Page 1

®

User’s Manual

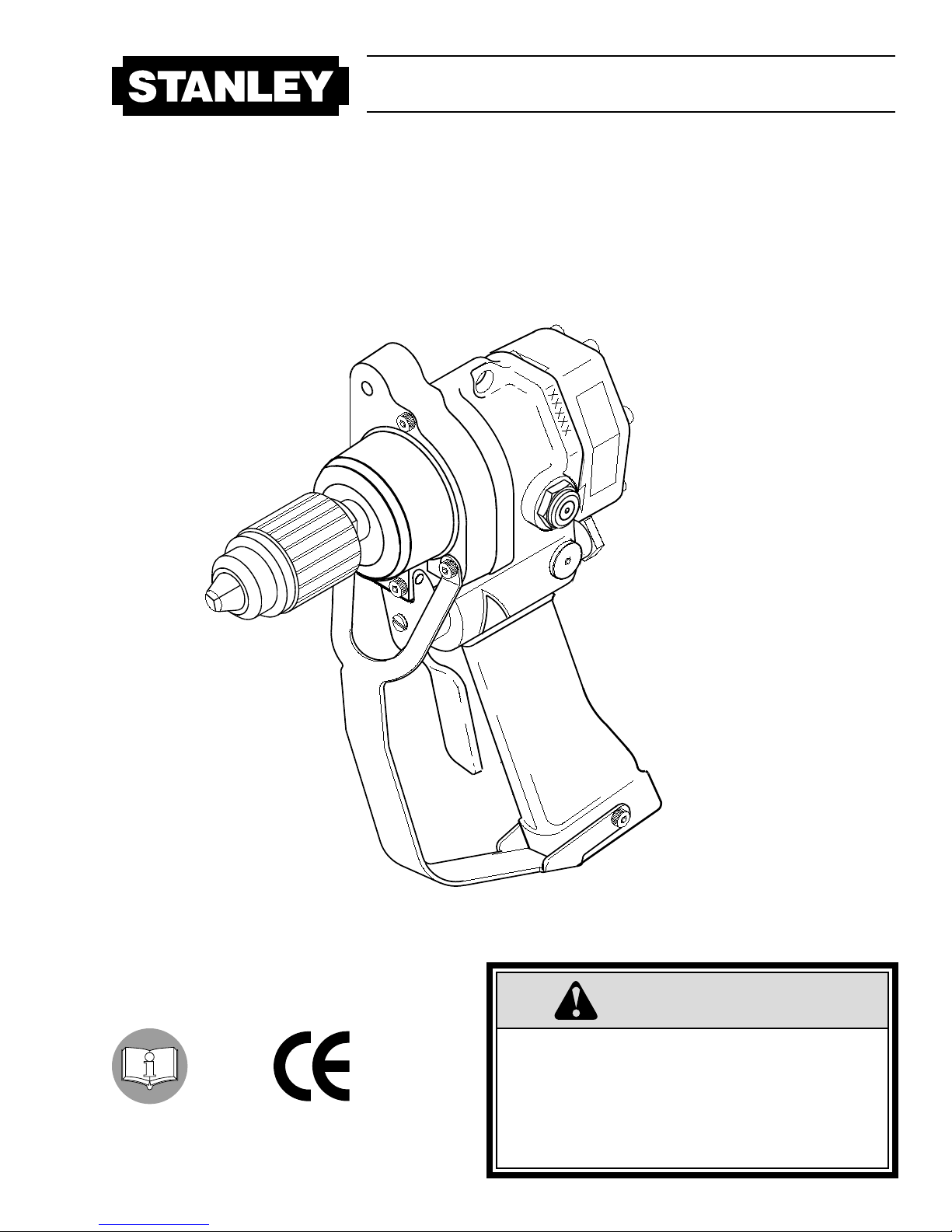

DL09

Hydraulic Drill

This Manual Covers The Following Models:

DL09150

DL09152S

DL09152SN

DL09152SUP

DL09172S

DL09172SN

DL09550D

DL0955001

DL09652

DL0965201

Copyright © 2002 The Stanley Works

OPS USA & CE Version

25077 7/2002 Ver. 2

(Depth Rod Not Pictured)

DANGER

SERIOUS INJURY OR DEATH COULD RESULT

FROM THE IMPROPER REPAIR OR SERVICE OF

THIS TOOL.

REPAIRS AND/OR SERVICE TO THIS TOOL

MUST ONLY BE DONE BY AN AUTHORIZED AND

CERTIFIED DEALER.

Page 2

Table of Contents

DL09

Hydraulic Drill

SERVICING THE

DL09 HYDRAULIC DRILL:

This manual contains Safety,

Operation, and Troubleshooting

information. Stanley Hydraulic Tools

recommends that servicing of

hydraulic tools, other than routine

maintenance, must be performed

by an authorized and certified

dealer. Please read the DANGER

warning on the cover and the

SAFETY warning below.

Certificate of Conformity

Specifications

General Safety Instructions

Tool Decals and Tags

Hydraulic Hose Requirements

HTMA Requirements

Hydraulic Recommendations

Operating Instructions

Troubleshooting

Parts Illustration

Parts List

3

3

4

5

6

7

8

9

11

13

14

Copyrightc2002 The Stanley Works

All rights reserved.

Under copyright law, this document may

not be copied in whole or in part without

the prior written consent of The Stanley

Works. This exception does not permit

copies to be made for others, whether or

not sold. Under the law, copying includes

translating into another language, format

or medium. This copyright notice must

appear on any permittedcopies.

2

Warranty

SAFETY FIRST

It is the responsibility of the operator and

service technician to read rules and

instructions for safe and proper operation

and maintenance.

A cautious worker using common sense is

the greatest safety device.

