Page 1

Argon F500 Gas

Models

INSTALLATION AND OPERATING INSTRUCTIONS

This appliance is hot while in operation and retains its heat for a long period of time after use. Children,

aged or infirm persons should be supervised at all times and should not be allowed to touch the hot

working surfaces while in use or until the appliance has thoroughly cooled.

To ensure safety, satisfaction and reliable service, this appliance must be installed by a suitably qualified and component person.

PLEASE RETAIN

F500 OVAL F500 SLIM

Page 2

TABLE OF CONTENTS

PAGE NO.

1. Stanley Stove Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2. Important Operation/ Maintenance Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3. Commissioning Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4. Installation & Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6. Electrical Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

7. Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

8. Clearance To Combustibles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

9. Floor Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

10. Gas Pipes & Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

11. Meters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

12. Gas Pipe Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

13. Gas Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

14. Gas Soundness Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

15. Flue Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

16. Fuel Bed Arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

17. Stove Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

18. Commissioning the Stove . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

19. Pilot Ignition Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

20. Main Burner Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

21. Pressure Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

22. Pairing the Remote Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

23. Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

24. First Time Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

25. Remote Control Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

26. Manual Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

27. Setting Celsius or Fahrenheit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

28. Setting the Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

29. Automatic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

30. Thermostatic Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

31. Program Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

32. Eco Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

33. Additional Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

34. Child Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

35. Countdown Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

36. Rear Burner Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

37. Wi-Fi Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

38. Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

39. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

40. CO Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

41. Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

42. Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2

Page 3

TABLE OF CONTENTS

PAGE NO.

43. Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

44. Exploded View - F500 Oval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

45. Exploded View - F500 Slim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

46. Service Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

47. Fault Finding- General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

48. Fault Codes - Remote Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3

Page 4

4

STANLEY STOVE WARRANTY

CONDITIONS OF WARRANTY

Your Stanley Stove is guaranteed against any part that fails (under normal operating conditions) for a two year period

from the date of installation of the appliance. If the unit is not installed within six months of date of purchase, the warranty will commence six months from the date of purchase.

All warranty claims must be reported to the Waterford Stanley Service Department and must be submitted with the product serial number (located on the back of the bottom door on Slim models & on the bottom of the back face of the front

panel on Oval models), date of purchase, proof of purchase (if requested) and details of the specific nature of the problem.

The warranty is given to the original consumer/purchaser only and is non-transferable. The appliance must be installed

by a suitable qualified person (RGI Registered in ROI & Gas Safe Registered in NI/UK or equivalent) and installed as

per the requirements of the manual. Failure to comply with the Installation Requirements or Building Regulations will

void your warranty. Waterford Stanley reserve the right to replace any part due to manufacturing defect that fails within the warranty period under the terms of the warranty. The unit must be used for normal domestic purposes only and

in accordance with manufacturer's operation instructions.

LIMITS OF LIABILITY

The warranty does not cover:

* Bulbs and Batteries.

* Special, incidental or consequential damages, injury to persons or Property, or any other consequential loss.

* Any issue caused by negligence, misuse, abuse or circumstances beyond Waterford Stanley’s control.

* Any issue with wear and tear, modification, alteration, or servicing by anyone other than an authorized service

engineer.

* Damage resulting from installation & usage where the appliance has not been installed or used in accordance

with the installation or operation instructions or if the installation does not conform to local building, fire &

safety regulations.

* Damage caused to the unit while in transit.

* Damage caused by storing the unit in a damp, unheated environment.

* Fading of Paint Finish.

* Aesthetic damage & missing parts on units purchased off display.

* Removal & re-installation costs.

Note: Adequate clearance must be maintained around the appliance to ensure the ease of part removal in the possible event of their damage/failure. Waterford Stanley are not responsible for any costs incurred in the removal of items

installed in the vicinity of the appliance that have to be moved to facilitate a part replacement.

Page 5

IMPORTANT OPERATION / MAINTENANCE NOTES

Now that your Stanley Stove is installed and no doubt you are looking forward to the many comforts it will provide, we would like to give you some tips on how to get the best results from your unit.

1. Carefully read all instructions before using this unit.

2. The unit is hot when in use. To avoid burns, do not let bare skin touch hot surfaces.

3. Keep combustible materials, such as furniture, pillows, bedding, papers, clothes and curtains at least 1

metre from the front of the unit.

4. Extreme caution is necessary when any heater is used by or near children or invalids and

whenever the unit is left operating and unattended.

5. Do not operate this unit if the glass panel has been broken (or cracked), removed or with firebox access

panels open.

6. Do not use the unit for other than its intended use. Do not use outdoors.

7. This appliance must be installed by a RGI Registered Installer (ROI) or a Gas Safe Installer (NI or UK)

or equivalent.

8. Before installation, check that the stove is configured for the type of gas that it is to be run on (i.e.

Natural Gas or L.P.G.)

9. Do not install the unit on a surface which may restrict air circulation around the unit.

10. Only flue approved by Waterford Stanley for this appliance may be used.

11. This stove is a balanced flue product and is room sealed and as such requires no additional ventilation

for operation. However an adequate supply of fresh air to maintain temperatures and a comfortable

environment is recommended.

12. Do not modify this unit. Use it only as described in this manual. Any other use not recommended by the

manufacturer may cause fire, electric shock or injury to persons.

13. The unit may emit a slight, harmless odour and smoke when first used. This odour and smoke

is normal and it is caused by the paint completing the curement process. It is recommended

to ventilate the room during the first firing.

14. Do not strike the glass.

15. Do not attempt to burn rubbish on this appliance.

16. If this appliance is extinguished, on purpose or other, no attempt to relight should be made within 3

minutes.

17. Always clean the glass panel before the fire is ignited. Any finger prints must be removed, as these may

burn into the glass and be un-removable.

18. Ensure that the Flue Terminal is not in any way obstructed and is clear of vegetation, i.e. tress, shrubs

etc and that no objects are leant against the terminal or guard.

19. Do not use the unit in small rooms when they are occupied by persons not capable of leaving the

room on their own, unless constant supervision is provided.

20. Children of less than 3 years should be kept away from the unit unless constantly supervised.

21. Children aged from 3 years and less than 8 years shall only switch on/off the unit provided that it has

been placed or installed in its intended normal operating position and they have been given supervision

or instruction concerning the use of the unit in a safe way and understand the hazards involved. Children

aged from 3 years and less than 8 years shall not plug in, regulate and clean the appliance or perform

user maintenance.

22. This unit can be used by children aged from 8 years & above and persons with reduced physical,

sensory or mental capabilities or lack of experience & knowledge if they have been given supervision

or instruction concerning the use of the unit in a safe way and understand the hazards involved. Children

shall not play with the unit. Cleaning and user maintenance shall not be made by children without

supervision.

5

Page 6

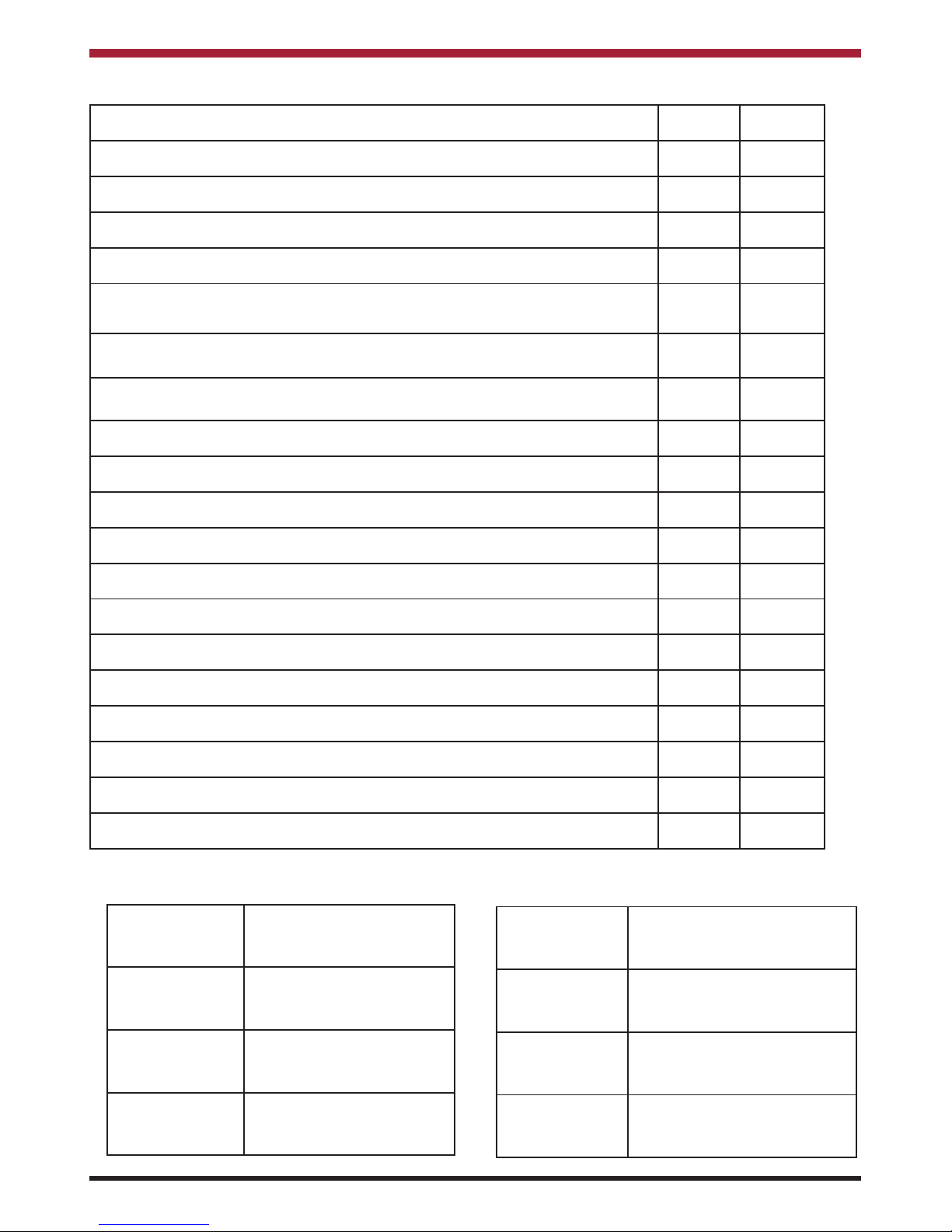

COMMISSIONING CHECK LIST

6

FLUE SYSTEM PASS FAIL

1. Flue Routing in compliance with Guidelines (see Flue Installation)

2. Waterford Stanley Flue Pipes & Fittings Used.

3. Flue Terminal positioned correctly & clear of obstructions.

LOCATION PASS FAIL

1.Clearance to combustible materials must be adhered to (see Clearance

to Combustible section).

