Page 1

DR19

HYDRAULIC

DIGGER

USER MANUAL

Safety, Operation and Maintenance

© 2014 STANLEY Black & Decker, Inc.

New Britain, CT 06053

U.S.A.

62213 8/2018 Ver. 8

Page 2

Page 3

TABLE OF CONTENTS

SAFETY SYMBOLS .................................................................................................................................................4

TOOL STICKERS & TAGS ...................................................................................................................................... 6

HOSE TYPES ..........................................................................................................................................................7

HOSE RECOMMENDATIONS ................................................................................................................................ 8

HTMA / EHTMA REQUIREMENTS ........................................................................................................................9

OPERATION ..........................................................................................................................................................10

TOOL PROTECTION & CARE .............................................................................................................................. 11

TROUBLESHOOTING ..........................................................................................................................................12

SPECIFICATIONS .................................................................................................................................................13

DR19 PARTS ILLUSTRATION .............................................................................................................................. 14

DR19 PARTS LIST .................................................................................................................................................15

To ll out a product warranty validation form, and for information on your warranty,

visit www.stanleyinfrastructure.com and select the Company tab > Warranty.

Note: The warranty validation record must be submitted to validate the warranty.

SERVICING: This manual contains safety, operation and routine maintenance instructions. STANLEY Infrastructure

recommends that servicing of hydraulic tools, other than routine maintenance, must be performed by an authorized

and certied dealer. Please read the following warning.

SERIOUS INJURY OR DEATH COULD RESULT FROM THE IMPROPER REPAIR OR

SERVICE OF THIS TOOL.

REPAIRS AND / OR SERVICE TO THIS TOOL MUST ONLY BE DONE BY AN

AUTHORIZED AND CERTIFIED DEALER.

For the nearest certied dealer, call STANLEY Infrastructure at (503) 659-5660 and ask for a Customer Service Representative.

