Stanley Dura-Glide 2000, Dura-Glide 5300, Dura-Glide 3000, Dura-Glide 5200, ProCare 8300A Installation And Operation Manual

Page 1

iQ Controller

Installation and Operation Manual

204144

INCLUDES INSTRUCTIONS FOR

DURA-GLIDE™ 2000/3000, 5200/5300,

DURA-GUARD™, DURA-STORM™, DURACARE™, *5400-SERIES,

*PROCARE™ 8300A, AND DURACARE 7500A TL-FBO

AUTOMATIC SLIDE DOOR SYSTEMS

*Refer to product-specic Installaon Manuals for Wiring Diagrams as they contain the relevant system wiring.

Stanley Part Number 204144

REV B 01.2019

All manuals can be found at

www.stanleymobileapps.com

Copyright 2019, Stanley Access Technologies, LLC.

Prohibition on Copying: Any unauthorized reproduction, disclosure or distribution of copies by

any person of any portion of this work may be a violation of copyright law of the United States

of America and other countries, could result in the awarding of statutory damages of up to

$250,000 (17 USC 504) for infringement, and may result in further civil and criminal penalties.

All rights reserved.

Page 2

Table of Contents

General Description ........................................................................................................... 2

Intended Use ............................................................................................................................................. 2

Applicability ............................................................................................................................................... 3

Prerequisites .............................................................................................................................................. 3

Precautions ................................................................................................................................................3

Installation Instructions .................................................................................................... 3

Installing the iQ Controller ................................................................................................................. 3

Wiring Instructions ............................................................................................................ 3

Evaluating Power Requirements ........................................................................................................ 3

Connecting Main Power Wiring ........................................................................................................4

Connecting Accessories (As Applicable) ......................................................................................... 4

Tune-In Instructions ........................................................................................................... 4

Handing for FIS Only .............................................................................................................................. 5

Tuning In the iQ Controller Using the Controller Pushbuttons ........................................... 6

Tables ............................................................................................................................................................ 7

Final Tune-In Adjustments .................................................................................................................18

Attachments ..................................................................................................................... 19

Attachment 1 - iQ Controls and Indicators .................................................................................19

Attachment 2 - iQ System Wiring Diagram ...............................................................................21

Attachment 3 - iQ Terminal Block Connections TB1-TB7 ..................................................... 31

Attachment 4 - ANSI/BHMA and UL Compliance Requirements for Sliding Doors ..32

Attachment 5 - Troubleshooting Aid ............................................................................................ 35

Attachment 6 - iQ Troubleshooting Aid ...................................................................................... 36

Attachment 7 - Fine Tuning Slide Doors .....................................................................................37

1

GENERAL DESCRIPTION

Intended Use

This manual provides installaon instrucons, wiring instrucons, and tune-in instrucons for the iQ

Controller. It includes instrucons for Dura-Glide™ 2000/3000, 5200/5300, Dura-Guard™, Dura-Storm™,

All rights reserved. Reproduction

Dura-Max™ 5400-Series*, ProCare™ 8300A*, and DuraCare™ 7500A TL-FBO Automac Slide door systems.

On Dura-Glide sliding doors, the iQ Controller replaces the MC521 and MC521Pro, or both the

microprocessor control box and the interface board on older models. The door acvaon devices (SU-100

moon sensors, carpets, control mats, push plates, etc.), lock, funcon switch, doorway holding beams, and

door posion switches previously connected to the interface board must be connected to the iQ Controller.

Aachment 1 illustrates the iQ Controller controls and indicators. Aachment 2 illustrates system wiring for

Dura-Glide series sliders.

This manual supports the hardware and rmware at the me of this released revision.

Applicability

Copyright 2019 Stanley Access Technologies, LLC.

in whole or in part without the express written permission of Stanley is prohibited.

This manual is applicable to the Dura-Glide series sliding doors used on Dura-Glide™ 2000/3000, 5200/5300,

Dura-Guard™, Dura-Storm™, Dura-Max™ 5400-Series, ProCare™ 8300A, and DuraCare™ 7500A TL-FBO

Automac Slide door systems.

Instrucons for connecng oponal accessories are not provided in this manual.

01.25.2019

2 Document # 204144 REV B • www.stanleyaccess • 1.800.7.ACCESS

Page 3

iQ Control Box

Prerequisites

Special Items Required:

• Stanley Access Technologies document No. 203957, “SU-100 Moon Sensor Installaon and Operaon” (if

installed).

• SU-100 tune-in remote control (if SU-100 Moon Sensor is installed).

• Stanley Access Technologies document No. 203768, “StanguardTM Threshold Sensor Installaon and Operaon”

(if installed).

• Optex X Zone T or X Zone ST manufacturer’s installaon and tune-in instrucons (if installed).

• Hotron HR100 ST manufacturer’s installaon and tune-in instrucons (if installed).

• Bluetooth adapter or cable to connect compable handheld device to iQ Controller.

• Degreaser.

• Instrucons for any other device to be wired into the iQ Controller.

Precautions

All ANSI/BHMA and UL Requirements in Attachment 4 must be met before the door is put into operation.

2

INSTALLATION INSTRUCTIONS

Installing the iQ Controller

NOTE: This manual covers new door installaons in which the iQ is factory-installed and wired.

3

WIRING INSTRUCTIONS

Evaluating Power Requirements

• ENSURE power source is a dedicated 115 VAC, 50/60 Hz source with 20A circuit rang. If four operators are

used, the source should have a 30A rang.

• ENSURE no more than four operators will be connected to one circuit.

• ENSURE power source is not shared with other equipment, i.e., cash registers, EAS systems, or other

electromagnec interference generators.

Copyright 2019, Stanley Access Technologies, LLC. All rights reserved. Reproduction

1.800.7.ACCESS • www.stanleyaccess.com • Document # 204144 REV B 3

in whole or in part without the express written permission of Stanley is prohibited.

01.25.2019

Page 4

iQ Control Box

Connecting Main Power Wiring

Warning: To prevent injury to personnel, incoming electrical power to the header must be de-energized

before connecng electrical service to the control box.

Warning: All electrical wiring must conform to Naonal Electrical Code Requirements.

1. DE-ENERGIZE incoming electrical power to header.

2. Refer to Aachment 2, and, using wire nuts, CONNECT incoming line, neutral, and ground wires

to the controller power harness.

3. IF adhesive wire clamps will be used, DE-GREASE metal surfaces on inside of header cover

where clamps will mount.

4. SECURE wiring to top of the header track tube, and ENSURE the following:

• All wires are clear of belts and belt brackets.

• Header cover opens and closes without interference.

Connecting Accessories (As Applicable)

