Page 1

CS25/28

HYDRAULIC

POLE CHAIN SAW

SAFETY, OPERATION AND MAINTENANCE

USER'S MANUAL

© Stanley Hydraulic Tools 2006

OPS/MAINT USA / CE

Printed in U.S.A.

66205 2/2010 ver 4

Page 2

WARNING

TABLE OF CONTENTS

CERTIFICATE OF CONFORMITY .............................................................................................................................................................4

SAFETY SYMBOLS ...................................................................................................................................................................................5

SAFETY PRECAUTIONS ...........................................................................................................................................................................6

ELECTRICAL HAZARDS ...........................................................................................................................................................................8

TOOL STICKERS & TAGS .......................................................................................................................................................................10

HYDRAULIC HOSE REQUIREMENTS .................................................................................................................................................... 11

HTMA REQUIREMENTS ..........................................................................................................................................................................12

OPERATION .............................................................................................................................................................................................13

PREOPERATION PROCEDURES .....................................................................................................................................................13

CHECK POWER SOURCE .................................................................................................................................................................13

CHECK TOOL .....................................................................................................................................................................................13

CHECK TRIGGER MECHANISM .......................................................................................................................................................13

SETTING THE DUAL SPOOL FOR OPERATION ..............................................................................................................................13

SETTING FOR OPEN-CENTER (OC) OR CLOSED-CENTER (CC) OPERATION ...........................................................................13

TO DISABLE DUAL SPOOL OPERATION AND CONVERT TO OC ONLY OPERATION ..................................................................13

TO DISABLE DUAL SPOOL OPERATION AND CONVERT TO CC ONLY OPERATION ..................................................................13

CONNECTING HOSES ......................................................................................................................................................................13

TOOL OPERATION .............................................................................................................................................................................14

CUTTING TIPS ...................................................................................................................................................................................14

FELLING OR TOPPING ......................................................................................................................................................................14

NOTCHING OR UNDERCUTTING .....................................................................................................................................................14

FELLING OR BACK CUT ....................................................................................................................................................................14

LOGS/LIMBS WITH PRESSURE ON BOTTOM .................................................................................................................................14

PRUNING & TRIMMING .....................................................................................................................................................................14

TOPPING/LOWERING LIMBS ............................................................................................................................................................15

LIMING AND BUCKING ......................................................................................................................................................................15

COLD WEATHER OPERATION .........................................................................................................................................................15

EQUIPMENT PROTECTION & CARE .....................................................................................................................................................17

TROUBLESHOOTING .............................................................................................................................................................................18

SPECIFICATIONS ....................................................................................................................................................................................19

ACCESSORIES........................................................................................................................................................................................19

SERVICE TOOLS .....................................................................................................................................................................................19

CS25/28 PARTS ILLUSTRATION ............................................................................................................................................................20

CS25/28 PARTS LIST ..............................................................................................................................................................................21

WARRANTY ...................................................................................................................... .......................................................................22

SERVICING THE STANLEY HYDRAULIC Pole Chain Saw. This manual contains safety, operation, and

routine maintenance instructions. Stanley Hydraulic Tools recommends that servicing of hydraulic tools,

other than routine maintenance, be performed by an authorized and certifi ed dealer. Please read the fol-

lowing warning.

SERIOUS INJURY OR DEATH COULD RESULT FROM THE IMPROPER REPAIR OR SERVICE OF THIS TOOL.

REPAIRS AND / OR SERVICE TO THIS TOOL MUST ONLY BE

DONE BY AN AUTHORIZED AND CERTIFIED DEALER.

For the nearest authorized and certifi ed dealer, call Stanley Hydraulic Tools at the number listed on the

back of this manual and ask for a Customer Service Representative.

3

Page 3

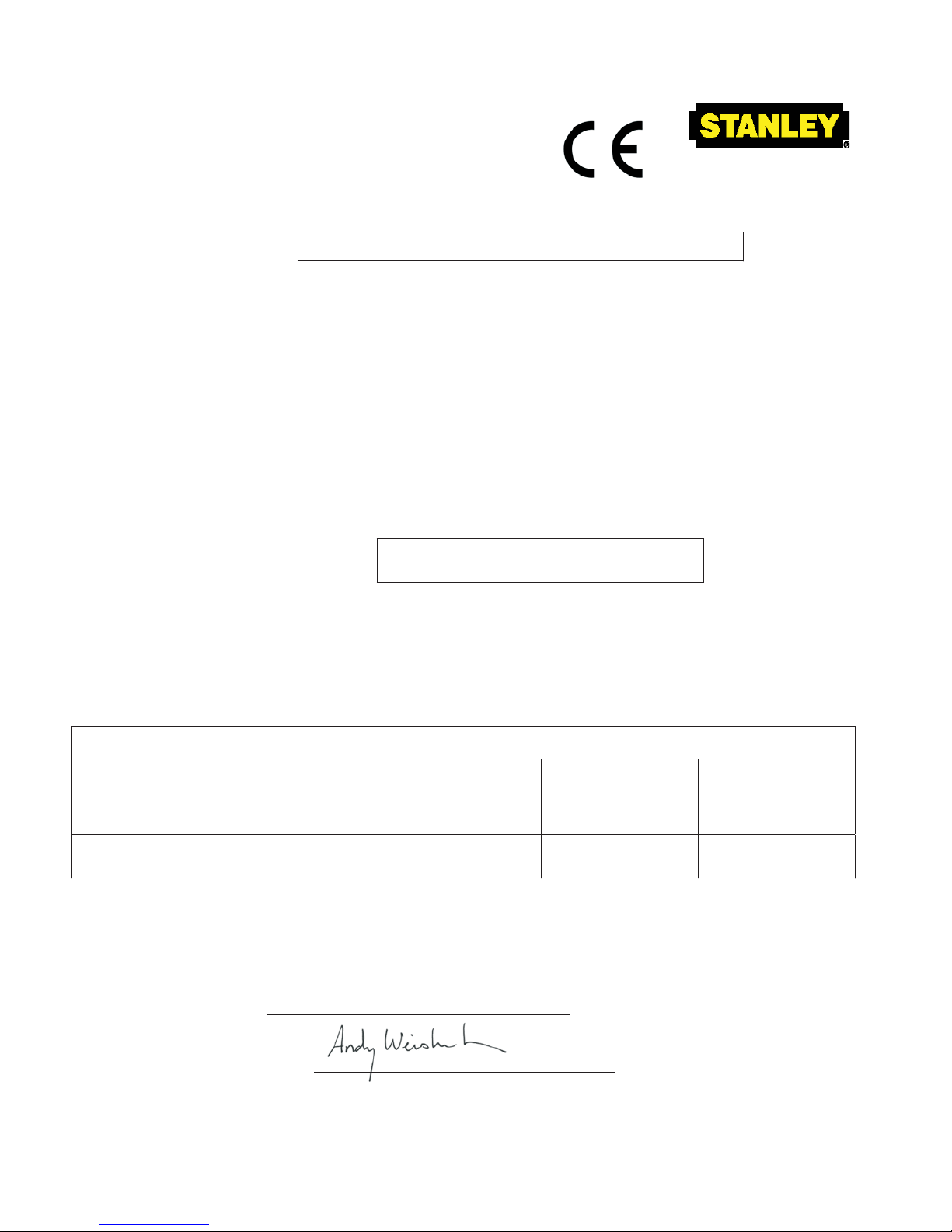

CERTIFICATE OF CONFORMITY

ÜBEREINSTIMMUNGS-ZERTIFIKAT

CERTIFICAT DE CONFORMITE CEE

CERTIFICADO DE CONFORMIDAD

CERTIFICATO DI CONFORMITA

Hydraulic Tools

______________________________________________________________________

I, the undersigned:

Ich, der Unterzeichnende:

Je soussigné:

El abajo firmante:

lo sottoscritto:

hereby certify that the construction plant or equipment specified hereunder:

bestätige hiermit, daß das im folgenden genannten Werk oder Gerät:

certifies par ceci que l’ usine ou l’ équipement de constructio n indiqué cidessous:

por el presente certifico que la fabrica o el equipo especificado a continuacion:

certifico che l’impianto o l’attrezzatura sotto specificata:

1. Category: Pole Chain Saws, Hydraulic

Kategorie:

Catégorie:

Categoria:

Categoria:

2. Make/Ausführung/Marque/Marca/Marca

3. Type/Typ/Type/Tipo/Tipo: CS2581101, CS2881101

4. Serial number of equipment:

Seriennummer des Geräts:

Numéro de série de l’équipement:

Numero de serie del equipo:

Matricola dell´attrezzatura:

5. Year of manufacture/Baujahr/année de fabrication/Año de fabricacion/Anno di fabbricazione Beginning 2002

Has been manufactured in conformity with - EEC Type examination as shown.