2. Floor Protection extends 300mm in front, 150mm to sides & 50mm from

back.

3. Clearance must be maintained to allow for maintenance and part

replacement.

GAS CHECK PASS FAIL

1. Gas Soundness Test

2. Inlet Gas Pressure mbar

3. Burner Pressure mbar

OPERATIONAL CHECK PASS FAIL

1. Spillage Test

2. Remote Control Operation

3. Pilot Ignition Check

4. Main Burner Check

5. Customer advised on use of the Stove

SAFETY CHECK PASS FAIL

1. CO Alarm Fitted

PRODUCT & INSTALLER INFORMATION

MODEL:

SERIAL NO:

GAS TYPE:

DATE OF

PURCHASE:

INSTALLER:

CONTACT NO:

RGI/ GAS SAFE

REGISTRATION

NO:

DATE OF

INSTALL:

Page 7

INSTALLATION & OPERATING INSTRUCTIONS

GENERAL

When installing, operating and maintaining your

Stanley Stove, respect basic standards of fire safety.

Read these instructions carefully before commencing the installation. Failure to do so may result in

damage to persons and property. Consult your local

Municipal office and your insurance representative

to determine what regulations are in force. Save

these instructions for future reference. Please note

that it is a legal requirement under the Building

Regulations that the installation of the stove is either

carried out by a RGI Registered Installer (ROI) or a

Gas Safe Installer (NI or UK) or equivalent.

It is important to note that once a type of gas has

been specified the stove cannot be run off any

other type of gas (i.e. Natural Gas or L.P.G.).

The burner units are not interchangeable

between Natural Gas & L.P.G.

Special care must be taken when installing the stove

such that the requirements of the Health & Safety at

Work Act are met.

Handling

Adequate facilities must be available for loading,

unloading and site handling.

Asbestos

This stove contains no asbestos. If there is a possibility of disturbing any asbestos in the course of

installation then please seek specialist guidance and

use appropriate protective equipment.

Metal Parts

When installing or servicing this stove care should

be taken to avoid the possibility of personal injury.

“IMPORTANT WARNING”

This stove must not be installed into a chimney system that serves any other heating appliance.

7

The complete installation must be done in accordance with current Standards and Local Codes. It

should be noted that the requirements and these

publications may be superseded during the life of

this manual.

Northern Ireland & UK Installation

Install in accordance with the following:

* The Gas Safety Regulations 1998 (as amended).

* B.S. 5440: Parts 1 & 2, Installation & Maintenance

of Flues and Ventilation for Gas Appliances of rated

input not exceeding 70kW

* B.S. 5871: Parts 1, 2 & 3, Specification for

Installation of Gas Fires, Convector Heaters,

Fire/Back Boilers and Decorative Fuel Effect Gas

Appliances.

* Building Regulations for England, Scotland, Wales

& Northern Ireland.

Your Stanley Gas stove is supplied with the following

items:

• Ceramic Log Set

• Remote Control

• Flue Restrictor Plates

ELECTRICAL SUPPLY

All wiring external to the appliance must conform to

the current BS 7671 (UK) BS 7462 Safety Document

635: ETC Part 1, Section 5.4.6 and The Electricity at

Work Regulations.

If connecting the optional Wi-Fi module (for remote

smart phone control), the unit requires a 220V-240V

50L/2 supply connection and any system controls to

the mains supply must be through a fused double

pole switch having contact separation of at least

3mm with a fuse rated at 3 amp and located in a

readily accessible position close to the appliance.

Connection should be made through the cable supplied only.

LOCATION

There are several conditions to be considered in

selecting a location for your Stanley Stove.

a. Position in the area to be heated, central

locations are usually best.

b. Allowances for proper clearances to

combustibles.

c. Proposed Routing of Flueing System.

d. Allowances for proper clearances for

maintenance work.

Republic of Ireland Installation

Install in accordance with the following:

* Building Regulations Part J

* I.S. 813 - Domestic Gas Installations

* I.S. 265 - Part 1 & 2 - Installation of Gas Service

Pipes

* I.S. 327 1990 - Domestic Installation using

Liquidified Petroleum Gases.

CLEARANCES TO COMBUSTIBLES

Maintain at least the following clearances to all

combustible material - refer to Fig 1:

Clearance to

Combustibles (mm)

Clearance to Non

Combustibles(mm)

Rear (R) 75 50

Side (S) 500 50

Top (T) 300 50

Front (F) 1000 75

Page 8

8

Fig.1

FLOOR PROTECTION

It is recommended that the appliance is installed on

a solid, level, concrete base of non combustible

hearth conforming to the current Building

Regulations and must extend 300mm in front of the

appliance, 150mm to the sides and 50mm from the

rear.

* B.S. 1387 - Steel tubes.

* B.S. 6362 - stainless steel tubes.

* B.S. 1740 - Wrought steel pipes.

* B.S. 4089 - L.P.G. hoses and assemblies.

METERS

A suitable gas meter must be connected to the service pipe either by a representative of the gas board

or by an appointed contractor. If using an existing

meter have it checked to ensure that the meter is

capable of dealing with the total rate of gas needed.

GAS PIPE SIZE

It is important that the correct service pipe size be

used for adequate gas supply. This depends on the

distance between the supply meter and the appliance relative to the input requirements. The gas

supply to the appliance should be terminated near

the appliance with an approved safety type service

tap.

GAS CONNECTION

The stove has a ø8mm gas inlet connection located

underneath the underside of the burner as shown in

Fig 3. The stove is designed to accommodate the

routing of the gas feed pipe up through the base of

the stove. If the gas feed pipe is to be routed through

the back of the stove, a suitably sized hole can be

drilled in the steel body (away from the combustion

chamber) to accommodate same.

Note: An isolation tap must be fitted outside of

the stove and positioned to allow for ease

of access when required.

Fig.2

50mm

300mm

150mm

150mm

WARNING: Before connecting the stove make

sure the gas supply pipe is clear of grit and debris

as this will cause blockage within the stove control, pilot burner, injectors and pipework. Failure

to do so may void product warranty.

WARNING: Only connect to gas type indicated

on the rating plate.

GAS PIPES & FITTINGS

Materials used for installation work should be fire

resistant and gas tight and should conform to the following or their equivalent.

* I.S. 238, I.S. 239 and prEN 1057 - Copper

tubes.

* I.S. 265 - Installation of gas service pipes.

* I.S. 266 - Polyethylene pipes.

* EN 29453 & I.S.O. 9453 - Soft Solders.

* B.S. 669 - flexible hoses, fittings & sockets.

* B.S. 759 - valves, gauges and other safety

equipment.

