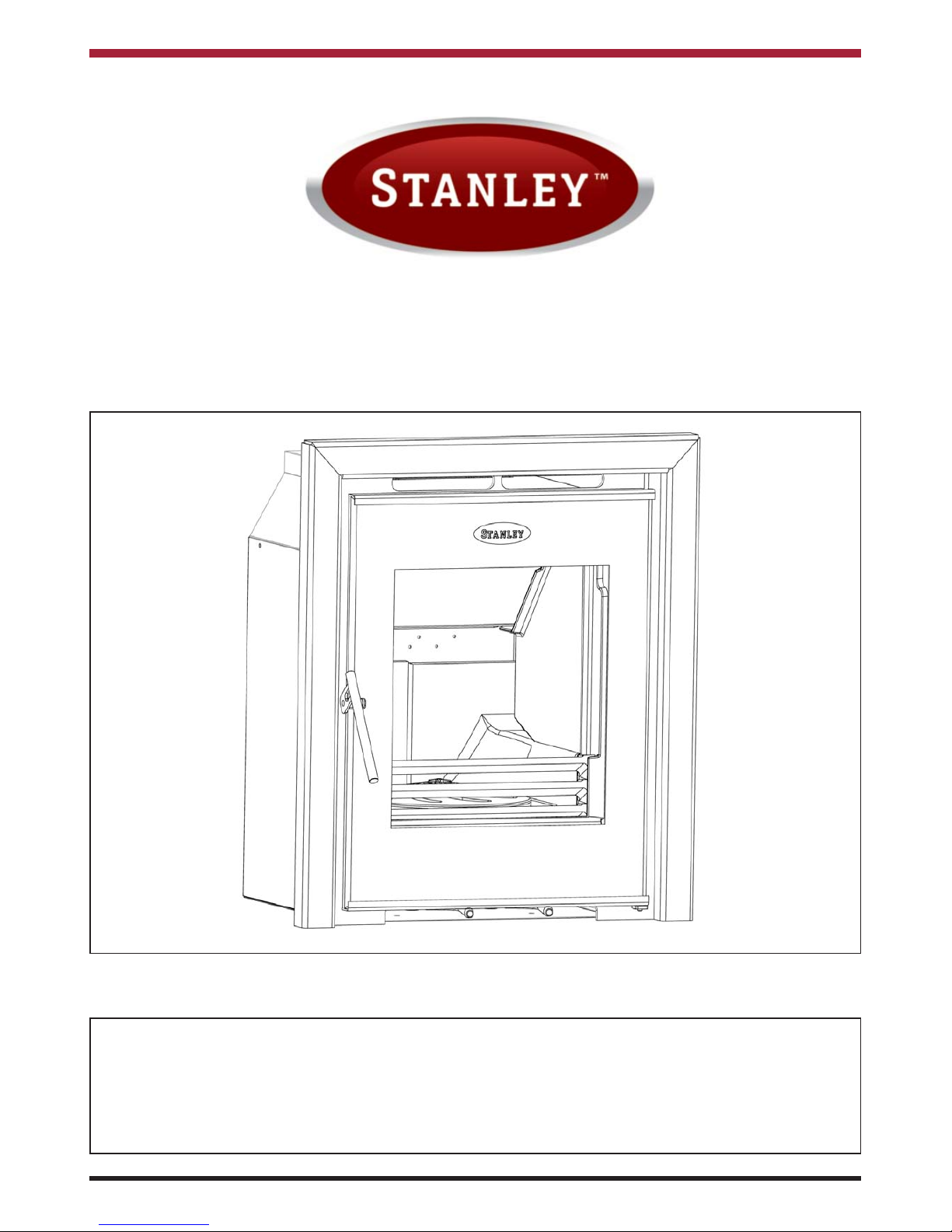

Cara Glass Non Boiler

Insert Stove

PLEASE RETAIN

INSTALLATION AND OPERATING INSTRUCTIONS

This appliance is hot while in operation and retains its heat for a long period of time after use. Children,

aged or infirm persons should be supervised at all times and should not be allowed to touch the hot

working surfaces while in use or until the appliance has thoroughly cooled.

When using the stove in situations where children, aged and/or infirm persons are present a fireguard

must be used to prevent accidental contact with the stove. The fireguard should be

manufactured in accordance with BS 8423:2010.

