Page 1

ERRIGAL OIL FIRED COOKER

DRY, DHW & HPB MODELS

INSTALLATION & OPERATING INSTRUCTIONS

Page 2

1

TABLE OF CONTENTS

PAGE NO.

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2. Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3. Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4. Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

5. Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

6. Hearth Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

7. Fuel Supply / Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

8. Oil Storage Tanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

9. Fuels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

10. Fuel Supply Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

11. Clearance to Combustibles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

12 Flue System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

13. Flue Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

14. Flue Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

15. Use of Existing Flues and Chimneys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

16. Flue Liners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

17. Sealing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

18. Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

19. Ventilation & Combustion Air Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

20. Draught Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

21. Down Draughts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

22. Factory Made Insulated Chimneys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

23. Suitable Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

24. Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

25. Safety Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

26. Pipe Fittings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

27. Indirect Domestic Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

28. Direct Domestic Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

29. Interlink System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

30. General Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

31. Draining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

32. Pre-Installation Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

33. Fitting of Legs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

34. Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

35. Burner Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

36. Burner Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

37. Flame Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

38. Cooker Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

39. Lighting The Cooker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

40. Turning The Cooker Off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

41. Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

42. Control Valve Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

43. Vitreous Enamel Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

44. Exploded View 20K Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

45. Exploded View DHW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

46. Exploded View Dry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

47. Fault Finding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

48. Installation Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Page 3

INTRODUCTION

Congratulations on purchasing this fine Irish made Oil Fired cooker which is built to exacting standards and will

give you every satisfaction in use.

This appliance is hot while in operation and retains its heat for a long period of time after use. Children, aged

or infirm persons should be supervised at all times and should not be allowed to touch the hot working surfaces

while in use or until the appliance has thoroughly cooled.

Please read the Operation & Installation Instructions provided before operating the cooker.

To ensure safety, satisfaction and reliable operation, this quality cooker should be installed and commissioned

by a trained and competent person. The Domestic Hot Water facility involved must conform fully to good plumbing practice, established standards and OFTEC Recommendations.

The complete installation must be done in accordance with current Standards and Local Codes. It should be

noted that the requirements and these publications may be superseded during the life of this manual.

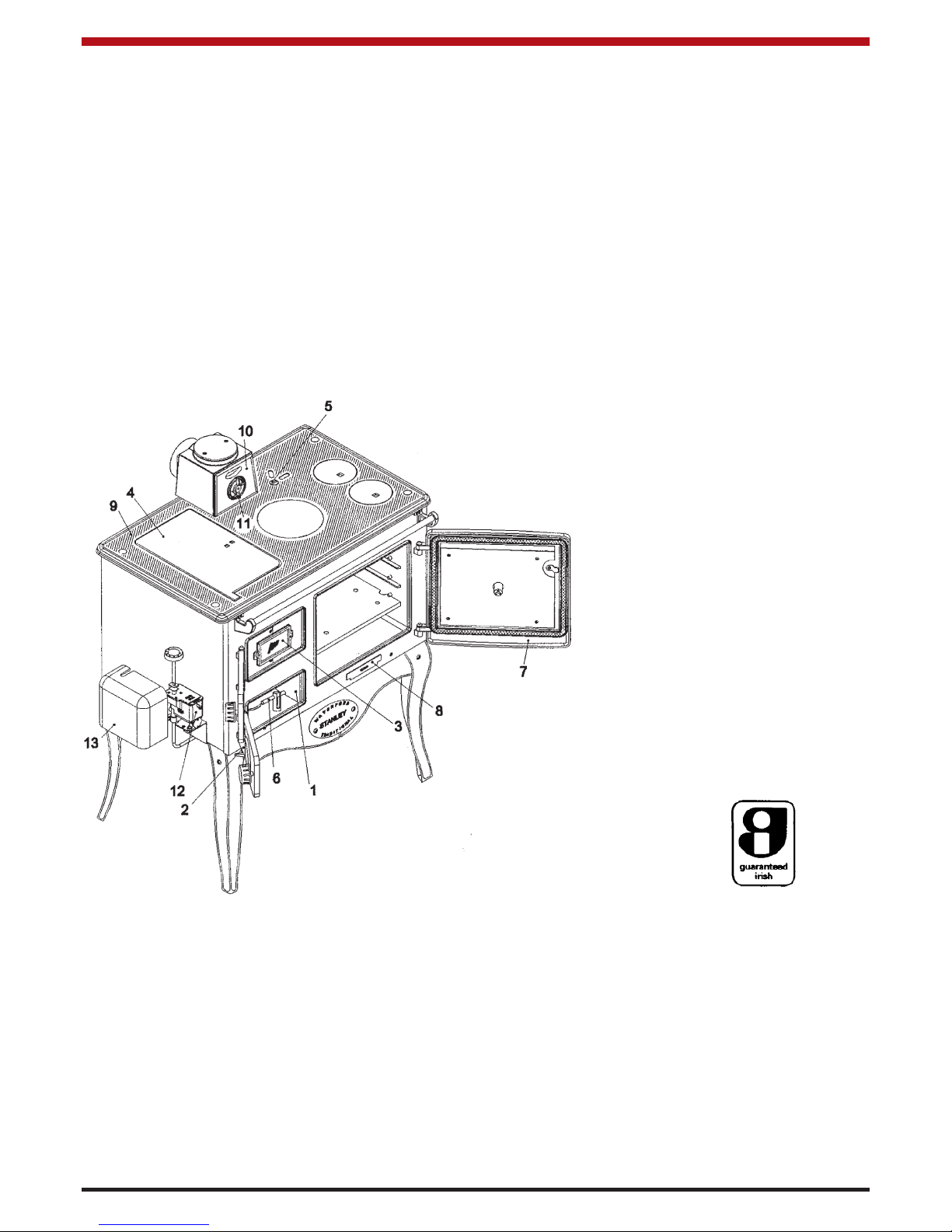

1. Burner Compartment

2. Air Intake Spin Valve

3. Burner Viewing Glass

4. Hot Plate

5. Chimney Damper

6. Fire Valve Phial

7. Oven Door

8. Cleaning Door

9. Hob

10. Bonnet Door

11. Spin Valve

12. Oil Control Valve

13. Oil Control Valve

Cover

14. Fire Valve Bracket

IMPORTANT - CONTROL OF SUBSTANCES HARMFUL TO HEALTH

It is the users/installer responsibility to ensure that the necessary personal protective clothing is worn

when handling materials that could be interpreted as injurious to health and safety.

When handling firebricks, fire cement or fuels use disposable gloves. Exercise caution, use disposable masks and gloves when handling glues and sealants. When working with kerosene oil, fibre

glass or mineral wool. Avoid contact with skin, eyes, nose and throat, use disposable protection.

This cooker is designed for continuous or intermittent use. When cooker is in continuous use, it should

be serviced at least every 6 months. If it is not used for extended periods, the service period may be

extended.

The manufacturers reserve the right to make alterations to design, materials or construction for manufacturing or other reasons, subsequent to publication.