DR19 User Manual ◄ 3

Page 4

SAFETY SYMBOLS

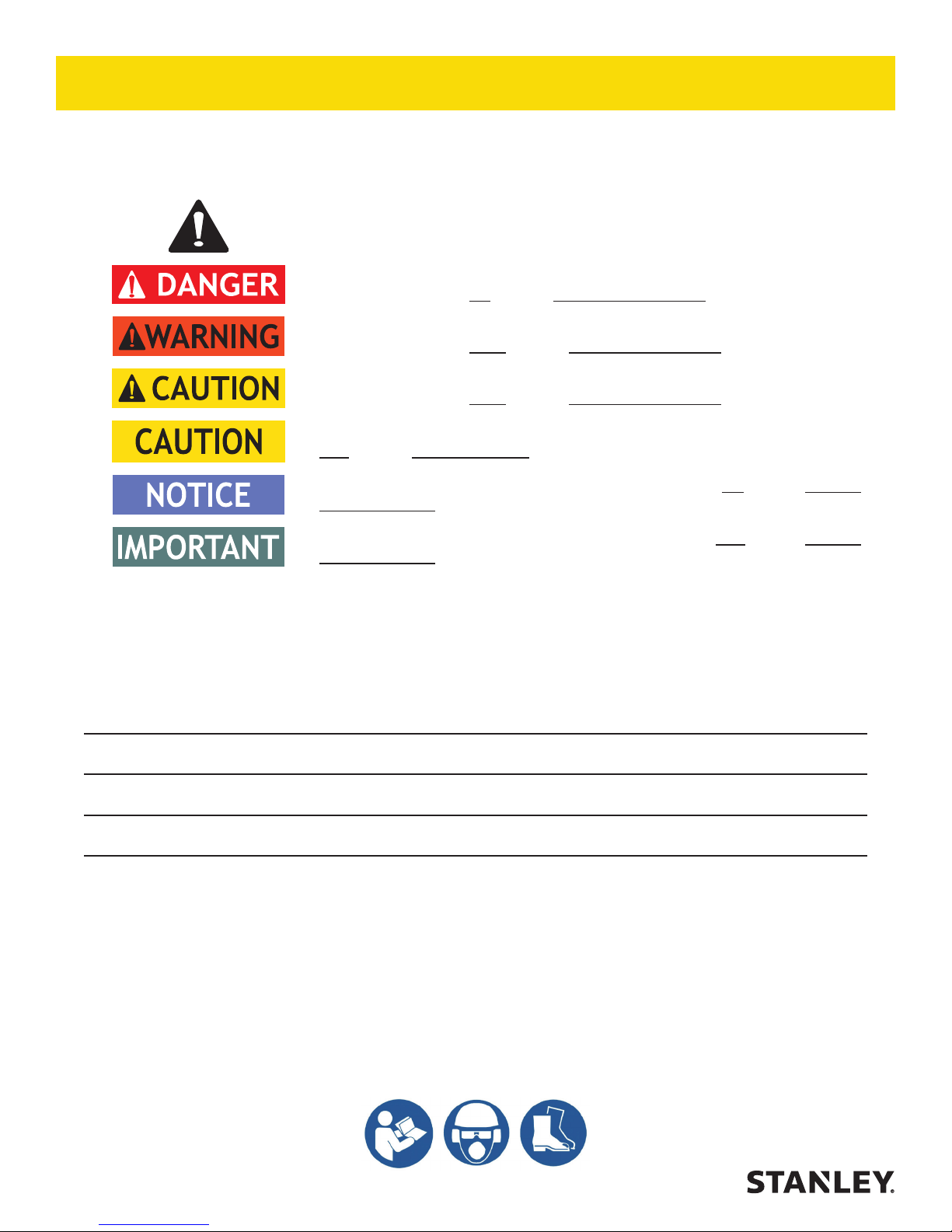

Safety symbols and signal words, as shown below, are used to emphasize all operator, maintenance and repair

actions which, if not strictly followed, could result in a life-threatening situation, bodily injury or damage to equipment.

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid possible

injury or death.

This safety alert and signal word indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

This safety alert and signal word indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

This safety alert and signal word indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

This signal word indicates a potentially hazardous situation which, if not avoided,

may result in property damage.

This signal word indicates a situation which, if not avoided, will result in damage

to the equipment.

This signal word indicates a situation which, if not avoided, may result in damage

to the equipment.

Always observe safety symbols. They are included for your safety and for the protection of the tool.

LOCAL SAFETY REGULATIONS

Enter any local safety regulations here. Keep these instructions in an area accessible to the operator and

maintenance personnel.

Tool operators and maintenance personnel must comply with safety precautions given in this manual, and on the

stickers and tags attached to or on the tool and hoses.

These precautions are for your safety. Review them carefully before operating the tool or performing any maintenance

or repairs.

Supervising personnel may specify additional precautions for your work area to comply with company policies and

local safety regulations. Enter added precautions in the space provided in this manual.

The DR19 Hydraulic Digger will provide safe, dependable service if operated in accordance with the instructions

given in this manual. Read and understand the manual any decals, labels, or tags attached to the tool and hoses.

Failure to do so can cause serious personal injury or damage to the equipment.

4 ► DR19 User Manual

Page 5

SAFETY PRECAUTIONS

• Operator must start in a work area without

bystanders. The operator must be familiar with all

prohibited work areas such as excessive slopes and

dangerous terrain conditions.

• Establish a training program for all operators to

ensure safe operation of the tool.

• Do not operate the tool unless thoroughly trained or

under the supervision of the instructor.

• Always wear personal protection equipment (PPE)

such as goggles, safety shoes, head, eye, breathing,

and ear protection when operating the tool. Use

gloves and aprons when necessary.

• Do not inspect or clean the tool while the hydraulic

power source is connected. Accidental engagement

of the equipment can cause serious injury.

• Supply hoses must have a minimum working

pressure rating of 2500 psi/175 bar.

• Be sure all hose connections are tight.

• The hydraulic circuit control valve must be in the

OFF position when coupling or uncoupling the tool.

Wipe all couplers clean before connecting. Use only

lint-free cloths. Failure to do so may result in damage

to the quick couplers and cause overheating of the

hydraulic system.

• Do not operate the tool at uid temperatures above

140 °F/60 °C. Operation at high temperatures can

cause operator discomfort.

• Keep the hydraulic uid clean at all times.

Contaminated uid causes rapid wear and early

failure of internal parts.

• Do not operate the tool if it is damaged, improperly

adjusted or incompletely assembled.

• Do not weld, cut with an acetylene torch or hard-

face the tool bit.

• To avoid personal injury or equipment damage,

all tool maintenance, repair, and service must be

performed by properly trained personnel.

• Do not exceed the rated limits of the tool or use the

tool for applications beyond its design capacity.

• Check fastener tightness before each use daily.

• Never operate the tool if you cannot be sure that

underground utilities are not present.

• Never wear loose clothing or unrestrained long hair

that can get entangled in the working parts of the

tool.

• Keep your work area clean and clear of tripping

hazards. Oily surfaces and hoses lying around can

be hazardous.

• Be alert and cautious around any pressurized

hydraulic system. High-pressure oil can be very

dangerous. Know your equipment and operate it

properly.

• Ensure adequate lighting for the area where the tool

is being used.