Fig.3

Page 9

9

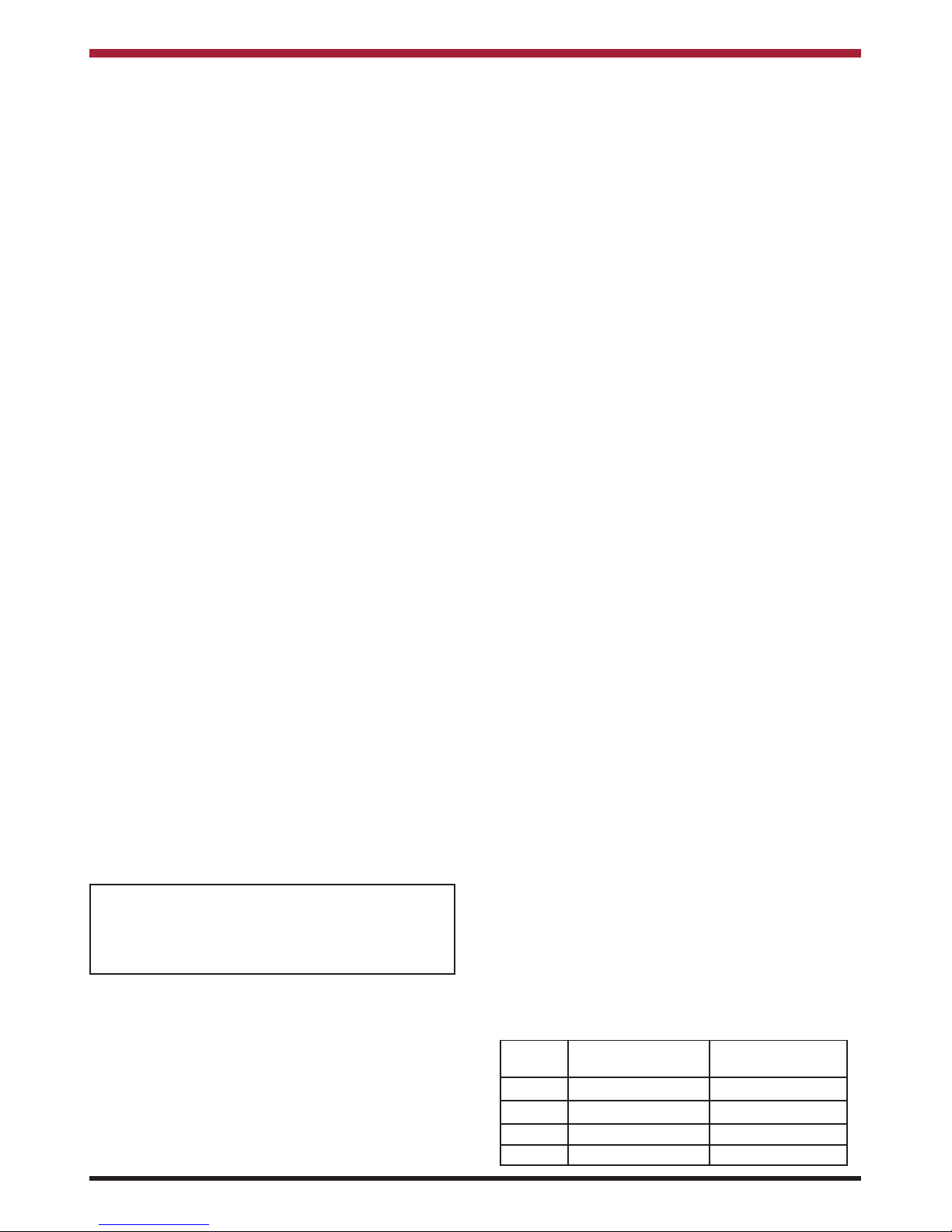

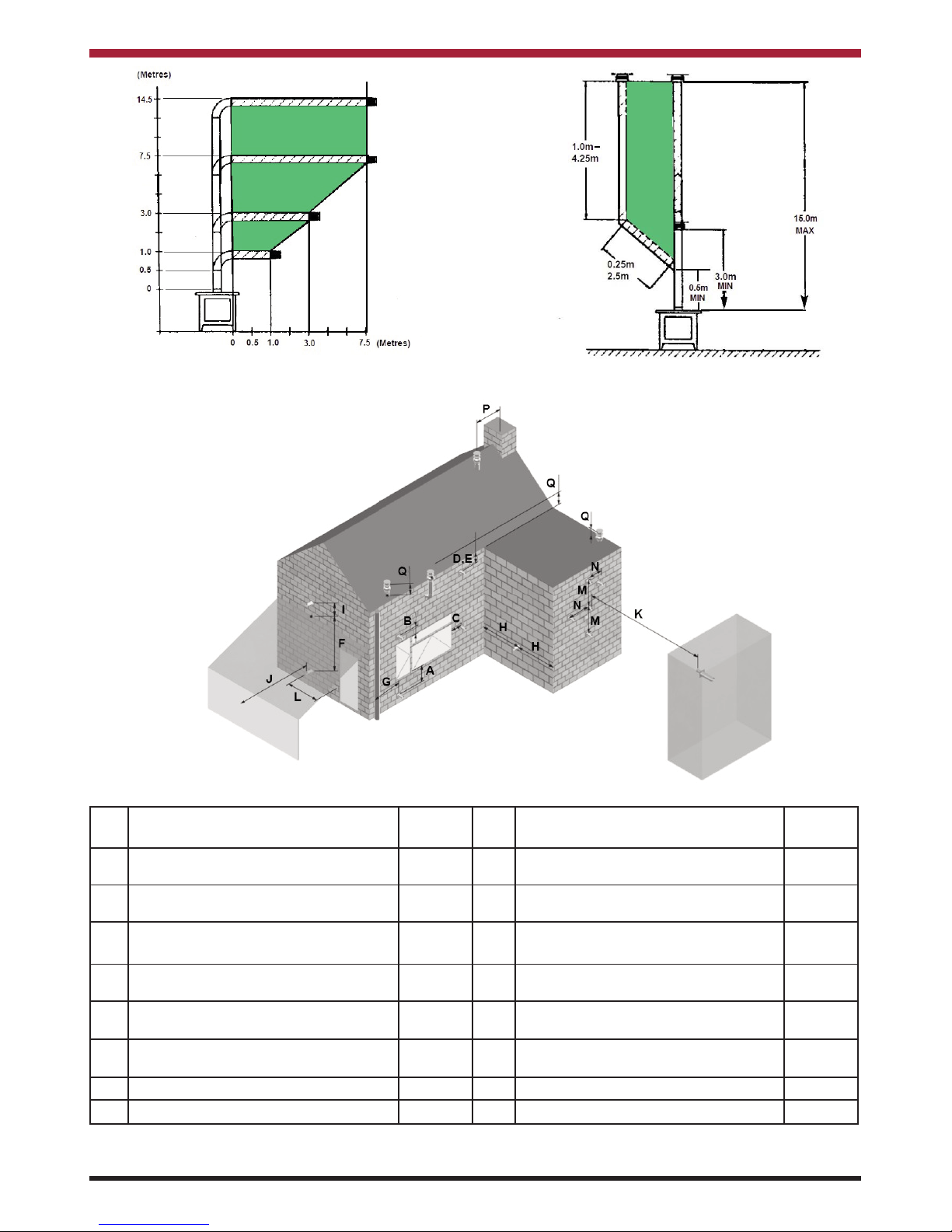

FLUE INSTALLATION

NOTE: Only flue approved by Waterford Stanley

for this appliance may be used.

When installing the flue system the following must

be adhered to:

1. Flue terminals should be sited to ensure total

clearance of combustion products in

accordance with BS5440: Part 1 (latest

edition) - see Fig 7.

2. A terminal guard should be fitted to protect

against contact for any terminal less than 2

metres above any access from ground level,

balcony or flat roof.

3. The flue system must be constructed from

the appliance upwards, with all joints being

fully locked and sealed using the Waterford

Stanley specified parts.

4. Two types of flue terminals are available,

horizontal and vertical.

5. A Horizontal Flue Configuration should

comply with the following (see Fig 5):

* The horizontal flue run can not exceed the

vertical flue rise.

* Minimum vertical flue rise of 0.5 metres.

* Maximum vertical flue rise of 14.5 metres.

* Maximum horizontal flue run of 7.5 metres.

6. A Vertical Flue Configuration should

comply with the following (see Fig 6):

* Minimum vertical flue rise of 0.5 metres (from

top of unit before bend fitting).

* Maximum vertical flue rise of 15 metres.

* Maximum vertical flue rise reduced by 0.25

metres for every 45 degree bend fitted.

* Length of Vertical flue rise must be twice the

length of Horizontal flue run/offset.

GAS SOUNDNESS TESTING

Gas soundness testing should be in accordance

with I.S. 813 (I.E.) and B.S. 6891 (U.K.). Correct gas

pressure and proper gas supply pipe sizing is important for the successful performance of this stove.

Make sure that the plumber or gas supplier checks

the gas supply line and gas pressure at installation.

CAUTION: The stove must be isolated from gas

supply system during any gas soundness testing

at pressures in excess of 50 mbar

.

After testing gas supply pipe work, open the isolation

valve to stove and carry out gas soundness testing

at normal working pressure 20 mbar for natural gas

and 37 mbar for LPG models.

With the stove lighting carry out a leak test downstream of control using gas leak detection fluid.

CAUTION: If using a gas leak detection fluid for

leak testing DO NOT spray solution onto the control body.

7. Allow enough room above & to the side of

the stove to allow for connection & assembly

of the flue system to the top of the stove.

8. Depending on the flue height, a restrictor

plate may needed to be fitted to the inner

spigot (see Fig 4). The following details when

a restrictor plate needs to be fitted:

Part Code Description

34100610/9030 HORIZONTAL FLUE TERMINATION

KIT

34100654 VERTICAL FLUE TERMINATION KIT

37100438/9032 COMBUSTIBLE WALL KIT

34100405/9032 950mm STRAIGHT PIPE

34100404/9032 450mm STRAIGHT PIPE

34100403/9032 250mm STRAIGHT PIPE

34100402/9030 100mm STRAIGHT PIPE

34100441/9032 90 DEGREE BEND

34100421/9032 45 DEGREE BEND

45150169 FLAT ROOF FLASHING KIT

75000006 SLATE ROOF FLASHING KIT

45150173/9019 30-45 DEGREE TILE FLASHING KIT

The table below details the list of Waterford Stanley

Approved Flue Fittings for this stove.

Flue Height Flue Restrictor Plate

0 -2 metres None

2 - 4 metres 35mm Restrictor Plate

4 -6 metres 40mm Restrictor Plate

6 - 8 metres 30mm Restrictor Plate

8 - 15 metres None

Note: House position & wind direction can

cause variances in the above guide lines

and if the glass starts to blacken, soot

forms on the logs or the flame pattern is

too small in height, a flue restrictor plate

will need to be fitted.

Fig.4

Page 10

10

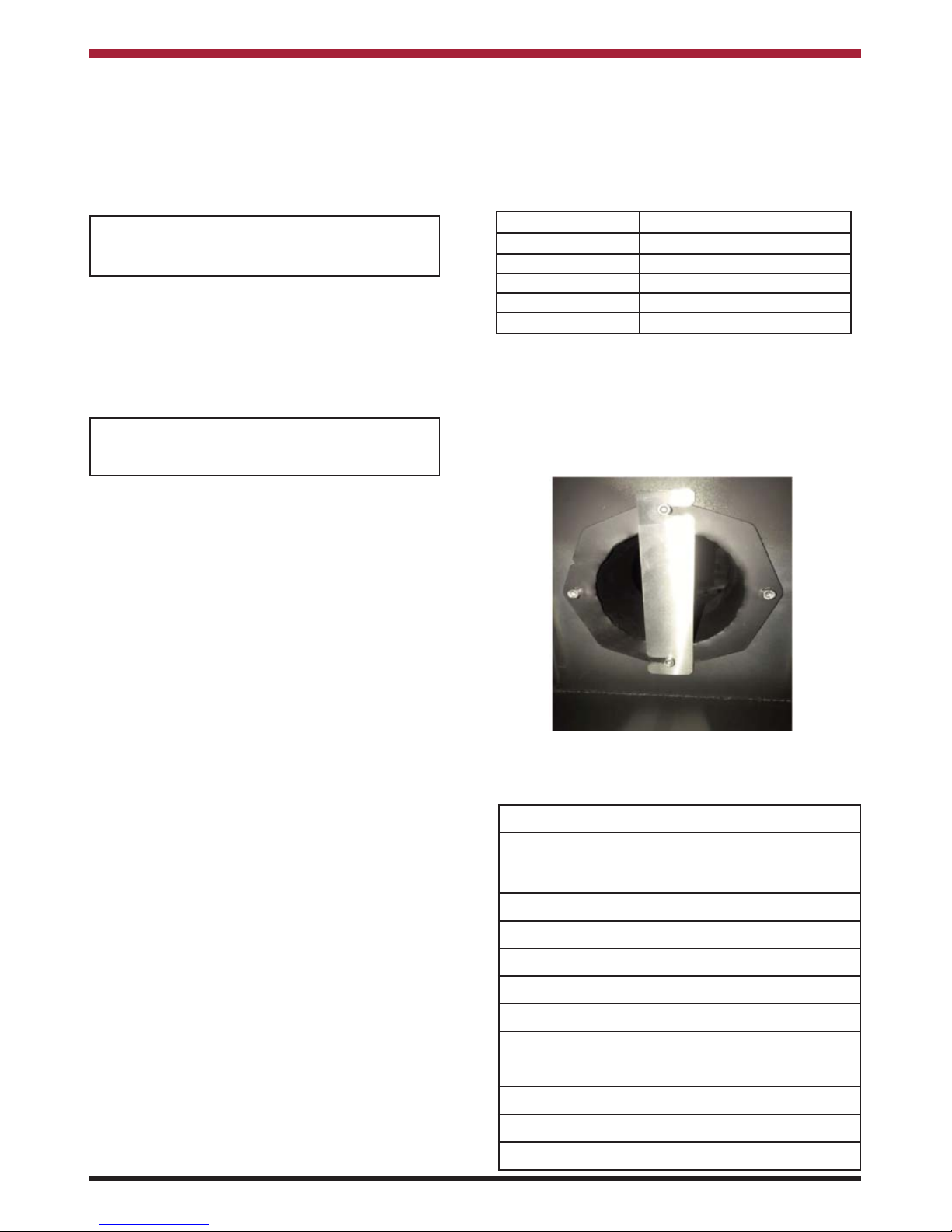

Fig.7

* In addition, the terminal should not be nearer than 300mm to an opening in the building fabric formed for the purpose of

accommodating a built in element such as a window frame.

Terminal Position Distance

(mm)

Terminal Position Distance

(mm)

A* Directly below an opening, air brick,

opening window etc.