2

Fig.1

Page 4

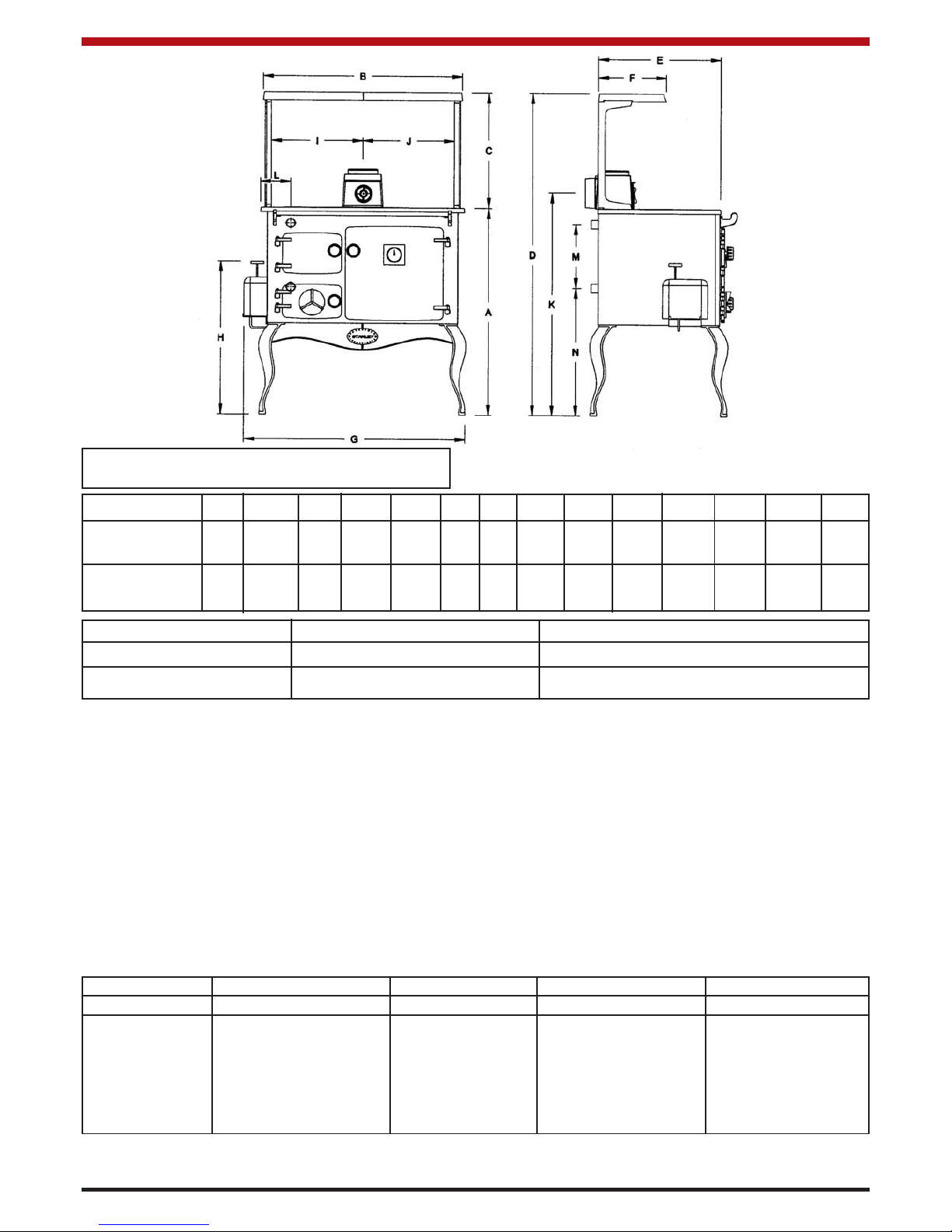

DIMENSIONS ABCDEFGHIJKLMN

METRIC 880 905 508 1388 565 290 990 665 452 452 960 130 260 565

(millimetre)

IMPERIAL

34

5

/8 355/8 20 545/8 221/4 111/2 39 263/4 173/4 173/4 37 3/4 51/8 101/4 221/4

(inches)

FEATURE METRIC IMPERIAL

HOT PLATE 911.25 cm

2

144 in

2

OVEN 400W x 330H x 400D 15

3

/4W x 13H x 153/4D

TECHNICAL DATA

FUEL: Kerosene 28 sec. (Class C2)

CHIMNEY DRAUGHT: 0.02” - 0.06” wg. (0.50mm - 1.5mm)

FLUE DIAMETER: 5” (127mm)

EXIT FLUE GAS TEMPERATURE: 90oC - 200

o

C

BOILER CONSTRUCTION-WHERE APPLICABLE: 6mm & 4mm Mild Steel Plate (HPB)

3MM S/Steel Grade 304 2B (DHW)

TEST PRESSURE OF BOILER: 40 PSI (2.75 Bar)

OPERATING TEMPERATURE LIMIT: 96

0

C (205OF)

BOILER CAPACITY - WHERE APPLICABLE: 7.5 Litres (HPB) or 5.5 Litres (DHW)

COOKER WEIGHT: 232 Kgs (510 lbs)

SPACE HEATING: 3 kW’s (10, 000) Btu’s

Valve Setting Oil Consumption Burner Input Oven Temperature Heat Output to Water

1/h kW (Btu/hr)

o

C kW (Btu/hr)

6 1.14 13.38 (45,690) 225 5.86 (20,000)

5 0.98 11.51 (39,300) 210 4.54 (15,500)

4 0.83 9.74 (33,270) 190 4.10 (14,000)

3 0.67 7.86 (26,850) 145 3.37 (11,500)

2 0.52 6.10 (20,840) 125 1.82 (6,200)

1 0.36 4.23 (14,430) 100 1.49 (5,100)

Fig.2

3

NOTE: Dimensions stated below may be subject

to a slight +/- variation.

All technical data are taken under laboratory conditions and may vary in use, flue draught conditions will effect

performance

CONTINUOUS RUNNING HPB Cooker

SPECIFICATION

Page 5

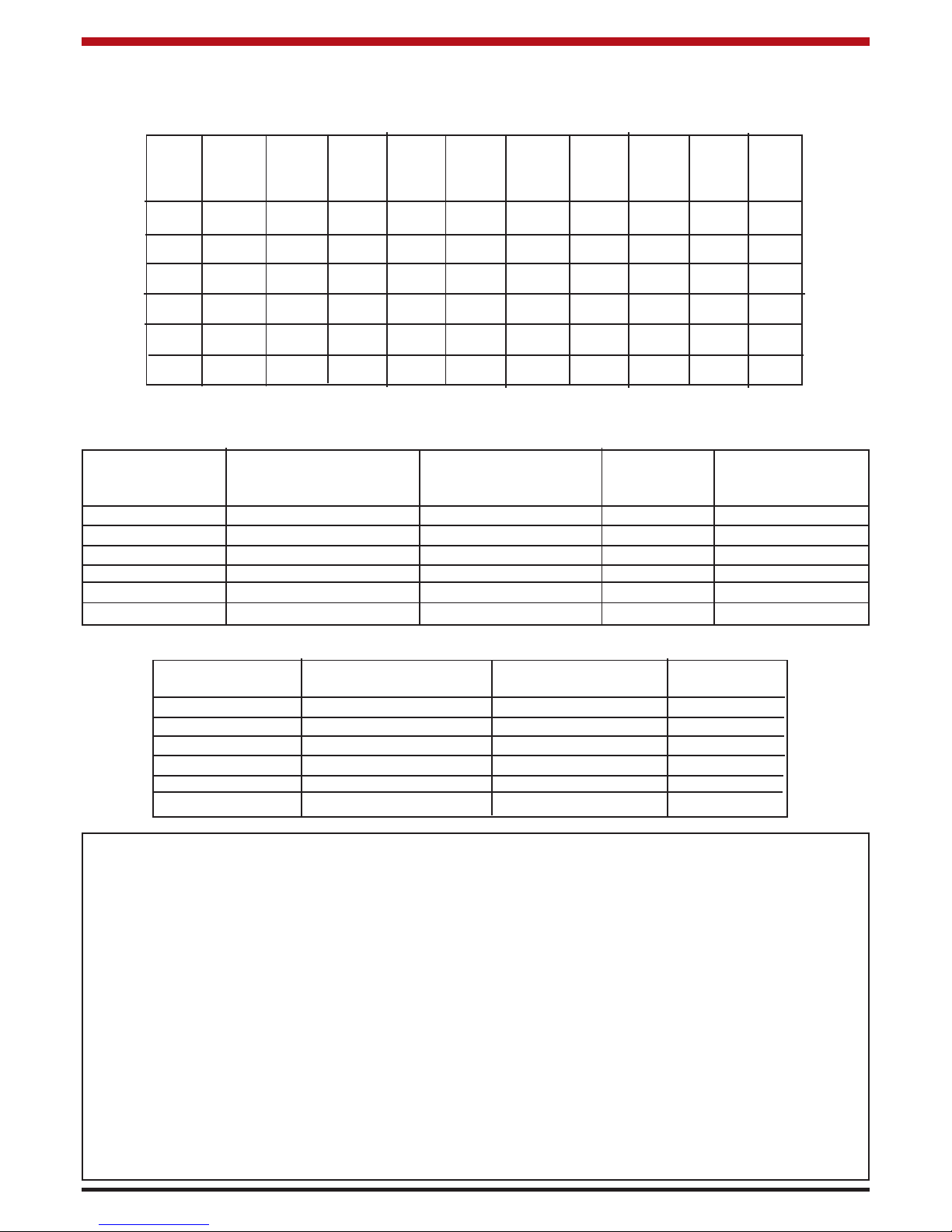

The following table gives approximate cooker heat up times on different settings. (These times are taken with

the cooker running continuously on setting 1 when not in use).

Setting Max.

Temp. 120°C 140°C 160°C 170°C 180°C 190°C 200°C 210°C 220°C

(°C)

6 225 10 20 30 40 50 60 75 100 170

5 210 12 25 35 45 55 70 95 140 ---

4 195 23 40 66 88 126 200 --- --- ---

3 145 45 120 --- --- --- --- --- --- ---

2 125 620 --- --- --- --- --- --- --- ---

1 100 --- --- --- --- --- --- --- --- ---

TIME IN MINUTES

INSTALLATION

As manufacturers and suppliers of cooking and heating appliances, we take every possible care to ensure as

reasonably practicable that these appliances are so designed and constructed as to meet the general Safety

Requirements when properly used and installed.

THE INSTALLATION MUST COMPLY WITH THE FOLLOWING:

* B.S. 5410 Part 1 Oil Installations.

* The Building Regulations: Part J England, Wales.

Part F Section III Scotland.

Part L Northern Ireland.

Part J Ireland.

* The Control of Pollution (Oil) Regulations.

* B.S. 5449 Forced Circulation Hot Water Central Heating System for Domestic Installation.

* Safety, Health and Welfare at Work Act for Ireland, England, Wales & Scotland.

