Page 1

BRANDON

DRY & DHW OIL MODELS

OPERATION INSTRUCTIONS

THIS MANUAL IS TO BE LEFT WITH THE END USER

Page 2

1

TABLE OF CONTENTS

PAGE NO.

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2. Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

3. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Programmable Controller - Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Pre-Operational Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Time Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Coarse Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Fine Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Setting the Switching Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Power Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Programmable Controller Digital . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

To Set Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Interval Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Operation Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Manual Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Correcting or Clearing Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Operating the Appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

4. Ovens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

The Main Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

The Lower Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Hotplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Reset Button/High Limit Stat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Burner Control Box Lock-out Reset Button . . . . . . . . . . . . . . . . . . . . . . . . .7

Hot Water Output Reduction (DHW Only) . . . . . . . . . . . . . . . . . . . . . . . . . .7

Burner Does Not Ignite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Hotplate Insulating Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Cooking Utensils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

5. Opening Cooker Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

6. Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Chimney Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Mild Steel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Ovens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Hot Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

7. Cooking Guidance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Grilling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

The Care of your Cooker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Cookware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

8. User Cooking Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

9. Wiring Diagram (Digital Timer) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

10. Wiring Diagram (Mechanical Timer) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

11. Fault Finding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Page 3

2

INTRODUCTION

To help you make the best use of your cooker, PLEASE READ THIS BOOKLET CAREFULLY.

To ensure safety, satisfaction and reliable operation, this quality cooker should be installed and commissioned

by a trained and competent person.

Please note for DHW Models the domestic hot water facility involved must fully conform to good plumbing

practices, established standards, Regulations and OFTEC Recommendations.

As manufacturers and suppliers of cooking and heating appliances, we take every possible care to ensure as

reasonably practicable, that these appliances are so designed and constructed as to meet the general safety

requirements when properly used and installed.

Section 10 of the Consumer Protection Act 1987.

Safety, Health and Welfare at Work Act.

Your new cooker is guaranteed, the guarantee is only applicable if the cooker has been installed in accordance

with the Installation Instructions.

IMPORTANT NOTICE: Any alteration to this appliance that is not approved in writing by Waterford Stanley will

render the guarantee void.

The cooker is designed specifically for domestic use and responsibility will not be accepted for use in any other

installation. When the Cooker is first used, a slight odour may be noticed - this should cease after a short period

of use.

The Installation must comply with the following:

B.S. 5410: Oil Installations Part 1 under 45kW.

The Building Regulations : Part J England & Wales Part F Section 4 Scotland.

Part L Northern Ireland and Part J Ireland.

The Control of Pollution (Oil) Regulations.

Health and Safety at Work Act.

B.S. 7671: Requirements for Electrical Regulations.

Safety Document 635: The Electricity at Work Regulations.

For DHW Models additionally the installation must comply with the following:

B.S. 7593: Treatment of Water in Domestic Hot Water Systems.

B.S. 7074: Parts 1 & 2 Hot Water Supply.

Important: Control of Substances Harmful to Health -

It is the Users/Installers responsibility to ensure that the necessary personal clothing is worn when handling

materials that could be interpreted as being injurious to health and safety.

When handling Firebricks, Fire Cement or Fuels, use disposable gloves.

Exercise caution and use disposable masks and gloves when handling glues and sealants.

When working with fibre glass, mineral wool, insulation materials, ceramic blanket/board, avoid inhalation as it

may be harmful if inhaled. Avoid contact with skin, eyes, nose and throat, use disposable protection.

Installation should be carried out in a well ventilated area.

This appliance is hot while in operation and retains its heat for a long period of time after use. Children,

aged or infirm persons should be supervised at all times and should not be allowed to touch the hot

working surfaces while in use or until the appliance has thoroughly cooled.

The manufacturers reserve the right to make alterations to design, materials or construction for manufacturing or other reasons subsequent to publication

.

Page 4

TECHNICAL DATA

FUEL: 28 Sec Kerosene

MAINS SUPPLY: 230-240V, 50Hz A.C.

I.P. PROTECTION DEGREE: IP20

ELECTRICAL INPUT: 90 Watts

SUPPLY FUSE RATING: 3A

COOKER WEIGHT: 356 Kgs (783 lbs)

GROSS HEAT INPUT: 15.6 kW (53,355 Btu’s)

NOZZLE: DANFOSS 0.45 60

o

ES

PRESSURE SETTING: 115 p.s.i.

CO

2 RANGE: 10.4 - 11.2%

ADDITIONAL TECHNICAL DATA FOR DHW MODELS:

MAX. DHW BOILER WORKING PRESSURE: 28 p.s.i.

TEST PRESSURE IN DHW BOILER: 40 p.s.i.