600 I Above ground roof or balcony level 300

B Above an opening, air brick, opening win-

dow etc.

300 J From a surface facing the terminal 600

C Adjacent to an opening, air brick, open-

ing window etc.

400 K From a terminal facing the terminal 600

D Below gutters, soil pipes or drain pipes 300 L From an opening in the car port (e.g.

door, window into the dwelling)

1200

E Below eaves 300 M Vertically from a terminal on the same

wall

1500

F Below balconies of car port roof 600 N Horizontally from a terminal on the same

wall

300

G From a vertical drain pipe or soil pipe 300 P From a vertical structure on the roof 600

H From an internal or external corner 600 Q Above intersection with roof 150

Fig.5

Fig.6

Page 11

11

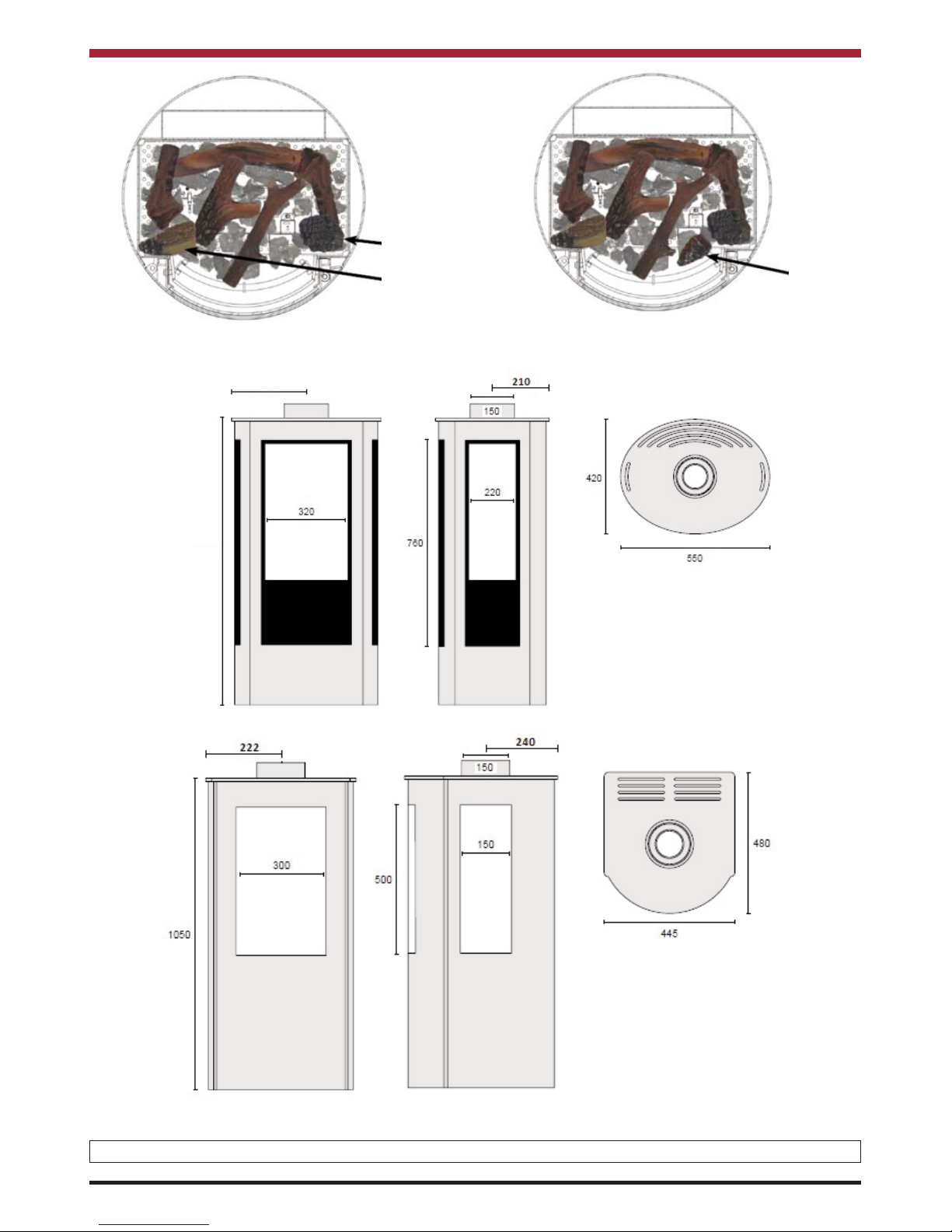

FUEL BED ARRANGEMENT

NOTE: When arranging the Media into the

Firebed, it is important that the Pilot Area

& the second thermocouple is kept clear

and that no Media enters the Pilot Shield

- see Fig 11.

Fig 7 details the various fuel bed media components

and they are arranged using the following procedure:

1. Remove the Top Panel from the Stove.

2. Remove the Front Panel by loosening the

two front fixing screws (see Fig 9) and lifting

the front upwards to remove.

3. Remove the firebox glass panel by removing

the fixing screws - see Fig 10.

Fig.8

4. Scatter the bags of embers over the top of

the burners as shown in Fig 11 keeping the

pilot area & second thermocouple clear.

5. Position Logs S1, S2 & S3 as shown in

Figure 12.

6. Position Logs S4 & S5 as shown in Figure

13.

7. Position Logs S6 & S7 as shown in Figure

14.

8. Position the Firecone/Log S8 as shown in

Figure 15.

9. Check the appliance for Pilot Ignition and

cross lighting ensuring that no material is

impinging the operation of the Pilot.

10. Refit the firebox glass panel, front panel &

top panel.

Fig.9

Fig.10

Fig.11

Fig.12

Fig.13

Pilot & Cross

Light kept clear

2nd Thermocouple

kept clear

Log S1

Log S2

Log S3

Log S5

Log S4

FRONT FIXING SCREWS

GLASS

FIXING

SCREWS

Page 12

12

Fig.14 Fig.15

STOVE DIMENSIONS

F500 OVAL

F500 SLIM

Note: Dimensions stated are in millimetres unless otherwise stated and may be subject to a slight +/- variation.

Log S7

Log S6

Fircone /

Log S8

275

1060

Page 13

13

The Appliance Commissioning Checklist (see Page

6) must be filled out in conjunction with

conducting the following checks:

1. Pilot Ignition Check

A. Ignite the pilot light as described in the

Remote Control Operation Section.

B. Check that the pilot light flame stays light.

C. Extinguish the pilot light.

2. Main Burner Check

A. Ignite the pilot light as described in the

Remote Control Operation Section.

B. Turn on the main burner as described in the

Remote Control Operation Section.

C. Check that the pilot smoothly cross-lights to

the main burner and that the main burner &

pilot light stay alight.

D. Check the operation of the burners at the

various flame settings.

E. Extinguish the stove fully.

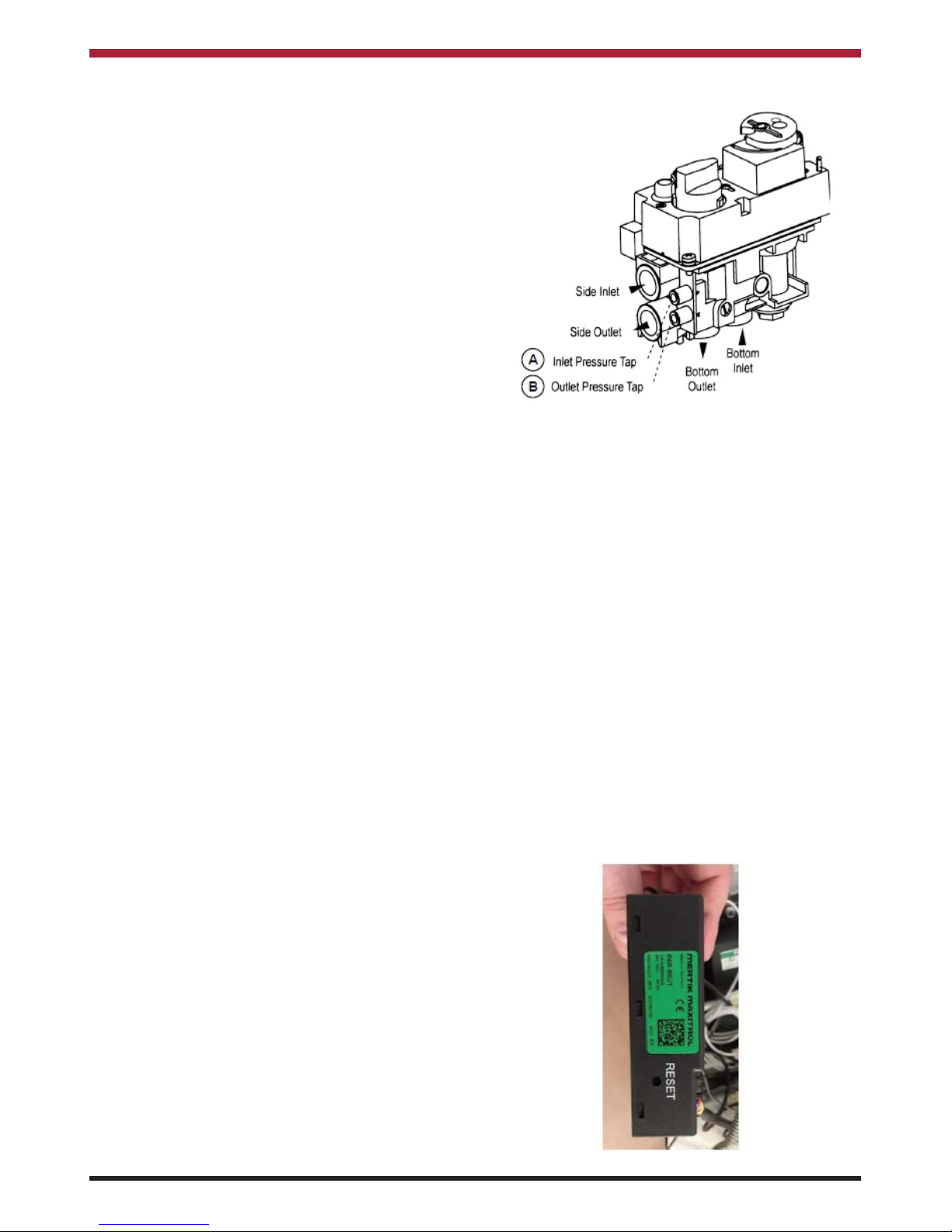

3. Pressure Check

The stove is preset to the correct heat inputs as listed in the Technical Data Section and the pressure

flows MUST not be adjusted. The inlet & burner

pressures must be checked using the following procedure (see Fig 16):

A. Turn off the gas valve on the stove.

B. Turn the screw on the Inlet Pressure Test

Point (A) on the gas valve by one turn (DO

NOT REMOVE) and connect a

manometer.