2

TABLE OF CONTENTS

PAGE NO.

1. Stanley Solid Fuel Stove Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. Installation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3. Important Operation/ Maintenance Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

4. Installation & Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..6

5. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..6

6. Pre Installation Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

7. Flues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..7

8. Chimney . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

9. Fitting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

10. Fully Lined Chimney . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

11. Not Fully Lined Chimney . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

12. Down Draughts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

13. Ventilation & Combustion Air Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

14. Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

15. Clearance to Combustibles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

16. Floor Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

17. Stove Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

18. Commissioning & Handover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

19. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

20. Air Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

21. Recommended Fuels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

22. Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

23. Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

24. Lighting The Stove . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

25. Refuelling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

26. Slow Burning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

27. De-Ashing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

28. Disposal of Ashes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

29. Monthly Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

30. Grate Removal & Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

31. Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

32. Chimney Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

33. Glass Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

34. Cleaning The Outer Casing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

35. Prolonged Periods of Non Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

36. Fire Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

37. Glass Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

38. CO Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

39. Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..20

STANLEY SOLID FUEL STOVE WARRANTY

CONDITIONS OF WARRANTY

Your Stanley Solid Fuel Stove is guaranteed against any part that fails (under normal operating conditions) as detailed

in the following table with timelines specified from the date of installation of the appliance. If the unit is not installed with-

in six months of date of purchase, the warranty will commence six months from the date of purchase.

Warranty Period Parts Covered (Parts & Labour unless Stated)

Up to 1 Year • Refractory materials (supply only)

• Rope seals, glass seals and cement seals.

• Surface Finish on Seno models.

• Grates and fire bars.

• Ceramic glass is covered for Thermal breakage (supply only).

• Rust (if reported before installation)

• Aesthetic Damage (provided reported on date of receipt)

Up to 5 Years • All external castings & enamel finishes (excluding impact damage or

damage caused by overfiring). Pictures of damage must be submitted to

WS Service Department.

All warranty claims must be reported to the Waterford Stanley Service Department and must be submitted with the product serial number (located on the bottom RH corner of the front plate), date of purchase, proof of purchase (if requested) and details of the specific nature of the problem.

The warranty is given only to the original consumer/purchaser only and is non- transferable. The appliance must be

installed by a suitable qualified person and installed as per the requirements of the manual. Failure to comply with the

Installation requirements or Building Regulations will void your warranty. Waterford Stanley reserve the right to replace

any part due to manufacturing defect that fails within the warranty period under the terms of the warranty. The unit must

be used for normal domestic purposes only and in accordance with manufacturer's operation instructions.

3

LIMITS OF LIABILITY

The warranty does not cover:

* Special, incidental or consequential damages, injury to persons or Property, or any other consequential loss.

* Any issue caused by negligence, misuse, abuse or circumstances beyond Waterford Stanley’s control.

* Any issue with wear and tear, modification, alteration, or servicing by anyone other than an authorized service

engineer.

* Installation and operational related problems such as draught related issues external to the stove, inadequate

venting or ventilation, excessive flue offsets, negative air pressure caused by insufficient burning of improper

fuel.

* Damage caused to the unit while in transit.

* Enamel discolouration due to over firing, enamel damage caused by impact, damage to baffles caused by

over firing and fading of surface finish on casting.

* Stress fractures on bricks.

* Rust on cast iron parts unless reported prior to unit being installed.

* Aesthetic damage, rust & missing parts on units purchased off display.

Note: Adequate clearance must be maintained around the appliance to ensure the ease of part removal in the possible event of their damage/failure. Waterford Stanley are not responsible for any costs incurred in the removal of items

installed in the vicinity of the appliance that have to be moved to facilitate a part replacement.

INSTALLATION CHECK LIST

Tick

Flue System

1. Minimum Flue Height of 4.6 metres (15 feet).

2. Appliance should be connected to a 125mm (5”) flue pipe within a metre and then

the flue size increased to a minimum of 150mm (6”) diameter.

3. The horizontal flue run should not exceed 150mm (6”)

4. All flue pipework passing through walls must be sleeved & adequately insulated in line

with current Building Regulations.

5. Appliance should be connected to a chimney of less than 200mm (8”) in diameter

(otherwise the chimney must be lined with a 6” flue liner).