OPERATING TEMPERATURE LIMIT IN

DHW BOILER: 96

o

C (194oF)

DHW BOILER OUTPUT: 3.8 kW (13,000 Btu’s) (Continuous Running)

DHW BOILER CAPACITY: 10 Litres (2.2 gallons)

DHW BOILER MATERIAL: 3mm Stainless Steel

COOKER WEIGHT: 360 kg (790 lbs)

3

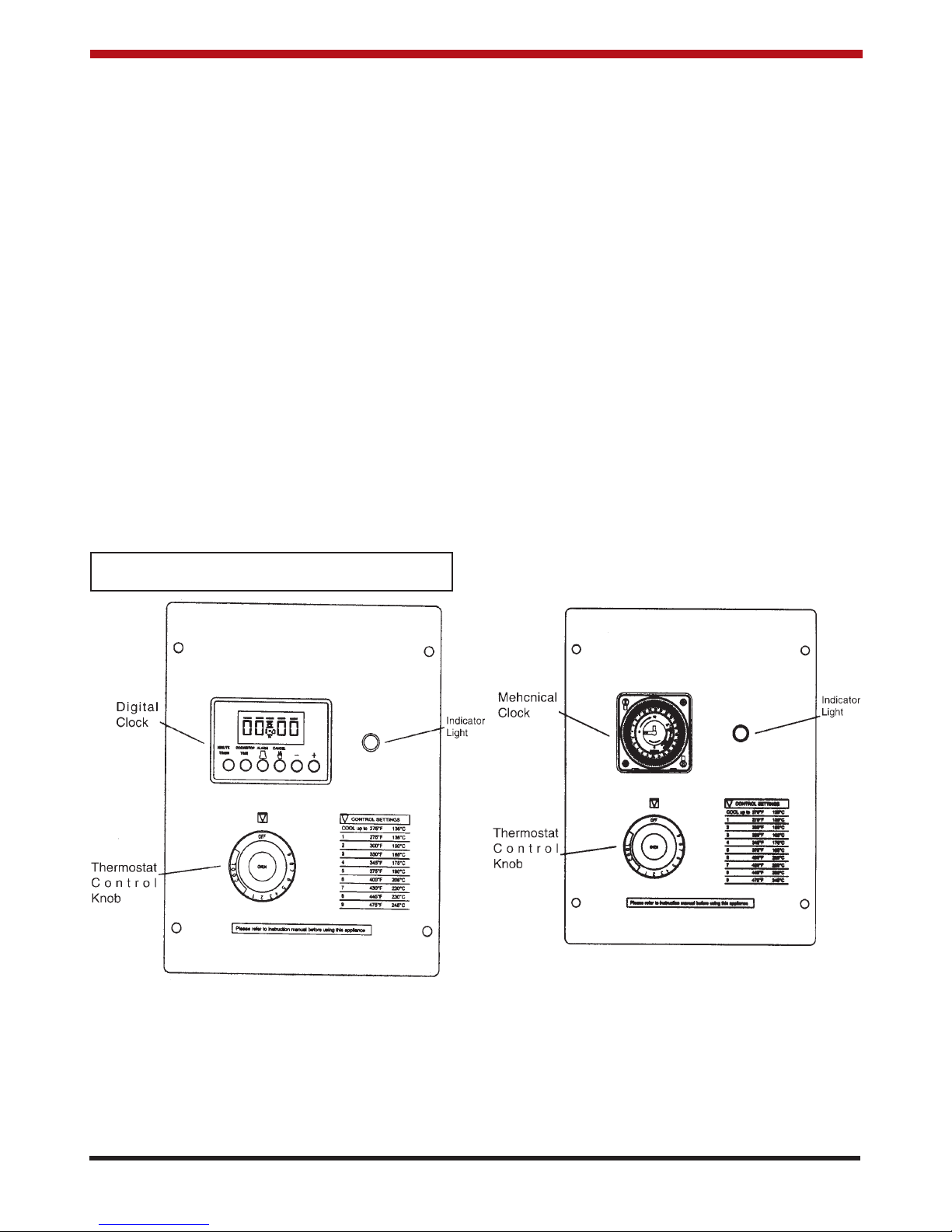

OPERATION

Note: The controls are located behind the top left

hand door.

PROGRAMMABLE CONTROLLER

(MECHANICAL)

The programmer controls your cooker which allows

you to set your cooking times. It will enable you to

pre-set the times when cooking is switched ON and

OFF.

PRE-OPERATIONAL CHECKS

(a) Check that the cooker is connected to the mains

electricity.

(b) Check that the oil supply line is purged of air

and that all valves are open.

(c) Check that appliance thermostats are in the off

position.