C. Check that the measured pressure is as the

prescribed supply pressure.

D. Perform the test when the appliance is

burning on full and with only the pilot alight.

E. If the pressure is low, check the gas supply

pipes are the correct size.

F. If the pressure is too high (more than 5 mbar

over) the appliance may be installed, but the

gas supply company should be contacted to

rectify same.

G. Retighten the screw on the Inlet Pressure

Test Point (A).

H. Turn the screw on the Burner Pressure

test point (B) on the gas valve by one turn

(DO NOT REMOVE) and connect a

manometer.

I. Check that the measured pressure is as

detailed in the Technical Data Section. The

measured value should be within +/- 10% of

the prescribed value.

J. Retighten the screw on the Burner Pressure

Test Point (B).

K. Test the system and gas valve for gas

soundness.

COMMISSIONING THE STOVE

Fig.16

4. Pairing the Remote Control

The remote control that comes with the stove should

already be paired to the burner. However if it

becomes un-paired or a you have had a replacement remote control, it can be paired to the burner

using the following procedure:

A. Turn on the Remote Control by pushing &

holding the power button (refer to Remote

Control Operation Section).

B. Hold the Reset Button on the side of the

gas control box under the burner unit until

it beeps twice (see Fig 17).

C. Press and hold the Down arrow button on

the Remote Control until you hear a single

beep.

D. Turn off the Remote Control by pushing the

power button.

E. Turn on the Remote Control by pushing &

holding the power button. If the remote has

been successful paired, the burner will ignite

after approximately ten seconds.

Fig.17

Page 14

14

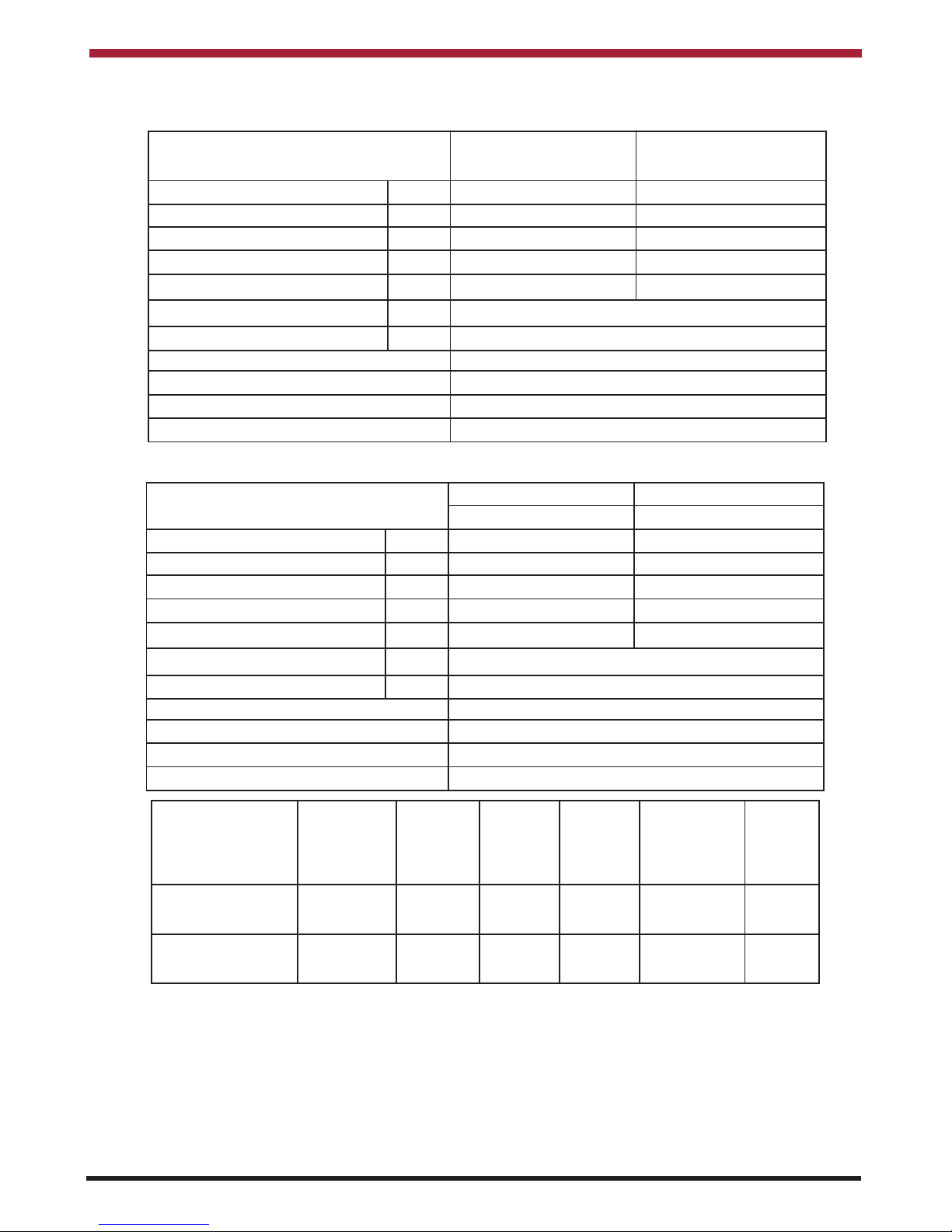

TECHNICAL DATA

Gas Type G20

I

2H

, I

2E

G20

I

2E+

Supply Pressure mbar 20 20

Nominal Heat Input Gross (Hs) kW 8.0 8.0

Nominal Heat Input Nett (Hi) kW 7.7 7.7

Consumption

m3/hr

0.796 0.796

Burner Pressure (hot) mbar 19 19

Maximum Heat Output kW 5.5

Minimum Heat Output kW 1.8

Injector Marking 320 (Front) / 280 (Rear)

Pilot 446.1385.44

Efficiency Class/Efficiency 2 / 81%

Nox Class 5

NATURAL GAS

Gas Type G30/31 G31

I

3+

I

3P(37)

Supply Pressure mbar 28/37 37

Nominal Heat Input Gross (Hs) kW 7.5 8.5

Nominal Heat Input Nett (Hi) kW 7.2 7.2

Consumption

m3/hr

0.167 0.206

Burner Pressure (hot) mbar 27/36.7 36.7

Maximum Heat Output kW 5.0

Minimum Heat Output kW 1.7

Injector Marking 120 (Front) / 100 (Rear)

Pilot 446.1385.24

Efficiency Class/Efficiency 2 / 83%

Nox Class 5

LPG

FIRST TIME OPERATION

Before lighting the stove check with the installer that the installation work and commissioning checks described

previously have been carried out correctly. Ensure that all packaging, safety stickers & any protective wrapping

have been removed and that the glass has been cleaned including all fingerprints on the glass. As part of the

stove’s commissioning and handover the installer should demonstrate how to operate the stove correctly.

Ensure that the room is adequately ventilated the first time the stove is lit with the windows open. Run the stove

at the maximum setting for a few hours so that the paint gets an opportunity to fully cure. During this period it

is possible for some fumes and vapours to be given off as the paint completes the curement process.

