Page 1

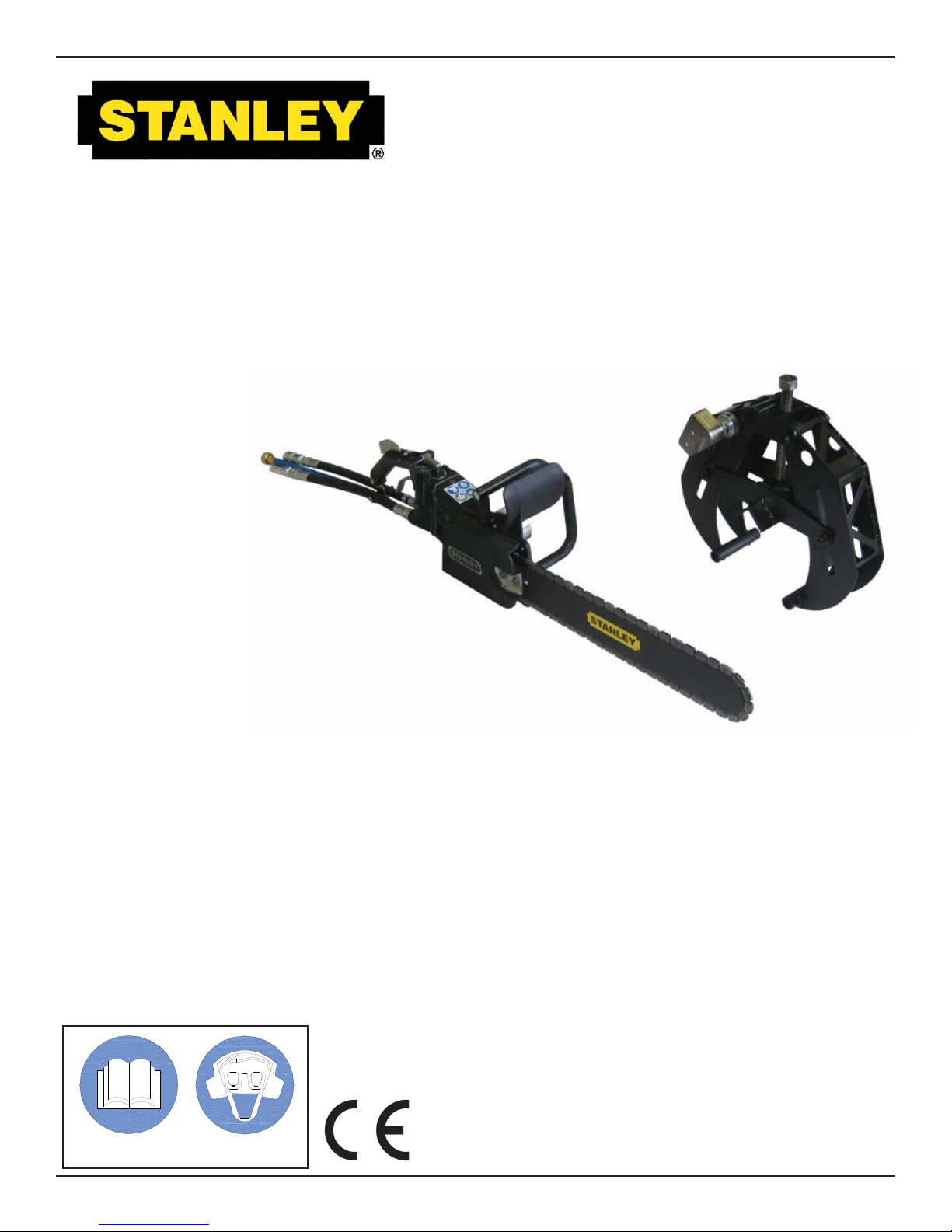

DS12

HYDRAULIC

UTILITY SAW

Read the Manual

Wear your PPE

SAFETY, OPERATION AND MAINTENANCE

USER’S MANUAL

Copyright © 2009, The Stanley Works

71069 11/2009 Ver 2

Page 2

Page 3

TABLE OF CONTENTS

Safety Symbols and Precautions .......................................................................................................4

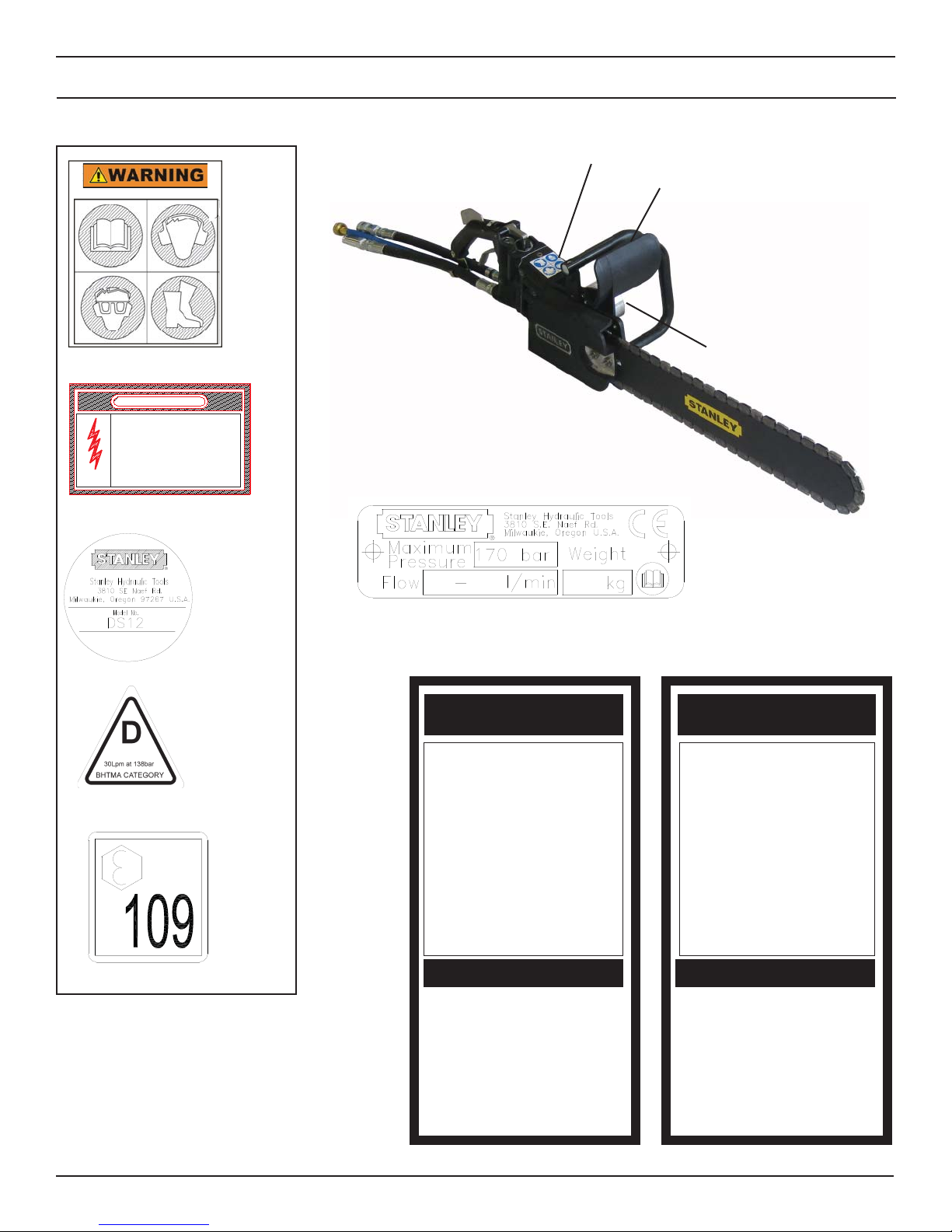

Tool Stickers and Tags........................................................................................................................7

Hydraulic Hose Requirements ............................................................................................................8

HTMA Requirements ........................................................................................................................10

Operation .........................................................................................................................................11

Tool Equipment and Care .................................................................................................................15

Troubleshooting ................................................................................................................................16

Specifi cations ...................................................................................................................................18

Accessories ......................................................................................................................................18

Parts Illustration ................................................................................................................................19

Parts List .........................................................................................................................................20

Utility Saw Clamp Instruction Sheet .................................................................................................21

Warranty ...........................................................................................................................................22

SERVICING THE STANLEY UTILITY CHAINSAW: This manual contains safety, operation, and routine

maintenance instructions. Stanley Hydraulic Tools recommends that servicing of hydraulic tools, other

than routine maintenance, must be performed by an authorized and certifi ed dealer. Please read the fol-

lowing warning.