Page 5

4

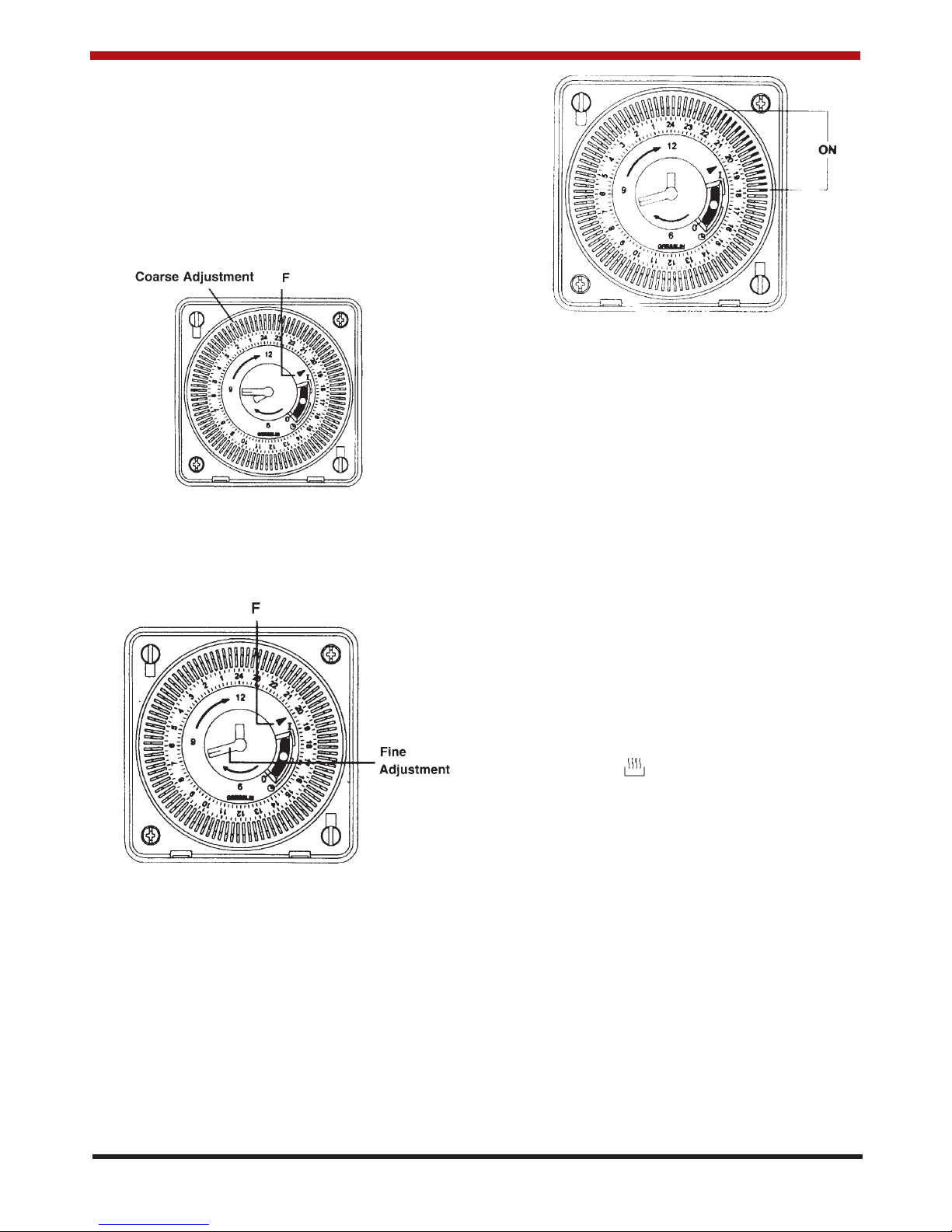

TIME SETTING - For DHW Models Only

Mechanical Clock Programmable

Controller

COARSE ADJUSTMENT

Rotate switching dial (section containing numbers 1

- 24) in direction of the arrow until the current time is

almost opposite the arrow marked F (here: 19.45)

Fig.1

Fig.1

FINE ADJUSTMENT

Push the minute hand in the direction of the arrow

until the current time is opposite the arrow marked F

(here: 20.00) Fig.2.

Fig.2

SETTING THE SWITCHING TIMES

To operate the appliance using the automatic

switching set the large slider to position marked

On the outer ring there are 96 small sliders, each

slider represents a time period of fifteen minutes.

The cooker switches “ON” or “OFF” depending on

the position of these sliders. When the slider is

nearest the centre of the clock it is in the “OFF”

mode, and when the slider is moved away from the

centre of the clock it is in the “ON” mode.

Switching example:

ON - Function from 18 - 22 h

OFF - Function from 22 - 18 h

Fig.3

POWER FAILURE

In the event of power failure, the programmer will

need to be reset, but switching times will not be

altered. If appliance does not operate normally

please refer to Fault Finding.

TIME SETTING FOR DRY MODELS ONLY

DIGITAL CLOCK PROGRAMMABLE

CONTROLLER

TO SET TIME (NOTE: Cooker cannot be operated

until the time is set).

1. When Power is applied, display flashes

“AUTO” and “000” alternatively.

2. Press buttons 1 & 2 from left, “0.00” is

displayed steadily . Letters “AUTO” flash.

3. Press plus or minus button until the actual Time

- Of - Day is displayed.

4. When releasing the buttons Time - of - Day

starts precisely to the second --.--. the cooking

INTERVAL TIME

Note: Interval Time does not control the cooker, it

sets off an alarm after the preset period of time.

1. Press interval time button (first button on

the left) display shows “0.00” and the bell

symbol is displayed.

2. Press plus button until the desired setting is

displayed.

3. On releasing the button, run down of interval

time starts after the 4 - seconds time window.

Time - of - Day re-appears in the display with

the cooking pot symbol illuminated steadily.

4. The interval time having elapsed. The acoustic

signal sounds with two beeps, pause, two

beeps etc....