• Use proper lifting techniques when handling the

tool. Do not overreach. Maintain secure footing and

balance at all times.

• Make sure all critical tool markings, such as labels

and warning decals, are securely in place and

legible. Replace any that are damaged or missing.

• Always replace hoses, couplings, and other parts

with replacement parts recommended by STANLEY.

Refer to the parts list at the end of this manual for

part numbers.

• WARNING: Some dust created by power sanding,

sawing, grinding, drilling, and other construction

activities contains chemicals known to the State

of California to cause cancer, birth defects or

other reproductive harm. Some examples of these

chemicals are:

• Lead from lead-based paints,

• crystalline silica from bricks and cement

and other masonry products, and

• arsenic and chromium from chemically-

treated lumber.

Your risk from these exposures varies, depending

on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well

ventilated area, and work with approved safety

equipment, such as those dust masks that are

specially designed to lter out microscopic particles.

Protect yourself and those around you. Research

and understand the materials you are cutting.

Follow correct safety procedures and comply with

all applicable national, state or provisional health

and safety regulations relating to them, including,

if appropriate arranging for the safe disposal of the

materials by a qualied person.

DR19 User Manual ◄ 5

Page 6

28853

Name Tag

TOOL STICKERS & TAGS

03786

GPM Sticker

NOTE:

THE INFORMATION LISTED

ON THE STICKERS SHOWN,

MUST BE LEGIBLE AT ALL

TIMES.

REPLACE DECALS IF

THEY BECOME WORN OR

DAMAGED. REPLACEMENTS

ARE AVAILABLE FROM

YOUR LOCAL STANLEY

DISTRIBUTOR.

The safety tag (P/N 15875) at right is

attached to the tool when shipped from

the factory. Read and understand the

safety instructions listed on this tag before

removal. We suggest you retain this tag and

attach it to the tool when not in use.

1. FAILURE TO USE HYDRAULIC HOSE LABELED AND CERTIFIED AS NON-CONDUCTIVE WHEN USING HYDRAULIC

TOOLS ON OR NEAR ELECTRICAL LINES MAY RESULT IN

DEATH OR SERIOUS INJURY.

BEFORE USING HOSE LABELED AND CERTIFIED AS NON-

CONDUCTIVE ON OR NEAR ELECTRIC LINES BE SURE THE

HOSE IS MAINTAINED AS NON-CONDUCTIVE. THE HOSE

SHOULD BE REGULARLY TESTED FOR ELECTRIC CURRENT LEAKAGE IN ACCORDANCE WITH YOUR SAFETY

DEPARTMENT INSTRUCTIONS.

2. A HYDRAULIC LEAK OR BURST MAY CAUSE OIL INJECTION INTO THE BODY OR CAUSE OTHER SEVERE

PERSONAL INJURY.

A. DO NOT EXCEED SPECIFIED FLOW AND PRESSURE

FOR THIS TOOL. EXCESS FLOW OR PRESSURE MAY

CAUSE A LEAK OR BURST.

B. DO NOT EXCEED RATED WORKING PRESSURE OF

HYDRAULIC HOSE USED WITH THIS TOOL. EXCESS

PRESSURE MAY CAUSE A LEAK OR BURST.

C. CHECK TOOL HOSE COUPLERS AND CONNECTORS

DAILY FOR LEAKS. DO NOT FEEL FOR LEAKS WITH

YOUR HANDS. CONTACT WITH A LEAK MAY RESULT

IN SEVERE PERSONAL INJURY.

IMPORTANT

READ OPERATION MANUAL AND

SAFETY INSTRUCTIONS FOR THIS

TOOL BEFORE USING IT.

USE ONLY PARTS AND REPAIR

PROCEDURES APPROVED BY

STANLEY AND DESCRIBED IN THE

OPERATION MANUAL.

TAG TO BE REMOVED ONLY BY

TOOL OPERATOR.

SEE OTHER SIDE

DANGERDANGER

D. DO NOT LIFT OR CARRY TOOL BY THE HOSES. DO

NOT ABUSE HOSE. DO NOT USE KINKED, TORN OR

DAMAGED HOSE.

3. MAKE SURE HYDRAULIC HOSES ARE PROPERLY CONNECTED TO THE TOOL BEFORE PRESSURING SYSTEM.

SYSTEM PRESSURE HOSE MUST ALWAYS BE CONNECTED TO TOOL “IN” PORT. SYSTEM RETURN HOSE

MUST ALWAYS BE CONNECTED TO TOOL “OUT” PORT.

REVERSING CONNECTIONS MAY CAUSE REVERSE

TOOL OPERATION WHICH CAN RESULT IN SEVERE

PERSONAL INJURY.