16

Page 3

Certificate of Conformity

I, the undersigned:

Winterling, David

Surname and First Names

hereby certify that the construction plant or equipment specified hereunder:

1. Category:

2. Make:

3. Type:

4. Type Serial Number of equipment:

5. Year of manufacture:

Drill

Stanley

DL0955001, & DL0965201

ALL

Stampedon tool

Has been manufactured in conformity with- EEC Type examination as shown:

Directive:

EN792-3

Approved body:

Self

EN28662-1

EN ISO 3744

Date:

6. Special Provisions:

Done at: Date:

2001

None

StanleyHydraulic Tools, Milwaukie, Oregon USA 2002

Date of expiration:

N/A

Signature: Position:

Engineering Manager

Specifications

Drive Size______ 1/2 in./ 1.3 cm 3-Jaw Adjustable

5/8 - 16 THD Chuck

Pressure Range______1000Flow Range_____________4-12 gpm / 15-45 lpm

Optimum Flow________________ 8 gpm / 30 lpm

System Type__open or closed center, HTMA TYPE I-III

Porting_______________________-8 SAE O-ring

Connect Size & Type___ 3/8

Weight_______________________ 6

Overall Length__________________ 9

Width_______________________ 3-1/2

Motor____________________________ Integral

TORQUE (proportional to Oil Pressure) Drill Speed (proportional to Oil Flow)

USA METRIC

4 ft-lb @ 500 psi 5 Nm @ 35 bar

9 ft-lb @ 1000 psi 12 Nm @ 70 bar

14 ft-lb @ 1500 psi 19 Nm @ 105 bar

19 ft-lb @ 2000 psi 26 Nm @ 140 bar

2000 psi / 70-140 bar

in. NPT Male Adapter

lbs. / 2.7 kg

in. / 23 cm

in. / 9 cm

DL09 TORQUE AND DRILL SPEEDS

Drill Torque___20 ft lbs / 27 Nm at 2000 psi/ 140 bar

Drill Speed__________1000 rpm at 8 gpm/ 30 lpm

RPM Range______________________350-1500

Max. Fluid Temp._____________

HTMA Class II___________

30Lpmat 138bar

BHTMACATEGORY

Weighted Vibration Level____________1.2(m/s2)

Sound Pressure Level_Less than 85 dBA @ 1 m

EHTMA Category_____

HYDRAULIC FLOW DRILL SPEED

3 gpm (11.3 lpm) 350 rpm

4 gpm (15 lpm) 475 rpm

6 gpm (23 lpm) 750 rpm

8 gpm (30 lpm) 1000 rpm

10 gpm (38 lpm) 1250 rpm

7-9 gpm @ 2000 psi

30 lpm @ 138 bar

° F / 60° C

140

3

Page 4

General Safety Instructions

Always observe safety symbols. They are included for your safety and the protection of the tool.

DANGER

This safety symbol may appear on

thetool.Itisusedtoalertthe

operator of an action that could

placehim/herorothersinalife

threatening situation.

WARNING

This safety symbol appears in these

instructions to identify an action

that could cause bodily injury to the

operator or other personnel.

This safety symbol appears in these

instructions to identify an action or

condition that could result in

damage to the tool or other

equipment.

CAUTION

This tool will provide safe and dependable service if operated in accordance with the instructions

given in this manual. Read and understand this manual and any stickers and tags attached to the

tool and hoses before operation. Failure to do so could result in personal injury or equipment

damage.

A Operator must start in a work area without bystanders. The operator must be familiar with all prohibited

work areas such as excessive slopes and dangerous terrain conditions.

Establish a training program for all operators to ensure safe operations.

A

Do not operate the tool unless thoroughly trained or under the supervision of an instructor.

A

Always wear safety equipment such as goggles, head protection, and safety shoes at all times when

A

operating the tool.

Do not inspect or clean the tool while the hydraulic power source is connected. Accidental engagement of

A

the tool can cause serious injury.

Do not operate this tool without first reading the Operating Instructions.

A

Do not install or remove this tool while the hydraulic power source is connected. Accidental engagement

A

of the tool can cause serious injury.

Never operate the tool if you cannot be sure that underground utilities are not present. Underground

A

electrical utilities present an electrocution hazard. Underground gas utilities present an explosion hazard.

Other underground utilities may present other hazards.

Do not wear loose fitting clothing when operating the tool. Loose fitting clothing can get entangled with

A

the tool and cause serious injury.

Supply hoses must have a minimum working pressure rating of 2500 psi/175 bar.

A

Be sure all hose connections are tight.

A

The hydraulic circuit control valve must be in the “OFF” position when coupling or uncoupling the tool.

A

Wipe all couplers clean before connecting. Failure to do so may result in damage to the quick couplers

and cause overheating. Use only lint-free cloths.

Do not operate the tool at oil temperatures above 140 F/60 C. Operation at higher oil temperatures can

A

°°

cause operator discomfort and may cause damage to the tool.

Do not operate a damaged, improperly adjusted, or incompletely assembled tool.

A

To avoid personal injury or equipment damage, all tool repair, maintenance and service must only be

A

performed by authorized and properly trained personnel.

Do not exceed the rated limits of the tool or use the tool for applications beyond its design capacity.

A

Always keep critical tool markings, such as labels and warning stickers legible.

A

Always replace parts with replacement parts recommended by Stanley Hydraulic Tools.

A

Check fastener tightness often and before each use daily.

A

When working near electrical conductors, always assume that all conductors are energized and that insulation,

A

Clothing and hoses can conduct electricity. Use hose labeled and certified as non-conductive.

4

Page 5

Tool Decals & Tags

A model sticker is attached to the tool. Neverexceed the flow and pressure levels specified onthis

sticker. The information listed on the model sticker must be legible at all times. Replace this

sticker if it becomes worn or damaged. A replacement is available from your local Stanley

distributor.

28323

“CE” Decal

(CE Models only)

28788

Manual Sticker

(Not used on all models)

15211

Danger Sticker

Failureto use hydraulic hose labeled and certified as

non-conductivewhen using hydraulic tools on or

nearelectric lines may result in death or serious

injury.

Forproper and safe operation read owners manual

andmake sure that you have been properly trained in

correctprocedures required for work on or around

ELECTROCUTION

electriclines.

HAZARD

DANGER

7-10GPM/ 24-36 LPM

DONOT EXCEED 2000 PSI/ 140 BAR

nn

DONOT EXCEED SPECIFIED FLOW OR PRESSURE. USECLOSED-CENTER

n

TOOLON CLOSED-CENTER SYSTEM. USEOPEN-CENTERTOOL ON OPEN-

n

CENTERSYSTEM. CORRECTLYCONNECTHOSES TO TOOL "IN" AND "OUT"

n

PORTS. IMPROPER HANDLING, USE OR MAINTENANCE OF TOOL COULD

RESULTINA LEAK, BURST OR OTHER TOOL FAILURE. CONTACT AT A LEAK

ORBURST CAN CAUSE OIL INJECTION INTO THE BODY. FAILURE TO

OBSERVETHESE PRECAUTIONS CAN RESULT IN SERIOUS PERSONAL

INJURY.

n

n

DL09

29149

Rotation Direction Sticker

(Not used on all models)

Stanley Hydraulic Tools

3810 SE Naef Rd

®

Milwaukie, Oregon 97267

Model No.