Wurde hergestellt in Übereinstimmung mit - EEC Typ-Prüfung nach.

Est fabriqué conformément - au(x) type(s) examiné(s) comme indiqué dans le tableau ci-après.

Ha sido fabricado de acuerdo con - tipo examen EEC como dice.

E’ stata costruita in conformitá con - le norme CEE come illustrato.

Weisbeck, Andy

Surname and First names/Familiennname und Vornamen/Nom et prénom/Nombre y apellido/Cognome e nome

Stanley

All

Examen CEE de type

Directive

Richtlinie

Directives particulières

Directriz

Direttiva

Certificate

Machinery Directive

6. Special Provisions: None

Dispositions particulières:

Provisiones especiales:

Disposizioni speciali:

7. Representative in the Union: Stanley Dubuis 17-19, rue Jules Berthonneau-BP 3406 41034 Blois Cedex, France.

Done at/Ort/Fait à/Dado en/Fatto a Stanley Hydraulic Tools, Milwaukie, Oregon USA

Signature/Unterschrift/Signature/Firma/Firma

Position/Position/Fonction/Puesto/Posizione Engineering Manager_____________________

No.

Nr

Numéro

No

n.

0466/96/32-1

98/37/EC

Rev. 3 2/3/10

Date

Datum

Date

Fecha

Data

25 June 1998

1998

Approved body

Prüfung durch

Organisme agréé

Aprobado

Collaudato

AEA Technology

Self

Date/Datum/le/Fecha/Data 7-30-02

Date of expiry

Ablaufdatum

Date d´expiration

Fecha de caducidad

Data di scadenza

NA

NA

4

Page 4

WARNING

DANGER

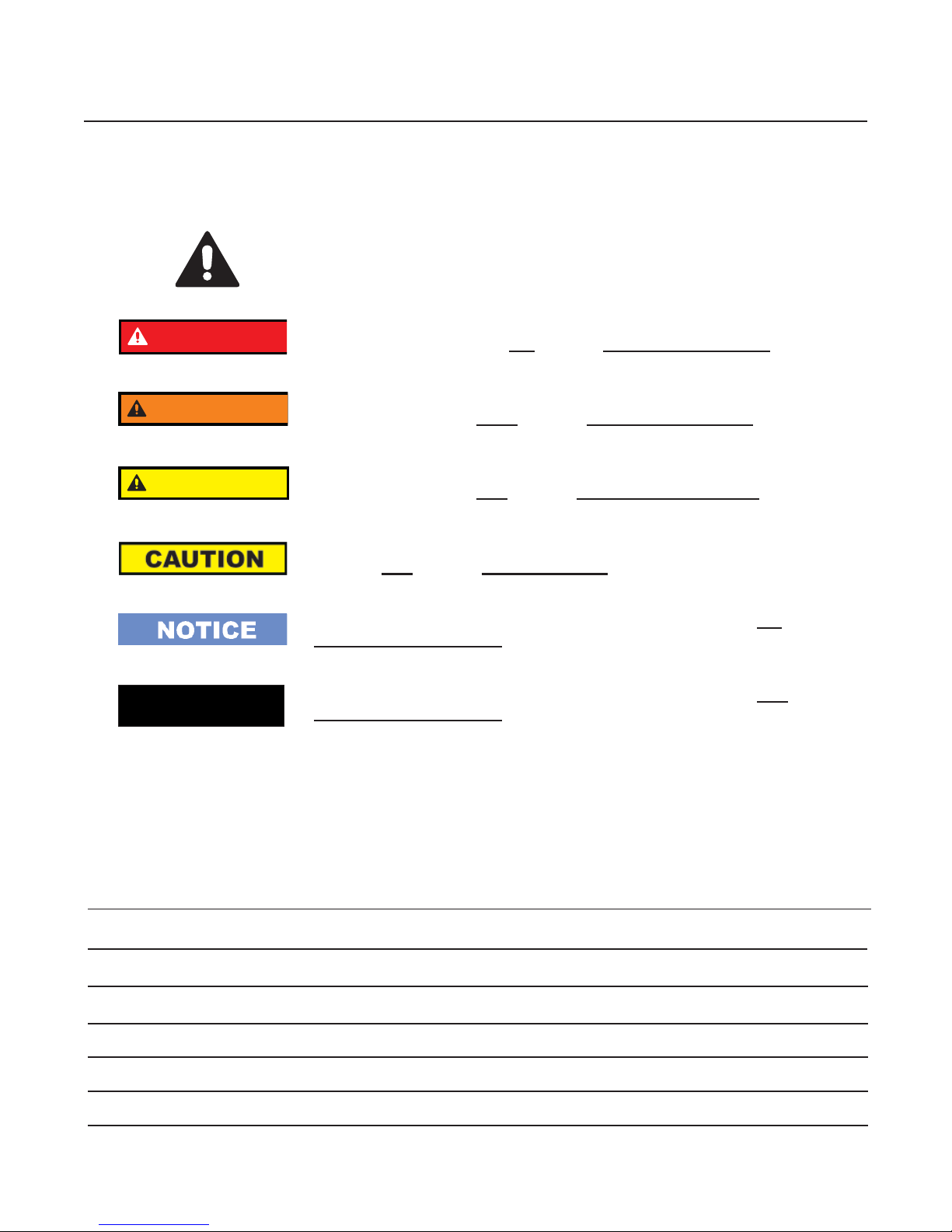

SAFETY SYMBOLS

Safety symbols and signal words, as shown below, are used to emphasize all operator, maintenance and repair

actions which, if not strictly followed, could result in a life-threatening situation, bodily injury or damage to equipment.

This is the safety alert symbol. It is used to alert you to potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

This safety alert and signal word indicate an imminently hazardous situation which, if not avoided, will result in death or serious injury.

This safety alert and signal word indicate a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION

IMPORTANT

Always observe safety symbols. They are included for your safety and for the protection of the tool.

This safety alert and signal word indicate a potentially hazardous situation

which, if not avoided, may result in minor or moderate injury.

This signal word indicates a potentially hazardous situation which, if not

avoided, may result in property damage.

This signal word indicates a situation which, if not avoided, will result in

damage to the equipment.

This signal word indicates a situation which, if not avoided, may result in

damage to the equipment.

LOCAL SAFETY REGULATIONS

Enter any local safety regulations here. Keep these instructions in an area accessible to the operator and maintenance personnel.

5

Page 5

SAFETY PRECAUTIONS

Tool operators and maintenance personnel must always comply with the safety precautions given in this manual and on

the stickers and tags attached to the tool and hose.

These safety precautions are given for your safety. Review them carefully before operating the tool and before performing

general maintenance or repairs.

Supervising personnel should develop additional precautions relating to the specifi c work area and local safety regula-

tions. If so, place the added precautions in the space provided in this manual.

The CS25/28 Hydraulic Pole Chain Saw will provide safe and dependable service if operated in accordance with the

instructions given in this manual. Read and understand this manual and any stickers and tags attached to the tool and

hoses before operation. Failure to do so could result in personal injury or equipment damage.

• Operator must start in a work area without bystanders. The operator must be familiar with all prohibited work areas such

as excessive slopes and dangerous terrain conditions.

• Establish a training program for all operators to ensure safe operation.

• Do not operate the tool unless thoroughly trained or under the supervision of an instructor.

• Always wear safety equipment such as goggles, ear, head protection, and safety shoes at all times when operating the

tool.

• Do not overreach. Maintain proper footing and balance at all times.

• Do not inspect or clean the tool while the hydraulic power source is connected. Accidental engagement of the tool can

cause serious injury.

• Supply hoses must have a minimum working pressure rating of 2500 psi/175 bar.

• Be sure all hose connections are tight.

• The hydraulic circuit control valve must be in the “OFF” position when coupling or uncoupling the tool. Wipe all couplers

clean before connecting. Use only lint-free cloths. Failure to do so may result in damage to the quick couplers and cause

overheating of the hydraulic system.