4. DO NOT CONNECT OPEN-CENTER TOOLS TO CLOSEDCENTER HYDRAULIC SYSTEMS. THIS MAY RESULT IN

LOSS OF OTHER HYDRAULIC FUNCTIONS POWERED BY

THE SAME SYSTEM AND/OR SEVERE PERSONAL INJURY.

5. BYSTANDERS MAY BE INJURED IN YOUR WORK AREA.

KEEP BYSTANDERS CLEAR OF YOUR WORK AREA.

6. WEAR HEARING, EYE, FOOT, HAND AND HEAD PROTECTION.

7. TO AVOID PERSONAL INJURY OR EQUIPMENT DAMAGE,

ALL TOOL REPAIR MAINTENANCE AND SERVICE MUST

ONLY BE PERFORMED BY AUTHORIZED AND PROPERLY

TRAINED PERSONNEL.

IMPORTANT

READ OPERATION MANUAL AND

SAFETY INSTRUCTIONS FOR THIS

TOOL BEFORE USING IT.

USE ONLY PARTS AND REPAIR

PROCEDURES APPROVED BY

STANLEY AND DESCRIBED IN THE

OPERATION MANUAL.

TAG TO BE REMOVED ONLY BY

TOOL OPERATOR.

SEE OTHER SIDE

6 ► DR19 User Manual

SAFETY TAG P/N 15875 (Shown smaller then actual size)

Page 7

HOSE TYPES

The rated working pressure of the hydraulic hose must be equal to or higher than the relief valve setting on the

hydraulic system. There are three types of hydraulic hose that meet this requirement and are authorized for use with

STANLEY hydraulic tools. They are:

Certi ed non-conductive — constructed of thermoplastic or synthetic rubber inner tube, synthetic ber braid

reinforcement, and weather resistant thermoplastic or synthetic rubber cover. Hose labeled certifi ed non-

conductive is the only hose authorized for use near electrical conductors.

Wire-braided (conductive) — constructed of synthetic rubber inner tube, single or double wire braid

reinforcement, and weather resistant synthetic rubber cover. This hose is conductive and must never be used

near electrical conductors.

Fabric-braided (not certi ed or labeled non-conductive) — constructed of thermoplastic or synthetic rubber

inner tube, synthetic ber braid reinforcement, and weather resistant thermoplastic or synthetic rubber cover.

This hose is not certifi ed non-conductive and must never be used near electrical conductors.

HOSE SAFETY TAGS

To help ensure your safety, the following DANGER tags are attached to all hose purchased from STANLEY. DO

NOT REMOVE THESE TAGS.

If the information on a tag is illegible because of wear or damage, replace the tag immediately. A new tag may be

obtained from your STANLEY Distributor.

THE TAG SHOWN BELOW IS ATTACHED TO “CERTIFIED NON-CONDUCTIVE” HOSE

DANGER

1. FAILURE TO USE HYDRAULIC HOSE LABELED AND CERTIFIED AS NON-CONDUCTIVE

WHEN USING HYDRAULIC TOOLS ON OR NEAR ELECTRIC LINES MAY RESULT IN

DEATH OR SERIOUS INJURY.

FOR PROPER AND SAFE OPERATION MAKE SURE THAT YOU HAVE BEEN PROPERLY

TRAINED IN CORRECT PROCEDURES REQUIRED FOR WORK ON OR AROUND

ELECTRIC LINES.

2. BEFORE USING HYDRAULIC HOSE LABELED AND CERTIFIED AS NON-CONDUCTIVE

ON OR NEAR ELECTRIC LINES. WIPE THE ENTIRE LENGTH OF THE HOSE AND FITTING

WITH A CLEAN DRY ABSORBENT CLOTH TO REMOVE DIRT AND MOISTURE AND TEST

HOSE FOR MAXIMUM ALLOWABLE CURRENT LEAKAGE IN ACCORDANCE WITH SAFETY

DEPARTMENT INSTRUCTIONS.

DO NOT REMOVE THIS TAG

SEE OTHER SIDE

SIDE 1

3. DO NOT EXCEED HOSE WORKING PRESSURE OR ABUSE HOSE. IMPROPER USE

OR HANDLING OF HOSE COULD RESULT IN BURST OR OTHER HOSE FAILURE.

KEEP HOSE AS FAR AWAY AS POSSIBLE FROM BODY AND DO NOT PERMIT DIRECT

CONTACT DURING USE. CONTACT AT THE BURST CAN CAUSE BODILY INJECTION

AND SEVERE PERSONAL INJURY.