6. The chimney/ flue termination must be located in accordance with building regulations part J.

7. The chimney serving this appliance should not serve any other appliance.

8. Access should be provided to the chimney serving the appliance to allow for cleaning.

9. It is a requirement by Building Regulations to have a carbon monoxide alarm

fitted to any room with a solid fuel appliance.

Location

10. Clearance to combustible materials must be adhered to as described in the Clearance

to Combustible section.

11. The stove must be installed on a floor protector that covers the area under the stove

and extends 14” to the front and 10” to the sides.

12. Clearance must be maintained to allow for maintenance and part replacement.

Ventilation & Combustion Air Requirements

13. The room in which the appliance is located should have an air vent of adequate

size to support correct combustion (see Ventilation & Combustion Air Requirement

Section for specific details).

14. The stove must not be installed in the same room as an extractor fan.

4

5

IMPORTANT OPERATION / MAINTENANCE NOTES

Now that your Stanley Solid Fuel Stove is installed and no doubt you are looking forward to many comforts it

will provide, we would like to give you some tips on how to get the best results from your stove.

1. We would like if you could take some time to read the operating instructions/hints, which we are

confident, will be of great benefit to you.

2. Do not burn fuel with a high moisture content, such as a damp peat or unseasoned timber. This will

only result in a build up of tar in the stove and in the chimney.

3. IMPORTANT: The first few fires should be relatively small to permit the refractory to set properly

and season the stove. During these firings it is recommended to ventilate the room as an

unpleasant (not toxic) odour may be emitted as the paint is completing curement.

4. Inspect the flue-ways of the stove weekly and ensure that there are no blockages. Check flue

ways before lighting especially after a shut down period. Please see chimney cleaning section.

5. Before loading fresh fuel into the firebox, riddle fully to remove all ashes. This will allow better and

cleaner burning. See Re-Fuelling section.

6. Never allow a build up of ashes in the ash pan, as this will cause the grate to burn out prematurely.

Empty the ashpan when refuelling.

7. Avoid slow burning of damp or unseasoned fuel as this will result in tarring flue ways and chimney i.e. peat or timber.

8. Allow adequate air ventilation to ensure plenty of air for combustion.

9. Do not burn rubbish/household plastic.

10. Clean the chimney at least twice a year.

11. Burning soft fuels such as timber and peat will stain the glass. Regular cleaning will prevent

permanent staining. Clean with soapy water when cool.

12. Keep all combustible materials a safe distance away from unit, please see section for clearances

to combustibles.

13. Never use aerosol spray near the appliance when it is in operation.

14. For safety reasons never leave children or the elderly unaccompanied while stove is in use. Use a

fire guard.