DL09

15-45 lpm/4-12 gpm

140 bar/2000 psi

28769

DL09 Model Sticker

RPM Sticker

29148

(Not used on all models)

30Lpm at 138bar

BHTMA CATEGORY

11207

Circuit Type “D” Decal

(Not used on all models)

The SAFETY TAG, P/N 15875, shown at right, smaller

than actual size, is attached to the tool when shipped

from the factory. Read and understand the safety

instructions listed on this tag before removal. We

suggest you retain this tag and attach it to the tool

when not in use.

DANGER DANGER

1. FAILURE TO USE HYDRAULIC HOSE

CERTI-FIED AS NON-CONDUCTIVE

HYDRAULIC TOOLS ON OR NEAR ELECTRICAL LINES

MAYRESULTIN DEATHOR SERIOUSINJURY.

BEFORE USING HOSE

NON- CONDUCTIVE

BESURE THE HOSEIS . T HE

HOSE SHOULD BE REGULARLY TESTED FOR ELECTRIC CURRENT

LEAKAGE IN ACCORDANCE WITH YOUR SAFETY DEPARTMENT

INSTRUCTIONS.

2. A HYDRAULIC LEAK OR BURST MAY CAUSE OIL

INJECTIONINTO THE BODYOR CAUSEOTHER SEVERE P ERSONAL

INJURY.

A. DO NOT EXCEED SPECIFIED FLOW AND

PRESSURE FOR THIS TOOL. EXCESS FLOW OR

PRESSUREMAY CAUSEA LEAK ORBURST.

B. DO NOT EXCEED RATED WORKING PRESSURE

OF HYDRAULIC HOSE USED WITH THIS TOOL.

EXCESS PRESSURE MAY CAUSE A LEAK OR

BURST.

C. CHECK TOOL, HOSE, COUPLERS &

CONNECTORS DAILY FOR

LEAKS. DO NOT FEEL FOR LEAKS WITH

YOUR HANDS. CONTACT WITH A LEAK MAY

RESULTIN SEVEREPERSONAL INJURY.

ON OR NEAR ELECTRIC LINES.

MAINTAINEDAS NON- COND UCTIV E

LABELED AND

WHEN USING

LABELED AND CERTIFIED AS

D. DO NOT LIFT OR CARRY TOOL BY THE HOSES. DO NOT ABUSE

HOSE.DO NOT USEKINKED, TORNOR DAMAGED HOSES.

3. MAKE SURE HYDRAULIC HOSES ARE PROPERLY

CONN-ECTED TO THE TOOL BEFORE PRESSURIZING

SYSTEM. SYSTEM PRESSURE HOSE MUST ALWAYS

BE CONNECTED TO TOOL “IN” PORT. SYSTEM

RETURN HOSE MUST ALWAYS BE CONNECTED AT

TOOL “OUT” PORT. REVERSING CONNECTIONS MAY

CAUSE REVERSE TOOL OPERATION WHICH CAN

CAUSESEVERE PERSONAL INJURY.

4. DO NOT CONNECT CLOSED-CENTER TOOLS TO

OPEN-CENTER HYDRAULIC SYSTEMS. THIS MAY

CAUSE EXTREME SYSTEM HEAT AND/OR SEVERE

PERSONALINJURY.

DONOT CONNECT OPEN-CENTERTOOLS TO CLO S ED -C E NT ER

HYDRAULIC SYSTEMS. THIS MAY RESULT IN LOSS OF OTHER

HYDRAULIC FUNCTIONS POWERED BY THE SAME SYSTEM AND/OR

SEVEREPERSONAL INJURY.

5. BYSTANDERS MAY BE INJURED IN YOUR WORK

AREA. KEEP BYSTANDERS CLEAR OF YOUR WORK

AREA.

6. WEAR HEARING,EYE, FOOT,HAND ANDHEAD PROTECTION.

7. TO AVOIDPERSONAL INJURYOR EQUIPMENT DAMAGE, ALL TOOL

REPAIR,MAINTENANCE AND SERVICE MUST BE

PERFORMEDBY AUTHORIZED A ND P R O PE R LY

TRAINEDPERSONNEL.

IMPORTANT IMPORTANT

READ OPERATION MANUAL AND

SAFETY INSTRUCTIONS FOR THIS

TOOL BEFORE USING IT.

USE ONLY PARTS AND REPAIR

PROCEDURES APPROVED BY

STANLEY AND DESCRIBED IN THE

OPERATION MANUAL.

TAG TO BE REMOVED ONLY BY TOOL

(517) (517)15875 15875

OPERATOR.

SEE OTHER SIDE SEE OTHER SIDE

READ OPERATION MANUAL AND

SAFETY INSTRUCTIONS FOR THIS

TOOL BEFORE USING IT.

USE ONLY PARTS AND REPAIR

PROCEDURES APPROVED BY

STANLEY AND DESCRIBED IN THE

OPERATION MANUAL.

TAG TO BE REMOVED ONLY BY TOOL

OPERATOR.

5

Page 6

Hydraulic Hose Requirements

HOSE TYPES

Hydraulic hose types authorized for usewithStanleyHydraulicTools areas follows:

Certified non-conductive

Wire-braided(conductive)

Fabric-braided (not certified or labeled non-conductive)

Hose listed above is the only hoseauthorizedfor use near electrical conductors.

Hoses and listed above are and be nearelectricalconductors.

