Page 1

CO25

HYDRAULIC

CUT-OFF SAW

USER MANUAL

Safety, Operation and Maintenance

© 2014 Stanley Black & Decker, Inc.

New Britain, CT 06053

U.S.A.

34962 4-2016 Ver-15

Page 2

Weisbeck, Andy

Directive/Standards

No.

Approved body

DECLARATION OF CONFORMITY

DECLARATION OF CONFORMITY

ÜBEREINSTIMMUNGS-ERKLARUNG

DECLARATION DE CONFORMITE CEE

DECLARACION DE CONFORMIDAD

DICHIARAZIONE DI CONFORMITA

________________ ___________________ ____________________ _______________

I, the undersigned:

Ich, der Unterzeichnende:

Je soussigné:

El abajo firmante:

lo sottoscritto:

hereby declare that the equipment specified hereunder:

bestätige hiermit, daß erklaren Produkt genannten Werk oder Gerät:

déclare que l’équipement visé ci-dessous:

Por la presente declaro que el equipo se especifica a continuación:

Dichiaro che le apparecchiature specificate di seguito:

Surname and First names/Familiennname und Vornamen/Nom et pr énom/Nombre y apellido/Cognome e nome

Hydraulic Tools

1. Category:

Kategorie:

Catégorie:

Categoria:

Categoria:

2. Make/Marke/Marque/Marca/Marca

3. Type/Typ/Type/Tipo/Tipo: CO2554101, CO2514101

4. Serial number of equipment:

Seriennummer des Geräts:

Numéro de série de l’équipement:

Numero de serie del equipo:

Matricola dell´attrezzatura:

Has been manufactured in conformity with

Wurde hergestellt in Übereinstimmung mit

Est fabriqué conformément

Ha sido fabricado de acuerdo con

E’ stata costruita in conformitá con

Richtlinie/Standards

Directives/Normes

Directriz/Los Normas

Direttiva/Norme

ISO

ISO

Machinery Directive

ISO

ISO

Nr

Numéro

No

n.

3744:2010

20643-A1:2012

2006/42/EC:2006

19432:2012

11148-7:2012

Cut-Off-Saw, Hydraulic

Stanley

All

Prüfung durch

Organisme agréé

Aprobado

Collaudato

Self

Self

Self

Self

Self

5. Special Provisions: None

Spezielle Bestimmungen:

Dispositions particulières:

Provisiones especiales:

Disposizioni speciali:

6. Representative in the Union: Patrick Vervier, Stanley Dubuis 17-19, rue Jules Berthonneau-BP 3406 41034 Blois Cedex, France.

Vertreter in der Union/Représentant dans l’union/Representante en la Union/Rappresentante presso l’Unione

Done at/Ort/Fait à/Dado en/Fatto a Stanley Hydraulic Tools, Milwaukie, Oregon USA

Signature/Unterschrift/Signature/Firma/Firma

Position/Position/Fonction/Cargo/Posizione Director of Product Development

2 ► CO25 User Manual

Date/Datum/le/Fecha/Data 8-10-2013

Page 3

TABLE OF CONTENTS

CERTIFICATE OF CONFORMITY ...................................................................................................................................................2

SAFETY SYMBOLS .........................................................................................................................................................................4

SAFETY PRECAUTIONS ................................................................................................................................................................5

TOOL STICKERS & TAGS ..............................................................................................................................................................7

HYDRAULIC HOSE TYPES ............................................................................................................................................................8

HOSE RECOMMENDATIONS .........................................................................................................................................................9

HTMA / EHTMA REQUIREMENTS ................................................................................................................................................10

OPERATION .................................................................................................................................................................................. 11

PREOPERATION PROCEDURES ................................................................................................................................................11

CONNECT HOSES ........................................................................................................................................................................11

TOOL OPERATION ....................................................................................................................................................................... 11

STARTUP .......................................................................................................................................................................................11

GENERAL OPERATION ................................................................................................................................................................ 12

WET CUTTING ..............................................................................................................................................................................12

BROKEN CUT-OFF WHEELS .......................................................................................................................................................12

SHUTDOWN ..................................................................................................................................................................................12

PERIODIC MAINTENANCE ..........................................................................................................................................................13

THRUST COLLAR AND INSIDE/OUTSIDE COLLAR INSPECTION ............................................................................................13

DRIVE-SHAFT SPEED CHECK ....................................................................................................................................................13

BEARING CHECK .........................................................................................................................................................................13

CARE AND STORAGE ..................................................................................................................................................................13

CUTOFF WHEELS ........................................................................................................................................................................13

TOOL .............................................................................................................................................................................................13

CUTOFF WHEEL REPLACEMENT ...............................................................................................................................................14

COLD WEATHER OPERATION ....................................................................................................................................................14

SAW CART ASSEMBLY ........................................................................................................................................................ 15 - 17

EQUIPMENT PROTECTION & CARE ...........................................................................................................................................18

TROUBLESHOOTING ...................................................................................................................................................................19

SPECIFICATIONS .........................................................................................................................................................................20

ACCESSORIES .............................................................................................................................................................................20

CO25 PARTS ILLUSTRATION ......................................................................................................................................................21

CO25 PARTS LIST ........................................................................................................................................................................22

IMPORTANT

To ll out a Product Warranty Validation form, and for information on your warranty,

visit Stanleyhydraulics.com and select the Company tab, Warranty.

(NOTE: The warranty Validation record must be submitted to validate the warranty).

SERVICING: This manual contains safety, operation, and routine maintenance instructions. Stanley Hydraulic Tools

recommends that servicing of hydraulic tools, other than routine maintenance, must be performed by an authorized

and certied dealer. Please read the following warning.

WARNING

SERIOUS INJURY OR DEATH COULD RESULT FROM THE IMPROPER REPAIR OR

SERVICE OF THIS TOOL.

REPAIRS AND / OR SERVICE TO THIS TOOL MUST ONLY BE DONE BY AN

AUTHORIZED AND CERTIFIED DEALER.

For the nearest authorized and certied dealer, call Stanley Hydraulic Tools at the number listed on the back of this

manual and ask for a Customer Service Representative.