15. Avoid contact with the appliance when in use as stove reaches very high operating temperatures.

16. This appliance should be regularly maintained by a competent service engineer.

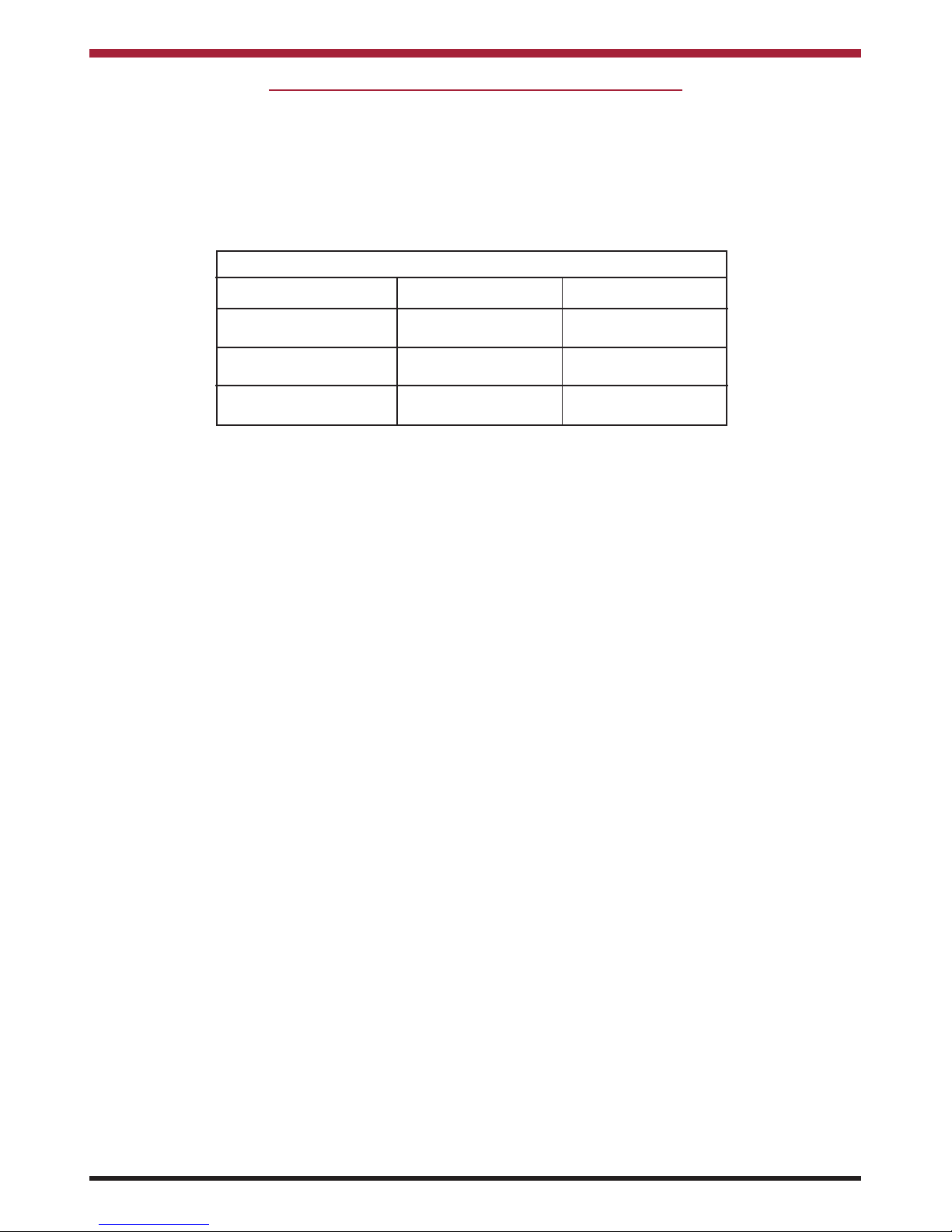

FUEL CALORIFIC VALUES - SOLID FUELS

Anthracite 25-50mm C.V.: 8.2kW/Kg 14,000 BTUs/lb

House Coal 25-75mm C.V.: 7.2kW/Kg 12,000 BTUs/lb

Timber - Firebox size C.V.: 5.0kW/Kg 8,600 BTUs/lb

Peat Briquettes C.V.: 4.8kW/Kg 8,300 BTUs/lb

6

THE CARA GLASS SOLID FUEL NON BOILER STOVE

INSTALLATION & OPERATING INSTRUCTIONS

GENERAL

When installing, operating and maintaining your

Cara Stove respect basic standards of fire safety.

Read these instructions carefully before commencing the installation. Failure to do so may result in

damage to persons and property. Consult your local

Municipal office and your insurance representative

to determine what regulations are in force. Save

these instructions for future reference.

Please note that it is a legal requirement under

England & Wales Building Regulations that the

installation of the stove is either carried out under

Local Authority Building Control approval or is

installed by a Competent Person registered with a

Government approved Competent Persons

Scheme. HETAS Ltd operate such a scheme and a

listing of their Registered Competent Persons can

be found on their website at www.hetas.co.uk.

Special care must be taken when installing the stove

such that the requirements of the Health & Safety at

Work Act are met.

Handling

Adequate facilities must be available for loading,

unloading and site handling.

Fire Cement

Some types of fire cement are caustic and should

not be allowed to come into contact with the skin. In

case of contact with the skin wash immediately with

plenty of water.

Asbestos

This stove contains no asbestos. If there is a possibility of disturbing any asbestos in the course of

installation then please seek specialist guidance and

use appropriate protective equipment.

Metal Parts

When installing or servicing this stove care should

be taken to avoid the possibility of personal injury.

“IMPORTANT WARNING”

This stove must not be installed into a chimney that

serves any other heating appliance.

The complete installation must be done in accordance with current Standards and Local Codes. It

should be noted that the requirements and these

publications may be superseded during the life of

this manual.