Model

Energy

Efficiency

Class

Heat

Output to

Room

Heat

Output to

Water

Preferred

Fuel

Nominal Heat

Output

Net

Efficiency

Argon F500

Oval/Slim Nat Gas A 5.5kW NA

Natural

Gas 5.5kW 81%

Argon F500

Oval/Slim LPG

A 5.0kW NA LPG 5.0W 83%

Page 15

15

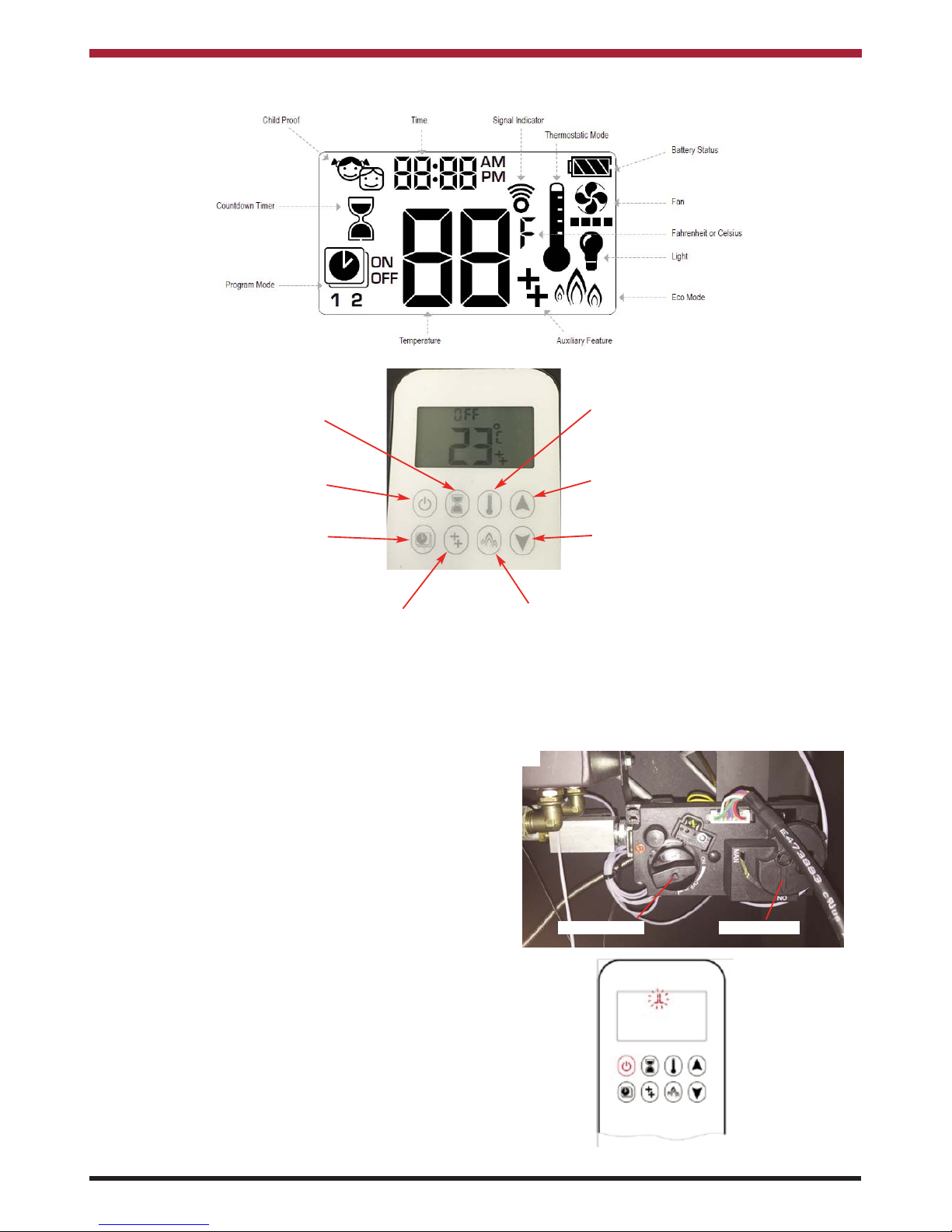

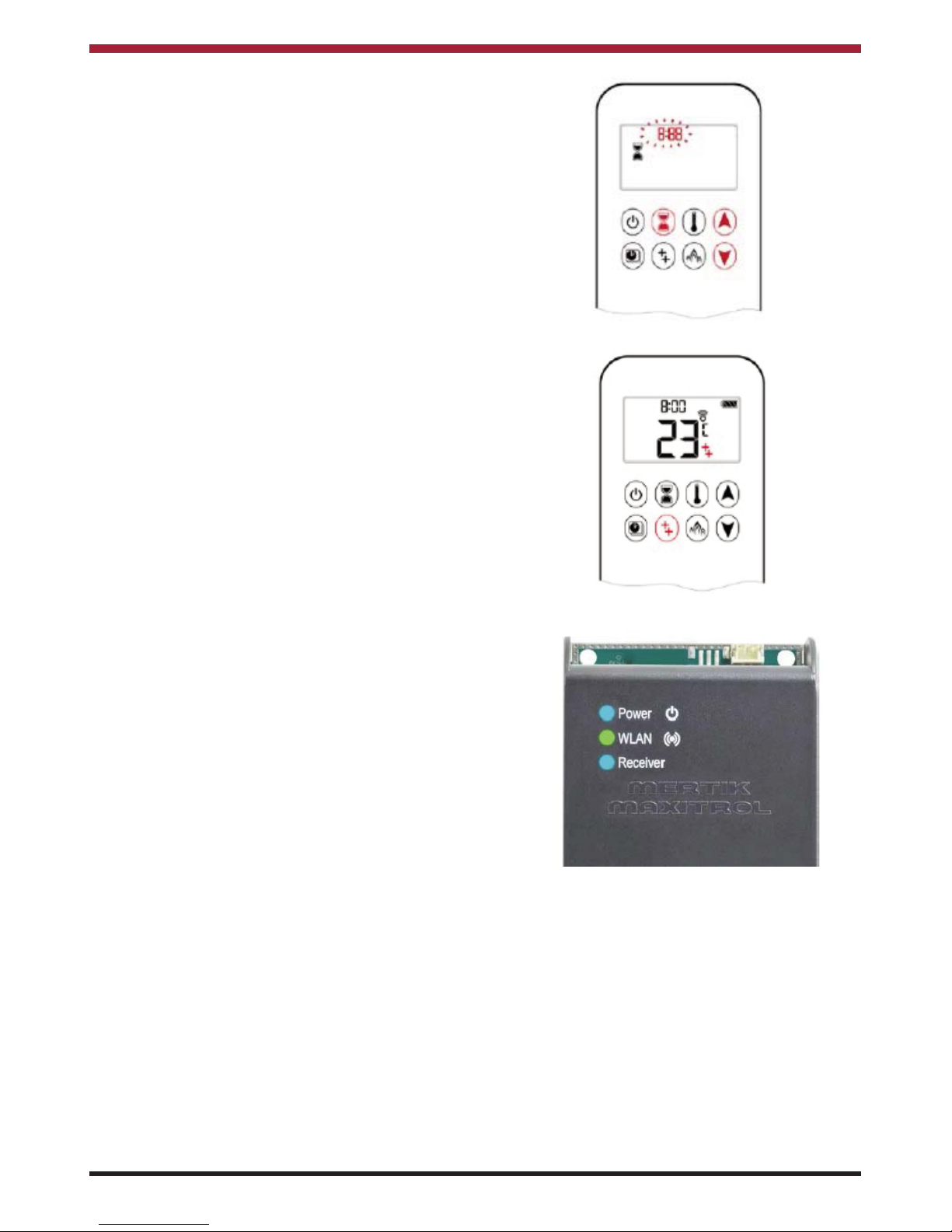

REMOTE CONTROL OPERATION

NOTE: If not using the mains adapter, it is recommended that the batteries are replaced in the gas

control box at the beginning of the heating season (see Battery Replacement Section). The

control box will provide frequent beeps for 3 seconds when the batteries are low. A low battery

indicator will be shown on the remote control display when the batteries are low on the remote.

MANUAL MODE

To allow for remote control operation, make sure

that the Manual Knob on the gas valve is in the ON

(Full counterclockwise position) and the ON/OFF

switch is in the I (ON) position - refer to Fig 18.

Press & hold the Power Button two short beeps are

heard and a blinking series of lines appears on the

remote display (see Fig 19). This indicates that the

start sequence has begun during which the ignitor

will spark until the pilot flame lights. When the pilot

flame has lit and stabilised, the main burner will

ignite & light.

NOTE: If the pilot light does not stay lit

after several attempts, turn the

main valve knob to OFF and

contact your local service

engineer.

When the main burner flame has been established,

the flame height can be adjusted by (refer to Fig 20):

* Increase - Press & Hold the Up Arrow Button.

* Decrease - Press & Hold the Down Arrow

Button

Fig.19

Fig.18

POWER BUTTON

COUNTDOWN

TIMER

TEMPERATURE

BUTTON

UP ARROW

DOWN ARROW

PROGRAM

BUTTON

REAR BURNER BUTTON

ECO BUTTON

ON/OFF SWITCH

MANUAL KNOB

Page 16

16

Fig.20

Fig.21

Fig.22

Fig.23

The flame height can also be adjusted to the two

preset flame heights by:

* Low Fire (LO) - Double Click the Down Arrow

Button - see Fig 21.

* High Fire (HI) - Double Click the Up Arrow

Button - see Fig 22.

To turn off the stove, press & hold the Power Button

until the display shows OFF - see Fig 23.

NOTE: The burner must cool down for 30

seconds before reignition can be

attempted.

Fig.24

SETTING CELSIUS OR FAHRENHEIT

The remote control comes preset to show the temperature in Fahrenheit and it can be changed to

Celsius by pressing & holding the Power Button &

Timer Button simultaneously - see Fig 24.

NOTE: Choosing Fahrenheit results in a 12

hour clock being displayed and

choosing Celsius results in a 24 hour

clock being displayed.

Page 17

17

Fig.25

SETTING THE TIME

1. Press the Up Arrow Button & Down Arrow

Button simultaneously until the DAY flashes

on the display - see Fig 25.

2. Press the Up Arrow Button & Down Arrow

Button to select the number that corresponds

to the current day (e.g. 1 = Monday, 2 =

Tuesday, 3 = Wednesday etc).

3. Press the Up Arrow Button & Down Arrow

Button simultaneously until the HOUR

flashes on the display - see Fig 26.

4. Press the Up Arrow Button & Down Arrow

Button to select the current hour.

5. Press the Up Arrow Button & Down Arrow

Button simultaneously until the MINUTES

flashes on the display - see Fig 27.

6. Press the Up Arrow Button & Down Arrow

Button to select the current minute.

7. To confirm the settings, press and hold the

Up Arrow Button & Down Arrow

Button simultaneously until the display

returns to normal operating mode or the

display will return to standby mode if no

button is pressed.

Fig.27

Fig.26

AUTOMATIC OPERATION

The Argon Stove has three automatic operation

models:

A. Thermostatic Mode - The room temperature

is compared to the set temperature and the

flame height is automatically adjusted until

the set temperature is reached.

B. Program Mode - The stove operates for a set

period of time (Two ON/OFF periods per

day).

C. Eco Mode - The Flame Height modulates

from High to Low Flame settings. If the room

temperature is less than the set temperature,

the flame height is maintained at the High

setting. If the room temperature is greater

than the set temperature, the flame height is

maintained at the Low setting. Each cycle

will last approximately 20 minutes.

Thermostatic Mode

To activate the Thermostatic Mode, press the

Temperature Button. The Temperature Symbol will

be displayed , the preset temperature will be displayed briefly followed by the current room

temperature (see Fig 28).

To change the preset temperature, press and hold

the Temperature Button until the Temperature

Symbol is displayed and the preset temperature

flashes (see Fig 29). Press the Up Arrow Button &

Down Arrow Button to select the desired temperature setting and press & hold the Temperature

Button to confirm the setting until the display returns

to Thermostatic Mode.

To deactivate the Thermostatic Mode & return to

Manual Mode, press the Temperature Button until

the Temperature Symbol disappears.

Page 18

18

Fig.28

Fig.29

Program Mode

The following procedure should be used when

setting the Temperature and Timer Program:

1. To set the temperature, press & hold the

Program Button until the Program

Mode display flashes ON & the set

temperature is displayed. Then the

Program Mode display flashes OFF & the set

temperature flashes (see Fig 30).

2. Press the Up Arrow Button & Down Arrow

Button to select the desired temperature

setting.

3. Press the Program Button to confirm the

temperature setting.

The program mode can be set to operate as follows:

* ALL - The same programme every day

* SA:SU - The same programme for weekdays

& a different setting for Saturday & Sunday

* 1,2,3,4,5,6,7. - Different setting for each day.

4. Having confirmed the temperature setting,

the Program Mode symbol & ALL will flash

on the display - see Fig 31. Press the Up

Arrow Button & Down Arrow Button to select

the desired setting (e.g. ALL, SA:SU or

1,2,3,4,5,6,7).

5. To confirm press the Program Button.

6. The Program 1 ON setting will be displayed

with the hour setting flashing - see Fig 32.

Press the Up Arrow Button & Down Arrow

Button to select the desired ON hour.

7. To confirm press the Program Button.

8. The minute setting will flash and press the

Up Arrow Button & Down Arrow Button to

select the desired ON minute.

9. To confirm press the Program Button.

10. The Program 1 OFF setting will be displayed

with the hour setting flashing - see Fig 33.

Press the Up Arrow Button & Down Arrow

Button to select the desired OFF hour.

11. To confirm press the Program Button.

12. The minute setting will flash and press the

Up Arrow Button & Down Arrow Button to

select the desired OFF minute.

13. To confirm press the Program Button.

14. The Program 2 ON setting will be displayed

with the hour setting flashing & repeat steps

6 to 13 to set the times for Program 2. If not

using a time period, set the ON & OFF times

to the same time.

15. If you have selected SA:SU or 1,2,3,4,5,6,7,

adjust the day setting (1,2,3,4,5,6,7) using

the Up Arrow Button & Down Arrow Button

and follow steps 6 to 13 to set the times for

each day.