4. HANDLE AND ROUTE HOSE CAREFULLY TO AVOID KINKING, ABRASION, CUTTING, OR

CONTACT WITH HIGH TEMPERATURE SURFACES. DO NOT USE IF KINKED. DO NOT

USE HOSE TO PULL OR LIFT TOOLS, POWER UNITS, ETC.

5. CHECK ENTIRE HOSE FOR CUTS CRACKS LEAKS ABRASIONS, BULGES, OR DAMAGE TO COUPLINGS IF ANY OF THESE CONDITIONS EXIST, REPLACE THE HOSE

IMMEDIATELY. NEVER USE TAPE OR ANY DEVICE TO ATTEMPT TO MEND THE HOSE.

6. AFTER EACH USE STORE IN A CLEAN DRY AREA.

(Shown smaller than actual size)

DANGER

DANGER

SEE OTHER SIDE

SIDE 2

THE TAG SHOWN BELOW IS ATTACHED TO “CONDUCTIVE” HOSE.

DANGER

DANGER

1. DO NOT USE THIS HYDRAULIC HOSE ON OR NEAR ELECTRIC LINES. THIS HOSE IS

NOT LABELED OR CERTIFIED AS NON-CONDUCTIVE. USING THIS HOSE ON OR NEAR

ELECTRICAL LINES MAY RESULT IN DEATH OR SERIOUS INJURY.

2. FOR PROPER AND SAFE OPERATION MAKE SURE THAT YOU HAVE BEEN PROPERLY

TRAINED IN CORRECT PROCEDURES REQUIRED FOR WORK ON OR AROUND ELECTRIC LINES.

3. DO NOT EXCEED HOSE WORKING PRESSURE OR ABUSE HOSE. IMPROPER USE OR

HANDLING OF HOSE COULD RESULT IN BURST OR OTHER HOSE FAILURE. KEEP HOSE

AS FAR AWAY AS POSSIBLE FROM BODY AND DO NOT PERMIT DIRECT CONTACT

DURING USE. CONTACT AT THE BURST CAN CAUSE BODILY INJECTION AND SEVERE

PERSONAL INJURY.

4. HANDLE AND ROUTE HOSE CAREFULLY TO AVOID KINKING, CUTTING, OR CONTACT

WITH HIGH TEMPERATURE SURFACES. DO NOT USE IF KINKED. DO NOT USE HOSE TO

PULL OR LIFT TOOLS, POWER UNITS, ETC.

DO NOT REMOVE THIS TAG

SEE OTHER SIDE

SIDE 1

5. CHECK ENTIRE HOSE FOR CUTS CRACKS LEAKS ABRASIONS, BULGES, OR DAMAGE TO

COUPLINGS IF ANY OF THESE CONDITIONS EXIST, REPLACE THE HOSE IMMEDIATELY.

NEVER USE TAPE OR ANY DEVICE TO ATTEMPT TO MEND THE HOSE.

6. AFTER EACH USE STORE IN A CLEAN DRY AREA.

(Shown smaller than actual size)

DANGER

SEE OTHER SIDE

SIDE 2

DO NOT REMOVE THIS TAG

DO NOT REMOVE THIS TAG

DR19 User Manual ◄ 7

Page 8

Min. Working Pressure

USE

Press/Return)

(

HOSE RECOMMENDATIONS

Certi ed Non-Conductive Hose - Fiber Braid - for Utility Bucket Trucks

Oil Flow Hose Lengths Inside Diameter

GPM LPM FEET METERS INCH MM PSI BAR

4-9 15-34 up to 10 up to 3 3/8 10 Both 2250 155

Conductive Hose - Wire Braid or Fiber Braid -DO NOT USE NEAR ELECTRICAL CONDUCTORS

4-6 15-23 up to 25 up to 7.5 3/8 10 Both 2500 175

4-6 15-23 26-100 7.5-30 1/2 13 Both 2500 175

5-10.5 19-40 up to 50 up to 15 1/2 13 Both 2500 175

5-10.5 19-40 51-100 15-30 5/8 16 Both 2500 175

5/8 16 Pressure 2500 175

3/4 19 Return 2500 175

5-10.5 19-40 100-300 30-90

10-13 38-49 up to 50 up to 15 5/8 16 Both 2500 175

5/8 16 Pressure 2500 175

3/4 19 Return 2500 175

10-13 38-49 51-100 15-30

3/4 19 Pressure 2500 175

1 25.4 Return 2500 175

10-13 38-49 100-200 30-60

5/8 16 Pressure 2500 175

13-16 49-60 up to 25 up to 8

3/4 19 Return 2500 175

3/4 19 Pressure 2500 175

1 25.4 Return 2500 175

13-16 49-60 26-100 8-30

PRESSURE

<<< FLOW

RETURN

FLOW >>>

Figure 1. Typical Hose Connections

Tool to Hydraulic Circuit Hose

Recommendations

The chart to the right shows recommended

minimum hose diameters for various

hose lengths based on gallons per minute

(GPM)/liters per minute (LPM). These

recommendations are intended to keep return

line pressure (back pressure) to a minimum

acceptable level to ensure maximum tool

performance.