Please refer to the current standards, BS EN 152871:2007 Design, Installation and Commissioning of

chimneys. BS EN 14336:2004: Heating Systems in

Buildings. Installation & Commissioning of Water

Based Heating Systems. BS EN 12828: 2003;

Heating Systems in Buildings. Design of Water

Based Heating Systems. BS EN 12831: 2003;

Heating Systems in Buildings. method for

calculation of the design heat load.

PRE-INSTALLATION ASSEMBLY

After removing the stove from the packaging, open

the fire door and remove the loose packing. Prior to

installation all the internal components of the stove

are removed to gain access to fixings and to make it

lighter for installation.

Remove the refractory fire bricks, these bricks are

loose and just need to be lifted clear of the grate

support plate before they can be removed.

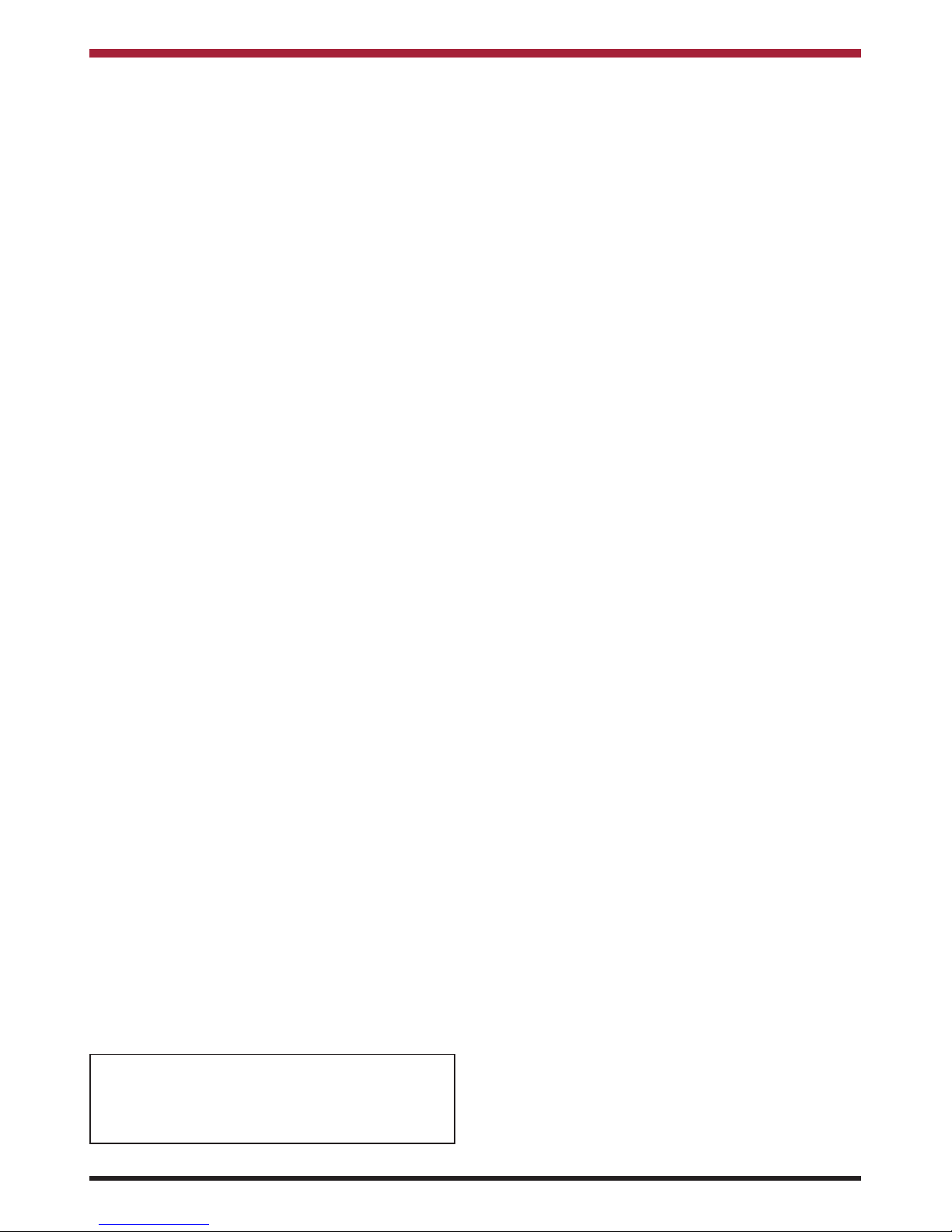

To remove the loose baffle, lift on right side and

move this up and to the right to give maximum clearance at the opposite side to allow the baffle be lowered clear of the supporting ledge on the left hand

side casting.