CO25 User Manual ◄ 3

Page 4

DANGER

WARNING

CAUTION

NOTICE

IMPORTANT

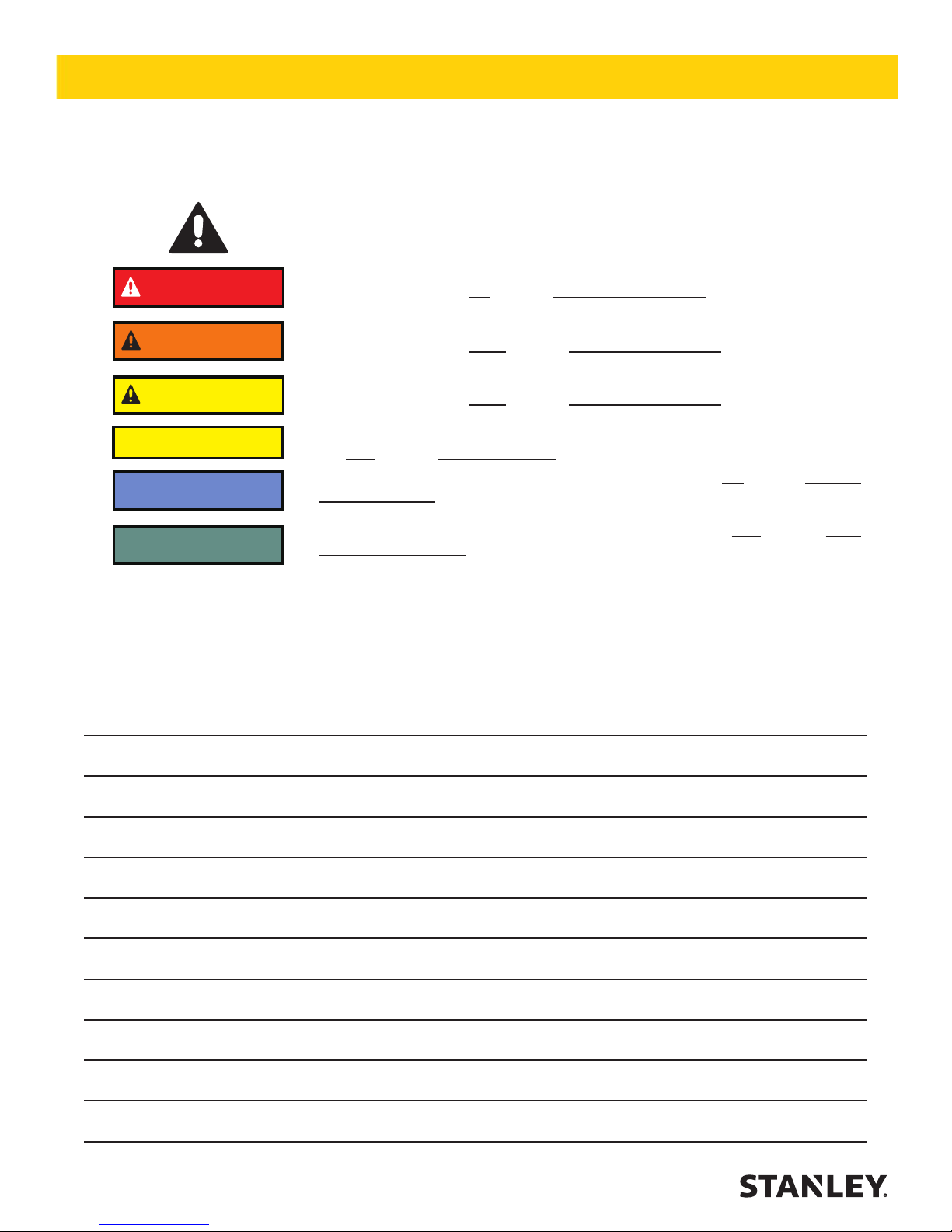

SAFETY SYMBOLS

Safety symbols and signal words, as shown below, are used to emphasize all operator, maintenance and repair actions which, if not strictly followed, could result in a life-threatening situation, bodily injury or damage to equipment.

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid possible

injury or death.

This safety alert and signal word indicate an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

This safety alert and signal word indicate a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

This safety alert and signal word indicate a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION

Always observe safety symbols. They are included for your safety and for the protection of the tool.

This signal word indicates a potentially hazardous situation which, if not avoided, may result in property damage.

This signal word indicates a situation which, if not avoided, will result in damage

to the equipment.

This signal word indicates a situation which, if not avoided, may result in damage to the equipment.

LOCAL SAFETY REGULATIONS

Enter any local safety regulations here. Keep these instructions in an area accessible to the operator and maintenance personnel.

4 ► CO25 User Manual

Page 5

SAFETY PRECAUTIONS

Tool operators and maintenance personnel must always

comply with the safety precautions given in this manual and

on the stickers and tags attached to the tool and hose.

These safety precautions are given for your safety. Review

them carefully before operating the tool and before performing general maintenance or repairs.

Supervising personnel should develop additional precau-

tions relating to the specic work area and local safety

regulations. If so, place the added precautions in the

space provided on the previous page.

The CO25 Hydraulic Cut-Off Saw will provide safe and

dependable service if operated in accordance with the

instructions given in this manual. Read and understand

this manual and any stickers and tags attached to the tool

and hose before operation. Failure to do so could result in

personal injury or equipment damage.

• The operator must start in a work area without bystanders. Flying debris can cause serious injury.

• Do not operate the tool unless thoroughly trained or under

the supervision of an instructor. Establish a training program for all operators to ensure safe operation.

• Always wear safety equipment such as goggles, ear,

breathing and head protection, and safety shoes at all

times when operating the tool. Use gloves and aprons

when necessary.

• Do not operate a damaged, improperly adjusted, or

incompletely assembled tools.

• Never wear loose clothing that can get entangled in the

working parts of the tool.

• Keep all parts of your body away from the rotating

parts. Long hair or loose clothing can become drawn into

rotating components.

• Always use accessories that conform to the specications given in this manual.

• Release the trigger if the power supply has been interrupted.

• When working near electrical conductors, always assume that all conductors are energized and that insulation, clothing and hoses can conduct electricity. Use hose

labeled and certied as non-conductive.

• To avoid personal injury or equipment damage, all tool

repair, maintenance and service must only be performed

by authorized and properly trained personnel.

Warning: Use of this tool on certain materials during

demolition could generate dust potentially containing

a variety of hazardous substances such as asbestos,

silica or lead. Inhalation of dust containing these or other

hazardous substances could result in serious injury,

cancer or death. Protect yourself and those around you.

Research and understand the materials you are cutting. Follow correct safety procedures and comply with

all applicable national, state or provisional health and

safety regulations relating to them, including, if appropriate arranging for the safe disposal of the materials by a

qualied person.

• The operator must be familiar with all prohibited work

areas such as excessive slopes and dangerous terrain

conditions.

• Maintain proper footing and balance at all times. Alway

hold the tool with both hands when the unit is running. Use

a rm grip.

• Do not inspect or clean the tool while the hydraulic power

source is connected. Accidental engagement of the tool

can cause serious injury.

• Always connect hoses to the tool hose couplers before

energizing the hydraulic power source. Be sure all hose

connections are tight and are in good condition.

• Do not operate the tool at oil temperatures above

140°F/60°C. Operation at higher temperatures can cause

higher than normal temperatures at the tool which can

result in operator discomfort.

CO25 User Manual ◄ 5

Page 6

SAFETY PRECAUTIONS

• Never carry the tool or put it down while the wheel is

rotating. Make sure it is completely stopped before moving

your position or set the tool down.

• Do not operate the tool with the wheel guard removed.

• Keep the handles dry, clean and free of oil at all times.

• Operate the tool in well ventilated areas only.

• Do not operate the tool if the wheel does not stop when

the trigger is released.

• Inspect the wheel guard and collars for damage after any

wheel breakage on the tool.

• Always use full throttle when cutting.

• Never cock, jam or wedge the wheel during the cut. Do

not use the side of the wheel as a cutting surface and be

aware of kick-back from the saw.

• Make sure the tool is designed for the wheel direction

suitable for the job. Do not reverse the direction of the

wheel rotation by changing the direction of the oil ow.

• Always operate the tool within its rated capacity. Never

exceed the maximum operating speed marked on the

wheel.

• Do not operate the tool near ammable materials, sparks

can ignite ammable or combustible materials.

• Do not over-reach.

• Do not use the tool for applications for which it was not

designed.

• Keep the wheel off all surfaces when starting the saw.

• Do not attempt to adjust the ow control on the valve

handle.

• Know the location of buried or covered services before

starting work.

• Adjust the wheel guard so it is between you and the cutting wheel.

• Never operate the tool when you are tired.

CUT-OFF WHEEL SAFETY

mounted on the saw.

• If the cut-off saw is dropped with a cutting wheel installed, thoroughly examine the cutting wheel before use.

• Make sure the cutting wheel is correctly mounted and

tightened before use.

• Operate the cut-off saw at no load for 30 seconds in a

safe position. If considerable vibration or other defects

are detected, stop operation of the tool immediately and

determine the cause. Do not use the tool until the defect

is corrected.

• Only use cutting wheels that comply with ANSI B7.5/

ISO 525, 603.

• Check that the maximum operating speed of the cutting

wheel is equal to or greater than the rated shaft speed

of the cut-off saw. Wheels must be rated at 4700 rpm

minimum.

