 3/16, 4 in. Reversed (50 pack)

72989 Railbond 3/16, 6 in. Reversed (50 pack)

73016 300MCM Rail Bond

67635 Extension Bond 300 mcm x 200 mm crimp sleeve 35837

(2) 9.5 Pins Required

47530 Bungalow Grounding Bond 3/16" 35836

67634 Pictured

67635 Pictured

"T" CONNECTORS

(for Pin Brazing)

TYPE C

Part No. Description Brazing Pin Reqd

35857 Copper Plate with M8 x 18 Brass Threaded Stud 35835 x 2

TYPE D

Part No. Description Brazing Pin Reqd

35860 Copper Plate with M16 x 26 Staniless Steel Threaded Stud 35837 x 4

35861 Copper Plate with M16 x 32 Stainless Steel Threaded Stud 35837 x 4

35857 Pictured

35860 Pictured

18 ► EP30200 / EP30250 User Manual

Page 19

ACCESSORIES

Grinder Abrasives

Part No. Description

73358 Carbide Burr (1/4 in. Shank)

35810 Grinding Wheel “Note, Not for SAFEBONDING!”

73052 Bull Nose Stone 2 inch (1/4 inch Shank)

Fuses, Chargers, & Batteries

Part No. Description

56557 Fuse, PCB EP30/60

56558 Fuse, Grinder Outlet EP30

56559 Fuse, Control Cable EP30

56560 Auto Fuse, 5A EP60

56561 Auto Fuse, 15A EP60

56562 Auto Fuse, 30A EP60

35866 Charger 36 VDC 7 AMP EP30/60 W/ Special DC plug.

47320 Inverter 12V DC-110VAC

41769 Battery Charger for EP60 20A 36V DC PLG Continuous Use

40409 Battery 16 AH 12 Volt EP30

39434 Battery 30 AH EP60

56557 Pictured

56561 Pictured

40409 Pictured

EP30200 / EP30250 User Manual ◄ 19

Page 20

ACCESSORIES

CABLES

Part No. Description

35809 Ground Cable_____________________________________

35806 Carrying Harness__________________________________

35820 Extension Cable for Grinding_________________________

35819 Extension Cable for Ground__________________________

41768 Adapter, Charging__________________________________

62214 Pigtail Charge Adapter_______________________________

66266 Ground Clamp Assembly (Vise Grip Style)________________________

72999 Econect Ground Magnet (Magnetic ground for econect kit) (Not Pictured)

35818 Extension Cable for S4 Brazing Gun (Not Pictured)

35816 Standard Cable for S4 Pistol 2.7m/8.8ft (Not Pictured)

35817 Long Cable for S4, 4.5m/14.75ft (Not Pictured)

GRINDER

Part No. Qty Description

HGE12141 Grinder Only (NO Battaery or Charger)

HGE12151 Includes: Grinder, Battery and Charger.

HGE12161 Includes: Grinder, Battery, Charger and Bull Nose Stone

HGE12161B Includes: Grinder, Battery, Charger and Bull Nose Stone & BNSF Stone.