Next, remove the grate by pushing it from underneath, the riddling bar is not fixed to the grate.

The cast iron side liners must be removed prior to

the fixed baffle, to remove the side liners lift the bottom edge clear of the grate support and slide the

bottom edge towards the opposite side of the stove,

when the casting is moved to a diagonal position it

will be free to be lifted from the stove.

To remove the fixed baffle, loosen the two roof bolts,

support the baffle with one hand while removing the

L shaped brackets with the other hand, see Fig.1.

Your Cara Glass stove is supplied with the following

items:

• Ashpan

• Operating Tool

• Glove

• Side Bricks

• Clay Adaptor

• Rigid Pipe

•15

o

Adaptor

Do not overtighten the roof bolts when refitting the

baffle. It is adequate to leave them in a position

where the L shaped bracket has just enough room to

be removed.

Remove the flue spigot and gasket by removing the

four bolts.

To remove the insert stove from the external casing,

lift out the grate support, this will allow access to two

M6 fixings which attach the stove to the outer casing. Remove the 2 fixings, allowing the insert stove

to be removed from the external casing.

FLUES

Flues should be vertical wherever possible and

where a bend is necessary, it should not make an

angle of more than 45

o

with the vertical. Horizontal

flue runs should be avoided in order to minimise flue

resistance and to make sweeping easier it is recommended to use 2 x 45obends rather than a 90

o

bend.

CHIMNEY

Do not connect to a chimney serving another

appliance.

The stove is a radiant room heater and must be connected to a chimney of the proper size and type.

The chimney must have a cross-sectional area of at

least 30 square inches 19350sq. mm or a diameter

of at least 6” (150mm). It is best to connect to a

chimney of the same size, as connection to a larger

size may result in a somewhat less draught.

A flue that has proved to be unsatisfactory, particularly with regard to down draught should not be used

for venting this appliance until it has been examined

and any faults corrected. An existing masonry chimney should be inspected and if necessary repaired

by a competent mason or relined using an approved

lining system.

The stove must be connected to a chimney with a

minimum continuous draught of 0.06 w.g. Poor

draught conditions will result in poor performance.

All register plates, restrictor plates, damper etc.,

which could obstruct the flue at a future date should

be removed before connecting this appliance.

If connecting to an existing chimney with a flue

diameter of more that 8” it is recommend to line the

flue using a suitable stainless steel flue liner.

Where a masonry chimney is not available a proprietary type of 6”/150mm - twin wall, fully insulated

pipe may be used.