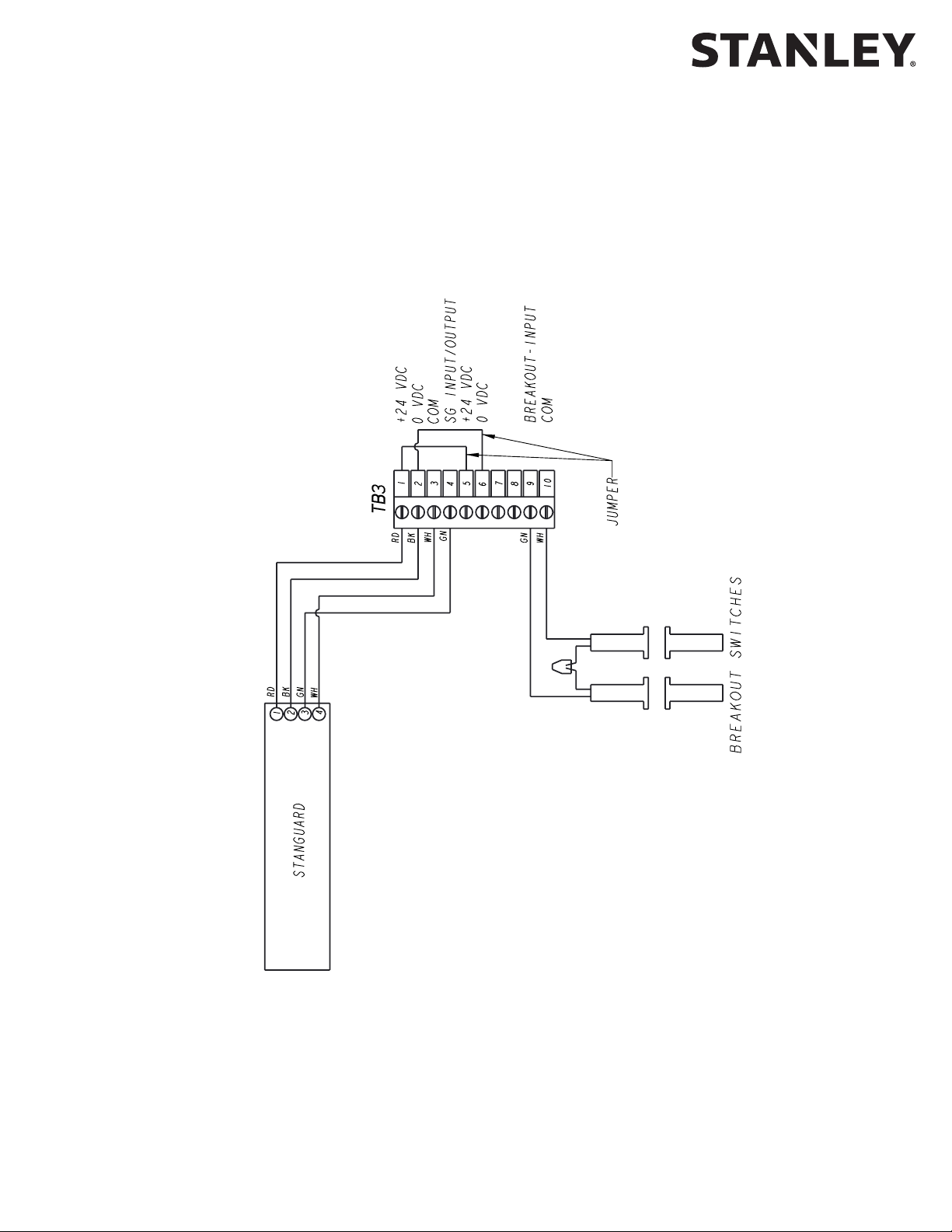

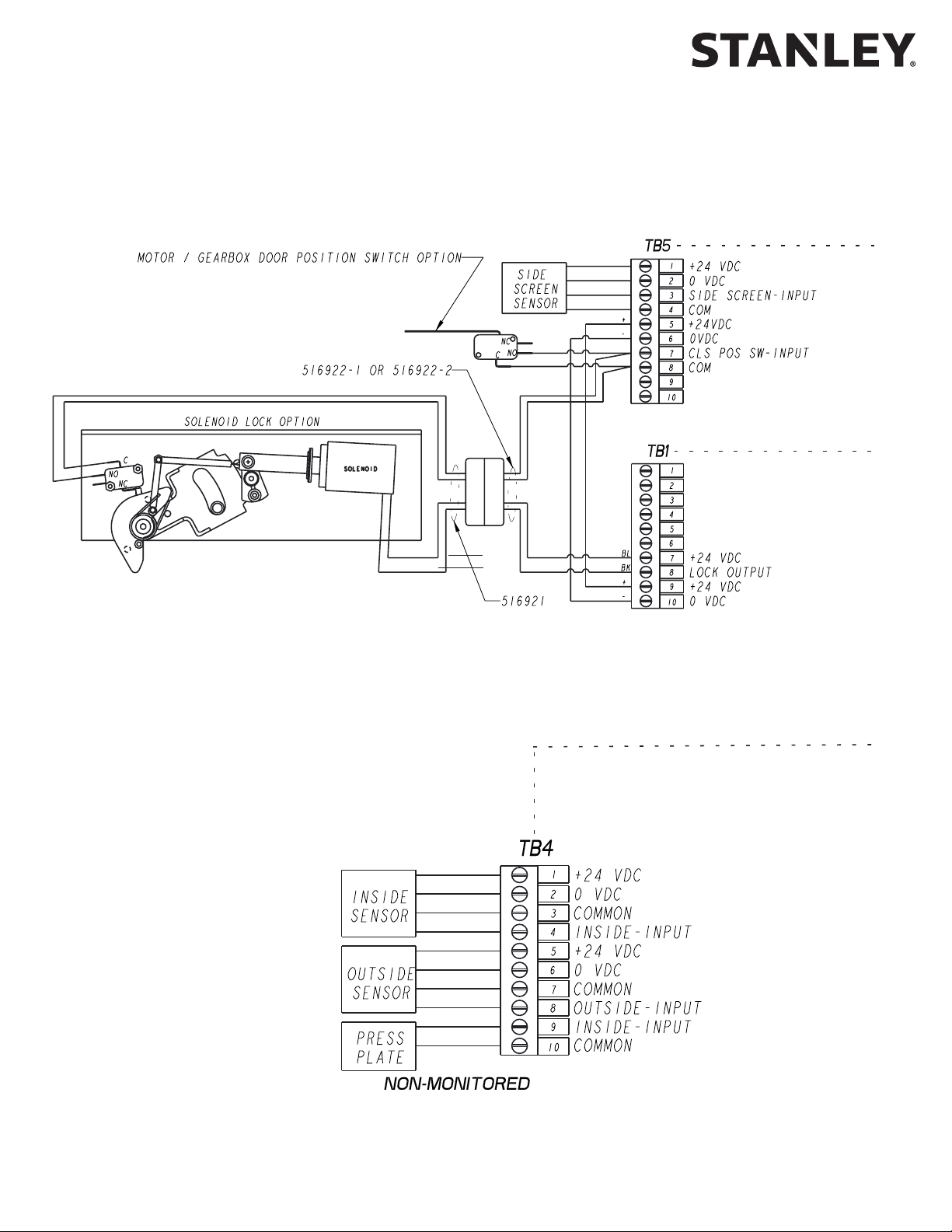

Refer to Aachments 2 and 3, and CONNECT any of the following subsystems to the iQ Controller:

• Funcon switch (rotary, rocker and “POWER” switch wiring).

• StanguardTM threshold sensor.

• Doorway holding beam(s).

• Breakout switch.

• Solenoid lock.

• SU-100 moon sensor(s) wiring (refer to Stanley Document #203957).

• Optex X Zone T and X Zone ST Sensor(s) wiring.

• Push plate wiring.

• Door posion switch closed contact (with door closed).

• Hotron HR100 ST Sensor(s) wiring.

All rights reserved. Reproduction

4

TUNE-IN INSTRUCTIONS

Warning: The door path must be free of objects and remain clear unl the First Install Sequence (FIS)

is complete. During this sequence the sensors are inacve and the door has no SAFETY. To stop the door,

turn power off or put the doors into breakout.

NOTES:

1. Tune-In: The iQ Controller can be tuned-in using a handheld device or using the pushbuon switches

located on the controller. Tune-in using a handheld device is the preferred method.

Copyright 2019, Stanley Access Technologies, LLC.

in whole or in part without the express written permission of Stanley is prohibited.

01.25.2019

4 Document # 204144 REV B • www.stanleyaccess.com • 1.800.7.ACCESS

2. Status Codes: During normal operaon, the digital display indicates status codes. The “UP” and “DOWN”

pushbuon switches can be used to enter and display data values. The user interface values are shown

in Tables 2 through 4.

Page 5

iQ Control Box

PULLEY ROTATES CCW

WHILE OPENING

USE RIGHT HAND IN FIS

PULLEY ROTATES CW

WHILE OPENING

USE LEFT HAND IN FIS

RIGHT HAND

LEFT HAND

HANDING

3. Solenoid Lock: If a solenoid lock is installed with no lock circuit board (new style), set Lock Logic to the

actual lock type (Fail Safe or Fail Secure). If a Fail Safe or Fail Secure Lock is being installed with a lock circuit

board (old style), the Lock Logic must be set to Fail Secure.

4. Handing (For purpose of FIS only): Manually open door nong rotaon of belt pulleys. If counter clockwise (CCW)

use right hand during FIS. If clockwise (CW) use le hand during FIS. See gure below.

5. FIS: The rst installaon sequence (FIS) is used to perform the inial conguraon. Upon compleon of FIS, all

setup parameters are stored in non-volale memory. Subsequent power cycles will reload the

conguraon parameters that were congured during FIS.

6. Decimal points on digital display are encoder 1 signals. Rotang motor will cause decimal points to blink

and appear to dim.

7. Aer changing values, the values must be saved in non-volale memory by cycling the door to full open.

Copyright 2019, Stanley Access Technologies, LLC. All rights reserved. Reproduction

in whole or in part without the express written permission of Stanley is prohibited.

1.800.7.ACCESS • www.stanleyaccess.com • Document # 204144 REV B 5

01.25.2019

Page 6

iQ Control Box

Tuning In the iQ Controller Using the Controller Pushbuttons

1. To change the INDEX and VALUE:

To show the INDEX press and hold ENTER, the current INDEX will display. Once ENTER is released, the display

will show the VALUE of that INDEX. Aer 2.5 seconds, the display will return to the current status code.

2. To change the INDEX:

Hold ENTER switch while pressing UP or DOWN to get desired INDEX.

3. To change a VALUE:

a. Unlock the keypad by seng index 99 to value 00.

b. Aer the desired INDEX is selected, release ENTER and within 2.5 seconds press UP or DOWN to get the

desired VALUE. (If the UP or DOWN buons are not pressed within 2.5 seconds of releasing the ENTER

buon, the display will change from the VALUE back to the STATUS.)

4. To display STATUS CODE:

A few seconds aer the VALUE is selected, the display indicates the STATUS CODE.

5. Refer to Tables 2 and 3 for a list of index seng descripons and values. Read the descripons enrely

before performing each step. Check the INDEX and VALUE aer each step.

6. To STORE CHANGES in permanent memory:

Cycling door open one me will store changes.

7. To LOCK keypad:

Lock keypad by seng index 99 to value 01 or by turning power OFF and then ON.

8. To ACCESS the door cycle counter funcon:

a. Ensure that the keypad is locked by seng index 99 to 01.

b. Ensure that the index is set to any index but 99.

c. Press the up or down key to access the door cycle counter.

The display will show “dc” followed by four pairs of digits, followed by “dc”.

Example: If the Door Count was 12345678 cycles the controller will display “dc” “12” “34” “56” “78” “dc”.

All rights reserved. Reproduction

Copyright 2019, Stanley Access Technologies, LLC.

in whole or in part without the express written permission of Stanley is prohibited.