73399 Battery 18V and Charger 120V

73400 Battery Lithium 18V LI-ION

20 ► EP30200 / EP30250 User Manual

Page 21

ACCESSORIES

GUNS

Part No. Description

BG10100 Pin Brazing Gun____________________________________

BG10101 Angle Head Gun____________________________________

Plugs

Part No. Description

35823 Plug Male Grinder 4-Pin______________

65831 Plug Male Controller Gun 3-Pin______________

66696 Plug Male Power Supply Gun Cable__________________

66697 Plug Male Ground Cable_________________________________

56556 Carger/Generator Plug___________________________________________

Tools

Part No. Description

37946 Hole Punch Tool 9.5mm

35824 Hole Punch Tool 8.0mm

62394 Lift Height Tool BG10100 Pin Braze Gun

EP30200 / EP30250 User Manual ◄ 21

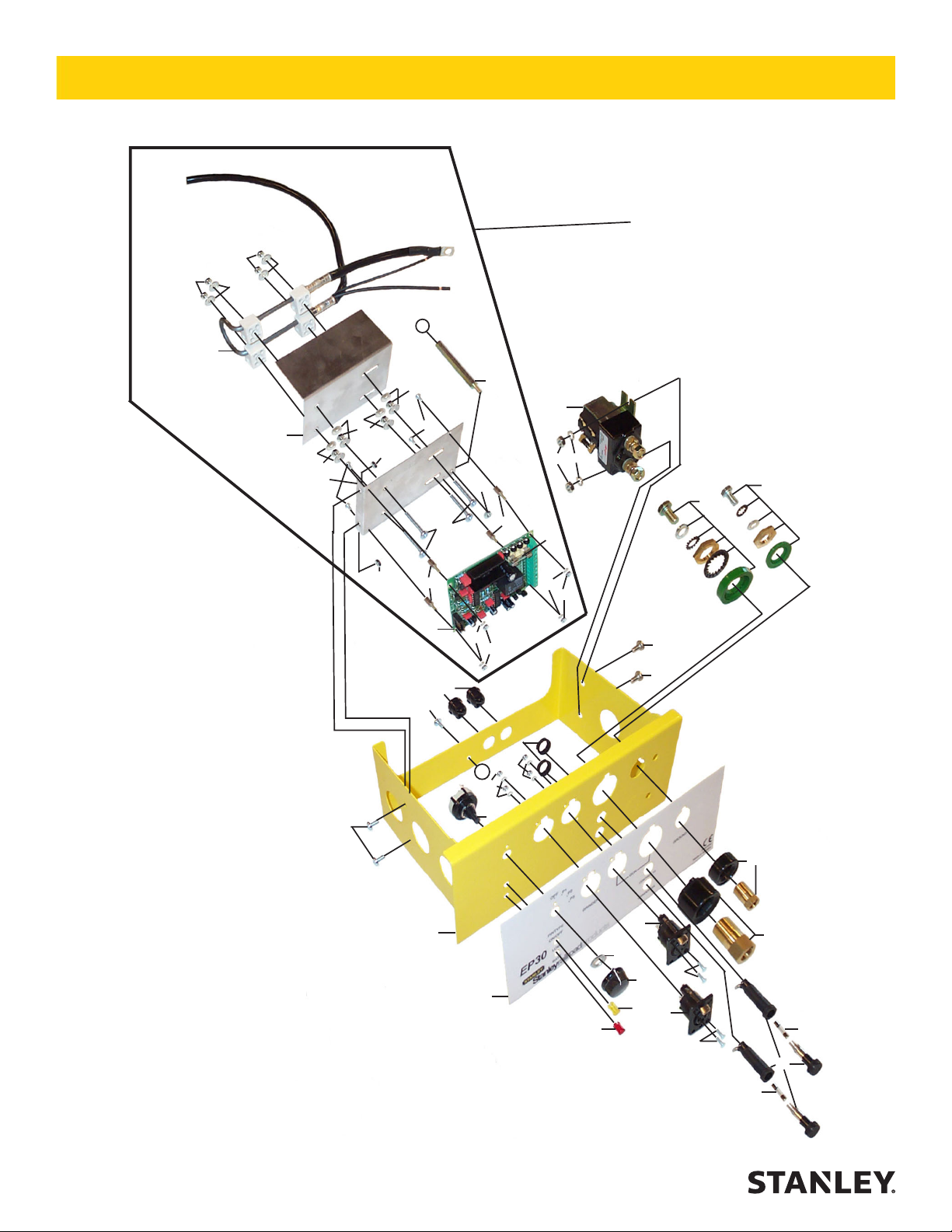

Page 22

Electronic box for EP30 XC

EP30 PARTS ILLUSTRATION

INTERNAL ELECTRONIC CONTROL BOX

25

26

25

26

A

07

26

25

26

06

25

25

05

31

31

2526

27

25

28

03

20

04

25

28

29

30

33

29

34. Resistor & Circuit Board Unit

Assembled and precalibrated

22

21

16

15

30

23

19

24

14

30

A

29

30

29

24

01

11

02

09

23

16

13

11

32

10

08

12

32

15

18

14

17

22 ► EP30200 / EP30250 User Manual

Page 23

EP30 PARTS LIST

Item Part No. Qty Description

01 66838 1 FRAME EP30

02 66846 1 LABEL EP30

03 66839 1 CIRCUIT BOARD

04 66018 1 RELAY

05 66840 1

06 66841 1 RESISTOR MOUNTING PLATE

07 66698 1 RESISTOR ASSY W/CABLE

08 66843 1 YELLOW LED LENS

09 66844 1 RED LED LENS

10 66694 1 KNOB FOR ROTARY SWITCH

11 66695 1 ROTARY SWITCH

12 66691 1 GRINDER RECEPTACLE

13 65830 1 GUN CONTROL RECEPTACLE

14 66847 2 FUSE BRACKET 5x20

15 66692 1

16 66693 1 GROUND RECEPTACLE

17 56558 1 FUSE FOR GRINDER 15A

18 56559 1 FUSE 1A

19 2 STRAIN RELIEF BUSHINGS

20 1 SPACER

21 2 NUT M6

22 2 SHAKEPROOF WASHER M6

23 2 SCREW M6x10

24 3 SCREW M4x8

25 10 NUT M4

26 12 WASHER M4

27 4 SCREW M4x30

28 4 SPACER

29 8 WASHER M3

30 8 NUT M3

31 4 SCREW M3x6

32 4 SCREW M3x10

33 56557 1 GLASS FUSE FOR PCB

34 66845 1

66131 1

CIRCUIT BOARD MOUNTING

PLATE

GUN POWER SUPPLY

RECEPTACLE

RESISTOR & CIRCUIT BOARD

UNIT (As shown on previous page

outlined by black line).

EP30 ELECTRONIC BOX

Complete unit as shown on previous page.

35801 1 Battery Box

EP30200 / EP30250 User Manual ◄ 23

Page 24

Stanley Hydraulic Tools

3810 SE Naef Road

Milwaukie, Oregon 97267-5698 USA

(503) 659-5660 / Fax (503) 652-1780

www.stanleyhydraulics.com

Loading...

Loading...