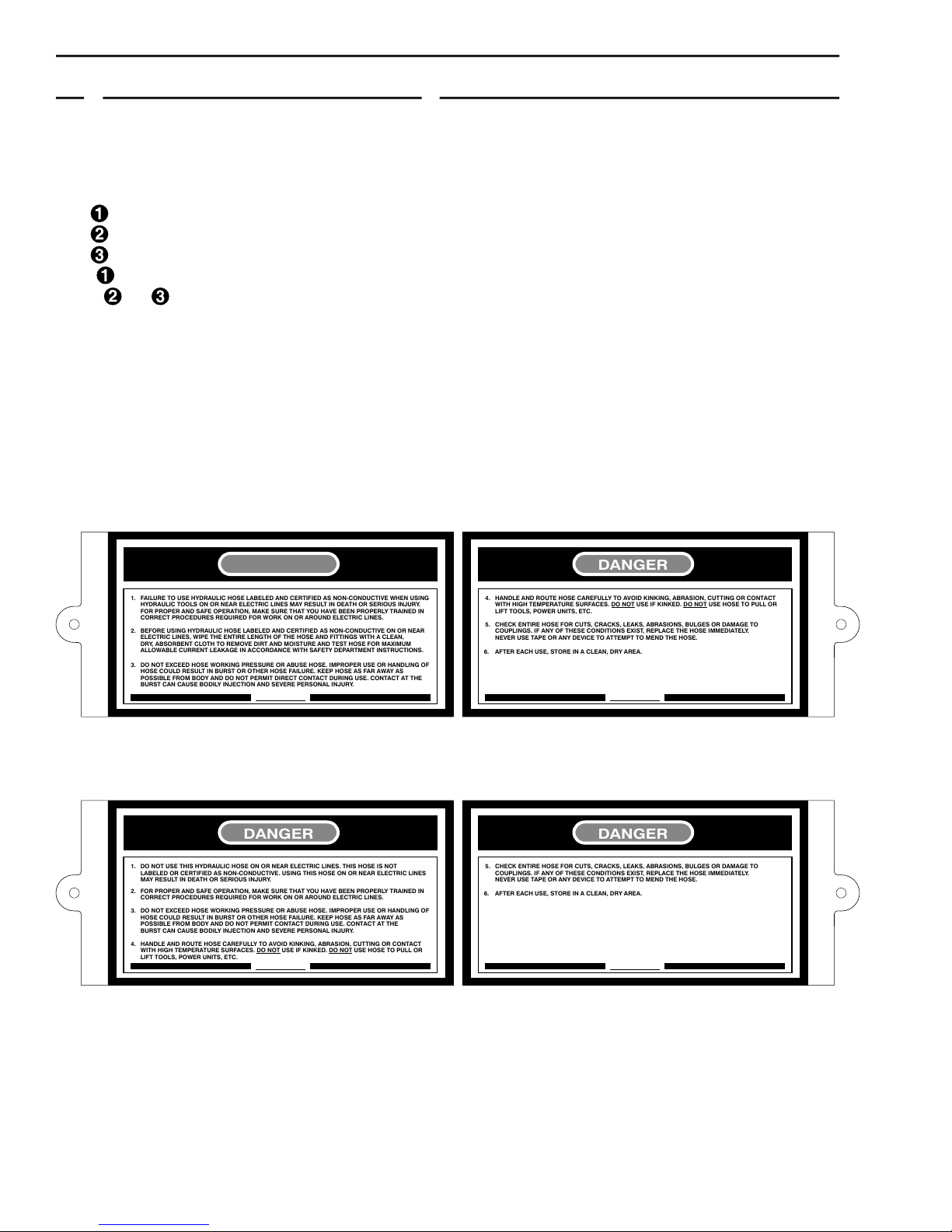

HOSE SAFETY TAGS

To help ensure your safety, the following DANGER tags are attached to all hoses purchased from Stanley

Hydraulic Tools. DO NOT REMOVE THESE TAGS.

If the information in a tag is illegible because of wear or damage, replace the tag immediately. A new tag

may be obtained at no charge from yourStanley Distributor.

This Tag attached to “Certified Non-Conductive” hose.

conductive must never

(shown smaller than actual size) p/n 27987

DO NOT REMOVE THIS TAG

DANGER

1.

FAILURE TO USE HYDRAULIC HOSE LABELED AND CERTIFIED AS NON-CONDUCTIVE WHEN USING

HYDRAULIC TOOLS ON OR NEAR ELECTRIC LINES MAY RESULTIN DEATH OR SERIOUS INJURY.

FOR PROPER AND SAFE OPERATION, MAKE SURE THAT YOU HAVE BEEN PROPERLY TRAINED IN

CORRECT PROCEDURES REQUIRED FOR WORK ON OR AROUND ELECTRIC LINES.

BEFORE USING HYDRAULIC HOSE LABELED AND CERTIFIED AS NON-CONDUCTIVE ON OR NEAR

2.

ELECTRIC LINES, WIPE THE ENTIRE LENGTH OF THE HOSE AND FITTINGS WITH A CLEAN,

DRY,ABSORBENT CLOTH TO REMOVE DIRT AND MOISTURE AND TEST HOSE FOR MAXIMUM

ALLOWABLE CURRENT LEAKAGE IN ACCORDANCE WITH SAFETY DEPARTMENTINSTRUCTIONS.

3.

DO NOT EXCEED HOSE WORKING PRESSURE OR ABUSE HOSE. IMPROPER USE OR HANDLING OF

HOSE COULD RESULT IN BURST OR OTHER HOSE FAILURE.KEEP HOSE AS FAR AWAY AS

POSSIBLE FROM BODY AND DO NOT PERMIT DIRECT CONTACT DURING USE. CONTACT AT THE

BURST CAN CAUSE BODILYINJECTION AND SEVERE PERSONAL INJURY.

SEE OTHER SIDE

DO NOT REMOVE THIS TAG

Side 1 Side 2

This Tag attached to “Conductive” hose.

(shown smaller than actual size) p/n 29144

DANGER

1.

DO NOT USE THIS HYDRAULIC HOSE ON OR NEAR ELECTRIC LINES. THIS HOSE IS NOT

LABELED OR CERTIFIED AS NON-CONDUCTIVE. USING THIS HOSE ON OR NEAR ELECTRIC LINES

MAY RESULTIN DEATH OR SERIOUS INJURY.

FOR PROPER AND SAFE OPERATION, MAKE SURE THAT YOU HAVE BEEN PROPERLY TRAINED IN

2.

CORRECT PROCEDURES REQUIRED FOR WORK ON OR AROUND ELECTRIC LINES.

DO NOT EXCEED HOSE WORKING PRESSURE OR ABUSE HOSE. IMPROPER USE OR HANDLING OF

3.

HOSE COULD RESULT IN BURST OR OTHER HOSE FAILURE.KEEP HOSE AS FAR AWAY AS

POSSIBLE FROM BODY AND DO NOT PERMIT CONTACT DURING USE. CONTACT AT THE

BURST CAN CAUSE BODILYINJECTION AND SEVERE PERSONAL INJURY.