* B.S. 7593: Treatment of Water in Domestic Hot Water Systems.

* B.S. 7074: Part 1 & 2 Hot Water Supply.

* B.S. 4814: Sealed Systems.

4

NOTE: These times may differ subject to draught conditions, oil rates, boiler output and usage.

VALVE SETTING OIL CONSUMPTION BURNER INPUT OVEN TEMP. HEAT OUTPUTS

(L/H) kW (BTU/hr) (oC) TO WATER

kW (BTU/hr)

6 1.02 9.98 (34,040) 230 3.57 (12,180)

5 0.87 8.51 (29,035) 220 3.21 (10,950)

4 0.73 7.14 (24,360) 208 2.89 (9,864)

3 0.58 5.67 (19,355) 179 2.42 (8,290)

2 0.44 4.30 (14,685) 59 0.88 (3,005)

1 0.29 2.84 ( 9,680) 46 0.70 (2,390)

VALVE SETTING OIL CONSUMPTION BURNER INPUT OVEN TEMP.

(L/H) kW (BTU/hr) (

o

C)

6 0.69 6.75 (23,035) 240

5 0.60 5.87 (20,030) 228

4 0.51 4.99 (17,025) 206

3 0.42 4.11 (14,020) 190

2 0.33 3.23 (11,015) 122

1 0.24 2.35 ( 8,010) 66

DHW Cooker

Dry Cooker

Page 6

LOCATION

When choosing a location for this appliance you

must have the following:

A. Sufficient room for installation and servicing.

B. Adequate clearance to combustibles (see

Clearance to Combustibles Section).

C. A satisfactory flue system (See Flues).

D. Fixed fuel supply line and shut off valve (See

Fuel Supply).

E. Adequate air supply to support combustion

(See Ventilation & Combustion Air

Requirements).

F. Solid floor or base of non-combustible mate-

rial which is capable of supporting the total

weight of the stove. (See Hearth

Construction).

Note: When passing through walls or ceilings with

the flue system:

G. Always check for obstructions, for example

electrical fittings, wiring, ducting, plumbing

and fixed furnishings.

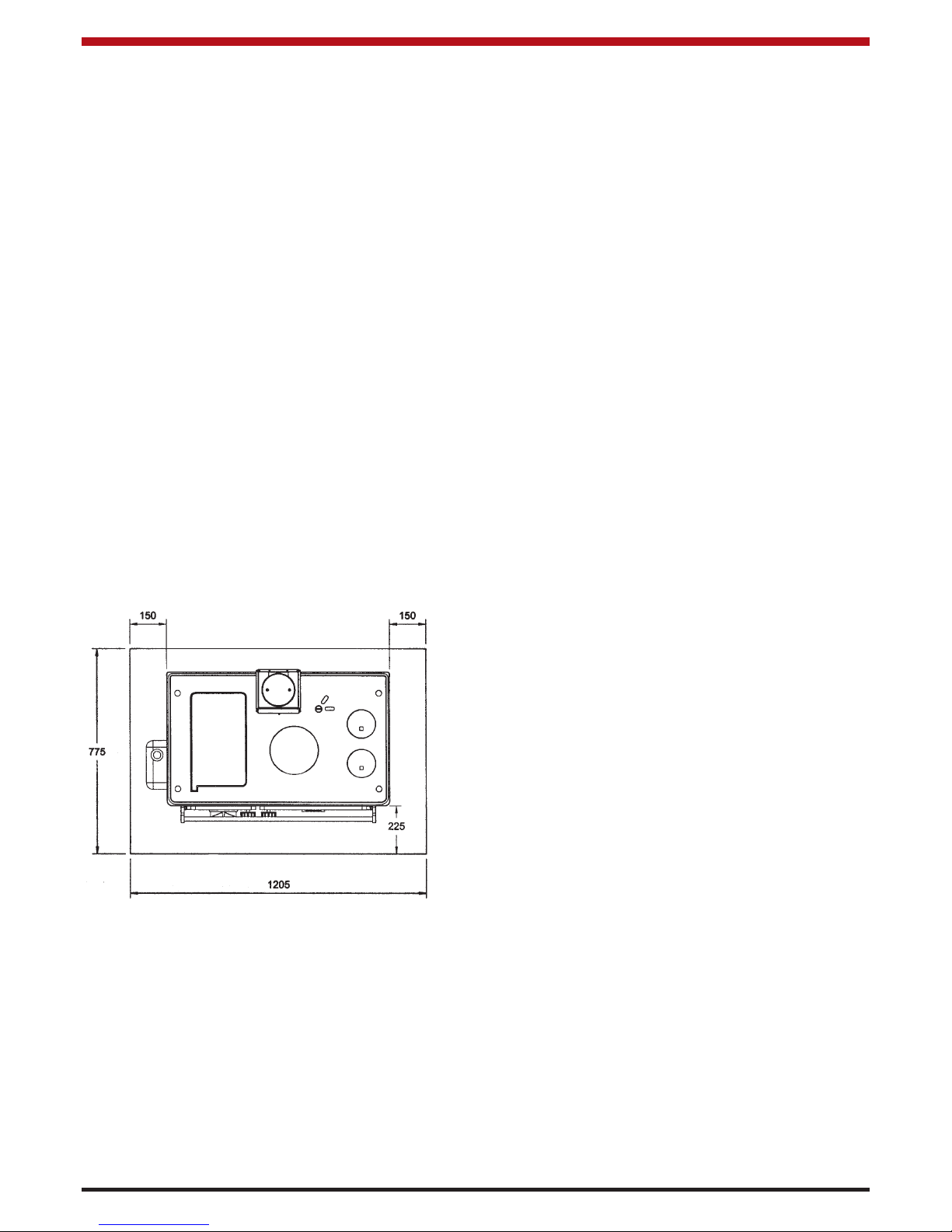

HEARTH CONSTRUCTION

When a properly constructed hearth is not available

we recommend that the cooker be placed on a slab

of framed concrete of 75mm (3”) deep or a slab of

other insulating material. The hearth should be a

minimum size of 1205mm (47”) wide, 775mm (30

1

/2”) length with the cooker located as shown in fig.3

An isolating valve should be fitted at the tank outlet,

in an accessible position so that the oil supply to the

appliance can be shut off if required. This isolating

valve must be of a type suitable for use with oil. (see

fig.4)

Oil storage tanks support must be carried out in

accordance with the tank manufacture recommendations. Tanks should be located in the most unobstructive position possible having taken safety, filling, maintenance and the need, to provide a head of

oil for the burner into consideration.

FUELS

Use only 28 second viscosity kerosene fuel oil to

B.S. 2869 Part 2 class C2 and or equivalent.

FUEL SUPPLY LINE

The oil supply line from the oil storage tank to the

appliance should be of an approved and suitable

pipe with a minimum internal diameter of 8mm

(5/16”) and connected to the oil control valve.

Supply pipes are normally run in annealed copper

tube complying to EN 1057. It can be obtained in

coil or half hard form for use with bending machines.

This pipe can also be obtained with protective plastic sheathing applied. Fittings for copper pipe

should be compression of the flared manipulative

type to B.S. 864: Part 2. Steel pipes complying with

B.S. 1387: 1985, if used, must be protected from

corrosion. Galvanised pipe and fittings must not be

used.

Screwed joints must only be made with taper

threads complying to B.S. 1740 : Part 1.

Jointing materials must be of types intended for use

with oil fuel. Special petroleum - resisting compounds and PTFE tape are suitable. External pipes

should preferably be run with a continuous rise

towards the direction of flow, so that air can be vented off. It is important to avoid high points which

could cause air locks.

Exposed lengths of oil supply pipe must be properly

supported by purpose made clips securely fixed in

place. Metal clips formed so as to hold the pipe on

to a saddle are preferred. Consideration should be

given to avoiding routes which expose the pipe to

severe chilling which could cause freezing of the oil.

Where pipes are buried, they must be protected

from accidental damage. The use of joints underground should be avoided if at all possible. If joints

have to be fitted in pipes laid below ground, access

to them must be provided.

5

Fig.3

FUEL SUPPLY / INSTALLATION

OIL STORAGE TANKS

In order to enable sediment and water to be

removed from steel tanks a drain valve must be fitted.Oil storage tanks made of steel and all connecting equipment (e.g. filling pipes, and vent pipes)

should comply with B.S. 799 Part 5. Galvanised

steel must not be used. Polyethylene (Plastic) tanks

should comply with OFTEC standard OFS T100 and

or equivalent. Oil should never be stored in transulent plastic containers.