• Warning: Hydraulic uid under pressure could cause

skin injection injury. If you are injured by hydraulic

uid, get medical attention immediately

• Always support and secure items being worked on.

• Caution when handling the work piece after cutting,

object can be hot and have sharp edges, use your personal protection equipment.

• Keep your work area clean and clear of tripping hazards, oily surfaces and hoses laying about can be hazardous.

• Make sure adequate lighting is always available.

• Never operate the tool if you cannot be sure that

underground utilities are not present. Underground

electrical utilities present an electrocution hazard.

Underground gas utilities present an explosion hazard.

Other underground utilities may present other hazards.

• Do not operate this tool in a potentially explosive environment. Do not grind on vessels containing combustible

substances.

• Any use of this tool outside those stated in this manual

are forbidden.

• Always inspect the cut-off wheels for possible damage before operating the tool. Do not use a wheel that is cracked

or otherwise damaged.

• Never transport or store the tool with the cut-off wheel

6 ► CO25 User Manual

Page 7

Stanley Hydraulic tools

Division of the Stanley Works

3810 SE Naef Road

Milwaukie, OR 97267

D

PROTECT YOUR EYES...

WEAR SAFETY GOGGLES

30 LPM @ 138 BAR

EHTMA CATEGORY

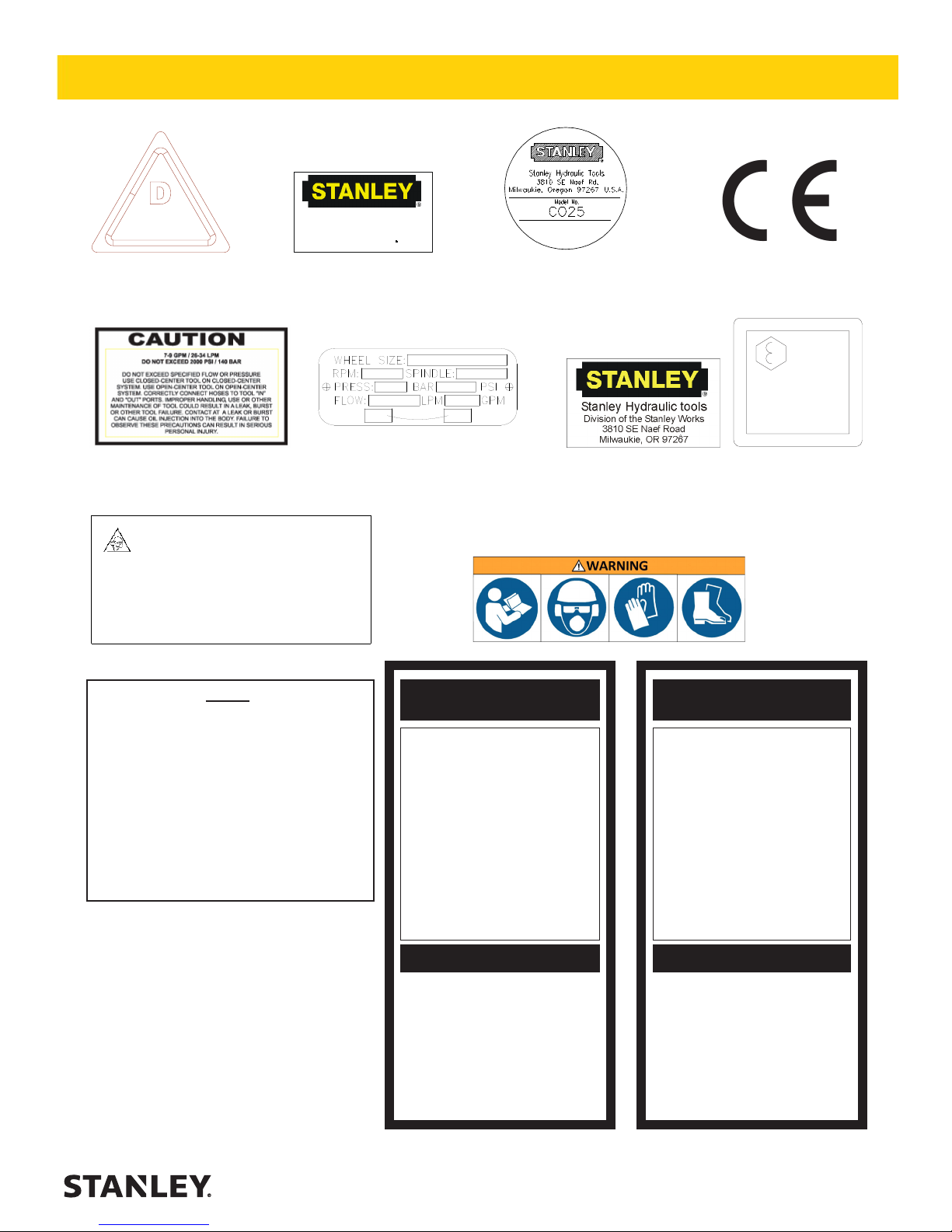

TOOL STICKERS & TAGS

11207

CIRCUIT TYPE D DECAL

05152

ADDRESS DECAL

(CE MODELS ONLY)

03786

GPM DECAL

28811

INFORMATION PLAQUE

CAUTION

1. DO NOT USE DAMAGED WHEELS.

2. USE FULL TROTTLE ONLY WHILE CUTTING.

3. USE ONLY WHEELS MARKED HIGH SPEED REINFORCED THAT MEET

REQUIREMENTS OF ANSI B7.1,B7.5 WHEELS SHOULD BE NO LARGER THAN

14" DIA X 5/32" THICK WITH A 1" ARBOR HOLE & RATED FOR 5300 RPM

MINIMUM SPEED.

4. INSPECT WHEEL GUARD & COLLARS FOR DAMAGE AFTER ANY WHEEL

BREAKAGE ON THE MACHINE.

5. MAXIMUM SPINDLE SPEED IS 5300 RPM.

6. READ OPERATION MANUAL.

05868 SAFETY LABEL

NOTE

33206

CO25 NAME TAG

05153

ADDRESS DECAL

(CE MODELS ONLY)

28322

CE DECAL

(CE MODELS ONLY)

Lwa

113

52539

SOUND POWER DECAL

(CE MODELS ONLY)

28886

COMPOSITE DECAL

(CE MODELS ONLY)

DANGERDANGER

THE INFORMATION LISTED ON

THE STICKERS SHOWN, MUST BE

LEGIBLE AT ALL TIMES.

REPLACE DECALS IF THEY

BECOME WORN OR DAMAGED.

REPLACEMENTS ARE AVAILABLE

FROM YOUR LOCAL STANLEY

DISTRIBUTOR.

The safety tag (P/N 15875) at right is attached to

the tool when shipped from the factory. Read and

understand the safety instructions listed on this tag

before removal. We suggest you retain this tag and

attach it to the tool when not in use.

1. FAILURE TO USE HYDRAULIC HOSE LABELED AND CERTIFIED AS NON-CONDUCTIVE WHEN USING HYDRAULIC

TOOLS ON OR NEAR ELECTRICAL LINES MAY RESULT IN

DEATH OR SERIOUS INJURY.

BEFORE USING HOSE LABELED AND CERTIFIED AS NON-

CONDUCTIVE ON OR NEAR ELECTRIC LINES BE SURE THE

HOSE IS MAINTAINED AS NON-CONDUCTIVE. THE HOSE

SHOULD BE REGULARLY TESTED FOR ELECTRIC CURRENT LEAKAGE IN ACCORDANCE WITH YOUR SAFETY

DEPARTMENT INSTRUCTIONS.