01.25.2019

6 Document # 204144 REV B • www.stanleyaccess.com • 1.800.7.ACCESS

Page 7

iQ Control Box

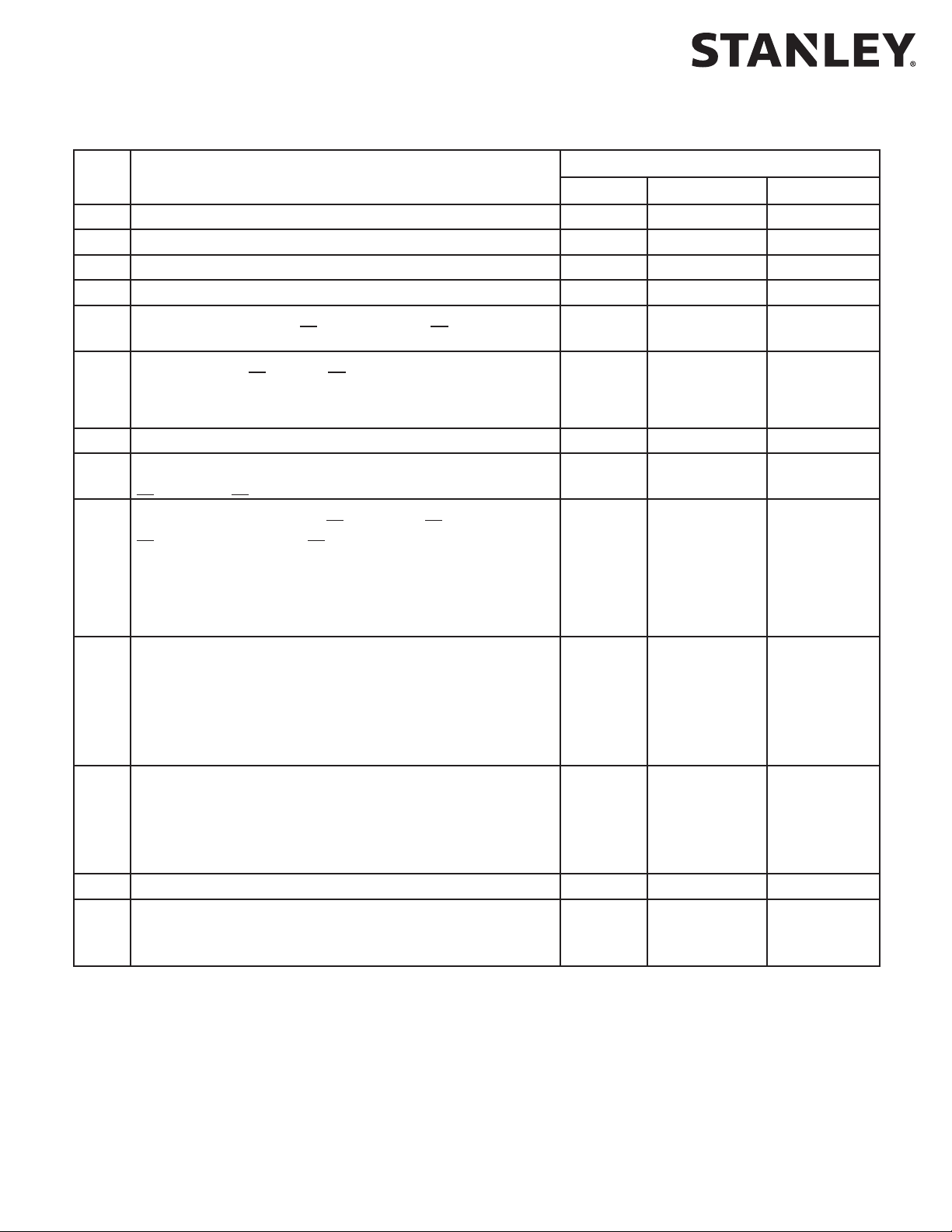

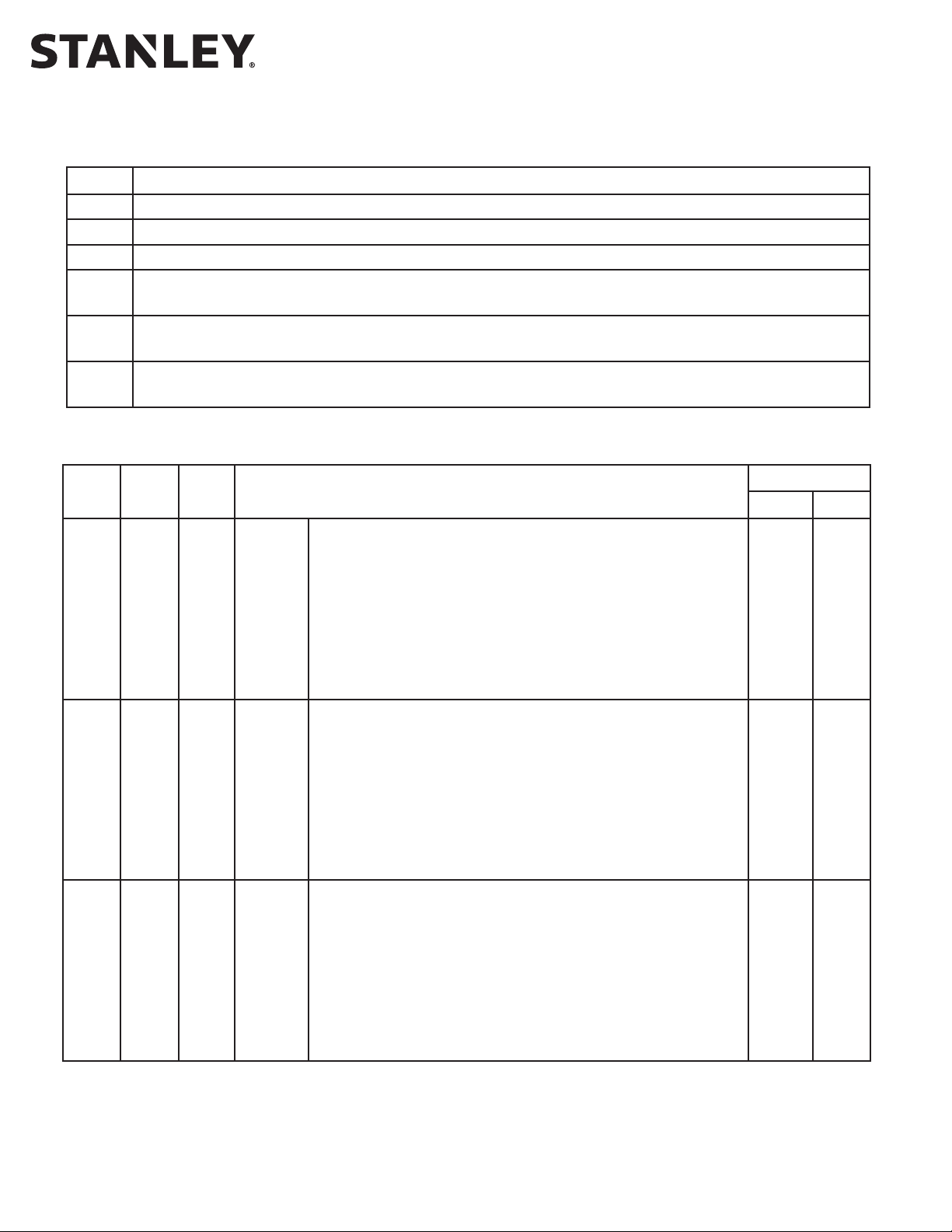

Table 1. FIS Procedure using Pushbuttons

Step Description Display

Index Value Status Code

1 Set Funcon Switch to Closed.

2 Turn power on.

3 Unlock keypad. 99 00 00

4 Restart FIS. 96 01 A0

5 Select door type: Slide, 01 single motor or 02 dual motor. 00 01 (Single)

02 (Dual)

6 Select Handing: 00 Right or 01 Le.

Manually open door and note rotation of belt pulleys.

If counterclockwise (CCW) use right hand during FIS.

If clockwise (CW) use left hand during FIS.

01

7 Accept FIS. Display will go to A1. 03 01 A1

8 Make changes: Funcon Switch

11 01 (Rocker)

01 Rocker or 00 Rotary. The INDEX will start at 00.

9 Select Lock Logic: Lock Logic, 00 = Fail Safe; 01 = Fail Secure;

07 Lock Logic:

02 = Fail Safe Dura-Max; 03 = Fail Secure Dura-Max.

NOTE: For locks with circuit board, set to 01 Fail Secure.

For locks with no circuit board, set to Fail Safe

or Fail Secure.

10

Warning: During this sequence the sensors are inactive and the door

has NO SAFETY. To stop the door, TURN POWER OFF or PUT THE DOOR

INTO BREAKOUT.

Function Switch: Switch to OPEN, momentarily, then CLOSED/

LOCKED. The door opens fully, delays and then closes fully.

The iQ displays A2 when FIS is completed.

11 Aer FIS is complete it might be necessary to change index

11 (safety logic) and Index 20 (Safety Beam Type) to match

the systems installed.

Adjust any other index sengs as needed (refer to Table 3

for opons).

12 Lock keypad. 99 01 00

13 Final Tune-In.

Walk test doors to conrm compliance with applicable ANSI

Standards and local codes.

00 (Right)

01 (Le)

00 (Rotary)

00 = Fail Safe

01 = Fail Secure

02 = Fail Safe

Dura-Max

03 = Fail Secure

Dura-Max

A0

A1

A2

Copyright 2019, Stanley Access Technologies, LLC. All rights reserved. Reproduction

1.800.7.ACCESS • www.stanleyaccess.com • Document # 204144 REV B 7

in whole or in part without the express written permission of Stanley is prohibited.

01.25.2019

Page 8

iQ Control Box

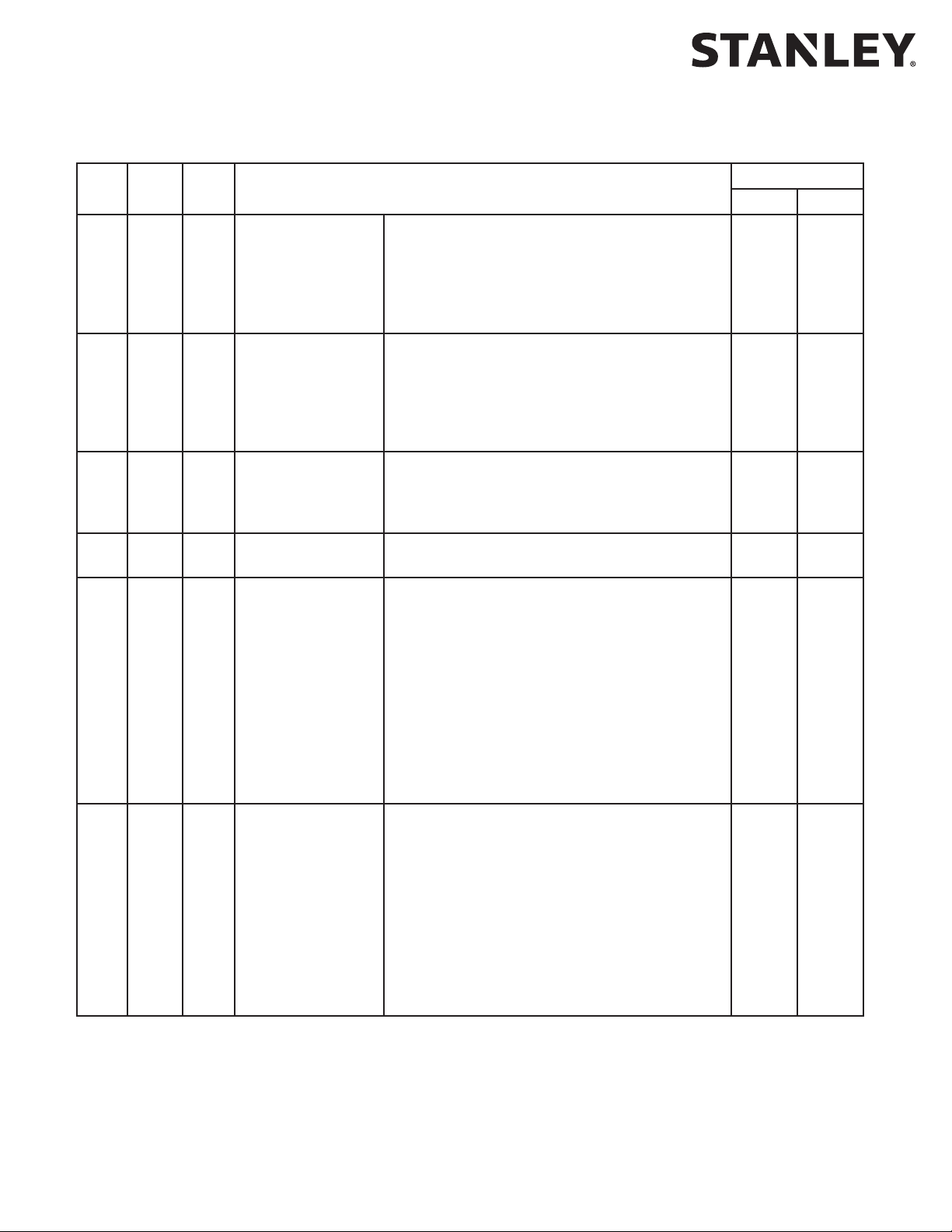

Table 2. Index List

Index Description

0 - 99 Sengs Values, see Table 3.

90 - 95 Reserved.

96 Command – Restart FIS. Entering “01” will cause FIS to restart.

97 Firmware – Entering “01” will display “FE” followed by two pairs of digits followed by “FE”. For example,

if the rmware was 0609 the controller will display “FE” “06” “09” “FE”.

98 Command – Restart auto conguraon. Entering “01” sets the Control Box to “A1” keeping all previous

values and then re-learns the encoder count.

99* Command – Lock. Entering “01” will lock all value inputs except this index. This prevents inadvertent

changes to input values. Values may be unlocked by entering “00” in this index.

Table 3. Settings

Index Min.

Value

0 1 99* Open

1 1 99* Close

All rights reserved. Reproduction

2 1 99* Open

Copyright 2019, Stanley Access Technologies, LLC.

in whole or in part without the express written permission of Stanley is prohibited.

Max

Value

Speed

Speed

Check

Speed

Open Speed is the speed used during normal operaon

in the opening state (02).

This speed is set to change how long it takes the door

to open.

This parameter sets the target speed seng. Other

parameters like open torque, open startup torque, open

startup length, and open acceleraon as well as door

properes like fricon, door length, and door weight

aect door speed.

Close Speed is the speed used during normal operaon in the

closing state (07).

This speed is set to change how long it takes the door

to close.

This parameter sets the target speed seng. Other

parameters like Close Torque, Close Startup Torque, Close

Startup Length, and Close Acceleraon as well as door

properes like fricon, door length, and door weight aect

door speed.

Open Check Speed is the speed used during normal

operaon in the open check state (04) prior to arriving at

full open.

This speed is set to determine how fast the door arrives at

full open aer open speed.

This parameter sets the target speed seng. Other

parameters like open check torque, open acceleraon,

and open braking as well as door properes like fricon,

door length, and door weight aect door speed.

Defaults

Single Dual

99 99

35 25

10 10

NOTE: With the iQ Toolbox, the Max Values are 125.

Table 3 Settings continued next page.