Page 7

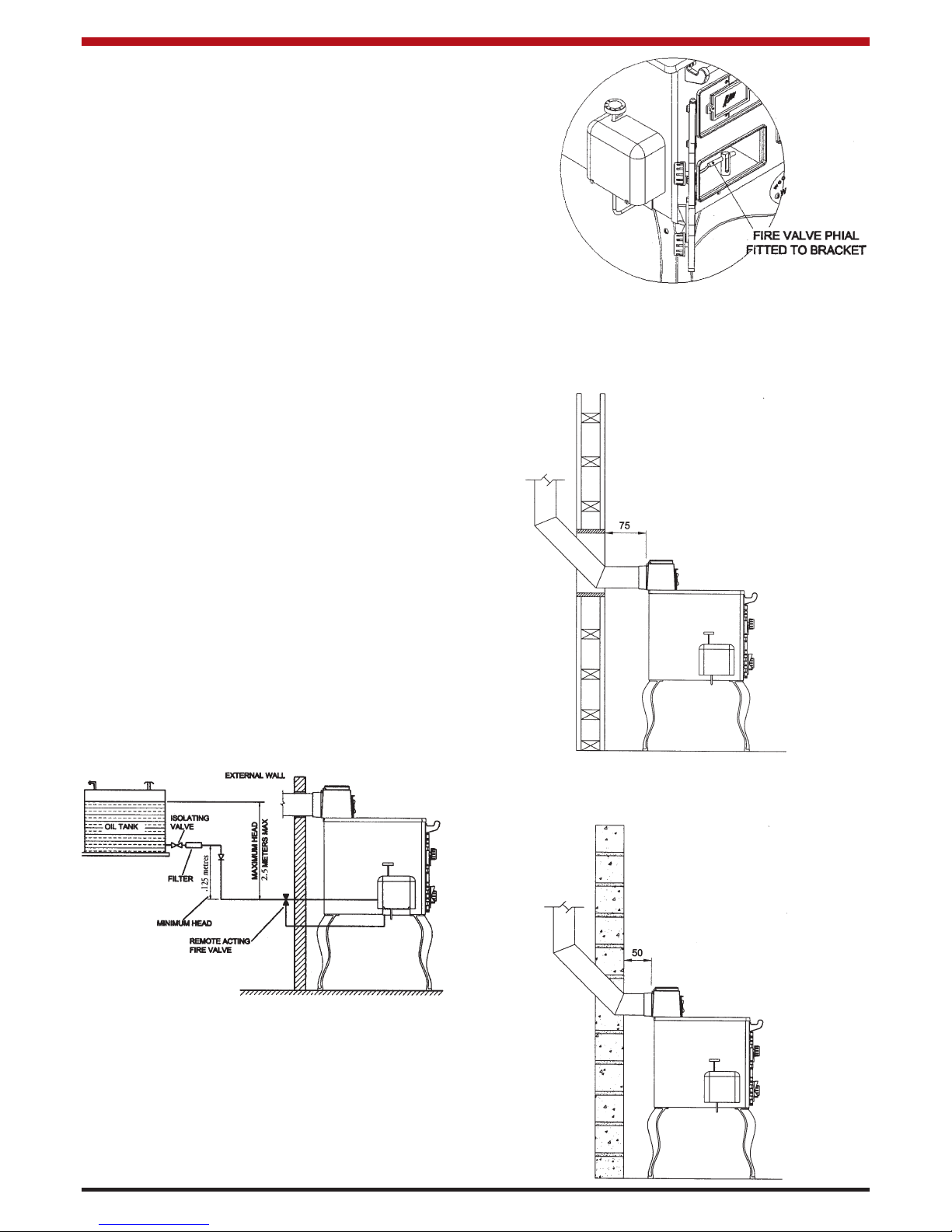

An oil filter (5 - 10 micron) and stop valve must be fitted to the fuel feed line and located near the supply

tank and facilities should be provided to enable it to

be serviced without draining down the oil supply system. (See fig.4).

At the point where the oil line enters the building, the

oil line must be fitted with an approved remote acting fire valve which meets the requirements of B.S.

5410 : Part 1, fitted with the appropriate length of

capillary. The temperature rating limit should be

90

o

C. The heat sensoring phial of the fire valve

should be passed through the base of the burner

compartment and fitted through the fire valve bracket provided in the burner compartment (see Fig.5). It

is absolutely essential that the fire valve is located

externally and is as close as possible to the appliance. For existing installations where the oil supply

is built into the structure internally, the remote acting

fire valve should be fitted where the oil supply line is

first exposed internally. This type of layout is not

recommended for new installations.

These requirements are further explained within the

following documents:

* BS 5410: Part : Code of practice for Oil

Firing installations up to 45 kW output

capacity for space heating and hot water

supply purposes.

* OFTEC Technical Information Book Three:

Installation Requirement for Oil Fired Boilers

and Oil Storage Tanks.

* The Building Regulations Part J: England

Wales, Part F - Section 4 Scotland and Part

L Northern Ireland.

CLEARANCES TO COMBUSTIBLES

The minimum clearance to combustible materials

should be maintained at least 75mm (3”) from rear of

cooker (see Fig. 6).

Fig.4

Fig.5

6

Fig.6

The minimum clearance to non-combustible materials should be maintained at least 50mm (2”) from

rear. (see Fig.7)

If there are other oil fired appliances connected to

the oil storage tank especially appliances with oil

pumps e.g. oil fired boilers or stoves, it is recommended that a separate oil supply line is taken from

the oil tank to the cooker. The separate oil supply

line to the cooker will avoid the possibility of the

pumped appliance taking oil from the cooker burner.

A suitable shut off valve should be fitted near the

cooker and be accessible at all times.

NOTE: Ensure that the fire valve phial is not touching any point of the base casting.

Fig.7

Page 8

Fig.9

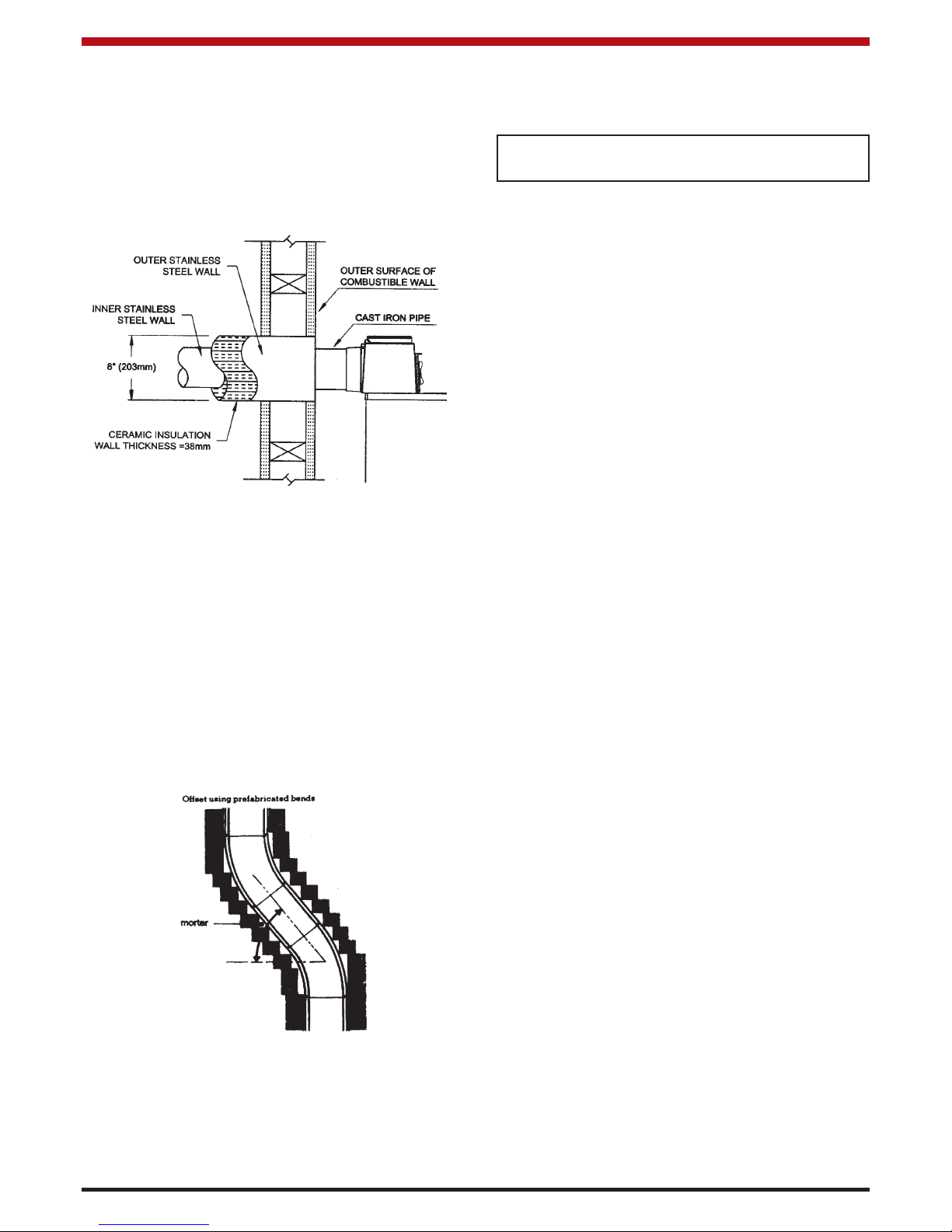

FLUE SYSTEM

Generally the most effective chimney is one that is

straight, avoids offsets, and terminates with a

straight sided pot. Horizontal runs more than

305mm (12”) and 90

o

bends numbering more than 2

per installation should be avoided. Where the standard masonry chimney is not available, a proprietary

type of 125mm (5”) twin wall, fully insulated pipe

may be used.