2. A HYDRAULIC LEAK OR BURST MAY CAUSE OIL INJECTION INTO THE BODY OR CAUSE OTHER SEVERE

PERSONAL INJURY.

A. DO NOT EXCEED SPECIFIED FLOW AND PRESSURE

FOR THIS TOOL. EXCESS FLOW OR PRESSURE MAY

CAUSE A LEAK OR BURST.

B. DO NOT EXCEED RATED WORKING PRESSURE OF

HYDRAULIC HOSE USED WITH THIS TOOL. EXCESS

PRESSURE MAY CAUSE A LEAK OR BURST.

C. CHECK TOOL HOSE COUPLERS AND CONNECTORS

DAILY FOR LEAKS. DO NOT FEEL FOR LEAKS WITH

YOUR HANDS. CONTACT WITH A LEAK MAY RESULT

IN SEVERE PERSONAL INJURY.

IMPORTANT

READ OPERATION MANUAL AND

SAFETY INSTRUCTIONS FOR THIS

TOOL BEFORE USING IT.

USE ONLY PARTS AND REPAIR

PROCEDURES APPROVED BY

STANLEY AND DESCRIBED IN THE

OPERATION MANUAL.

TAG TO BE REMOVED ONLY BY

TOOL OPERATOR.

SEE OTHER SIDE

D. DO NOT LIFT OR CARRY TOOL BY THE HOSES. DO

NOT ABUSE HOSE. DO NOT USE KINKED, TORN OR

DAMAGED HOSE.

3. MAKE SURE HYDRAULIC HOSES ARE PROPERLY CONNECTED TO THE TOOL BEFORE PRESSURING SYSTEM.

SYSTEM PRESSURE HOSE MUST ALWAYS BE CONNECTED TO TOOL “IN” PORT. SYSTEM RETURN HOSE

MUST ALWAYS BE CONNECTED TO TOOL “OUT” PORT.

REVERSING CONNECTIONS MAY CAUSE REVERSE

TOOL OPERATION WHICH CAN RESULT IN SEVERE

PERSONAL INJURY.

4. DO NOT CONNECT OPEN-CENTER TOOLS TO CLOSEDCENTER HYDRAULIC SYSTEMS. THIS MAY RESULT IN

LOSS OF OTHER HYDRAULIC FUNCTIONS POWERED BY

THE SAME SYSTEM AND/OR SEVERE PERSONAL INJURY.

5. BYSTANDERS MAY BE INJURED IN YOUR WORK AREA.

KEEP BYSTANDERS CLEAR OF YOUR WORK AREA.

6. WEAR HEARING, EYE, FOOT, HAND AND HEAD PROTECTION.

7. TO AVOID PERSONAL INJURY OR EQUIPMENT DAMAGE,

ALL TOOL REPAIR MAINTENANCE AND SERVICE MUST

ONLY BE PERFORMED BY AUTHORIZED AND PROPERLY

TRAINED PERSONNEL.

IMPORTANT

READ OPERATION MANUAL AND

SAFETY INSTRUCTIONS FOR THIS

USE ONLY PARTS AND REPAIR

PROCEDURES APPROVED BY

STANLEY AND DESCRIBED IN THE

TAG TO BE REMOVED ONLY BY

SAFETY TAG P/N 15875 (Shown smaller then actual size)

TOOL BEFORE USING IT.

OPERATION MANUAL.

TOOL OPERATOR.

SEE OTHER SIDE

CO25 User Manual ◄ 7

Page 8

HOSE TYPES

The rated working pressure of the hydraulic hose must be equal to or higher than the relief valve setting on the hydraulic system. There are three types of hydraulic hose that meet this requirement and are authorized for use with

Stanley Hydraulic Tools. They are:

Certied non-conductive — constructed of thermoplastic or synthetic rubber inner tube, synthetic ber braid

reinforcement, and weather resistant thermoplastic or synthetic rubber cover. Hose labeled certied non-

conductive is the only hose authorized for use near electrical conductors.

Wire-braided (conductive) — constructed of synthetic rubber inner tube, single or double wire braid reinforcement, and weather resistant synthetic rubber cover. This hose is conductive and must never be used near

electrical conductors.

Fabric-braided (not certied or labeled non-conductive) — constructed of thermoplastic or synthetic rubber inner tube, synthetic ber braid reinforcement, and weather resistant thermoplastic or synthetic rubber cover. This

hose is not certied non-conductive and must never be used near electrical conductors.

HOSE SAFETY TAGS

To help ensure your safety, the following DANGER tags are attached to all hose purchased from Stanley Hydraulic

Tools. DO NOT REMOVE THESE TAGS.

If the information on a tag is illegible because of wear or damage, replace the tag immediately. A new tag may be

obtained from your Stanley Distributor.

THE TAG SHOWN BELOW IS ATTACHED TO “CERTIFIED NON-CONDUCTIVE” HOSE

DANGER

1. FAILURE TO USE HYDRAULIC HOSE LABELED AND CERTIFIED AS NON-CONDUCTIVE

WHEN USING HYDRAULIC TOOLS ON OR NEAR ELECTRIC LINES MAY RESULT IN

DEATH OR SERIOUS INJURY.

FOR PROPER AND SAFE OPERATION MAKE SURE THAT YOU HAVE BEEN PROPERLY TRAINED IN CORRECT PROCEDURES REQUIRED FOR WORK ON OR AROUND

ELECTRIC LINES.

2. BEFORE USING HYDRAULIC HOSE LABELED AND CERTIFIED AS NON-CONDUCTIVE

ON OR NEAR ELECTRIC LINES. WIPE THE ENTIRE LENGTH OF THE HOSE AND FITTING WITH A CLEAN DRY ABSORBENT CLOTH TO REMOVE DIRT AND MOISTURE AND

TEST HOSE FOR MAXIMUM ALLOWABLE CURRENT LEAKAGE IN ACCORDANCE WITH

SAFETY DEPARTMENT INSTRUCTIONS.

DO NOT REMOVE THIS TAG

SEE OTHER SIDE

SIDE 1

3. DO NOT EXCEED HOSE WORKING PRESSURE OR ABUSE HOSE. IMPROPER USE

OR HANDLING OF HOSE COULD RESULT IN BURST OR OTHER HOSE FAILURE.

KEEP HOSE AS FAR AWAY AS POSSIBLE FROM BODY AND DO NOT PERMIT DIRECT

CONTACT DURING USE. CONTACT AT THE BURST CAN CAUSE BODILY INJECTION

AND SEVERE PERSONAL INJURY.

4. HANDLE AND ROUTE HOSE CAREFULLY TO AVOID KINKING, ABRASION, CUTTING, OR

CONTACT WITH HIGH TEMPERATURE SURFACES. DO NOT USE IF KINKED. DO NOT

USE HOSE TO PULL OR LIFT TOOLS, POWER UNITS, ETC.

5. CHECK ENTIRE HOSE FOR CUTS CRACKS LEAKS ABRASIONS, BULGES, OR DAMAGE TO COUPLINGS IF ANY OF THESE CONDITIONS EXIST, REPLACE THE HOSE

IMMEDIATELY. NEVER USE TAPE OR ANY DEVICE TO ATTEMPT TO MEND THE HOSE.

6. AFTER EACH USE STORE IN A CLEAN DRY AREA.

(Shown smaller than actual size)

DANGER

DANGER

SEE OTHER SIDE

SIDE 2

THE TAG SHOWN BELOW IS ATTACHED TO “CONDUCTIVE” HOSE.

DANGER

DANGER

1. DO NOT USE THIS HYDRAULIC HOSE ON OR NEAR ELECTRIC LINES. THIS HOSE IS

NOT LABELED OR CERTIFIED AS NON-CONDUCTIVE. USING THIS HOSE ON OR NEAR

ELECTRICAL LINES MAY RESULT IN DEATH OR SERIOUS INJURY.

