Page 1

TO BE INSTALLED BY A TRAINED COMPETENT PERSON

Installation and Commissioning Instructions

This Manual is to be left with end user.

BRANDON

60K/80K/100K OIL FIRED COOKER

Page 2

TABLE OF CONTENTS

PAGE NO.

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3. Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4. Burner Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5. Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6. Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

7. Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

8. Hearth Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

9. Electrical Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

10. To Access The Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

11. Clearances to Combustibles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

12. Flue Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

13. Pre-Installation Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

14. Chimney . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

15. Sealing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

16. Flue Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

17. Flue System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

18. Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

19. Suitable Materials. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

20. Flue Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

21. Use of Existing Flues and Chimneys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

22. Draught Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

23. Flue Liners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

24. Factory Made Insulated Chimneys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

25. Ventilation & Combustion Air Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

26. Outside Air Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

27. Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

28. Pipe Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

29. Down Draughts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

30. Water Pipe Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

31. Draining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

32. Internal Pump Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

33. Water Circuit Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

34. Care For Your Central Heating System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

35. Indirect Domestic Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

36. Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

37. General Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

38. Safety Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

39. By-Pass Loop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

40. Open System (with pump on return) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

41. Sealed System (with pump on flow) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

42. Open System (with pump on flow). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

43. Interlink System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

44. Provision For Filling Sealed System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

45. S Plan System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

46. Y Plan Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1

Page 3

PAGE NO.

47. Wiring Diagram 100K/80K/60K . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

48. S Plan Wiring Diagram Using Multi Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

49. S Plan Wiring Diagram Using Same Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

50. S Plan Wiring Diagram Showing Zone Controlled By Underfloor Heating . . . . . . . . . . 23

51. Fuel Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

52. Oil Storage Tanks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

53. Fuels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

54. Fuel Supply Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

55. Single Pipe Supply System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

56. Two Pipe Supply System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

57. Single Pipe System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

58. Tiger Loop Oil Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

59. Installation Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

60. Removal of Transport Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

61. Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

62. Door Handle Replacement Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

63. Installation Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

64. Spares Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

65. Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2

Page 4

3

Introduction

Congratulations on purchasing this fine Irish made Oil-fired Central Heating Cooker. It is built to exacting

standards and it will give you every satisfaction in use.

Please read the following information before operating this excellent product.

This appliance is hot while in operation and retains its heat for a long period of time after use. Children,

aged or infirm persons should be supervised at all times and should not be allowed to touch the hot

working surfaces while in use or until the appliance has thoroughly cooled.

To ensure safety, satisfaction and reliable operation, this quality cooker should be installed by a trained and

competent person. The central heating facility and the hot water systems involved must conform fully to good

plumbing practice, established Standards/Regulations and OFTEC recommendations.

The complete installation must be done in accordance with current Standards and Local Codes. It should be

noted that the requirements and these publications may be superseded during the life of this manual.

IMPORTANT NOTICE: Any alteration to this appliance that is not approved in writing by Waterford Stanley will

render the guarantee void.

IMPORTANT — Control of Substances Harmful to Health:

It is the Users/Installers responsibility to ensure that the necessary personal protective clothing is worn when

handling materials that could be interpreted as being injurious to health and safety.

When handling Firebricks, Fire Cement or Fuels, use disposable gloves.

Exercise caution and use disposable masks and gloves when handling glues and sealants.

When working with fibre glass, mineral wool, insulation materials, ceramic blanket/board or kerosene fuel oil,

avoid inhalation as it may be harmful. Avoid contact with skin, eyes, nose and throat. Use disposable protection.

Installation should be carried out in a well ventilated area.

As manufacturers and suppliers of cooking and heating appliances, we take every possible care to ensure, as

reasonably practicable, that these appliances are so designed and constructed as to meet the general safety

requirements when properly used and installed.

* Section 10 of the Consumer Protection Act 1987.

* Safety, Health and Welfare at Work Act.