01.25.2019

8 Document # 204144 REV B • www.stanleyaccess.com • 1.800.7.ACCESS

Page 9

iQ Control Box

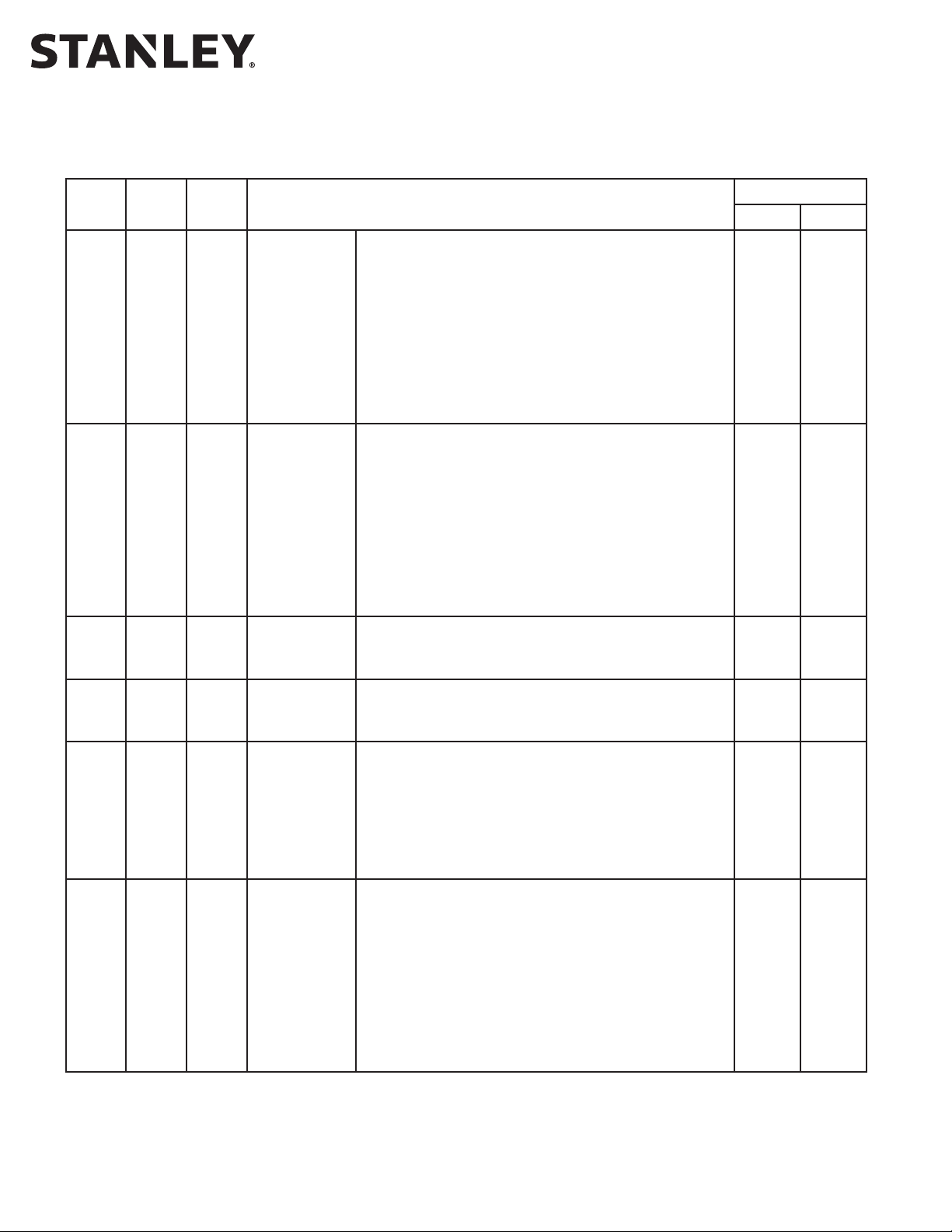

Table 3. Settings (continued)

Index Min

Value

Max

Value

Description Defaults

3 5 99 Open Check Length Open Check Length is the percent of door

length in which the door starts to slow down to

open check speed.

This parameter typically is adjusted based on

door weight and open speed seng.

4 5 99 Close Check Length Close Check Length is the percent of door length

in which the door starts to slow down to Close

Check Speed.

This parameter typically is adjusted based on

door weight and Close Speed seng.

5 1 99 Reduced Open

Length

Reduced Open Length is the percent of door length

from the full open posion the door will stop at if in

reduced open mode.

6 1 99 Hold Open Delay Delay that the door stays open aer all sensors

have cleared (0 to 25 seconds).

7 0 3 Lock Logic Select to choose desired Lock Logic.

NOTE: Dura-Max 5400 logic is dierent and has

its own two opons:

00 = Fail Safe (unlocked when power

is removed),

01 = Fail Secure (locked when power

is removed),

02 = Dura-Max Fail Safe (unlocked when power

is removed),

03 = Dura-Max Fail Secure (locked when power

is removed).

8 1 99* Open Torque Open Torque is the torque used during normal

operaon following the end of open startup

length.

Single Dual

40 25

15 15

1 1

15 15

1 1

40 45

This torque must be set to comply with BHMA/

ANSI door force requirements.

This parameter sets the maximum current

available to the motor which is directly

proporonal to the door force. This torque

seng is used in conjuncon with open speed.

Table 3 Settings continued next page.

1.800.7.ACCESS • www.stanleyaccess.com • Document # 204144 REV B 9

Copyright 2019, Stanley Access Technologies, LLC. All rights reserved. Reproduction

in whole or in part without the express written permission of Stanley is prohibited.

01.25.2019

Page 10

Table 3. Settings (continued)

iQ Control Box

Index Min

Value

Max

Value

Description Defaults

9 1 99 Close Torque Close Torque is the torque used during normal

operaon following the end of Close Startup Length.

This torque must be set to comply with BHMA/ANSI

door force equirements.

This parameter sets the maximum current available

to the motor which is directly proporonal to the

door force. This torque seng is used in

conjuncon with Close Speed.

10 1 99 Close Check

Torque

Close Check Torque is the torque used during normal

operaon in close check state.

This torque must be set to comply with BHMA/ANSI

door force requirements.

This parameter sets the maximum current available

to the motor which is directly proporonal to the

door force. This torque seng is used in conjuncon with close check speed.

11 0 2 Funcon

Switch Type

00 = Double pole rotary

01 = Rocker

02 = ICU

12 0 1 2S Operaon; 00 = 2S mode disabled / normal

01 = Push switch to open, push switch to close;

Single Dual

30 25

35 25

1 1

0 0

13 1 60 Close

Obstrucon

Time

Close Obstrucon Time is the amount of me in

increments of 0.025s the door applies force when

almost stopped or stopped when the controller

indicates a state of “07”.

All rights reserved. Reproduction

Before increasing this parameter, check mechanical

issues, and speed and torque parameter sengs.

14 0 40 Open

Acceleraon

Open Acceleraon aects the rate at which the door

gets to its target speed.

This parameter is used when the door is lagging

open speed; open startup torque and open startup

length should be invesgated prior to increasing.

This parameter aects all open moon speeds: open

speed, open check speed, open learn speed, as well

Copyright 2019, Stanley Access Technologies, LLC.

in whole or in part without the express written permission of Stanley is prohibited.

Table 3 Settings continued next page.

01.25.2019

10 Document # 204144 REV B • www.stanleyaccess.com • 1.800.7.ACCESS

as open braking.

50 50

30 30

Page 11

iQ Control Box

Table 3. Settings (continued)

Index Min

Value

Max Value Description Defaults

15 1 10 Open

Braking

16 0 40 Close

Acceleraon

17 1 10 Close

Braking

The Open Braking parameter adjusts

how quickly the door slows down prior

to check speed.

Increasing this parameter increases

braking power.

Close Acceleraon aects the rate at

which the door gets to its target speed.

This parameter is used when the door is

lagging close speed, close startup torque

and close startup length should be

invesgated prior to increasing.

This parameter aects all close moon

speeds: close speed, close check speed,

close learn speed, as well as close

braking.

The Close Braking parameter adjusts

how quickly the door slows down prior

to check speed.

Single Dual

8 8

20 20

4 2

Increasing this parameter increases

braking power.

18 0 6 Delayed Egress Special Locking Applicaon. See the

Delay Egress Instrucon Manual for use.

00 = O

01 = 15 sec delay 1 second nuisance

02 = 30 sec delay 1 second nuisance

03 = 15 sec delay 2 second nuisance

04 = 30 sec delay 2 second nuisance

05 = 15 sec delay 3 second nuisance

06 = 30 sec delay 3 second nuisance

19 0 5 Safety Logic 00 - Monitored 2 Sensors: Threshold

zone control (the threshold zone

is enabled and disabled by the iQ).

1 - Monitored 4 Sensors: Threshold

zone control (the threshold zone is

enabled and disabled by the iQ).

2 - Monitored StanGuard™: (not

recommended for Telescopic doors).

3 - Monitored 2 sensors.

4 - Non-monitored sensors.

5 - Monitored 4 sensors.

0 0

2 2

Copyright 2019, Stanley Access Technologies, LLC. All rights reserved. Reproduction

in whole or in part without the express written permission of Stanley is prohibited.

Table 3 Settings continued next page.

1.800.7.ACCESS • www.stanleyaccess.com • Document # 204144 REV B 11

01.25.2019

Page 12

Table 3. Settings (continued)

iQ Control Box

Index Min

Value

Max

Value

Description Defaults

20 0 1 Hold Beam Type 00 - Non-monitored Hold Beam

01 - Monitored Hold Beam

Selects the hold beam type to be used for

monitored or non-monitored applicaons.

For Monitored Hold Beams: Photobeam Pro or

Optex OSC12CT refer to wiring diagrams

per applicaon.

21 1 50 Lock Delay This allows the lock to mechanically unlock

before door moon. Lock Delay in 0.1 second

increments.

22 0 99 Open Stop Distance Distance from full open that the door will stop.

This will be in 0.25” increments.

23 1 99 Close Check Speed Close Check Speed is the speed used during

normal operaon in the close check state (09)

prior to arriving at full closed.

This speed is set to determine how fast the

door arrives at full closed aer close speed.

This parameter sets the target speed seng.

Other parameters like close check torque, close

acceleraon, and close braking as well as door

properes like fricon, door length, and door

weight aect door speed.

24 0 1 Access Control Pro

Enabled

Inside sensor lockout funcon.

00= OFF

01= ON

When set to 01-On, the interior acvaon input is inhibited if the exterior acvaon input

is acve. Acvaon override can be

accomplished through TB2 pin 9 and 10.

25 0 5 Close Press Close Press aects how the doors press

All rights reserved. Reproduction

together at full closed. If the value selected is

0, the door does not press at the closed

posion. A value of 1 will have a soer release

of motor energy and a value of 5 will be a

quicker release.

27 1 99 Lock Release Torque Lock Release Torque is the torque used on

lock release state. A closed posion switch is

required, connected to TB-5.

This parameter sets the maximum current

available to the motor which is directly

proporonal to the door force.

28 1 60 Close Check

Copyright 2019, Stanley Access Technologies, LLC.

in whole or in part without the express written permission of Stanley is prohibited.

Obstrucon Time

Close Check Obstrucon Time is the amount of

me in increments of 0.025s the door

applies force when almost stopped or stopped

when the controller indicates a state of “09”.

Before increasing this parameter, check

01.25.2019

mechanical issues, and speed and torque

parameter sengs.

Single Dual

1 1

1 1

4 4

8 8

0 0

2 2

20 20

50 50

12 Document # 204144 REV B • www.stanleyaccess.com • 1.800.7.ACCESS

Page 13

iQ Control Box

Table 3. Settings (continued)

Index Min

Value

Max

Value

31 1 99* Close Learn

Speed

32 1 99 Close Learn

Torque

33 0 99 Close Startup

Length

Description Defaults

Close Learn Speed is the speed used on power up,

during FIS and aer an obstrucon. The controller

display may indicate either 07 or 09 as a door state

and sll use Close Learn Speed based on the

condions listed prior.

This speed is typically set higher than check speed,

to allow faster door moon when not in the check

zones, but sll slower door moon than normal

operaon.

This parameter sets the target speed seng. Other

parameters like close learn torque and close

acceleraon as well as door properes like fricon,

door length, and door weight aect door speed.

Close Learn Torque is the torque used on power up,

during FIS, aer an obstrucon.

This torque must be set to comply with ANSI/

BHMA door force requirements.

This parameter sets the maximum current available

to the motor which is directly proporonal to the

door force. This torque seng is used in

conjuncon with Close Learn Speed.

Close Startup Length is the percent of door length

in which Close Startup Torque parameter is used.

These parameters are used to overcome fricon

encountered at the begining of close door moon.

Single Dual

20 20

30 25

0 0

35 1 99 Close Startup

Torque

Table 3 Settings continued next page.

This parameter should be set as low as possible to

ensure reliable operaon.

Close Startup Torque is the torque used when

35 25

entering the closing state (07). It is used for a

congurable door length (determined by the Close

Startup Length parameter). Aer this door length,

the torque seng will revert to the Close Torque.

This torque should be set greater than Close Torque

to ensure that the controller can start door moon,

overcome stac fricon, and avoid obstrucons.

This torque must be set to comply with ANSI/BHMA

door force requirements.

Copyright 2019, Stanley Access Technologies, LLC. All rights reserved. Reproduction

This parameter sets the maximum current available

to the motor which is directly proporonal to the

door force.

1.800.7.ACCESS • www.stanleyaccess.com • Document # 204144 REV B 13

in whole or in part without the express written permission of Stanley is prohibited.