4.

HANDLE AND ROUTE HOSE CAREFULLY TO AVOIDKINKING, ABRASION, CUT TING OR CONTACT

WITH HIGH TEMPERATURE SURFACES. USE IF KINKED. USE HOSE TO PULL OR

LIFT TOOLS, POWER UNITS, ETC.

DO NOT REMOVE THIS TAG

DO NOT DO NOT

SEE OTHER SIDE

Side 1 Side 2

DANGER

4.

HANDLE AND ROUTE HOSE CAREFULLY TO AVOIDKINKING, ABRASION, CUT TING OR CONTACT

WITH HIGH TEMPERATURE SURFACES. USE IF KINKED. USE HOSE TO PULL OR

LIFT TOOLS, POWER UNITS, ETC.

CHECK ENTIRE HOSE FOR CUTS, CRACKS, LEAKS, ABRASIONS, BULGES OR DAMAGE TO

5.

COUPLINGS. IF ANY OF THESE CONDITIONS EXIST,REPLACE THE HOSE IMMEDIATELY.

NEVER USE TAPE OR ANY DEVICE TO ATTEMPT TO MEND THE HOSE.

6.

AFTER EACH USE, STORE IN A CLEAN, DRY AREA.

DO NOT DO NOT

SEE OTHER SIDE

DANGER

CHECK ENTIRE HOSE FOR CUTS, CRACKS, LEAKS, ABRASIONS, BULGES OR DAMAGE TO

5.

COUPLINGS. IF ANY OF THESE CONDITIONS EXIST,REPLACE THE HOSE IMMEDIATELY.

NEVER USE TAPE OR ANY DEVICE TO ATTEMPT TO MEND THE HOSE.

6.

AFTER EACH USE, STORE IN A CLEAN, DRY AREA.

SEE OTHER SIDE

DO NOT REMOVE THIS TAG

HOSE PRESSURE RATING

The rated working pressure of the hydraulic hose must be equal to or higher than the relief valve setting on

the hydraulic system.

6

Page 7

HTMA Requirements

NOTE: These are general hydraulic system requirements. See tool specification page for tool

specific requirements.

Tool Category

C

Hydraulic System

Requirements

20Lpm at 138bar

BHTMA CATEGORY

Type I

30Lpm at 138bar

BHTMA CATEGORY

Type II

40Lpm at 138bar

EHTMA CATEGORY

Type III

Flow rate

Tool Operating Pressure

(at the power supply outlet)

System relief valve setting

(at the power supply outlet)

Maximum back pressure

(at tool end of the return hose)

Measured at a max. fluid viscosity of:

(at min. operating temperature)

Temperature

Sufficient heat rejection capacity

to limit max. fluid temperature to:

(at max. expected ambient temperature)

Min. cooling capacity

at a temperature difference of

between ambient and fluid temps

NOTE: Do not operate the tool at oil

temperatures above 140

at higher temperatures can cause operator

discomfort at the tool.

° F (60° C). Operation

4-6

gpm 7-9 gpm 10.5-11.6 gpm 11-13 gpm

(15-23 lpm) (26-34 lpm) (36-44 lpm) (42-49 lpm)

2000 psi

(138 bar) (138 bar) (138 bar) (138 bar)

2100-2250 psi

(145-155 bar)

200 psi

(14 bar)

400 ssu*

(82 centistokes)

°F °F °F °F

140 140 140 140

3hp 5hp 6hp 7hp

40 40 40 40

(60° C) (60° C) (60° C) (60° C)

(2.24 kW) (3.73 kW) (4.47 kW) (5.22 kW)

(22° C) (22° C) (22° C) (22° C)

°F °F °F °F

2000 psi 2000 psi 2000 psi

2100-2250 psi 2100-2250 psi 2100-2250 psi

(145-155 bar) (145-155 bar) (145-155 bar)

200 psi 200 psi 200 psi

(14 bar) (14 bar) (14 bar)

400 ssu* 400 ssu* 400 ssu*

(82 centistokes) (82 centistokes) (82 centistokes)

Filter

Min. full-flow filtration

Sized for flow of at least:

(For cold temp. startup and max. dirt-holding

capacity)

Hydraulic fluid

Petroleum based

(premium grade, anti-wear, non-conductive)

Viscosity

(at min. and max. operating temps)

NOTE: When choosing hydraulic fluid, the

expected oil temperature extremes that will be

experienced in service determine the

most suitable temperature viscosity

characteristics. Hydraulic fluids with a viscosity

index over 140 will meet the requirements over

a wide range of operating temperatures.

* ssu = Saybolt Seconds Universal

25 microns 25 microns 25 microns 25 microns

18 gpm 30 gpm 35 gpm 40 gpm

100-400 100-400 100-400 100-400

(20-82 centistokes) (20-82 centistokes) (20-82 centistokes) (20-82 centistokes)

(68 lpm) (114 lpm) (132 lpm) (151 lpm)

ssu* ssu* ssu* ssu*

7

Page 8

Hydraulic Recommendations

SPECIFICATIONS

Fluids for Mobile Hydraulic

Tool Circuits

The specification listed here will

provide good all season operation

if your circuit is of proper design

and normal maintenance is performed.

(Periodic filter change,

draining of condensate, etc.

Recommended Fluid

s

ITEM U.S.A. METRIC

Viscosity (Fluid Thickness) 50 F 450 SSU Max 10 C 95 Centistokes Max.

Viscosity (Fluid Thickness) 100 F 130-225 SSU 38 C 27-42 Centistokes

Viscosity (Fluid Thickness) 140 F 85 SSE Min. 60 C 16.5 Centistokes Min.

Pour Point (Min. for cold startup) -10 F 23 C

Viscosity Index (ASTM D2220) 140 Minimum

Demulsibility (ASTM D1401) 30 Minutes Max.

Flash Point (ASTM D92) 340 F Min.

Rust Inhibition (ASTM D665 A&B) Pass

Oxidation (ASTM D943) 1000 Hours Min.

Pump Wear Test (ASTM D2882) 60 mg Max.

°°

°°

°°

°°

°

RECOMMENDED FLUIDS

BRAND BIODEGRADABLE DESCRIPTION

AMS-Oil No Hydraulic Fluid MN 150 SSU, 100 V.I.