This chart is intended to be used for hydraulic

8 ► DR19 User Manual

tool applications only based on STANLEY tool

operating requirements and should not be

used for any other applications.

All hydraulic hose must have at least a

rated minimum working pressure equal to

the maximum hydraulic system relief valve

setting.

All hydraulic hose must meet or exceed

speci cations as set forth by SAE J517.

Page 9

HTMA / EHTMA REQUIREMENTS

HTMA / EHTMA REQUIREMENTS

TOOL TYPE

HTMA

HYDRAULIC SYSTEM REQUIREMENTS

Flow range

Nominal operating pressure

(At the power supply outlet)

System relief valve setting

(At the power supply outlet)

Maximum back pressure

(At tool end of the return hose)

Measured at a max uid viscosity of:

(At minimum operating temperature)

Temperature: Suffi cient heat rejection capacity to limit

maximum uid temperature to:

(At maximum expected ambient temperature)

Minimum cooling capacity at a temperature di erence of

between ambient and uid temps

Note: Do not operate the tool at oil temperatures above 140° F (60° C). Operation at higher temperatures can cause operator

discomfort at the tool.

Filter minimum full- ow ltration 25 microns 25 microns 25 microns 25 microns

Sized for ow of at least:

(For cold temp startup and maximum dirt-holding capacity)

Hydraulic uid, petroleum based (premium grade, antiwear, non-conductive) Viscosity (at minimum and maximum

operating temps)

Note: When choosing hydraulic uid, the expected oil temperature extremes that will be experienced in service determine the most

suitable temperature viscosity characteristics. Hydraulic uids with a viscosity index over 140 will meet the requirements over a wide

range of operating temperatures.

TYPE I TYPE II TYPE RR TYPE III

4-6 GPM

(15-23 LPM)

1500 psi

(103 bar)

2100-2250 psi

(145-155 bar)

250 psi

(17 bar)

400 ssu*

(82 centistokes)

140° F

(60° C)

3 hp

(2.24 kW)

40° F

(22° C)

30 GPM

(114 LPM)

100-400 ssu

(20-82

centistokes)

7-9 GPM

(26-34 LPM)

1500 psi

(103 bar)

2100-2250 psi

(145-155 bar)

250 psi

(17 bar)

400 ssu*

(82 centistokes)

140° F

(60° C)

5 hp

(3.73 kW)

40° F

(22° C)

30 GPM

(114 LPM)

100-400 ssu

(20-82

centistokes)

9-10.5 GPM

(34-40 LPM)

1500 psi

(103 bar)

2200-2300 psi

(152-159 bar)

250 psi

(17 bar)

400 ssu*

(82 centistokes)

140° F

(60° C)

6 hp

(5.22 kW)

40° F

(22° C)

30 GPM

(114 LPM)

100-400 ssu

(20-82

centistokes)

11-13 GPM

(42-49 LPM)

2100-2250 psi

(145-155 bar)

(82 centistokes)

100-400 ssu

centistokes)

1500 psi

(103 bar)

250 psi

(17 bar)

400 ssu*

140° F

(60° C)

7 hp

(4.47 kW)

40° F

(22° C)

30 GPM

(114 LPM)

(20-82

*SSU = Saybolt Seconds Universal

EHTMA

HYDRAULIC SYSTEM

REQUIREMENTS

Flow range

Nominal operating pressure

(At the power supply outlet)

System relief valve setting

(At the power supply outlet)

Note: These are general hydraulic system requirements. See tool speci cation page for tool speci c requirements.

B

3.5-4.3 GPM

(13.5-16.5

LPM)

1870 psi

(129 bar)

2495 psi

(172 bar)

C

4.7-5.8 GPM

(18-22 LPM)

1500 psi

(103 bar)

2000 psi

(138 bar)

CLASSIFICATION

D

7.1-8.7 GPM

(27-33 LPM)

1500 psi

(103 bar)

2000 psi

(138 bar)

9.5-11.6 GPM

(36-44 LPM)

1500 psi

(103 bar)

2000 psi

(138 bar)

DR19 User Manual ◄ 9

11.8-14.5 GPM

(45-55 LPM)

1500 psi

(103 bar)

2000 psi

(138 bar)

Page 10

OPERATION

PREPARATION PROCEDURES

PREPARATION FOR INITIAL USE

The tool, as shipped, has no special unpacking or

assembly requirements prior to usage. Inspection to

assure the tool was not damaged in shipping and does

not contain packing debris, is all that is required.

