Page 1

BR67

HYDRAULIC BREAKER

USER MANUAL

Safety, Operation and Maintenance

© 2014 STANLEY Black & Decker, Inc.

New Britain, CT 06053

U.S.A.

09278 11/2017 Ver. 27

Page 2

DECLARATION OF CONFORMITY

Nuerenberg, David

(For Underwater Use Only)

Directive/Standards

No.

Approved body

ISO

28927-10:2011

Self

DECLARATION OF CONFORMITY

ÜBEREINSTIMMUNGS-ERKLARUNG

DECLARATION DE CONFORMITE CEE

DECLARACION DE CONFORMIDAD

DICHIARAZIONE DI CONFORMITA

______________________________________________________________________

I, the undersigned:

Ich, der Unterzeichnende:

Je soussigné:

El abajo firmante:

lo sottoscritto:

hereby declare that the equipment specified hereunder:

bestätige hiermit, daß erklaren Produkt genannten Werk oder Gerät:

déclare que l’équipement visé ci-dessous:

Por la presente declaro que el equipo se especifica a continuación:

Dichiaro che le apparecchiature specificate di seguito:

Surname and First names/Familiennname und Vornamen/Nom et prénom/ Nombre y apellido/Cognome e nome

Hydraulic Tools

1. Category:

Kategorie:

Catégorie:

Categoria:

Categoria:

2. Make/Marke/Marque/Marca/Marca

3. Type/Typ/Type/Tipo/Tipo: BR6713801A, BR6717801A, BR6717801AA,

STANLEY

Hydraulic Hand Held Concrete Breaker

(BR67320 – For Underwater Use Only)

4. Serial number of equipment:

Seriennummer des Geräts:

Numéro de série de l’équipement:

Numero de serie del equipo:

Matricola dell´attrezzatura:

BR6713801A All

BR6717801A All

BR6717801AA All

BR6717802AA All

BR67320 Serial # 030212033 and above

5. Mass/Masse/Masse/Masa/Massa 31 kg

Has been manufactured in conformity with

Wurde hergestellt in Übereinstimmung mit

Est fabriqué conformément

Ha sido fabricado de acuerdo con

E’ stata costruita in conformitá con

Richtlinie/Standards

Directives/Normes

Directriz/Los Normas

Direttiva/Norme

ISO

Noise Directive

Machinery Directive

Nr

Numéro

No

n.

11148-4:2012

2000/14/EC:2005

3744:2010

2006/42/EC:2006

Prüfung durch

Organisme agréé

Aprobado

Collaudato

Self

AkustikNet (Notified body ID 1585)

Bagsvard Hovedgade 141, 2880 Bagsvard, Denmark

Certificate #863/2011/004 (Verification 2015-08-04) Valid 12-31-2018

Self

6. Special Provisions: None 7. Measurements: Measured Sound Power Level 103 LwA

Spezielle Bestimmungen: Messungen Guaranteed Sound Power Level 105 LwA

Dispositions particulières: Mesures Measured in accordance to Directive 2000/14/EC,

Provisiones especiales: Mediciones Annex III, Part B, No 10, m ≥ 30

Disposizioni speciali: Misurazioni

8. Representative in the Union: Patrick Vervier, Stanley Dubuis 17-19, rue Jules Berthonneau-BP 3406 41034 Blois Cedex, France.

Vertreter in der Union/Représentant dans l’union/Representante en la Union/Rappresentante presso l’Unione

Done at/Ort/Fait à/Dado en/Fatto a Stanley Infrastructure, Portland, Oregon USA Date/Datum/le/Fecha/Data 8-4-2015

Signature/Unterschrift/Signature/Firma/Firma

Position/Position/Fonction/Cargo/Posizione North America Quality Manager

2 ► BR67 User Manual

Page 3

TABLE OF CONTENTS

SAFETY SYMBOLS ..................................................................................................................................................4

SAFETY PRECAUTIONS .......................................................................................................................................... 5

TOOL STICKERS & TAGS ........................................................................................................................................ 7

HOSE TYPES ............................................................................................................................................................8

HOSE RECOMMENDATIONS ..................................................................................................................................9

HTMA / EHTMA REQUIREMENTS .........................................................................................................................10

OPERATION ............................................................................................................................................................ 11

TOOL PROTECTION & CARE ................................................................................................................................12

TROUBLESHOOTING ............................................................................................................................................13

CHARGING THE ACCUMULATOR .........................................................................................................................14

SPECIFICATIONS ................................................................................................................................................... 16

ACCESSORIES.......................................................................................................................................................17

BR67 ANTI-VIB PARTS ILLUSTRATION ................................................................................................................18

BR67 ANTI-VIB PARTS LIST ..................................................................................................................................19

BR67 STD PARTS ILLUSTRATION ........................................................................................................................21

BR67 STANDARD PARTS LIST ..............................................................................................................................22

BREAKER FOOT ASSEMBLY 05466......................................................................................................................23

BREAKER FOOT ASSEMBLY 05467......................................................................................................................24

BREAKER FOOT ASSEMBLY 07524......................................................................................................................25

BREAKER FOOT ASSEMBLY 07525......................................................................................................................26

BREAKER FOOT ASSEMBLY 08855......................................................................................................................27

BREAKER FOOT ASSEMBLY 11236 ...................................................................................................................... 28

UNDERWATER TOOLS DEPTH GUIDELINE .........................................................................................................29

To ll out a product warranty validation form, and for information on your warranty,

visit www.stanleyinfrastructure.com and select the Company tab > Warranty.

Note: The warranty validation record must be submitted to validate the warranty.

SERVICING: This manual contains safety, operation and routine maintenance instructions. STANLEY Infrastructure

recommends that servicing of hydraulic tools, other than routine maintenance, must be performed by an authorized

and certied dealer. Please read the following warning.

SERIOUS INJURY OR DEATH COULD RESULT FROM THE IMPROPER REPAIR OR

SERVICE OF THIS TOOL.

REPAIRS AND / OR SERVICE TO THIS TOOL MUST ONLY BE DONE BY AN

AUTHORIZED AND CERTIFIED DEALER.

For the nearest certied dealer, call STANLEY Infrastructure at (503) 659-5660 and ask for a Customer Service Representative.