• Do not operate the tool at oil temperatures above 140°F/60°C. Operation at higher oil temperatures can cause operator

discomfort and may damage the tool.

• Do not operate a damaged, improperly adjusted, or incompletely assembled tool.

• To avoid personal injury or equipment damage, all tool repair, maintenance and service must only be performed by authorized and properly trained personnel.

• Do not exceed the rated limits of the tool or use the tool for applications beyond its design capacity.

• Always keep critical tool markings, such as lables and warning stickers legible.

• Always replace parts with replacement parts recommended by Stanley Hydraulic Tools.

• Check fastener tightness often and before each use daily.

• Do not wear loose fi tting clothing when operating the tool.

6

Page 6

SAFETY PRECAUTIONS

POLE CHAIN SAW SPECIFIC SAFETY PRECAUTIONS

• Do not rely exclusively upon the safety devices built into the saw. As a pole saw user, several steps must be taken to

keep your cutting jobs free from accident or injury.

• With basic understanding of kickback, you can reduce or eliminate the element of surprise. Sudden surprise contributes

to accidents.

• Keep a good fi rm grip on the pole chain saw with both hands. Place your right hand on the rear handle and your left

hand on the outer tube assembly when operating. Use a fi rm grip with your thumbs and fi ngers encircling the chain saw

handle and outer tube assembly. A fi rm grip helps reduce kickback and maintains control of the pole chain saw. Do not let

go.

• Make sure the area in which you are cutting is free of obstructions. Never allow the nose of the guide bar to contact a

branch or any other obstruction that can be accidently hit while operating the saw.

• Cut at the rated operating speeds (gpm).

• Follow the manufacturer’s sharpening and maintenance instructions for the saw chain.

• Only use repalcement bars and chains specifi ed by Stanley or equivalent.

• Make sure you’re well rested and mentally alert before operating the pole chain saw.

• Do not start cutting until you have a clear work area, secure footing and a planned drop area for falling branches.

• Keep all parts of the body away from the saw chain during operation.

• Carry the saw with the unit deenergized.

• Do not opeate a pole chain saw that is damaged, improperly adjusted or not completely and securely assembled. Make

sure the chain stops moving when the control trigger is released.

• Use extreme caution when cutting small branches. Twigs may catch the saw chain and be whipped toward the operator

or pull the operator off balance.

• When cutting a limb that is under tension, be aware of springback so you will not be struck when the tension on the limb

is released. Always cut on the outside arc or curve.

• Keep the handle dry, clean and free of hydraulic fl uid.

• When using tools near energized transmission lines, make sure to use only hoses labeled and certifi ed non-conductive.

• Turn off the power unit or move the hdyraulic control valve to neutral before setting the pole chain saw down.

• Use a chain bar scabbard when transporting the saw.

• Know the location of buried or covered electrical services before starting work.

• to avoid personal injury or equipment damage, all tool repair, maintenance and service must only be performed by authorized and properly trained personnel.

7

Page 7

ELECTRICAL HAZARDS

The following guidelines must be followed to prevent accidental contact with overhead electrical conductors and/or communication wires and cables. (ref. ANSI Z133.1-2000)

Working in Proximity to Electrical Hazards:

An inspection shall be made by a qualifi ed arborist to determine whether an electrical hazard exists before climbing, or

otherwise entering, or performing work in or on a tree.

Only qualifi ed line-clearance arborists or qualifi ed line-clearance arborist trainees shall be assigned to work where an

electrical hazard exists. Qualifi ed line-clearance arborist trainees shall be under the direct supervision of qualifi ed line-

clearance arborist.

A second qualifi ed line-clearance arborists or line-clearance arborist trainees shall be within vision or voice communica-

tion during line-clearing operations aloft when line-clearance arborists or line-clearance arborist trainees must approach

closer than 10 feet (3.05 meters) to any energized electrical conductor in excess of 750 volts (primary conductor) or when:

(1) Branches or limbs being removed cannot fi rst be cut (with a pole pruner/pole saw) to suffi ciently clear electrical

conductors, so as to avoid contact.

(2) Roping is required to remove branches or limbs from such electrical conductors. This does not apply to indi viduals working on behalf of, or employed by, electrical system owners/operators engaged in line-clearing

operations incidental to their normal occupation.

Qualifi ed line-clearance arborists and line-clearance arborist trainees shall maintain minimum approach distances from

energized electrical conductors in accordance with Table 1.

All other arborists shall maintain a minimum approach distance from energized electrical conductors in accordance with

Table 2.

Branches hanging on an energized electrical conductor shall be removed using non-conductive equipment.

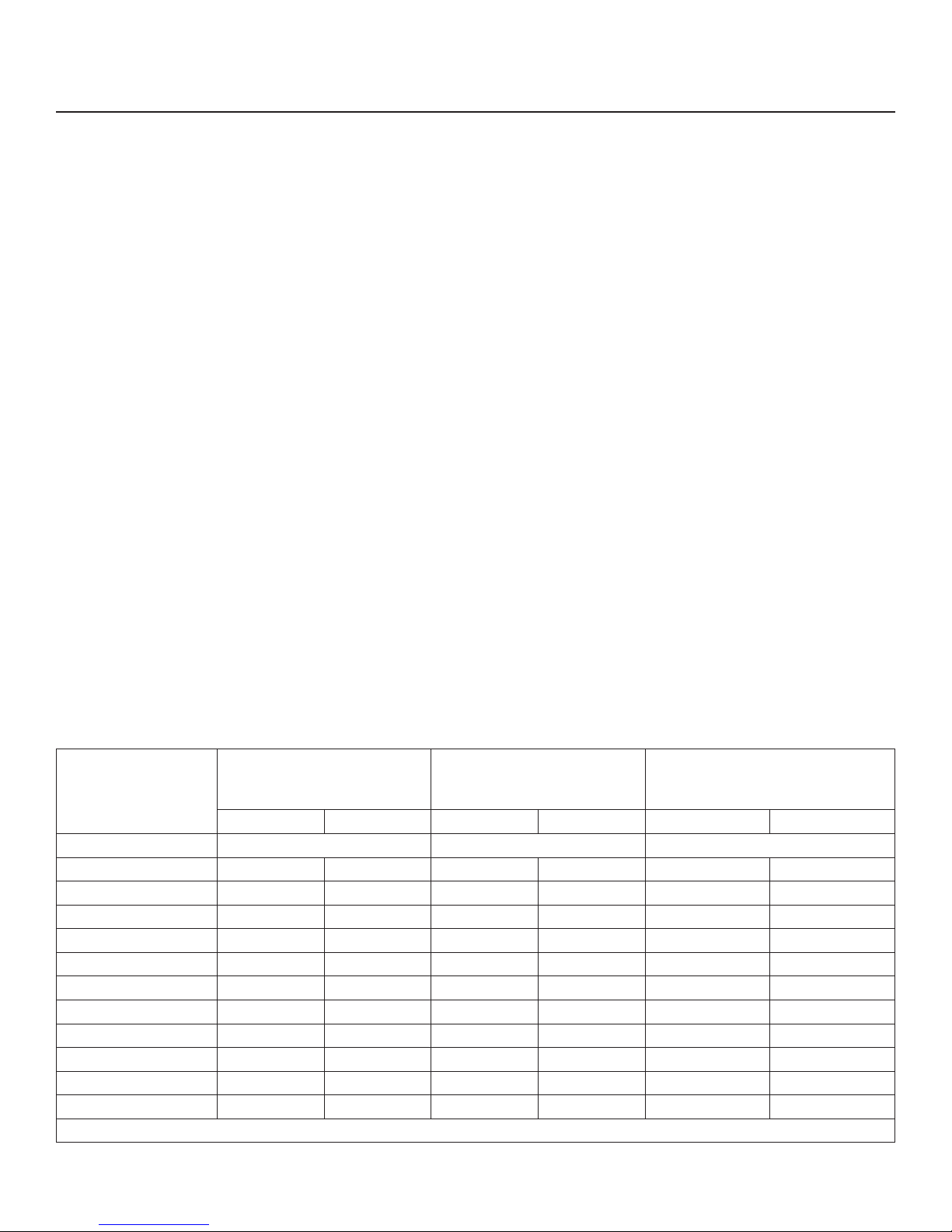

Table 1 - Minimum approach distances from energized conductors for qualifi ed line-clearance ar-

borists and qualifi ed line- clearance arborist trainees.