2. FOR PROPER AND SAFE OPERATION MAKE SURE THAT YOU HAVE BEEN PROPERLY

TRAINED IN CORRECT PROCEDURES REQUIRED FOR WORK ON OR AROUND ELECTRIC LINES.

3. DO NOT EXCEED HOSE WORKING PRESSURE OR ABUSE HOSE. IMPROPER USE OR

HANDLING OF HOSE COULD RESULT IN BURST OR OTHER HOSE FAILURE. KEEP HOSE

AS FAR AWAY AS POSSIBLE FROM BODY AND DO NOT PERMIT DIRECT CONTACT

DURING USE. CONTACT AT THE BURST CAN CAUSE BODILY INJECTION AND SEVERE

PERSONAL INJURY.

4. HANDLE AND ROUTE HOSE CAREFULLY TO AVOID KINKING, CUTTING, OR CONTACT

WITH HIGH TEMPERATURE SURFACES. DO NOT USE IF KINKED. DO NOT USE HOSE TO

PULL OR LIFT TOOLS, POWER UNITS, ETC.

DO NOT REMOVE THIS TAG

SEE OTHER SIDE

SIDE 1

5. CHECK ENTIRE HOSE FOR CUTS CRACKS LEAKS ABRASIONS, BULGES, OR DAMAGE TO

COUPLINGS IF ANY OF THESE CONDITIONS EXIST, REPLACE THE HOSE IMMEDIATELY.

NEVER USE TAPE OR ANY DEVICE TO ATTEMPT TO MEND THE HOSE.

6. AFTER EACH USE STORE IN A CLEAN DRY AREA.

(Shown smaller than actual size)

DANGER

SEE OTHER SIDE

SIDE 2

DO NOT REMOVE THIS TAG

DO NOT REMOVE THIS TAG

8 ► CO25 User Manual

Page 9

Min. Working Pressure

USE

(Press/Return)

HOSE RECOMMENDATIONS

Certied Non-Conductive Hose - Fiber Braid - for Utility Bucket Trucks

Oil Flow Hose Lengths Inside Diameter

GPM LPM FEET METERS INCH MM PSI BAR

4-9 15-34 up to 10 up to 3 3/8 10 Both 2250 155

Conductive Hose - Wire Braid or Fiber Braid -DO NOT USE NEAR ELECTRICAL CONDUCTORS

4-6 15-23 up to 25 up to 7.5 3/8 10 Both 2500 175

4-6 15-23 26-100 7.5-30 1/2 13 Both 2500 175

5-10.5 19-40 up to 50 up to 15 1/2 13 Both 2500 175

5-10.5 19-40 51-100 15-30 5/8 16 Both 2500 175

5/8 16 Pressure 2500 175

3/4 19 Return 2500 175

5-10.5 19-40 100-300 30-90

10-13 38-49 up to 50 up to 15 5/8 16 Both 2500 175

5/8 16 Pressure 2500 175

3/4 19 Return 2500 175

10-13 38-49 51-100 15-30

3/4 19 Pressure 2500 175

1 25.4 Return 2500 175

10-13 38-49 100-200 30-60

5/8 16 Pressure 2500 175

13-16 49-60 up to 25 up to 8

3/4 19 Return 2500 175

3/4 19 Pressure 2500 175

1 25.4 Return 2500 175

13-16 49-60 26-100 8-30

PRESSURE

<<< FLOW

RETURN

FLOW >>>

Figure 1. Typical Hose Connections

Tool to Hydraulic Circuit Hose

Recommendations

The chart to the right shows recommended

minimum hose diameters for various hose

lengths based on gallons per minute (gpm)/

liters per minute (lpm). These recommenda-

tions are intended to keep return line pressure

(back pressure) to a minimum acceptable lev-

el to ensure maximum tool performance.

This chart is intended to be used for hydraulic

tool applications only based on Stanley Hy-

draulic Tools tool operating requirements and

should not be used for any other applications.

All hydraulic hose must have at least a rated

minimum working pressure equal to the maxi-

mum hydraulic system relief valve setting.

All hydraulic hose must meet or exceed

specications as set forth by SAE J517.

CO25 User Manual ◄ 9

Page 10

HTMA / EHTMA REQUIREMENTS

HTMA / EHTMA REQUIREMENTS

HTMA

HYDRAULIC SYSTEM REQUIREMENTS

Flow Range

Nominal Operating Pressure

(at the power supply outlet)

System relief valve setting

(at the power supply outlet)

Maximum back pressure

(at tool end of the return hose)

Measured at a max. uid viscosity of:

(at min. operating temperature)

Temperature: Sufcient heat rejection

capacity to limit max. uid temperature to:

(at max. expected ambient temperature)

Min. cooling capacity at a temperature

difference of between ambient and uid

temps

NOTE:

Do not operate the tool at oil temperatures above 140° F (60° C). Operation at higher temperatures can cause operator

discomfort at the tool.

Filter

Min. full-ow ltration

Sized for ow of at least:

(For cold temp. startup and max.

dirt-holding capacity)

4-6 gpm 7-9 gpm 9-10.5 gpm 11-13 gpm

(15-23 lpm) (26-34 lpm) (34-40 lpm) (42-49 lpm)

1500 psi 1500 psi 1500 psi 1500 psi

(103 bar) (103 bar) (103 bar) (103 bar)

2100-2250 psi 2100-2250 psi 2200-2300 psi 2100-2250 psi

(145-155 bar) (145-155 bar) (152-159 bar) (145-155 bar)

250 psi 250 psi 250 psi 250 psi

(17 bar) (17 bar) (17 bar) (17 bar)

400 ssu* 400 ssu* 400 ssu* 400 ssu*

(82 centistokes) (82 centistokes) (82 centistokes) (82 centistokes)

140° F 140° F 140° F 140° F

(60° C) (60° C) (60° C) (60° C)

3 hp 5 hp 6 hp 7 hp

(2.24 kW) (3.73 kW) (5.22 kW) (4.47 kW)

40° F 40° F 40° F 40° F

(22° C) (22° C) (22° C) (22° C)

25 microns 25 microns 25 microns 25 microns

30 gpm 30 gpm 30 gpm 30 gpm

(114 lpm) (114 lpm) (114 lpm) (114 lpm)

TYPE I TYPE II

TOOL TYPE

TYPE RR

TYPE III

Hydraulic uid Petroleum based

(premium grade, anti-wear, non-conductive)

Viscosity (at min. and max. operating temps)

NOTE:

When choosing hydraulic uid, the expected oil temperature extremes that will be experienced in service determine the

most suitable temperature viscosity characteristics. Hydraulic uids with a viscosity index over 140 will meet the requirements

over a wide range of operating temperatures.

*SSU = Saybolt Seconds Universal

EHTMA

100-400 ssu* 100-400 ssu* 100-400 ssu* 100-400 ssu*

(20-82 centistokes)

CLASSIFICATION

HYDRAULIC SYSTEM

REQUIREMENTS

Flow Range

Nominal Operating Pressure

(at the power supply outlet)

System relief valve setting

(at the power supply outlet)

NOTE: These are general hydraulic system requirements. See tool specication page for tool specic requirements

B

3.5-4.3 gpm 4.7-5.8 gpm 7.1-8.7 gpm 9.5-11.6 gpm 11.8-14.5 gpm

(13.5-16.5 lpm) (18-22 lpm) (27-33 lpm) (36-44 lpm) (45-55 lpm)

1870 psi 1500 psi 1500 psi 1500 psi 1500 psi

(129 bar) (103 bar) (103 bar) (103 bar) (103 bar)

2495 psi 2000 psi 2000 psi 2000 psi 2000 psi

(172 bar) (138 bar) (138 bar) (138 bar) (138 bar)

C

D

10 ► CO25 User Manual

Page 11

OPERATION

PREOPERATION PROCEDURES

CHECK THE POWER SOURCE

Careful inspection of the tool and hydraulic system before

startup is important for safe, reliable operation of the tool.