BR67 User Manual ◄ 3

Page 4

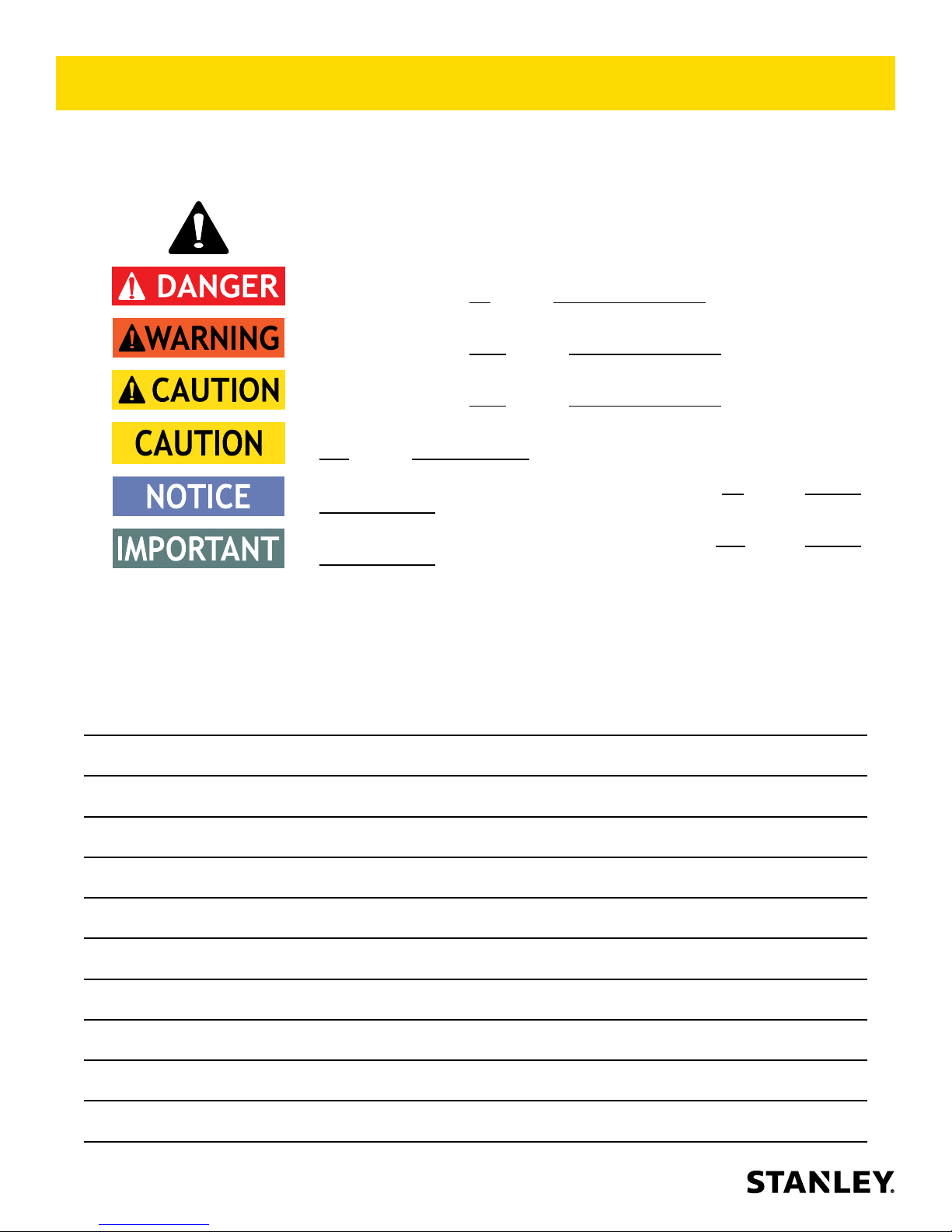

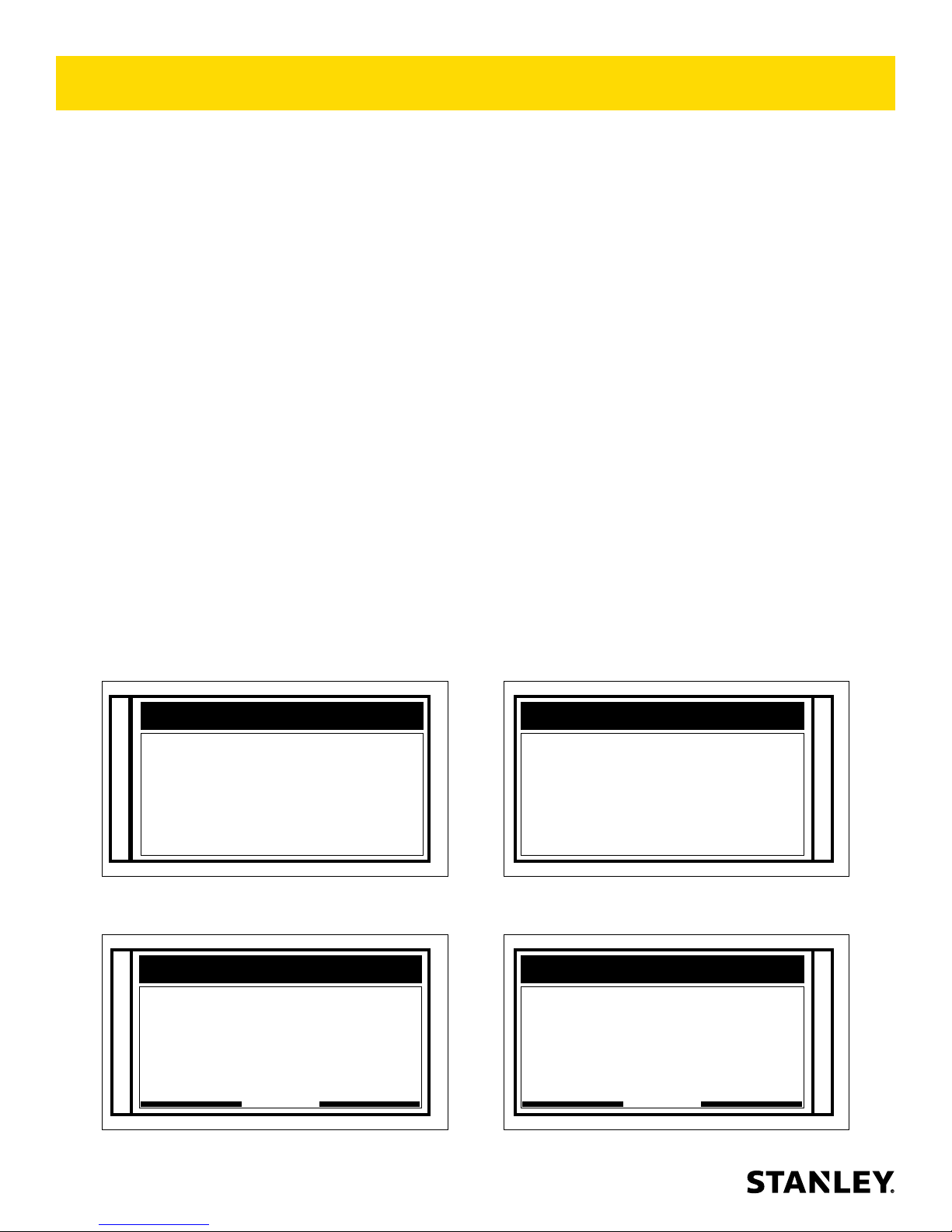

SAFETY SYMBOLS

Safety symbols and signal words, as shown below, are used to emphasize all operator, maintenance and repair

actions which, if not strictly followed, could result in a life-threatening situation, bodily injury or damage to equipment.

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid possible

injury or death.

This safety alert and signal word indicate an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

This safety alert and signal word indicate a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

This safety alert and signal word indicate a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

This signal word indicates a potentially hazardous situation which, if not avoided,

may result in property damage.

This signal word indicates a situation which, if not avoided, will result in damage

to the equipment.

This signal word indicates a situation which, if not avoided, may result in damage

to the equipment.

Always observe safety symbols. They are included for your safety and for the protection of the tool.

LOCAL SAFETY REGULATIONS

Enter any local safety regulations here. Keep these instructions in an area accessible to the operator and

maintenance personnel.

4 ► BR67 User Manual

Page 5

SAFETY PRECAUTIONS

Tool operators and maintenance personnel must always

comply with the safety precautions given in this manual

and on the stickers and tags attached to the tool and

hose.

These safety precautions are given for your safety. Re-

view them carefully before operating the tool and before

performing general maintenance or repairs.

Supervising personnel should develop additional pre-

cautions relating to the specic work area and local

safety regulations. If so, place the added precautions in

the space provided in this manual.

The BR67 Hydraulic Breaker will provide safe and dependable service if operated in accordance with the in-

structions given in this manual. Read and understand

this manual and any stickers and tags attached to the

tool and hoses before operation. Failure to do so could

result in personal injury or equipment damage.

• Operator must start in a work area without bystand-

ers. The operator must be familiar with all prohibited

work areas such as excessive slopes and danger-

ous terrain conditions.

• Establish a training program for all operators to ensure safe operation.

• Do not operate the tool unless thoroughly trained or

under the supervision of an instructor.

• Always wear safety equipment such as goggles,

gloves, ear, head and breathing protection, and

safety shoes at all times when operating the tool.

• Do not inspect, carry or clean the tool while the hydraulic power source is connected. Accidental en-

gagement of the tool can cause serious injury.

• Supply hoses must have a minimum working pressure rating of 2500 psi/175 bar.

• Be sure all hose connections are tight.

• The hydraulic circuit control valve must be in the

“OFF” position when coupling or uncoupling the tool.

Wipe all couplers clean before connecting. Use only

lint-free cloths. Failure to do so may result in damage to the quick couplers and cause overheating of

the hydraulic system.

• Do not operate the tool at oil temperatures above

140 °F/60 °C. Operation at higher oil temperatures

can cause operator discomfort and may damage the

tool. Never come in contact with the tool bit as the

bit can get hot.

• Do not operate a damaged, improperly adjusted or

incompletely assembled tool.

• Do not weld, cut with an acetylene torch or hard-

face the tool bit.

• To avoid personal injury or equipment damage, all

tool repair, maintenance and service must only be

performed by authorized and properly trained personnel.

• Do not exceed the rated limits of the tool or use the

tool for applications beyond its design capacity.

• Always keep critical tool markings, such as labels

and warning stickers, legible.

• Always replace parts with replacement parts recom-

mended by STANLEY.

• Check fastener tightness daily and before each use.

• Never operate the tool if you cannot be sure that

underground utilities are not present.

• Do not wear loose tting clothing when operating the

tool.

• Warning: Use of this tool on certain materials during

demolition could generate dust potentially containing a variety of hazardous substances such as asbestos, silica or lead. Inhalation of dust containing

these or other hazardous substances could result

in serious injury, cancer or death. Protect yourself

and those around you. Research and understand

the materials you are cutting. Follow correct safety

procedures and comply with all applicable national,

state or provisional health and safety regulations

relating to them, including, if appropriate, arranging

for the safe disposal of the materials by a qualied

person.

BR67 User Manual ◄ 5

Page 6

SAFETY PRECAUTIONS

• Warning: Hydraulic uid under pressure could

cause skin injection injury. If you are injured by

hydraulic uid, get medical attention immediately.

• Keep all body parts away from the working tool.

• When handling material or the tool bit, wear your

Personal Protection Equipment (PPE).

• Be observant of the hydraulic hoses lying about the

work area as they can be a tripping hazard.

• Always de-energize the hydraulic system when

changing a tool bit.

• Take caution when changing a tool bit. Tool bits can

get very hot.

• Never use the tool in an explosive atmosphere.

Sparks from the breaking process could ignite

explosive gas.

• Use proper lifting techniques when handling the tool.

Get help from a co-worker and do not over-reach.

• Use proper protection from falling or ying debris.

Keep bystanders at a safe distance.

• Do not exceed the rated ow and pressure. See

“SPECIFICATIONS” on page 16 for correct ow

rate and pressure rating. Rapid failure of the internal

seals may result.

6 ► BR67 User Manual

Page 7

D

30 LPM @ 138 BAR

EHTMA CATEGORY

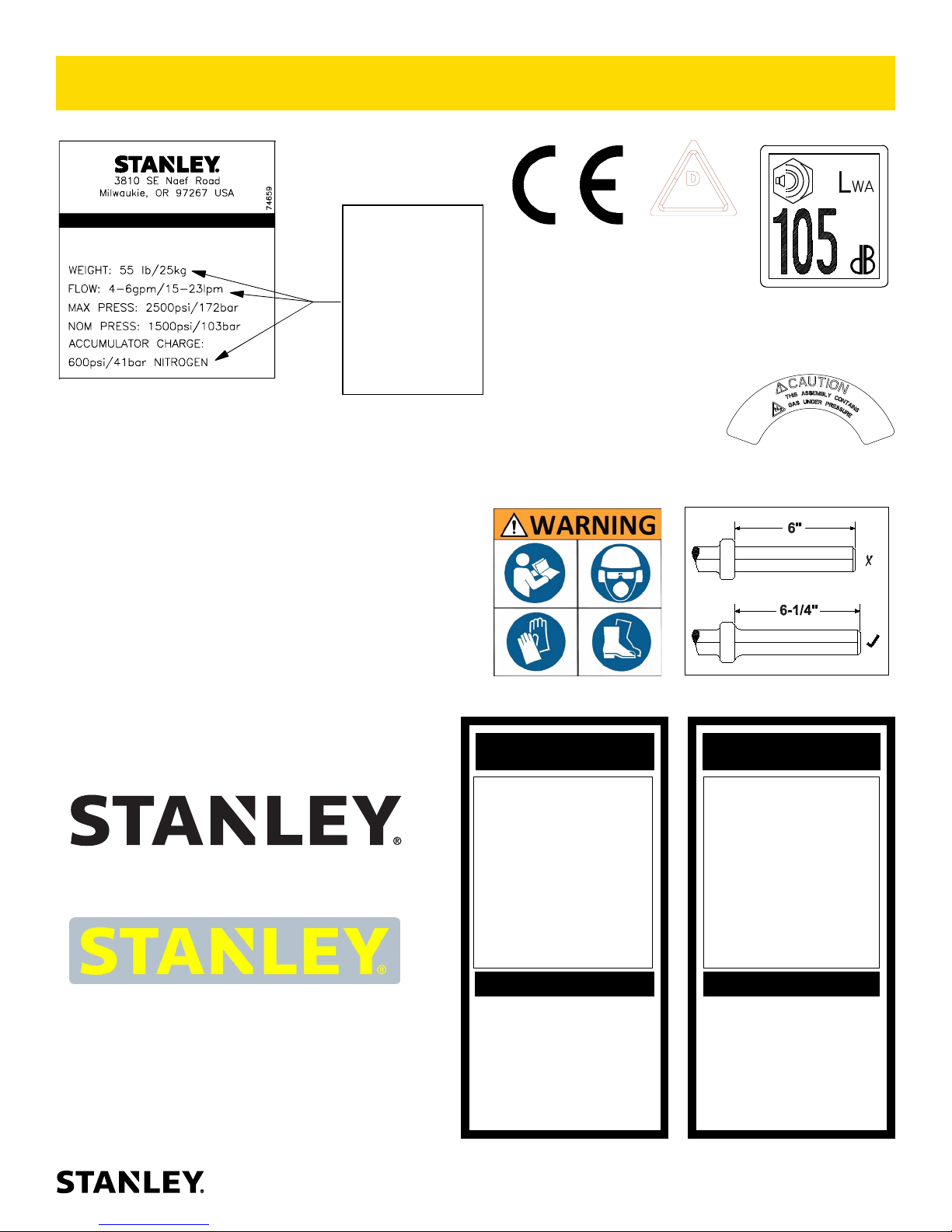

TOOL STICKERS & TAGS

Please refer to the Parts Illustration for location of stickers.