01.25.2019

Page 14

Table 3. Settings (continued)

iQ Control Box

Index Min

Value

Max

Value

36 1 60 Open Check

Obstrucon

Time

37 1 99 Open Check

Torque

39 1 99* Open Learn

Speed

Description Defaults

Open Check Obstrucon Time is the amount of me

in increments of 0.025s the door applies force when

almost stopped or stopped when the controller

indicates a state of “04”.

Before increasing this parameter, check mechanical

issues, and speed and torque parameter sengs.

Open Check Torque is the torque used during

normal operaon in open check state.

This torque must be set to comply with ANSI/BHMA

door force requirements.

This parameter sets the maximum current available

to the motor which is directly proporonal to the

door force. This torque seng is used in

conjuncon with open check speed.

Open Learn Speed is the speed used on power up,

during FIS, aer an obstrucon, and return from

breakout. The controller display may indicate either

02 or 04 as a door state and sll use Open Learn

Speed based on the condions listed prior.

Single Dual

50 50

40 40

25 25

All rights reserved. Reproduction

Copyright 2019, Stanley Access Technologies, LLC.

in whole or in part without the express written permission of Stanley is prohibited.

40 1 99 Open Learn

Torque

41 1 60 Open

Obstrucon

Time

This speed is typically set higher then check speed,

to allow faster door moon when not in the check

zones, but sll slower door moon than normal

operaon.

This parameter sets the target speed seng.

Other parameters like open learn torque, and open

acceleraon as well as door properes like fricon,

door length, and door weight aect door speed.

Open Learn Torque is the torque used on power up,

during FIS, aer an obstrucon, and return from

breakout.

This torque must be set to comply with ANSI/BHMA

door force requirements.

This parameter sets the maximum current available

to the motor which is directly proporonal to the

door force. This torque seng is used in

conjuncon with open learn speed.

Open Obstrucon Time is the amount of me in

increments of 0.025s the door applies force when

almost stopped or stopped when the controller

indicates a state of “02”.

Before increasing this parameter, check mechanical

issues, and speed and torque parameter sengs.

48 25

50 50

Table 3 Settings continued next page.

01.25.2019

14 Document # 204144 REV B • www.stanleyaccess.com • 1.800.7.ACCESS

Page 15

iQ Control Box

Table 3. Settings (continued)

Index Min

Value

42 0 99 Open Startup

Max

Value

Length

Description Defaults

Open Startup Length is the percent of door length in which

open startup torque parameter is used. These parameters

are used to overcome fricon encountered at the begining

of open door moon.

This parameter should be set as low as possible to

ensure reliable operaon.

44 1 99 Open Startup

Torque

Open Startup Torque is the torque used when entering

the opening state (02) and recycles. It is used for

a congurable door length (determined by the

Open Startup Length parameter). Aer this door

length, the torque seng will revert to the Open Torque.

This torque should be set greater than Open Torque

to ensure that the controller can start door moon,

overcome stac fricon, and avoid obstrucons.

This torque must be set to comply with ANSI/BHMA

door force requirements.

This parameter sets the maximum current available

to the motor which is directly proporonal to the

door force.

45 0 99 Recycle Speed Recycle Speed is the percent of open speed that is used

when recycling in the open check or open braking zone.

46 0 50 Lock Release

Time

The amount of me (seconds) that the door will press

closed before going open when the lock needs to

release at the closed posion. The value zero

disables the lock release. A closed posion switch is

required, connected to TB-5.

47 0 4 Fire Alarm

Mode

Allows a normally closed contact to force the door

open or closed slowly, upon contact opening.

Single Dual

15 15

85 85

30 20

0 0

0 0

Used in conjuncon with Congurable I/O parameter.

Opons 00 to 04 are minimum and maximum values:

00 = Disabled,

01 = Open,

02 = Close,

03 = Open with Retry,

04 = Close with Retry.

Aer an obstrucon, retry modes (03 and 04) will retry

with short delay.

Table 3 Settings continued next page.

1.800.7.ACCESS • www.stanleyaccess.com • Document # 204144 REV B 15

Copyright 2019, Stanley Access Technologies, LLC. All rights reserved. Reproduction

in whole or in part without the express written permission of Stanley is prohibited.

01.25.2019

Page 16

Table 3. Settings (continued)

iQ Control Box

Index

Min

Value

Max

Value

Description Defaults

Single Dual

0 3 IO conguraon 0 0

48

00 (Default)

TB2-5 TB2-7 TB2-9

1 way / 2 way Reduced Access Control Pro acvaon override (highest priority

when selected).

4 Monitored Sensors (when selected).

Delay egress reset (default).

01 1 way / 2 way Reduced Fire Alarm.

02 1 way / 2 way Fire alarm Access Control Pro acvaon override (highest priority

when selected).

4 Monitored Sensors (when selected).

Delay egress reset (default).

03 Fire alarm Reduced Access Control Pro acvaon override (highest priority

when selected).

4 Monitored Sensors (when selected).

Delay egress reset (default).

IO Configuration Parameter Description

Allows the Fire Alarm to be used instead of funcons normally used with the selected input:

0 = Standard Funcons (NO Fire Alarm Input).

1 = Fire Alarm Input is TB2-9 (Removes Funcons: Access Control Pro acvaon override, Delayed Egress Reset,

and 4 Monitored Sensor capability).

2 = Fire Alarm Input is TB2-7 (Removes Reduced Open funcon).

3 = Fire Alarm Input is TB2-5 (Removes One-way funcon).

All rights reserved. Reproduction

Index

49

Min

Value

0 99 Open Power

Max

Value

Assist Torque

Descriptions Defaults

This parameter sets the current to the motor which

is used to make the door feel easier to move open

when in “Manual” mode. This value should be

set only as high as is needed to reduce the force

required to move the door. Seng this value too

high can cause the door to move by itself.

Only available when index 11 is set to 02-ICU.

50 0 99 Close Power

Assist Torque

This parameter sets the current to the motor which

is used to make the door feel easier to move closed

when in “Manual” mode. This value should be

set only as high as is needed to reduce the force

required to move the door. Seng this value too

Copyright 2019, Stanley Access Technologies, LLC.

in whole or in part without the express written permission of Stanley is prohibited.

high can cause the door to move by itself.

Only available when index 11 is set to 02-ICU.

01.25.2019

16 Document # 204144 REV B • www.stanleyaccess.com • 1.800.7.ACCESS

Single Dual

60 60

50 50

Page 17

iQ Control Box

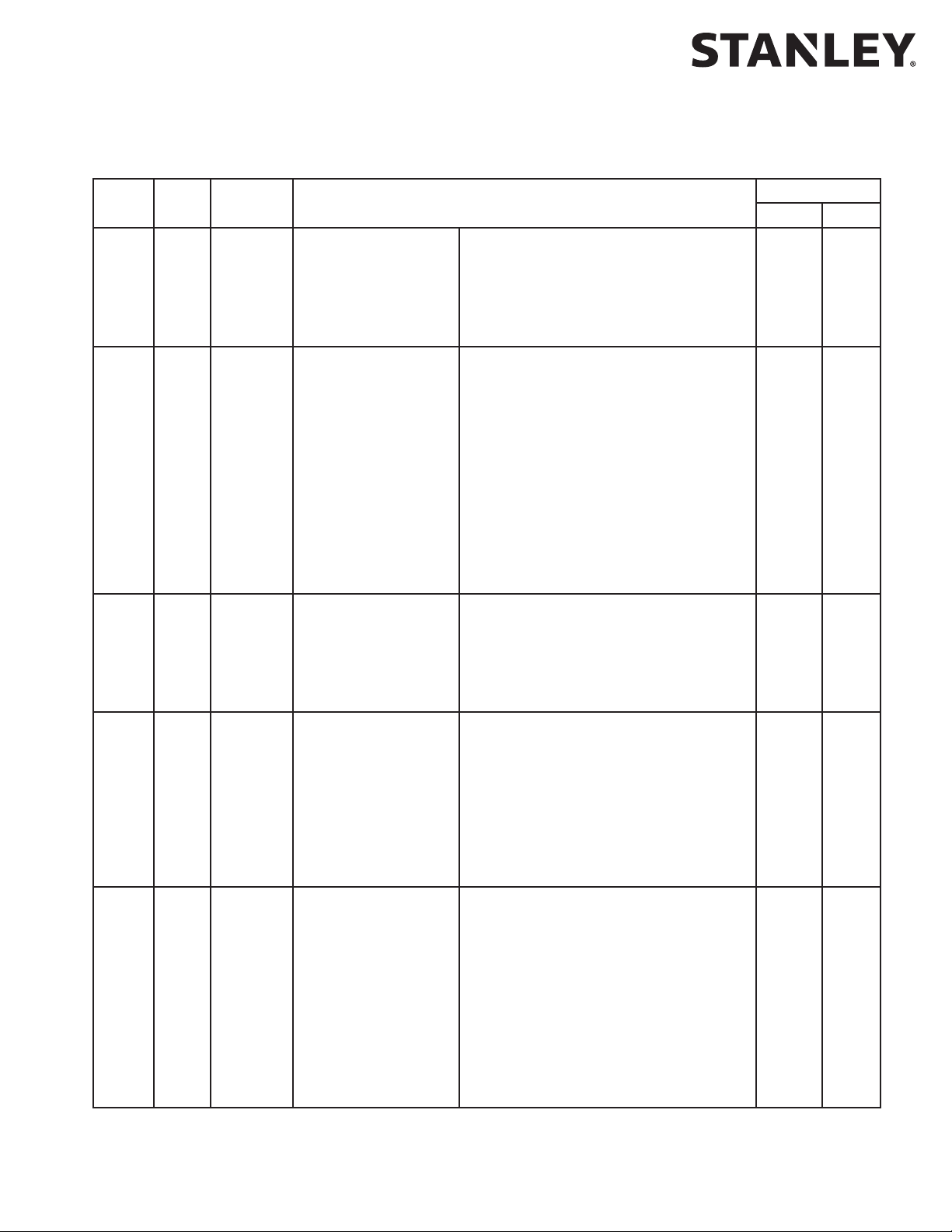

Table 4. Status Codes

Status Code Description Remediation IF Necessary

00 Normal operaon—All OK

20 Breakout

33 System error See aachment 7

34 Internal communicaon error – Type 1 See aachment 7

35 Motor drive failure Replace controller

36 Internal communicaon error – Type 2 See aachment 7

0b Obstrucon

A0 First Installaon Sequence (FIS)

A1 Auto-conguraon sequence

A2 Auto-conguraon conrmaon sequence

b1 Encoder error > cable failure Verify magnet/encoder pair

b2 Encoder mismatch > wrong encoder/magnet Verify magnet/encoder pair

b3 Encoder fault > wrong encoder/magnet or

cable falure

bE Blocked egress

c1 Posion learn error

Ld Lock down (shear lock energized)

db Output control See Aachment 6, Sheet 2 of 2

dc Display door cycle counter

dE Delayed egress

d0 Free egress

E2 Door held open by any sensor input other than

the Hold Open switch on TB2-1.

E3 Door length error Re-do First Installaon Sequence (FIS)

E4 Presence sensor monitoring failure Verify sensor wiring and safety logic seng

E5 Motor drive failure

F0 Inside monitored sensor failure Verify sensor wiring and safety logic seng

F1 Outside monitored sensor failure Verify sensor wiring and safety logic seng

F2 Upper Monitored Photo Beam failure Check transmier, receiver, and hold beam type

F3 Lower Monitored Photo Beam failure Check transmier, receiver, and hold beam type

F6 Inside (2) monitored sensor failure Verify sensor wiring and safety logic seng

F7 Outside (2) monitored sensor failure Verify sensor wiring and safety logic seng

ho Door held open Check sensors and hold beam type

FA Fire Alarm Acve

uL Unlocked delay egress

Verify magnet/encoder pair

Copyright 2019, Stanley Access Technologies, LLC. All rights reserved. Reproduction

in whole or in part without the express written permission of Stanley is prohibited.