Flues should be vertical wherever possible and

where a bend is necessary, it should not make an

angle of more than 37.5

o

with the vertical.

Fig.8

Never obstruct free air circulation from around or

entering the cooker grills.

Where the flue passes through a combustible material a twin wall solid packed insulated chimney connector must be used and come flush with the outer

surface material and run all the way to the masonry

chimney or to the point of termination of the factory

made chimney. (see Fig. 8).

may be caused by roof structures, other chimney

stacks etc. The venting terminal position should be

in accordance with Building Regulations BS 5410:

Part 1.

FLUE CLEANING

The flue pipe must be fitted with a cleaning pipe.

The flue must be inspected annually and cleaned

when necessary.

USE OF EXISTING FLUES AND CHIMNEYS

When connecting to an existing chimney it is necessary to line the flue using either 5” (125mm) rigid or

flexible stainless steel flue liner.

An existing flue pipe or chimney that has proved to

be satisfactory when used for solid fuel can normally be used for this appliance provided that its construction, condition and dimensions are acceptable.

Flues that have proven to be unsatisfactory, particularly with regard to down draught, must not be considered for venting this appliance until they have

been examined and any faults corrected. If there is

any doubt about an existing chimney, a smoke test

should be carried out.

Before connecting this appliance to a chimney or

flue pipe which has previously been used with

another fuel, the chimney or flue pipe must be thoroughly swept and/or lined accordingly.

All register plates, restricter plates and dampers etc.

which could obstruct the flue at a future date must

be removed before connecting this appliance.

The combustion products from this appliance will

have a descaling effect on hardened soot deposits

left from burning solid fuels.

ALTHOUGH THE CHIMNEY MAY HAVE BEEN

CLEANED OF LOOSE SOOT PRIOR TO INSTALLATION, IT IS IMPERATIVE THAT THE CHIMNEY

IS INSPECTED FOR SCALED SOOT PARTICLES

AFTER THE FIRST MONTH OF OPERATION AND

ANY LOOSE MATERIALS REMOVED TO AVOID

BLOCKAGE.

NOTE: Never connect to a chimney or flue

system serving another appliance.

7

FLUE HEIGHT

The flue must be high enough 4.5mts (15ft minimum) measured vertically from the appliance outlet

to the top of the flue terminal to allow flue gases to

vent into the clear air, away from turbulence that

A bend should not

make an angle of

more than 37.5

o

with the vertical.

Page 9

8

FLUE LINERS

Chimney’s lined with salt glazed earthenware pipes

are acceptable if the pipes comply with EN 1457 and

must be 125mm (5”). When lining an existing chimney, a liner approved to B.S. 4543, Parts 1, 2, & 3

should be used. The liner should be secured at the

top and bottom by using a closure/clamping plate

firmly sealed and secured, and an approved terminal used at the top.

It is essential that every flue system be inspected

and tested by a competent person for its correct

effectiveness, to ensure that the combustion products are completely discharged to the outside

atmosphere.

SEALING

This cooker and flue system operate under a negative pressure, it is essential that all flue joints are

tightly sealed against flue gas leakage and tested

accordingly.

CONNECTIONS

This appliance may be connected either direct vertical or horizontal. THE HORIZONTAL CONNEC-

TION MUST NOT EXCEED 300MM IN LENGTH.

Blocked chimneys are dangerous. Keep chimneys and flueways clear.

Where an appliance spigot or flue pipe protrudes into the chimney, care should be taken to

ensure that it does not block the chimney.

VENTILATION AND COMBUSTION AIR

REQUIREMENTS

It is imperative that there is sufficient air supply to

the burner of the cooker in order to support correct

combustion.

The air supply to this appliance must comply with

B.S. 5410 Part 1.

The minimum effective air requirement for this appliance is 50 cm

2

. When calculating combustion air

requirements for this appliance use the following

equation: 550mm2per each kW of maximum rated

output above 5 kW. These requirements are illustrated in OFTEC Technical Book No.3 & B.S. 5410

Part 1.

If there is another appliance using air fitted in the

same or adjacent room, it will be necessary to refer

to B.S. 5410 Part 1 to calculate the additional air

supply. All materials used in the manufacture of air

vents should be such that the vent is dimensionally

stable, corrosion resistant, and has no provision for

closure. The effective free area of any vent should

be ascertained before installation.

The effect of any grills should be allowed for when

determining the effective free area of any vent.

Air vents direct to the outside of the building should

be located so that any air current produced will not

pass through normally occupied areas of the room.

An air vent outside the building should not be located less than the dimensions specified within the

Building Regulations and B.S 5410 Part 1 from any

part of any flue terminal. These air vents must also

be satisfactorily fire proofed as per Building

Regulations and BS 5410 Part 1.

Air vents in internal walls should not communicate

with bedrooms, bedsits, toilets, bathrooms or rooms

containing a shower.

Air vents traversing cavity walls should include a

continuous duct across the cavity. The duct should

be installed in such a manner as not to impair the

weather resistance of the cavity.

Joints between air vents and outside walls should be

sealed to prevent the ingress of moisture. Existing

air vents should be of the correct size and unobstructed for the appliance in use. If there is an

extraction fan fitted in the room or adjacent rooms

where this appliance is fitted, additional air vents will

be required to eleviate the possibility of spillage of

products of combustion from the appliance/flue

while the fan is in operation. (Refer to B.S. 5410

Part 1).

Where such an installation exists, a test for spillage

should be made with the fan or fans and other

appliances using air in operation at full rate, (i.e.

extraction fans, tumble dryers) with all external

doors and windows closed.

If spillage occurs following the above operation, an

additional air vent of sufficient size to prevent this

occurrence should be installed. If spillage continues

then the appliance should be shut down and the flue

system examined.

DRAUGHT REQUIREMENTS

The Errigal Oil Cooker requires a steady draught of

:

0.02” wg - 0.06” wg

(0.5mm wg - 1.5mm wg)

When a draught of over 0.06”wg is recorded, the

spin valve on the bonnet door can be opened

(draught stabiliser) allowing the flue pull on the cooker to be reduced. (see Fig. 10)

Page 10

DOWN DRAUGHTS

However well designed, constructed and

positioned, the satisfactory performance of

the flue can be adversely affected by down

draught caused by nearby hills, adjacent tall

buildings or trees. These can deflect wind

to blow directly down the flue to create a

zone of high pressure over the terminal.

(See Fig.11).

A suitable anti-down draught terminal or

cowl will usually effectively combat direct

down draught but no cowl is likely to prevent down draught due to a high pressure

zone.

Ensure that any cowl used will not restrict

the flue exit, or cause excessive back pressure.

Fig.10

FACTORY-MADE INSULATED CHIMNEYS

Factory-made insulated chimneys should be constructed and tested to meet the relevant standards

and recommendations given in:

* B.S. 7566 – Installation of factory-made chimneys

conforming to B.S. 4543 for domestic appliances.

Part 1: Method of specifying installations design

information.

Part 2: Specification for installation design.

Part 3: Specification for site installation.

Part 4: Recommendation for installation design

and installation.

SUITABLE MATERIALS

* Mineral Fibre cement pipes conforming to

B.S 7435.

Fig.11

9

IMPORTANT: THIS APPLIANCE SHOULD NOT

BE CONNECTED TO A CHIMNEY THAT IS

PRONE TO DOWN DRAUGHTING.

Page 11

* Insulated metal chimneys conforming to

B.S.4543 (a galvanised finish is not suitable

for exterior use).

* Clay flue linings conforming to B.S. EN

1457.

* Pre-cast concrete chimney blocks,

incorporated into the building structure. It is

particularly important that the correct

connection block be provided at the base

of the flue conforming to B.S. 3572.

* Cast iron or acid resistant vitreous enamel

lined mild steel conforming to B.S. 41.

* Sheet metal conforming to B.S. 4076.

SAFETY VALVE

A non-adjustable 3 bar safety valve must be fitted to

the primary flow pipe adjacent to boiler connection

ensuring that any discharge will not create a hazard

to occupants or cause damage to electrical components or property.

The use of room thermostats, radiator thermostatic

valves, domestic hot water controllers, etc, can

greatly enhance a heating system and we recommend their use.

Only competent personnel should be employed to

carry out your heating installation.

PIPE FITTINGS

Materials used for installation work should be resistant, sound and should conform to the current editions of the following or their equivalent.

1.1 Ferrous Materials

BS 4127 Stainless steel tubes.

BS 1387 Steel tubes.

BS 1740 Steel pipe fittings.