Includes 1910.269 eleva-

Nominal Voltage

(kV phase-to-phase)

0.05 to 1.0 Avoid contact Avoid contact Avoid contact

1.1 to 15.0 2-04 0.71 2-08 0.81 2-10 0.86

15.1 to 36.0 2-09 0.84 3-02 0.97 3-05 1.04

36.1 to 46.0 3-00 0.92 3-05 1.04 3-09 1.14

46.1 to 72.5 3-09 1.14 4-03 1.30 4-07 1.40

72.6 to 121.0 4-06 1.37 5-02 1.58 5-07 1.70

138.0 to 145.0 5-02 1.58 5-11 1.80 6-05 1.96

161.0 to 169.0 6-00 1.83 6-10 2.08 7-05 2.26

230.0 to 242.0 7-11 2.41 9-00 2.75 9-09 2.97

345.0 to 362.0 13-02 4.02 15-00 4.58 16-03 4.96

500.0 to 550.0 19-00 5.80 21-09 6.63 23-06 7.17

765.0 to 800.0 27-04 8.34 31-03 9.53 33-10 10.32

tion factor, sea level to

5000 ft

ft-in m ft-in m ft-in m

1)

Exceeds phase-to-ground; elevation factor per 29 CFR 1910.269.

1)

Includes 1910.269 elevation factor, 5001 - 10,000

1)

ft

Includes 1910.269 elevation fac-

tor, 10,000 - 14,000 ft

1)

8

Page 8

ELECTRICAL HAZARDS CONTINUED

Table 2 - Minimum approach distances to energized conductors for persons other than qualifi ed

line-clearance arborists and qualifi ed line- clearance arborist trainees.

Nominal Voltage

kV phase-to-phase

0.0 - 1.0 10-00 3.05

1.1 - 15.0 10-00 3.05

15.1 - 36.0 10-00 3.05

36.1 - 50.0 10-00 3.05

50.1 - 72.5 10-09 3.28

72.6 - 121.0 12-04 3.76

138.0 - 145.0 13-02 4.00

161.0 - 169.0 14-00 4.24

230.0 - 242.0 16-05 4.97

345.0 - 362.0 20-05 6.17

500.0 - 550.0 26-08 8.05

785.0 - 800.0 35-00 10.55

1)

The tie-in position should be above the work area and located in such a way that a slip would swing the arborist away

from any energized electrical conductors or other identifi ed hazard.

1)

Exceeds phase-to-ground.

Distance

ft-in m

While climbing, the arborist should climb on the side of the tree that is away from energized electrical conductors as required in Tables 1 and 2.

Footwear, including lineman’s overshoes, having electrical-resistant soles, shall not be considered as providing any measure of safety from electrical hazards.

Rubber gloves, with or without leather or other protective covering, shall not be considered as providing any measure of

safety from electrical hazards.

Ladders, platforms and aerial devices, including insulated aerial devices, shall be subject to minimum approach distances

in Table 1 and 2.

Aerial devices and attached equipment (such as chippers) contacting energized electrical conductors shall be considered

energized. Contact shall be avoided, except where emergency rescue procedures are being carried out. Emergency rescue should be performed in accordance with 4.3.

Storm Work and Emergency Conditions-Line Clearance

Line clearance shall not be performed during adverse weather conditions such as thunderstorms, high winds and snow

and ice stroms.

Qualifi ed line-clearance arborists and qualifi ed line-clearance arborists trainees performing line clearance in the aftermath

of a storm or under similar conditions shall be trained in the special hazards associated with this type of work.

Line-clearance operations shall be suspended when storm work or emergency conditions develop involving energized

electrical conductors. Electrical system owners/operators shall be notifi ed immediately.

9

Page 9

TOOL STICKERS & TAGS

Failure to use hydraulic hose labeled and certified

as non-conductive when using hydraulic tools on

or near electric lines may result in death or

For proper and safe operation read owners manual

and mwke sure that you have been properly

trained in correct procedures required for work

serious injury.

on or around electric lines.

ELECTROCUTION

HAZARD

28323

CE Decal

65839 - CS25 (shown)

65840 - CS28

Name Tag

28409

Composite Decal

03693

Closed Center Decal

15863

Danger Decal

05153

Stanley Decal

DANGER

Failure to use hydraulic hose labeled and certified

as non-conductive when using hydraulic tools on

or near electric lines may result in death or

serious injury.

For proper and safe operation read owners manual

and mwke sure that you have been properly

trained in correct procedures required for work

on or around electric lines.

12412

Electrical Warning Decal

03786

7-9 GPM Decal

11206

Circuit Type C Decal

The safety tag (p/n

15875) at right is attached

to the tool when shipped

from the factory. Read

and understand the safety

instructions listed on this

tag before removal. We

suggest you retain this tag

and attach it to the tool

when not in use.

11207

Circuit Type D Decal

34685

Sound Power Decal

THIS CHAIN SAW IS

EQUIPPED WITH AN

AUTOMATIC CHAIN

OILER.

SEE YOUR PARTS &

SERVICE BOOK FOR

PROPER ADJUSTING

PROCEDURES

04746

Automatic Oiler

Decal

DANGER

1. FAILURE TO USE HYDRAULIC HOSE LABELED

AND CERTIFIED AS NON-CONDUCTIVE WHEN

USING HYDRAULIC TOOLS ON OR NEAR

ELECTRICAL LINES MAY RESULT IN DEATH

OR SERIOUS INJURY.

BEFORE USING HOSE LABELED AND CERTI-

FIED AS NON-CONDUCTIVE ON OR NEAR

ELECTRIC LINES BE SURE THE HOSE IS

MAINTAINED AS NON-CONDUCTIVE. THE

HOSE SHOULD BE REGULARLY TESTED FOR

ELECTRIC CURRENT LEAKAGE IN ACCORDANCE WITH YOUR SAFETY DEPARTMENT

INSTRUCTIONS.

2. A HYDRAULIC LEAK OR BURST MAY CAUSE

OIL INJECTION I N T O T H E

BODY OR CAUSE OTHER SEVERE PERSONAL

INJURY.

A DO NOT EXCEED SPECIFIED FLOW AND

PRESSURE FOR

IMPORTANT

READ OPERATION MANUAL AND

SAFETY INSTRUCTIONS FOR THIS

TOOL BEFORE USING IT.

USE ONLY PARTS AND REPAIR

PROCEDURES APPROVED BY

STANLEY AND DESCRIBED IN THE

OPERATION MANUAL.

TAG TO BE REMOVED ONLY BY

TOOL OPERATOR.

SAFETY TAG P/N 15875

10

03782

4-6 GPM Decal

DANGER

D DO NOT LIFT OR CARRY TOOL BY THE

HOSES. DO NOT ABUSE HOSE. DO NOT

USE KINKED, TORN OR DAMAGED HOSE.

3. MAKE SURE HYDRAULIC HOSES ARE PROPERLY CONNECTED TO THE TOOL BEFORE

PRESSURING SYSTEM. SYSTEM PRESSURE

HOSE MUST ALW A YS BE CONNECTED TO TOOL

“IN” PORT. SYSTEM RETURN HOSE MUST

ALWA YS BE CONNECTED TO TOOL “OUT” PORT .

REVERSING CONNECTIONS MAY CAUSE REVERSE TOOL OPERATION WHICH CAN RESUL T

IN SEVERE PERSONAL INJURY.

4. DO NOT CONNECT OPEN-CENTER TOOLS TO

CLOSED-CENTER HYDRAULIC SYSTEMS. THIS

MAY RESULT IN LOSS OF OTHER HYDRAULIC

FUNCTIONS POWERED BY THE SAME SYSTEM

AND/OR SEVERE PERSONAL INJURY.

5. BYSTANDERS MAY BE INJURED IN YOUR WORK

AREA. KEEP BYSTANDERS CLEAR OF YOUR

WORK AREA.

IMPORTANT

READ OPERATION MANUAL AND

SAFETY INSTRUCTIONS FOR THIS

TOOL BEFORE USING IT.

USE ONLY PARTS AND REPAIR

PROCEDURES APPROVED BY

STANLEY AND DESCRIBED IN THE

OPERATION MANUAL.

TAG TO BE REMOVED ONLY BY

TOOL OPERATOR.