BR67

B

R

AKE

E

74667

Name Tag Sticker

T-Handle

Used On Models:

BR67120

BR67120E

BR67120D

BR67130

BR67130E

74671

Name Tag Sticker

Under Water

Used On Model:

BR67320

R

74668

Name Tag Sticker

Anti-Vibe

Used On Models:

BR67125

BR67135

BR6713516

BR6717801A

These numbers are

for example only

and may not relate

to your model of

breaker, see part

numbers below for

name tag stickers

that ts your model

breaker.

28322 - CE Sticker

11207

Circuit Type D

Decal

(CE Only)

66654

Guaranteed Sound Level

Decal (CE Only)

10180 - Caution Decal

74832 Decal STANLEY Logo (5.5” x 1.1” Black on Clear)

Used on: BR67120, BR67120E, BR67125, BR67130,

BR67130E, BR67135 and BR6717801A.

74770 Decal STANLEY Logo (6.5” x 1.3” Yellow on Clear)

Used on: BR67120D, BR6713516 and BR67320.

The safety tag (P/N 15875) at right is attached to

the tool when shipped from the factory. Read and

understand the safety instructions listed on this tag

before removal. We suggest you retain this tag and

attach it to the tool when not in use.

28409 - Composite Decal

(CE Only)

1. FAILURE TO USE HYDRAULIC HOSE LABELED AND CERTIFIED AS NON-CONDUCTIVE WHEN USING HYDRAULIC

TOOLS ON OR NEAR ELECTRICAL LINES MAY RESULT IN

DEATH OR SERIOUS INJURY.

BEFORE USING HOSE LABELED AND CERTIFIED AS NON-

CONDUCTIVE ON OR NEAR ELECTRIC LINES BE SURE

THE HOSE IS MAINTAINED AS NON-CONDUCTIVE. THE

HOSE SHOULD BE REGULARLY TESTED FOR ELECTRIC

CURRENT LEAKAGE IN ACCORDANCE WITH YOUR SAFETY

DEPARTMENT INSTRUCTIONS.

2. A HYDRAULIC LEAK OR BURST MAY CAUSE OIL INJECTION INTO THE BODY OR CAUSE OTHER SEVERE

PERSONAL INJURY.

A. DO NOT EXCEED SPECIFIED FLOW AND PRESSURE

FOR THIS TOOL. EXCESS FLOW OR PRESSURE MAY

CAUSE A LEAK OR BURST.

B. DO NOT EXCEED RATED WORKING PRESSURE OF

HYDRAULIC HOSE USED WITH THIS TOOL. EXCESS

PRESSURE MAY CAUSE A LEAK OR BURST.

C. CHECK TOOL HOSE COUPLERS AND CONNECTORS

DAILY FOR LEAKS. DO NOT FEEL FOR LEAKS WITH

YOUR HANDS. CONTACT WITH A LEAK MAY RESULT

IN SEVERE PERSONAL INJURY.

IMPORTANT

READ OPERATION MANUAL AND

SAFETY INSTRUCTIONS FOR THIS

TOOL BEFORE USING IT.

USE ONLY PARTS AND REPAIR

PROCEDURES APPROVED BY

STANLEY AND DESCRIBED IN THE

OPERATION MANUAL.

TAG TO BE REMOVED ONLY BY

TOOL OPERATOR.

SEE OTHER SIDE

Safety Tag P/N 15875 (shown smaller then actual size)

11208 - Hex Shank Sticker

DANGERDANGER

D. DO NOT LIFT OR CARRY TOOL BY THE HOSES. DO

NOT ABUSE HOSE. DO NOT USE KINKED, TORN OR

DAMAGED HOSE.

3. MAKE SURE HYDRAULIC HOSES ARE PROPERLY CONNECTED TO THE TOOL BEFORE PRESSURING SYSTEM.

SYSTEM PRESSURE HOSE MUST ALWAYS BE CONNECTED TO TOOL “IN” PORT. SYSTEM RETURN HOSE

MUST ALWAYS BE CONNECTED TO TOOL “OUT” PORT.

REVERSING CONNECTIONS MAY CAUSE REVERSE

TOOL OPERATION WHICH CAN RESULT IN SEVERE

PERSONAL INJURY.

4. DO NOT CONNECT OPEN-CENTER TOOLS TO CLOSEDCENTER HYDRAULIC SYSTEMS. THIS MAY RESULT IN

LOSS OF OTHER HYDRAULIC FUNCTIONS POWERED BY

THE SAME SYSTEM AND/OR SEVERE PERSONAL INJURY.

5. BYSTANDERS MAY BE INJURED IN YOUR WORK AREA.

KEEP BYSTANDERS CLEAR OF YOUR WORK AREA.

6. WEAR HEARING, EYE, FOOT, HAND AND HEAD PROTECTION.

7. TO AVOID PERSONAL INJURY OR EQUIPMENT DAMAGE,

ALL TOOL REPAIR MAINTENANCE AND SERVICE MUST

ONLY BE PERFORMED BY AUTHORIZED AND PROPERLY

TRAINED PERSONNEL.

IMPORTANT

READ OPERATION MANUAL AND

SAFETY INSTRUCTIONS FOR THIS

TOOL BEFORE USING IT.

USE ONLY PARTS AND REPAIR

PROCEDURES APPROVED BY

STANLEY AND DESCRIBED IN THE

OPERATION MANUAL.

TAG TO BE REMOVED ONLY BY

TOOL OPERATOR.

SEE OTHER SIDE

BR67 User Manual ◄ 7

Page 8

HOSE TYPES

The rated working pressure of the hydraulic hose must be equal to or higher than the relief valve setting on the hydraulic system. There are three types of hydraulic hose that meet this requirement and are authorized for use with

Stanley Hydraulic Tools. They are:

Certied non-conductive — constructed of thermoplastic or synthetic rubber inner tube, synthetic ber braid

reinforcement, and weather resistant thermoplastic or synthetic rubber cover. Hose labeled certied non-

conductive is the only hose authorized for use near electrical conductors.

Wire-braided (conductive) — constructed of synthetic rubber inner tube, single or double wire braid reinforcement, and weather resistant synthetic rubber cover. This hose is conductive and must never be used near

electrical conductors.

Fabric-braided (not certied or labeled non-conductive) — constructed of thermoplastic or synthetic rubber inner tube, synthetic ber braid reinforcement, and weather resistant thermoplastic or synthetic rubber cover. This

hose is not certied non-conductive and must never be used near electrical conductors.

HOSE SAFETY TAGS

To help ensure your safety, the following DANGER tags are attached to all hose purchased from Stanley Hydraulic

Tools. DO NOT REMOVE THESE TAGS.

If the information on a tag is illegible because of wear or damage, replace the tag immediately. A new tag may be

obtained from your Stanley Distributor.

THE TAG SHOWN BELOW IS ATTACHED TO “CERTIFIED NON-CONDUCTIVE” HOSE

DANGER

1. FAILURE TO USE HYDRAULIC HOSE LABELED AND CERTIFIED AS NON-CONDUCTIVE

WHEN USING HYDRAULIC TOOLS ON OR NEAR ELECTRIC LINES MAY RESULT IN

DEATH OR SERIOUS INJURY.

FOR PROPER AND SAFE OPERATION MAKE SURE THAT YOU HAVE BEEN PROPERLY TRAINED IN CORRECT PROCEDURES REQUIRED FOR WORK ON OR AROUND

ELECTRIC LINES.

2. BEFORE USING HYDRAULIC HOSE LABELED AND CERTIFIED AS NON-CONDUCTIVE

ON OR NEAR ELECTRIC LINES. WIPE THE ENTIRE LENGTH OF THE HOSE AND FITTING WITH A CLEAN DRY ABSORBENT CLOTH TO REMOVE DIRT AND MOISTURE AND

TEST HOSE FOR MAXIMUM ALLOWABLE CURRENT LEAKAGE IN ACCORDANCE WITH

SAFETY DEPARTMENT INSTRUCTIONS.

DO NOT REMOVE THIS TAG

SEE OTHER SIDE

SIDE 1

3. DO NOT EXCEED HOSE WORKING PRESSURE OR ABUSE HOSE. IMPROPER USE

OR HANDLING OF HOSE COULD RESULT IN BURST OR OTHER HOSE FAILURE.

KEEP HOSE AS FAR AWAY AS POSSIBLE FROM BODY AND DO NOT PERMIT DIRECT

CONTACT DURING USE. CONTACT AT THE BURST CAN CAUSE BODILY INJECTION

AND SEVERE PERSONAL INJURY.

4. HANDLE AND ROUTE HOSE CAREFULLY TO AVOID KINKING, ABRASION, CUTTING, OR

CONTACT WITH HIGH TEMPERATURE SURFACES. DO NOT USE IF KINKED. DO NOT

USE HOSE TO PULL OR LIFT TOOLS, POWER UNITS, ETC.

5. CHECK ENTIRE HOSE FOR CUTS CRACKS LEAKS ABRASIONS, BULGES, OR DAMAGE TO COUPLINGS IF ANY OF THESE CONDITIONS EXIST, REPLACE THE HOSE

IMMEDIATELY. NEVER USE TAPE OR ANY DEVICE TO ATTEMPT TO MEND THE HOSE.

6. AFTER EACH USE STORE IN A CLEAN DRY AREA.

(Shown smaller than actual size)

DANGER

DANGER

SEE OTHER SIDE

SIDE 2

THE TAG SHOWN BELOW IS ATTACHED TO “CONDUCTIVE” HOSE.

DANGER

DANGER

1. DO NOT USE THIS HYDRAULIC HOSE ON OR NEAR ELECTRIC LINES. THIS HOSE IS

NOT LABELED OR CERTIFIED AS NON-CONDUCTIVE. USING THIS HOSE ON OR NEAR

ELECTRICAL LINES MAY RESULT IN DEATH OR SERIOUS INJURY.

2. FOR PROPER AND SAFE OPERATION MAKE SURE THAT YOU HAVE BEEN PROPERLY

TRAINED IN CORRECT PROCEDURES REQUIRED FOR WORK ON OR AROUND ELECTRIC LINES.

3. DO NOT EXCEED HOSE WORKING PRESSURE OR ABUSE HOSE. IMPROPER USE OR

HANDLING OF HOSE COULD RESULT IN BURST OR OTHER HOSE FAILURE. KEEP HOSE

AS FAR AWAY AS POSSIBLE FROM BODY AND DO NOT PERMIT DIRECT CONTACT

DURING USE. CONTACT AT THE BURST CAN CAUSE BODILY INJECTION AND SEVERE

PERSONAL INJURY.

4. HANDLE AND ROUTE HOSE CAREFULLY TO AVOID KINKING, CUTTING, OR CONTACT

WITH HIGH TEMPERATURE SURFACES. DO NOT USE IF KINKED. DO NOT USE HOSE TO

PULL OR LIFT TOOLS, POWER UNITS, ETC.

DO NOT REMOVE THIS TAG

SEE OTHER SIDE

SIDE 1

5. CHECK ENTIRE HOSE FOR CUTS CRACKS LEAKS ABRASIONS, BULGES, OR DAMAGE TO

COUPLINGS IF ANY OF THESE CONDITIONS EXIST, REPLACE THE HOSE IMMEDIATELY.

NEVER USE TAPE OR ANY DEVICE TO ATTEMPT TO MEND THE HOSE.