Page 5

SPECIFICATION

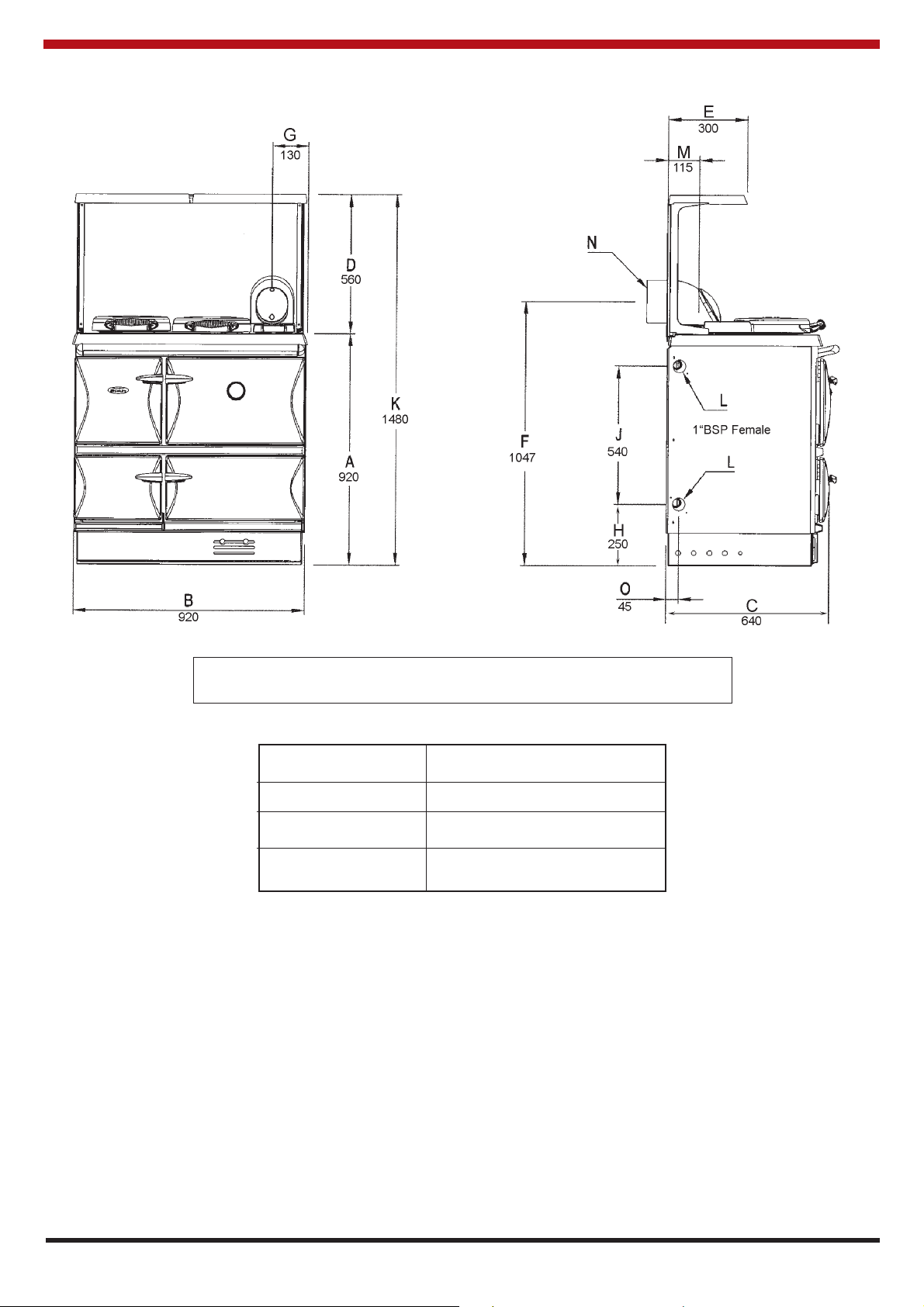

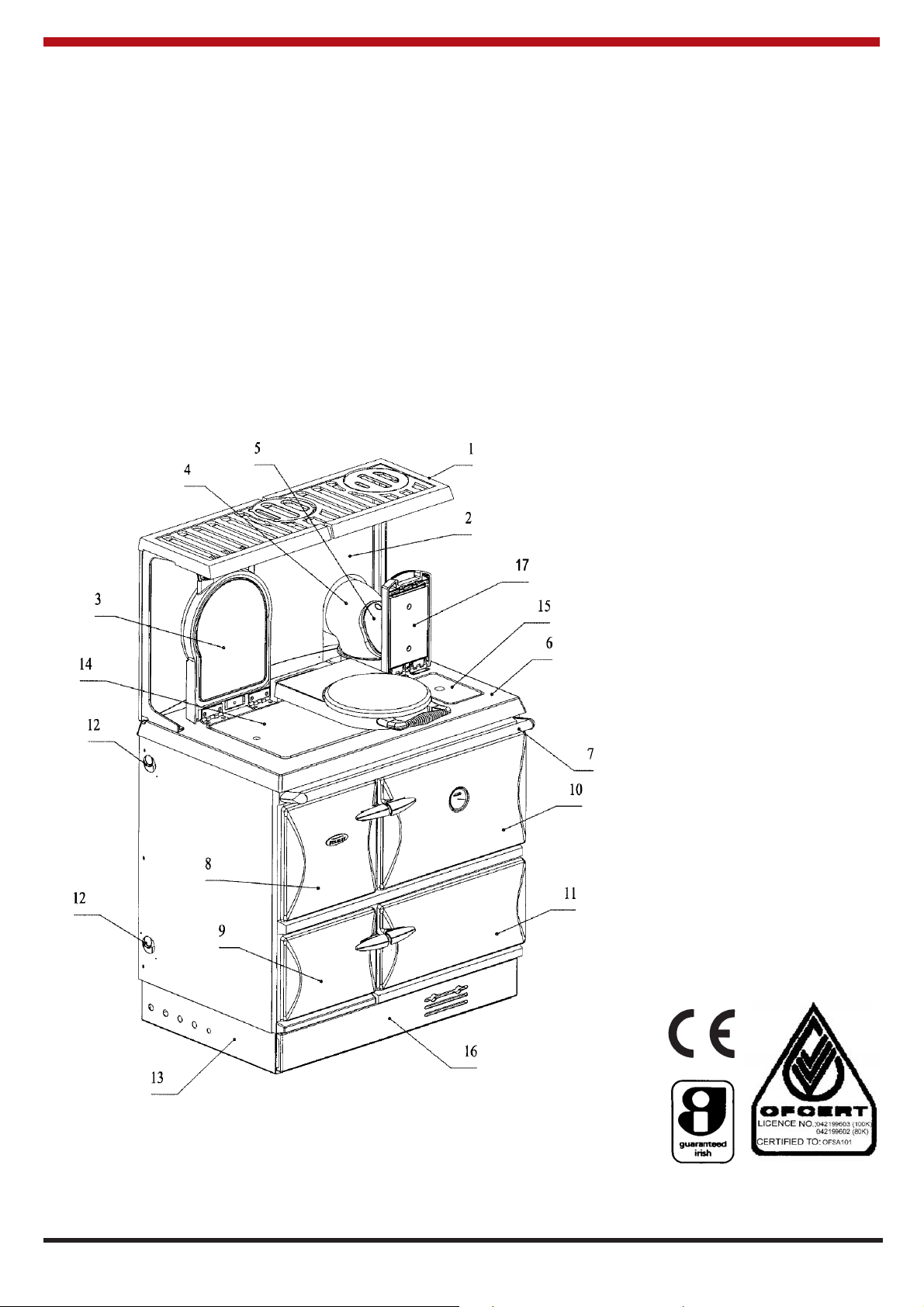

Fig. 1

FEATURE METRIC (mm)

Hot Plate 550W x 323L

Roasting Oven 390W x 310H x 406D

Simmering Oven: 390W x 220H x 406D

Note: Dimensions stated in Fig.1 are in millimetres unless

otherwise stated and may be subject to a slight +/- variation.

4

Ø

150

Page 6

100K

BOILER OUTPUTS: 29.3kW - 100,000 Btu’s/Hr.

RADIATOR SURFACE: 53 m

2

(571 ft.2) heating surface only.

48 m

2

(514 ft.2) heating surface and domestic hot water.

FLUE GAS FLOW: Boiler: 0.005m

3

/s Oven: 0.0026m3/s.

SPACE HEATING: 2.91 kW (10,000 Btu’s/hr) cooking mode / 0.7 kW (2,500 Btu’s/hr) boiler

mode.

FLUE GAS TEMPERATURE: Boiler: 180°C (356°F) Cooker: 250°C. (482°F)

BOILER CAPACITY: 17 litres (3.74 Gal.).

BOILER MATERIAL: Mild steel.

COOKER WEIGHT: 385Kg (850 lbs).

80K

BOILER OUTPUTS: 23.45kW - 80,000 Btu’s/Hr.

RADIATOR SURFACE: 42.5 m

2

(457 ft.2) heating surface only.

37.2 m

2

(400 ft.2) heating surface and domestic hot water.

FLUE GAS FLOW: Boiler: 0.0044m

3

/s Oven: 0.0026m3/s.

SPACE HEATING: 2.91 kW (10,000 Btu’s/hr) cooking mode / 0.7 kW (2,500 Btu’s/hr) boiler

mode.

FLUE GAS TEMPERATURE: Boiler: 200°C (392°F) Cooker: 230°C. (446°F)

BOILER CAPACITY: 17 litres (3.74 Gal).

BOILER MATERIAL: Mild Steel.

COOKER WEIGHT: 380Kg (838 lbs).

60K

BOILER OUTPUTS: 17.58kW - 60,000 Btu’s/Hr.

RADIATOR SURFACE: 32 m

2

(344.45 ft.2) heating surface only.

26.5 m

2

(285 ft.2) heating surface and domestic hot water.

FLUE GAS FLOW: Boiler: 0.0031m

3

/s Oven: 0.0026m3/s.

SPACE HEATING: 2.91 kW (10,000 Btu’s/hr) cooking mode / 0.7 kW (2,500 Btu’s/hr) boiler

mode.

FLUE GAS TEMPERATURE: Boiler: 170°C (356°F) Cooker: 250°C. (482°F)

BOILER CAPACITY: 17 litres (3.74 Gal.).

BOILER MATERIAL: Mild steel.

COOKER WEIGHT: 385Kg (850 lbs).

5

FUEL: 28 Sec Kerosene

MAINS CURRENT: 230v - 240v, 50 Hz A.C.

I.P. PROTECTION: IP 20

ELECTRICAL INPUT: 90 Watts

SUPPLY FUSE RATING:3A

MAX BOILER WORKING

PRESSURE: 1.9 bar 27.3 P.S.I.

TEST PRESSURE OF

BOILER: 3 bar 43.5 P.S.I

OPERATING TEMPERATURE

LIMIT IN BOILER: 96

o

C (205oF)

TECHNICAL DATA

Page 7

THIS APPLIANCE MUST BE CONNECTED TO A FULLY PUMPED SYSTEM.

6

BURNER SPECIFICATION

BOILER BURNER COOKER BURNER

100K 80K 60K 100K/80K/60K

Burner Input

(kW) Continuous Running 34.2 27.7 21.4 19.5

(kW) Cycling N/A N/A N/A 4.4

(Btu’s) Continuous Running 116,760 94,600 73,000 66,875

(Btu’s) Cycling N/A N/A N/A 14,950

Boiler Output

(kW) Continuous Running 29.3 23.5 17.6 2.1

(kW) Mean Cycling N/A N/A N/A 1.2

(Btu’s) Continuous Running 100,000 80,000 60,000 7,000

(Btu’s) Mean Cycling N/A N/A N/A 4,000

Nozzle 0.85 80

o

S (C.E.N) 0.65 80oS (C.E.N) 0.55 80oS (C.E.N) 0.5 60oS (C.E.N)

Pressure

(Bar) 7.4 7.4 7.1 7.1

(PSI) 107 108 103 110

Fuel Consumption

(L/Hr) Continuous Running 3.6 2.9 2.2 2.1

(L/Hr) Cycling N/A N/A N/A 0.47

US Gal/Hr

Continuous Running 0.95 0.77 0.58 0.55

US Gal/Hr Cycling N/A N/A N/A 0.12

All data are taken under laboratory conditions and may vary in use

Design flow rate through the boiler 38.2 L/min / 8.4 Gpm

Static differential across the boiler 52.4 mbar / 21” wg

Dynamic pressure differential across the boiler 33 mbar / 13.23” wg

Differential Pressure Across the Boiler

Note: Design temperature differential across the boiler = 11°C (20°F)

Page 8

7

REGULATIONS

The installation must comply with the current editions of the following:

BS 5410: Oil Installations Part 1 under 45kW.

The Building Regulations: Part J England, Wales,

Part F Section 4 Scotland, Part L Northern Ireland and Part J Ireland.

The Control of Pollution (Oil) Regulations.

BS 5449: Forced circulation hot water central heating systems for domestic installations.

Health and Safety at Work Act.

BS 7671: Requirements for Electrical Regulations. Safety Document 635: The Electricity at Work

Regulations.

BS 7593: Treatment of Water in Domestic Hot Water Systems.

BS 7074 Part 1 & 2: Hot Water Supply.

BS 4814: Sealed System.

SCHEMATIC

1. Platerack (to order)

2. Splashback (to order)

3. Hotplate Covers

4. 150mm (6”) 90° Bend

5. Bend Cleaning Plate

6. Hob

7. Towel Rail

8. Firedoor

9. Burner Door

10. Main Oven Door

11. Simmer Oven Door

12. Boiler Tappings

13. Base Frame

14. Hotplate

15. Simmer and Cleaning

Plate

16. Plinth

17. Simmer Plate Cover

Fig 2.

Page 9

8

LOCATION

When choosing a location for this appliance you

must have:

(a) Sufficient room for the installation (see

clearances), a satisfactory flue (see flue

system), and an adequate air supply for correct

combustion and operation (see Ventilation and

Combustion air supply).

(b) Adequate space for maintenance and air

circulation.

(c) Solid floor or base of non-combustible material

which is capable of supporting the total weight.

(see Technical Data).

Note: Installation should be carried out in a well

ventilated area.

HEARTH CONSTRUCTION

When a non-combustible floor surface is not

available, then the cooker must be placed on other

insulating material. We recommend a slab of

precast concrete 40mm (1

1

/2

) inches deep. If other

insulating material is being used, the dimensions of

the slab of this insulating material must afford similar

protection. This hearth must extend 150mm (6

inches) to either side of the appliances and 225mm

(9 inches) to the front.

ELECTRICAL SUPPLY

All wiring external to the appliance must conform to

the current BS 7671 (U.K.), & Safety Document 635,

ETC: Part 1 Section 5.6.4. The Electricity at Work

Regulations. The cooker requires a 230V–240V, 50

Hz supply. Connection of the appliance and any

system controls to the mains supply must be

through a moulded on plug top, (which is fitted with

a 3 amp fuse) which is fitted to the appliance in

accordance with EN 60335, Consumer Protection,

SI 1994 No. 1768, plug and sockets etc. (safety)

Regulations 1994.

Always install in accordance with current local wiring

regulations.

You should always, when either exposing or working

with wiring, consult a qualified electrician.

WARNING: THIS SUPPLY MUST BE EARTHED

(Refer to B.S. 7430: Code for Practice of Earthing).

Where a risk of low voltage can occur, a voltage

sensitive device should be fitted to prevent start up

of the burner so as not to endanger the installation.

The primary fuse is located in the control box tray.

To isolate the appliance completely unplug from the

mains socket. Always ensure that this socket is

easily accessible and close to the appliance.

Persons in charge of this appliance should be aware

of this socket outlet position.