“ is illuminated steadily.

pot symbol “

Page 6

OPERATION PERIOD

Note: When setting the operation period, the

programmer automatically sets a stop time which is

equal to the operation period added to the current

time. If you do not want the cooker to start

immediately, you will have to adjust the STOP time

accordingly.

1. Press operation period button (second button

from the left), display shows “0.00” and

the cooking pot symbol is displayed steadily.

2. Press plus button until the desired operation

period is displayed.

3. Releasing the button starts the run down of

time.

4. The operation period having elapsed, the

acoustic signal sounds with four beeps, pause,

four beeps etc.. The cooking pot symbol

disappears, letters “AUTO” flash until the

manual button is pressed. The cooking pot

symbol is illuminated steadily.

STOP

(Time at which you want cooker to switch off)

1. Press operation stop button (third button from

left), display shows “0.00” and the cooking pot

symbol is displayed.

2. Press plus button until the desired operation

STOP is displayed (Time at which you want

oven to switch off).

3. Releasing the buttons start run down of time,

time - of - day reappears. Letters “Auto” and

the cooking pot symbol is illuminated steadily.

Operation Period starts at once.

4. The operation period having elapsed, the

acoustic signal sounds with four beeps, pause,

four beeps etc.. The cooking pot symbol

disappears, letters “AUTO” flash until the

manual button is pressed. Thus switching over

to manual mode. The cooking pot symbol is

illuminated steadily.

MANUAL MODE

When programming operation period or operation

stop, the timer automatically transfers into automatic

mode, being displayed by the letters “AUTO”

illuminated. The set programs being completed,

letters “AUTO” illuminated. The set programs being

completed, letters “AUTO” flash and the time can be

switched over to manual mode by pressing the

manual button. The cooking pot symbol is

illuminated steadily.

CORRECTING OR CLEARING PROGRAMS

Set programs can be corrected at any time by

pressing the respective button and either the plus or

minus button depending on whether the program is

to be cut short or prolonged.

Clearing is done by setting the program to “0.00”.

Clearing operation period automatically causes

clearing of operation stop and vice-versa. When

operation period or operation stop are programmed

Time-Of-Day cannot be corrected. The setting of

nonsensical programs is impossible (e.g. operation

period is programmed and operation stop is set too

early).

NOTE: In the event of a short term power failure the

clock display will disappear and then turn when the

power is reinstated. If the power supply is

interrupted for a lengthy period of time the clock

display will be lost.

OPERATING THE APPLIANCE

For the appliance to operate both the oven control

knob and the timer must be set correctly.

The oven control knob setting corresponds to a

temperature. The control setting and their

corresponding temperatures are shown on the

control panel to the right of the control knob. These

temperatures are a guideline to the average

temperature in the top oven.

Either time clock can be used to switch

automatically as outlined above. The mechanical

timer also has “continuous on” and continuous off”

mode on the digital time so the appliance must be

switched off using the oven control knob.

The indicator light on the control panel is illuminated

when the solenoid valve is open. It will take

approximately 8 seconds after the cooker is turned

on before the solenoid valve is opened.

OVENS

THE MAIN OVEN

This oven is your simmering oven, your baking oven

and your roasting oven. It is a generous size of 390

x 310 x 406 mm (15

1

/4

x 12

1

/4

x 16 inches) - big

5

Page 7

One of the outstanding features of the Stanley is its

hotplate. It is generous in size and is machine

ground for maximum heat transfer to your

cookware.

The temperature of the hotplate is controlled by the

oven control thermostat. During the cold winter

months, when you are busy in the kitchen and you

want warmth from the cooker and heat in the

hotplate, a thermostat setting of 100oC will give you

the heat you require. If you need the hotplate to be

hotter, turn the thermostat up to a higher setting.

The hottest part of the hotplate is at the left side, the

centre is a little cooler and the right side cooler still.

The type of cookware you use will affect the

hotplate’s performance. Good contact between pan

and hotplate is essential.

On the right there is a small simmering plate. This

is ideal for keeping the coffee-pot warm, or you can

keep a kettle of water there ready to move on to the

hotplate. All sorts of culinary jobs can be done over

this gentle heat - dissolving gelatin, melting fats and

chocolate, steaming vegetables, and cooking soups

and stocks.

RESET BUTTON/HIGH LIMIT STAT

A high limit thermostat is located behind plinth on

bottom of cooker. Remove plinth by sliding approx

10mm to the left.

The thermostat button will pop out if the temperature

selected is exceeded. To reset simply unscrew the

protective cap and press the plastic button inward.

(See Figs 4, 5, & 6) If this situation persists contact

your Service Engineer.

enough to take a large turkey. It is of a cast-iron

construction which gives a perfect roast, sealing in

all the juices and flavours. The oven is fitted with a

thermometer which gives the average temperature

in the oven. There are two chromed steel shelves

and four shelf positions. The main oven is controlled

by the thermostat inside the top left hand door. The

top shelf will be a shade hotter than the centre of the

oven and the bottom shelf will be a shade cooler,

giving you different zones of heat in the main oven this allows you to cook foods that require different

temperatures in the same oven. Lifting the

insulating lids on the hotplate and cooking for any

length of time, will not affect the oven temperature.