(shown smaller then actual size)

Page 10

HYDRAULIC HOSE REQUIREMENTS

HOSE TYPES

Hydraulic hose types authorized for use with Stanley Hydraulic Tools are as follows:

1 Certifi ed non-conductive

2 Wire-braided (conductive)

3 Fabric-braided (not certifi ed or labeled non-conductive)

Hose 1 listed above is the only hose authorized for use near electrical conductors.

Hoses 2 and 3 listed above are conductive and must never be used near electrical conductors.

HOSE SAFETY TAGS

To help ensure your safety, the following DANGER tags are attached to all hose purchased from Stanley Hydraulic Tools. DO NOT REMOVE THESE TAGS.

If the information on a tag is illegible because of wear or damage, replace the tag immediately. A new tag may be

obtained from your Stanley Distributor.

THE TAG SHOWN BELOW IS ATTACHED TO “CERTIFIED NON-CONDUCTIVE” HOSE

D A N G E R

1 FAILURE TO USE HYDRAULIC HOSE LABELED AND CERTIFIED AS NON-CONDUCTIVE

WHEN USING HYDRAULIC TOOLS ON OR NEAR ELECTRIC LINES MAYRESULT IN DEATH

OR SERIOUS INJURY.

FOR PROPER AND SAFE OPERATION MAKE SURE THAT YOU HAVE BEEN PROPERLY

TRAINED IN CORRECT PROCEDURES REQUIRED FOR WORK ON OR AROUND

ELECTRIC LINES.

2. BEFORE USING HYDRAULIC HOSE LABELED AND CERTIFIED AS NON-CONDUCTIVE ON

OR NEAR ELECTRIC LINES. WIPE THE ENTIRE LENGTH OF THE HOSE AND FITTING

WITH A CLEAN DRY ABSORBENT CLOTH TO REMOVE DIRT AND MOSISTURE AND TEST

HOSE FOR MAXIMUM ALLOWABLE CURRENT LEAKAGE IN ACCORDANCE WITH SAFETY

DEPARTMENT INSTRUCTIONS.

DO NOT REMOVE THIS TAG

SIDE 1 SIDE 2

3

(shown smaller than actual size)

3. DO NOT EXCEED HOSE WORKING PRESSURE OR ABUSE HOSE. IMPROPER USE OR

HANDLING OF HOSE COULD RESULT IN BURST OR OTHER HOSE FAILURE. KEEP

HOSE AS FAR AWAY AS POSSIBLE FROM BODY AND DO NOT PERMIT DIRECT CONTACT

DURING USE. CONTACT AT THE BURST CAN CAUSE BODILY INJECTION AND SEVERE

PERSONAL INJURY.

4. HANDLE AND ROUTE HOSE CAREFULLY TO AVOID KINKING, ABRASION, CUTTING, OR

CONTACT WITH HIGH TEMPERATURE SURFACES. DO NOT USE IF KINKED. DO NOT USE

HOSE TO PULL OR LIFT TOOLS, POWER UNITS, ETC.

5. CHECK ENTIRE HOSE FOR CUTS CRACKS LEAKS ABRASIONS, BULGES, OR DAMAGE TO

COUPLINGS IF ANY OF THESE CONDITIONS EXIST, REPLACE THE HOSE IMMEDIATELY.

NEVER USE TAPE OR ANY DEVICE TO ATTEMPT TO MEND THE HOSE.

6. AFTER EACH USE STORE IN A CLEAN DRY AREA.

D A N G E R

THE TAG SHOWN BELOW IS ATTACHED TO “CONDUCTIVE” HOSE.

D A N G E R

1 DO NOT USE THIS HYDRAULIC HOSE ON OR NEAR ELECTRIC LINES. THIS HOSE IS

NOT LABELED OR CERTIFIED AS NON-CONDUCTIVE. USING THIS HOSE ON OR NEAR

ELECTRICAL LINES MAY RESULT IN DEATH OR SERIOUS INJURY.

2. FOR PROPER AND SAFE OPERATION MAKE SURE THAT YOU HAVE BEEN PROPERLY

TRAINED IN CORRECT PROCEDURES REQUIRED FOR WORK ON OR AROUND

ELECTRIC LINES.

3. DO NOT EXCEED HOSE WORKING PRESSURE OR ABUSE HOSE. IMPROPER USE OR

HANDLING OF HOSE COULD RESULT IN BURST OR OTHER HOSE FAILURE. KEEP

HOSE AS FAR AWAY AS POSSIBLE FROM BODY AND DO NOT PERMIT DIRECT CONTACT

DURING USE. CONTACT AT THE BURST CAN CAUSE BODILY INJECTION AND SEVERE

PERSONAL INJURY.

4. HANDLE AND ROUTE HOSE CAREFULLY TO AVOID KINKING, CUTTING, OR CONTACT

WITH HIGH TEMPERATURE SURFACES. DO NOT USE IF KINKED. DO NOT USE HOSE TO

PULL OR LIFT TOOLS, POWER UNITS, ETC.

DO NOT REMOVE THIS TAG

SIDE 1 SIDE 2

(shown smaller than actual size)

5. CHECK ENTIRE HOSE FOR CUTS CRACKS LEAKS ABRASIONS, BULGES, OR DAMAGE TO

COUPLINGS IF ANY OF THESE CONDITIONS EXIST, REPLACE THE HOSE IMMEDIATELY.

NEVER USE TAPE OR ANY DEVICE TO ATTEMPT TO MEND THE HOSE.

6. AFTER EACH USE STORE IN A CLEAN DRY AREA.

D A N G E R

SEE OTHER SIDE

DO NOT REMOVE THIS TAG

DO NOT REMOVE THIS TAG

The rated working pressure of the hydraulic hose must be equal to or higher than the relief valve setting on the

hydraulic system.

HOSE PRESSURE RATING

11

Page 11

HTMA REQUIREMENTS

TOOL CATEGORY

HYDRAULIC SYSTEM

REQUIREMENTS TYPE 1 TYPE II TYPE III TYPE RR

FLOW RATE

TOOL OPERATING PRESSURE

(at the power supply outlet)

SYSTEM RELIEF VALVE SETTING

(at the power supply outlet)

MAXIMUM BACK PRESSURE

(at tool end of the return hose)

Measured at a max. fl uid viscosity of:

(at min. operating temperature)

TEMPERATURE

Suffi cient heat rejection capacity

to limit max. fl uid temperature to:

(at max. expected ambient temperature)

Min. cooling capacity

at a temperature difference of

between ambient and fl uid temps

NOTE:

Do not operate the tool at oil temperatures above 140° F (60° C). Operation at higher temperatures can cause operator

discomfort at the tool.

4-6 gpm 7-9 gpm 11-13 gpm 9-10.5 gpm

(15-23 lpm) (26-34 lpm) (42-49 lpm) (34-40 lpm)

2000 psi 2000 psi 2000 psi 2000 psi

(138 bar) (138 bar) (138 bar) (138 bar)

2100-2250 psi 2100-2250 psi 2100-2250 psi 2200-2300 psi

(145-155 bar) (145-155 bar) (145-155 bar) (152-159 bar)

250 psi 250 psi 250 psi 250 psi

(17 bar) (17 bar) (17 bar) (17 bar)

400 ssu* 400 ssu* 400 ssu* 400 ssu*

(82 centistokes) (82 centistokes) (82 centistokes) (82 centistokes)

140° F 140° F 140° F 140° F

(60° C) (60° C) (60° C) (60° C)

3 hp 5 hp 7 hp 6 hp

(2.24 kW) (3.73 kW) (4.47 kW) (5.22 kW)

40° F 40° F 40° F 40° F

(22° C) (22° C) (22° C) (22° C)

FILTER

Min. full-fl ow fi ltration

Sized for fl ow of at least:

(For cold temp. startup and max. dirt-holding capacity)

HYDRAULIC FLUID

Petroleum based

(premium grade, anti-wear, non-conductive)

VISCOSITY

(at min. and max. operating temps)

NOTE:

When choosing hydraulic fl uid, the expected oil temperature extremes that will be experienced in service determine the

most suitable temperature viscosity characteristics. Hydraulic fl uids with a viscosity index over 140 will meet the require-

ments over a wide range of operating temperatures.

*SSU = Saybolt Seconds Universal

NOTE:

These are general hydraulic system requirements. See tool Specifi cation page for tool specifi c requirements.