SERIOUS INJURY OR DEATH COULD RESULT FROM THE IMPROPER REPAIR OR SERVICE OF THIS TOOL.

REPAIRS AND / OR SERVICE TO THIS TOOL MUST ONLY BE

DONE BY AN AUTHORIZED AND CERTIFIED DEALER.

For the nearest authorized and certifi ed dealer, call Stanley Hydraulic Tools at the number listed on the

back of this manual and ask for a Customer Service Representative.

3

Page 4

CERTIFICATE OF CONFORMITY

CERTIFICATE OF CONFORMITY

ÜBEREINSTIMMUNGS-ZERTIFIKAT

CERTIFICAT DE CONFORMITE CEE

CERTIFICADO DE CONFORMIDAD

CERTIFICATO DI CONFORMITA

______________________________________________________________________

Hydraulic Tools

I, the undersigned:

Ich, der Unterzeichnende:

Je soussigné:

El abajo firmante:

lo sottoscritto:

hereby certify that the construction plant or equipment specified hereunder:

bestätige hiermit, daß das im folgenden genannten Werk oder Gerät:

certifies par ceci que l’ usine ou l’ équipement de constructio n indiqué cidessous:

por el presente certifico que la fabrica o el equipo especificado a continuacion:

certifico che l’impianto o l’attrezzatura sotto specificata:

1. Category: Utility Chain Saw

Kategorie:

Catégorie:

Categoria:

Categoria:

2. Make/Ausführung/Marque/Marca/Marca

3. Type/Typ/Type/Tipo/Tipo: DS1231801

4. Serial number of equipment:

Seriennummer des Geräts:

Numéro de série de l’équipement:

Numero de serie del equipo:

Matricola dell´attrezzatura:

5. Year of manufacture/Baujahr/année de fabrication/Año de fabricacion/Anno di fabbricazione Beginning 2009

Has been manufactured in conformity with - EEC Type examination as shown.

Wurde hergestellt in Übereinstimmung mit - EEC Typ-Prüfung nach.

Est fabriqué conformément - au(x) type(s) examiné(s) comme indiqué dans le tableau ci-après.

Ha sido fabricado de acuerdo con - tipo examen EEC como dice.

E’ stata costruita in conformitá con - le norme CEE come illustrato.

Piert, Charlie

Surname and First names/Familiennname und Vornamen/Nom et prénom/Nombre y apellido/Cognome e nome

Stanley

All

Examen CEE de type

Directive

Richtlinie

Directives particulières

Directriz

Direttiva

Machinery Directive

EN

EN

ISO

ISO

ISO

6. Special Provisions: None

Spezielle Bestimmungen:

Dispositions particulières:

Provisiones especiales:

Disposizioni speciali:

7. Representative in the Union: Stanley Dubuis 17-19, rue Jules Berthonneau-BP 3406 41034 Blois Cedex, France.

Done at/Ort/Fait à/Dado en/Fatto a Stanley Hydraulic Tools, Milwaukie, Oregon USA

Signature/Unterschrift/Signature/Firma/Firma____________________________________________________________________________

Position/Position/Fonction/Puesto/Posizione Quality Assurance Manager

No.

Nr

Numéro

No

n.

98/37/EC

ISO 12100-1

ISO 12100-2

8662-1

3744

10726

Date

Datum

Date

Fecha

Data

1998

2007

2006

1988

1994

1992

Approved body

Prüfung durch

Organisme agréé

Aprobado

Collaudato

Self

Self

Self

Self

Self

Self

Date/Datum/le/Fecha/Data 10/22/2009

Date of expiry

Ablaufdatum

Date d´expiration

Fecha de caducidad

Data di scadenza

NA

NA

NA

NA

NA

NA

rev01 11/09

Page 5

WARNING

SAFETY SYMBOLS

Safety symbols and signal words, as shown below, are used to emphasize all operator, maintenance and repair actions

which, if not strictly followed, could result in a life-threatening situation, bodily injury or damage to equipment.

This is the safety alert symbol. It is used to alert you to potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

This safety alert and signal word indicate an imminently hazardous situa-

DANGER

CAUTION

tion which, if not avoided, will result in death or serious injury.

This safety alert and signal word indicate a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

This safety alert and signal word indicate a potentially hazardous situation

which, if not avoided, may result in minor or moderate injury.

This signal word indicates a potentially hazardous situation which, if not

CAUTION

NOTICE

IMPORTANT

Always observe safety symbols. They are included for your safety and for the protection of the tool.

avoided, may result in property damage.

This signal word indicates a situation which, if not avoided, will result in

damage to the equipment.

This signal word indicates a situation which, if not avoided, may result in

damage to the equipment.

LOCAL SAFETY REGULATIONS

Enter any local safety regulations here. Keep these instructions in an area accessible to the operator and maintenance personnel.

4

Page 6

SAFETY PRECAUTIONS

To avoid seriou s injury or death

• Establish a training program for all operators to ensure safe operation.

• The operator must be familiar with all prohibited work areas such as excessive slopes and dangerous terrain conditions.

• Do not operate the chain saw unless thoroughly trained or under the supervision of an instructor.

• Always wear safety equipment such as goggles, ear protection, breathing protection, head protection, leg protection, gloves, snug fi tting clothing

(do not operate the saw when wearing loose clothing) and safety shoes at all times when operating the chain saw.

• Do not overreach or cut above shoulder height. Maintain proper footing and balance at all times.

• Do not inspect or clean the chain saw while the hydraulic power source is connected. Accidental engagement of the chain saw can cause serious

injury.

Tool operators and maintenance personnel must always comply with the safety precautions given in this

manual and on the stickers and tags attached to the tool and hose.

These safety precautions are given for your safety. Review them carefully before operating the tool and

before performing general maintenance or repairs.

Supervising personnel should develop additional precautions relating to the specifi c work area and local

safety regulations. If so, place the added precautions in the space provided on page 4.

This tool will provide safe and dependable service if operated in accordance with the instructions given in this

manual. Read and understand this manual and any stickers and tags attached to the tool and hoses before

operation. Failure to do so could result in personal injury or equipment damage.

• Always connect hoses to the chain saw hose couplers before energizing the hydraulic power source. Make sure all hose connections are tight.

• Do not operate the chain saw at fl uid temperatures above 140°F/60°C. Operation at higher temperatures can cause higher than normal tempera-

tures at the chain saw which can result in operator discomfort.

• Do not rely exclusively upon the safety devices built into the chain saw. As a chain saw user, several steps must be taken to keep your cutting

jobs free from accident or injury:

1. With a basic understanding of kickbacks, you can reduce or eliminate the element of surprise. Sudden surprise contributes to accidents.

2. Keep a good fi rm grip on the chain saw with both hands, the right hand on the rear handle and the left hand on the front handle when

operating the chain saw. Use a fi rm grip with thumbs and fi ngers encircling the chain saw handles. A fi rm grip helps reduce kickbacks and

maintains control of the chain saw. Do not let go.

3. Make sure the area in which you are cutting is free of obstructions.

4. Cut at rated operating speeds (gpm).

5. Do not overreach or cut above shoulder height.

6. Only use replacement bars and chains specifi ed by Stanley or the equivalent.

• Make sure the chain guard is in place before operating the chain saw.

• Remove or control the water slurry to prevent yourself or others from slipping while cutting.

• Provide adequate ventilation in closed areas when operating a gas or diesel hydraulic power source.

5

Page 7

SAFETY PRECAUTIONS

• Always be well rested and mentally alert before operating the chain saw.

• Do not allow bystanders near the chain saw when starting or cutting.

• Do not start cutting until you have a clear work area and secure footing.

• Keep all parts of the body away from the chain saw during operation.