1.800.7.ACCESS • www.stanleyaccess.com • Document # 204144 REV B 17

01.25.2019

Page 18

iQ Control Box

Table 5. Door States

Door State Description

00 Door State is Closed

02 Door State is Opening

04 Door State is in Open Check

06 Door State is Full Open

07 Door State is Closing

09 Door State is in Close Check

10 Open Assist (manual mode door state)

11 Close Assist (manual mode door state)

12 Close Assist (manual mode door state)

14 Door Fault

15 Door State is in Open Stop

16 Door State is in Obstrucon while Closing

17 Door State is in Close Press

19 Lock Release (door state)

NOTE: If the current status code is “Normal operaon—All OK”, the iQ will show the current door state.

Otherwise, the iQ alternates between showing the current status code and the door state.

Final Tune-In Adjustments

1. Refer to ANSI/BHMA A156.10, “Standard for Power Operated Pedestrian Doors,” and aachment 4 and

DETERMINE ANSI and UL door operang requirements.

2. IF StanguardTM threshold sensor is installed, refer to Stanley Access Technologies document No. 203768,

“StanguardTM Threshold Sensor Installaon and Operaon,” and TUNE-IN StanguardTM threshold sensor.

Ensure that the JP301 Jumper is properly installed for StanGuardTM Sensors.

3. IF SU-100 moon sensor(s) are installed, refer to Stanley Access Technologies document No. 203957,

All rights reserved. Reproduction

Copyright 2019, Stanley Access Technologies, LLC.

in whole or in part without the express written permission of Stanley is prohibited.

“SU-100 Moon Sensor Installaon and Operaon,” and TUNE-IN SU-100 moon sensor(s).

4. IF Optex X Zone T or X Zone ST Sensors are installed, refer to the manufacturer’s installaon and tune-in instrucons.

5. If Hotron HR100 ST sensors are installed, refer to the manufacturer’s instrucons.

6. Aer all changes have been made, cycle the door to have the sengs stored in Non-Volale memory.

Then turn power OFF and then back ON to ensure that all of the sengs are permanently stored.

• Verify that the correct Safety Logic has been selected for Sensor Monitoring and that the JP301 is in the

correct posion.

• DO NOT remove JP301 when Stanguard™ is installed. X Zone T, X Zone ST and HR100 ST monitored sensors

require JP301 to be removed.

7. This step only applies to the Stanley Automac ICU series doors: Refer to ANSI/BHMA A156.38, “American

Naonal Standard for Low Energy Power Operated Sliding and Folding Doors” and Aachment 4 (Page 3 of 3)

and determine ANSI and IBC-2018 door operang requirements.

01.25.2019

18 Document # 204144 REV B • www.stanleyaccess.com • 1.800.7.ACCESS

Page 19

iQ Control Box

Attachment 1

iQ Controls and Indicators

(Sheet 1 of 2)

NOTE: See next page for indicators and descriptions

1

2

3

4

SEE DETAIL A

5

6

7

8

15

15

9

9

11

11

1212

13

13

14

10

10

19

18

17

DETAIL A

16

1.800.7.ACCESS • www.stanleyaccess.com • Document # 204144 REV B 19

Copyright 2019, Stanley Access Technologies, LLC. All rights reserved. Reproduction

in whole or in part without the express written permission of Stanley is prohibited.

01.25.2019

Page 20

iQ Control Box

Attachment 1

iQ Controls and Indicators

(Sheet 2 of 2)

ITEM CONTROL/INDICATOR DESCRIPTION

1 Motor 2 Connector Motor No. 2 connector.

2 Power Connector Connecon point for incoming line, neutral, and common power wiring.

3 Fuse Controller fuse-- 5 Amp, 250V.

4 Motor 1 Connector Motor No. 1 connector.

5 Terminal Block Connector TB1 Connecon point for 24V power supply and solenoid lock.

6 Terminal Block Connector TB2 Connection point for function switch (rotary or rocker) and Fire

Alarm input.

7 Terminal Block Connector TB6 Push plate outside. Monitored Photo Beam and Test output.

8 Encoder 2 Connector Encoder # 2 Connector.

9 Two Digit Display Displays Controller Status. Also serves as the display for tune-in by

pushbuon switches and indicates encoder movement. High resoluon

encoder may be dim.

10 Encoder 1 Connector Connecon point for motor encoder No. 1.

11 Up Pushbuon Switch Used for manual setup and tuning of door when handheld

is not available.

12 Down Pushbuon Switch Used for manual setup and tuning of door when handheld

is not available.

13 Enter Pushbuon Switch Used for manual setup and tuning of door when handheld is

14 RS232 RS232 connector. Connecon point for Bluetooth harness.

15 Jumper JP301 Keep jumper installed for StanguardTM installaons. See wiring diagrams

16 Terminal Block Connector TB7 Connecon for ECO Pro.

17 Terminal Block Connector TB5 Side screen sensor, door posion switch.

18 Terminal Block Connector TB4 Connecon point for INSIDE / OUTSIDE sensor and push plate.

All rights reserved. Reproduction

19 Terminal Block Connector TB3 Connecon point for StanguardTM, safety sensor and breakout switch.

not available.

to determine when to remove JP301 for monitored sensor installaons.

Using jumper wires across TB3 terminals 1 to 5 and 2 to 6,

internal 24 VDC supplies power to mulple external sensors.

Copyright 2019, Stanley Access Technologies, LLC.

in whole or in part without the express written permission of Stanley is prohibited.

01.25.2019

20 Document # 204144 REV B • www.stanleyaccess.com • 1.800.7.ACCESS

Page 21

iQ Control Box

Attachment 2

iQ System Wiring Diagram

(Sheet 1 of 10)

NOTE: JP 301 must be installed.

Copyright 2019, Stanley Access Technologies, LLC. All rights reserved. Reproduction

in whole or in part without the express written permission of Stanley is prohibited.

1.800.7.ACCESS • www.stanleyaccess.com • Document # 204144 REV B 21

01.25.2019

Page 22

Attachment 2

iQ System Wiring Diagram

(Sheet 2 of 10)

iQ Control Box

All rights reserved. Reproduction

Copyright 2019, Stanley Access Technologies, LLC.

in whole or in part without the express written permission of Stanley is prohibited.

01.25.2019

22 Document # 204144 REV B • www.stanleyaccess.com • 1.800.7.ACCESS

Page 23

iQ Control Box

Attachment 2

iQ System Wiring Diagram

(Sheet 3 of 10)

SEE NEXT PAGE

OR

Copyright 2019, Stanley Access Technologies, LLC. All rights reserved. Reproduction

in whole or in part without the express written permission of Stanley is prohibited.

1.800.7.ACCESS • www.stanleyaccess.com • Document # 204144 REV B 23

01.25.2019

Page 24

Attachment 2

iQ System Wiring Diagram

(Sheet 4 of 10

iQ Control Box

SEE PREVIOUS PAGE

OR

All rights reserved. Reproduction

Copyright 2019, Stanley Access Technologies, LLC.

in whole or in part without the express written permission of Stanley is prohibited.

01.25.2019

24 Document # 204144 REV B • www.stanleyaccess.com • 1.800.7.ACCESS

Page 25

iQ Control Box

Attachment 2

iQ System Wiring Diagram

(Sheet 5 of 10)

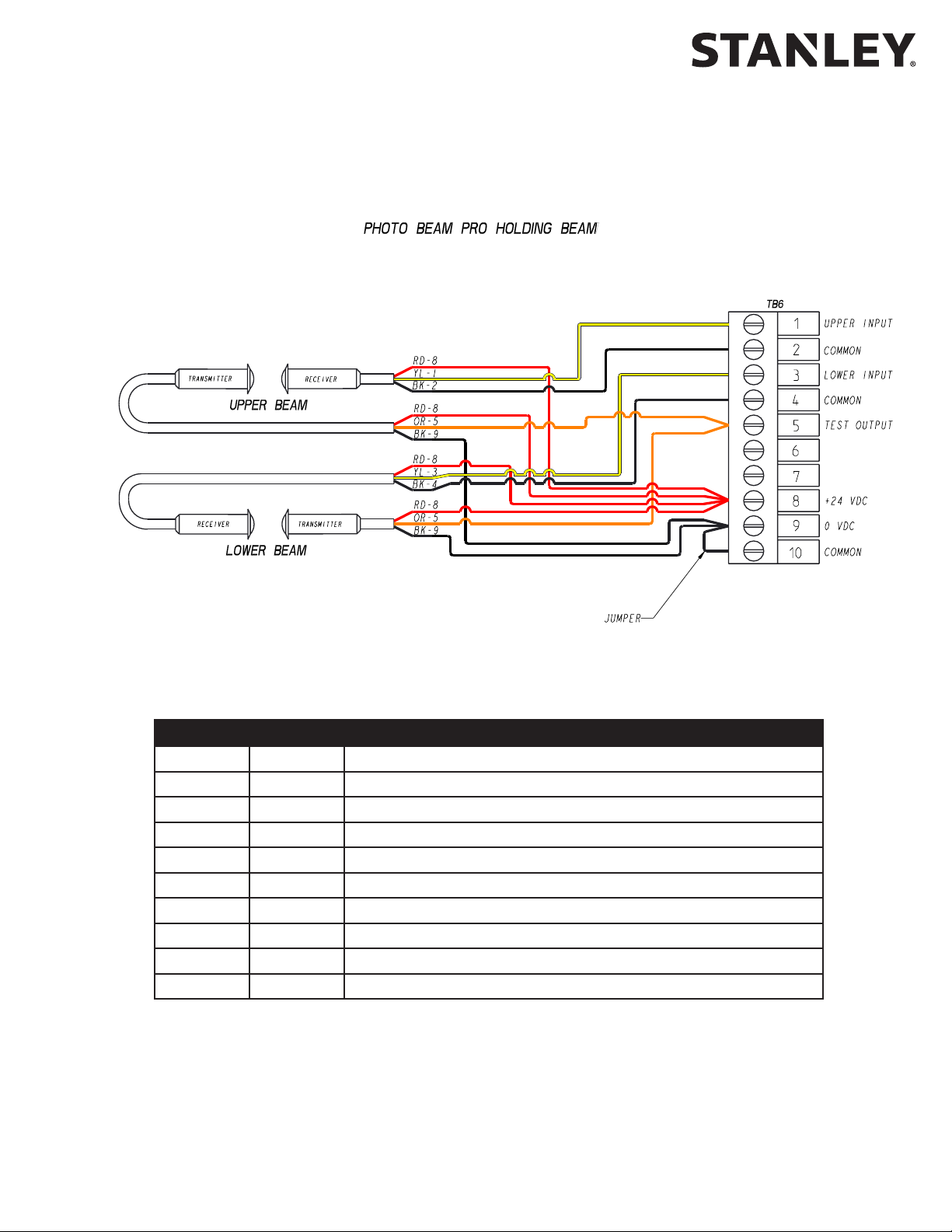

STANLEY PHOTO BEAM

On the iQ: Set INDEX 20 to VALUE 01 (Monitored Beam).

TB6 COLOR DUAL HOLDING BEAM WIRING

1 YL OUTPUT UPPER RECEIVER

2 BK (-) UPPER RECEIVER

3 YL OUTPUT LOWER RECEIVER

4 BK (-) LOWER RECEIVER

5 OR TRANSMITTER CONTROL LOWER AND UPPER

6 -- NO CONNECTION

7 -- NO CONNECTION

8 RD (+) ALL RECEIVERS AND TRANSMITTERS

9 BK (-) LOWER AND UPPER TRANSMITTERS, JUMPER TO TB6-10

10 BK JUMPER FROM TB6-9

Copyright 2019, Stanley Access Technologies, LLC. All rights reserved. Reproduction

in whole or in part without the express written permission of Stanley is prohibited.

1.800.7.ACCESS • www.stanleyaccess.com • Document # 204144 REV B 25

01.25.2019

Page 26

Attachment 2

iQ System Wiring Diagram

(Sheet 6 of 10)

iQ Control Box

All rights reserved. Reproduction

Copyright 2019, Stanley Access Technologies, LLC.

in whole or in part without the express written permission of Stanley is prohibited.