The fluids listed here work well

over a wide temperature range at

start-up, allow moisture to settle

out, and resist biological growth

likely in cool-operating hydraulic

Circuits.

These fluids are recommended by

Stanley Hydraulic Tools for use in

our tools. Other fluids that meet or

exceed the specifications of these

fluids may also be used.

Chevron No AW-MV-32

Exxon No “Univis” J-26

Mobil No D.T.E. 13

Gulf No “Harmony” AW-HVI-1 50-32

Shell No “Lo-Hydraul” 32

Sun No “Sunvis” 805 MG

Texaco No “Rando” HD-AZ

Union No “Unax” AW-WR-32

Mobil Yes EAL 224H

Texaco Yes BioStar 32

Terresole Yes EnviroLogic 132

Shell Yes Naturelle HF-E-32

Pennzoil Yes Pennzsafe Sl200

P/N 15596 04/98 .5M

Page 9

Operating Instructions

CAUTION

Make certain that the chuck has been securely mounted.

Check Power Source

1. Using a calibrated flowmeter and pressure

gauge during the intial set-up, check that the

hydraulic power source develops a flow of 412 gpm/ 15-45 lpm at 1000-2000 psi/ 70-140

bar.

2. Make certain that the hydraulic power source

is equipped with a relief valve set to open at

2100 psi/ 145 bar maximum.

Connect Hoses

1. Wipe all hose couplers with a clean lint-free

cloth before making connections.

2. Connect hoses from the hydraulic power

supply to the tool quick disconnects. It is a

good practice to connect the return hose first

and disconnect it last to minimize or avoid

trapped pressure within the drill.

3. Observe the arrow on hose couplers to ensure

that the flow is in the proper direction. The

male coupler on the circuit hose end is the

supply (pressure) coupler.

4. Make sure the circuit PRESSURE hose (with

male quick disconnect) is connected to the

port at the back of the drill handle. The circuit

RETURN hose (with female quick disconnect)

is connected to the port closest to the trigger.

5. Move the hydraulic circuit control valve to the

position to direct hydraulic flow to the

ON

drill.

NOTE: If uncoupled hoses are left in the

sun, pressure increase inside the hose

may result in making them difficult to

connect. Whenever possible, connect the

free ends of the hoses together.

Drill Operation

1. Observe all safety precautions.

2. Place the selected drill bit fully into the chuck.

Center the bit and tighten the chuck using the

key provided. Remove the key and store away

from the drill.

3. Momentarily press the trigger to ensure that

the drill bit rotates clockwise and runs true.

4. Select a work position that gives secure

footing and balance while operating the drill.

5. Press the drill against the work and squeeze

the trigger.

The drilling method used is determined by the

material being drilled and the size and depth

requirements of the hole.

Ductile material such as metal or wood is drilled

efficiently when a steady down force is applied to

the drill center to cause the bit to slice chips of

material from the hole bottom. When drilling in

metal, use a cutting lubricant to prolong bit life

and reduce the amount of force required to drill

effectively.

Large drill holes are more productively created

from small drill holes. Drill bits are incrementally

selected to enlarge the hole until the desired hole

size is obtained. Each bit selected must always be

too large to thread and jam into an existing hole;

otherwise the bit may break and endanger the

operator.

9

Page 10

Operating Instructions

Cold Weather Operation

Damage to the hydraulic system or tool can result

from use with fluid that is too viscous or thick.

If the tool is to be used during cold weather, preheat

the hydraulic fluid at low engine speed. Follow

steps 1 through 5 (connect hoses) page#9ofthe

operating instructions. With the hoses connected to

the power supply and to the tool, turn the circuit on

DO NOT OPERATE THE TOOL)

( and allow the

hydraulic oil to preheat with the engine at low

speed. Preheat the hydraulic fluid until the

temperature is at or above 50

centistokes) when using the normally recommended

fluids.

Open Center/ Closed Center Setup

(OC/CC)

° F/10° C (400 ssu/82

The adjustment for open center/ closed center is

obtained by a flat screw slot located at front of tool.

To adjust from OC to CC or vice ver-sa hold on to

the trigger keeping it from being depressed. While

using a flat screw driver push in and rotate the

selector to the desired Open Center or Closed Center

position (see illustration on this page).

Note: Make sure that the four notches on the

selector lock into the four cutouts in the trigger.

For Closed Center operation turn the selector so that

the slot is in the horizontal position (as shown in the

illustration below). For Open Center operation

rotate the selector until the slot is in the vertical

position.

10

Page 11

Troubleshooting

This section describes how to find and resolve problems users may experience.If a situation occurs that is not covered,

call your Stanley Customer Servicerepresentative for assistance.

WARNING

Inspecting the tool or installing parts with the hydraulic hoses connected can result in severe personal injury or equipment

damage.

To prevent accidental startup, disconnect the hydraulic power before beginning any inspection or installation task.

If symptoms of poor performance develop, the following chart can beused as a guide to correct the problem.

When diagnosing faultsin operation of the tool, always check that the hydraulic power source is supplying the correct

hydraulic flow and pressure to the tool as listed in the table. Use a flowmeter known to be accurate. Check the flow

with the hydraulic oil temperature at least 80° F/27° C.

Symptom Possible Cause Solution

Tool will not start. Power not being supplied. Check to make certain that both

hoses are connected.

Turn hydraulic circuit control valve

ON.

Defective quick disconnects.

Check each quick disconnect

separately. Replace as necessary.

Low drilling

Relief valve setting too low. Set relief valve at 2100 psi/ 145 bar.

torque.

Fluid restriction in hose or valve.

Excess flow and pressure loss.

Locate and remove restriction.

Use correct fluid.

Fluid not warmed-up. Preheat

system.

Hoses too long for hose I.D. Use

shorter hose.

Hoses I.D. too small for hose

length. Use larger I.D. hose.

Low tool speed. Fluid flow rate is too low. Check circuit flow rate.

Tool speed too

high.

Oil leaks around

gear housing.

Fluid flow rate is excessive. Check circuit flow rate; add a

proper flow control valve.

Hydraulic pressure and return

hoses reversed.

Correct hose connections. Pressure

should be to the handle port away

from the trigger, return is near the

trigger, or see your Authorized

Dealer for servicing.

Main shaft seal o-ring leaking.

See your Authorized Dealer for

servicing.

11

continued

Page 12

Troubleshooting

Symptom Possible Cause Solution

Oil gets hot,

power unit

working hard.