1. Using a calibrated owmeter and pressure gauge, check

that the hydraulic power source develops a ow of 7–9 gpm

(26–34 lpm) at 2000 psi (140 bar).

2. Make certain the hydraulic power source is equipped

with a relief valve set to open at 2100–2250 psi (145–155

bar).

CHECK THE TOOL

The following items should be checked daily.

Make sure the hydraulic system control valve is in the

“OFF” position and the hoses are disconnected before

inspecting the cutoff saw.

1. Inspect the cut-off wheel and guard. Make sure the correct cut-off wheel is installed for the job. If not, follow the

instructions for Cut-off Wheel Replacement section of this

manual.

3. Check that the safety catch on the handle assembly is

operating properly. It should prevent engagement of the

trigger unless the catch is pressed down fully in the handle

slot.

CONNECT HOSES

1. Wipe all hose couplers with a clean, lint-free cloth before

making connections.

2. Connect hoses from the hydraulic power source to the

tool ttings or quick disconnects. It is good practice to connect the return hose rst and disconnect it last to minimize

or eliminate trapped pressure within the wrench.

3. Observe the ow indicators stamped on the valve handle

assembly and the hose couplers to ensure that the ow is

in the proper directions. The female couple on the tools “IN”

port is the inlet (pressure) coupler.

Note:

If the uncoupled hoses are left in the sun, pressure

increase within the hoses can make them difcult to

connect. Whenever possible, connect the free ends of

hoses together.

TOOL OPERATION

2. Inspect the wheel for chips, cracks, or other damage. For

maximum tool performance, replace the wheel if it is worn

or defective.

3. Inspect the wheel guard for cracks or other structural

damage.

4. There should be no signs of leaks.

5. Inspect the handlebar. Make sure the handlebar is securely fastened to the cutoff saw and is clean of any oil to

ensure a rm grip.

IMPORTANT

Check the speed of the motor output shaft after every

100 hours of operation.

CHECK TRIGGER MECHANISM

1. Inspect the trigger and safety catch. Make sure the trigger operates smoothly and is free to travel between the

“ON: and “OFF” positions.

STARTUP

1. Move the hydraulic system control valve to the “ON”

position.

2. At the beginning of each shift, or after a new wheel is

installed, run the cut-off saw at operating speed for at least

one minute before starting work.

HANDHELD CONFIGURATION:

1.Press the safety catch into the handle, then slowly

squeeze the trigger.

2. Run the saw at least one minute.

3. Release the trigger and safety catch.

MOUNTED CONFIGURATION (SAW CART):

1. Make sure the lower edge of the cutoff wheel is at least 1

inch above the work surface.

2. Slowly squeeze the hand control lever.

2. Make sure the trigger is set to disengage the cut-off saw

when released.

3. Run the saw at least one minute, then release the control

lever.

CO25 User Manual ◄ 11

Page 12

OPERATION

If excessive vibration or any other defect is detected, stop

the tool immediately and determine the cause. Do not use

the tool until the problem is corrected.

GENERAL OPERATION

HANDHELD CONFIGURATION:

1. Whenever possible, clamp or hold down the work and

support it securely on both sides of the cut.

terclockwise (CCW).

Periodically look at the depth gauge and pointer to check

the actual depth of the cutting blade.

6. Move slowly and safely forward along the cutting line

until the desired cut is complete. The safe forward rate

depends on your blade type.

7. Release the hand control lever.

2. Press the safety catch into the handle, then slowly

squeeze the trigger.

3. Start the cut with the wheel rotating. Start the work gently

with consistent pressure. Do not bump the saw into the

workpiece.

4. Feed the wheel through the material as fast as possible

without slowing the wheel rotation speed.

Cutting through the material too slowly causes heat expansion and can result in wheel “pinching” in the material. This

is one of the most common causes or wheel breakage.

MOUNTED CONFIGURATION (SAW CART): SEE PAGES

15 THRU 17 FOR MOUNTING CO25 TO SAW CART.

When the cutoff saw is mounted on a saw cart, always use

a motor-type hydraulic system control valve to turn the saw

“ON” and “OFF”. All ports must be connected to the tank

(hydraulic system reservoir) when the control valve is in

neutral. Alternatively, use a direct line from the tool outlet to

the tank.

IMPORTANT

Keep all four wheels of the cart on the cutting surface

at all times. Do not tip the front of the cart up during

operation or while the blade is in motion.

8. To raise the blade from of the cutting surface, wait until

the blade comes to a complete stop in the work material.

Turn the depth-control crank clockwise (CW) until the blade

clears the surface.

WET CUTTING

1. Make sure the cutting wheel is suitable for wet cutting.

2. When shutting down a wet-cutting operation:

a. Stop the tool.

b. Shut off the water.

Restart the tool and allow the wheel to spin off the excess

water.

BROKEN CUT-OFF WHEELS

Cut-off wheels designed for use with portable saws are

extremely tough. When used as directed, they are difcult

to break during normal use.

If a wheel breaks while operating the cut-off saw, investigate the cause of the failure and correct the problem as

soon as possible. If you cannot determine the cause of

failure, contact the wheel manufacturer.

1. Align the cut line indicator on the line to be cut.

2. Lower the blade to approximately 1/2 to 1-inch above the

cutting surface. Set the depth gauge to ensure accurate

cutting depth.

3. Make sure the water hose and its connections are se-

cure and there is a steady ow of coolant water.

4. Slowly squeeze the hand control lever.

5. Slowly and safely lower the rotating blade into the cutting

surface to the desired depth:

Increase the depth by turning the depth-control crank coun-

12 ► CO25 User Manual

SHUTDOWN

1. Move the hydraulic system control valve to the “OFF”

position.

2. Disconnect the hydraulic hoses from the tool (rst the

input (supply) hose, then the output (return) hose).

3. Place dust plugs in the hose ends, couplers or tool ports,

as applicable.

4. Wipe the tool thoroughly with a clean dry cloth.

5. Clean any foreign matter from the cut-off wheel surfaces.

Page 13

OPERATION

PERIODIC MAINTENANCE

For maximum performance and reliability of the tool, periodically check the following components.

THRUST COLLAR AND INSIDE/OUTSIDE

COLLAR INSPECTION

Periodically inspect the thrust collar for damage when you

remove the cut-off wheel (refer to Cutoff Wheel Replacement).

1. Remove the key and thrust collar from the motor shaft.

2. Check the thrust collar for burrs. Remove burrs as required.

3. Check the threads on the clamping setscrew.

4. Inspect the collar bores and anges.

5. Check for burrs. Remove burrs as required.

6. Check that the bearing surfaces are at and run true

when mounted on the motor shaft and thrust collar.

DRIVE-SHAFT SPEED CHECK

CARE AND STORAGE

Remove the cutoff wheel from the tool after use. Do not

store or transport the saw with the wheel installed. Clean

and inspect the wheel and tool before storing.

CUTOFF WHEELS

All abrasive cutoff wheels are breakable. Exercise care in

handling and storage to prevent damage.

1. Clean used wheels to remove any dirt, debris, or grease.

Dry thoroughly.

2. Inspect the wheel for chips, cracks, or other damage. For

maximum tool performance, replace the wheel if it is worn

or defective.

3. Store cutoff wheels on a at surface of steel or similar

rigid material.

4. If wheels are supplied with blotters attached, insert suitable separators between each wheel and the supporting

surface to preserve atness.

5. Do not store wheels where they will be exposed to high

humidity, water or other liquids, excessive heat, or freezing

temperatures.