Program the OS-12 CT set to “D” - Acve High / N.C.

On the iQ: Set INDEX 20 to VALUE 01 (Monitored Beam).

01.25.2019

26 Document # 204144 REV B • www.stanleyaccess.com • 1.800.7.ACCESS

Page 27

iQ Control Box

Attachment 2

iQ System Wiring Diagram

(Sheet 7 of 10)

TB3 COLOR PHOTO BEAM PRO BREAKOUT BEAM

1 RD JUMPER FROM TB3-5

2 BK JUMPER FROM TB3-6

3 -- NO CONNECTION

4 -- NO CONNECTION

5 RD JUMPER FROM TB3-1, (+) RECEIVER AND TRANSMITTER

6 BK JUMPER FROM TB3-2, (-) RECIEVER AND TRANSMITTER

7 -- NO CONNECTION

8 -- NO CONNECTION

9 YL OUTPUT RECEIVER

10 -- NO CONNECTION

Copyright 2019, Stanley Access Technologies, LLC. All rights reserved. Reproduction

in whole or in part without the express written permission of Stanley is prohibited.

1.800.7.ACCESS • www.stanleyaccess.com • Document # 204144 REV B 27

01.25.2019

Page 28

Attachment 2

iQ System Wiring Diagram

(Sheet 8 of 10)

iQ Control Box

All rights reserved. Reproduction

Copyright 2019, Stanley Access Technologies, LLC.

in whole or in part without the express written permission of Stanley is prohibited.

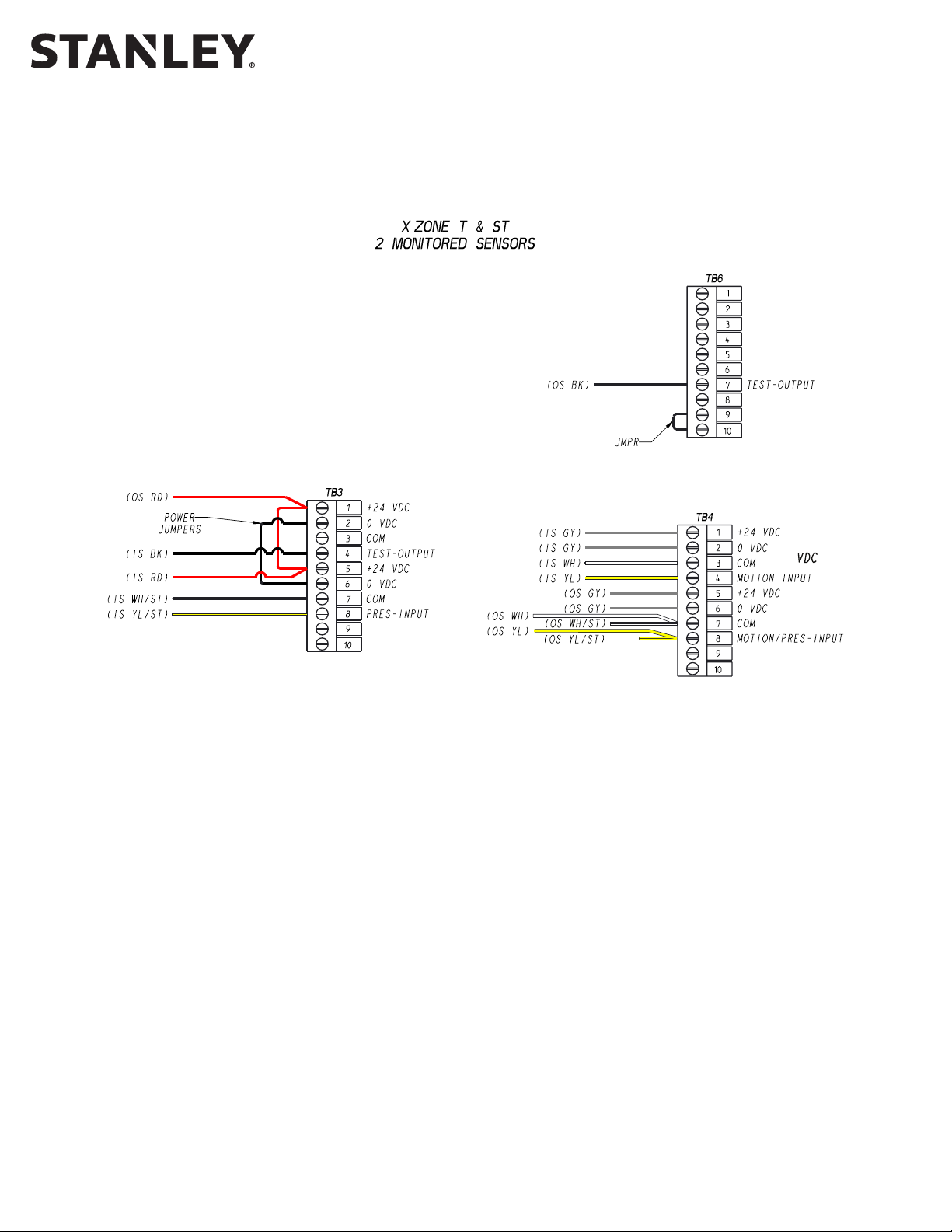

X-Zone ST

For Security Applicaons / 1-WAY

Key DIP Switch sengs: 10 and 11 DOWN; 12, 13, 14, 15 and 16 UP.

X-Zone ST and X-Zone (ST)

Key DIP Switch sengs: 10 and 11 DOWN; 12, 14 and 15 UP.

iQ

Remove JP301.

Set index 19 to Value = 00 (Sensor Monitoring with Threshold Control).

X-Zone T

Key DIP Switch sengs: 11 and 12 DOWN; 13 and 15 UP.

iQ

Remove JP301.

Set index 19 to Value = 03 (Monitored 2 Sensors).

NOTE:: The X-Zone ST will replace the X-Zone (ST) in 2019.

01.25.2019

28 Document # 204144 REV B • www.stanleyaccess.com • 1.800.7.ACCESS

Page 29

iQ Control Box

Attachment 2

iQ System Wiring Diagram

(Sheet 9 of 10)

X-Zone ST

For Security Applicaons / 1-WAY

Key DIP Switch sengs: 10 and 11 DOWN; 12, 13, 14, 15 and 16 UP.

X-Zone ST and X-Zone (ST)

Key DIP Switch sengs: 10 and 11 DOWN; 12, 14 and 15 UP.

iQ

Remove JP301.

Set index 19 to Value = 01 (Monitored 4 Sensors - Threshold Zone Control).

X-Zone T

Key DIP Switch sengs: 11 and 12 DOWN; 13 UP and 15 UP.

iQ

Remove JP301.

Set index 19 to Value = 05 (Monitored 4 Sensors).

Copyright 2019, Stanley Access Technologies, LLC. All rights reserved. Reproduction

in whole or in part without the express written permission of Stanley is prohibited.

NOTE: The X-Zone ST will replace the X-Zone (ST) in 2019.

1.800.7.ACCESS • www.stanleyaccess.com • Document # 204144 REV B 29

01.25.2019

Page 30

Attachment 2

iQ System Wiring Diagram

(Sheet 10 of 10)

iQ Control Box

All rights reserved. Reproduction

Copyright 2019, Stanley Access Technologies, LLC.

in whole or in part without the express written permission of Stanley is prohibited.

HR100 ST

Recommended DIP Switch sengs:

DIP Switch X: (2, 3, and 4 = UP) (1 = DOWN).

DIP Switch Y: (1, 2, 3 and 4 = UP)

DIP Switch Z: (1, 2, 3 and 4 = UP) (5 and 6 = DOWN).

{UP = OFF} {DOWN = ON}

iQ Sengs

Remove JP301.

Set index 19 to Value = 03 (Monitored 2 Sensors).

CAUTION: Tapered HR100 ST base plate must removed before sensor

is installed for threshold sensor detecon.

01.25.2019

30 Document # 204144 REV B • www.stanleyaccess.com • 1.800.7.ACCESS

Page 31

iQ Control Box

TB2

TB2

1

TB3

4

2

3

Attachment 3

iQ Terminal Block Connections -- TB1 through TB7

(Sheet 1 of 1)

2

4

6

8

5

9

7

10

1

TB7

5

3

8

6

7

9

10

VDC -

0

24 VDC +

EXT+

EXT-

COMMON (WH)

STANGUARD(GN)

EXT-

SEENOTE1

1

2

3

4

(ROTARYSWITCHWIRING)

COMMON (YL)

HOLD OPEN (BK)

1

COMMON (OR)

AUTOMATIC (RD)

3

2

4

COMMON (WH)

INT-

6

7

5

REDUCEDOPEN(GN)

ENTER-ONEWAY (BN)

6

7

5

BREAKOUT (GN)

OPTEXHOLDING BEAM (GN)

8

9

FIRE ALARM INPUT

8

9

COMMON (WH)

10

NOTE: Requires proper

setting of index 47 and 48.

Refer to Table 3 - Settings.

10

15 VDC +

1

TB6

PHOTO BEAM PRO UPPER RCVR

1

SEE NOTE 1SEE NOTE 1

VDC -

0

COMMON

COMMON

2

3

4

COMMON

PHOTO BEAM PRO LOWER RCVR

PHOTO BEAM PRO TEST OUTPUT

3

4

2

7

5

6

COMMON

OUT_SPARE2

7

5

6

COMMON

8

9

10

VDC -

0

24 VDC +

COMMON

8

9

10

(ROCKERSWITCHWIRING)

COMMON

HOLD OPEN (YL)

COMMON (OR)

AUTOMATIC (BN)

COMMON (BL)

COMMON(VI)

REDUCEDOPEN(VI )

ENTER-ONEWAY (BL)

EXT+

EXT-

EXT-

COMMON

SIDE SCREEN SENSOR

CH

VDC -

0

24 VDC +

INT-

COMMON

SEE NOTE 1

CLOSED POSITION SWIT

1

EXT+

2

EXT-

COMMON (WH)

EXT-

6

8

2

4

1

TB1

15 VDC +

5

3

SOLENOID LOCK (BL)

9

7

SOLENOID LOCK (BK)

10

TB TB54

VDC -

0

24 VDC +

POWER

INPUT

5

6

8

4

3

VDC -(BK)

0

24 VDC + (RD)

INSIDE SENSOR

COMMON (WH)

INT-

9

7

OUTSIDESENSOR(GN)

10

COMMON

PUSH PLATE

TO THE EXTERNAL POWER SUPPLY BUS (EXT).

NOTE 1. REMOVE JUMPERS ON TB3 IF EXTERNAL POWER SUPPLY IS USED.

JUMPERS ON TB3 CONNECT INTERNAL POWER SUPPLY (INT)

Copyright 2019, Stanley Access Technologies, LLC. All rights reserved. Reproduction

in whole or in part without the express written permission of Stanley is prohibited.

01.25.2019

1.800.7.ACCESS • www.stanleyaccess.com • Document # 204144 REV B 31

Page 32

iQ Control Box

Attachment 4

ANSI/BHMA and UL Compliance Requirements for Sliding Doors

(Sheet 1 of 3)

Final adjustment and proper operaon of the door system must be and shall be performed in the eld.

NOTE: These instrucons are for informaonal purposes and do not substute for review against the current

revision of the referenced standards. Where a requirement exists in mulple standards, such as the ANSI/BHMA

standard and the UL standard, the more restricve condion applies. Other local codes and re codes likely exist,

and must also be followed.

ANSI/BHMA A156.10 Sliding Door Systems

Sliding door systems must be installed and adjusted for compliance with the current version of ANSI/BHMA

A156.10, “American Naonal Standard for Power Operated Pedestrian Doors”.

Crical aspects of the installaon for compliance with ANSI/BHMA A156.10 include:

• Control mat size, layout, molding height, acve areas and sensivity.

• Sensor paern size, sensivity, and funcon.