6. AFTER EACH USE STORE IN A CLEAN DRY AREA.

(Shown smaller than actual size)

DANGER

SEE OTHER SIDE

SIDE 2

DO NOT REMOVE THIS TAG

DO NOT REMOVE THIS TAG

8 ► BR67 User Manual

Page 9

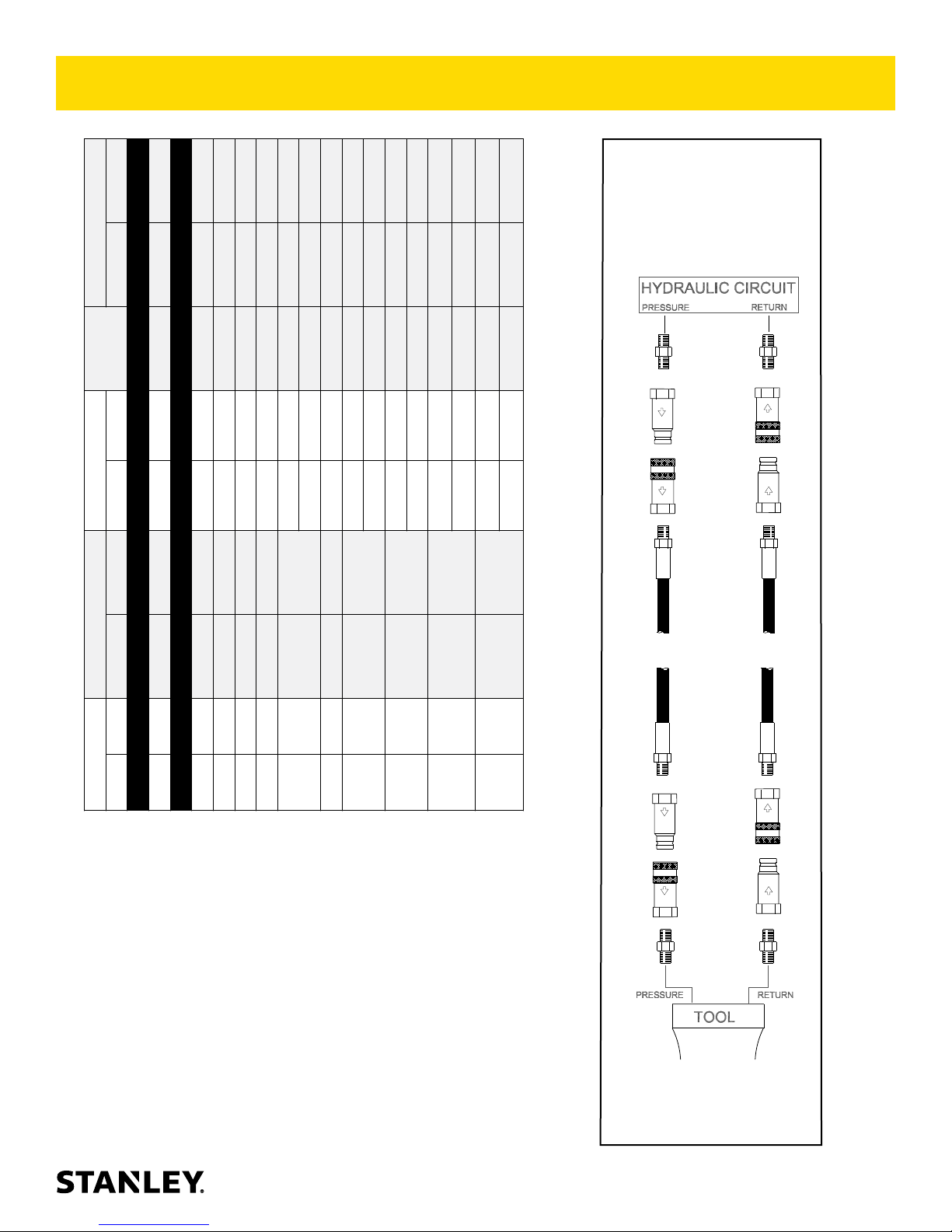

Min. Working Pressure

USE

(Press/Return)

HOSE RECOMMENDATIONS

Certied Non-Conductive Hose - Fiber Braid - for Utility Bucket Trucks

Oil Flow Hose Lengths Inside Diameter

GPM LPM FEET METERS INCH MM PSI BAR

4-9 15-34 up to 10 up to 3 3/8 10 Both 2250 155

Conductive Hose - Wire Braid or Fiber Braid -DO NOT USE NEAR ELECTRICAL CONDUCTORS

4-6 15-23 up to 25 up to 7.5 3/8 10 Both 2500 175

4-6 15-23 26-100 7.5-30 1/2 13 Both 2500 175

5-10.5 19-40 up to 50 up to 15 1/2 13 Both 2500 175

5-10.5 19-40 51-100 15-30 5/8 16 Both 2500 175

5/8 16 Pressure 2500 175

3/4 19 Return 2500 175

5-10.5 19-40 100-300 30-90

10-13 38-49 up to 50 up to 15 5/8 16 Both 2500 175

5/8 16 Pressure 2500 175

3/4 19 Return 2500 175

10-13 38-49 51-100 15-30

3/4 19 Pressure 2500 175

1 25.4 Return 2500 175

10-13 38-49 100-200 30-60

5/8 16 Pressure 2500 175

3/4 19 Return 2500 175

13-16 49-60 up to 25 up to 8

3/4 19 Pressure 2500 175

1 25.4 Return 2500 175

13-16 49-60 26-100 8-30

PRESSURE

<<< FLOW

RETURN

FLOW >>>

Figure 1. Typical Hose Connections

Tool to Hydraulic Circuit Hose

Recommendations

The chart to the right shows recommended

minimum hose diameters for various hose

lengths based on gallons per minute (GPM)/

liters per minute (LPM). These recommenda-

tions are intended to keep return line pressure

(back pressure) to a minimum acceptable lev-

el to ensure maximum tool performance.

This chart is intended to be used for hydraulic

tool applications only based on Stanley Hy-

draulic Tools tool operating requirements and

should not be used for any other applications.

All hydraulic hose must have at least a rated

minimum working pressure equal to the maxi-

mum hydraulic system relief valve setting.

All hydraulic hose must meet or exceed

specications as set forth by SAE J517.

BR67 User Manual ◄ 9

Page 10

250 psi 250 psi 250 psi 250 psi

(17 bar) (17 bar) (17 bar) (17 bar)

400 ssu* 400 ssu* 400 ssu* 400 ssu*

(60° C) (60° C) (60° C) (60° C)

(22° C) (22° C) (22° C) (22° C)

30 gpm 30 gpm 30 gpm 30 gpm

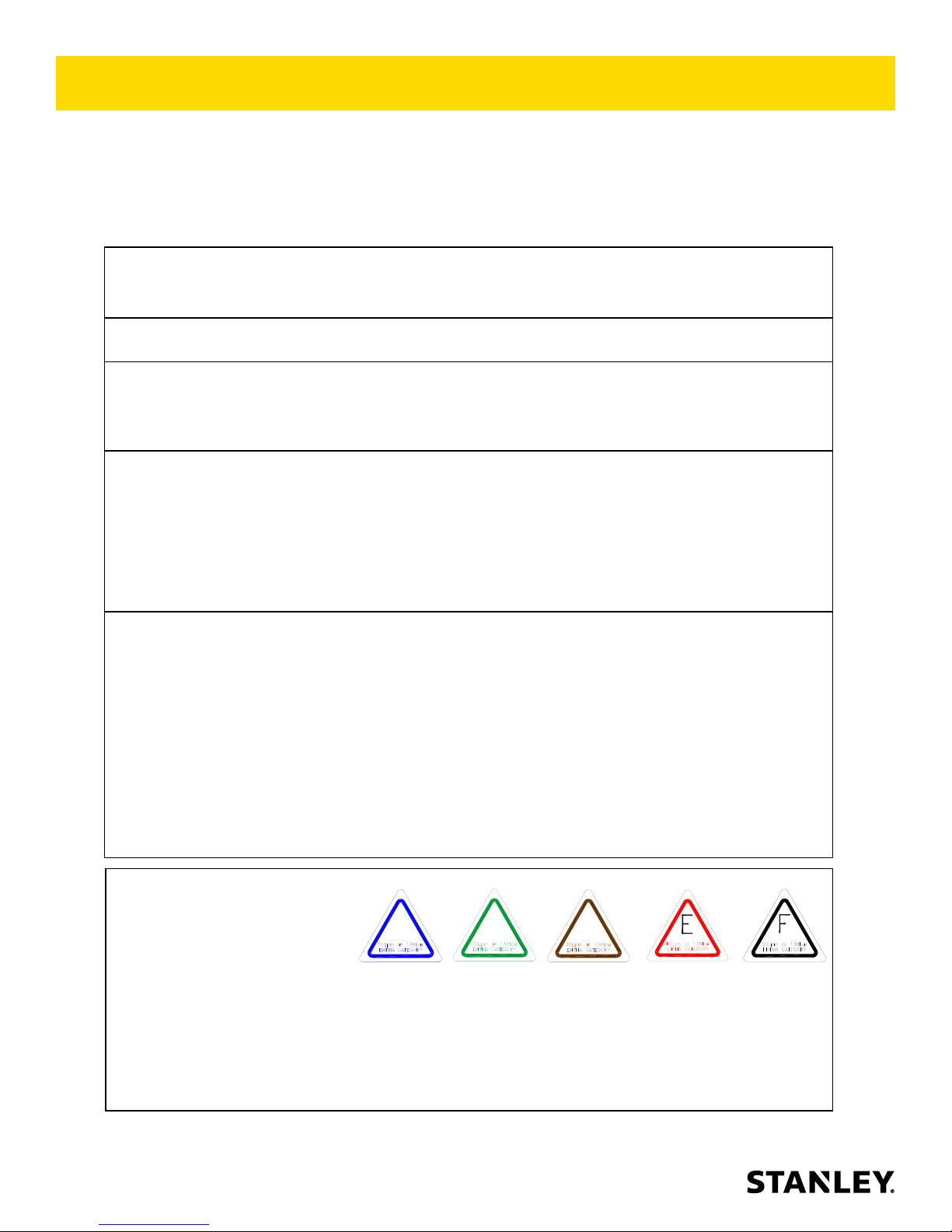

HTMA / EHTMA REQUIREMENTS

HTMA / EHTMA REQUIREMENTS

HTMA

HYDRAULIC SYSTEM REQUIREMENTS

Flow Range

Nominal Operating Pressure

(at the power supply outlet)

System relief valve setting

(at the power supply outlet)

Maximum back pressure

(at tool end of the return hose)

Measured at a max. uid viscosity of:

(at min. operating temperature)

Temperature: Suf cient heat rejection

capacity to limit max. uid temperature to:

(at max. expected ambient temperature)

Min. cooling capacity at a temperature

difference of between ambient and uid

temps

NOTE:

Do not operate the tool at oil temperatures above 140° F (60° C). Operation at higher temperatures can cause operator

discomfort at the tool.