The Stanley has hot flue gases flowing around four

faces of the main oven. The all-round heat allows

you to cook on the base of the main oven marvellous for browning and crisping the bases of

fruit pies and for finishing off pizzas and quiches.

You can also oven fry on the base of the oven using

metal or cast-iron cookware,and its ideal for

poaching smoked haddock - no more tell-tale

cooking smells in the kitchen, as these pass directly

into the flue.

THE LOWER OVEN

The lower oven measures 390 x 220 x 406 mm (15

1

/4

x 8

3

/4

x 16 inches). It has one chromed shelf

with two shelf positions. Like the main oven, it has

a cast-iron interior and gives a similarly superb

finish to dishes that need more gentle cooking.

The lower oven is heated from its top face as the

flue gases pass between the two ovens. The

temperature of this oven is approximately half that

of the main oven and the top shelf position is hotter

than the lower one.

The lower oven really comes into its own when you

are cooking a large family meal or having a baking

session - any time, in fact, when cooking foods that

need different temperatures.

HOTPLATE

The hotplate in this appliance is treated with a

protective coating, which when heated will

evaporate and will cause an odour for a short period

of time on first lighting.

IMPORTANT: DO NOT ALLOW THE COOKER

BURNER TO RUN WITH THE MAIN OVEN DOOR

OPEN, OTHER THAN WHEN ATTENDING TO

FOOD.

Fig.4

6

PLINTH

Page 8

Fig.6

Fig.5

BURNER CONTROL BOX LOCK-OUT RESET

BUTTON

The control box reset button, located on the base

underneath the left hand door will illuminate if the

burner experiences a problem.

Press the button to reset the control box. If this

situation persists, contact your Service Engineer.

(See fig. 7)

Fig.7

7

HOT WATER OUTPUT REDUCTION (DHW ONLY)

The requirement for hot water differs from

household to household. If excess hot water is

provided the temperature in the boiler will reach its

limit temperature and the appliance will shut down

until the limit stat is manually reset. The amount of

hot water provided can be reduced by hanging

optional boiler insulation panels to the boiler. (See

Fig. 8). These are available to order. The panels

can be hung individually or together for a further

reduction in boiler outputs.

When fitting both panels together, the panel must be

fitted to the left hand side first. Both panels are the

same size.

Fig.8

BURNER DOES NOT IGNITE

Check:

(a) that the electricity is switched on.

(b) that the oil supply valve is open and the line is

purged of air.

(c) that the thermostat reset button is pressed in.

(d) that the programmer is on and the thermostat is

calling for heat.

(e) that the “lock out” button on the control box at

the base of the cooker is not illuminated.

(f) If in doubt contact your local Stanley Engineer.

HOT PLATE INSULATING COVERS

The insulating covers retain most of the heat that

would otherwise be radiated into the kitchen. They

also retain the heat in the hot plates so that rapid

heating of cooking utensils will occur when one or

both of them are lifted for cooking purposes.

UNSCREW CAP IN

DIRECTION SHOWN

PLINTH

Page 9

COOKING UTENSILS

For best cooking results and economy of operation

use heavy based, flat bottomed utensils.

IMPORTANT: WHEN HOTPLATE IS NOT IN USE

ENSURE THAT HOTPLATE COVERS ARE IN A

DOWN POSITION.

IMPORTANT: DO NOT USE MIS-SHAPED PANS

WHICH MAY BE UNSUITABLE. DO NOT USE

ROUND BASED WOKS.

OPENING COOKER DOOR

Fig.10

To open the cooker door grip the door handle

between the fingers and thumb as per Fig.C, swing

the door handle in an outwards and upwards

direction as shown in Fig. D.

Fig.11

8

Fig.12

Fig.13

Fig.14

IMPORTANT: WE DO NOT RECOMMEND DEEP

FAT FRYING ON THIS APPLIANCE.

CLEANING

IMPORTANT: BE CAREFUL OF THE HOT

APPLIANCE.

General cleaning must be carried out when the

cooker is cool.

Stanley cookers are finished in a high gloss vitreous

enamel. To keep the enamel in the best condition

observe the following tips:

1. Wipe over daily with a soapy damp cloth,

followed by a polish with a clean dry duster.

2. If milk, fruit juice or anything containing acid is

spilt on the hob or down the cooker, be sure to

wipe it immediately or the vitreous enamel may

be permanently discoloured. Jam and

preservatives containing sugar can permanently

damage the vitreous enamel.

Hotplate

Covers

Simmer

Plate

Cover

Fig.9

Page 10

9

3. Keep a damp cloth to hand while cooking, to

wipe up any spills as they occur, so they do not

harden and become more difficult to remove

later.

4. If spills do become baked on, a cream cleanser

can be used. For stubborn deposits a soap

impregnated pad can be carefully used on the

vitreous enamel.

5. Use only products recommended by the

Vitreous Enamel Association, these products

carry the Vitramel label.

6. In the oven, spills and fat splashes are

carbonised at high temperatures: occasionally

brush out with a stiff brush. The shelves can be

soaked and cleaned with a cream cleanser.

7. Both insulating covers should be raised and

allowed to cool before cleaning the enamel with

a soapy damp cloth. Use a wire brush to keep

the cast iron hotplate clean.