• Carry the chain saw with the tool de energized and the bar and chain to the rear of your body.

• Do not operate a chain saw that is damaged, improperly adjusted, or not completely and securely assembled. Make sure the chain stops moving

when the control trigger is released.

• Keep the handle dry, clean and free of hydraulic fl uid.

• Do not use the chain saw near energized transmission lines.

• Turn off the power source or move the hydraulic control valve to neutral before setting the chain saw down.

• Use a guide bar scabbard when transporting the chain saw.

• Know the location of buried or covered electrical services before starting work.

• To avoid personal injury or equipment damage, all chain saw repair, maintenance and service must only be performed by authorized and properly trained personnel.

• Make sure the chain breaker and rivet spinner are securely mounted on fl at, clean work surfaces. Check the mounting screws/bolts often.

• Check all chain breaker and rivet spinner components regularly for wear and general condition.

• Provide adequate lighting when operating the saw in a darkened area or at night.

• Always keep critical tool markings, such as labels and warning stickers legible. Always replace stickers or decals that have become worn or damaged.

• Be observant of hydraulic and water hoses that lay about the work area, especially in trenches where they can be hidden from view due to liquids

that have accumulated within the space.

• Keep all parts of the body away from the cleats that are attached to the saw, as these are sharp and can be a puncture hazard.

• Improper handling, use, or maintenance can result in an oil leak or burst. Do not contact an oil leak as high pressure oil can cause injection into

the body.

• Never stand in the path of the discharge, ejection of material from the work piece can cause personal injury.

• Never use the saw in a potentially explosive atmosphere.

WARNING

Exposure to crystalline Silica (sometimes called “silica dust”) as a result of

cutting, breaking, drilling, or hammering of rock, concrete, asphalt or other

materials may cause Silicosis (a serious lung disease), silicosis-related illnesses, cancer, or death.

Respiratory protection is highly recommended when working with materials

containing Silica Dust.

Always wear a respirator approved for protection against crystalline silica.

6

Page 8

Failure to use hydraulic hose labeled and certifiedFailure to use hydraulic hose labeled and certified

as non-conductive when using hydraulic tools onas

non-conductive when using hydraulic tools on

or near electric lines may result in death oror

near electric lines may result in death or

For proper and safe operation read owners manualFor

proper and safe operation read owners manual

and mwke sure that you have been properlyand

mwke sure that you have been properly

trained in correct procedures required for worktrained

in correct procedures required for work

serious injury.serious

injury.

on or around electric lines.on

or around electric lines.

ELECTROCUTION

HAZARD

DANGER

To avoid serious injury or death

28409

12412

TOOL STICKERS & TAGS

28409

Composit Decal

Always keep critical tool markings, such as labels and

warning stickers legible. Always replace stickers or decals

that have become worn or damaged.

12412

Warning Decal

71071

Name Tag Decal

71071 Name Tag

11207

LWA

11212

The safety tag (p/n 15875) at

right is attached to the tool

when shipped from the factory.

Read and understand the safety

instructions listed on this tag

before removal. We suggest

you retain this tag and attach it

to the tool when not in use.

71073 CE Tool Plate

1. FAILURE TO USE HYDRAULIC HOSE LABELED AND CERTIFIED AS

NON-CONDUCTIVE WHEN USING HYDRAULIC TOOLS ON OR NEAR

ELECTRICAL LINES MAY RESULT IN DEATH OR SERIOUS INJURY.

BEFORE USING HOSE LABELED AND CERTIFIED AS NON-

CONDUCTIVE ON OR NEAR ELECTRIC LINES BE SURE THE HOSE

IS MAINTAINED AS NON-CONDUCTIVE. THE HOSE SHOULD BE

REGULARLY TESTED FOR ELECTRIC CURRENT LEAKAGE IN ACCORDANCE

WITH YOUR SAFETY DEPARTMENT INSTRUCTIONS.

2. A HYDRAULIC LEAK OR BURST MAY CAUSE OIL INJECTION INTO TH E

BODY OR CAUSE OTHER SEVERE PERSONAL INJURY.

A DO NOT EXCEED SPECIFIED FLOW AND PRESSURE FOR

THIS TOOL. EXCESS FLOW OR PRESSURE MAY CAUSE A

LEAK OR BURST.

B DO NOT EXCEED RATED WORKING PRESSURE OF HYDRAU

LIC HOSE USED WITH THIS TOOL. EXCESS PRESSURE MAY

CAUSE A LEAK OR BURST.

C CHECK TOOL HOSE COUPLERS AND CONNECTORS DAILY

FOR LEAKS. DO NOT FEEL FOR LEAKS WITH YOUR HANDS.

CONTACT WITH A LEAK MAY RESULT IN SEVERE PERSONAL

INJURY.

IMPORTANT

READ OPERATION MANUAL AND

SAFETY INSTRUCTIONS FOR THIS

TOOL BEFORE USING IT.

USE ONLY PARTS AND REPAIR

PROCEDURES APPROVED BY

STANLEY AND DESCRIBED IN THE OPERA-

TAG TO BE REMOVED ONLY BY

SAFETY TAG P/N 15875

TION MANUAL.

TOOL OPERATOR.

SEE OTHER SIDE

7

D DO NOT LIFT OR CARRY TOOL BY THE HOSES. DO NOT ABUSE HOSE.

DO NOT USE KINKED, TORN OR DAMAGED HOSE.

3. MAKE SURE HYDRAULIC HOSES ARE PROPERLY CONNECTED TO THE

TOOL BEFORE PRESSURING SYSTEM. SYSTEM PRESSURE HOSE MUST

ALWAYS BE CONNECTED TO TOOL “IN” PORT. SYSTEM RETURN HOSE

MUST ALWAYS BE CONNECTED TO TOOL “OUT” PORT. REVERSING CONNECTIONS MAY CAUSE REVERSE TOOL OPERA TION WHICH CAN RESUL T

IN SEVERE PERSONAL INJURY.

4. DO NOT CONNECT OPEN-CENTER TOOLS TO CLOSED-CENTER HYDRAULIC

SYSTEMS. THIS MAY RESULT IN LOSS OF OTHER HYDRAULIC FUNCTIONS

POWERED BY THE SAME SYSTEM AND/OR SEVERE PERSONAL INJURY.

5. BYSTANDERS MAY BE INJURED IN YOUR WORK AREA. KEEP BYST ANDERS

CLEAR OF YOUR WORK AREA.

6. WEAR HEARING, EYE, FOOT, HAND AND HEAD PROTECTION.

7. TO AVOID PERSONAL INJUR Y OR EQUIPMENT DAMAGE, ALL TOOL REPAIR

MAINTENANCE AND SERVICE MUST ONLY BE PERFORMED BY AUTHORIZED AND PROPERLY TRAINED PERSONNEL.

READ OPERATION MANUAL AND

SAFETY INSTRUCTIONS FOR THIS

USE ONLY PARTS AND REPAIR

STANLEY AND DESCRIBED IN THE OPERA-

TAG TO BE REMOVED ONLY BY

(shown smaller then actual size)

IMPORTANT

TOOL BEFORE USING IT.

PROCEDURES APPROVED BY

TION MANUAL.

TOOL OPERATOR.

SEE OTHER SIDE

Page 9

TOOL HOSE INFORMATION

HOSE TYPES

The rated working pressure of the hydraulic hose must be equal to or higher than the relief valve setting on the

hydraulic system. There are three types of hydraulic hose that meet this requirement and are authorized for use

with Stanley Hydraulic Tools. They are:

Certifi ed non-conductive - constructed of thermoplastic or synthetic rubber inner tube, synthetic fi ber

braid reinforcement, and weather resistant thermoplastic or synthetic rubber cover. Hose labeled certifi ed non-

conductive is the only hose authorized for use near electrical conductors.

Wire-braided (conductive) - constructed of synthetic rubber inner tube, single or double wire braid reinforcement, and weather resistant synthetic rubber cover. This hose is conductive and must never be used near

electrical conductors.

Fabric-braided (not certifi ed or labeled non-conductive) - constructed of thermoplastic or synthetic rubber

inner tube, synthetic fi ber braid reinforcement, and weather resistant thermoplastic or synthetic rubber cover. This

hose is not certifi ed non-conductive and must never be used near electrical conductors.