• Knowing Act guidelines and secondary acvang zone.

• Entrapment protecon rules including door speeds, forces, and me delays.

• Signage. (Decals and applicaon instrucons are provided with the door system.)

NOTE: For Procare and Duracare series Automac series refer to the current version of ANSI/BHMA A156.38.

UL 325 Compliance

All power operated door systems must be installed in compliance with the current edion of UL 325, “Standard for

Safety for Door, Drapery, Gate, Louver, and Window Operators and Systems”.

Wiring

1. To reduce the risk of electric shock proper and reliable grounding is mandatory. See Main Power Wiring instruc-

All rights reserved. Reproduction

ons and Wiring Diagrams in this guide for grounding techniques.

2. Permanent wiring is to be employed as required by the Naonal Electrical Code and/or local codes.

3. Connecon of external devices is shown in the wiring diagrams and terminal block layouts elsewhere in this

guide. Refer to these gures for proper wiring of external devices to ensure compliance with UL 325.

Knowing Act

Doors acvated by a manual switch (Knowing Act switch in ANSI/BHMA terms) must have the switch installed

in a locaon from which operaon of the door can be observed by the person operang the switch and not

located in a positon where the user would be in the path of the moving door.

Copyright 2019, Stanley Access Technologies, LLC.

in whole or in part without the express written permission of Stanley is prohibited.

01.25.2019

32 Document # 204144 REV B • www.stanleyaccess.com • 1.800.7.ACCESS

Page 33

iQ Control Box

Attachment 4

ANSI/BHMA and UL Compliance Requirements for Sliding Doors

(Sheet 2 of 3)

To ensure that a sliding door operates in accordance with UL 325 entrapment protecon criteria the following must

be established:

• Manual opening force (sliding doors without breakout) or breakout force with power on or o must be less

then 50 lbf (222.4 N).

• Closing force must be less than 30 lbf (133.4 N).

• A closing sliding door must not develop kinec energy in excess of 2.5 -lbf (3.39 J). This is achieved by proper

seng of the closing speed. See secon entled “Closing Speed”.

• Maximum recommended door weight:

• Dura-Glide 5000 Series = 150 lbs (70 kg) per panel.

• Dura-Glide/Dura-Guard/Dura-Storm and similar 2000/3000 Series = 220 lbs (100 kg) per panel.

• IS10000/Double Diamond and similar Industrial Series = 300 lbs (90 kg) per panel

Closing Speed

Closing speed is measured over a travel distance of 2 or 3 feet. On smaller bi-part doors there may only be

2 feet of movement before the door system enters close-check (latch check). The me measurement should

start once the door has achieved closing speed, usually 6 inches from full open. Mark this point on the oor

with tape or other object. Measure from this point 2 or 3 feet toward the closed posion and mark the next

point. Use a stopwatch to measure the me it takes for the sliding panel to travel this distance during

normal closing cycles. Make sure the door system is not braking or entering close-check during the

measurement. Repeat the measurement 3 mes and use the average value. The allowed me for a

sliding panel to cover this distance during the closing cycle is given in the table below.

Door Weight

(pounds)

160 or less 2.0 3.0

161 to 180 2.1 3.2

181 to 200 2.2 3.3

201 to 220 2.3 3.5

221 to 240 2.4 3.7

241 to 260 2.5 3.8

261 to 280 2.6 4.0

281 to 300 2.7 4.1

Closing Time (seconds)

2 foot measurement

Closing Time (seconds)

3 foot measurement

NOTE: For low energy slide door applicaons refer to aachment 4 sheet 3 of 3.

1.800.7.ACCESS • www.stanleyaccess.com • Document # 204144 REV B 33

Copyright 2019, Stanley Access Technologies, LLC. All rights reserved. Reproduction

in whole or in part without the express written permission of Stanley is prohibited.

01.25.2019

Page 34

iQ Control Box

Attachment 4

ANSI/BHMA and IBC Compliance Requirements for

Low Energy Power Operated Sliding Doors

(Sheet 3 of 3)

To ensure that a Low Energy Power Operated Sliding Door operates in accordance with ANSI/BHMA and the

the IBC-2018, the following must be established:

• Acvaon of the door must be by a Knowing Act.

• The Opening Time (speed) of the Door(s) shall be adjusted so that the door(s) open at a speed of 12 inches

per second maximum, from fully closed to fully open.

• When powered open, the door shall remain at the fully open posion for not less than 5 seconds before

starng the closing cycle.

• The Closing Time (speed) of Door(s) shall be adjusted so that the door(s) close at a speed of 6 inches per

second maximum per leaf, from fully open to latch check.

• Latch check shall occur at no less than 2 inches from fully closed.

All rights reserved. Reproduction

• The force required to prevent a stopped door from opening or closing shall not exceed 15 lbf (67 N).

• The required Signage must be present.

NOTE: In special applicaons where safety sensors or secondary acvaon sensors are used on

a low energy door, refer to ANSI/BHMA A156.10 for guidance on sensor performance criteria

for the type of sensor selected.

Copyright 2019, Stanley Access Technologies, LLC.

in whole or in part without the express written permission of Stanley is prohibited.

01.25.2019

34 Document # 204144 REV B • www.stanleyaccess.com • 1.800.7.ACCESS

Page 35

iQ Control Box

Attachment 5

Troubleshooting Aid (Sheet 1 of 1)

Terminal and Pin Descripon State

TB1-8 Solenoid Lock Output Dark = Unlocked

w/o PCB, fail secure Dark = Unlocked

w/o PCB, fail safe Dark = Locked

NOTE: Black color indicates a low signal (Approx. 0 VDC).

Rotary Function Switch States for TB2

Hold

Open

TB2-1

TB2-3

TB2-5 Don’t Care Don’t Care

TB2-7

Closed

Locked

Automac One Way Reduced Reduced

One Way

Rocker Function Switch States for TB2

Hold

Open

TB2-1

TB2-3

TB2-5 Don’t Care Don’t Care

TB2-7 Don’t Care Don’t Care

Terminal and Pin Descripon State

TB3-4 StanguardTM Input/Output Dark = triggered or detecng

TB3-8 & TB4-8

Non-Monitored Holding Beam Input Input

and Outside Sensor (connected internally)

TB3-9 Breakout Input Dark = no breakout

TB4-4 & TB4-9

TB4-8 & TB3-8

TB4-9 & TB4-4

Inside Sensor Input and

Push Plate Input (connected internally)

Inside Presence Sensor Input and

Holding Beam Input (connected internally)

Push Plate Input and

Inside Sensor Input (connected internally)

TB5-3 Side Screen Sensor Input Dark = detecng

TB5-7 Closed-Door Posion Switch Input Dark = closed

TB5-10 Spare

TB6-1 Monitored Beam Upper Holding Beam Dark = unobstructed White = detecng

TB6-3

Monitored Beam Lower Holding Beam

TB6-5 Photo Beam Pro Test Output Dark = tesng

TB6-7 Sensor Test Output Dark = normal operaon

Closed

Locked

Automac One Way Reduced Reduced

One Way

Dark = detecng

Dark = detecng

Dark = detecng

Dark = detecng

Dark = unobstructed White = detecng

Copyright 2019, Stanley Access Technologies, LLC. All rights reserved. Reproduction

in whole or in part without the express written permission of Stanley is prohibited.

01.25.2019

1.800.7.ACCESS • www.stanleyaccess.com • Document # 204144 REV B 35

Page 36

Attachment 6

iQ Troubleshooting Aid

(Sheet 1 of 1)

Symptom Remedy

Use best pracces to troubleshoot using handheld device and

Door does not close and/or

Status code displays ho/E2

NOTE: E2 indicates door held open by any sensor

input other than Hold Open Switch on TB-2.

Handheld will not update rmware Controller is not displaying 00. Re-FIS the door.

Door hits Open Stop/full open bumper Increase the Open Check Length (Index 3).

Door moon is not the same as the MC521/

MC521PRO for the same sengs

Status code displays E3

Status code displays E4

Status code displays F0-F1, F6-F7 Verify sensor wiring and safety logic seng.

Status code displays F2-F3

provided wiring diagrams.

Check hold beam type (index 20). Monitored beams should

be set to “Monitored Beam” and non-monitored beams

should be set to “Non-monitored Beam.”

Reference latest Photo Beam Pro Troubleshoong Tech Tip.

Parameters value for the iQ are not the same as MC521/

MC521PRO. Refer to Table 3.

Check mechanical issues, components.

Re-do rst installaon sequence (FIS).

Verify sensor wiring and safety logic seng.

Monitored beam Failure. Verify proper wiring and “holding

beam type”(index 20 = appropraite seng, Monitored Beam

or Non-Monitored Beam.

iQ Control Box

Door moves slowly on one cycle.

Status code displays 33 or 34 or 36 momentarily

(3 seconds).

Door moves slowly on several cycles.

All rights reserved. Reproduction

Status code displays 33 or 34 or 36 on

slow cycles.

Door tuning issues

Copyright 2019, Stanley Access Technologies, LLC.

in whole or in part without the express written permission of Stanley is prohibited.

01.25.2019

Reference latest Photo Beam Pro Troubleshoong Tech Tip.

Note it. No acon required.

1. Reset Power.

2. If code does not clear, Call Tech Support.

Refer to parameter descripons for useful adjustments.

36 Document # 204144 REV B • www.stanleyaccess.com • 1.800.7.ACCESS

Page 37

iQ Control Box

Attachment 7

Fine Tuning Slide Doors

(Sheet 1 of 2)

Tuning the Stanley Automatic Door

Match your actual door to one from the list of doors described in the aachment. Start by installing these sengs.

Use the guide below to make adjustments to these sengs.

If the door:

OPENS TOO SLOWLY

If it is too slow

Increase Open Speed. Maximum seng is 99 with keypad or

125 with handheld.

Increase Open Torque

If it is too slow

NOTES: Max Values go to 125 via handheld.

Open Torque is also used to set the door open force.

HITS THE OPEN STOP

When the door braking and moon are under control, reduce the Open Check length as desired.

CLOSES TOO SLOWLY

If it is too slow

If it is too slow

NOTE: Close Torque is also used to set the door closing force.

Close Speed and Close Force cannot exceed the value specied by ANSI/BHMA 156.10.

Increase Open Acceleration

Increase Open Stop to 8 and Open Check Length to 45

Increase Open Brake unl there is good braking.

Increase or decrease unl there is good moon

entering and in Open Check.

Increase Close Speed to 16

Increase Close Torque

Increase Close Acceleration

Copyright 2019, Stanley Access Technologies, LLC. All rights reserved. Reproduction

1.800.7.ACCESS • www.stanleyaccess.com • Document # 204144 REV B 37

in whole or in part without the express written permission of Stanley is prohibited.

01.25.2019

Page 38

Attachment 7

Fine Tuning Slide Doors

(Sheet 2 of 2)

Tuning the Stanley Automatic Door (Continued).

Match your actual door to one from the list of doors described in the aachment. Start by installing these

sengs. Use the guide below to make adjustments to these sengs.

If the door:

HITS THE CLOSE STOP too hard

Set Close Check Length to 50. Set Close Press to 1 and test.

Increase the Close Brake seng unl there is good braking.

Increase or decrease Close Check unl there is smooth moon entering and in Close Check.

STALLS during opening without any

mechanical reason. . .

Connues to stall and it seems

to happen at the transion

from Open Brake to Open Check

STALLS during closing without any

obvious reason. . .

Connues to stall and it seems to

happen at the transion to Close

Check

SPEEDS UP during Close Check

Increase Obstruction Time from .5 seconds to 1.0 seconds

Make small increases to Open Brake.

Increase Obstruction Time

Increase Close Check one count at a me

Close Check Speed is set too high. Reduce Close Check one count at a

me unl door moon is suitable.

Stanley Access Technologies

65 Scott Swamp Road

Farmington, CT 06032

Document # 204144 REV B • www.stanleyaccess.com • 1.800.7.ACCESS

Loading...

Loading...