Filter

Min. full- ow ltration

Sized for ow of at least:

(For cold temp. startup and max.

dirt-holding capacity)

4-6 gpm 7-9 gpm 9-10.5 gpm 11-13 gpm

(15-23 lpm) (26-34 lpm) (34-40 lpm) (42-49 lpm)

1500 psi 1500 psi 1500 psi 1500 psi

(103 bar) (103 bar) (103 bar) (103 bar)

2100-2250 psi 2100-2250 psi 2200-2300 psi 2100-2250 psi

(145-155 bar) (145-155 bar) (152-159 bar) (145-155 bar)

(82 centistokes) (82 centistokes) (82 centistokes) (82 centistokes)

140° F 140° F 140° F 140° F

3 hp 5 hp 6 hp 7 hp

(2.24 kW) (3.73 kW) (5.22 kW) (4.47 kW)

40° F 40° F 40° F 40° F

25 microns 25 microns 25 microns 25 microns

(114 lpm) (114 lpm) (114 lpm) (114 lpm)

TYPE I TYPE II

TOOL TYPE

TYPE RR

TYPE III

Hydraulic uid Petroleum based

(premium grade, anti-wear, non-conductive)

Viscosity (at min. and max. operating temps)

NOTE:

When choosing hydraulic uid, the expected oil temperature extremes that will be experienced in service determine the

most suitable temperature viscosity characteristics. Hydraulic uids with a viscosity index over 140 will meet the requirements

over a wide range of operating temperatures.

*SSU = Saybolt Seconds Universal

EHTMA

100-400 ssu* 100-400 ssu* 100-400 ssu* 100-400 ssu*

(20-82 centistokes)

CLASSIFICATION

HYDRAULIC SYSTEM

REQUIREMENTS

Flow Range

Nominal Operating Pressure

(at the power supply outlet)

System relief valve setting

(at the power supply outlet)

NOTE: These are general hydraulic system requirements. See tool speci cation page for tool speci c requirements

B

3.5-4.3 gpm 4.7-5.8 gpm 7.1-8.7 gpm 9.5-11.6 gpm 11.8-14.5 gpm

(13.5-16.5 lpm) (18-22 lpm) (27-33 lpm) (36-44 lpm) (45-55 lpm)

1870 psi 1500 psi 1500 psi 1500 psi 1500 psi

(129 bar) (103 bar) (103 bar) (103 bar) (103 bar)

2495 psi 2000 psi 2000 psi 2000 psi 2000 psi

(172 bar) (138 bar) (138 bar) (138 bar) (138 bar)

C

D

10 ► BR67 User Manual

Page 11

OPERATION

The recommended hose size is .500 inch/12 mm I.D. up

to 50 ft/15 m long and .625 inch/16 mm I.D. minimum up

to 100 ft/30 m.

PRE-OPERATION PROCEDURES

CHECK POWER SOURCE

1. Using a calibrated ow meter and pressure gauge,

check that the hydraulic power source develops a

ow of 7-9 GPM/26-34 LPM at 1500-2000 psi/105-

140 bar.

2. Make certain the hydraulic power source is equipped

with a relief valve set to open at 2100-2250 psi/145-

155 bar maximum.

INSTALL TOOL BIT

1. Rotate the latch on the breaker foot downward

(pointing away from the tool).

2. Insert the tool bit into the foot and pull the latch up to

lock the tool bit in place.

CONNECT HOSES

1. Wipe all hose couplers with a clean, lint-free cloth

before making connections.

2. Connect the hoses from the hydraulic power source

to the tool ttings or quick disconnects. It is a good

practice to connect return hoses rst and disconnect

them last to minimize or avoid trapped pressure

within the tool.

3. Observe ow indicators stamped on hose couplers

to ensure that uid ow is in the proper direction. The

female coupler on the tool hose is the inlet coupler.

4. Move the hydraulic circuit control valve to the ON

position to operate the tool.

NOTE: If uncoupled hoses are left in the sun,

pressure increase within the hoses may make them

difcult to connect. When possible, connect the free

ends of the hoses together.

NOTE: Partially depressing the trigger allows the

tool to run at slow speed. Slow-speed operation

permits easier starting of the tool bit into the work

surface.

5. To start, break an opening (hole) in the center of

the surface. After making a hole, break portions

of the material into the original opening. For best

productivity, the breaking should be done around

the original hole.

The size of the broken material will vary with the

strength and thickness of the base material and the

amount of any reinforcement wire or rebar.

Harder material or more reinforcing wire or rebar will

require taking smaller bites. To determine the most

effective bite, start with 2 in. / 50 mm or smaller bites.

Bites can then be gradually increased until the

broken piece becomes too large, requiring increased

time to break off the piece.

Sticking of the tool bit occurs when too large a bite

is being taken and the tool bit hammers into the

material without the material fracturing. This causes

the tool bit to become trapped in the surrounding

material.

COLD WEATHER OPERATION

If the breaker is to be used during cold weather, preheat

the hydraulic uid at low engine speed. When using the

normally recommended uid, uid temperature should

be at or above 50 °F/10 °C (400 ssu/82 centistokes)

before use.

Damage to the hydraulic system or breaker can result

from use with uid that is too viscous or thick.

OPERATION PROCEDURES

1. Observe all safety precautions.

2. Install the appropriate tool bit for the job.

3. Place the bit rmly on the surface to be broken.

4. Squeeze the trigger to start the breaker. Adequate

down pressure is very important. When the tool bit

breaks through the obstruction or becomes bound,

release the trigger and reposition the tool bit.

BR67 User Manual ◄ 11

Page 12

TOOL PROTECTION & CARE

In addition to the Safety Precautions found in

this manual, observe the following for equipment

protection and care.

• Make sure all couplers are wiped clean before

connection.

• The hydraulic circuit control valve must be in

the “OFF” position when coupling or uncoupling

hydraulic tools. Failure to do so may result in damage

to the quick couplers and cause overheating of the

hydraulic system.

• Always store the tool in a clean dry space, safe from

damage or pilferage.

• Make sure the circuit PRESSURE hose (with male

quick disconnect) is connected to the “IN” port. The

circuit RETURN hose (with female quick disconnect)

is connected to the opposite port. Do not reverse

circuit ow. This can cause damage to internal seals.

• Always replace hoses, couplings and other parts

with replacement parts recommended by STANLEY.

Supply hoses must have a minimum working

pressure rating of 2500 psi/172 bar.

• Do not exceed the rated ow and pressure. See

Specications in this manual for correct ow rate

and pressure rating. Rapid failure of the internal

seals may result.

• Always keep critical tool markings, such as warning

stickers and tags, legible.

• Do not force a small breaker to do the job of a large

breaker.

• Keep tool bits sharp for maximum breaker

performance. Make sure that tool bits are not

chipped or rounded on the striking end.

• Never operate a breaker without a tool bit or without

holding it against the work surface. This puts

excessive strain on the breaker foot.

• Tool repair should be performed by experienced

personnel only.

• Make certain that the recommended relief valves

are installed in the pressure side of the system.

• Do not use the tool for applications for which it was

not intended.

12 ► BR67 User Manual

Page 13

TROUBLESHOOTING

PROBLEM CAUSE REMEDY

Tool does not run. Power unit not functioning. Check power unit for power ow and pressure

(7–9 GPM/26–-34 LPM, 1500–2000 psi/

105–140 bar).

Couplers or hoses blocked. Remove restriction.

Pressure and return line hoses

reversed at ports.

Mechanical failure of piston or

automatic valve.

Tool does not hit effectively. Power unit not functioning. Check power unit for power ow and pressure

Couplers or hoses blocked. Remove restriction.

Low accumulator charge (pressure hose will pulse more than

normal).

Fluid too hot (above 140 °F/

60 °C).

Tool operates slow. Low GPM supply from power

unit.

High back-pressure. Check hydraulic system for excessive back

Couplers or hoses blocked. Remove restriction.

Orice plug blocked. Remove restriction.

Fluid too hot (above 140 °F/

60 °C) or too cold (below 60 °F/

16 °C).

Relief valve set too low. Adjust relief valve to 2100–2250 psi/

Tool gets hot. Hot uid going through tool. Check power unit. Be sure ow rate is not too

Fluid leakage on tool bit. Lower piston seal failure. Replace seal.

Fluid leakage around trigger. Valve spool seal failure. Replace seals.

Be sure hoses are connected to their proper

ports.

Disassemble breaker and inspect for damaged

parts.

(7–9 GPM/26–34 LPM, 1500–2000 psi/

105–140 bar).

Recharge accumulator. Replace diaphragm if

charge loss continues.

Provide cooler to maintain proper uid temperature (130 °F/55 °C).

Check power unit for proper ow (7–9 GPM/

26–34 LPM).

pressure (over 200 psi/14 bar).

Check power unit for proper uid temperature.

Bypass cooler to warm the uid or provide cool-

er to maintain proper temperature.

145–155 bar.

high causing part of the uid to go through the

relief valve. Provide cooler to maintain proper

uid temperature (140 °F/60 °C max).

Check the relief valve setting.

Eliminate ow control devices.

BR67 User Manual ◄ 13

Page 14

CHARGING THE ACCUMULATOR

ACCUMULATOR TESTING

PROCEDURE

To check or charge the accumulator the following

equipment is required.

• 31254 Charge Kit, which includes the following:

– Accumulator Tester (Part Number 02835).

– Charging Assembly (P/N 15304) (15304

includes a liquid lled gauge with snub valve,

hose and ttings).

• NITROGEN bottle with an 800 psi/55 bar minimum

charge.(Not included in 31254 kit)

This assembly contains nitrogen under pressure

1.

Remove the plug from the handle or handle pivot.

2. Holding the chuck end of Accumulator Tester (P/N

02835) turn the gauge fully counterclockwise to

ensure that the stem inside the chuck is completely

retracted.

3. Thread the tester onto the accumulator charging

valve. Do not advance the gauge-end into the

chuck-end. Turn as a unit. Seat the chuck on the

accumulator charging valve and hand tighten only.

4. Advance the valve stem of the tester by turning the

gauge-end clockwise until a pressure is read on the

gauge (charge pressure should be 500-700 psi/3448 bar).

5. If pressure is OK, unscrew the gauge-end from

the chuck to retract the stem, then unscrew the

tester assembly from the accumulator charging

valve. If pressure is low, charge the accumulator as

described in the following paragraph.

6. Install the plug.

ACCUMULATOR CHARGING

1. Perform steps 1 through 4 of the accumulator testing

procedure.

2. Connect the chuck of the charging assembly to

the charging valve on the accumulator tester or, if

preferred, remove the tester from the charging valve

and connect the charging assembly chuck directly to

the charging valve.

3. Adjust the snub valve to a charging pressure of 600

psi/42 bar.

NOTE: While watching the pressure gauge, open

snub valve slowly until it reaches the proper charge

pressure (600-700 psi).

NOTE:

It may be necessary to set the gauge at 650-700

psi/45-48 bar to overcome any pressure drop

through the charging system.

4. When the accumulator is fully charged close the

snub valve on the charging assembly hose and

remove the charging assembly chuck from the

accumulator tester or tool charging valve.

5. If the accumulator tester has been used, be sure to

turn the gauge-end fully counterclockwise before

removing the tester from the charging valve of the

tool. Install the valve cap.