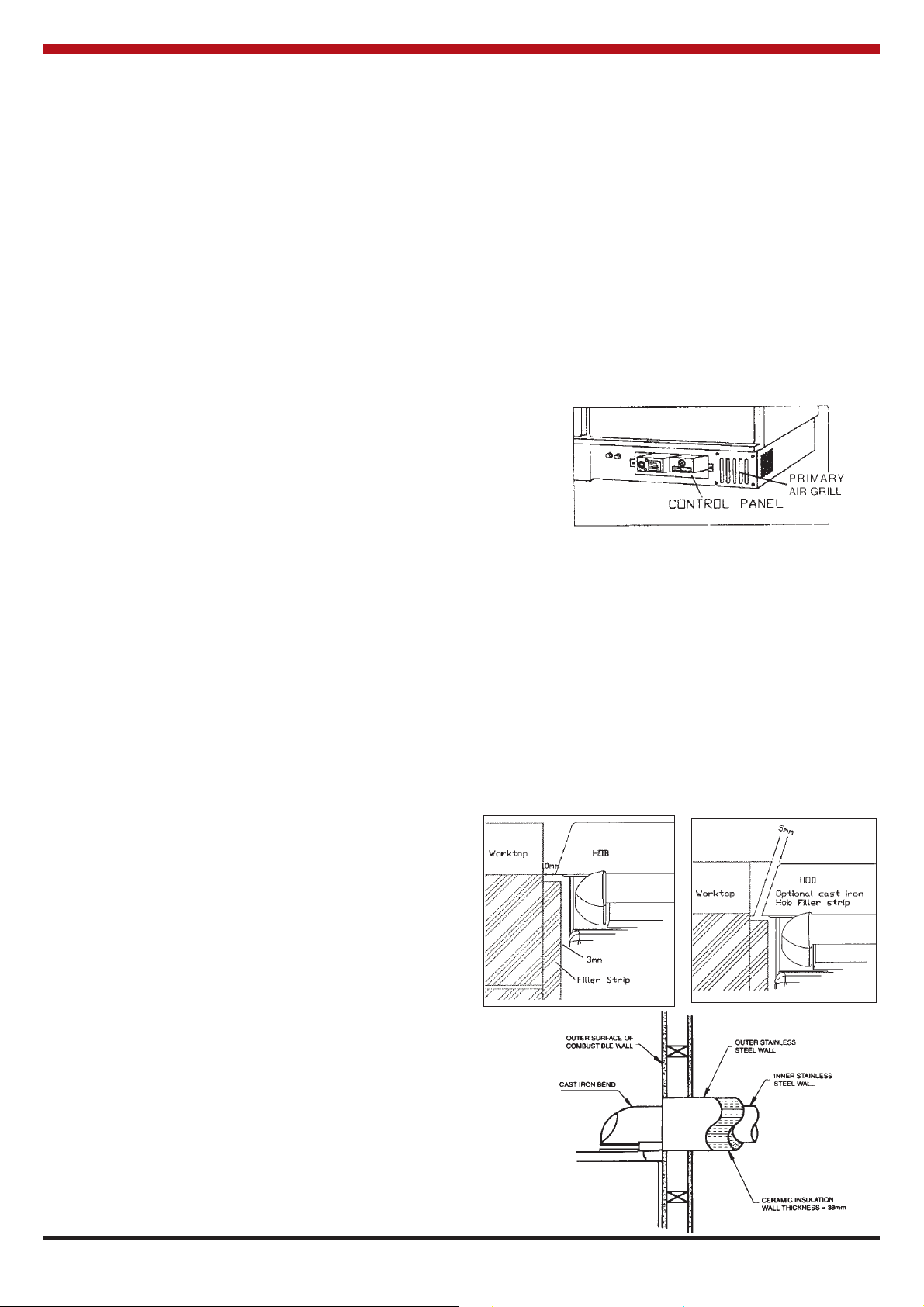

TO ACCESS THE CONTROL PANEL (See Fig.3)

a. The plinth can be removed by sliding it

approximately 20mm to the left.

b. Remove the 6 screws which hold the kicker

panel in place.

c. Remove the 2 retaining screws on either

side of the Control Consul.

d. Carefully withdraw the Control Consul, ensuring

that no strains are subjected to the wiring.

e. Connection to be carried out in accordance with

the Wiring Diagrams. (See fig’s 26 to 29

Inclusive)

Fig. 3

CLEARANCES TO COMBUSTIBLES

When bringing your kitchen units up to the sides of

the cooker leave a 10mm gap between the Stanley

and adjacent units, this gap can be reduced by

fitting an optional hob side filler strip to the Stanley

leaving a 5mm gap (see fig. 4 & 5). Likewise the

base of your units can be brought up flush to the

Stanley’s built-in plinth.

When bringing the work top up to the side of the hob

leave a 10mm gap to combustible material (see fig.

4).

Fig 4

Fig 5

Fig. 6

Page 10

9

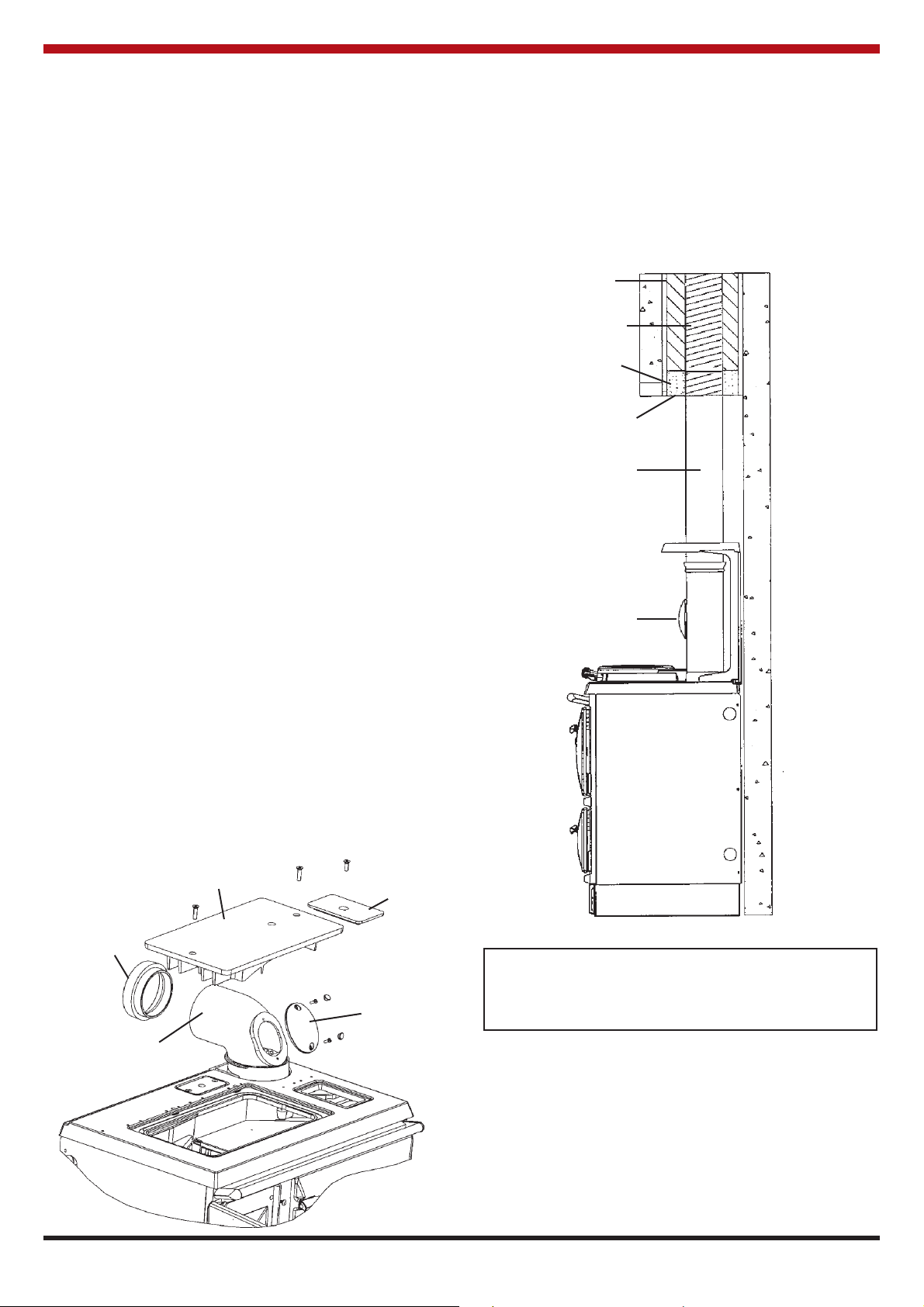

FLUE SYSTEMS

PRE-INSTALLATION CHECK

Before installing the cooker, check that the chimney

is clean and clear of obstructions. Cracked

brickwork and leaking joints should be made good.

You must reassure yourself (with the benefit of

professional advice) that the brickwork and system

generally is of the standard suitable to support the

cooker in a safe and efficient manner.

Where flue piping passes through a closure plate

with a sliding door, ensure that the pipe continues up

and is ultimately connected to the flue liner and well

sealed with fire cement.

Do not connect to a flue serving another appliance.

Always ensure that the connection is to a chimney of

the same size - never connect to one of smaller

dimensions. Flues wholly constructed of single skin

pipe are not recommended under any

circumstances. Due to their inability to retain heat

such flues will inevitably give rise to the formation of

condensation.

IT IS NOT RECOMMENDED TO CONNECT TO A

FLUE SMALLER THAN 150mm (6”) OR IN

EXCESS OF 175mm (7”) DIAMETER.