BS 6956 Jointing Materials

1.2 Non-Ferrous Materials.

EN 29453 Soft Solder Alloys .

BS 864 Compression tube fittings.

BS 2871 & BS E.N. 1057 Copper and

Copper Alloys.

INDIRECT DOMESTIC CYLINDER

This cooker can only be connected to an in-direct

domestic cylinder of 136 litres (30 gallons).

See Fig. 12.

Fig.12

10

HEATING

Care should be taken to ensure that the heating system is correctly installed and that it complies with all

relevant codes of practice.

Note: We strongly advise the use of pipe lagging if

the installation is likely to be exposed to situations

where the temperature will dip to a level consistent

with frost.

The HPB model produces up to 5.8 kW to water on

maximum setting therefore it is necessary to fit a

heat sink radiator. See output on page 3.

DIRECT DOMESTIC CYLINDER (DHW MODEL

ONLY)

A 113 litre (30 gallon) direct domestic cylinder can be

connected to this cooker. (See Fig. 13)

Fig.13

Errigal

Oil

Cooker

(HPB Model)

Errigal

Oil

Cooker

(DHW Model)

Page 12

GENERAL MAINTENANCE

It is important that the user is familiar with their heating system and that they ensure regular checks and

maintenance are carried out, which can limit unnecessary breakdowns.

We recommend that you evaluate the overall insulation in your house, i.e. attic, external walls, window

and external doors.

Insulation and draught proofing can greatly reduce

running costs while equally enhancing living conditions.

DRAINING

Key operated drain taps conforming to B.S. 2879,

should be provided in an accessible position in all

low parts of the system. However, it should be noted

that there may be short sections, e.g. when passing

under doorways that may not be possible to drain.

PRE-INSTALLATION ASSEMBLY

1. Remove packing strip from the top of cooker.

Remove all loose components supplied from

the top of the cooker and the oven. Remove

all doors. (See Fig.15)

Fig.16

FITTING OF LEGS

11

Fig. 15

INTERLINK SYSTEM

Fig.14

Errigal Oil

Cooker

Page 13

2. Place cement blocks or other strong supports about 458mm (13”) high behind the

cooker. Space the supports behind it and lay

the cooker on its back. (See Fig.16)

3. Fit the four legs to the four base corners

using the hexagon-head bolts and washers.

Note: Ensure that each of the front legs has a screw

hole in the front.

4. Join the two sections of the front skirting

together by screwing the name-plate with its

back fixing strip into position between the

two sections and secure the two sections

tightly to the name-plate.

5. Fit the complete skirting under the front of

the range inside the front legs using a screw

and nut to secure it to each leg. (See Fig.17)

6. Lift cooker off the supports. Stand it upright

without putting any strain on the legs.

10. Move the cooker into position for installation,

taking care not to damage the legs. Ensure

that all the requirements in section 5 have

been met.

11. Place the oblong hotplate, simmering plate

and the two round cleaning cups in position.

12. Place the bonnet in position and fit the bonnet door with flue damper to the front of it.

Seal the bonnet when in place, with cement.

Depending on the flue configuration

required, top or back, the blanking plate is

fitted to the top or back of the bonnet. (See

Fig.19)

12

Fig.17

Fig.18

7. Bolt the float valve bracket to the underside

of the base using the two

1

/2

” x

1

/4

” round

head screws provided. (See Fig.18).

8. Connect the formed fuel line to the control

valve outlet and the elbow connection in the

burner compartment, running the fuel line

through the slot provided in the burner compartment base. Seal both connections using

a suitable jointing compound.

9. FIT THE REMOTE ACTING FIRE VALVE

PHIAL THROUGH THE SAME SLOT AS

THE FORMED FUEL LINE. ENSURE THAT

THE FIRE VALVE PHIAL IS FITTED

THROUGH THE FIRE VALVE CLIP SO

THAT NO PART OF THE PHIAL TOUCHES

THE BASE.

Fig.19

13. Screw the towel rail brackets to the top front

of the cooker and fix the towel rail in position

between the brackets. Tighten up the

screws.

14. Hang the fire door and the ashpit door on

their hinges.

15. Place the oven shelves in position with the

cast iron shelf below the sheet steel shelf.

16. Place the cleaning door in position beneath

the oven door.

17. Connect the fuel line to the control valve

inlet.

18. Check all joints on fuel line for leaks before

completion of installation.

19. Connect and seal the flue to the bonnet.

Page 14

COMMISSIONING

Burner Set-up

1. Using a spirit level, check that the control

valve is level in all directions. Adjust the

locking nuts on the valve legs if levelling is

necessary. (See Fig.20).

Fig..20

Fig.21

2. Check that the burner is level in all directions. If levelling is necessary remove the

fire valve phial from the fire valve bracket

and place it to one side of burner compartment. Loosen the 1/4” bolt, holding down

the burner stand. The level is adjusted by

adjusting the three M8 bolts on the base of

the burner stand (See Fig. 22). Re-tighten

the 1/4” bolt when finished adjusting the

M8 bolts.

Fig.22

13

3. Push the control valve trigger up to set the

valve (See Fig.20). Turn the control knob

to 6 for 10 minutes to commence filling the

burner. If oil does not flow to the central

reservoir after 5 minutes, it may be necessary to bleed the oil line at the elbow connector in the burner compartment.

4. Check the oil in the burner rings. The oil

level should be 4mm. (See Fig. 23). If the

level is greater than required, the control

valve should be lowered. The control valve

bracket can be moved up and down by loosening the M4 lock nuts. If the level is less

than required, the control valve should be

raised until the oil level is correct. Each time

an adjustment is made, the oil in the central

reservoir and burner rings should be soaked

up with absorbent paper and the filling

process repeated.

Note: Do not check oil depth adjacent to fuel ports.

Fig.23

5. After any adjustments to the control valve,

check that it is level in all directions.

6. Once the oil depth and burner level are set,

the burner can be re-assembled. Refer to

Burner Assembly section.

7. Attach the control spindle to the control valve

using the M8 lock nut, and place the oil control valve cover in place over the valve.

Page 15

8. Turn the control valve to 6 and after 10 minutes, light the stove through the lighting

port as shown in Fig.25.

14

Fig.25

Fig.26

9. Adjust the spin valve opening until a blue

flame with yellow tip is obtained around the

outer shell. (See Fig. 26). The spin valve

should be set for an opening of approximately 6mm. (This may vary slightly depending

on flue draught performance).

10. Check that the Bacharach smoke number is

<2.

WARNING: OPEN DIRECT FLUE DAMPER

WHEN LIGHTING. SEE FIG.24.

Note: Ensure that the lighting port is closed

after the stove is lit.

Fig.24

ALWAYS OPEN THE DIRECT FLUE DAMPER

BEFORE LIGHTING THE COOKER. NEVER RELIGHT THE COOKER UNTIL IT IS COMPLETELY

COOLED DOWN. (SEE FIG. 24)

BURNER ASSEMBLY

With the burner level and the correct depth of oil in

the burner rings, the following tips should be followed for assembling the burner.

1. Replace the wicks in the burner rings.

Ensure that the cut-outs in the wicks line up

with the fuel ports between the central reservoir, and the burner rings. (See Fig.27)

2. Replace the cast iron centre well cap, grinding it into position to ensure it sits down properly.

3. Fit the outer shell, ensuring that it sits firmly

on the burner base and that it does not interfere with the outer wick. The outer shell is

fitted such that the lighting port is offset to

the right of the burner. (See Fig. 28).

4. Fit the remaining burner shells ensuring that

the seams are staggered as shown in Fig.28.

Ensure that all the shells sit firmly on the

burner base and that they do not interfere

with the wicks.

Fig.27

Page 16

5. Fit the burner baffle and the burner lid

on top of the shells. (See Fig.29).

When the stove has reached a stable condition (on

setting 6), the burner shells should glow red.

If the flame is yellow/orange in colour, there is not

sufficient air supply to the burner and the spin valve

on the ashpit door should be adjusted.

If after adjusting the spin valve, there is still a yellow/orange flame, consult the Fault Finding Section

of this manual.

Fig.29

COOKER OPERATION

Lighting the Cooker

1. Turn the control valve to setting 6 (anti-clock

wise) and allow 10 minutes for the burner to

fill.

2. Light the burner by putting a lighted paper or

taper through the lighting port (See Fig.25).

3. When the cooker is up to temperature, i.e.

when the burner shells are red, close the

direct flue damper and turn the control valve

(clockwise) to the desired setting.

Note: It is advisable that the control valve is set for

setting 1 or 2 when the cooker is not being used in

order to reduce the heat-up time when cooker operation is required. Running the cooker at 1 or 2 will

keep the flue system warm and help maintain flue

buoyancy.

15

Fig.30

ALWAYS OPEN THE DIRECT FLUE DAMPER

BEFORE LIGHTING THE COOKER. NEVER RELIGHT THE COOKER UNTIL IT IS COMPLETELY

COOLED DOWN. (SEE FIG. 24)

Note: The angle on the DHW/Dry baffle is directed

towards the oven. See Fig. 29.