UNDERWATER MODEL

PREVENTATIVE MAINTENANCE

After each use, the movable portions of the tool that

were exposed to water should be ushed with a water

displacing oil such as WD40®. Remove any remaining

water and debris as follows:

1. Turn the tool upside down (without the tool bit) and

spray oil through the drive hex and side holes in the

breaker foot assembly to displace any remaining

water in the lower piston cavity.

2. Spray oil into the On/Off valve trigger slot area.

3. Dip or spray the entire tool.

4. Cycle the tool hydraulically several times before

storing away.

14 ► BR67 User Manual

Page 15

CHARGING THE ACCUMULATOR

Charging the Accumulator Anti-Vibration Handles

Charging the Accumulator T-Handles

BR67 User Manual ◄ 15

Page 16

SPECIFICATIONS

Pressure Range.............................................................................................................. 1500–2000 psi/104–140 bar

Flow Range ............................................................................................................................ 7–9 GPM / 26–34 LPM

Nominal Flow .................................................................................................................................... 8 GPM / 30 LPM

Maximum Back Pressure......................................................................................................................250 Psi/17 bar

Couplers ...................................................................................... HTMA/EHTMA Flush Face Type Male and Female

Connect Size & Type ...........................................................................................................3/8 in. Male Pipe Adapter

Weight ....................................................................................................................................T-Handle 67 lbs / 30 kg

Anti-Vibration Handle 75 lbs / 34 kg

Overall Length ........................................................................................................................T-Handle 27 in. / 69 cm

Anti-Vibration Handle 29 in. / 74 cm

Overall Width at Handles ........................................................................................................T-Handle 16 in. / 41 cm

Anti-Vibration Handle 18 in. / 46 cm

Max. Fluid Temperature ........................................................................................................................ 140 °F / 60 °C

System Type ...........................................................................................................................Open or Closed Center

Port Size .................................................................................................................................................SAE 8 O-ring

HTMA/EHTMA Category .................................................................................................................................Type 2

Nominal Pressure ............................................................................................................................. 1500 psi/103 bar

Max Pressure ................................................................................................................................... 2500 psi/172 bar

Max Relief Pressure ......................................................................................................................... 2150 psi/148 bar

BR67 SOUND AND VIBRATION DECLARATION

TEST CONDUCTED ON BR6717801,OPERATED AT STANDARD 8 GPM INPUT.

MEASURED A-WEIGHTED SOUND POWER LEVEL, LWA (REF. 1PW) IN DECIBELS .......................... 103 DBA

UNCERTAINTY, KWA, IN DECIBELS ......................................................................................................... 1.7 DBA

GUARANTEED SOUND POWER LEVEL ..................................................................................................105 DBA

MEASURED A-WEIGHTED SOUND PRESSURE LEVEL, LPA (REF. 20 ΜPA) AT OPERATOR'S POSITION, IN

DECIBELS ...................................................................................................................................................99 DBA

UNCERTAINTY, KPA, IN DECIBELS .............................................................................................................3 DBA

VALUES DETERMINED ACCORDING TO NOISE TEST CODE GIVEN IN ISO 15744, USING THE BASIC

STANDARD ISO3744. TEST CONDUCTED BY INDEPENDENT NOTIFIED BODY TO COMPLY WITH 2000/14/

EC:2005 REQUIREMENTS. NOTE- THE SUM OF A MEASURED NOISE EMISSION VALUE AND ITS ASSOCIATED UNCERTAINTY REPRESENTS AN UPPER BOUNDARY OF THE RANGE OF VALUES WHICH IS

LIKELY TO OCCUR IN MEASUREMENTS.

BR67 ANTI-VIB MODELS

DECLARED VIBRATION EMISSION VALUE IN ACCORDANCE WITH ISO-28927-10 2011, EN 12096

MEASURED VIBRATION EMISSION VALUE: 3-AXIS ....................................................................... 12.7 M/SEC²

UNCERTAINTY: K ................................................................................................................................. 1.9 M/SEC²

MEASURED VIBRATION EMISSION VALUE WITH UNCERTAINTY: 3-AXIS ................................... 14.6 M/SEC²

MEASURED VIBRATION EMISSION VALUE: Z-AXIS ...........................................................................11 M/SEC²

UNCERTAINTY: K ................................................................................................................................. 2.3 M/SEC²

MEASURED VIBRATION EMISSION VALUE WITH UNCERTAINTY: Z-AXIS ................................... 13.3 M/SEC²

BR67 T-HANDLE MODELS

MEASURED VIBRATION EMISSION VALUE: 3-AXIS ....................................................................... 18.3 M/SEC²

UNCERTAINTY: K ................................................................................................................................. 0.7 M/SEC²

MEASURED VIBRATION EMISSION VALUE WITH UNCERTAINTY: 3-AXIS ................................... 19.0 M/SEC²

16 ► BR67 User Manual

Page 17

ACCESSORIES

ACCESSORIES

1-1/8 IN. HEX × 6 IN. SHANK

Moil Point – 14 in. Long UC ................................................................................................................................................... 02333

Chisel Point – 14 in. Long UC ............................................................................................................................................... 03990

3-inch Chisel – 14 in. Long UC .............................................................................................................................................. 02334

Clay Spade – 5-1/2 in. Blade ................................................................................................................................................. 02331

Asphalt Wedge – 12 in. .........................................................................................................................................................08106

Asphalt Cutter – 5 in. Wide .................................................................................................................................................... 02332

Ground Rod Driver – 1 in. Rod .............................................................................................................................................. 04176

1-1/4 in. Hex × 6 in. Shank

Moil Point – 14 in. Long UC ................................................................................................................................................... 02336

3-inch Chisel – 14 in. Long UC .............................................................................................................................................. 02337

Clay Spade – 5-1/2 in. Blade ................................................................................................................................................. 09262

Asphalt Cutter – 5 in. Wide .................................................................................................................................................... 02335

Ground Rod Driver – 1 in. Rod .............................................................................................................................................. 04367

Heavy Duty Chisel – 1 in.. ..................................................................................................................................................... 02338

Heavy Duty Moil Point – 18 in. .............................................................................................................................................. 04404

Clay Spade – 8 in. ................................................................................................................................................................. 04405

Detachable Shank (Requires 17783) .................................................................................................................................... 17782

Tamping Pad – 6 in. (Requires 17782) .................................................................................................................................. 17783

TEST EQUIPMENT

Accumulator Tester ................................................................................................................................................................ 02835

Flow and Pressure Tester ...................................................................................................................................................... 04182

Accumulator Charge Assembly (Incl. Liquid Filled Gauge w/ Valve, Hose, & Charge Fitting) ............................................... 15304

Accumulator Charge Kit (Incl. 02835 Tester, 15304 Charge Assy and 372047 Charge Kit Box) ..........................................31254

SERVICE TOOLS

Flow Sleeve Removal Tube ................................................................................................................................................... 04910

Seal Kit .................................................................................................................................................................................. 04596

Split Ring (Auto Valve Removal) ...........................................................................................................................................04908

Accumulator Cylinder Puller .................................................................................................................................................. 05640

Accumulator Disassembly Tool .............................................................................................................................................. 05508

Spacer (Flow Sleeve Installation) .......................................................................................................................................... 04909

KITS

Flow Sleeve Kit (See note on page 20 or page 22 for items included in kit) ......................................................................... 74396

BR67 User Manual ◄ 17

Page 18

BR67 ANTI-VIB PARTS ILLUSTRATION

BR67 ANTI-VIBRATION HANDLE PARTS ILLUSTRATION

Coupler Set

P/N-03971

18 ► BR67 User Manual

See pages 23 through 28

for Breaker Foot Parts.

Page 19

BR67 ANTI-VIB PARTS LIST

BR67 ANTI-VIBRATION HANDLE PARTS LIST

WITHOUT

ITEM

TRIGGER

NO.

LOCK

1 24067 24067 1 RETAINING RING

2 04055 04055 1 WASHER

3 04056 04056 1 ROD WIPER

4 26451 26451 1 BUSHING

5 01362 01362 1 O-RING

6 00293 00293 1 O-RING

7 20515 20515 1 VALVE SPOOL

8 04058 04058 1 SPRING

9 07628 07628 4 CAPSCREW

10 20511 20511 1 LEVER

11 28369 28369 1 HANDLE

12 20502 20502

13 29045 29045

14 — 26599 1 PIN

15 — 24964 1 SPRING

16 — 16607 1 SAE PLUG, -10

17 04070 04070 1 PISTON

18 — 24948 1 TRIGGER LOCK

19 — 31917 1 PIN

20 07493 07493 1 PLUG

21 20499 20499 1 CHARGE VALVE

22 — 21089 1 ROLL PIN

23 20500 20500 2 SPIROL PIN

24 20541 20541 2 SPRING

25 20498 20498 2 SPRING

26 02494 02494 2 HANDLE GRIP

27 11207 11207 1 CIRCUIT TYPE "D" STICKER

28 01605 01605 2 O-RING

29 01652 01652 2 HOSE ASSY

30 12832 12832 1 ORIFICE PLUG

31 06891 06891 1 O-RING

32 31067 31067 1 PLUG

33 26452 26452 1 SINTERED FILTER

34 04795 04795 2 O-RING

35 16732 16732 1 O-RING

36 26448 26448 1 SPACER

WITH

TRIGGER

LOCK QTY DESCRIPTION

TRIGGER

5852611

TRIGGER (USED ON TOOLS

WITH AN “A” OR “AA” AT

THE END OF THE MODEL

NUMBER)

TRIGGER HANDLE

5852911

TRIGGER HANDLE (USED

ON TOOLS WITH AN “A” OR

“AA” AT THE END OF THE

MODEL NUMBER)

(CE ONLY)

(INCL ITEM 28)

ITEM

NO.

WITHOUT

TRIGGER

LOCK

WITH

TRIGGER

LOCK QTY DESCRIPTION

37 04062 04062 1 BACK-UP WASHER

38 03973 03973 1 MALE COUPLER BODY

39 03972 03972 1 FEMALE COUPLER BODY

40 04068 04068 1 FLOW SLEEVE TUBE

41 74668 74668 1 NAME TAG, BR67

42 04064 04064 1 WASHER

43 04063 04063 1 CUP SEAL

44 04054 04054 2 O-RING

45 04069 04069 1 FLOW SLEEVE (SEE NOTE

46 04071 04071 4 SIDE ROD

47 04065 04065 1 AUTOMATIC VALVE

48 04571 04571 2 PUSH PIN

49 20508 20508 2 PIVOT SCREW

50 26596 26596 1 ACCUMULATOR VALVE

51 26574 26574 1 ACCUMULATOR

52 26449 26449 1 ACCUMULATOR PLUG

54 04067 04067 4 PUSH PIN

55 07890 07890 1 ROLL PIN

56 04066 04066 1 AUTOMATIC VALVE BODY

59 ----- ----- 1 HANDLE

66 04075 04075 4 SIDE ROD NUT

71 — 28322 1 CE STICKER (CE ONLY)

72 28409 28409 1 COMPOSITE STICKER

73 66654 66654 1 GUARANTEED SOUND

74 73025 73025 2 FILLER SNAP-ON

75 74832 74832 2 STANLEY LOGO STICKER

74770 2 STANLEY LOGO STICKER

92 26450 26450 1 TOP PLATE

93 — 11208 1 HEX SHANK STICKER

94 — 00077 1 RETAINING RING (CHECK

95 — 32297 1 TRUSS HEAD SCREW

96 — 58527 1 TRIGGER LOCK (USED ON

PAGE 20)

BLOCK

DIAPHRAGM

(CE ONLY)

POWER LEVEL STICKER 105

(CE ONLY)

(USED ON: BR67125,

BR67135 AND BR6717801A)

(USED ON: BR6713516,

(UK MODELS ONLY)

ITEM # 19 TO SEE IF IT

USES A SCREW OR RET.