Oil leaks at

reversing spool.

Oil leak at motor

cap face.

Open center tool on a closed center

circuit and vice versa.

Circuit relief set too low. Adjust relief valve to 2100 psi/ 145

Too much oil going through tool. Adjust flow for 12 gpm/ 45 lpm

Damaged o-rings. Replace as required.

Wrong hydraulic fluid. Circuit too

hot.

Fasteners loose. Tighten to specification (see service

Face o-ring worn or missing.

Motor cap/ main housing damaged. See your Authorized Dealer.

Use tools to match circuit.

bar.

maximum, or less.

See OPERATING INSTRUCTIONS

for correct fluid/ circuit

specifications.

manual.

See your Authorized Dealer.

12

Page 13

DL09 Parts Illustration

13

Page 14

NOTE:

Part Number

Use and

Description

when ordering.

DL09 Parts List

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

DescriptionDescriptionPartPartItem

1

38676

2

38685

3

15211

4

08175

5

26655

24412

6

09623

7

09622

00753

8

09687

00111

9

09621

09778

09624

27628

08163

08162

00354

08165

09779

08161

08440

08166

06635

20767

13995

18206

00146

26297

00231

00145

20770

01262

24271

05207

00713

27559

20790

20758

00026

20782

20760

20769

28769

28323

28788

28316

29149

20781

01605

06617

29313

24161

23175

23174

20783

02178

Depth Guage Rod (ModelsDL09172S,DL09172SN, & DL09152S Only)Shipped uninstalled.

Thumb Screw (ModelsDL09172S,DL09172SN, & DL09152S Only)Shipped uninstalled.

Danger Sticker (Not used on Models )

Ball Bearing

Gear Housing

Gear Housing (Model ONLY)

Lockwasher # 10

Capscrew 10-24x1-1/4 HSH Stainless

Capscrew 10-24x1-1/4 HSH (Model ONLY)

Capscrew 10-24x2 HSH Stainless

Capscrew 10-24x1-1/2 Hex Socket head (Model ONLY)

Shaft Seal

Seal Nut

Chuck 3 Jaw Adjustable, 5/8-16 THD (All Models Except DL09172S & DL09172SN)

Chuck 3 Jaw Adjustable, 5/8-16 THD (Used on Models DL09172S & DL09172SN only)

Bearing Keeper

Shaft Keeper

O-ring 1/2 x 11/16 x 3/32 - 112

Planet Gear Assembly

Output Shaft

Planet Shaft

Retaining Ring

Ring Gear

Retaining Ring

Seal Back-up Washer

Back-up Ring - 112

Capscrew 5/16-18x1-3/4 HSH STNLS

Capscrew 5/16-18x1-3/4 HEX SOC HEAD (Model ONLY)

Capscrew 5/16-18x1-3/4 ZNC PLT (Model DL09152SN ONLY)

Lockwasher 5/16 High Collar

Lockwasher 5/16 High Collar (Model ONLY)

Motor Cap Assy (Includes Items 28 & 29)

O-ring 1-3/4 x 1-7/8 x 1/16 - 031

Main Shaft

Bushing

Dowel Pin

Main Housing Assy (Includes Items 28,31,32)

Main Housing Assy (Models DL09550D, , & ONLY) (Includes Items 28,

31,32)

Bushing

O-ring

Idler Shaft

Bushing

Idler Gear Assy (Includes Item 34)

DL09 Model Number Sticker

CE Sticker (Models ONLY)

Manual Sticker (Models 1 ONLY)

CN Sticker (Model DL09152SN ONLY)

Rotation Direction Sticker (Models ONLY)

Spring Cap

O-ring 1/2 x 5/8 x 1/16 - 014

Spring

Valve Spool Assy-OC/CC

Valve Spool-OC (Model ONLY)

Capscrew 12-24x3/8 Hex Soc Flat Head

Capscrew 12-24x3/8 Hex Soc Flat Head (Models ONLY)

Stop Washer

Wiper Seal

DL09150

DL0955001 & DL0965201

DL0965201 & DL095500

DL09150

DL0955001 & DL0965201

DL09150

DL09150

DL09150

DL09150

DL09150 DL0955001

DL0955001 & DL0965201

DL09150, DL09550D, & DL0955001

Qty.

1

1

1

1

1

1

3

3

3

3

2

1

1

1

1

1

1

2

2

1

2

1

1

1

1

1

6

6

6

6

6

1

1

1

2

2

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

2

2

14

Page 15

NOTE:

Part Number

Use and

Description

when ordering.

DL09 Parts List (Continued)

DescriptionDescriptionPartPartItem Qty.

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

----

----

----

20786

01604

00106

34893

12100

03709

08130

18919

14019

14028

14024

24411

14022

07724

06971

00936

28234

24058

03972

24059

03973

06345

12621

07970

11207

26299

11191

29456

Seal Cap

O-ring .755x.949x.097 -012 R16

O-ring 3/8x1/2x1/16 -012 R16

Reversing Spool

Steel Ball 3/8 Dia. (Not Used on Model )

DL09150

SAE Plug -5 Hex Soc Head

Cross Handle (Not Used On Models )

Pin To Socket Adaptor (Not Used On Model )

DL09150, DL09550D, & DL0955001

DL09150

Spool End Socket (Not Used On Model DL09150)

Retaining Ring

Trigger

Trigger (Model ONLY)

Trigger Guard (Not Used On Model )

DL09150

DL09150

Locknut 10-24 STNLS

Locknut 10-24 (Used On Model DL09152SN ONLY)

Adaptor Fitting (Used On Models , & DL09550D ONLY)

Hose Whip (Not Used On Models , & DL09550D)

Female Coupler Body 3/8”(Not Used On Models

DL0955001

&)

Female Coupler Body (Used On Model ONLY)

Male Coupler Body 3/8”(Not Used On Models , DL09550D, ,

DL09150, DL0955001

DL09150, DL0955001

DL09150, DL09550D, DL09652

DL0955001

DL09150 DL09652

& DL0955001)

Male Coupler Body (Used On Model ONLY)

DL0955001

Plastic Plug ( Not Illustrated)

Seal Gasket

Spirol Pin 3/16x1-3/8

Circuit Type “D” Decal

Lockout Kit (shipped unassembled) Not Used On Model

Chuck Key used on 3/8 chuck All Models except

C

huck Key used on ½ chuck (Used on models DL09172S & DL09172SN ONLY)

( DL09172S & DL09172SN)

DL09150

2

2

4

1

2

2

1

1

1

1

1

1

1

1

1

2

2

1

1

1

1

2

1

1

1

1

1

1

A Supplied with Item # 53

Seal Kit P/N 25078

00026

00106

00354

00717

01262

01604

01605

02003

02178

03364

08928

09621

13995

12621

25079

Note: No Male or Female Couplers are Provided with Models DL09150,

DL09652, & DL09550D.