Fig.30

Fig.31

Page 19

19

Fig.32

Fig.33

To activate the Program Mode, press the Program

Button. The Program Mode Symbol will be

displayed as shown in Fig 34.

To deactivate the Program Mode & return to Manual

Mode, press the Program Button and then press

either the Up Arrow Button or Down Arrow Button.

Eco Mode

To activate the Eco Mode, press the Eco Button. The

Eco Mode Symbol will be displayed as shown in Fig

35.

To deactivate the Eco Mode & return to Manual

Mode, press the Eco Button.

ADDITIONAL OPERATIONAL FEATURES

The Argon Stove has three standard additional operational features:

A. Child Lock

B. Countdown Timer

C. Rear Burner Operation

Child Lock

To activate the Child Lock and disable the remote

control (with the exception of the OFF function),

press the Power Button and Down Arrow Button

simultaneously until the Child Lock Symbol is

displayed - see Fig 36.

To deactivate the Child Lock & return to Manual

Mode, press the Power Button and Down Arrow

Button simultaneously until the Child Lock Symbol

disappears.

Fig.34

Fig.35

Fig.36

Page 20

20

Fig.37

Fig.38

Countdown Timer

The Countdown Timer allows for the Stove to be

operated for a set period (up to maximum of 9 hours

& 50 minutes) provided the Stove is set to Manual,

Thermostatic or Eco Modes.To set the Countdown

Timer:

1. Press & hold the Countdown Timer Button

until the Countdown Timer Symbol is

displayed and the hour setting flashes- see

Fig 37.

2. Press the Up Arrow Button & Down Arrow

Button to select the desired hour operating

period.

3. Press the Countdown Timer Button to

confirm the setting.

4. The minute setting will flash and press the

Up Arrow Button & Down Arrow Button to

select the desired minute operating period.

5. Press the Countdown Timer Button to

confirm the setting. The Countdown Timer

Symbol & Timer Clock will be shown on the

remote display with the remaining time on

the period shown.

To deactivate the Countdown Timer, press & hold

the Countdown Timer Button until the Countdown

Timer Symbol & Countdown Timer Clock disappears.

Rear Burner Operation

The Rear Burner can be turned On or Off as desired

by pressing the Rear Burner Button until the Rear

Button Symbol is displayed and the rear burner is

ignited (see Fig 38). To deactivate, press the Rear

Burner Button until the Rear Button Symbol disappears.

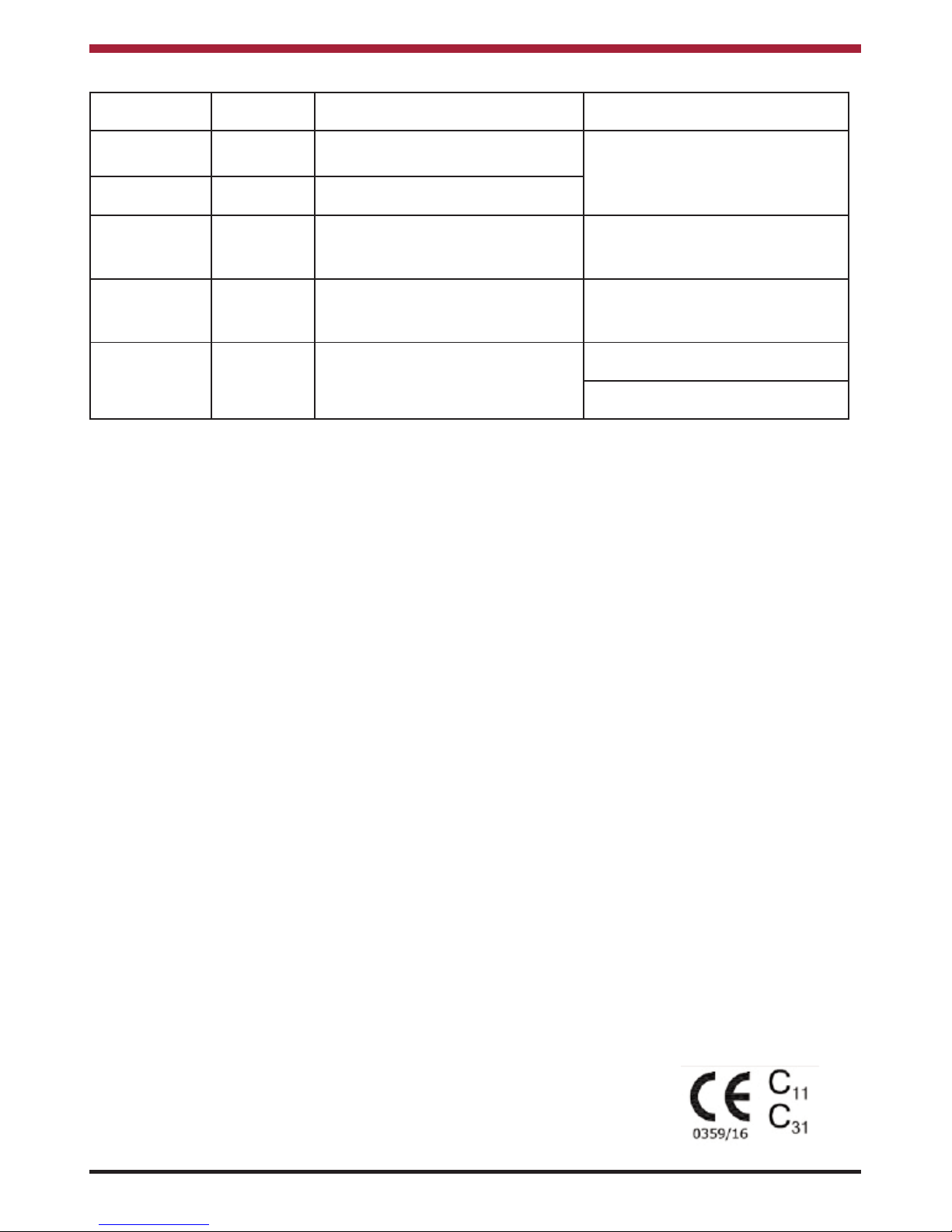

WI-FI OPERATION

The Argon Stove can be operated remotely using

the myfire app by connecting the optional myfire WiFi Box (Part Code: B6R-W) and connecting same to

a Home Network (Wi-Fi Router). The myfire Wi-Fi

Box will operate for a short period of time using batteries but if mains power is lost for a period of time,

it is recommended to disconnect the Wi-Fi Box from

the Gas Valve Control Box.

To set-up the myfire Wi-Fi Box, use the following

procedure:

1. Connect the data cable to the Gas Valve

Control Box & myfire Wi-Fi Box (refer to

Wiring Diagram).

2. Connect the Mains Adaptor to the Gas

Control Valve. After 30 seconds the myfire

Wi-Fi Box goes into Access Point Mode)

green LED flashes - see Fig 39.

Fig.39

Page 21

21

3. Download the myfire App from Apple App

Store or Google Play Store.

4. Start App setup.

5. Choose language, temperature (Celsius or

Fahrenheit) and time format (12 or 24 hour).

6. Complete the registration process and Login

to the App.

7. Touch the + icon and a message will tell you

to go to your smart device Wi-Fi settings.

8. Touch myfire_WiFi-Box_<number>.

9. Enter the password “MYFIREPLACE”.

10. Select a name for your stove.

11. Type in the name (SSID) of your Wi-Fi router.

12. Type in the password of your Wi-Fi router.

13. Touch “Connect” button.

14. After successful connection a pop-up will tell

you to go to your smart device Wi-Fi settings.

Touch “OK” if the settings are correct.

15. After confirming fireplace settings touch

“Finish”.

16. Touch “Start App” to finish the installation &

setup process.

NOTE: If any of the Automatic Operation

Modes are activated using the App,

“APP” will be displayed on the

Remote Control.

For further instructions & video on how to set-up the

myfire App, see http://myfireapp.com/en/setup/.

CLEANING

Cleaning should be done when the stove is cold by

removing any dust or dirt using a dry cloth. Do not

use any water on the matt black finish as this will

cause it to discolour. It is recommended to clean the

stove of any dust & debris regularly and especially if

the stove has not been used for some time.

MAINTENANCE

This stove must be inspected and serviced once

a year by a qualified/competent Gas Engineer.

CO ALARM

The fitting of CO Alarms in the same room as the

appliance is a compulsory requirement under current Building Regulations. For ROI an additional CO

Alarm must be fitted either inside each bedroom or

within 5 metres of the bedroom door, refer to

Building Regulations Part J. Further guidance on the

installation of a carbon monoxide alarm is available

in BS EN 50292:2002 and from the alarm manufacturers instructions.

WARNING NOTE:

Properly installed, operated and maintained this

stove will not emit fumes into the dwelling. In the

event of a gas escape or if you can smell gas then

the following immediate action should be taken:

(a) Immediately turn off the gas supply at the

meter/emergency control valve.

(b) Extinguish all sources of ignition.

(c) Do not smoke.

(d) Do not operate any electrical light or power

switches (ON or OFF).

(e) Ventilate the building(s) by opening doors &

windows.

(f) Ensure access to the premises can be made.

Please report the incident immediately to Gas

Networks Ireland (1850 20 50 50), National Gas

Emergency Service Call Centre (0800111999 for

UK or 0800002001 for Northern Ireland) or in the

case of LPG, the gas supplier whose details can be

found on the bulk storage vessel or cylinder.

The gas supply must not be used until remedial

action has been taken to correct the defect and the

installation has been recommissioned by a competent person.

Provision of an alarm must not be considered a

substitute for either installing the appliance

correctly or ensuring regular servicing and

maintenance of the appliance and chimney

system.

WARNING:-

If the CO Alarm sounds unexpectedly:-

1. Turn off the stove immediately.

2. Open Doors and windows to ventilate the

room and then leave the premises.

Page 22

22

BATTERY REPLACEMENT

The Gas Valve Control Box requires four AA

Batteries which are fitted by removing the front

cover and inserting the batteries into the housing as

shown in Fig 40.

The Remote Control requires two AAA Batteries

which are fitted by removing the back cover and

inserting the batteries into the housing as shown in

Fig 41.

NOTE: It is recommended to use Duracell

Ultra Power alkaline batteries.

Rechargeable batteries are not to be

used. Under normal conditions

batteries should last approximately

12 months.

SERVICING

Before carrying out any maintenance, ensure

that the Stove is cold and isolate the main gas

supply.

ALL SERVICING & REPAIR WORK MUST BE

CARRIED OUT BY A QUALIFIED/COMPETENT

GAS ENGINEER.

The following is the recommended procedure for

servicing the Stove:

1. Remove the Top Panel from the Stove.

2. Remove the Front Panel by loosening the

two front fixing screws (see Fig 9) and lifting

the front upwards to remove.

3. Remove the firebox glass panel by removing

the fixing screws - see Fig 10.