RING)

(CHECK ITEM # 19

TO SEE IF IT USES A

SCREW OR RET. RING)

TOOLS WITH AN “A” OR “AA”

AT THE END OF THE MODEL

NUMBER)

BR67 User Manual ◄ 19

Page 20

BR67 ANTI-VIB PARTS LIST

BR67 ANTI-VIBRATION HANDLE PARTS LIST (CONTINUED)

WITHOUT

ITEM

TRIGGER

NO.

LOCK

97 — 66828 1 TORSION SPRING (USED

98 — 07624 1 ROLL PIN (USED ON TOOLS

04596 04596 1 SEAL KIT

WITH

TRIGGER

LOCK QTY DESCRIPTION

ON TOOLS WITH AN “A” OR

“AA” AT THE END OF THE

MODEL NUMBER)

WITH AN “A” OR “AA” AT

THE END OF THE MODEL

NUMBER)

NOTE: There is a ow sleeve kit available

P/N-74396 that includes:

item # 44 (Qty-2 04054 O-Ring),

item # 54 (Qty-4 04067 push pin),

item # 45 (Qty-1 04069 ow sleeve),

item # 62 (Qty-1 04073 O-Ring)

and inst sheet.

20 ► BR67 User Manual

Page 21

BR67 STD PARTS ILLUSTRATION

BR67 STANDARD HANDLE PARTS ILLUSTRATION

Coupler Set

P/N-03971

See pages 23 through 28

for Breaker Foot Parts.

BR67 User Manual ◄ 21

Page 22

BR67 STANDARD PARTS LIST

WITHOUT

ITEM

TRIGGER

NO.

LOCK

2 04055 04055 1 WASHER

3 04056 04056 1 ROD WIPER

4 04057 04057 1 BUSHING

5 01362 01362 1 O-RING

6 00293 00293 1 O-RING

7 04077 04077 1 VALVE SPOOL

8 04058 04058 1 SPRING

12 04053 11434 1 TRIGGER

17 04070 04070 1 PISTON

21 04051 04051 1 CHARGE VALVE

09349 09349 1 VALVE CAP (NOT SHOWN)

26 02494 02494 2 HANDLE GRIP

27 — 11207 1 CIRCUIT TYPE "D" STICKER

28 01605 01605 2 O-RING

29 01652 01652 2 HOSE ASSY (INCL ITEM 28)

30 04350 04350 1 ORIFICE PLUG

35 04054 04054 1 O-RING

36 — — 1 SPACER

37 04062 04062 1 BACK-UP WASHER

38 03971 03971 1 COUPLER SET (MALE &

39 03971 03971 1 COUPLER SET (MALE &

40 04068 04068 1 FLOW SLEEVE TUBE

42 04064 04064 1 WASHER

43 04063 04063 1 CUP SEAL

44 04054 04054 2 O-RING

45 04069 04069 1 FLOW SLEEVE (SEE NOTE

46 04071 04071 4 SIDE ROD

47 04065 04065 1 AUTOMATIC VALVE

48 04571 04571 2 PUSH PIN

49 04060 04060 1 ACCUMULATOR CYLINDER

51 04059 04059 1 ACCUMULATOR DIAPHRAGM

54 04067 04067 4 PUSH PIN

55 07890 07890 1 ROLL PIN

56 04066 04066 1 AUTOMATIC VALVE BODY

59 04049 11435 1 HANDLE

66 04075 04075 4 SIDE ROD NUT

71 — 28322 1 CE STICKER (CE ONLY)

72 28409 28409 1 COMPOSITE STICKER

WITH

TRIGGER

LOCK QTY DESCRIPTION

(CE ONLY)

FEMALE COUPLERS)

FEMALE COUPLERS)

PAGE 22)

(CE ONLY)

WITHOUT

ITEM

TRIGGER

NO.

LOCK

73 66654 66654 1 GUARANTEED SOUND

74 04050 04050 1 VALVE CAP ASSY (INCLUDES

75 04052 04052 1 O-RING

76 00844 00844 1 SPIROL PIN

77 22891 22891 1 SPRING PIN

78 10180 10180 STICKER

79 04061 04061 1 ACCUMULATOR CHAMBER

80 — 11430 1 SPRING

86 74667 74667 1 NAME TAG (T-HANDLE)

74671 NAME TAG (T-HANDLE)

88 — 01003 1 BUTTON

89 — 11435 1 HANDLE

90 — 11431 1 LOCK PIN

91 — 11432 1 KEY

93 — 11208 1 HEX SHANK STICKER

94 —- 00077 1 RETAINING RING

95 73025 73025 2 FILLER SNAP-ON

96 74832 74832 2 STANLEY LOGO STICKER

74770 2 STANLEY LOGO STICKER

04596 04596 1 SEAL KIT

WITH

TRIGGER

LOCK QTY DESCRIPTION

POWER LEVEL STICKER 105

(CE ONLY)

ITEM 75)

BR67320 ONLY.

(UK MODELS ONLY)

(USED ON MODELS: BR67120,

BR67120E, BR67130,

BR67130E).

(USED ON MODELS: BR67120D

and BR67320).

NOTE: There is a ow sleeve kit available

P/N-74396 that includes:

item # 44 (Qty-2 04054 O-Ring),

item # 54 (Qty-4 04067 push pin),

item # 45 (Qty-1 04069 ow sleeve),

item # 62 (Qty-1 04073 O-Ring)

and inst sheet.

22 ► BR67 User Manual

Page 23

ITEM

PART

NO

QTY. DESCRIPTION

1 01269 2 TAPER SLEEVE

2 01744 1 COMPRESSION COIL SPRING

3 01837 1 LATCH (CASTING)

4 04073 1 O-RING 2-5/8 X 2-7/8 X 1/8 -231

5 04074 1 ROD WIPER (DISOGRIN #006-021)

6 04080 1 BREAKER FOOT

7 04081 1 HEX BUSHING 1-1/8"

8 04983 1 FOOT LATCH BOLT

9 04984 1 NYLOCK NUT 3/4-16UNF

10 04985 2 SPRING WASHER

11 05464 1 SEAL INSERT

12 08411 1 DETENT

13 34127 1 CUP SEAL (DISOGRIN #500-151-000A)

BREAKER FOOT ASSEMBLY 05466

BREAKER FOOT ASSEMBLY FOR MODEL BR67120, BR67120D & BR67125.

6

7

2

12

3

9

1

10

8

4

13

5

ALIGN HEX AS SHOWN

11

ITEM

NO. PART NO. QTY DESCRIPTION

1 01269 2 TAPER SLEEVE

2 01744 1 COMPRESSION COIL SPRING

3 01837 1 LATCH (CASTING)

4 04073 1 0-RING (2-5/8 X 2-7/8 X 1/8-

231)

5 04074 1 ROD WIPER

6 05466 1 BREAKER FOOT (IF

ORDERING THE FOOT, YOU

MUST ORDER COMPLETE

FOOT ASSEMBLY, PART

NUMBER 05466)

7 05466 1 HEX BUSHING (IF ORDERING

HEX BUSHING, YOU MUST

ORDER COMPLETE FOOT

ASSEMBLY, PART NUMBER

05466)

8 04983 1 FOOT LATCH BOLT

9 04984 1 NYLOCK NUT 3/4-16 UNF

10 04985 2 SPRING WASHER

11 05466 1 SEAL INSERT (IF ORDERING

SEAL INSERT, YOU MUST

ORDER COMPLETE FOOT

ASSEMBLY, PART NUMBER

05466)

12 08411 1 DETENT

13 34127 1 CUP SEAL

BR67 User Manual ◄ 23

Page 24

ITEM

PART

NO

QTY. DESCRIPTION

1 01269 2 TAPER SLEEVE

2 01744 1 COMPRESSION COIL SPRING

3 01837 1 LATCH (CASTING)

4 04073 1 O-RING 2-5/8 X 2-7/8 X 1/8 -231

5 04074 1 ROD WIPER (DISOGRIN #006-021)

6 04080 1 BREAKER FOOT

7 04597 1 HEX BUSHING 1-1/4"

8 04983 1 FOOT LATCH BOLT

9 04984 1 NYLOCK NUT 3/4-16UNF

10 04985 2 SPRING WASHER

11 05464 1 SEAL INSERT

12 08411 1 DETENT

13 34127 1 CUP SEAL (DISOGRIN #500-151-000A)

BREAKER FOOT ASSEMBLY 05467

BREAKER FOOT ASSEMBLY FOR MODEL BR67130, BR6713016, BR67135 & BR6713516.

6

7

2

12

3

9

1

10

8

4

13

5

ALIGN HEX AS SHOWN

11

ITEM

NO. PART NO. QTY DESCRIPTION

1 01269 2 TAPER SLEEVE

2 01744 1 COMPRESSION COIL SPRING

3 01837 1 LATCH (CASTING)

4 04073 1 0-RING (2-5/8 X 2-7/8 X 1/8-231)

5 04074 1 ROD WIPER

6 05467 1 BREAKER FOOT (IF ORDERING FOOT, YOU

MUST ORDER COMPLETE FOOT ASSEMBLY,

PART NUMBER 05467)

7 05467 1 HEX BUSHING - 1-1/4”

(IF ORDERING HEX BUSHING, YOU MUST

ORDER COMPLETE FOOT ASSEMBLY, PART

NUMBER 05467)

8 04983 1 FOOT LATCH BOLT

9 04984 1 NYLOCK NUT 3/4-16 UNF

10 04985 2 SPRING WASHER

11 05467 1 SEAL INSERT (IF ORDERING SEAL INSERT,

YOU MUST ORDER COMPLETE FOOT

ASSEMBLY, PART NUMBER 05467)

12 08411 1 DETENT

13 34127 1 CUP SEAL

24 ► BR67 User Manual

Page 25

ITEM

PART

NO

QTY. DESCRIPTION

1 01269 2 TAPER SLEEVE

2 01744 1 COMPRESSION COIL SPRING

3 01837 1 LATCH (CASTING)

4 04073 1 O-RING 2-5/8 X 2-7/8 X 1/8 -231

5 04074 1 ROD WIPER (DISOGRIN #006-021)

6 04983 1 FOOT LATCH BOLT

7 04984 1 NYLOCK NUT 3/4-16UNF

8 04985 2 SPRING WASHER

9 05464 1 SEAL INSERT

10 07514 1 COMPRESSION COIL SPRING

11 07518 1 HEX BUSHING 1-1/4"

12 07521 1 BREAKER FOOT

13 07522 1 RETAINING RING

14 08116 1 COLLAR SUPPORT ASSY. 1-1/4

15 08411 1 DETENT

16 34127 1 CUP SEAL (DISOGRIN #500-151-000A)

BREAKER FOOT ASSEMBLY 07524

BREAKER FOOT ASSEMBLY FOR MODEL BR6713015E & BR67130E.