Check the speed of the motor output shaft at least every

100 hours of operation. The test should be performed only

by a trained, experienced technician.

• Maintain a record of the speed checks.

• The maximum rated speed of the CO25 Hydraulic Cutoff

Saw is 4500 rpm.

• The rated speed of the cutting wheel must be equal to,

or greater than that of the tool to ensure the integrity of the

wheel at maximum tool speed.

• Use the hydraulic power supply normally used with the

cutoff saw when conducting this test.

• Excessive speed may be caused by excessive hydraulic

uid ow to the tool.

BEARING CHECK

Periodically inspect the bearings and associated parts for

proper operation. A worn or damaged bearing can cause

motor damage.

6. Avoid temperatures low enough to cause condensation

on the wheels if they are moved from storage to an area of

higher temperature.

7. Wheels carried on emergency vehicles should be removed after use, and discarded or stored carefully (steps 1

and 2).

TOOL

1. Clean the tool to remove any dirt, debris, or grease. Dry

with compressed air or clean dry cloths.

2. Replace any damaged or missing safety labels and tags

before storing the tool. Otherwise, the tool might be improperly used by someone who is not familiar with the safety

requirements.

3. Store the tool in a clean, dry place.

CO25 User Manual ◄ 13

Page 14

OPERATION

CUTOFF WHEEL REPLACEMENT

1. Move the hydraulic system control valve to the Off position.

2. Disconnect the hydraulic hoses from the tool (rst the

input (supply) hose, then the output (return) hose).

3. Install the inside collar and blotter, rotate the collar to

align the slot in the collar with the pin on the thrust collar.

4. The maximum rated speed of the hydraulic cutoff saw

is 4500 rpm. Never install a cutoff wheel that is not rated

equal to or greater than that of the tool to ensure the integrity of the wheel at the maximum tool speed.

5. Prior to installing the wheel, inspect it for chips, cracks or

other damage and replace if damaged.

6. Install the outside blotter and collar, rotate the collar so

that the at on the motor shaft aligns with the at on the

outside collar.

7. Install the wheel nut using a wrench while gripping the

cutoff wheel. Tighten securely.

COLD WEATHER OPERATION

Before using the tool in cold weather, preheat the hydraulic

uid with the power unit operating at a low speed. The oil

should be at or above 50°F (10°C) with a viscosity of 400

SSU (82 cs) before operating the tool.

14 ► CO25 User Manual

Page 15

SAW CART ASSEMBLY

SAW CART ASSEMBLY INSTRUCTIONS

1. Your slab saw cart comes fully assembled from the factory, the only adjustments necessary may be the throttle

cable after the cut-off saw has been installed.

2a. When mounting the cut-off saw to the saw cart, the tubular handle attached to the cut-off-saw must be removed.

This will allow the cut-off-saw to be mounted on the saw

cart.

2b. Cut-off saw with handle removed shown below.

Safety Catch

NOTE:

Prior to mounting the cut-off saw the safety catch on

the cut-off saw must be depressed and is held down by

the safety latch plate on the saw cart at all times for the

trigger to operate. See location of safety latch plate pictured below and safety catch pictured above.

Cable Guide

Remove this handle

from the cut-off saw.

Safety Latch

Plate

Trigger Plate

Cable Adjustment

Holes

Cable Lock

CO25 User Manual ◄ 15

Page 16

SAW CART ASSEMBLY

3a. When mounting the cut-off saw, make sure it is pushed

backed fully into the motor mount, rotate the handle up to

where it locks in. Make sure the safety catch on the cut-off

saw is depressed and under the safety latch plate for the

trigger to operate.

3c Side view of mounting.

3b. Motor mount.

4 After mounting the cut-off-saw, make sure the cutting

blade is perpendicular to the oor and parallel with the cart

frame.

16 ► CO25 User Manual

Page 17

SAW CART ASSEMBLY / OPERATION

5. Adjust the cable lock and the adjustment screw on

the control lever on the handle to acquire the correct

trigger control. Additional full trigger movement can be

attained by moving the cable to a different hole location

on the trigger plate (see below).

Cable Guide

Safety Latch

Plate

Trigger Plate

Cable Adjustment

Holes

Cable Lock

NOTE:

The safety catch on the cut-off saw must be depressed by the safety latch plate at all times for the

trigger to operate.

6 Before operating the cut-off saw and before attaching

any hydraulic power source check that the wheel guard

on the cut-off saw is in place and that the cutting wheel

is secure.

NOTE:

If the saw is to be removed from the cart and used

in a hand-held manner, make sure to re-attach the

tubular handle to the cutting head body before

using.

Saw cart operating

instructions

• For operation of the attached tool (saw motor) and power

source, consult the respective operating manuals before

you begin.

• Follow all safety precautions in this manual along with any

respective manuals relating to attached tools and power

sources.

• When you are ready to cut, align the cut line indicator on

the line to be cut.

• Make sure the water hose and its connections are secure

and the water coolant is owing easily.

•To engage the motor and blade, slowly squeeze the hand

control lever.

• Slowly and safely descend the blade into the cutting surface to the desired depth by turning the depth control crank

counter-clockwise.

•Move slowly and safely forward along cutting line until

desired cut is achieved.

• Disengage the motor and blade by releasing the hand

control lever.

•After the blade has stopped rotating, lift the blade out of

the cutting surface by turning the depth control crank clockwise until the blade is safely clear of the surface.

•When operation is complete, turn off power source and

disconnect hoses.

Maintenance

1. Item 24 on the parts illustration page of the slab saw

cart manual is a grease tting, apply grease once a month

under normal use or twice a month under heavy use.

2. Lubricate all moving parts weekly with a general lubricant.

CO25 User Manual ◄ 17

Page 18

NOTICE

TOOL PROTECTION & CARE

In addition to the Safety Precautions found in

this manual, observe the following for equipment

protection and care.

• Make sure all couplers are wiped clean before connection.

• The hydraulic circuit control valve must be in the “OFF” position when coupling or uncoupling

hydraulic tools. Failure to do so may result in damage to the quick couplers and cause overheating

of the hydraulic system.

• Always store the tool in a clean dry space, safe from damage or pilferage.

• Make sure the circuit PRESSURE hose (with male quick disconnect) is connected to the “IN” port.

The circuit RETURN hose (with female quick disconnect) is connected to the opposite port. Do not

reverse circuit ow. This can cause damage to internal seals.

• Always replace hoses, couplings and other parts with replacement parts recommended by Stanley

Hydraulic Tools. Supply hoses must have a minimum working pressure rating of 2500 psi/172 bar.

• Do not exceed the rated ow (see Specications) in this manual for correct ow rate and

model number. Personal Injury and rapid failure of the internal seals may result.

• Always keep critical tool markings, such as warning stickers and tags legible.

• Tool repair should be performed by experienced personnel only.

• Make certain that the recommended relief valves are installed in the pressure side of the system.

• Do not use the tool for applications for which it was not intended.

18 ► CO25 User Manual

Page 19

TROUBLESHOOTING

If symptoms of poor performance develop, the following chart can be used as a guide to correct the problem. When diagnosing faults in operation of the wrench, always check that the hydraulic power source is supplying the correct hydraulic

ow and pressure to the tool as listed in the following table. Use a ow meter known to be accurate. Check the ow with

the hydraulic uid temperature at least 80o F/27o C.

PROBLEM CAUSE SOLUTION

Hydraulic ontrol valve OFF. Turn the hydraulic system control

valve ON.

Tool does not operate.

Tool operates in reverse.

Oil leakage between motor housing

and ON/OFF vlave block or motor.

Trigger difcult to operate.

Saw cuts too slowly.

Hydraulic hoses not connected properly.

Hydraulic system not functioning. Check power unit for correct ow and

Couplers or hoses blocked. Remove obstruction.