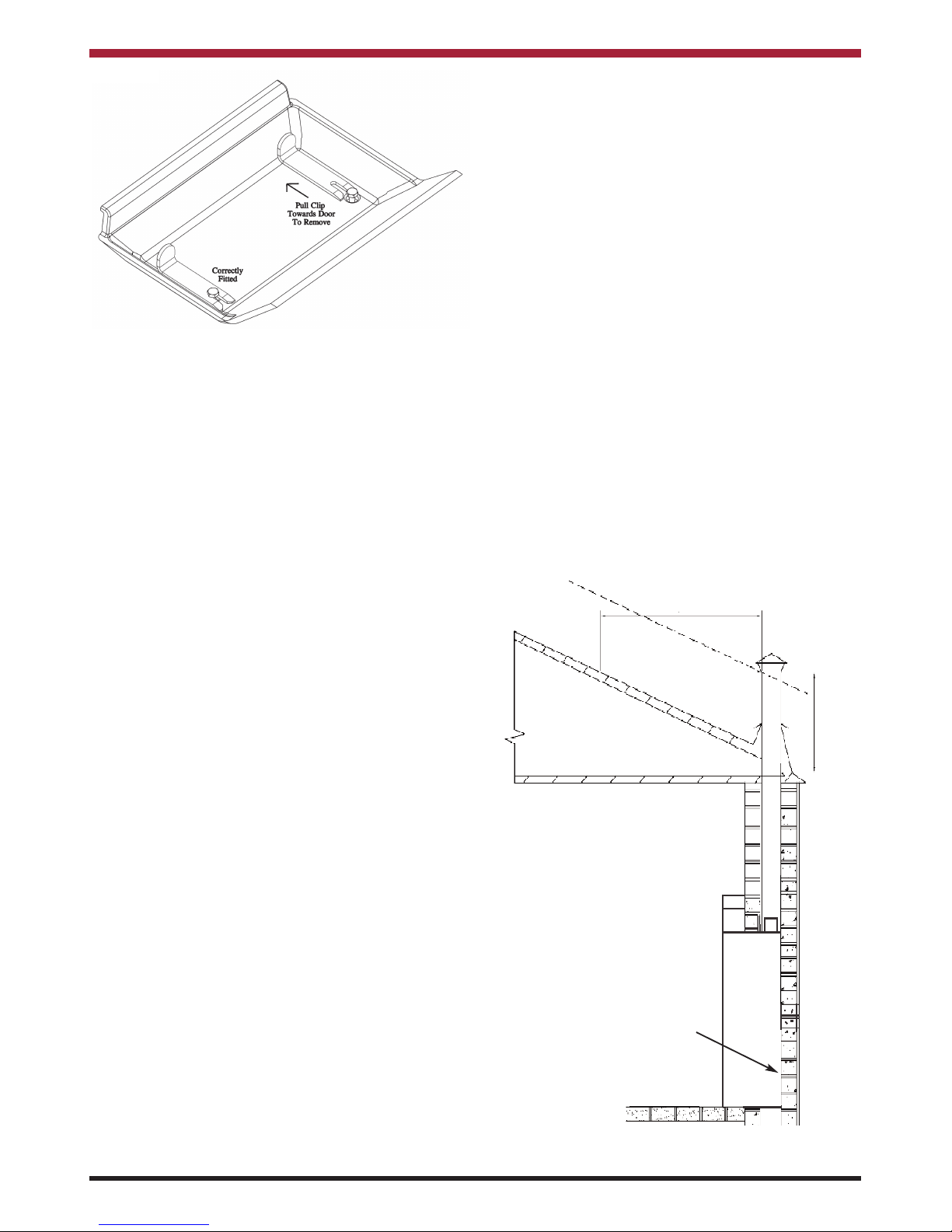

A chimney / flue termination must be located to minimise wind effects, a basic guide is that the distance

from the termination to the roof should be at be at

least 2300mm when measured horizontally and at

least 1000mm when measured vertically, (see

Fig.2). In circumstances where there are adjoining

buildings/ structures/ roof openings there are additional requirements, please refer to building regulations part J.