150mm (6”) Diameter Flue Liner

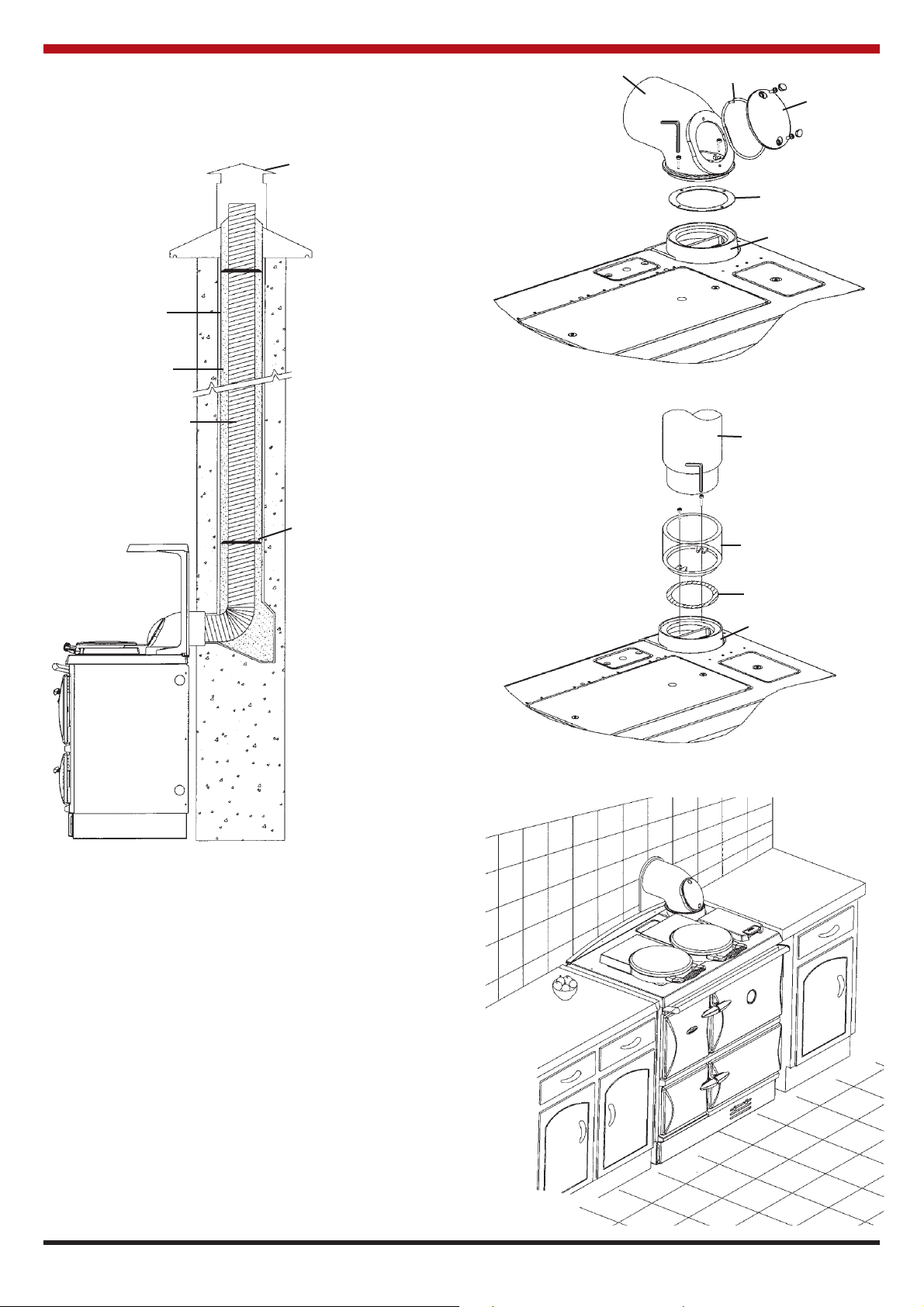

Fig. 8.

Note:

Fill voids and area around liner with vermiculite or a

comparable approved material. (See Fig. 8)

Fig.7

CHIMNEY

Generally the most effective chimney for oil is one

that is straight, avoid offsets and terminate with a

straight sided pot.

Where the flue passes through a combustible

material, a twin wall solid packed insulated chimney

connector must be used and must come flush with

the outer surface of the material and run all the way

to the masonry chimney or to the point of termination

of the factory made chimney. (See Fig.6)

(You should discuss the installation of your Stanley

cooker with your builder in this regard in the case of

a newly fitted kitchen.

When installing a non combustible worktop, it is

necessary to allow adequate clearance for the

removal of the hob.

Vermiculite or a

comparable material

150mm (6”)

flexible flue liner

Fire Sealing

Cement

Closure Plate

Flue Diameter of

150mm (6”)

Cleaning Plate

Simmer

Plate

Pipe Bend

Cleaning Plate

Hotplate

Flex Pipe

Adaptor

Seal Bend to

Connecting Collar

Page 11

10

Flue greater than 150mm

(6”) Diameter

SEALING

This cooker and flue system operate under a

positive pressure. It is essential that all flue joints

are tightly sealed against flue gas leakage and

tested accordingly. (See fig. 7, 8, 9, 10 & 10a)

There is a flue pipe collar available which surrounds

the flue pipe where it meets the wall, giving a tidier

finish to a tiled background. The hob back filler piece

and flue collar rosette are available as an optional

extra. (See Fig.11)

Fig.11

Fig. 9

Fig.10

Fig.10a

Refer to Flue Assembly Instruction sheets

Approved

Flue Terminal

Bend

Gasket

Cleaning

Cover

Gasket

Collar

Pipe

Spigot

Gasket

Collar

Clay Liner

Vermiculite Filler

150mm (6”) Flexible Flue

Liner

Sealing & Clamping

Plate

Seal Flue

Connector

Page 12

FLUE HEIGHT

The flue must be high enough 4.5 mts (15ft)

minimum measured vertically from the appliance

outlet to the top of the flue terminal to allow the flue

gases to vent into the clear air, away from the

turbulence that may be caused by roof structures,

other chimney stacks, etc. The terminal position

should be in accordance with the relevant Building

Regulations.

FLUE SYSTEM

Where the standard masonry chimney is not

available, a proprietary type of non-combustible or

non-corrosive material 150mm (6”) twin wall fully

insulated pipe may be used. The pipe must

terminate at a point not lower than the main ridge or

adjacent outside obstructions. With such

installations, access to the chimney must be

provided for cleaning purposes.

Horizontal runs more than 450mm (18”) and 90°

bends numbering more than 2 per installation

should be avoided.

Fig.12

STANLEY CAST IRON PIPES AND BENDS ARE

HIGHLY RECOMMENDED FOR INTERIOR USE.

WHERE THE APPLIANCE SPIGOT OR FLUE

PIPE PROTRUDES INTO THE CHIMNEY, CARE

SHOULD BE TAKEN TO ENSURE THAT IT DOES

NOT BLOCK THE CHIMNEY.

SUITABLE MATERIALS

* Mineral Fibre cement pipes.

* Insulated metal chimneys conforming to B.S.

4543. (a galvanised finish is not suitable for

exterior use).

* Clay flue linings.

* Pre-cast concrete chimney blocks,

incorporated into the building structure. It is

particularly important that the correct

connection block be provided at the base of

the flue.

* Cast iron or acid resistant vitreous enamel

lined mild steel to B.S. 41.

* Sheet metal.

FLUE CLEANING

The flue pipe must be fitted with a cleaning plate.

The flue must be inspected annually and cleaned

when necessary.

USE OF EXISTING FLUES AND CHIMNEYS

When connecting to an existing chimney it is

necessary to line the flue using approved 150mm

(6”) rigid or flexible stainless steel flue liner.

An existing flue pipe or chimney that has proved to

be satisfactory when used for solid fuel can

normally be used for this appliance provided that its

construction, condition and dimensions are

acceptable. Flues that have proved to be

unsatisfactory, particularly with regard to down

draught, must not be considered for this appliance

until they have been examined and any faults

corrected. If there is any doubt about an existing

chimney a smoke test should be carried out.

Before connecting this appliance to a chimney or

flue pipe which has previously been used with

another fuel, the chimney or flue pipe should be

thoroughly swept and lined accordingly.

All register plates, restricter plates and dampers etc.

which could obstruct the flue at a future date should

be removed before connecting this appliance.

Where a chimney is not required to be lined a

suitable void should be provided at the base to

contain any debris which might fall from the inside

wall, so as to prevent debris from obstructing the

appliance flue outlet. (Removal of debris should be

facilitated by the provision of an access door).

If it is necessary to offset the chimney the

recommended angle is 60° to the horizontal and the

statutory minimum is 45°. (See Fig.12)

CONNECTIONS

Stanley produces the appropriate pipes and bends

used in conjunction with this cooker. Waterford

Stanley Limited will accept no liability whatsoever

ever in the event that alternative pipes and bends

are used in the installation. A cast iron 90° bend

with cleaning door is provided with the cooker. A

vertical cast iron outlet pipe with cleaning door is

also available. A flexible flue adaptor is supplied,

this is to connect the cooker 150mm (6”) bend or

straight pipe to the 150mm (6”) chimney liner.

ALL FLUE CONNECTIONS MUST BE

THOROUGHLY SEALED. Blocked chimneys are

dangerous, keep chimneys and flue ways clean,

read the operating instructions.

11

Page 13

12

This void should have a depth of not less than

250mm (10”) below the appliance connection.

The combustion products will have a descaling

effect on hardened soot deposits left from burning

solid fuels.

ALTHOUGH THE CHIMNEY MAY HAVE BEEN

CLEANED OF LOOSE SOOT PRIOR TO

INSTALLATION, IT IS IMPERATIVE THAT THE

CHIMNEY IS INSPECTED FOR SCALED SOOT

PARTICLES AFTER THE FIRST MONTH OF

OPERATION AND ANY LOOSE MATERIALS

REMOVED TO AVOID BLOCKAGE.

DRAUGHT REQUIREMENTS

While inadequate draught can seriously effect the

efficient operation of the appliance, chimney’s over

5.4m (18ft) for houses built on high ground can

experience excessive draught. A steady draught of

between 1mm (.04) and 1.5mm (.06) inches W.G. is

required for satisfactory operation.