11

16

8

1

ALIGN HEX AS SHOWN

13

3

7

15

4

12

10

5

2

14

1

8

6

9

ITEM

NO. PART NO. QTY DESCRIPTION

1 01269 2 TAPER SLEEVE

2 01744 1 COMPRESSION COIL SPRING

3 01837 1 LATCH (CASTING)

4 04073 1 0-RING (2-5/8 X 2-7/8 X 1/8-231)

5 04074 1 ROD WIPER

6 04983 1 FOOT LATCH BOLT

7 04984 1 NYLOCK NUT 3/4-16 UNF

8 04985 2 SPRING WASHER

9 07524 1 SEAL INSERT (IF ORDERING SEAL INSERT,

YOU MUST ORDER COMPLETE FOOT

ASSEMBLY, PART NUMBER 07524)

10 07514 1 COMPRESSION SPRING COIL

11 07524 1 HEX BUSHING 1-1/4”

(IF ORDERING HEX BUSHING, YOU MUST

ORDER COMPLETE FOOT ASSEMBLY, PART

NUMBER 07524)

12 07524 1 BREAKER FOOT (IF ORDERING FOOT, YOU

MUST ORDER COMPLETE FOOT ASSEMBLY,

PART NUMBER 07524)

13 07522 1 RETAINING RING

14 08116 1 COLLAR SUPPORT ASSY. 1/1/4”

15 08411 1 DETENT

16 34127 1 CUP SEAL

BR67 User Manual ◄ 25

Page 26

ITEM

PART

NO

QTY. DESCRIPTION

1 01269 2 TAPER SLEEVE

2 01744 1 COMPRESSION COIL SPRING

3 01837 1 LATCH (CASTING)

4 04073 1 O-RING 2-5/8 X 2-7/8 X 1/8 -231

5 04074 1 ROD WIPER (DISOGRIN #006-021)

6 04983 1 FOOT LATCH BOLT

7 04984 1 NYLOCK NUT 3/4-16UNF

8 04985 2 SPRING WASHER

9 05464 1 SEAL INSERT

10 07514 1 COMPRESSION COIL SPRING

11 07517 1 HEX BUSHING 1-1/8"

12 07521 1 BREAKER FOOT

13 07522 1 RETAINING RING

14 08115 1 COLLAR SUPPORT ASSY.

15 08411 1 DETENT

16 34127 1 CUP SEAL (DISOGRIN #500-151-000A)

BREAKER FOOT ASSEMBLY 07525

BREAKER FOOT ASSEMBLY FOR MODEL BR67120E.

11

16

13

3

7

15

110

8

ALIGN HEX AS SHOWN

4

12

5

2

14

1

8

6

9

ITEM

NO. PART NO. QTY DESCRIPTION

1 01269 2 TAPER SLEEVE

2 01744 1 COMPRESSION COIL SPRING

3 01837 1 LATCH (CASTING)

4 04073 1 0-RING (2-5/8 X 2-7/8 X 1/8-

231)

5 04074 1 ROD WIPER

6 04983 1 FOOT LATCH BOLT

7 04984 1 NYLOCK NUT 3/4-16 UNF

8 04985 2 SPRING WASHER

9 07525 1 SEAL INSERT (IF ORDERING

SEAL INSERT, YOU MUST

ORDER COMPLETE FOOT

ASSEMBLY, PART NUMBER

07525)

10 07514 1 COMPRESSION SPRING COIL

11 07525 1 HEX BUSHING 1-1/8”

(IF ORDERING HEX

BUSHING, YOU MUST ORDER

COMPLETE FOOT ASSEMBLY,

PART NUMBER 07525)

12 07525 1 BREAKER FOOT (IF

ORDERING FOOT YOU MUST

ORDER COMPLETE FOOT

ASSEMBLY, PART NUMBER

07525

13 07522 1 RETAINING RING

14 08115 1 COLLAR SUPPORT ASSY.

15 08411 1 DETENT

16 34127 1 CUP SEAL

26 ► BR67 User Manual

Page 27

ITEM

PART

NO

1 01269 2 TAPER SLEEVE

2 01744 1 COMPRESSION COIL SPRING

3 01837 1 LATCH (CASTING)

4 04073 1 O-RING 2-5/8 X 2-7/8 X 1/8 -231

5 04074 1 ROD WIPER (DISOGRIN #006-021)

6 04081 1 HEX BUSHING 1-1/8"

7 04983 1 FOOT LATCH BOLT

8 04984 1 NYLOCK NUT 3/4-16UNF

9 04985 2 SPRING WASHER

10 05464 1 SEAL INSERT

11 06643 1 BREAKER FOOT U/W

12 08411 1 DETENT

13 34127 1 CUP SEAL (DISOGRIN #500-151-000A)

BREAKER FOOT ASSEMBLY 08855

BREAKER FOOT ASSEMBLY FOR MODEL BR67320 & BR67120U.

11

6

2

3

12

8 9

1

4

7

13

5

ITEM

NO. PART NO. QTY DESCRIPTION

1 01269 2 TAPER SLEEVE

2 01744 1 COMPRESSION COIL SPRING

3 01837 1 LATCH (CASTING)

4 04073 1 0-RING (2-5/8 X 2-7/8 X 1/8-

231)

5 04074 1 ROD WIPER

6 08855 1 HEX BUSHING -1 1/8” (IF

ORDERING HEX BUSHING,

YOU MUST ORDER

COMPLETE FOOT ASSEMBLY,

PART NUMBER 08855)

7 04983 1 FOOT LATCH BOLT

8 04984 1 NYLOCK NUT 3/4-16 UNF

9 04985 2 SPRING WASHER

10 08855 1 SEAL INSERT (IF ORDERING

SEAL INSERT, YOU MUST

ORDER COMPLETE FOOT

ASSEMBLY, PART NUMBER

08855)

11 08855 1 BREAKER FOOT U/W (IF

ORDERING SEAL FOOT YOU

MUST ORDER COMPLETE

FOOT ASSEMBLY, PART

NUMBER 08855)

12 08411 1 DETENT

13 34127 1 CUP SEAL

BR67 User Manual ◄ 27

Page 28

ITEM

PART

NO

QTY. DESCRIPTION

1 01269 2 TAPER SLEEVE

2 01744 1 COMPRESSION COIL SPRING

3 01837 1 LATCH (CASTING)

4 04073 1 O-RING 2-5/8 X 2-7/8 X 1/8 -231

5 04074 1 ROD WIPER (DISOGRIN #006-021)

6 04983 1 FOOT LATCH BOLT

7 04984 1 NYLOCK NUT 3/4-16UNF

8 04985 2 SPRING WASHER

9 05464 1 SEAL INSERT

10 07514 1 COMPRESSION COIL SPRING

11 07522 1 RETAINING RING

12 08411 1 DETENT

13 11230 1 HEX BUSHING 1-1/4"

14 11234 1 COLLAR SUPPORT ASSY.

15 11235 1 BREAKER FOOT

16 34127 1 CUP SEAL (DISOGRIN #500-151-000A)

13

BREAKER FOOT ASSEMBLY 11236

BREAKER FOOT ASSEMBLY FOR MODEL BR6717801A, BR6717801AA & BR6717802AA.

16

15

10

2 34

7

1

8

6

5

14

11

12

ALIGN HEX AS SHOWN

9

ITEM

NO. PART NO. QTY DESCRIPTION

1 01269 2 TAPER SLEEVE

2 01744 1 COMPRESSION COIL SPRING

3 01837 1 LATCH (CASTING)

4 04073 1 0-RING (2-5/8 X 2-7/8 X 1/8-

231)

5 04074 1 ROD WIPER

6 04983 1 FOOT LATCH BOLT

7 04984 1 NYLOCK NUT 3/4-16 UNF

8 04985 2 SPRING WASHER

9 11236 1 SEAL INSERT (IF ORDERING

SEAL INSERT, YOU MUST

ORDER COMPLETE FOOT

ASSEMBLY, PART NUMBER

11236)

10 07514 1 COMPRESSION SPRING COIL

11 07522 1 RETAINING RING

12 08411 1 DETENT

13 11236 1 HEX BUSHING 1-1/4”

(IF ORDERING HEX

BUSHING, YOU MUST ORDER

COMPLETE FOOT ASSEMBLY,

PART NUMBER 11236)

14 11234 1 COLLAR SUPPORT ASSY.

15 11236 1 BREAKER FOOT (IF

ORDERING FOOT YOU MUST

ORDER COMPLETE FOOT

ASSEMBLY, PART NUMBER

11236)

16 34127 1 CUP SEAL

28 ► BR67 User Manual

Page 29

UNDERWATER TOOLS DEPTH GUIDELINE

UNDERWATER MODELS ONLY

DO NOT USE HYDRAULIC TOOLS UN-

DERWATER THAT ARE NOT DESIGNATED

AS AN “UNDERWATER” MODEL, OR THIS

WILL RESULT IN DAMAGE TO THE TOOL.

For underwater hydraulic tools the applications are

broken down into four quadrants depending on

type of tool and method of operation.

The types of tools are percussive and rotational,

each with different characteristics allowing for

different depth operation. With percussive tools,

the nitrogen accumulator PSI must counter the

increase in ambient pressure found at lower

depths. Since there is a maximum PSI for

percussive tools they are limited to certain depths.

Rotational tools do not have accumulators and

thus capable of deeper depths.

Operation Overview

Percussive Rotational

Tools: Breakers,

Hammer Drills and

Chipping Hammers

Max Depth: 500' -

DiverROV

limitations due to

accumulator PSI

max (increase 40

PSI for every 100')

Tools: Breakers,

Hammer Drills and

Chipping Hammers

Max Depth: 500' -

limitations due to

accumulator PSI

max (increase 40

PSI for every 100')

Tools: Grinders,

Saws, Chain Saws

Max Depth: 1000' -

Reference hose

sizing guide below

Tools: Grinders,

Saws, Chain Saws

Max Depth: 1000' -

Reference hose

sizing guide below

The methods are broken into diver operated or

remote operated vehicle (ROV). ROV's can reach

lower depths and with an on-board hydraulic

power source that is depth compensated, can

operate hydraulic tools at depths of thousands of

feet. ROV operation is still limited to the tool, for

example a percussive tool has the same depth

limitation whether ROV or diver operated.

Recommended Hose Diameters

Depth (ft) 8 GPM 12 GPM

100 5/8” 5/8”

300 3/4” 1”

600 1” 1”

1000 1” 1-1/4”

BR67 User Manual ◄ 29

Page 30

NOTES

30 ► BR67 User Manual

Page 31

Page 32

STANLEY Infrastructure

6430 SE Lake Road

Portland, Oregon 97222 USA

(503) 659-5660 / Fax (503) 652-1780

www.stanleyinfrastructure.com

Loading...

Loading...