25 microns 25 microns 25 microns 25 microns

30 gpm 30 gpm 30 gpm 30 gpm

(114 lpm) (114 lpm) (114 lpm) (114 lpm)

100-400 ssu* 100-400 ssu* 100-400 ssu* 100-400 ssu*

(20-82 centistokes)

12

Page 12

OPERATION

PREOPERATION PROCEDURES

CHECK POWER SOURCE

1. Using a calibrated fl owmeter and pressure gauge, make

sure the hydraulic power source develops a fl ow of 4-6 gpm

/15-22 lpm at 1500-2000 psi/105/140 bar for the CS25 or a

fl ow of 7-9 gpm/26-34 lpm at 1000-2000 psi/70-140 bar for

the CS28.

2. Make sure the power source is equipped with a relief

valve set to open at 2100-2250 psi/145-155 bar.

3. Check that the dual spool valve is set to the hydraulic system type (open-center (CC) or closed-center (CC)

operation).

CHECK TOOL

1. Make sure all tool accessories are correctly installed.

Failure to install tool accessories properly can result in

damage to the tool or personal injury.

2. There should be no signs of leaks.

SETTING FOR OPEN-CENTER (OC) OR

CLOSED-CENTER (CC) OPERATION

To set the tool for OC system operation turn the selector

screw located in the top of the valve spool fully out (counter-clockwise) until it hits the stop.

To set the tool for CC system operation turn the selector

screw located in the top of the valve spool fully in (clockwise) until it bottoms.

TO DISABLE DUAL SPOOL OPERATION

AND CONVERT TO OC ONLY OPERATION

Turn the selector screw located in the top of the valve spool

fully out (counter-clockwise) until it hits the stop.

2. Insert the small plug from the kit (furnished with the tool)

into the hole located in the top of the selector screw. Tap

the plug down using a small punch and hammer. DO NOT

USE ANY ADHESIVES.

TO DISABLE DUAL SPOOL OPERATION

AND CONVERT TO CC ONLY OPERATION

3. The tool should be clean, with all fi ttings and fasteners

tight.

CHECK TRIGGER MECHANISM

1. Check that the trigger operates smoothly and is free to

travel between the "ON" and "OFF" positions.

SETTING THE DUAL SPOOL FOR OPERATION

This tool is furnished with a on-off spool commonly

referred to as a "dual spool" which permits adjustment so the tool may be operated on either a opencenter hydraulic system or a closed-center hydraulic

system. The dual spool is normally set to the opencenter (OC) position at time of manufacture. The

dual spool can also be disabled so that the tool may

be set to open-center only operation or closed-center

only operation. For more details, please refer to the

following instructions.

1. Turn the selector screw located in the top of the valve

spool fully in (clockwise) until it bottoms.

2. Insert the small plug from the kit (furnished with the tool)

into the hole located in the top of the selector screw. Tap

the plug down using a small punch and hammer. DO NOT

USE ANY ADHESIVES.

CONNECTING HOSES

1. Wipe all hose couplers with a clean lint-free cloth before

making connections.

2. Connect the hoses from the hydraulic power source to

the tool fi ttings or quick disconnects. It is a good practice

to connect return hoses fi rst and disconnect them last to

minimize or avoid trapped pressure within the tool.

3. Observe the arrow on the couplers to ensure that the

fl ow is in the proper direction. The female coupler on the

tool is the inlet (pressure) coupler.

4. Move the hydraulic circuit control valve to the ON position to operate the tool.

Note:

If uncoupled hoses are left in the sun, pressure increase inside the hoses can make them diffi cult to

connect. If possible, connect the free ends of the hoses

together.

13

Page 13

OPERATION

TOOL OPERATION

WARNING

The following are general woodcutting procedures

and techniques. Differences in the terrain, vegetation

and type of wood will make this information more or

less valid for particular areas. For adivce on specifi c

wood cutting problems or techniques for your area,

consult you local Stanley representative or your

county agent. They can often provide information that

will make your work safer and more productive.

CUTTING TIPS

1. Check the lean of the tree. tie a weight to a piece of

string about 2 feet long. Hang the weight in your line of

sight. the string is a good vertical line to help you judge

the lean of a tree. The tree should fall the way the string is

leaning. Trees that are straight (leaning no more than 5o)

generall can be felled in any direction.

2. Check the weight distribution. A tree is heavier on the

side with the most limbs. It will try to fall on its heavy side.

Trim a few limbs to balance the tree.

WARNING

Watch for falling limbs.

4. Make a diagonal cut down to meet the horizontal cut and

remove the wood from the notch.

FELLING OR BACK CUT

5. the felling or back cut is made on the side opposite and

at least 2-inches above the horizontal undercut (the felling

cut is made higher as the size of the tree increases).

6. Start the cut horizontally parallel to the notch cut. Cut until the saw is about 1- or 2-inches from the notch. DO NOT

CUT THROUGH THE NOTCH.

Note:

The uncut wood between the felling and notch cuts is

called the hinge. The hinge controls the fall of the tree

and should be of uniform thickness.

7. As the saw nears the back cut, watch the tree-top and

the cut for signs of meovement. Be alert as soon as the

tree starts to move, turn off the saw, pull it from the tree and

move away quickly on your escape route.

3. Clear the work area. You need a clean area all around

the tree. Get everything out of the area where the limbs

might fall. Do not cut trees near structures. Because of the

danger of electrocu tion, use extreme care when cutting

trees near power lines.

4. The chain saw should cut with very little pressure applied

to the handle. If you have to force the cut or if the cut is not

straight, cease cutting immediately to prevent further saw

chain and bar damage. See the MAINTENANCE AND ADJUSTMENTS section in this manual for chain replacement,

sharpening or adjustment proce dures.

FELLING OR TOPPING

1. Observe safety precautions.

NOTCHING OR UNDERCUTTING

2. The notching or undercutting cut is made on the side you

want the gree to fall.

3. Start the cut horizontally. Cut to about one-quarter of the

tree’s diameter.

Figure 1. Felling a Tree

LOGS/LIMBS WITH PRESSURE ON BOTTOM

1. Observe all safety precautions.

2. Begin with a bottom-cut. The depth of the cut should be

about one-third of the log diameter.

3. Finish with an upper cut, down from the top. The saw

cuts should meet.

PRUNING & TRIMMING

1. Observe all safety precautions.

14

Page 14

OPERATION

2. Use both hands. Keep a fi rm grip.

3. Be alert for kickback. Do not allow the tip of the bar to

touch anything while the chain is in motion.

Figure 2. Crosscutting Logs/Limbs with

Pressure on Bottom

4. Pole chain saws must be hung securely in a vertical

position to prevent dislodgement. Pole chain saws must not

be hung on utility wires or cables and must not be left in the

tree overnight. Pole chain saws must be hung so the sharp

edge is away from the worker, if possible.

5. Warnings, when necessary, must be given by the worker

in the tree before a limb is dropped. “Timber” or “heads up”

are common terms used for this purpose.

6. A separate line should be attached to limbs that cannot be dropped safely or are too heavy to be controlled by

hand. The line should be held by workers on the ground

end of the rope. Use of the same crotch for both the safety

rope and the work rope should be avoided.

7. The safety line or climbing rope must not be used for any

purpose but for climbing.

3. Workers performing topping operations should make

sure the trees are able to stand the strain of a topping procedure. If not, some other means of lowering the branches

should be provided, such as a tree crane.

4. If large limbs are lowered in sections, the worker in the

tree should be above the limb being lowered.

5. Guidelines, handlines, or tag lines must be used when

conditions warrant their use.

LIMING AND BUCKING

1. Observe all safety precautions.

2. Use both hands. Keep a fi rm grip.

3. When it is possible to do so, the tree worker must work

on the side opposite the side on which the limb is being cut.

4. Branches bent under tension must be considered hazardous.

COLD WEATHER OPERATION

If the pole chain saw is to be used during cold weather,

preheat the hydraulic fl uid at low engine speed. When us-

ing the normally recommended fl uids, fl uid should be at or

above 50º F/10º C (400 ssu/82 centistokes) before use.

Damage to the hydraulic system or pole chain saw can

result from use with fl uid that is too viscous or thick.

Cutting frozen wood causes the cutters to wear, crack and

break at the back rivet hole unless proper precautions are

taken. To extend chain life when cutting in cold weather:

• Be sure the automatic oiler is working.

• Keep the chain tensioned and check often.

• Keep the chain properly sharpened. Touch up at

least every hour. Never force a dull chain to cut.

• Clean out the bar groove and keep the oil hole

open. Turn the bar over to equalize wear on the

rails.

• Always install a new sprocket with a new chain.