FLUE LINERS

Chimney’s lined with salt glazed earthenware pipes

are acceptable if the pipes comply with BS EN 1457

and must be 150mm (6”). When lining an existing

chimney, a liner approved to BS 4543, Parts 1, 2 &

3 should be used. The liner should be secured at the

top and bottom by using closure/clamping plate

firmly sealed and secured and an approved low

resistance terminal used at the top.

It is essential that every flue system be inspected

and tested by a competent person for its correct

effectiveness, to ensure that the combustion

products are completely discharged to the outside

atmosphere.

FACTORY MADE INSULATED CHIMNEYS

Factory-made insulated chimneys should be

constructed and tested to meet the relevant

standards and recommendations given in:

* B.S. 7566 - Installation of factory-made

chimneys conforming to B.S. 4543 for

domestic appliances.

Part 1: Method of specifying installations

design information.

Part 2: Specification for installation design.

Part 3: Specification for site installation.

Part 4: Recommendation for installation

design and installation.

VENTILATION & COMBUSTION AIR

REQUIREMENTS

1. It is imperative that there is sufficient air supply

to the burners of the cooker in order to support

correct combustion.

2. The air supply to this appliance must comply

with BS 5410 Part 1.

3. The minimum effective air requirement for this

appliance is 215 cm

2

(100K), 193 cm2(80K) or

155cm

2

(60K). When calculating combustion air

requirements for this appliance use the following

equation: 550mm

2

per kW of maximum rated

output above 5kW. These requirements are

illustrated in OFTEC Technical Book No. 3 &

B.S. 5410.

4. If there is another appliance using air fitted in the

same or adjacent room, it will be necessary to

refer to B.S. 5410 to calculate the additional air

supply.

5. All materials used in the manufacture of air

vents should be such that the vent is

dimensionally stable and corrosion resistant.

6. The effective free area of any vent should be

ascertained before installation. The effect of

any screen or grill should be allowed for when

determining the effective free area of any vent.

7. Air vents direct to the outside of the building

should be located so that any air current

produced will not pass through normally

occupied areas of the room.

An air vent outside the building should not be

located less than the dimensions specified

within the Building Regulations (See Technical

Data) from any part of any flue terminal. These

air vents must also be satisfactorily fire proofed

as per Building Regulations.

8. Air vents in internal walls should not

communicate with bedrooms, bedsits, toilets,

bathrooms or rooms containing a shower.

9. Air vents traversing cavity walls should include a

continuous duct across the cavity. The duct

should be installed in such a manner as not to

impair the weather resistance of the cavity.

10. Joints between air vents and outside walls

should be sealed to prevent the ingress of

moisture. Existing air vents should be of the

correct size and unobstructed for the appliance

in use.

11. If there is an air extraction fan fitted in the room

or adjacent rooms where this appliance is fitted,

additional air vents will be required to aleviate

the possibility of spillage of combustion products

from the appliance/flue while the fan is in

operation. (Refer B.S. 5410).

Page 14

13

12. Where such an installation exists, a test for

spillage should be made with the fan or fans

and other burning appliances in operation at full

rate (i.e. extraction fans, tumble dryers) with all

external doors and windows closed.

13. If spillage occurs following the above operation,

an additional air vent of sufficient size to prevent

this occurrence should be installed.

OUTSIDE AIR CONNECTION

If this option is used additional air as indicated in BS

5410 is not required.

1. This appliance may be connected direct to the

outside of the house for its combustion air

supply.

2. Remove the blanking plate located at the back

right hand corner and remove the primary air

grill located at the front right hand corner. Fix

the blanking plate over the front primary air

inlet. (See fig. 14)

3. Connect the optional 125mm (5”) spigot to the

base. (See fig. 14a).

4. To connect this appliance to an outside air

supply use either 125mm (5”) rigid or flexible

stainless steel pipes or non-combustible

corrosion-resistant materials not more than

965mm (38”) in length and having no sharp

bends or corners other than the down turn at the

terminus.

5. Air inlets traversing cavity walls should include

a continuous duct across the cavity. The duct

should be installed in such a manner as not to

impair the weather resistance of the cavity.

6. Joints between air vents and outside walls

should be sealed to prevent ingress of moisture.

HEATING

PIPE FITTINGS

Materials used for insulation work should be fire

resistant. Standards should conform to all

appropriate regulations in force at the time and

place of installation.

1.1 Ferrous Materials

BS 1387 Steel tubes.

BS 1740 Steel pipe fittings.

BS 4127 Stainless steel tubes.

BS 6956 Jointing Materials.

1.2 Non-Ferrous Materials

EN 29453 Soft Solder Alloys.

BS 864 Compression tube fittings.

BS 2871 & BS EN 1057 Copper & Copper

Alloys.

Fig.14

Fig.14a

Fig.13

Air Inlet

Blanking Plate

Outside Air Spigot

(Not Supplied)

Page 15

DOWN DRAUGHTS

However well designed, constructed and positioned,

the satisfactory performance of the flue can be

adversely affected by down draught caused by

nearby hills, adjacent tall buildings or trees. These

can deflect wind to blow directly down the flue or

create a zone of high pressure over the terminal.

A suitable anti-down draught terminal or cowl will

usually effectively combat direct down blow but no

cowl is likely to prevent down blow due to high

pressure zone. Ensure that any cowl used will not

restrict the flue exit, or cause excessive back

draught. (See Fig.15)

14

Fig.15

WATER PIPE SIZE

The flow and return pipe must be 28mm diameter.

Care should be taken to ensure that the heating

system is correctly installed and that it complies with

all relevant codes of practice. If this appliance is

being connected to an existing system, we strongly

recommend that you engage an appropriately

qualified person to check the following:

(a) That the system is sound.

(b) That pipework is adequately insulated (where

applicable).

(c) Check all controls, i.e. pump, motorised valves,

time control etc. are operating satisfactorily and

are compatible with the requirements of the

cooker.

(d) Are any modifications necessary to make the

heating system more efficient?

(e) Cleanse the system and add suitable inhibitor.

The use of motorised valves, room thermostats,

radiator thermostatic valves, domestic hot water

controllers, etc, can greatly enhance a heating

system and we recommend their use.

Only competent personnel should be employed to

carry out your heating installation.

It is important that no external control devices e.g.

economisers be directly fitted to this appliance

unless covered by these installation instructions or

agreed with the manufacturer in writing. Any direct

connection of a control device not approved by the

manufacturer could make the guarantee void.

The flow and return can be taken either side of the

cooker. (See Fig.16)

1. To take off from the left simply connect directly

onto the exposed boiler connection.

2. To take off from the right side:

a. Remove the two blanks on the right hand side

of the cooker. Then remove the two cover plates

from the cooker’s back panel.

b. Remove the plugs from the boiler connections.

To avoid insulation from going into the flow and

return ports, cover with insulating tape.

c. Using copper pipe, punch out a passage way

through the insulation material to the boiler

connections. Clear any insulation away from the

boiler connections.

d. Before passing the flow and return pipes

through the cooker, cover the ends with tape to

avoid insulation entering them.

e. Remove tape from pipes and boiler ports.

Connect pipes to boiler.

Page 16

15

DRAINING

Key-operated drain taps to BS 2879 should be

provided in accessible positions in all low parts of

the system. However, it should be noted that there

may be short sections of pipework, e.g. when

passing under doorways, that may not be possible to

drain.

INTERNAL PUMP THERMOSTAT

This appliance has the capability for switching the

circulating pump ‘on’ and ‘off’ automatically. To wire

in the pump, connect the phase to terminal marked

CIRC Pump (L) and connect the Neutral to terminal

marked CIRC Pump (N). The earth wire is to be

connected into the earth block.

The connection circuit board/control panel is located

within the appliance beneath the warming oven.

(See Fig.17)

f. Replace blanking plates.

g. Plug the boiler tappings on the left hand side of

the boiler with 1” BSP plugs.

h. Test for leaks.

Fig. 16

Fig.17

WATER CIRCUIT TEMPERATURE

The return water temperature should be maintained

at not less than 50°C (122°F) so as to avoid

condensation forming within the boiler.

CARE FOR YOUR CENTRAL HEATING SYSTEM

The use of suitable corrosion inhibitors and anti

freeze solution in your heating system is essential to

minimise black oxide, sludge and scale build-up,

which effects efficiency.

In hard water areas the use of a suitable limescale

preventer / remover is advised.

Use only quantities specified by the water treatment

product manufacturer. Only add to the heating

system after flushing and finally refilling. Refer to

BS 7953.

INDIRECT DOMESTIC CYLINDER

The cooker must only be connected to an indirect

cylinder of no less than 180 litres using 28mm

diameter flow and return piping. It is recommended

that the cylinder is lagged together with pipework

with runs in excess of 4 meters (12’).

SERVICING

To ensure continued efficient and safe operation of

the appliance, it is recommended that it is checked

and serviced by an Authorised Stanley Service

Engineer at least once a year.

In the event that the cooker is not serviced by such

an engineer, at least once a year, Waterford Stanley

Limited regrets that it can entertain no claims

whatsoever in respect of alleged problems in the

efficiency or safety of the cooker supplied.

Flexible oil lines should be inspected at each

and every service visit. There are varying types

of line with guarantee periods between 1 and 5

years. It is important in the interest of safety that

flexible lines are changed at regular intervals.

Inspect for date code stamp and if the line is out

of its guarantee period or shows signs of being

kinked or damaged, replace immediately.

GENERAL MAINTENANCE

It is important that the user is familiar with their

heating system and that they ensure regular checks

and maintenance which can limit unnecessary

break-downs.

If in doubt, the user should consult an appropriately

qualified person such as a plumber or heating

engineer.