DO NOT USE ABRASIVE PADS OR OVEN

CLEANERS CONTAINING CITRIC ACID ON

ENAMELLED SURFACES. ENSURE THAT

THE CLEANSER MANUFACTURERS

INSTRUCTIONS ARE ADHERED TO.

CHIMNEY CLEANING

Whichever type of flue is chosen, there must be

cleaning access to the whole of the flue system. The

flue of the chimney will need to be cleaned regularly.

The combustion products of any oil burning

appliance will have a descaling effect on hardened

soot deposits left from burning solid fuels.

Although, the chimney may have been cleaned of

loose soot prior to installation, it is imperative that

the chimney is inspected for scaled soot particles

after the first month of operation and any loose

material removed to avoid blockage.

SERVICING

We recommend that the cooker and burner be

serviced annually by an Authorised Stanley Service

Engineer.

MILD STEEL

The steel side panels and splash back must not be

cleaned with steel wool. Use only washing-up liquid

in hot water with a lint free cloth. Dry off and apply

a coat of good quality furniture polish.

Association

OVENS

Grease spillages will burn off from the oven interior

when the oven is hot and any other loose materials

can be emptied out with a cloth when cold. Stubborn

stains in the oven and on the shelves can be

cleaned off with a paste of bread soda and water.

HOT PLATE

The hotplate may be cleaned using a small amount

of paraffin oil or fine steel wool to remove rust or

cooking stains, dry off with a lint free cloth and apply

a light coat of cooking oil to preserve the finish.

COOKING GUIDANCE

GENERAL INFORMATION

GRILLING

Turn the oven thermostat to a reasonably high

setting and this will give a greater temperature at the

top of the main oven. The roasting tin supplied with

the cooker contains a grill rack. Place any foods that

require grilling onto the rack, and place the roasting

tin as near to the top of the oven as possible. Any

gratin type recipe that requires browning, place the

dish on a shelf as near to the top of the oven as it

will allow. For a delicious breakfast, lightly grease

the base of the roasting tin and place slices of bread

with a hole cut out of the centre, onto the base,

carefully breaking an egg into each hole. Foods

such as mushrooms and halved tomatoes can be

placed around the eggs. Place the grilling rack over

the eggs and lay the bacon, sausage, black pudding

etc., onto the grilling rack. The fat will drop onto the

eggs, helping to cook and flavour them. Fatty foods

such as lamb cutlets are best suited to this method

of oven grilling, most of the fats are drawn out into

the roasting tin. Certain foods with little fat, benefit

from pan frying/dry frying on the hotplate, using a

ribbed frying or griddle pan. The foods cooked this

way look attractive with the bar markings from the

pan.

THE CARE OF YOUR COOKER

The vitreous enamel finish on your cooker is tough

and hard wearing but should be treated with care.

Acidic spills on the hob should be wiped off with a

clean damp cloth. The vitreous enamel front, sides

and hob only need a wipe with a warm soapy cloth,

then a polish with a dry one. Do not use an abrasive

cleaning material on the vitreous enamel. If there

are stubborn marks on the hob, use a good quality

enamel cleaner. Look for cleansers carrying the

VEDC (Vitreous Enamel Development Council)

Page 11

Follow the manufacturers instructions carefully. The

hotplate will carbonise any food spilt on it, which

should be removed with a wire brush or metal

scraper. This will ensure a good contact between

cooking utensil and the hotplate. Take care when

cleaning the insulating lids, the hotplate may be hot.

The ovens are self cleaning, any food that spills on

the oven floors will carbonise and can be brushed or

scraped away. It is often easier to use the vacuum

cleaner to remove all the bits.

COOKWARE

You do not have to rush out and buy a new set of

pans when you take delivery of your new Stanley

cooker, but it is advisable to check your cookware.

Thin, lightweight saucepans are liable to buckle, so

it is recommended that you use saucepans which

have a flat, thermic base. This design of saucepan

will give you complete contact with the hotplate and

maximum heat retention for a good cooking

performance. This design is usually of 18/20

stainless steel, with the thermic base encapsulated

onto the bottom of the pan. The base will have a

core of aluminium sandwiched between two layers

of stainless steel. The aluminium does not come

into contact with the food while cooking, but will very

quickly pick up the heat and evenly distribute it over

the base of the pan. Some continental designs of

saucepans will have this inner sandwich of

aluminium, not only at the base but up the sides as

well. Many people prefer the look of cast iron

cookware. This cookware is just as versatile as

stainless steel, absorbing and distributing the heat

evenly, and serving from the oven to table. They are

available in a range of colours and designs, some

with knobs and handles of a heat resistant material.

Good quality saucepans can be expensive to buy,

but the versatility they offer means that fewer items

need to be purchased. Oven proof earthenware will

also produce satisfactory results. Your traditional

cake tins, baking trays, loaf tins and any other

favourite ovenware you use, will be suitable. There

is bakeware on the market of Continental design

which has a steel base, ideal for quickly absorbing

the heat. It is covered with a magnum (enamel like)

coating, which is safe to cook on, non stick effect

and easy to clean. A roasting tin, containing the

grilling rack is provided. You can use a pressure

cooker on the hotplate but however, do check that

the base of the pressure cooker makes good contact

with the hotplate.