8. Cut branches must not be left in trees overnight.

TOPPING/LOWERING LIMBS

1. Observe all safety precautions.

2. Use both hands. Keep a fi rm grip.

AUTOMATIC OILER ADJUSTMENT

1. Observe all safety precautions.

2. The automatic oiler is located in the front of the motor

housing. The oil volume can be adjusted with a 3/16-inch

allen wrench by turning the plug counter clockwise to in-

15

Page 15

crease output and turning clock wise to decrease output.

Note: Oil output varies proportionally to load and operating pressure. It should be adequate for most operations as adjusted from the factory.

3. Initial oiler adjustment is made with the saw bar and

chain removed.

The following step can be hazard ous. Failure to heed the

instructions could result in serious injury.

4. Connect the pole chain saw to a hydraulic power source

and check for proper operation. READ THE FOLLOWING

CAREFULLY BEFORE PROCEEDING.

7. Connect the pole chain saw to a hydraulic power source.

Operate the chain at low speed (gpm) for a minute or two

while pumping extra oil on the chain.

8. Stop the pole chain saw and check the tension.

If it has loosened, disconnect the pole chain saw from the

hydraulic power source and perform steps 3 through 6

again to tighten the chain to the correct tension.

9. Reconnect the pole chain saw to the hydraulic power

source. Operate the saw and make a few easy cuts. Check

chain tension and readjust if necessary (disconnect it from

the hydraulic power source and perform steps 3 through 6).

a. Make sure the hydraulic power source is running at the

lowest gpm/lpm rate it can while still producing full pressure.

b. Secure the pole chain saw fi rmly in a bench vise and

place the correct size wrench on the 1/2-20 nut securing

the sprocket.

c. Connect the hydraulic power source to the pole chain

saw and turn the circuit control valve to the “ON” position.

d. With a fi rm grip on the pole chain saw and wrench,

SLOWLY squeeze the trigger to ac tivate it.

e. Adjust the oiler for a fl ow of approximately one drop

every one to two seconds.

f. Release the trigger and remove the wrench.

CHAIN TENSION ADJUSTMENT

1. Observe all safety precautions.

2. When the chain appears loose, lubricate it well and let it

cool for a few minutes to allow for contraction of the chain.

Disconnect the pole chain saw from its hydraulic power

source.

Note: Never break in a new chain under a heavy cutting

load.

10. Watch the chain tension carefully for the fi rst half-hour

of cutting.

Note: Perform steps 3 through 6 while holding the top

end of the saw bar upward.

3. Loosen the two saw bar nuts slightly.

4. Tighten the chain tension screw until the bot toms of the

tie straps and cutters just touch the saw bar rails of the bottom of the saw bar.

5. Pull the chain around the saw bar by hand to be sure it

fi ts the sprocket and saw bar properly. The chain should

move easily.

6. Hold the saw bar tip up as you tighten the two saw bar

nuts.

16

Page 16

EQUIPMENT PROTECTION & CARE

In addition to the Safety

Precautions in this manual,

observe the following for

equipment protection and

care.

• Make sure all couplers are wiped clean before connection.

• The hydraulic circuit control valve must be in the “OFF” position when coupling or uncoupling

hydraulic tools. Failure to do so may result in damage to the quick couples and cause overheating

of the hydraulic system.

• Always store the tool in a clean dry space, safe from damage or pilferage.

• Make sure the circuit PRESSURE hose (with male quick disconnect) is connected to the “IN” port.

The circuit RETURN hose (with female quick disconnect) is connected to the opposite port. Do not

reverse circuit fl ow. This can cause damage to internal seals.

• Always replace hoses, couplings and other parts with replacement parts recommended by Stanley

Hydraulic Tools. Supply hoses must have a minimum working pressure rating of 2500 psi/172 bar.

• Do not exceed the rated fl ow (see Specifi cations) in this manual for correct fl ow rate and

model number. Rapid failure of the internal seals may result.

• Always keep critical tool markings, such as warning stickers and tags legible.

• Do not use the tool for applications it was not designed for. The chain saw is intended to cut wood only.

• Keep chain sharp for maximum tool performance.

• Tool repair should be performed by experienced personnel only.

• Make certain that the recommended relief valves are installed in the pressure side of the system.

• Do not use the tool for applications for which it was not intended.

17

Page 17

TROUBLESHOOTING

If symptoms of poor performance develop, the following chart can be used as a guide to correct the problem.

When diagnosing faults in operation of the pole chain saw, always make sure the hydraulic power source is supplying the

correct hydraulic fl ow and pressure as listed in the table. Use a fl owmeter know to be accurate. check the fl ow with the

hydraulic fl uid temperature at least 80o F/27o C.

PROBLEM CAUSE SOLUTION

Cuts slow. Insuffi cient fl uid fl ow or low relief valve

setting.

Chain dull. Sharpen per instructions or replace.

Backpressure too high. Should not exceed 250 psi/17 bar at

Bar turns color. Insuffi cient oiler fl ow. Adjust oiler per service instructions.

Tool does not run. Power unit not functioning. Check power unit for proper fl ow and

Coupler or hoses blocked. Remove obstruction.

Mechanical failure. Disassemble tool and inspect for dam-

Tool runs backwards. Pressure and return hoses reversed. Correct for proper fl ow direction.

Oil leakage around drive sprocket. Motor shaft seal failure. Replace as required. Make sure that

On/Off trigger is hard to press. Pressure and return hoses reversed. Correct for proper fl ow direction.

Backpressure too high. Should not exceed 250 psi/17 bar at

Motor sections oil leakage. Motor face seal failure. Replace as required.

Adjust fl uid fl ow to proper gpm. for op-

timum performance adjust relief vlave

to 2250 psi/155 bar.

rated fl ow measured at the end of the

tool operating hoses.

pressure 4-6 gpm/15-22 lpm at 1500

psi/104 bar minimum for CS28. 7-9

gpm/26-34 lpm at 1000 psi/70 bar

minimum for the CS25.

age.

Motor shaft rotates clockwise.

oil present is not the result of excess

oiler fl ow.

rated fl ow measured at the end of the

tool operating hoses.

18

Page 18

SPECIFICATIONS

Capacity

CS25 and CS28 ............................................................................................12 and 15 inch / 30 and 38 cm Cut Lengths

Weight (w/o Bar and Chain) ..............................................................................................................................8.5 lbs / 4 kg

Overall Length

10 inch Bar .........................................................................................................................................75 inches / 190 cm

12 inch Bar .........................................................................................................................................90 inches / 229 cm

15 inch Bar .........................................................................................................................................92 inches / 234 cm

Pressure

CS25 ....................................................................................................................................1500-2000 psi / 105-140 bar

CS28 ......................................................................................................................................1000-2000 psi / 70-140 bar

Flow Range

CS25 .................................................................................................................................................4-6 gpm / 15-22 lpm

CS28 .................................................................................................................................................7-9 gpm / 26-34 lpm

Optimum Flow

CS25 ..........................................................................................................................................................5 gpm / 19 lpm

CS28 ..........................................................................................................................................................8 gpm / 30 lpm

Porting ...........................................................................................................................................-8 (1/2 inch) SAE O-Ring

Connect Size and Type .............................................................................................................................. Adapter w/ Male

Hose Whips .......................................................................................................................................................................No

ACCESSORIES

Description Part Number

12 inch / 30 cm Saw Bar..............................................................................................................................................08347

15 inch / 38 cm Saw Bar..............................................................................................................................................07638

Saw Holster ................................................................................................................................................................. 05096

Saw Chain for 12 inch / 30 cm Bar 34SL (56 Drive Links) .......................................................................................... 08348

Saw Chain for 15 inch / 38 cm Bar 34SL (64 Drive Links) .......................................................................................... 07641

Sprocket 7T, .325 Pitch................................................................................................................................................ 07629

Grease Gun for Roller & Sprocket Nose Bars ............................................................................................................. 05132

Chain Guard for 18 inch / 46 cm Bar Length ............................................................................................................... 05144

File Guides ................................................................................................................................................................. 07935

Flat File .........................................................................................................................................................................11294

Scrench ........................................................................................................................................................................11464

SERVICE TOOLS

O-Ring Tool Kit ............................................................................................................................................................ 04337

19

Page 19

CS25/28 PARTS ILLUSTRATION

64

20

Page 20

CS25/28 PARTS LIST

Item Part No. Qty Description

1 19212 1 Capscrew

2 65834 1 Chain Guard

3 07631 2 Nut

4

5 07621 1 Chain Guide Plate

6 07630 2 Stud

7 07620 1 Bar Adjustment Nut

8 07632 1 Screw

9 04044 2 Needle Roller

10 04106 2 Driver Gear (8 gpm)

11 ---- -- No Item

12 07652 1 Rear Gear Housing Assy. (8 gpm)

13 00753 8 Capscrew

14 04041 4 Bushing

15 ---- -- No Item

16 07612 1 Idler Shaft

17 00020 1 O-ring

18 66201 1 Motor Housing Service Assy.