O-ring 3/16 x 5/16 x 1/16 - 008

O-ring 3/8 x 1/2 x 1/16 - 012

O-ring ½ x 11/16 x 3/32 - 112

O-ring 2-112 R16

O-ring 1-3/4 x 1-7/8 x 1/16 - 031

O-ring .755 x .949 x .097 -910

O-ring 1/2x5/8x1/16-014

O-ring 2-113 R16

Wiper Seal 3/8 x 5/8 x 1/8

O-ring 3-905 R17

Back-up Ring

Shaft Seal

Back-up Ring - 112

Seal Gasket

INST. For seal kit

2

4

2

1

1

2

1

1

2

2

1

1

1

1

1

15

Page 16

Warranty

Stanley Hydraulic Tools (hereinafter called “Stanley”), subject to the exceptions contained below, warrants new hydraulic tools for a period of one

year from the date of sale to the first retail purchaser, or for a period of 2 years from the shipping date from Stanley, whichever period expires first,

to be free of defects in material and/or workmanship at the time of delivery, and will, at its option, repair or replace any tool or part of a tool, or new

part, which is found upon examination by a Stanley authorized service outlet or by Stanley’s factory in Milwaukie, Oregon to be DEFECTIVE IN

MATERIAL AND/OR WORKMANSHIP.

EXCEPTIONS FROM WARRANTY

NEW PARTS:

workmanship at the time of delivery and for a period of 6 months after the date of first usage. Seals and diaphragms are warranted to be free of

defects in material and/or workmanship at the time of delivery and for a period of 6 months after the date of first usage or 2 years after the date of

delivery, whichever period expires first. Warranty for new parts is limited to replacement of defective parts only. Labor is not covered.

FREIGHT COSTS:

credit, are covered under this policy if the claimed part or parts are approved for warranty credit. Freight costs for any part or parts which are not

approved for warranty credit will be the responsibility of the individual.

SEALS & DIAPHRAGMS:

period of 6 months after the date of first usage, or for a period of 2 years from the shipping date from Stanley, whichever period expires first.

CUTTING ACCESSORIES:

the time of delivery only.

ITEMS PRODUCED BY OTHER MANUFACTURERS:

manufacturers.

ALTERATIONS & MODIFICATIONS:

new tool or part is altered or modified in any way.

NORMAL WEAR:

bumpers, retaining rings and plugs, rubber bushings, recoil springs, etc.

INCIDENTAL/CONSEQUENTIAL DAMAGES:

incidental, consequential or special damages and/or expenses.

FREIGHT DAMAGE:

New parts which are obtained individually are warranted, subject to the exceptions herein, to be free of defects in material and/or

Freight costs to return parts to Stanley, if requested by Stanley for the purpose of evaluating a warranty claim for warranty

Seals and diaphragms installed in new tools are warranted to be free of defects in material and/or workmanship for a

Cutting accessories such as breaker tool bits are warranted to be free of defects in material and or workmanship at

Components which are not manufactured by Stanley and are warranted by their respective

a. Costs incurred to remove a Stanley manufactured component in order to service an item manufactured by other

manufacturers.

Alterations or modifications to any tool or part. All obligations under this warranty shall be terminated if the

Any failure or performance deficiency attributable to normal wear and tear such as tool bushings, retaining pins, wear plates,

To the fullest extent permitted by applicable law, in no event will STANLEY be liable for any

Damage caused by improper storage or freight handling.

LOSS TIME:

IMPROPER OPERATION:

the tool’s operation and maintenance manual.

MAINTENANCE:

Operation and Maintenance Manual.

HYDRAULIC PRESSURE & FLOW, HEAT, TYPE OF FLUID:

excess hydraulic back-pressure, excess hydraulic flow, excessive heat, or incorrect hydraulic fluid.

REPAIRS OR ALTERATIONS:

or contributed to the failure or deficiency.

MIS-APPLICATION:

which they were not originally intended or usage of products in such a matter which exposes them to abuse or accident, without first obtaining the

written consent of Stanley. PERMISSION TO APPLY ANY PRODUCT FOR WHICH IT WAS NOT ORIGINALLY INTENDED CAN ONLY BE OBTAINED

FROM STANLEY ENGINEERING.

WARRANTY REGISTRATION:

TION IS ON RECORD. In the event a warranty claim is submitted and no tool registration is on record, no warranty credit will be issued without first

receiving documentation which proves the sale of the tool or the tools’ first date of usage. The term “DOCUMENTATION” as used in this

paragraph is defined as a bill of sale, or letter of intent from the first retail customer. A WARRANTY REGISTRATION FORM THAT IS NOT ALSO ON

RECORD WITH STANLEY WILL NOT BE ACCEPTED AS “DOCUMENTATION”.

This limited warranty and the obligation of Stanley thereunder is in lieu of all other warranties, expressed or implied including merchantability or

Loss of operating time to the user while the tool(s) is out of service.

Any failure or performance deficiency attributable to a failure to follow the guidelines and/or procedures as outlined in

Any failure or performance deficiency attributable to not maintaining the tool(s) in good operating condition as outlined in the

Any failure or performance deficiency attributable to excess hydraulic pressure,

Any failure or performance deficiency attributable to repairs by anyone which in Stanley’s sole judgement caused

Any failure or performance deficiency attributable to mis-application. “Mis-application” is defined as usage of products for

STANLEY ASSUMES NO LIABILITY FOR WARRANTY CLAIMS SUBMITTED FOR WHICH NO TOOL REGISTRA-

NO ADDITIONAL WARRANTIES OR REPRESENTATIONS

16

Page 17

For additional Sales & Service information, contact:

®

Stanley Hydraulic Tools

Division of the Stanley Works

3810 SE Naef Road

Milwaukie, OR 97267 USA

Tel: (503) 659-5660

Fax: (503) 652-1780

Loading...

Loading...