Mechanical failure. Disassemble tool and inspect for dam-

Hoses connected to wrong ports on

tool.

Oil tube o-ring failure. Replace o-ring.

Motor face seal failure. Replace seal.

Hoses connected to wrong ports on

tool.

Excessive back-pressure. If back pressure is greater than 250

Wrong cut-off wheel for work material. Use correct wheel.

Insufcient oil ow. Adjust oil ow to 7-9 gpm/26-34 lpm.

Relief valve setting too low. Adjust relief valve to 2100-2250

Make sure the hoses are connected

and the couplers are tight.

presssure.

age.

Connect input (supply) line to IN port

and connect output (return) line to

OUT port.

Connect input (supply) line to IN port

and connect output (return) line to

OUT port.

psi/17 bar, correct the return line obstruction or restriction.

psi/145-155 bar.

CO25 User Manual ◄ 19

Page 20

SPECIFICATIONS

Wheel Capacity .............................................................................................................................................14-inch/15.6 cm

Weight ...................................................................................................................................................................20 lbs/9 kg

Overall Length ..................................................................................................................................................21-inch/53 cm

Width ................................................................................................................................................................ 11-inch/28 cm

Pressure Range........................................................................................................................... 1500-2000 psi/105-140 bar

Flow Range .............................................................................................................................................. 7-9 gpm/26-34 lpm

Optimum Flow ...................................................................................................................................................8 gpm/30 lpm

System Type ............................................................................................................................... Open Center, HTMA Type II

Porting ..............................................................................................................................................................8 SAE O-Ring

Connect Size and Type ............................................................................................................... 3/8-inch Male Pipe Adapter

Max Spindle Speed ................................................................................................................................................. 4700 rpm

ACCESSORIES

DESCRIPTION PART NUMBER

14-inch Abrasive Wheel for Metal, 1-inch Arbor ........................................................................................................... 02691

14-inch Abrasive Wheel for Masonry, 1-inch Arbor ....................................................................................................... 02692

Diamond Blade, 14-inch Dry Cut .................................................................................................................................. 62358

Water Attachment Kit for CO25 (Includes (1) Water Hose Assy P/N-33220, (1) 9.125-inch Long Tube P/N-33226, (1)-

7.812-inch Long Tube P/N-33227, (1) Brass Adaptor P/N-35196, (3) Male 90Deg Elbow 1/4” hose barb P/N-33223, (1)

Male Elbow Brass P/N-35197....................................................................................................................................... 33228

Slab Saw Cart............................................................................................................................................................... 69290

Water Tank Kit for Slab Saw Cart (Includes (1) Tank Top Bracket P/N-69296, (1) Tank Bracket P/N-69542, (1) Water tank

P/N-41240, (1) Needle Valve Clamp P/N-69914, (2) Capscrews P/N-32412, (9) Capscrews P/N-15476, and (11) Nuts P/N-

00719............................................................................................................................................................................ 69704

Handle Extension Kit (Includes- (2) Oil Tubes P/N-31945, (1) Handle Weldment P/N-34116, (1) Extension P/N-34172, (4)

O-Rings P/N-00175, Hardware- (2) Lockwashers P/N-01459, (2) 3/8” Capscrews P/N-02116, (4) 5/16” Capscrews P/N-

10888 and Inst Sheet .................................................................................................................................................. 34175

SOUND POWER AND VIBRATION DECLARATION

Test conducted on CO25541, S/N 673 operated at standard 12 gpm input ....................................................................................

Measured A-weighted sound power level, Lwa (ref. 1pW) in decibels ........................................................................... 109.4 dBA

Uncertainty, Kwa, in decibels ................................................................................................................................................. 3 dBA

Measured A-weighted sound pressure level, Lpa (ref. 20 µPa) at operator's position, in decibels ................................ 101.5 dBA

Uncertainty, Kpa, in decibels ................................................................................................................................................. 3 dBA

Values determined according to noise test code given in ISO 15744, using the basic standard ISO3744 NOTEThe sum of a measured noise emision value and its associated uncertainty represents an upper boundry of the range of values

which is likely to occur in measurements. .......................................................................................................................................

Declared vibration emission value in accordance with EN 12096 ...................................................................................................

Measured vibration emmission value: a ......................................................................................................................... 4.9 m/sec²

Uncertainty: K ............................................................................................................................................................... 0.14 m/sec²

Values determined according to ISO 19432:2012, ISO 5349-1,2 ....................................................................................................

20 ► CO25 User Manual

Page 21

3

45

678

PARTS ILLUSTRATION

31

22

45

21

43

34

44

14

35

1

2

19

8 9

2

12

7

24

16 17

48

42

15

37 38 39

36

40

20

13

26

8

41

52

4 5

29

50 51

3

32

7

30

18 19

For Parts to Handle Extension

Kit, See Accessories on Page 17

10 11 12

12

46

49

27 28

CO25 User Manual ◄ 21

Page 22

PARTS LIST

Item

No.

1 00112 1 QUAD RING*

2 00175 4 O-RING*

3 00563 1 ROLL PIN

4 00720 1 SETSCREW

5 00772 1 WOODRUFF KEY

7 01594 2 WASHER

8 01604 2 O-RING*

9 01714 1 HEX JAM NUT CCW (RH)

10 02649 3 HANDLE BAR RETAINER

11 02654 1 HANDLE BAR

12 02688 8 CAPSCREW

13 02911 1 HOSE CLIP

14 02912 2 OIL TUBE

15 02916 1 COMPRESSION SPRING

16 02920 1 ON-OFF VALVE SPACER

17 02931 1 ON-OFF VALVE CAP

18 02950 1 MOTOR HOUSING

19 03006 2 CAPSCREW

20 17668 1 ROLL PIN

21 03013 1 RET RING

22 03025 1 CARRIAGE BOLT

24 03050 1 SWING OVER NUT ASSY

26 03786 1 GPM STICKER

27 03972 1 COUPLER,3/8FEM.

28 03973 1 COUPLER,3/8MALE

29 04673 1 THRUST COLLAR

30 05071 2 CAPSCREW

31 05152 1 STANLEY STICKER

32 05868 1 ABRASIVE SAFETY LABEL

34 17681 1 SPRING PIN

35 20461 1 HANDLE STRUT ASSY

36 22701 1 TORSION SPRING

37 22704 1 SAFETY CATCH

38 22707 1 TRIGGER

39 25635 1 FLOW REGLTR.CRTRDG.

Part No. Qty Description

03012 1 HEX JAM NUT CW (LH)

Item

No.

40 28552 1 VALVE HANDLE ASSY

41 31137 1 PLUG

42 31186 1 POPPET (CONE)

43 32026 1 VALVE SPOOL

44 32436 1 WHEEL GUARD

45 32445 1 GUARD CLAMP SECTOR

46 74698 1 NAME TAG STICKER - CO25

48 35963 1 SCREW, OVAL HEAD

49 56725 2 HOSE ASSY RAILROAD 18"

50 62290 1 INSIDE COLLAR

51 62291 1 OUTSIDE COLLAR

52 33084 1 MOTOR ASSY CO25

Part No. Qty Description

(INCLUDES - SAE PLUGS

(CCW MODELS ONLY)

31138 1 VALVE SPOOL

(CW MODELS ONLY)

CCW ROTATION

33083 1 MOTOR ASSY CO25

CW ROTATION

31845 1 SEAL KIT

• Denotes Part in Seal Kit

Coupler Set P/N-03971

Additional decals for CE tools can be found on page 7.

22 ► CO25 User Manual

Page 23

Page 24

Stanley Hydraulic Tools

3810 SE Naef Road

Milwaukie, Oregon 97267-5698 USA

(503) 659-5660 / Fax (503) 652-1780

www.stanleyhydraulics.com

Loading...

Loading...