4. Carefully remove the Ceramic Logs and

Embers.

5. Use a vacuum cleaner and a soft brush to

clean the pilot assembly and both injectors. It

may be easier to access the Injector by

removing the throttle.

NOTE: NEVER MODIFY OR BEND THE

THERMOCOUPLE.

6. Turn on the gas supply and check for leaks.

7. Check the operation of the burners & pilot.

8. Clean the Ceramic Logs & Embers external

to the building using a soft brush and a

vacuum cleaner. Any damaged parts should

be replaced.

9. Replace the Ceramic Logs and Embers see Fuel Bed Arrangement Section.

10. Clean the Firebox Glass Panel & refit same.

11. Refit the Front & Top Panels.

12. Check the flue system & terminal ensuring

that the terminal vent is fully clear.

Fig.40

Fig.41

13. Light the stove and test the pressure

settings (see Pressure Check).

14. Test the gas valve and gas system for

soundness.

15. Check the safe operation of the Stove.

16. Complete the Service Records Log on the

back of the manual.

Page 23

WIRING DIAGRAM

23

Page 24

EXPLODED VIEW - F500 OVAL

24

No. Description Part Number

1 Complete Burner - Nat Gas SW-DB-2TC-NG

Complete Burner - LPG SW-DB-2TC-LPG

2 Inner Flue Collar SW-PFC-INC-001

3 Outer Flue Collar SW-PFC-OFC-002

4 Top Plate Filler Piece SW-OIH-TPF-027

5 Grate Tray SW-UIH-GTB-004

6 Delayed Ignition Gasket SW-UIH-CPG-005

7 Delayed Ignition Pin SW-UIH-DIP-006

8 Delayed Ignition Flap SW-UIH-DIF-007

9 Front Glass Upper Clamp SW-OIH-FGUC-028

10 Side Glass Retaining Bracket SW-UIH-SGRB-029

11 Back Panel SW-OIH-OBP-030

12 Front Panel SW-OIH-FDP-031

13 Outer Side Glass SW-OIH-SGC-032

14 Front Glass Gasket SW-UIH-FGG-013

15 Firebox Front Glass SW-UIH-FGF-014

16 Firebox Glass Fixing Bracket SW-UIH-FGFB-015

17 Firebox Side Glass SW-UIH-FSG-016

18 Retainer Bar Bracket SW-UIH-RBB-017

19 Retaining Bar SW-OIH-SSRB-033

20 Front Glass SW-OIH-FGC-034

21 Top Panel SW-OIH-STP-035

22 Outer Shell SW-UIH-OBS-036

No. Description Part Number

23 Pilot Assembly - Nat Gas SW-UMM-PLA-NG

Pilot Assembly - LPG SW-UMM-PLA-LPG

24 Electrode SW-UMM-EL-022

25 Electrode Lead SW-UMM-ELL-023

26 Thermocouple SW-UMM-TCF-024

27 Gas Valve - Nat Gas SW-UMM-GV60-NG

Gas Valve - LPG SW-UMM-GV60-LPG

28 2nd Thermocouple Guard SW-UIH-SS2TCG-037

29 Main Thermocouple Guard SW-UIH-SSMTCG-038

30 Main Thermocouple Shield SW-UIH-SSMTCS-039

31 Side Panel SW-OIH-SPC-040

32 Firebox Side Glass Bracket SW-UIH-SGB-041

Front Injector - Natural Gas SW-UMM-FRI-NG

Front Injector - LPG SW-UMM-FRI-LPG

Rear Injector - Natural Gas SW-UMM-RRI-NG

Rear Injector - LPG SW-UMM-RRI-LPG

Ceramic Log Pack SW-UIH-CRP-025

Ember Pack SW-UIH-CEP-026

Remote Control SW-UMM-RC-SY2

Receiver Unit SW-UMM-RU2T-SY2

Wiring Loom SW-UMM-WRC-SY2

Mains Adaptor G60-ZMA3

myfire Wi-Fi Box B6R-W

Page 25

EXPLODED VIEW - F500 SLIM

24

No. Description Part Number

1 Complete Burner - Nat Gas SW-DB-2TC-NG

Complete Burner - LPG SW-DB-2TC-LPG

2 Inner Flue Collar SW-PFC-INC-001

3 Outer Flue Collar SW-PFC-OFC-002

4 Top Plate Filler Piece SW-OIH-TPF-003

5 Grate Tray SW-UIH-GTB-004

6 Delayed Ignition Gasket SW-UIH-CPG-005

7 Delayed Ignition Pin SW-UIH-DIP-006

8 Delayed Ignition Flap SW-UIH-DIF-007

9 Front Glass Upper Clamp SW-SIH-FGUC-008

10 Front Glass Lower Clamp SW-SIH-FGLC-009

11 Bottom Door SW-SIH-FBD-010

12 Front Panel SW-SIH-FDP-011

13 Bottom Door Hinge SW-SIH-BDH-012

14 Front Glass Gasket SW-UIH-FGG-013

15 Firebox Glass SW-UIH-FGF-014

16 Firebox Glass Fixing Bracket SW-UIH-FGFB-015

17 Side Glass SW-UIH-FSG-016

18 Retainer Bar Bracket SW-UIH-RBB-017

19 Retaining Bar SW-SIH-SSRB-018

20 Front Glass SW-SIH-FGC-019

21 Top Panel SW-SIH-STP-020

No. Description Part Number

22 Outer Shell SW-SIH-OBW-021

23 Pilot Assembly - Nat Gas SW-UMM-PLA-NG

Pilot Assembly - LPG SW-UMM-PLA-LPG

24 Electrode SW-UMM-EL-022

25 Electrode Lead SW-UMM-ELL-023

26 Thermocouple SW-UMM-TCF-024

27 Gas Valve - Nat Gas SW-UMM-GV60-NG

Gas Valve - LPG SW-UMM-GV60-LPG

28 Main Thermocouple Guard SW-UIH-SSMTCG-038

29 Main Thermocouple Shield SW-UIH-SSMTCS-039

2nd Thermocouple Guard SW-UIH-SS2TCG-037

Front Injector - Nat Gas SW-UMM-FRI-NG

Front Injector - LPG SW-UMM-FRI-LPG

Rear Injector - Natural Gas SW-UMM-RRI-NG

Rear Injector - LPG SW-UMM-RRI-LPG

Ceramic Log Pack SW-UIH-CRP-025

Ember Pack SW-UIH-CEP-026

Remote Control SW-UMM-RC-SY2

Receiver Unit SW-UMM-RU2T-SY2

Wiring Loom SW-UMM-WRC-SY2

Mains Adaptor G60-ZMA3

myfire Wi-Fi Box B6R-W

Page 26

26

SERVICE RECORDS

1ST SERVICE

Date of Service:........................................................

Next Service Due:.....................................................

Signed: .....................................................................

RGI/Gas Safe Registration No/Stamp:

3RD SERVICE

Date of Service:........................................................

Next Service Due:.....................................................

Signed: .....................................................................

RGI/Gas Safe Registration No/Stamp:

5TH SERVICE

Date of Service:........................................................

Next Service Due:.....................................................

Signed: .....................................................................

RGI/Gas Safe Registration No/Stamp:

7TH SERVICE

Date of Service:........................................................

Next Service Due:.....................................................

Signed: .....................................................................

RGI/Gas Safe Registration No/Stamp:

2ND SERVICE

Date of Service:........................................................

Next Service Due:.....................................................

Signed: .....................................................................

RGI/Gas Safe Registration No/Stamp:

4TH SERVICE

Date of Service:........................................................

Next Service Due:.....................................................

Signed: .....................................................................

RGI/Gas Safe Registration No/Stamp:

6TH SERVICE

Date of Service:........................................................

Next Service Due:.....................................................

Signed: .....................................................................

RGI/Gas Safe Registration No/Stamp:

8TH SERVICE

Date of Service:........................................................

Next Service Due:.....................................................

Signed: .....................................................................

RGI/Gas Safe Registration No/Stamp:

Page 27

27

FAULT FINDING - GENERAL

ISSUE POSSIBLE CAUSE SOLUTION

Remote Control

not working

Remote Control Batteries Low. Replace Batteries (See Battery Replacement Section

Gas Control Valve Batteries Low. Replace Batteries (See Battery Replacement Section

Optional Mains Adapter not operating correctly.

Check Mains Adapter.

Check link between remote &

receiver.

Repair Remote Control (see Pairing Remote Control

Section)

Pilot will not light.

No Gas Check Gas Supply.

Insufficient Gas Pressure Check Inlet & Outlet Pressures (see Pressure Check

Section).

Blocked Pilot Injector. Clear debris from Pilot Injector.

ON/OFF Switch in OFF (O)

Position.

Push switch to ON Posiiton (see Figure 18).

No Ignition Spark.

Check connection between ignition cable & electrode.

Check electrode spark gap and ensure electrode is

not shorting on burner body.

Replace electrode.

Replace ignition cable.

Main Burner will

not light

Thermocouple & Switch connections reversed.

Check connections to Gas Valve Control Box.

Magnet unit not operating properly. Replace Gas Valve.

Short between Interlopers and

Switch cable.

Check connection to Interrupter.

Insufficient Gas Pressure Check Inlet & Outlet Pressures (see Pressure Check

Section).

Resistance in thermocouple circuit

too high.

Check thermocouple cable.

Not enough heat on thermocouple. Check position of pilot to thermocouple and intensity

of pilot flame.

Low voltage from thermocouple.

Replace thermocouple (Hand tight +1/4 turn max)

Short because thermocouple is

damaged or not centreed.

Ignition stops. No reaction to transmitter command.

Press Reset Button on Gas Valve Control Box.

Main Burner Cuts

out after lighting

Too much draft at pilot Check Installation.

Page 28

28

Supplied by

Waterford Stanley Ltd.,

Unit 401-403, IDA Industrial Estate, Cork Road,

Waterford, Ireland.

Tel: (051) 302300 Fax (051) 302315

N00787AXX Rev: 001 SG 040718

FAULT CODES - REMOTE CONTROL

FAILURE

CODE

DURATION

DISPLAYED

SYMPTOM POSSIBLE CAUSE

F04 4 sec No Pilot Flame within 30 seconds.

See “Pilot Light will not Light” on

Fault Finding Section

F06 4 sec 3 Failed Ignition Sequences within 5

minutes.

F09 4 sec Fire is not responding. Remote Control not synced to

Burner. (See Pairing the Remote

Control Section)

F40

(Battery Symbol

shown)

Permanent Low Battery on Remote Control See Battery Replacement Section.

F46 4 sec Fire is not responding or only

responding intermittently.

Bad Connection between Remote

Control & Burner.

Battery Low on Gas Control Valve

(See Battery Replacement Section.)

Loading...

Loading...