We recommend that you evaluate the overall

insulation in your house, i.e. attic, external walls,

windows and external doors. Insulation and

draught-proofing can greatly reduce running costs

Blanking Plates

50mm Knockouts RH Boiler

Connections

Page 17

16

NOTE: We strongly advise the use of pipe lagging

and also the use of a frost thermostat if the

installation is likely to be exposed to situations

where the temperature will dip to a level consistent

with frost.

A 15mm system by-pass must be fitted not less

than 1.5 meters (4.9ft) from the cooker to allow

correct water circulation for the pump and to

prevent condensation forming in the boiler. This

should be balanced. A heat sink radiator / towel rail

may be installed if desired in addition to the ByPass Loop. (See Fig.18 & Fig 24)

BY-PASS LOOP

Fig.18

Safety Valve

Pump

28mm Return

By-pass Lock

Shield Valve

28mm Flow

Pipe

1.5m

By-pass not less than 1.5

meters from the cooker

while equally enhancing living conditions. Also

zoning of areas and fitting of room thermostat can

reduce running costs, (See Fig. 18, 19, 20, 21, 22,

23, 24).

SAFETY VALVE

A non-adjustable 3 bar safety valve must be fitted to

the primary flow pipe adjacent to the boiler

connection ensuring that any discharge will not

create a hazard to occupants or cause damage to

electrical components or property.

Page 18

17

The following diagrams illustrate the different types of central heating systems to which this appliance can be

connected, but are not to be used as working drawings.

Fig. 19

OPEN SYSTEM (WITH PUMP ON RETURN)

SEALED SYSTEM (WITH PUMP ON FLOW)

Fig. 20

Page 19

18

OPEN SYSTEM (WITH PUMP ON FLOW)

Fig.21

INTERLINK SYSTEM

Fig. 22

Page 20

PROVISION FOR FILLING SEALED SYSTEM

Fig.23

19

S PLAN SYSTEM

Fig.24

COLD FEED

PIPE & OPEN

VENT PIPE

NOT MORE THAN

150mm (6”) APART

EARTH

MAINS

EARTH POST

NEUTRAL

LIVE

FLUE FAN

INTERSTAT

PUMP L

PUMP N

NEUTRAL

GREEN/YELL

WHITE

BLUE

GREY

HONEYWELL

V4073A

L641A

Cyl.Stat

T6360B

Room Stat

ORANGE

HEATING Timer

DHW Timer

NO DHW Timer

Boiler Run

Brandon

TERMINALS

WIRING

CENTRE

PERMANENT

(FUSED) LIVE

PUMP

C

2

3

1

2

Y - PLAN WIRING DIAGRAM Fig.25

Note:

It is essential that the interstat can bring on the

motorised valves directly as shown, failure to observe

this will result in nuisance lockout.

Please Note:

EARTHS NOT SHOWN FOR CLARITY

CONNECT EARTHS IN ACCORDANCE

WITH REGULATIONS!

If wires are a different colour

code, please refer to the

manufacturers instructions.

1

2

4

5

6

7

8

9

10

11

12

13

3

Page 21

20

If wires are a different colour

code, please refer to the

manufacturers instructions.

WIRING DIAGRAM 100K / 80K / 60K Fig. 26

Page 22

21

S PLAN WIRING DIAGRAM USING MULTI TIMER FOR ALL CENTRAL HEATING ZONES Fig. 27

EARTH

MAINS

EARTH POST

NEUTRAL

LIVE

FLUE FAN

INTERSTAT

PUMP L

PUMP N

NEUTRAL

HEATING Timer

DHW Timer

NO DHW Timer

Boiler Run

Brandon

TERMINALS

WIRING

CENTRE

PERMANENT

(FUSED) LIVE

BROWN

BROWN

GREY

GREY

GREY

GREY

BLUE

BLUE

GREY

BLUE

BROWN

BROWN

ORANGE

Note:

It is essential that the interstat can bring on one of the motorised valves

directly as shown, failure to observe this will result in nuisance lockout.

Please Note:

EARTHS NOT SHOWN FOR CLARITY

CONNECT EARTHS IN ACCORDANCE

WITH REGULATIONS!

BROWN

T6360B

Room Stat

T6360B

Room Stat

T6360B

Room Stat

L641A

Cyl. Stat

Motorised Valve

Domestic Hot Water

Motorised Valve

Wet Heating ZONE 1

Motorised Valve

Wet Heating ZONE 2

Motorised Valve

Wet Heating ZONE 3

If wires are a different colour

code, please refer to the

manufacturers instructions.

1

2

4

5

6

7

8

9

10

11

12

13

3

Page 23

4 ZONE HEATING SYSTEM

When connecting the a Brandon cooker to a 4 zoned heating system (i.e. separate time switches

and thermostats for domestic hot water and four

central heating zones), the domestic hot water and

one zone must be controlled directly from the

cooker enabling the inter thermostat to

operate if necessary. All other zones can

be controlled from the cooker where a

constant live supply must be connected to

the time clocks only (see figure 27).

Under no circumstances can other supply

sources be connected directly to the cooker.

4 ZONE HEATING SYSTEM

22

EARTH

EARTH POST

MAINS

NEUTRAL

LIVE

FLUE FAN

INTERSTAT

PUMP L

PUMP N

NEUTRAL

HEATING Timer

DHW Timer

NO DHW Timer

Boiler Run

Brandon

TERMINALS

WIRING

CENTRE

PERMANENT

(FUSED) LIVE

PUMP

If wires are a different colour

code, please refer to the

manufacturers instructions.

L641A

Cyl.Stat

T6360B

Room Stat

T6360B

Room Stat

T6360B

Room Stat

Motorised Valve

Domestic Hot Water

Motorised Valve

WET HEATING ZONE 1

Motorised Valve

WET HEATING ZONE 2

Motorised Valve

WET HEATING ZONE 3

c

1

2

3

2

3

2

2

3

M

M

M

M

Blue

Blue

Blue

Brown

Brown

Brown

Orange

Grey

Grey

Grey

Grey

Brown

S PLAN WIRING DIAGRAM USING SAME TIMER FOR ALL CENTRAL HEATING

ZONES Fig. 28

1

2

4

5

6

7

8

9

10

11

12

13

3

Page 24

S PLAN WIRING DIAGRAM SHOWING ZONE CONTROLLED BY UNDERFLOOR HEATING ZONE Fig.29

23

EARTH

PUMP

M

L641A

Cyl.Stat

T6360B

Room Stat

Motorised Valve WET

HEATING ZONE 1

ZONE 2 UNDERFLOOR

HEATING SYSTEM &

CONTROL

Motorised Valve

Domestic Hot Water

EARTH POST

MAINS

Brandon

TERMINALS

WIRING

CENTRE

NEUTRAL

LIVE

FLUE FAN

INTERSTAT

PUMP L

PUMP N

NEUTRAL

HEATING Timer

DHW Timer

NO DHW Timer

Boiler Run

PERMANENT

(FUSED) LIVE

M

Orange

Grey

Grey

Brown

Brown

Brown

Blue

Blue

Grey

Orange

Orange

1

2

4

5

6

7

8

9

10

11

12

13

3

Page 25

24

FUEL INSTALLATION

Jointing materials must be of types intended for use

with oil fuel. Special petroleum - resisting

compounds and PTFE tape are suitable. External

pipes should preferably be run with a continuous

rise towards the direction of flow, so that one can be

vented off. It is important to avoid high points which

could cause air locks.

Exposed lengths of oil supply pipe must be properly

supported by purpose made clips securely fixed in

place. Metal clips formed so as to hold the pipe on

to a saddle are preferred. Consideration should be

given to avoiding routes which expose the pipe to

severe chilling which could cause freezing of the oil.

Where pipes are buried, they must be protected

from accidental damage. The use of joints

underground should be avoided if at all possible. If

joints have to be fitted in pipes laid below ground,

access to them must be provided.

An oil filter (5 - 10 micron) and stop valve must be

fitted to the fuel feed line and located near the

supply tank and facilities should be provided to

enable it to be serviced without draining down the oil

supply system. (See Figs, 32, 33, 34 & 35).

At the point where the oil line enters the building, the

oil line must be fitted with an approved remote

acting fire valve, which meets the requirements of

B.S. 5410 : Part 1, fitted with the appropriate length

of capillary. The heat sensoring phial of the fire

valve must be fitted to the clip provided in the burner

compartment. It is absolutely essential that the fire

valve is located externally and is as close as

possible to the appliance. For existing installations

where the oil supply are built into the structure

internally, the remote acting fire valve should be

fitted where the oil supply line is first exposed

internally. This type of layout is not recommended

for new installations.

When gravity feed is used (the most common) the

minimum head should not be below 1 meter (3’3”)

and the maximum head should not exceed 6.5

meters (21’ 3”).

NOTE: The pump is factory set for a single pipe

installation to convert to a two pipe system consult

manufacturers instructions.

Before connecting the oil supply, secure appliance

burner oil pipes to the base using the T junction (see

Fig. 30 & 31).

OIL STORAGE TANKS

Oil storage tanks made of steel and all connecting

equipment (eg: filling pipes and vent pipes) should

comply with B.S. 799 Part 5. Galvanised steel must

not be used. Polyethylene (Plastic) tanks should

comply with OFTEC standard OFS T100 and or

equivalent. Oil should never be stored in

translucent plastic containers.

An isolating valve should be fitted at the tank outlet,

in an accessible position so that the oil supply to the

appliance can be shut off if required. This isolating

valve must be of a type suitable for use with oil.

(See Fig. 32, 33, 34 & 35).

In order to enable the sediment and water to be

removed from tanks a drain valve should be fitted.

Oil storage tank support must be carried out in

accordance with the tank manufactures

recommendations. Tanks should be located in the

most unobstructive position possible having taken

safety, filling, maintenance and the need, if any, to

provide a head of oil for the burner into

consideration.