All timings in the cooking chart are guidelines only,

as there are no set rules for roasting meat - each cut

lends itself to several different ways of preparation

and cooking and each family will have a preference.

When meat is roasted quickly the juices are sealed

in, preserving the full flavour, but there will

sometimes be shrinkage. Some people prefer to

slow roast at a lower temperature, a method that will

reduce shrinkage and give a more tender joint.

Whichever roasting method you choose, the joint

should first be weighed to calculate the cooking

time. Place the meat on the grilling rack in the

roasting tin, fat side uppermost. This will baste the

meat as it is cooking, but check the roast from time

to time and using a metal spoon, baste the meat

yourself.

If you are using a meat thermometer, do take care

when inserting it that it does not touch bone or

excess fat. This will give you a false internal

reading.

Stuffed joints of meat will need extra cooking time approximately 10 minutes more for every 500g

(1 lb).

10

Page 12

TYPE OF MEAT TEMPERATURE TIMING per 500g (1 lb)

BEEF ON THE BONE 180oC RARE 10 mins + 10 mins over

SIRLOIN MED 12mins + 12 mins over

FORE RIB WELL DONE 20 mins + 20 mins over

BEEF BONED AND ROLLED 180oC RARE 12 mins + 12 mins over

TOPSIDE

TOP RUMP MED 15 mins + 15 mins over

FILLET WELL DONE 20 mins + 20 mins over

ROLLED RIB

PORK ON THE BONE 180oC 25 mins + 25 mins over

SHOULDER

LOIN

LEG

PORK BONED AND ROLLED 180oC 30 mins + 30 mins over

SHOULDER

LOIN

LEG

LAMB ON THE BONE 180oC MED 20 mins + 20 mins over

CROWN WELL DONE 25 mins + 25 mins over

GUARD OF HONOUR

LEG

BEST END

LOIN

LAMB BONED AND ROLLED 180oC MED 25 mins + 25 mins over

WELL DONE 30 mins + 30 mins over

VEAL BONED AND ROLLED 180oC MED 20 mins + 20 mins over

TOPSIDE WELL DONE 25 mins + 25 mins over

SHOULDER

FILLET

VENISON ON THE BONE 180oC RARE 12 mins + 12 mins over

HAUNCH (LEG) MED 15 mins + 15 mins over

SADDLE WELL DONE 20 mins + 20 mins over

RABBIT/HARE 180oC Up to 1 kg (2 lb): 45 - 60 mins

Up to 2 kg (4 1/2 lb): 60 - 90 mins

CHICKEN 190oC 20 mins + 20 mins over

TURKEY 160oC

3.6 - 4.5 kg (8 - 10 lb) 3 1/2 - 3 3/4 hrs

4.9 - 5.4 kg (11 - 12 lb) 3 3/4 - 4 hrs

5.4 - 6.3 kg (12 - 14 lb) 4 - 4 1/2

6.3 - 7.2 kg (14 - 16 lb) 4 1/4 - 4 1/2 hrs

7.2 - 8.1 kg (16 - 18 lb) 4 1/2 - 4 3/4 hrs

8.1 - 9 kg (18 - 20 lb) 4 3/4 - 5 hrs

DUCK 200oC MED 25 mins + 25 mins over

WELL DONE 30 mins + 30 mins over

GOOSE 180oC 20 mins + 20 mins over

PHEASANT 200oC 50 - 60 mins total cooking

GROUSE 220oC 30 - 45 mins total cooking

PARTRIDGE 220oC 45 mins total cooking

11

Page 13

You will soon come to look upon the Stanley as a

reliable companion to help you during a busy baking

session or when you are preparing that extra-special

meal. The following tips are ways in which you will

find the Stanley invaluable: no doubt you will quickly

add discoveries of your own to the list.

1. Baking: If you are using butter or margarine

from the refrigerator, simply place the required

amount of fat in a heatproof bowl on the hob,

near to the hotplate. It will be quickly brought

to room temperature, making it easier to work

with.

2. Breadmaking: Stand the required liquid for

the recipe in a heatproof jug on the hob near

the hotplate to warm. Take care not to overheat

as yeast is killed at high temperatures.

3. Breadmaking: Depending on what mode the

cooker is set at, the hob, plate rack or lower

oven can be used for proving the dough.

4. Baking: To dissolve gelatin, place two

tablespoons of water or liquid from the recipe in

a small heatproof bowl. Sprinkle the required

amount of gelatin on the liquid and place on or

near the hotplate to dissolve. A small stainless

steel bowl is useful for this type of job.

5. Baking: When melted chocolate is needed in

a recipe or for decoration work, simply place

the chocolate in a heatproof bowl near the

hotplate. This method is easier than placing

over a pan of hot water, which can often splash

into the chocolate and spoil it.

6. Baking: Syrup tins and jam jars with only a

little left in them are easier to empty when they

have warmed on the hob.