DHW AND DRY HPB

Fig.28

6. Place the air distribution baffle in the burner

compartment ensuring that it sits on top of

the carbon leg assembly fuel line. Ensure

that it is kept to the left side of the burner

compartment so that the lighting port can be

accessed.

FLAME PATTERN

The flame pattern should consist of a blue flame with

a yellow tip around the burner baffle.

NOTE: NEVER OPERATE THE COOKER ON

SETTING 1 WITH THE DIRECT DAMPER

CLOSED.

TURNING THE COOKER OFF

When the control valve is turned to 0, the oil feed to

the burner is cut off and the cooker goes out.

SERVICING

To ensure continued efficient and safe operation of

the appliance, it is recommended that it is checked

and serviced by an Authorised Stanley Service

Engineer. This stove should be serviced at least

every 6 months. However if the stove is not used for

long periods of time, the service period may be

extended.

The cooker must be cold before servicing. Allow 34 hours for the cooker to cool.

NOTE: TO AVOID VIOLENT IGNITION DO NOT

RESTART UNTIL COOKER HAS COMPLETELY

COOLED DOWN.

Page 17

Fig.31

Fig.33

16

Fig.32

1. Open the oblong hotplate and remove the

burner shells, wicks, centre well cap, baffle and burner lid from the fire box.

2. Open the ashpit door and place the fire

valve phial to one side of the burner compartment, so that the burner base can be

accessed. Remove the air distribution baffle.

3. Disconnect the oil line from the burner and

remove the burner from the firebox by undoing the M8 bolt on the side of the burner support frame (See Fig.31).

4. Remove any dirt from the burner rings and

ensure that the ports between the rings are

clear.

5. Remove the simmering plate and cleaning

cups and brush any soot deposits into the

firebox.

Vacuum any dirt from the firebox base and if

necessary, clean the viewing glass.

6. Remove the base cleaning door and rake the

deposits, from underneath the oven through

the cooker front into a container using the

scraper tool. (See Fig.32).

7. Open the bonnet door and check for any soot

deposits in the flue. If there is evidence of

substantial soot build-up, the flue may need

to be cleaned.

8. Replace the burner in the firebox and reconnect the oil line to the burner.

9. Check that the burner and oil control valve

are level in all directions. Check all oil connections to ensure that there are no leaks.

(See Fig.33).

10. Turn the control valve to 6 to fill the burner.

Check that the correct level of oil is present.

(See Commissioning Section.)

11. Fit new wicks in the burner rings, ensuring

that the cut-outs in the wicks line up with the

fuel ports between the burner rings. (The

wicks should be replaced every time the

cooker is serviced).

12. Fit the burner assembly as described in the

Burner Assembly Section.

13. Reposition the fire valve phial. Close the

ashpit door.

14. Light the stove and check the flame pattern

(See Commissioning Section).

Flexible oil lines should be inspected at each

and every service visit. There are varying types

of line with guarantee periods between 1 and 5

years. It is important in the interest of safety that

flexible lines are changed at regular intervals.

Inspect for date code stamp and if the line is out

of its guarantee period or shows signs of being

kinked or damaged, replace immediately.

Page 18

Note: The flow rate should not exceed 20 cc/min as

this will overheat the cooker and the control

equipment for the cooker.

When the required rates are obtained, the oil

line should be reconnected ensuring that

there are no leaks and that the level of the

control valve has not been affected.

VITREOUS ENAMEL CLEANING

General cleaning must be carried out when the

stove is cool.

If this stove is finished in a high gloss vitreous enamel, to keep the enamel in the best condition observe

the following tips:

1. Wipe over daily with a soapy damp cloth,

followed by a polish with a clean dry duster.

2. For stubborn deposits a soap impregnated

pad can be carefully used on the vitreous

enamel.

3. DO NOT USE ABRASIVE PADS OR OVEN

CLEANSERS CONTAINING CITRIC ACID

ON ENAMELLED SURFACES. ENSURE

THAT THE CLEANSER MANUFACTUR

ERS INSTRUCTIONS ARE ADHERED TO.

17

Fig.35

1. Disconnect the oil feed at the exit from the

control valve. (See Fig.34)

2. Place the collection vessel beneath the con

trol valve to catch the oil. Turn the control

valve to 6 and start the stopwatch when the

first drop of oil falls into the vessel.

3. Measure the oil flow for 5 minutes. (consult

table below for current rate).

4. Turn the control valve to 1 and repeat the

above procedure.

5. If either of the above rates is not correct, the

control valve can be adjusted. The high rate

screw is located above the control knob with

the low rate located below the control knob.

(See Fig.35) The screws are very sensitive

and the measurement procedure should be

carried out after each adjustment. The rates

are increased by turning the screws anti

clock-wise and decreased by turning the

screws clock-wise.

Setting Flow Rate

HPB DHW DRY

1 6cc/min 5cc/min 4cc/min

6 19cc/min 17cc/min 11.5cc/min

Fig.34

CONTROL VALVE RATING

The control valve must be rated by the

Commissioning Agent on site to give the required

fuel input for the cooker.

When the flame pattern is unsatisfactory, the air supply to the burner and flue passages should be thoroughly investigated before investigating the oil feed

rate to the burner.

Check the oil feed rate as follows:

Note: Great care should be taken to ensure the

accuracy of the flow rate, as it greatly affects

the cooker performance.

Apparatus Required: Collection Vessel

Stopwatch

Graduated Cylinder (capable

of measuring 150ml and graduated to the nearest ml)

Small flat screwdriver.