FUELS

THE RECOMMENDED FUEL IS KEROSENE 28

SECOND VISCOSITY FUEL OIL.

FUEL SUPPLY LINE

The oil supply line from the oil storage tank to the

appliance should be of an approved and suitable

pipe with a minimum internal diameter of 9mm (3/8”)

and connected to the oil inlet connection located at

the cooker left hand side.

Oil supply pipes are normally run in annealed

copper tube complying to B.S. E.N. 1057. It can be

obtained in coil or half hard form for use with

bending machines. This pipe can also be obtained

with protective plastic sheathing applied. Fittings

for copper pipe should be compression of the flared

manipulative type to B.S. 864: Part 2 1983. Steel

pipes complying with B.S. 1387: 1985, if used, must

be protected from corrosion. Galvanised pipe and

fittings must not be used.

Screwed joints must only be made with tapered

threads complying to B.S. 1740: Part 1: 1971.

Page 26

SINGLE PIPE SUPPLY SYSTEM:

BOTTOM OF OIL STORAGE TANK ABOVE

BURNER

(See fig. 32)

Single pipe supply system: Tanks servicing this

appliance by means of a single pipe need to be

positioned so that they will apply the minimum head

required 1 meter (3’ 3”) of oil to the burner when the

fuel level is at its lowest point.

Refer to B.S. 5410 to calculate the additional head

requirement relating to pipe length and size.

TWO PIPE SUPPLY SYSTEM:

BOTTOM OF OIL STORAGE TANK BELOW OR

LEVEL WITH BURNER

(see fig. 33)

If the tank base is below the level at which the

gravity feed to the burner can be maintained, a two

pipe oil supply system may be adopted. (See fig.

33). The non-return valve in the supply line of the

two pipe system is required to prevent oil running

back from the burner and unpriming the oil pump.

The non-return valve in the return line is only

required if the top of the tank is above the burner. Its

purpose is to prevent oil running back through the

burner during maintenance.

Fig.32

Fig.30

Fig.31

SINGLE PIPE SYSTEM: WITH

DE-AERATION DEVICE BOTTOM OF OIL

STORAGE TANK BELOW OR LEVEL WITH

BURNER. (see fig. 34):

This system can be used where the tank base is

below the level at which gravity feed to the burner

can be maintained and the burner incorporates an

oil pump. The chamber is fitted close to the burner

and is linked to the tank by a single pipe, thus saving

the return pipe required by the two pipe system as

described previously. Any air in the oil brought up

from the tank is bled off in the de-aeration chamber.

De-aeration chambers must always be installed

externally to buildings because they emit small

quantities of vapour. The chamber is connected to

the oil pump in the burner of the appliance by a

normal two pipe loop.

TIGER LOOP OIL SUPPLY (see fig. 35)

For installations normally requiring a two pipe

system but have long or difficult return line runs, an

alternative Tigerloop Deaerator system can be used.

Tigerloop Deaerators remove air from a two pipe oil

feed. Higher lift heights can be achieved than are

possible with a conventional two pipe system.

These requirements are fully explained within the

following documents:

* B.S. 5410: Part 1: Code of Practice for Oil

firing installations up to 45 kW output capacity

for space heating and hot water supply

purposes.

* OFTEC - Technical Information Book Three.

Installation requirements for oil fired boiler and

oil storage tanks.

* The Building Regulations Part J: Ireland Part F

Section 4 Scotland and Part L Northern Ireland.

* The Building Regulations Part J: England &

Wales.

25

Fig.33

Page 27

26

Fig. 35

Fig. 34

INSTALLATION CHECK LIST

1. Check all items from packaging are removed

from ovens and the shelves are properly fitted.

2. Check that electrical wiring is correct.

3. Check that the boiler and heating system is full

of water and purged of air.

4. Check that the boiler plate transport screws

have been removed and that the plates are in

their correct positions. (See section removal of

transport screw and Fig. 41)

5. Time switches and room thermostats must be

on.

6. Check that all valves in the oil line are open and

that the filter is purged of air. Check that the fire

valve is open.

7. Turn on the electrical supply and check that any

time switches are on and room thermostats

associated with the cooker are on and calling for

heat. Burners should now fire.

8. Check that the interstat connection has been

wired directly to a motorised valve. This is done

by turning off room thermostats, time switches

and temporarily linking terminals 6 & 9. This

should bring on a motorised valve which will

then call the boiler.

Note: When the interstat calls; normally the

motorised valve will open, but the burner will not

operate as the supply to No.6 will be disabled.

9. Check temperature differential between flow

and return 11°C (20°F) and adjust pump or bypass accordingly.

10. Check heating circuit and balance if necessary.

11. With fuel supply off, switch on the burners.

12. Complete the start sequence to lockout (8

seconds) for both burners observing the correct

operating functions.

13. Ensure both pumps are purged of air. Check

pump pressure with a calibrated pressure gauge

and adjust it as necessary. (See Figs. 36 & 37)

For further information refer to 100K and 80K

specification on page 5.

4 Meters Max.

Page 28

27

14. Re-instate fuel supply and switch on the

burners to ensure that they fire correctly.

15. After the appliance has achieved its operating

temperature, with each burner running, carry

out a flue gas analysis for each burner. (See

Fig. 38).

16. Check for smoke and flue draught reading.

Boiler Cooker

Air CO

2

% Air CO2%

Setting Setting

9 11.5 5 10

8 11.8 4 10.34

7 11.9 3 10.8

6 12.2 2 11.2

Fig. 36

Fig.38

Fig.37

17. Check and set combustion approximate

settings:

Fig.40

Fig.39

18. Find the correct position of the air control,

which gives the highest reading of CO

2 within

the range of the table above without exceeding

a smoke No. 0-1 (Bacharach Scale). (See

Figs. 39 & 40)

19. Check the oil supply for leaks from storage

tanks via oil filter.

20. Check if complete system is working correctly.

21. Make sure specified clearances are adhered

to.

22. Check flue joints are sealed correctly and that

no escapes are present.

23. If not satisfied check the trouble shooting

guide.

Boiler Burner

flue gas test

point

Oven Burner

flue gas test

point

Page 29

28

24. After withdrawing the mains cable tighten the

anti-tug gland located at the left side of the

cooker base level.

25. Refer to the Operation Instructions Manual for

correct operation of the appliance and

familiarise the occupants on the correct

method of operating the appliance.

LEAVE ALL DOCUMENTS WITH THE END USER

26. Check lockout (8 seconds)

26a. Check cooker burner is purged of air, check

cooker burner with a calibrated pressure gauge

and adjust if necessary to 110 p.s.i.

26b. To complete commissioning exercise refer

back to point number 14.

REMOVAL OF TRANSPORT SCREW/S

Remove the hotplate and boiler top plate. Remove

retaining screws from boiler plates. Check that all

plates have remained in their correct position and

that no debris has accumulated on them during

transport. Replace boiler top plate and hotplate

ensuring that all seals are intact (See Fig.41).

FUNCTION

Normal Start

Pre-ignition and pre-purging, after 7 seconds oil

released, and the burner operates, if the flame forms

within the safety time of 10 seconds.

Post ignition after oil release:

LOA 24 - 10 seconds.

False light at start

If oil is released and no flame is established the

control will cut out within the safety time of 10

seconds.

Flame failure in operation

In the event of flame failure in operation the oil

supply is cut off and the control restarts the burner

as described under the heading “Normal Start”. On

flame failure, immediately after burner start, the

control will initiate re-ignition.

Flame monitoring

The flame is monitored by a photocell unit. Note: In

accordance with the latest ISO and DIN standards,

type LOA activates the safety relay if the photocell

unit is exposed to light in the pre-purging period.

Control of flame signal

The photocell current is measured with a d.c.

ammeter (moving coil instrument) which is

connected in series with the photocell unit. Min

current for flame indication: 35 μA.

Fig.41

NOTE: If you are in any doubt whatsoever

about the above installation checks or anything

else in this booklet, please contact Waterford

Stanley Ltd - Service Department between the

hours of 8.00am and 4.30pm Monday to Friday,

who will be happy to answer your queries.

This booklet has been prepared by Waterford

Stanley Limited to set out the correct method to

be adopted in installing a Stanley Cooker. If the

cooker is not installed fully in compliance with

these instructions, Waterford Stanley Limited

will accept no liability whatsoever for any loss,

damage or personal injury (including death)

arising out of any alleged defect in the cooker.

IMPORTANT NOTE: Once you are satisfied that

the cooker is properly installed in accordance

with these instructions, you must turn off the

cooker which should not be re-lighted until it

has been commissioned by an accredited

Commissioning Agent.

Page 30

Remove the 2 round head screws and the retaining clip on the back of the door while ensuring the spring

behind does not spring out. See Fig. A & B.

Retaining

Clip

Round Head

Screws

DOOR HANDLE REPLACEMENT INSTRUCTIONS

Fig.A

Fig.C

Fig.B

Compression Spring

Tools required

* Small Philips head screw driver

* 2 mm allen key

* Flat head screwdriver.

Remove the compression spring and screw. See Fig. C.

Round Head

Screws

Retaining

Clip

Step 1

Step 2

29

Page 31

Replace the Nylon handle with the chromed handle and reverse the above procedure - Step 5 - 1. See Fig. I

Using a small flat head screwdriver remove the circlip from the end of the door handle axle. See Fig.E & F.

Circlip

Removed

Fig.I

While holding the handle pull out the door handle axle. See Fig.G & H.

Circlip

Fig.G

Step 4

Step 5

Step 6

Grub Screw

Step 3

Fig.D

Fig.E

Fig.F

Fig.H

From the front face loosen the grub screw on the underside of the latch using the 2mm allen key. See Fig.D.

30

Page 32

31

INSTALLATION CHECK LIST

Flue System

The relevant guidelines must be adhered to for the relevant flue system A, B & C:

A. Use of an Existing Chimney

1. If connecting to an existing chimney, the appliance should be connected to a 150mm (6”) diameter

continuous, rigid or flexible flue pipe suitable for oil-fired appliances that terminates in excess of 0.6

metres from the nearest point on the roof measured vertically, and in excess of 2.3 metres measured

horizontally.