7. Cooking: If a recipe requires a small amount

of fried or softened onion, place the finely

chopped onion and a little butter or oil in a

heatproof bowl on or near the hotplate to

soften. I use this method often, because it is so

much easier than having to wash up a fryingpan! Many different types of vegetables can be

prepared this way before adding to a recipe.

8. Cooking: To make breadcrumbs, simply place

the bread on a baking sheet in the lower oven

and allow to dry out. Crush and store for future

use.

9. Cooking: To make croutons, cut the bread into

small cubes, place in a shallow cast iron dish

with a little oil and fry, using the base of the

main oven. (If the oven is in use, fry on the

hotplate) Drain, spread out on a baking sheet

and put to crisp in the lower oven. Croutons

can be frozen for use when required.

10. Drying: An abundance of fresh herbs need not

be wasted. Place on a baking sheet, after

washing and patting dry with kitchen paper, and

leave to dry in the lower oven. Store for future

use.

11. Drying: Cooker rice can be spread out on a

baking sheet and left to dry in the lower oven.

12. Baking: When making fruit cakes, wash the

dried fruit, place on a baking sheet and allow to

dry off in the lower oven before use. Moist fruit

will sink to the bottom of a cake and spoil it.

13. Preserving: When you are bottling, the depth

of the main oven makes it easy to sit a tray of

bottled fruit all on the same shelf to cook in one

session.

14. Preserving: When you are making jam the

graduated hotplate enables you to control the

simmering of a large preserving pan much

more easily than on a conventional cooker,

where the pan is too large for the burner or ring.

The warming of sugar, drying of the prepared

fruit and the warming of jars and bottles can all

be done with plenty of space using the lower

oven and plate rack, if you have one.

USER COOKING TIPS

12

Page 14

13

WIRING DIAGRAM - DIGITAL TIMER

CYC - STAT:

Remove link between

Terminal 1 and Terminal

31. Connect cyc - stat

on to Terminals 1 & 31.

PL - 13 AMP PLUG TOP

F - FUSE BLOCK COMPLETE WITH 3 AMP FUSE

EVG - SOLENOID VALVE

TR - TRANSFORMER

MV - BURNER MOTOR

FR - PHOTOCELL

OT - OVEN THERMOSTAT

LT - HIGH LIMIT THERMOSTAT

RB - RUNNING LAMP

S - SUPPRESSER

Page 15

14

WIRING DIAGRAM (MECHANICAL TIMER)

CYC - STAT:

Remove link between

Terminal 1 and Terminal

31. Connect cyc - stat

on to Terminals 1 & 31.

PL - 13 AMP PLUG TOP

F - FUSE BLOCK COMPLETE WITH 3 AMP FUSE

EVG - SOLENOID VALVE

TR - TRANSFORMER

MV - BURNER MOTOR

FR - PHOTOCELL

OT - OVEN THERMOSTAT

LT - HIGH LIMIT THERMOSTAT

RB - RUNNING LAMP

S - SUPPRESSER

Page 16

15

FAULT FINDINGS

PROBLEM CAUSE REMEDY

1. Poor Flue Draught: (a) Obstruction. (a) Clear and clean.

(b) Chimney too low. (b) Raise height above ridge.

(c) Chimney not lined. (c) Fit flue liner 125mm (5”)

(d) Insufficient Air Supply (d) Increase provision of free air for ventilation and combustion

2. Excessive Flue Draught (a) High chimney. (a) Fit draught stabiliser venting to the outside atmosphere.

3. Down Draught: (a) High trees (a) Raise chimney height.

(b) High buildings (b) Raise chimney height.

(c) Low chimney. (c) Raise chimney height.

(d) Positive pressure zone. (d) Check flue termination

4. Cooker Smoking: (a) Insufficient primary air. (a) Provide additional room air inlet or adjust burner air intake.

(b) Chimney choked. (b) Clean chimney.

(c) Downdraught. (c) Raise chimney height.

(d) Poor combustion. (d) Check air supply.

5. Hot Plate Not Heating: (a) Burner cutting out. (a) Increase cooker thermostat setting.

(b) Utensils not flat. (b) Use machined based utensils.

6. Oven Not Heating: (a) Flueways blocked with soot. (a) Clean out.

7. Intermittent Performance: (a) Cooker starved of primary air. (a) Provide air inlet in room.

(b) Extraction fan in room. (b) Provide additional air inlet in room.

(c) Dirt in nozzle. (c) Clean or replace nozzle.

(d) Dirty burner. (d) Service burner.

(e) Faulty Thermostats. (e) Replace if defective.

(f) Dirty flueways. (f) Clean flueways.

(g) Dirty Oil Filter (g) Clean or replace

(h) Worn nozzle (h) Replace nozzle

DHW Model Only (J) Cylinder thermostat interruption (J) Release hot water from cylinder

It is of the utmost importance to keep the flue pipe and chimney clear of deposits. Blocked or

partially obstructed flueways and chimneys will cause dangerous fumes to be emitted into the room,

these may well be invisible.

Rev: 003 DP 070925

N00356AXX

Manufactured by

Waterford Stanley Ltd.,

Unit 210, IDA Industrial Estate, Cork Road,

Waterford, Ireland.

Tel: (051) 302300 Fax (051) 302315

Loading...

Loading...