Page 19

18

ERRIGAL OIL 20K EXPLODED VIEW

1. Oven Door

2. Spin Valve

3. Ashpit Door

4. Fire Door

5. Door Hinge

6. Door Knob

7. Fire Valve

8. Fire Valve Bracket

9. Air Distribution Baffle

10. Front

11. Towel Rail Bracket

12. Towel Rail

13. Door Knob Washer

14. Door Knob Spacer

15. Base Cleaning Door

16. Door Knob Locking

Nut

17. Door Catch

18. Oven Door Panel

19. Thermometer

20. Oven Bottom

21. Oven Shelves

22. Plinth R.H.S.

23. Nameplate

24. Plinth L.H.S.

25. Plinth Joining Clip

26. S.I. Base Protection Plate

27. Legs

28. Base

29. Sheet Iron Sides

30. R.H. Oven Side

31. Oven End Flue Bottom

32. Oven End Flue Top

33. Ashpit L.H.S.

34. Formed Fuel Line

35. Control Valve Bracket

36. Control Valve Cover

37. Control Knob

38. Oil Control Valve

39. 1/4” x 8mm Compression

Fitting

40. Ashpit R.H.S.

41. Flue Check

42. Grate Support Frame

43. Oven Back

44. Flue Back

45. LH Oven Side

46. Back Sealing Plate

47. Small Back Panel

48. Oven Top

49. Direct Damper

50. Ashpit Back

51. R.H. Window Frame

52. Viewing Glass Frame

53. Viewing Glass

54. L.H. Window Frame

55. S90 Boiler

56. Hob

57. Hob Rod Caps

58. Simmering Plate

59. Flue Deflector Plate

60. Hotplate

61. Bonnet Spin Valve

62. Bonnet Door

63. Bonnet

64. Back Outlet Adapter

65. Bonnet Blanking Plate

66. Bonnet Top Spigot

67. Boiler Rest

68. Large Back Panel

69. Cleaning Cup

70. Burner Stand

71. 1/4” x 8mm Compression

Elbow

72. Burner Pot Elbow Adapter

73. Carbon Leg Assembly

74. Bonnet Gasket

75. Centre Well Cap

76. 8mm Olive

77. 8mm Compression Nut

78. Burner

79. Wicks

80. Burner Shells

81. Burner Lid

82. Burner Baffle

83. Fixing Bolts

Page 20

ERRIGAL OIL DHW EXPLODED VIEW

1. Oven Door

2. Spin Valve

3. Ashpit Door

4. Fire Door

5. Door Hinge

6. Door Knob

7. Fire Valve

8. Fire Valve Clip

9. Air Distribution

Baffle

10. Front

11. Towel Rail Bracket

12. Towel Rail

13. Door Knob

Washer

14. Door Knob Spacer

15. Base Cleaning

Door

16. Door Knob

Locking Nut

17. Door Catch

18. Oven Door Panel

19. Thermometer

20. Oven Bottom

21. Oven Shelves

22. Plinth R.H.S.

23. Nameplate

24. Plinth L.H.S.

25. Plinth Joining Clip

26. S.I. Base Protection

Plate

27. Legs

28. Base

29. Sheet Iron Sides

30. R.H. Oven Side

31. Oven End Flue

Bottom

32. Oven End Flue Top

33. Ashpit L.H.S.

34. Formed Fuel line

35. Control Valve

Bracket

36. Control Valve Cover

37. Control Knob

38. Oil Control Valve

39. 1/4” x 8mm

Compression Fitting

40. Ashpit R.H.S.

41. Flue Check

42. Grate Support Frame

43. Oven Back

44. Flue Back

45. L.H. Oven Side

46. Back Sealing Plate

47. Small Back Panel

48. Oven Top

49. Direct Damper

50. Ashpit Back

51. R.H. Window Frame

52. Viewing Glass Frame

53. Viewing Glass

54. L.H. Window Frame

55. Superette Boiler

56. Hob

57. Hob Rod Caps

58. Simmering Plate

59. Flue Deflector Plate

60. Hotplate

61. Bonnet Spin Valve

62. Bonnet Door

63. Bonnet

64. Back Outlet Adapter

65. Bonnet Blanking

Plate

66. Bonnet Top Spigot

67. Boiler Rest

68. Large Back Panel

69. Cleaning Cup

70. Burner Stand

71. 1/4” x 8mm

Compression Elbow

72. Burner Pot Elbow

Adapter

73. Carton Leg Assembly

74. Bonnet Gasket

75. Center Wall Cap

76. 8mm Olive

77. 8mm Compression

Nut

78. Burner

79. Wicks

80. Burner Shells

81. Burner Lid

82. Burner Baffle

83. Burner Support Rod

19

Page 21

ERRIGAL OIL DRY EXPLODED VIEW

17. Door Catch

18. Oven Door Panel

19. Thermometer

20. Oven Bottom

21. Oven Shelves

22. Plinth R.H.S.

23. Nameplate

24. Plinth L.H.S.

25. Plinth Joining Clip

26. S.I. Base Protection

Plate

27. Legs

28. Base

29. Sheet Iron Sides

30. R.H. Oven Side

31. Oven End Flue

Bottom

32. Oven End Flue Top

33. Ashpit L.H.S.

34. Formed Fuel line

35. Control Valve

Bracket

36. Control Valve Cover

37. Control Knob

38. Oil Control Valve

39. 1/4” x 8mm

Compression Fitting

40. Ashpit R.H.S.

41. Flue Check

42. Grate Support Frame

43. Oven Back

44. Flue Back

45. L.H. Oven Side

46. Back Sealing Plate

47. Small Back Panel

48. Oven Top

49. Direct Damper

50. Ashpit Back

51. R.H. Window Frame

52. Viewing Glass Frame

53. Viewing Glass

54. L.H. Window Frame

55. Sham Cheek

56. Hob

57. Hob Rod Caps

58. Simmering Plate

59. Flue Deflector Plate

60. Hotplate

61. Bonnet Spin Valve

62. Bonnet Door

63. Bonnet

64. Back Outlet Adapter

65. Bonnet Blanking

Plate

66. Bonnet Top Spigot

67. RHS Back Fire Brick

(S90 No.2)

68. Back Panel

69. Cleaning Cup

70. Burner Stand

71. 1/4” x 8mm

Compression Elbow

72. Burner Pot Elbow

Adapter

73. Carton Leg Assembly

74. Bonnet Gasket

75. Center Wall Cap

76. 8mm Olive

77. 8mm Compression

Nut

78. Burner

79. Wicks

80. Burner Shells

81. Burner Lid

82. Burner Baffle

83. RHS Front Fire Brick

(S90 No.3)

84. Back Bottom Brick

85. Back Top Brick

86. Boiler Tapping

Blanking Plates

87. Burner Support Rod

1. Oven Door

2. Spin Valve

3. Ashpit Door

4. Fire Door

5. Door Hinge

6. Door Knob

7. Fire Valve

8. Fire Valve Bracket

9. Air Distribution

Baffle

10. Front

11. Towel Rail Bracket

12. Towel Rail

13. Door Knob

Washer

14. Door Knob Spacer

15. Base Cleaning

Door

16. Door Knob

Locking Nut

20

Page 22

21

FAULT FINDING

If the stove exhibits any of the following conditions, call your Commissioning Engineer.

PROBLEM CAUSE REMEDY

Stove will not light or goes No Oil in the Tank Fill Tank

out when lighting

Fire Valves off Reset valves, check for

cause of over temperature

Control valve trigger down (off) Reset trigger

Oil feed line filter blocked Free Oil filter

Fuel Line Air Locked Bleed Fuel Line

Carbon Leg Blocked Clean Carbon Leg Assembly

(Stove needs service)

Incorrect Depth of Oil in Burner Increase oil level to 4mm

Base

Down Draught in Flue Fit Anti-Down Draught Cowl

Flames burning under burner Incorrect Chimney Draught Check joint seals, increase

chimney height, adjust flue

bonnet spin valve.

Down Draught in Flue Fit Anti-Down Draught Cowl

Oil level too high in burner base Decrease oil level to 4mm

Oil Rate too high Lower control valve fuel input

rate

Dirty or Unstable Flame, Viewing Incorrect Chimney Draught Check joint seals, increase

Glass sooting up Chimney height, adjust flue

bonnet spin valve.

Incorrect Fuel Input Rate Check Fuel Input Rate, adjust

if necessary

Incorrect Spin Valve Setting Adjust Spin Valve Setting

Shells or Vapour Chamber Lid Ensure all shells are seated

not seated properly on Burner base and that their

seams are staggered.

Lighting Port Open Close Lighting Port

Wrong Grade of Oil Used Only Use Kerosene 28 sec C2

Wicks incorrectly Positioned Ensure that the cut-outs in the

wicks are properly aligned

and that the shells don’t

interfere with the wicks

Oil Smell Apparent Incorrect Chimney Draught Check joint seals, increase

chimney height, adjust the

bonnet spin valve.

Down Draught in Flue Fit Anti-Down Draught Cowl

Incorrect Fuel Input Rate Check fuel input rate, adjust if

necessary

Fuel Leaks Check all fuel pipe connec-

tions, and reseal if necessary.

Cooker Overheating Incorrect Fuel Input Rate Decrease Fuel Input Rate

Page 23

22

INSTALLATION CHECK LIST

Flue System

1. Minimum Flue Height of 4.6 metres (15 feet).

2. If connecting to an existing chimney, the chimney should be lined using either a flexible or rigid

125mm (5”) diameter suitable for oil-fired appliances that terminates in excess of 0.6 metres from the

nearest point of the roof, measured vertically and in excess of 2.3 metres measured horizontally.

3. If using an external flue, the appliance should be connected to a 125mm (5”) diameter rigid insulated

flue pipe, suitable for an oil-fired appliance, that terminates in excess of 0.6 metres from the nearest

point on the roof, measured vertically and in excess of 2.3 metres measured horizontally.

4. Any Horizontal flue sections should not exceed 300mm (12”).

5. The chimney serving this appliance should not serve any other appliance.

6. Connection of the flue should only be made through the bonnet on top of the cooker.

7. A suitable flue terminal, such as an OH cowl, should be fitted at the flue termination point.

8. If using an internal flue or chimney, closure-clamping plates should be used to seal the top &

bottom of the chimney.

9. Access should be provided to the chimney serving the appliance to allow for cleaning.

10. If the flue passes through a combustible wall, a twin wall insulated connector must be used and

come flush to the external surface of the wall.

11. The flue should be capable of producing a continuous draught of 0.06” w.g. during normal operation.

Location

1. Clearance to combustible materials must be adhered to as described in the Clearance to Combustibles

Section.

2. The cooker should be installed as to allow adequate air circulation around the cooker and to allow

access for installation & servicing.

3. The cooker must be installed on a non-combustible insulated floor protector that covers the area under

the cooker and extends 6” from the side and back and 9” from the front of the cooker.

Plumbing (Boiler Models Only)

1. Appliance must be connected to a gravity circuit supplying a 113 litre (30 gallon) cylinder using 1” ID

flow & return piping.

2. The length of pipes from the cylinder to the stove should not exceed 7.8 metres (25 feet).

3. A three bar safety valve must be fitted to the primary flow pipe adjacent to the boiler connection on

the stove.

4. The HPB model must be connected to a central heating circuit with a pipe stat, fitted on the feed pipe

to the cylinder, controlling a pump fitted on the return pipe from the central heating circuit.

Ventilation & Combustion Air Requirements

1. The room in which the appliance is located should have an air vent of adequate size to support correct

combustion when all other air-using appliances are operating at full capacity (see Ventilation &

Combustion Air Requirement Section for specific details).

Oil Supply

1. The oil supply tank should be fitted with an isolating valve and filter and should be positioned as to give

a minimum head of oil of 125mm (see Fuel Supply Line section).

2. The stove should be connected to a supply line with a minimum internal diameter of 8mm and must be

fitted with a remote acting fire valve.

3. Where other oil fired appliances are connected to the same oil supply tank, a separate oil supply line

should be taken from the tank to the stove.

Tick

√

Page 24

Rev:006 DP 070126

N00184AXX

23

Manufactured by

Waterford Stanley Ltd.,

Unit 210, IDA Industrial Estate, Cork Road,

Waterford, Ireland.

Tel: (051) 302300 Fax (051) 302315

Loading...

Loading...