CHECK HYDRAULIC POWER SOURCE

1. Using a calibrated ow meter and pressure gauge,

check that the hydraulic power source develops a

ow of 7–9 GPM/26–34 LPM at 1500–2000 psi/105–

140 bar.

2. Make certain the hydraulic power source is equipped

with a relief valve set to open at 2100–2250 psi/145–

155 bar minimum.

3. Check that the hydraulic circuit matches the tool for

open-center (OC) operation.

CHECK TOOL

1. Make sure all tool accessories are correctly installed.

Failure to install tool accessories properly can result

in damage to the tool or personal injury.

2. There should be no signs of leaks.

3. The tool should be clean, with all ttings and

fasteners tight.

Note: The pressure increase in uncoupled hoses

left in the sun may result in making them dicult to

connect. When possible, connect the free ends of

operating hoses together.

OPERATING PROCEDURES

1. Observe all safety precautions.

2. Move the hydraulic circuit control valve to the ON

position.

3. Place the tool bit rmly on the surface you are to

work on.

4. Squeeze the trigger to start the tool. Adequate down

pressure is very important.

Not for underwater use.

COLD WEATHER OPERATION

If the tool is to be used during cold weather, preheat

the hydraulic uid at low engine speed. When using the

normally recommended uids, uid temperature should

be at or above 50° F/10° C (400 ssu/82 centistokes)

before use.

CHECK TRIGGER MECHANISM

1. Check that the trigger operates smoothly and is free

to travel between the ON and OFF positions.

INSTALL TOOL BIT

The tool accepts standard 7/8 × 3-1/4 inch hex shank

tool bits.

TO INSTALL A HEX SHANK TOOL BIT

1. Push in the retainer, insert the hex shank tool bit and

move the retainer back into locked position. Note

the orientation of the particular tool bit that is being

installed.

CONNECT HOSES

1. Wipe all hose couplers with a clean lint-free cloth

before making connections.

2. Connect the hoses from the hydraulic power source

to the hose couplers on the tool. It is a good practice

to connect the return hose rst and disconnect it last

to minimize or avoid trapped pressure within the

tool.

3. Observe ow indicators stamped on hose couplers

to be sure that oil will ow in the proper direction.

The female coupler is the inlet coupler.

STORAGE

1. Disconnect the tool from the hydraulic power source.

2. Remove the tool bit and spray the tool bit retainer

area with WD-40™ inside and out.

3. Wipe clean and store in a clean, dry place.

10 ► DR19 User Manual

Page 11

TOOL PROTECTION & CARE

In addition to the Safety Precautions found in

this manual, observe the following for equipment

protection and care.

• Make sure all couplers are wiped clean before

connection.

• The hydraulic circuit control valve must be in the

OFF position when coupling or uncoupling hydraulic

tools. Failure to do so may result in damage to

the quick couples and cause overheating of the

hydraulic system.

• Always store the tool in a clean dry space, safe from

damage or pilferage.

• Make sure the circuit PRESSURE hose (with male

quick disconnect) is connected to the IN port. The

circuit RETURN hose (with female quick disconnect)

is connected to the opposite port. Do not reverse

circuit ow. This can cause damage to internal seals.

• Always replace hoses, couplings and other parts

with replacement parts recommended by STANLEY.

Supply hoses must have a minimum working

pressure rating of 2500 psi/172 bar.

• Do not exceed the rated ow (see “SPECIFICATIONS”

on page 13). Rapid failure of the internal seals

may result.

• Always keep critical tool markings, such as warning

stickers and tags, legible.

• Do not force a small tool to do the job of a large

breaker.

• Keep tool bit sharp for maximum tool performance.

Make sure that tool bits are not chipped or rounded

on the striking end.

• Never operate a tool without a tool bit or without

holding it against the work surface. This puts

excessive strain on the breaker foot.

• Tool repair should be performed by experienced

personnel only.

• Make certain that the recommended relief valves

are installed in the pressure side of the system.

• Do not use the tool for applications for which it was

not intended.

DR19 User Manual ◄ 11

Page 12

TROUBLESHOOTING

If symptoms of poor performance develop, the following chart can be used as a guide to correct the problem. When

diagnosing faults in operation of the tool, always check that the hydraulic power source is supplying the correct

hydraulic ow and pressure to the tool as listed in the following table. Use a ow meter known to be accurate. Check

the ow with the hydraulic uid temperature at least 80 °F/27 °C.