HOSE SAFETY TAGS

To help ensure your safety, the following DANGER tags are attached to all hose purchased from Stanley Hydraulic Tools. DO NOT REMOVE THESE TAGS.

If the information on a tag is illegible because of wear or damage, replace the tag immediately. A new tag may be

obtained from your Stanley Distributor.

THE TAG SHOWN BELOW IS ATTACHED TO “CERTIFIED NON-CONDUCTIVE” HOSE

D A N G E R

1 FAILURE TO USE HYDRAULIC HOSE LABELED AND CERTIFIED AS NON-CONDUCTIVE

WHEN USING HYDRAULIC TOOLS ON OR NEAR ELECTRIC LINES MAY RESULT IN DEATH

OR SERIOUS INJURY.

FOR PROPER AND SAFE OPERATION MAKE SURE THAT YOU HAVE BEEN PROPERLY

TRAINED IN CORRECT PROCEDURES REQUIRED FOR WORK ON OR AROUND

ELECTRIC LINES.

2. BEFORE USING HYDRAULIC HOSE LABELED AND CERTIFIED AS NON-CONDUCTIVE ON

OR NEAR ELECTRIC LINES. WIPE THE ENTIRE LENGTH OF THE HOSE AND FITTING

WITH A CLEAN DRY ABSORBENT CLOTH TO REMOVE DIRT AND MOSISTURE AND TEST

HOSE FOR MAXIMUM ALLOWABLE CURRENT LEAKAGE IN ACCORDANCE WITH SAFETY

DEPARTMENT INSTRUCTIONS.

DO NOT REMOVE THIS TAG

SIDE 1 SIDE 2

3

(shown smaller than actual size)

3. DO NOT EXCEED HOSE WORKING PRESSURE OR ABUSE HOSE. IMPROPER USE OR

HANDLING OF HOSE COULD RESULT IN BURST OR OTHER HOSE FAILURE. KEEP

HOSE AS FAR AWAY AS POSSIBLE FROM BODY AND DO NOT PERMIT DIRECT CONTACT

DURING USE. CONTACT AT THE BURST CAN CAUSE BODILY INJECTION AND SEVERE

PERSONAL INJURY.

4. HANDLE AND ROUTE HOSE CAREFULLY TO AVOID KINKING, ABRASION, CUTTING, OR

CONTACT WITH HIGH TEMPERATURE SURFACES. DO NOT USE IF KINKED. DO NOT USE

HOSE TO PULL OR LIFT TOOLS, POWER UNITS, ETC.

5. CHECK ENTIRE HOSE FOR CUTS CRACKS LEAKS ABRASIONS, BULGES, OR DAMAGE TO

COUPLINGS IF ANY OF THESE CONDITIONS EXIST, REPLACE THE HOSE IMMEDIATELY.

NEVER USE TAPE OR ANY DEVICE TO ATTEMPT TO MEND THE HOSE.

6. AFTER EACH USE STORE IN A CLEAN DRY AREA.

D A N G E R

DO NOT REMOVE THIS TAG

THE TAG SHOWN BELOW IS ATTACHED TO “CONDUCTIVE” HOSE.

D A N G E R

1 DO NOT USE THIS HYDRAULIC HOSE ON OR NEAR ELECTRIC LINES. THIS HOSE IS

NOT LABELED OR CERTIFIED AS NON-CONDUCTIVE. USING THIS HOSE ON OR NEAR

ELECTRICAL LINES MAY RESULT IN DEATH OR SERIOUS INJURY.

2. FOR PROPER AND SAFE OPERATION MAKE SURE THAT YOU HAVE BEEN PROPERLY

TRAINED IN CORRECT PROCEDURES REQUIRED FOR WORK ON OR AROUND

ELECTRIC LINES.

3. DO NOT EXCEED HOSE WORKING PRESSURE OR ABUSE HOSE. IMPROPER USE OR

HANDLING OF HOSE COULD RESULT IN BURST OR OTHER HOSE FAILURE. KEEP

HOSE AS FAR AWAY AS POSSIBLE FROM BODY AND DO NOT PERMIT DIRECT CONTACT

DURING USE. CONTACT AT THE BURST CAN CAUSE BODILY INJECTION AND SEVERE

PERSONAL INJURY.

4. HANDLE AND ROUTE HOSE CAREFULLY TO AVOID KINKING, CUTTING, OR CONTACT

WITH HIGH TEMPERATURE SURFACES. DO NOT USE IF KINKED. DO NOT USE HOSE TO

PULL OR LIFT TOOLS, POWER UNITS, ETC.

DO NOT REMOVE THIS TAG

SIDE 1 SIDE 2

5. CHECK ENTIRE HOSE FOR CUTS CRACKS LEAKS ABRASIONS, BULGES, OR DAMAGE TO

COUPLINGS IF ANY OF THESE CONDITIONS EXIST, REPLACE THE HOSE IMMEDIATELY.

NEVER USE TAPE OR ANY DEVICE TO ATTEMPT TO MEND THE HOSE.

6. AFTER EACH USE STORE IN A CLEAN DRY AREA.

(shown smaller than actual size)

D A N G E R

SEE OTHER SIDE

DO NOT REMOVE THIS TAG

8

Page 10

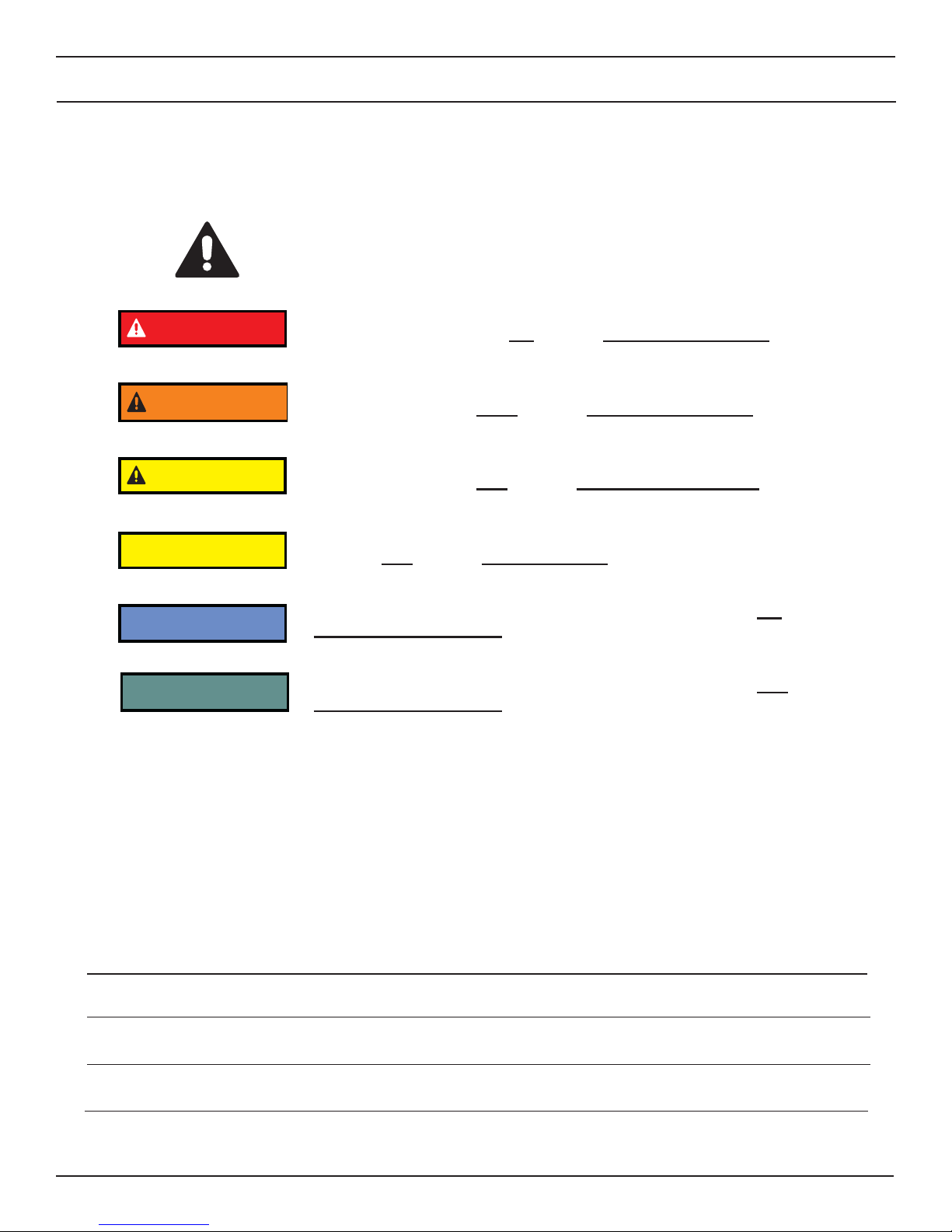

Min. Working Pressure

USE

Press/Return)