2. Minimum Flue Height of 4.6 metres (15 feet).

3. Any horizontal flue sections should not exceed 450mm (18”).

4. The chimney serving this appliance should not serve any other appliance.

5. A suitable flue terminal should be fitted at the flue termination point.

6. Closure-clamping plates should be used to seal the top & bottom of the chimney.

7. If the flue passes through a combustible wall, a twin wall insulated connector must be used and come

flush to the external surface of the wall.

8. The flue should be capable of producing a continuous draught of between 0.04” to 0.06” w.g.

B. Use of an External Flue

1. If using an external flue, the appliance should be connected to a 150mm (6”) diameter rigid insulated flue

pipe suitable for oil-fired appliances that terminates in excess of 0.6 metres from the nearest point on

the roof measured vertically and in excess of 2.3 metres measured horizontally.

2. Minimum Flue Height of 4.6 metres (15 feet).

3. Any horizontal flue sections should not exceed 450mm (18”).

4. The chimney serving this appliance should not serve any other appliance.

5. A suitable flue terminal should be fitted at the flue termination point.

6. The flue should be capable of producing a continuous draught of between 0.04” to 0.06” w.g.

C. Use of a Stanley Fan Flue

1. The flue terminal should be positioned to adhere to the minimum clearances to external obstructions as

described in the Position of Fan Flue Terminals for Oil Fired Cookers on the Brandon Fan Flue manual.

2. The exhaust point of the flue should be orientated to avoid any potential recirculation of flue gases

through the air vents.

Location

1. The cooker should be installed on a non-combustible material capable of supporting the weight of the unit.

2. The cooker should be positioned so as to maintain a 10mm gap between the cooker and the adjacent

kitchen units.

Plumbing

1. A three bar safety valve must be fitted to the primary flow pipe adjacent to the boiler connection on the

stove.

2. The cooker must be connected to a fully pumped system using 28mm flow & return supply pipes.

3. A 15mm system by-pass must be fitted not less than 1.5 metres from the cooker.

4. Hot supply to the central heating system should be controlled using a motorised valve with live supply to

valve provided by the relevant connection on the cooker control board.

Ventilation & Combustion Air Requirements

1. The room in which the appliance is located should have an air vent of adequate size to support correct

combustion when all air-using appliances are working at full capacity (See Ventilation & Combustion Air

Requirement Section for specific details).

Oil Supply

1. The oil supply tank should be fitted with an insolating valve and filter.

2. The stove should be connected to a supply line with a minimum internal diameter of 10mm (3/8”) and

must be fitted with a remote acting fire valve.

3. If a single pipe oil supply system is used, a minimum head of oil of 1 meter must be maintained (see

Fuel Installation Section).

Tick

√

Page 33

32

1. Cooker Burner - D00003BXX

2. Oil Burner Carrier Plate - Q00210AXX

3. Boiler Burner 100K - D00004BXX

Boiler Burner 80K - D00002AXX

Boiler Burner 60K - D00001AXX

4. 6” Bend - B00178AXX

5. Boiler Cleaning Door - B00187AXX

6. Hob Outer - B00192DXX

7. Flue Outlet Spigot - B00193AXX

8. Front Filler Casting - B00195AXX

9. Front - B00196CXX

10. Back Tile Trim - B00527AXX

11. Flue Cleaning Door - B00528AXX

12. Drip Tray - F00103AXX

13. Btm Cover Strip for Top Oven - F00119CXX

14. RH Side Cover Strip for Top Oven - F00120BXX

15. Control Cover Plate - F00126AXX

16. Oven Limit Stat Phial Clip - F00135AXX

17. Back Panel Blanking Plate - F00142BXX

18. Back Panel - F00154CXX

19. Side Panel RH - F00176AXX

20. Side Panel LH - F00177AXX

21. Burner Cover Plate (Oil) - F00767BXX

22. Base Edge Protectors - F00778AXX

23. Thermocouple Holder - F00785AXX

24. Insulation Panel For Oven Top - H00053AXX

25. Burner Ceramic Board - H00055BXX

26. Oven Wall Insul for Oven Firebox - H00185AXX

27. Boiler Assembly - L00076BXX

28. Hotplate Cover Assy RH - L00208AXX (B00221AXX)

29. Hotplate Cover Assy LH - L00209AXX (B00220AXX)

30. Warming Door Assy - L00361AXX (B00521AXX)

31. Control Door Assy - L00362AXX (B00522AXX)

32. Burner Door Assy - L00363AXX (B00523AXX)

33. Main Oven Door Assy - L00364AXX (B00520AXX)

34. Simmer Plate Cover Assy - L00367AXX (B00529AXX)

35. Base Assembly - L00368AXX (F00131AXX)

36. Control Panel Assembly - L00371AXX (B00525AXX)

37. Serial Number Plate - N00234BXX

38. Gasket For Simmering Plate - P00015AXX

39. Cleaning Plate Gasket - P00016AXX

40. Towel Rail Bracket Gasket - P00084AXX

41. Steam Escape - Q00107AXX

42. Shelf Diffuser - Q00126BXX

43. One Piece Oven Base - Q00168BXX

44. Warming Oven Cleaning Plate - Q00188AXX

45. Warming Oven Top - Q00189AXX

46. Simmering Plate - Q00198AXX

47. Hotplate - Q00200AXX

48. Inner Hob - Q00201CXX

49. Top Oven Bottom

- Q00202AXX

50. Oven Top - Q00203BXX

51. Oven End Flue - Q00204AXX

52. Warming Oven Flue Divider - Q00205AXX

53. LH Inner Oven Side - Q00206BXX

54. LH Oven Side - Q00207AXX

55. Oven Back - Q00208BXX

56. RH Oven Side - Q00209AXX

57. Bar Short Horizontal Side Oven - Q00212AXX

58. Boiler To Oven Clamp - Q00697BXX

59. Door Hinge - U00029AXX

60. Towel Rail Bracket LH - U00106AXX

61. Towel Rail Bracket RH - U00107AXX

62. Oven Shelf - V00092BXX

63. Door Stop - V00116AXX

64. Thermostat Bulb Spacer - V00117AXX

65. Towel Rail - V00505AXX

66. Plinth - V00506AXX

BRANDON MK3 OIL 100K/80K/60K - PARTS & BOM CODES

67. Screw Cover - V00512AXX

68. Towel Rail Bung - V00522AXX

69. Stay Rod - V00563AXX

70. Steam Vent - W00904AXX

71. Door Catch - W00918AXX

72. Flue Increaser - Q00197BXX

73. Vertical Flue Adaptor - B00184AXX

74. Hinge (Simmer Plate) - U00125AXX

75. Hob Cleaning Door Gasket - P00023AXX

76. Simmer Plate Cover Plate - F00774AXX

77. Hinge (Hotplate Assembly) - U00067AXX

78. Hotplate Cover Stop - V00083AXX

80. Bend Door Gasket - P00017AXX

81. Hotplate Cover Dome - F00183CXX

82. Hotplate Cover Handle Bracket RH - U00027AXX

83. Hotplate Cover Spring Handle - U00026AXX

84. Hotplate Cover Handle Bracket LH - U00028AXX

85. Insulation Panel - H00074AXX

86. Insulation Panel - H00073AXX

87. Insulation Panel - H00072AXX

88. Boiler Cleaning Plate - F00133AXX

89. Brandon Top Insulation Panel - H00071AXX

90. Top Boiler Baffle - L00194AXX

91. Middle Boiler Baffle - L00199AXX

92. Bottom Baffle - L00200AXX

93. Insulation Panel - H00103AXX

94. Gasket Boiler to Oven - P00026AXX

95. Boiler Blanking Plug - V00016AXX

96. Thermocouple - G00270AXX

97. Grill For Roasting Tin - V00099AXX

98. Roasting Tin - V00091AXX

99. Thermistor - G00268AXX

100. Bus Wire - G00269AXX

101. Round Hotplate Cover Filler RH - Q00617AXX

102. Round Hotplate Cover FIller LH - Q00616AXX

103. Burner PCB Board - G00266AXX

104. Wiring ID Label - N00359AXX

105. Control Box Bracket -F00780AXX

106. Oven Limit Stat - G00018AXX

107. Limit Stat - G00267AXX

108. Boiler Stat Plate - F00370AXX

109. Grommet - V00155AXX

110. Divider Plate - F00128AXX

111. Control Box Cover - F00812BXX

112. Grommet - V00100AXX

113. Air Inlet Blanking Plate - F00775AXX

114. Spacer - F00141AXX

115. Oven Door Panel - F00765AXX

116. Warming Oven Panel - F00151AXX

117. Door Handle RH - U00105BXX

118. Door Handle LH

- U00104BXX

119. Door Handle Axle - V00105AXX

120. Door Latch - V00504BXX

121. Door Handle Bracket LH - V00103AXX

122. Door Handle Bracket RH - V00104AXX

123. Door Handle Insulation - J00127AXX

124. Thermometer - G00261AXX

126. Burner Door Panel - F00150AXX

127. Fire Door Panel - F00764AXX

128. Door Latch Adjuster - F00808BXX

129. Spring - V00564AXX

130. Setting & Op Controller Label - N00331BXX

131. Control Panel Glass - T00038AXX

132. Timer Unit PCB Board - G00264AXX

Page 34

33

BRANDON OIL MK3 EXPLODED VIEW

Page 35

34

Page 36

N00334AXX DP100421 Rev 007

Manufactured by

Waterford Stanley Ltd.,

Unit 210, IDA Industrial Estate, Cork Road,

Waterford, Ireland.

Tel: (051) 302300 Fax (051) 302315

www.waterfordstanley.com

35

Loading...

Loading...