Problem Cause Solution

Tool does not run. Power unit not functioning. Check power unit for proper ow

and pressure (7–9 GPM/26–34

LPM, 1500–2000 psi/105–140 bar).

Couplers or hoses blocked. Remove restriction.

Pressure and return line hoses

reversed at ports.

Mechanical failure of piston or

internal parts.

Tool does not hit eectively. Power unit not functioning. Check power unit for proper ow

Couplers or hose blocked. Remove restriction.

Fluid too hot (above 140 °F/60 °C). Provide cooler to maintain proper

Incorrect tool bit. Ensure tool bit meets specications.

Tool operates slow. Low oil ow from power unit. Check power source for proper ow.

High back-pressure. Check hydraulic system for

Be sure hoses are connected to

their proper ports.

Have inspected and repaired by

authorized dealer.

and pressure (7–9 GPM/26–34

LPM, 1500–2000 psi/105–140 bar).

uid temperature.

excessive back-pressure and

correct as required.

12 ► DR19 User Manual

Page 13

SPECIFICATIONS

Weight ...................................................................................................................................................24 lbs/10.9 kg

Pressure Range.............................................................................................................. 1500–2000 psi/105–140 bar

Flow Range .............................................................................................................................. 7–9 GPM/26–34 LPM

Optimum Flow .................................................................................................................................... 8 GPM/30 LPM

Porting .................................................................................................................................. 3/8" male pipe hose end

Length................................................................................................................................................20 inches/51 cm

System Type ........................................................................................................................................... Open Center

Accessory Shank .............................................................................................................................. 7/8" hex × 3-1/4”

DR19 User Manual ◄ 13

Page 14

DR19 PARTS ILLUSTRATION

14 ► DR19 User Manual

Page 15

DR19 PARTS LIST

ITEM

1 02890 1 HANDLE BODY ASSEMBLY

2 02853 1 TRIGGER

3 24316 1 DOWEL PIN 3/16 × 1-1/2

4 02959 1 SPOOL SCREW

5 24348 1 WASHER

6 02901 1 O-RING .239 × .367 × .064

7 03252 2 O-RING 7/16 × 9/16 × 1/16

8 01412 2 HOSE ASSEMBLY

9 02846 1 SPRING

10 02881 1 ON/OFF SPOOL, OPEN CENTER

11 03252 2 O-RING

12 00752 1 RETAINING RING 7/16 EXT

13 03973 1 MALE COUPLER BODY

14 03972 1 FEMALE COUPLER BODY

15 28853 1 NAME TAG

16 03786 1 GPM STICKER

17 71475 1 FLOW SLEEVE ASSEMBLY

18 03958 1 OIL TUBE

19 01259 1 O-RING 1-1/2 × 1-5/8 × 1/16

20 03253 1 VALVE BODY

21 02848 4 BOLT ASSEMBLY

22 02880 1 REVERSING SPOOL

23 00211 2 O-RING 1 × 1-1/8 × 1/16

24 03254 1 VALVE GLAND

25 01772 1 O-RING 3/4 × 7/8 × 1/16

26 02454 4 ALLEN NUT (INCL WITH ITEM 21)

27 02177 1 O-RING 2-1/16 × 2-1/4 × 3/32

28 02865 1 BACK-UP RING

29 03959 1 PISTON

30 02907 1 ROD SEAL 1-1/4 × 1-1/2 × 5/16 × 3/16

31 04175 1 INSERT

32 03127 1 WIPER RING

33 03537 1 RETAINING NOSE ASSEMBLY

34 03536 1 RETAINER

35 03190 2 SPRING

36 02436 2 BALL

37 03552 1 RETAINER CAP

38 03553 2 CAPSCREW 3/8 × 24 × 2-1/2

39 02843 1 PIN

PART

NO. QTY DESCRIPTION

SEAL KIT PART NUMBER 03843

02901 O-RING 1

03252 O-RING 2

02865 BACK-UP RING 2

02177 O-RING 2

03127 ROD WIPER 1

02302 ROD SEAL 1

01259 O-RING 1

01772 O-RING 1

00211 O-RING 2

02907 ROD SEAL 1

REPAIR KIT PART NUMBER 03943

00752 RETAINING RING 1

02848 BOLT ASSEMBLY 2

02843 PIN 1

03536 RETAINER 1

03190 SPRING 2

02436 BALL 2

03331 SEAL KIT 1

DR19 User Manual ◄ 15

Page 16

STANLEY Infrastructure

6430 SE Lake Road

Portland, Oregon 97222 USA

(503) 659-5660 / Fax (503) 652-1780

www.stanleyinfrastructure.com

Loading...

Loading...