(

Certifi ed Non-Conductive Hose - Fiber Braid - for Utility Bucket Trucks

Oil Flow Hose Lengths Inside Diameter

GPM LPM FEET METERS INCH MM PSI BAR

4-9 15-34 up to 10 up to 3 3/8 10 Both 2250 155

Conductive Hose - Wire Braid or Fiber Braid -DO NOT USE NEAR ELECTRICAL CONDUCTORS

4-6 15-23 up to 25 up to 7.5 3/8 10 Both 2500 175

4-6 15-23 26-100 7.5-30 1/2 13 Both 2500 175

5-10.5 19-40 up to 50 up to 15 1/2 13 Both 2500 175

5-10.5 19-40 51-100 15-30 5/8 16 Both 2500 175

5/8 16 Pressure 2500 175

3/4 19 Return 2500 175

5-10.5 19-40 100-300 30-90

10-13 38-49 up to 50 up to 15 5/8 16 Both 2500 175

5/8 16 Pressure 2500 175

10-13 38-49 51-100 15-30

3/4 19 Return 2500 175

3/4 19 Pressure 2500 175

1 25.4 Return 2500 175

10-13 38-49 100-200 30-60

5/8 16 Pressure 2500 175

13-16 49-60 up to 25 up to 8

3/4 19 Return 2500 175

3/4 19 Pressure 2500 175

1 25.4 Return 2500 175

13-16 49-60 26-100 8-30

PRESSURE

<<< FLOW

RETURN

FLOW >>>

Typical Hose Connections

Tool to Hydraulic Circuit Hose Recom-

mendations

The chart to the right shows recommended mini-

mum hose diameters for various hose lengths

based on gallons per minute (gpm)/liters per min-

ute (lpm). These recommendations are intended

to keep return line pressure (back pressure) to a

minimum acceptable level to ensure maximum tool

performance.

This chart is intended to be used for hydraulic tool

applications only based on Stanley Hydraulic Tools

tool operating requirements and should not be used

for any other applications.

All hydraulic hose must have at least a rated

minimum working pressure equal to the maximum

hydraulic system relief valve setting.

All hydraulic hose must meet or exceed specifi -

cations as set forth by SAE J517.

9

Page 11

HTMA REQUIREMENTS

TOOL CATEGORY

HYDRAULIC SYSTEM

REQUIREMENTS TYPE 1 TYPE II TYPE III TYPE RR

FLOW RATE

TOOL OPERATING PRESSURE

(at the power supply outlet)

SYSTEM RELIEF VALVE SETTING

(at the power supply outlet)

MAXIMUM BACK PRESSURE

(at tool end of the return hose)

Measured at a max. fl uid viscosity of:

(at min. operating temperature)

TEMPERATURE

Suffi cient heat rejection capacity

to limit max. fl uid temperature to:

(at max. expected ambient temperature)

Min. cooling capacity

at a temperature difference of

between ambient and fl uid temps

NOTE:

Do not operate the tool at oil temperatures above 140° F (60° C). Operation at higher temperatures can cause operator

discomfort at the tool.

4-6 gpm 7-9 gpm 11-13 gpm 9-10.5 gpm

(15-23 lpm) (26-34 lpm) (42-49 lpm) (34-40 lpm)

2000 psi 2000 psi 2000 psi 2000 psi

(138 bar) (138 bar) (138 bar) (138 bar)

2100-2250 psi 2100-2250 psi 2100-2250 psi 2200-2300 psi

(145-155 bar) (145-155 bar) (145-155 bar) (152-159 bar)

250 psi 250 psi 250 psi 250 psi

(17 bar) (17 bar) (17 bar) (17 bar)

400 ssu* 400 ssu* 400 ssu* 400 ssu*

(82 centistokes) (82 centistokes) (82 centistokes) (82 centistokes)

140° F 140° F 140° F 140° F

(60° C) (60° C) (60° C) (60° C)

3 hp 5 hp 7 hp 6 hp

(2.24 kW) (3.73 kW) (4.47 kW) (5.22 kW)

40° F 40° F 40° F 40° F

(22° C) (22° C) (22° C) (22° C)

FILTER

Min. full-fl ow fi ltration

Sized for fl ow of at least:

(For cold temp. startup and max. dirt-holding capacity)

HYDRAULIC FLUID

Petroleum based

(premium grade, anti-wear, non-conductive)

VISCOSITY

(at min. and max. operating temps)

NOTE:

When choosing hydraulic fl uid, the expected oil temperature extremes that will be experienced in service determine the

most suitable temperature viscosity characteristics. Hydraulic fl uids with a viscosity index over 140 will meet the require-

ments over a wide range of operating temperatures.

*SSU = Saybolt Seconds Universal

NOTE:

These are general hydraulic system requirements. See tool Specifi cation page for tool specifi c requirements.

25 microns 25 microns 25 microns 25 microns

30 gpm 30 gpm 30 gpm 30 gpm

(114 lpm) (114 lpm) (114 lpm) (114 lpm)

100-400 ssu* 100-400 ssu* 100-400 ssu* 100-400 ssu*

(20-82 centistokes)

10

Page 12

OPERATION

PREOPERATION PROCEDURES

CHECK THE POWER SOURCE

1. Using a calibrated fl ow meter and pressure gauge, make sure the

hydraulic power source develops a fl ow of 7-9 gpm/26-34 lpm at 2000

psi/140 bar.

2. Make certain that the power source is equipped with a relief valve set

to open at 2100-2250 psi/145-155 bar.

3. Make certain that the power source return pressure does not exceed

250 psi/17 bar.

CONNECT HYDRAULIC HOSES

1. Wipe all hose couplers with a clean lint-free cloth before making connections. If necessary, use a light-weight penetrating oil in a spray can to

clean the hose couplers before each connection.

2. Connect the hoses from the hydraulic power source to the chain saw

fi ttings or quick disconnects. It is a good practice to connect return hoes

fi rst and disconnect them last to minimize or avoid trapped pressure

within the chain saw.

3. Observe the arrow on the couplers to ensure that the fl ow is in the

proper direction. The female coupler on the chain saw is the inlet (pressure) coupler.

CHAIN TENSIONING AND BAR ADJUSTMENT

A properly tensioned chain will optimize cutting performance. The tensioning rule of thumb for the utility cutting chain saw is that a properly tensioned chain must not be bowstring tight and can be pulled freely around

the guide bar by hand easily without binding. Caution should be used

when adjusting these chains as the bar rail can become very sharp. Lift

the chain away from the bar rail when rotating and use extreme caution.

Note: The chain on the utility saw is non-directional and may be installed to travel either direction.

PROPER CHAIN TENSION

Check the chain tension often during operation, especially during the fi rst

1/2 hour when using a new chain. Adjust the chain accordingly when it

becomes loose.

If the chain is too loose, it could come off the bar, or it will allow the drive

sprocket to spin without turning the chain, which can chew up the chain

drive links. If the chain is too tight, a lot of the saw’s power goes into turning the chain rather than into the cut. In extreme over-tightened cases,

the saw may not be able to turn the chain at all. In addition, damage can

occur to the bar nose and premature stretch may occur.

4. Move the hydraulic circuit control valve to the “ON” position to operate

the chain saw.

NOTE:

If uncoupled hoses are left in the sun, pressure increase inside the hoses might make them diffi cult to

connect. Whenever possible, connect the free ends of

the hoses together.