Fig.2

2300

1000

Fit

appliance

back into

wall

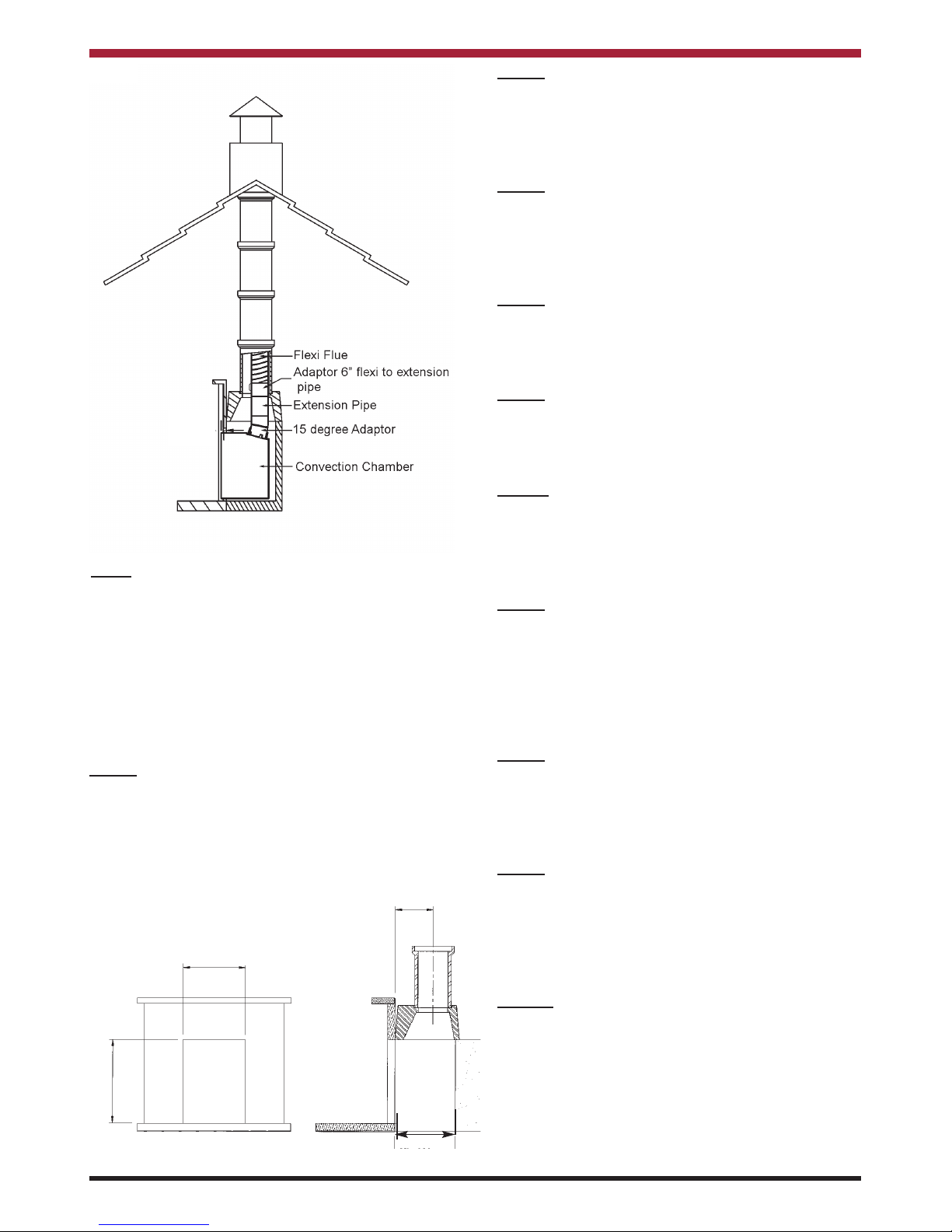

The liner should be approved for use with solid

fuel. (See Fig. 3)

Fig.1

7

8

Fig.3

405mm - 455mm

240mm - 320mm

550mm - 575mm

Min 400mm

Step 2

Ensure the floor area is level with the hearth, this

area needs to be level as the insert fire is screw

fixed to the floor. Remove all internal parts as per

pre-assembly instructions.

Step 3

Drop the flexi flue liner down through the chimney

and into the fireplace. Fit the adaptor ( not supplied

available to order) to the end of the flexible flue liner

along with the extension pipe which is supplied.

Step 4

Lay the external casing into the opening and position it so that the front plate is up against the front

edge of the opening.

Step 5

Mark the drill locations and drill the holes using a

5.5mm drill bit. Fix the casing to the floor using the

self tapping screws provided.

Step 6

Lift the stove into the casing approximately 75mm

first and then it can be pushed into the final position

while taking care to lift the front edge to preserve the

hearth.

Step 7

Lay the sealing gasket on to the flue spigot, then fit

the flue spigot to the end of the15 degree adaptor.

Fix the 15 degree adaptor to the flue spigot using the

grub screws provided. Then pass the 15 degree

adaptor through the flue opening and connect it to

the extension pipe.

Step 8

Then using the M6 x 10mm screws secure the stove

to the convection chamber. Push the insert stove

against the fireplace before fully tightening these

bolts.

Step 9

Pull the flue liner back up through the flue outlet until

the flue spigot is in position. Fix the flue spigot using

the M8 bolts provided. It may be necessary to cut a

prop to hold the spigot in place while the fixings are

being attached.

Step 10

Complete the installation of the flexi flue at the top of

the chimney in accordance with the manufacturers

instructions.

Note:

Where the product is to be installed at minimal clearances to non combustible rendered walls, it will be

necessary to have the adjacent surfaces rendered

using a heat resistant render/ plaster.

Fig.4

FITTING INSTRUCTIONS

Fully Lined Chimney

Step 1

Prepare the fireplace area with milner brick removal.

Ensure the opening is suitable for fitting of the insert

stove opening required, i.e. remove fire surround

trim if fitted. See Fig.4.

Loading...

Loading...