19 16668 4 O-ring

20 00453 1 Nut

21 07617 1 Washer

22 07629 1 Rim Sprocket

23 07616 1 Sprocket Adapter

24 06635 1 Retaining Ring

25 00335 1 Bearing

26 04856 1 Retaining Ring

27 07615 1 Seal Back-up Washer

28 04037 1 Seal

29 60975 1 Motor Shaft

30

31 18089 6 Capscrew

32

33

34 NA 1 Dielectric Test Decal

35 15863 1 Warning Decal

36 05153 1 Stanley Decal

37

38 15863 1 Danger Decal

39 12412 1 Electric Warning Decal

40 24833 1 Handle Assy

08348

07641

07832 2 Driver Gear (5 gpm)

07834 1 Rear Gear Housing Assy. (5 gpm)

65839

65840

65937

60973

62237

65936

00042

62238

03786

03782

11Saw Chain - 12 inch

Saw Chain - 15 inch

11Name Tag - CS25

Name Tag - CS28

Outer Tube Assy - CS258X1

Outer Tube Assy - CS288X1

1

Outer Tube Assy - CS288X2

Outer Tube Assy - CS258X2

Oil Tube Assy - CS2X8X1

2

Oil Tube Assy - CS2X8X2

7-9 GPM Decal

1

4-6 GPM Decal

Item Part No. Qty Description

41 07627 1 O-ring

42 19868 1 Spring

43 51183 1 Trigger

44 01534 1 Roll Pin

45 51182 1 Trigger Guard

46 22147 2 Capscrew

47 00936 2 Adapter

48 01605 2 O-ring

49 07626 1 O-ring

50 19874 1 Valve Spool

51 00026 1 O-ring

52 19875 1 Selector Spool

53 16070 1 Retaining Ring

54 26414 1 Lock Out Kit

55

56 02921 1 Automatic Oiler

57 01362 1 O-Ring

58 06971 1 Lock Nut

59 02634 2 Washer

60 07622 1 Chain Guide

61 04746 1 Automatic Oiler Decal

62 34685 1 Sound Power Level Decal (CE Only)

63

64 28323 1 CE Decal (CE Only)

65 28409 1 Composite Safety Decal (CE Only)

08347

07638

11206

11207

03693 1 Closed-Center Decal (Not Illustrated)

21053 1 Seal Kit

Saw Bar - 12 in.

1

Saw Bar - 15 in.

Circuit Type C Decal (CE Only)

1

Circuit Type D Decal (CE Only)

21

Page 21

WARRANTY

Stanley Hydraulic Tools (hereinafter called “Stanley”), subject to the exceptions contained below, warrants new hydraulic tools for a period of one year from the date of sale to

the fi rst retail purchaser, or for a period of 2 years from the shipping date from Stanley, whichever period expires fi rst, to be free of defects in material and/or workmanship at

the time of delivery, and will, at its option, repair or replace any tool or part of a tool, or new part, which is found upon examination by a Stanley authorized service outlet or by

Stanley’s factory in Milwaukie, Oregon to be DEFECTIVE IN MATERIAL AND/OR WORKMANSHIP.

EXCEPTIONS FROM WARRANTY

NEW PARTS: New parts which are obtained individually are warranted, subject to the exceptions herein, to be free of defects in material and/or workmanship at the time

of delivery and for a period of 6 months after the date of fi rst usage. Seals and diaphragms are warranted to be free of defects in material and/or workmanship at the time

of delivery and for a period of 6 months after the date of fi rst usage or 2 years after the date of delivery, whichever period expires fi rst. Warranty for new parts is limited to

replacement of defective parts only. Labor is not covered.

FREIGHT COSTS: Freight costs to return parts to Stanley, if requested by Stanley for the purpose of evaluating a warranty claim for warranty credit, are covered under this

policy if the claimed part or parts are approved for warranty credit. Freight costs for any part or parts which are not approved for warranty credit will be the responsibility of the

individual.

SEALS & DIAPHRAGMS: Seals and diaphragms installed in new tools are warranted to be free of defects in material and/or workmanship for a period of 6 months after the

date of fi rst usage, or for a period of 2 years from the shipping date from Stanley, whichever period expires fi rst.

CUTTING ACCESSORIES: Cutting accessories such as breaker tool bits are warranted to be free of defects in material and or workmanship at the time of delivery only.

ITEMS PRODUCED BY OTHER MANUFACTURERS: Components which are not manufactured by Stanley and are warranted by their respective manufacturers.

a. Costs incurred to remove a Stanley manufactured component in order to service an item manufactured by other manufacturers.

ALTERATIONS & MODIFICATIONS: Alterations or modifi cations to any tool or part. All obligations under this warranty shall be terminated if the new tool or part is altered or

modifi ed in any way.

NORMAL WEAR: any failure or performance defi ciency attributable to normal wear and tear such as tool bushings, retaining pins, wear plates, bumpers, retaining rings and

plugs, rubber bushings, recoil springs, etc.

INCIDENTAL/CONSEQUENTIAL DAMAGES: To the fullest extent permitted by applicable law, in no event will STANLEY be liable for any incidental, consequential or special

damages and/or expenses.

FREIGHT DAMAGE: Damage caused by improper storage or freight handling.

LOSS TIME: Loss of operating time to the user while the tool(s) is out of service.

IMPROPER OPERATION: Any failure or performance defi ciency attributable to a failure to follow the guidelines and/or procedures as outlined in the tool’s operation and

maintenance manual.

MAINTENANCE: Any failure or performance defi ciency attributable to not maintaining the tool(s) in good operating condition as outlined in the Operation and Maintenance

Manual.

HYDRAULIC PRESSURE & FLOW, HEAT, TYPE OF FLUID: Any failure or performance defi ciency attributable to excess hydraulic pressure, excess hydraulic back-pres-

sure, excess hydraulic fl ow, excessive heat, or incorrect hydraulic fl uid.

REPAIRS OR ALTERATIONS: Any failure or performance defi ciency attributable to repairs by anyone which in Stanley’s sole judgement caused or contributed to the failure

or defi ciency.

MIS-APPLICATION: Any failure or performance defi ciency attributable to mis-application. “Mis-application” is defi ned as usage of products for which they were not originally

intended or usage of products in such a matter which exposes them to abuse or accident, without fi rst obtaining the written consent of Stanley. PERMISSION TO APPLY ANY

PRODUCT FOR WHICH IT WAS NOT ORIGINALLY INTENDED CAN ONLY BE OBTAINED FROM STANLEY ENGINEERING.

WARRANTY REGISTRATION: STANLEY ASSUMES NO LIABILITY FOR WARRANTY CLAIMS SUBMITTED FOR WHICH NO TOOL REGISTRATION IS ON RECORD. In

the event a warranty claim is submitted and no tool registration is on record, no warranty credit will be issued without fi rst receiving documentation which proves the sale of

the tool or the tools’ fi rst date of usage. The term “DOCUMENTATION” as used in this paragraph is defi ned as a bill of sale, or letter of intent from the fi rst retail customer. A

WARRANTY REGISTRATION FORM THAT IS NOT ALSO ON RECORD WITH STANLEY WILL NOT BE ACCEPTED AS “DOCUMENTATION”.

NO ADDITIONAL WARRANTIES OR REPRESENTATIONS

This limited warranty and the obligation of Stanley thereunder is in lieu of all other warranties, expressed or implied including merchantability or fi tness for a particular purpose

except for that provided herein. There is no other warranty. This warranty gives

vary depending upon applicable law.

the purchaser specifi c legal rights and other rights may be available which might

22

Page 22

Stanley Hydraulic Tools

3810 SE Naef Road

Milwaukie, Oregon

503-659-5660 / Fax 503-652-1780

www.stanleyhydraulic.com

Loading...

Loading...