CONNECTING TO A WATER SUPPLY

1. Using a standard garden hose, connect the DS12 to a city or auxiliary

water supply.

2. If you plan on operating the chain saw in freezing weather, make sure

you purge all the water from the system after each use.

HOW TO CHECK

Before cutting, check for proper tension by pulling the chain around the

bar by hand. If you cannot easily pull by hand, the chain is too tight and

needs to be loosened.

11

Page 13

OPERATION

WHEN TO TENSION

All chains have a tendency to stretch when used. Diamond chains

stretch more than wood cutting chains because of the abrasive materials

they are cutting. When a chain stretches to a point where the drive links

are hanging approximately 1/2 in-3/4 in (12-18 mm) below the bar, it’s

time to tension the chain.

HOW TO TENSION

To tension the chain, fi rst loosen the side cover nuts, then while holding

the nose of the bar up, use a screw driver to turn the tensioning screw

clockwise until the chain drive links hanging below the bar are just beginning to enter the bar groove. Continue to hold up on the nose of the bar

and fi rmly tighten the side cover nuts, (20 ft-lbs, 27 Nm). And remember,

it’s the side cover nuts that hold the bar in position.

ADDITIONAL INFORMATION

Utility chainsaws operate with looser chain tension than wood chainsaws. It is common, on the utility chainsaw to have the drive links hang

completely out of the bar. Wood cutting chainsaws use oil to lubricate

the chain. The oil makes the chain very slippery and allows the drive

links to fully nest between the teeth of the drive sprocket. The utility

cutting chainsaws require water for cooling and fl ushing the cut. Water is

not as good as oil as a lubricant. Also, there are cutting particles mixed

in with the water. As a result, sometimes the drive links do not nest

properly on the drive sprocket. When this happens, the chain acts like it

got tighter. There seems to be “tight” spots and “loose” spots as you pull

the chain around the bar. If you tension when the chain is in one of the

loose spots, it will be too tight at some point in it’s rotation around the

bar. Rotating the chain completely around the bar by hand will let you

know you have the chain properly tensioned.

NOTE: MAKE SURE THE BAR ATTACHING NUTS ARE FULLY

TIGHTENED AND THE CHAIN GUARD IS IN PLACE.

HOW TO PREVENT CHAIN TENSIONER

BREAKAGE

Do not attempt to adjust the tensioner without fi rst loosening the side

cover nuts. Do not use the saw without making sure the side cover nuts

are tight. If the side cover nuts are not tight, the bar can slip backwards

during cutting and break the tensioner pin.

ADDITIONAL TENSIONING TIPS

1. To reduce chain stretch and tensioning downtime, use 20 PSI (1.5

bar) or greater water pressure.

2. Oil the chain at the end of the day to prevent rust but be careful not to

over tension in this condition.

3. When pulling the chain around the bar by hand, be careful not to

touch the bar with thumb or forefi nger. The bar rails can be very

sharp. Using leather gloves grab only the diamond segments to pull

the chain.

4. Always turn the hydraulic power source off before tensioning the

chain.

12

Page 14

OPERATION

CHECK THE WATER SUPPLY

Chain and bar damage will occur if the chain saw

operates without the proper water supply.

1. Always have water running before starting the chain saw.

2. Recommended water fl ow 4 gpm/15 lpm at 50 psi/3.5 bar (2-gp/7.5

lpm at 20-psi/1.3 bar minimum).

PRE-CUT CHECKLIST

• If using the clamp make sure it is securely fastened before attaching

the saw, tighten clamp nut with wrench.

• Proper Chain tension: Bottom tip of drive link hangs even with bottom

of bar.

• Ensure proper water fl ow and hydraulic supply to power unit.

• Ensure cut can be made clear of dirt contact.

• Protective clothing/protection in place.

• Mark cut on pipe.

• Block pipe from shifting, support weight of pipe.

CUTTING TIPS

If using pipe clamp (Applicable for 4”-12”, recommended for 8”-12”).

• Place clamp around top of pipe, hand tighten adjustment nut.

• Position saw on pipe for top down or bottom up (recommended) cut and

slide saw clamp mount through receiver hole at top of clamp, secure with

snap pin.

• Slide clamp/saw assembly around pipe to optimum cutting position and

tighten clamp nut with wrench.

• Ensure saw is positioned to allow handle to pivot during cut unobstructed, and ensure saw tip doesn’t contact dirt.

When the saw cut is complete be watchful of

sharp edges around the material that has been cut.

CUTTING FREE-HAND OR WITH PIPE CLAMP

Before cutting make sure the material being cut

is properly supported from falling or shifting.

OPERATING PROCEDURES

NEW SAW CHAIN BREAK-IN

1. Always make sure the bar and sprocket are in good condition.

2. Turn on the water supply.

3. Operate the chain saw for two minutes (away from the intended cut)

and then check the chain tension.

4. Adjust accordingly using the procedures contained in Chain Tensioning and Bar Adjustments section of this manual.

When exiting the cut, avoid applying high feed

loads as unexpected movement of the saw may

result. Using both hands, maintain fi rm control

of the tool throughout the entire cut.

• Position saw to avoid pinching the bar or chain as pipe is cut, support

pipe from top and side to prevent cut pipe from injuring operator.

• Hold saw so chain isn’t in contact with pipe, start water and activate saw

to recommended fl ow rate, press chain against pipe slowly, apply pres-

sure to cut through pipe.

• Pressure can be applied to cut until saw starts to lug, if need be back off

on the cutting pressure to maintain a good cutting speed.

• If cut in a 12” pipe exceeds 5 minutes, cut pulls to one side, or diamond

coating is gone, chain may need replacement.

13

Page 15

OPERATION

PLAN THE CUT

1. Plan your cuts to prevent injury to yourself and to keep from pinching the saw bar and chain as a result of falling pieces of iron pipe.

2. Outline the material being cut with a permanent marker for a visual

guide (especially when cutting free hand).

3. Know what kind of material you are cutting.

TYPES OF CUTS

The DS12 can be operated not only using the pipe clamp but also make

free-hand cuts, any size pipe can be cut free hand.

Utility Chain Saw Cuts

• Ductile Iron Pipe • Roofi ng Shingles

• Insituform Pipe Lining • CMU Concrete Block

• PVC Pipe • Non Reinforced Concrete

• Copper Pipe • Roofi ng Tile

• Steel Roofi ng Material • Lumber

• HDPE Pipe • Masonry

Top down Cut

1. When using the pipe clamp with a 15-inch bar the cut capacity is 4” to

10”.

2. When using the pipe clamp with a 18-inch bar the cut capacity is 4” to

12”.

3. Do not use a cutting force in excess of 45 lbs/20 kg. Excessive force

causes the chain to slow down or stall and causes premature wear of the

saw bar and chain.

4. Always maintain a high chain speed. High chain speeds produce the

best results.

5. Avoid aggressive/heavy forces. Aggressive force can causes premature

bar and chain wear.

COLD WEATHER OPERATION

If the saw is to be used during cold weather, preheat the hydraulic fl uid at

low power source speed. When using the normally recommended fl uids,

fl uid should be at or above 50°F/10°C (400 ssu/82 centistokes) before

use.

Bottom up Cut

Damage to the hydraulic system or chain saw can result from use with

fl uid that is too viscous or thick.

14

Page 16

TOOL EQUIPMENT & CARE

NOTICE

In addition to the Safety

Precautions on page in this

manual, observe the following for

equipment protection and care.

• Make sure all couplers are wiped clean before connection.

• The hydraulic circuit control valve must be in the “OFF” position when coupling or uncoupling

hydraulic tools. Failure to do so may result in damage to the quick couplers and cause overheating

of the hydraulic system.

• Always store the tool in a clean dry space, safe from damage or pilferage.

• Make sure the circuit PRESSURE hose (with male quick disconnect) is connected to the “IN” port.

The circuit RETURN hose (with female quick disconnect) is connected to the opposite port. Do not

reverse circuit fl ow. This can cause damage to internal seals.

• Always replace hoses, couplings and other parts with replacement parts recommended by Stanley

Hydraulic Tools. Supply hoses must have a minimum working pressure rating of 2500 psi/172 bar.

• Do not exceed the rated fl ow (see Specifi cations) page in this manual for correct fl ow rate and

model number. Rapid failure of the internal seals may result.

• Always keep critical tool markings, such as warning stickers and tags legible.

• Tool repair should be performed by experienced personnel only.

• Make certain that the recommended relief valves are installed in the pressure side of the system.

• Do not use the tool for applications for which it was not intended.

• Oil the chain at the end of the day to prevent rust but be careful not to over tension in this condition..

15

Page 17

TROUBLESHOOTING

CHAIN SAW TROUBLESHOOTING

Excessive vibration and cuts rough. Loose chain tension. Retension the chain.

Excessive feed force. Reduce feed force.

Chain saw will not cut straight. Operator feed force not applied move left hand closer to centerline

directly over centerline of saw. of saw bar.

Accumulated saw bar wear and Turn the saw bar over and dress rails

uneven chain segment profi le wear. square. Replace the saw bar and

chain.

Loss of power. Drive sprocket slipping on Adjust and tighten Trantorque®

Trantorque® adapter. adapter, (30 ft. lbs/40.6 Nm).

Chain saw does not run. Power source not functioning. Check power source for proper fl ow

and pressure (7-9 gpm/26-34 lpm @

2000 psi/140 bar).

Coupler or hoses are blocked. Remove obstruction.

Mechanical failure. Disassemble the chain saw and

inspect for damage.

Chain saw runs backwards. Pressure and return hoses Connect for proper fl ow direction.

reversed. Motor shaft must rotate clockwise.

Trigger is hard to press. Pressure and return hoses Connect to proper fl ow direction.

reversed. Motor shaft must rotate clockwise.

Back pressure too high. Should not exceed 250 psi/17 bar @

9 gpm/34 lpm measured at the end

of the chain saw’s operating hoses.

Fluid leakage around drive Motor shaft seal failure. Replace as required.

sprocket.

Fluid leakage between the rear Motor face seal failure. Replace as required.

gear housing and the chain saw

adaptor.

Fluid leakage between the valve Oil tube seal failure. Replace as required.

handle and the extension housing.

Fluid leakage between the ext- Oil tube seal failure. Replace as required.

ension housing assembly and

the chain saw adaptor.

Chain saw cuts slow. Insuffi cient hydraulic fl uid fl ow or Adjust proper hydraulic fl uid fl ow to

low relief valve setting. proper gpm. For optimum perf ormance, adjust relief valve to 2100 2250 psi/145-155 bar.

16

Page 18

TROUBLESHOOTING

CHAIN SAW TROUBLESHOOTING CONTINUED

Chain saw cuts slow. Back pressure too high. Should not exceed 250 psi/17 bar @

9 gpm/34 lpm measured at the end

of the chain saw’s operating hoses.

Loss of diamond segment side Replace the chain.

clearance.

Hydraulic fl uid mixed in water supply. Check motor for leaks.

Wrong chain for application. Scale down to a lower numbered

chain.

Wire edged bar rails. Dress rails square.

Excessive vibration and cuts rough. Segment(s) broken or missing Remove and repair broken segment

from chain. or replace chain.

17

Page 19

SPECIFICATIONS

Input Flow Range .............................................................................................................................................................................7-9 gpm / 26-34 lpm

Input Pressure ......................................................................................................................................................................................2000 psi / 140 bar

Chain Type ................................................................................................................................................................................Force 4 (.444) inch Pitch

Weight (with bar) ......................................................................................................................................................................................26 lbs / 11.8 kg

Length.................................................................................................................................................................................35 or 38 inches / 89 or 97 cm

Width ......................................................................................................................................................................................................9 inches / 23 cm

Lubrication / Cooling ........................................................................................................................................................ Internal Water Channels in Bar

Porting .......................................................................................................................................................................................................-8 SAE O-Ring

Connection .............................................................................................................................................3/8 inch Flush-Face Quick Disconnect Coupler

Hose Whips .................................................................................................................................................................................................................Yes

Sound Power Level .............................................................................................................................................................................................109 dBA

Vibration Level ................................................................................................................................................................................Main Handle 4.9 m/s²

........................................................................................................................................................................................................Assist Handle 5.2 m/s²

ACCESSORIES

Water Pump, 12 VDC, DC Plug, Marine Type .................................................................................................................................................DCP30100

Water Pump, 12 VDC, Battery Clips ................................................................................................................................................................DCP30101

3/8 inch Flush-Face Coupler Set ............................................................................................................................................................................03971

25 feet, 1/2 inch Dual Hose with Flush-Face Couplers ..........................................................................................................................................31972

50 feet, 1/2 inch Dual Hose with Flush-Face Couplers ..........................................................................................................................................31848

Chain 15-inch ........................................................................................................................................................................................................71050

Bar 15-inch ............................................................................................................................................................................................................ 71049

Chain 18-inch ........................................................................................................................................................................................................71048

Bar 18-inch ............................................................................................................................................................................................................ 71047

Pipe Clamp Assembly ............................................................................................................................................................................................. 71055

Drive Sprocket ........................................................................................................................................................................................................71046

Water Flow Meter, 0-7 GPM ................................................................................................................................................................................... 60859

Pipe Clamp Assembly 71055

18

Page 20

DS12 PARTS ILLUSTRATION

19

Page 21

DS12 PARTS LIST

ITEM P/N QTY DESCRIPTION

25688 1 Motor Assy - DS12315 & DS12318

1 00208 8 Capscrew, 1/4-20 x 1-3/4

2 06861 1 Rear Gear Housing

3 06316 4 Bushing

4 06838 1 Drive Gear

5 06840 1 Idler Shaft

6 06839 1 Idler Gear

7 00713 2 Dowel Pin

8 00178 1 O-Ring*

9 21417 1 Front Bearing Housing

10 350771 1 O-Ring*

11 00669 1 Quad Ring*

12 19884 1 Seal Gland

13 00170 1 Retaining Ring

14 03227 1 Needle Roller

15 20466 1 Motor Shaft

16 00148 1 Bearing

17 02905 1 O-Ring*

18 03104 1 Keeper Seal & Bearing

19 03110 1 Tefl on Seal*

20 00633 1 Retaining Ring

21 01211 1 O-Ring, 2-016 R16*

22 03280 1 Spacer, Seal Race

23 20472 1 Retaining Ring

24 71071 1 Name Tag

25 03278 1 Roll Pin

26 22701 1 Torsion Spring

27 31804 1 Roll Pin, 1/4 x 2 Stainless

28 22707 1 Trigger

29 02920 1 On/Off Valve Spacer

30 22704 1 Safety Catch

31 01605 2 O-Ring

32 01219 1 Pipe Plug (Before 2003)

340045 1 SAE Plug (2003 and Later)

33 00112 1 Quad Ring*

34 02931 1 Valve Cap

35 01604 2 O-Ring, 3-910 R17*

36 02925 1 Valve Spool

37 28552 1 Valve Handle Assy (incl. 32 & 41)

38 20459 1 Hose Clip

39 00787 1 Capscrew, 1/4-20 x 1-1/4

40 07226 2 Hose Assy, 18 inch

41 09437 1 Plug

42 02916 1 Comp. Coil Spring

43 20497 1 Water Hose Assy

44 00175 8 O-Ring, 2-014 R17*

45 00174 2 Oil Tube

46 20453 1 Extension Housing

47 00961 3 Pipe Plug

48 00018 1 O-Ring, 2-013 R17*

49 22717 3 Pipe Plug, 1/16-27

50 02912 2 Oil Tube

51 22713 1 Chain Saw Adaptor

52 25260 1 Quad Ring*

53 01211 1 O-Ring, 2-016 R16*

54 20463 1 Water Valve

55 20458 1 Spring

56 350237 1 Hollow Hex Plug

57 22752 1 Hex Nut, 5/16-18 ESNA

ITEM P/N QTY DESCRIPTION

58 71046 1 Drive Sprocket

59 20471 1 Trantorque® Adaptor

60 71051 1 Chain Guard

61 02766 2 Plain Washer

62 03276 2 Nut

63 22702 1 Bar Adjustment Nut

64 20465 2 Stud

65 22714 1 Screw, 5/16-18 x 2-3/4

66 02649 3 Handle Bar Retainer

67 02764 3 Screw, 5/16 x 3/4

68 02643 3 Neoprene Washer

69 20461 1 Handle Strut Assy

70 02936 1 Handle Bar

71 07473 1 Hand Guard

72 03006 2 Capscrew, 5/16-18 x 3/4

74 01758 4 Screw

77 12175 2 Washer, 5/16

78 22715 3 Capscrew, 5/16-18 x .625

79 12412 1 Danger Sticker

80 71049 Bar 15-inch

71047 1 Bar 18-inch

81 71050 Chain 15-inch

71048 1 Chain 18-inch

82 20721 1 Cord Stock

83 03971 1 Coupler Set

84 22945 1 Chain Cover

85 25635 1 Flow Regulator

86 23196 2 Capscrew, 5/16-18 UNC x 3

23517 1 Sprocket Wrench (Not Shown)

88 28409 1 Composit Sticker

89 11207 1 Type “D” Sticker

90 11212 1 Sound Power Level Sticker

91 71073 1 CE Tool Plate

92 02004 2 Drive Screw

SEAL KIT PART NUMBER 22798

00178 O-Ring 1

350771 O-Ring 1

00669 Quad Ring 1

02905 O-Ring 1

03110 Tefl on Seal 1

01211 O-Ring 2

00112 Quad Ring 2

01604 O-Ring 2

03847 Hose Washer 1

00175 O-Ring 8

00018 O-Ring 1

25260 Quad Ring 1

* Part of Seal Kit

01605 O-Ring 3

20

Page 22

Utility Saw Clamp

Instruction Sheet

A potentially hazardous situation exists which, if not

avoided, could result in death or serious injury

Before cutting, make sure the pipe is in a safe condition to be cut. Support the work piece in such a way that the

cut remains open during the cutting operation and when the cut is fi nished. Pinching the chain during the cut could

cause chain breakage and could result in death or serious injury to the operator.

If using the pipe clamp accessory, the clamp must be attached in such a way that it does not move during the cutting operation and/or when the cut is fi nished. Unexpected movement of the clamp could cause loss of control of

the saw and could result in death or serious injury to the operator.

CLAMP and SAW INSTALLATION

STEP 1

Attach the axle to the saw:

Remove the two nuts and washers that secure the chain guard to the saw and install the axle over the chain guard,

then re-install the two nuts and washers. Note: This is a good time to check the chain tension on your saw (see the

DS12 user manual for proper chain tension).

STEP 2

Place the clamp around top of the pipe. Hand tighten the adjustment nut.

STEP 3

Position the saw with the attached axle on the pipe clamp by sliding the saw clamp axle through the receiver hole at

top of the clamp. Secure with a snap pin.

STEP 4

Ensure that the saw is positioned to allow the handle to pivot during the cut unobstructed and to ensure that the saw

tip doesn’t contact dirt. If necessary, reposition the saw clamp/saw assembly around the pipe to optimum cutting position.

STEP 5

CUTTING TIPS

Position the saw to avoid pinching the blade or the chain as the pipe is cut. Support both ends of the pipe to prevent

movement and possible injury to the operator.

• Hold the saw so that the chain isn’t in contact with the pipe. Start the water and activate the saw to full power.

Press the chain against the pipe slowly, applying pressure to cut through the pipe.

• Pressure can be applied to the cut until the saw motor starts to lug.

AFTER CUTTING

When fi nished cutting, be sure to remove the saw fi rst, and then the clamp.

Stanley Hyrdaulic Tools. • 3810 SE Naef Road Milwaukie, OR 97267 USA • 503-659-5660 Fax 503-652-1780 • stanleyhydraulic.com

71346 11/2009

21

Page 23

WARRANTY

Stanley Hydraulic Tools (hereinafter called “Stanley”), subject to the exceptions contained below, warrants new hydraulic tools for a period of one year from the date of sale to

the fi rst retail purchaser, or for a period of 2 years from the shipping date from Stanley, whichever period expires fi rst, to be free of defects in material and/or workmanship at

the time of delivery, and will, at its option, repair or replace any tool or part of a tool, or new part, which is found upon examination by a Stanley authorized service outlet or by

Stanley’s factory in Milwaukie, Oregon to be DEFECTIVE IN MATERIAL AND/OR WORKMANSHIP.

EXCEPTIONS FROM WARRANTY

FREIGHT COSTS: Freight costs to return parts to Stanley, if requested by Stanley for the purpose of evaluating a warranty claim for warranty credit, are covered under

this policy if the claimed part or parts are approved for warranty credit. Freight costs for any part or parts which are not approved for warranty credit will be the responsibility

of the individual.

SEALS & DIAPHRAGMS: Seals and diaphragms installed in new tools are warranted to be free of defects in material and/or workmanship for a period of 6 months

after the date of fi rst usage, or for a period of 2 years from the shipping date from Stanley, whichever period expires fi rst.

CUTTING ACCESSORIES: Cutting accessories such as breaker tool bits are warranted to be free of defects in material and or workmanship at the time of delivery

only.

ITEMS PRODUCED BY OTHER MANUFACTURERS: Components which are not manufactured by Stanley and are warranted by their respective manufacturers.

a. Costs incurred to remove a Stanley manufactured component in order to service an item manufactured by other manufacturers.

ALTERATIONS & MODIFICATIONS: Alterations or modifi cations to any tool or part. All obligations under this warranty shall be terminated if the new tool or part is

altered or modifi ed in any way.

NORMAL WEAR: any failure or performance defi ciency attributable to normal wear and tear such as tool bushings, retaining pins, wear plates, bumpers, retaining rings

and plugs, rubber bushings, recoil springs, etc.

INCIDENTAL/CONSEQUENTIAL DAMAGES: To the fullest extent permitted by applicable law, in no event will STANLEY be liable for any incidental, consequen-

tial or special damages and/or expenses.

FREIGHT DAMAGE: Damage caused by improper storage or freight handling.

LOSS TIME: Loss of operating time to the user while the tool(s) is out of service.

IMPROPER OPERATION: Any failure or performance defi ciency attributable to a failure to follow the guidelines and/or procedures as outlined in the tool’s operation

and maintenance manual.

MAINTENANCE: Any failure or performance defi ciency attributable to not maintaining the tool(s) in good operating condition as outlined in the Operation and Mainte-

nance Manual.

HYDRAULIC PRESSURE & FLOW: Any failure or performance defi ciency attributable to excess hydraulic pressure, excess hydraulic back-pressure, or excess

hydraulic fl ow.

REPAIRS OR ALTERATIONS: Any failure or performance defi ciency attributable to repairs by anyone which in Stanley’s sole judgement caused or contributed to the

failure or defi ciency.

MIS-APPLICATION: Any failure or performance defi ciency attributable to mis-application. “Mis-application” is defi ned as usage of products for which they were not

originally intended or usage of products in such a matter which exposes them to abuse or accident, without fi rst obtaining the written consent of Stanley.

WARRANTY REGISTRATION: STANLEY ASSUMES NO LIABILITY FOR WARRANTY CLAIMS SUBMITTED FOR WHICH NO TOOL REGISTRATION IS ON

RECORD. In the event a warranty claim is submitted and no tool registration is on record, no warranty credit will be issued without fi rst receiving documentation which proves

the sale of the tool or the tools’ fi rst date of usage. The term “DOCUMENTATION” as used in this paragraph is defi ned as a bill of sale, or letter of intent from the fi rst retail

customer. A WARRANTY REGISTRATION FORM THAT IS NOT ALSO ON RECORD WITH STANLEY WILL NOT BE ACCEPTED AS “DOCUMENTATION”.

NO ADDITIONAL WARRANTIES OR REPRESENTATIONS

This limited warranty and the obligation of Stanley thereunder is in lieu of all other warranties, expressed or implied including merchantability or fi tness for a particular pur-

pose except for that provided herein. There is no other warranty. This warranty gives the purchaser specifi c legal rights and other rights may be available which might vary

depending upon applicable law.

22

Page 24

Stanley Hydraulic Tools

3810 SE Naef Road

Milwaukie OR 97267-5698

503-659-5660

FAX 503-652-1780

www.stanleyhydraulic.com

Loading...

Loading...