Page 1

06/10 EINS 514810

REMEMBER, when replacing a part on this appliance, use only spare parts that you can be assured conform to the safety

and performance specification that we require. Do not use reconditioned or copy parts that have not been clearly

authorised by Waterford Stanley.

PLEASE READ THESE INSTRUCTIONS BEFORE SERVICING THIS APPLIANCE

Alpha

120/150K

Servicing Instructions

Page 2

Contents

SECTION CONTENTS PAGE

CONSUMER PROTECTION 3

HEALTH & SAFETY 3

INTRODUCTION 4

SERVICE SCHEDULE 4

BURNER REMOVAL PREPARATION 5

BURNER ACCESS 5

BURNER REMOVAL 6

BURNER HEAD REMOVAL 6

CLEANING HEAT EXCHANGER CLEANING 7

HOTPLATE REMOVAL 8

OVEN & HOTPLATE FLUEWAY CLEANING 8

BURNER SERVICING INTRODUCTION 9

BURNER NOZZLE REMOVAL 10

BURNER NOZZLE REPLACEMENT 10

PHOTO ELECTRIC CELL (PEC) CLEANING 11

FAN CLEANING 11

RE-ASSEMBLE BURNER 11

OIL PUMP SERVICING INTRODUCTION 12

OIL PUMP STRAINER CLEANING 12

OIL LINE FILTER CLEANING 12

RE-COMMISSIONING BLEED AIR FROM OIL SUPPLY 13

FIT PRESSURE GAUGE 13

SWITCH ON ELECTRICITY 13

VENT OIL PUMP 13

ADJUST OIL PRESSURE 13

SET COMBUSTION AIR 14

CHECK SMOKE 14

REPLACEMENT OF FAN MOTOR 15

PARTS (BURNER) CHECK SMOKE 15

IGNITOR 16

RELAY 16

SOLENOID COIL 16

CONTROL BOX 17

PEC 17

PUMP ACCESS 17

REPLACEMENT OF ELECTRICAL COMPONENT ACCESS 18-19

PARTS (ELECTRICAL TO FIT NEW BOILER CONTROL THERMOSTAT 20

CONTROLS) TO FIT NEW BOILER PUMP OVERRUN THERMOSTAT 20

TO FIT NEW COOKER SAFETY OVERHEAT 21

THERMOSTAT

TO FIT NEW BOILER SAFETY OVERHEAT THERMOSTAT 21

TO FIT NEW OVEN CONTROL THERMOSTAT 22

TO FIT NEW SELECTOR SWITCH 22

RE-ASSEMBLE 23

ELECTRICAL CONTROLS PUMP OVERRUN FACILITY 24

OVERHEAT SAFETY THERMOSTATS 24

TERMINAL STRIP CONNECTIONS 25

FAULT-FINDING APPLIANCE WIRING DIAGRAM 26

BURNER DOES NOT START 27-29

FAULT FINDING (BOILER) 30-31

FAULT FINDING (COOKER) 32-33

HIGH SMOKE NUMBERS/OIL SMELLS 34

2

Page 3

Consumer Protection

As responsible manufacturers we take care to make sure that our products are designed and

constructed to meet the required safety standards when properly installed and used.

IMPORTANT NOTICE: PLEASE READ THE ACCOMPANYING WARRANTY.

Any alteration that is not approved by Waterford Stanley could invalidate the approval of the

appliance, operation of the warranty and could affect your statutory rights.

Health & Safety

This appliance may contain some of the materials that are indicated. It is the Users/Installers

responsibility to ensure that the necessary protective clothing is worn when handling where

applicable, the pertinent parts that contain any of the listed materials that could be interpreted as

being injurious to health and safety, see below for information.

Firebricks, Fuel beds, Artificial Fuels

When handling use disposable gloves.

Fire cement

When handling use disposable gloves.

Glues and Sealants

Exercise caution - if these are still in liquid form use face mask and disposable gloves.

Glass Yarn, Mineral Wool, Insulation Pads, Insulation Fibre

May be harmful if inhaled. May be irritating to skin, eyes, nose and throat. When handling avoid

contact with skin or eyes. Use disposable gloves, face-masks and eye protection. After handling

wash hands and other exposed parts. When disposing of the product, reduce dust with water

spray, ensure that parts are securely wrapped.

Kerosene and Gas Oil fuels (mineral oils)

1. The effect of mineral oils on the skin vary according to the duration of exposure.

2. The lighter fractions also remove the protective grease normally present on the surface of

the skin. This renders the skin dry, liable to crack and more prone to damage caused by cuts

and abrasions.

3. ‘Oil acne’ is recognised by the presence of skin rashes. The arms are most often affected,

but may occur where there is contact with oil or oil clothing.

- Seek medical attention for any rash.

- Avoid skin contact with mineral oil or clothing containing mineral oil.

4. Inhalation of mineral oil vapours must be avoided. Never fire the burner in the open air as

unburnt oil vapours are likely to occur.

5. Use a suitable barrier cream which will give protection against mineral oil, lanolin based hand

cream are usually very effective.

6. Never syphon minerals oil by mouth. If accidentally swallowed, call a doctor, do not induce

vomiting.

NOTE: SMOKE/SMELL EMITTED DURING INITIAL USAGE

Some parts of the cooker have been coated with a light covering of protective oil. During initial

operation of the cooker, this may cause smoke/smell to be emitted and is normal and not a fault

with the appliance, it is therefore advisable to open doors and or windows to allow for ventilation.

Lift the lids to prevent staining the linings.

3

Page 4

To ensure the best performance from your Stanley Alpha

it should be serviced once a year; preferably at the start

of the heating season.

This appliance must be commissioned by an approved

engineer.

Failure to install and maintain the appliance correctly

could lead to prosecution.

An additional flueway and combustion chamber clean

halfway through the heating season may be necessary in

some cases.

The Stanley Alpha cannot be serviced whilst hot, so both

oven and boiler thermostats should be turned off on the

evening before the service visit.

Annual Service

During annual service burner nozzles and burner head

seals MUST BE CHANGED. Flexible oil lines must be

changed every 2 years.

WIRING: Ensure there is no damage or loose

connections. This should be carried out by a competent

engineer.

BURNER REMOVAL - for cleaning and inspection.

CLEANING - Boiler heat exchanger, flueways, oven and

hotplate flueways together with insulation fibre burner

chambers.

BURNER SERVICING.

OIL PUMP SERVICING - Cleaning of fuel line strainer.

RE-COMMISSIONING

REPLACEMENT PARTS

Oven Door Fit - Both doors must be checked and adjusted

if necessary to ensure the alignment with the door catch

is correct, the keep is secure and the oven is sealed when

the door is closed.

Additional Flueway Clean

It may be necessary in some installations to give the

boiler flueways a clean out at the end of the heating

season.

4

INTRODUCTION SERVICE SCHEDULE

Page 5

WARNING: BEFORE REMOVING SERVICE ACCESS

COVERS OR THE OIL BURNERS ENSURE THAT ALL

ELECTRICAL SUPPLIES TO THE APPLIANCE HAVE

BEEN ISOLATED.

The burners can be removed without disconnecting the oil

supply pipe. However if the filters are being cleaned or a

pressure gauge fitted to the pump then the oil supply

should be turned OFF and arrangements made to catch

any oil which will leak from the oil pump.

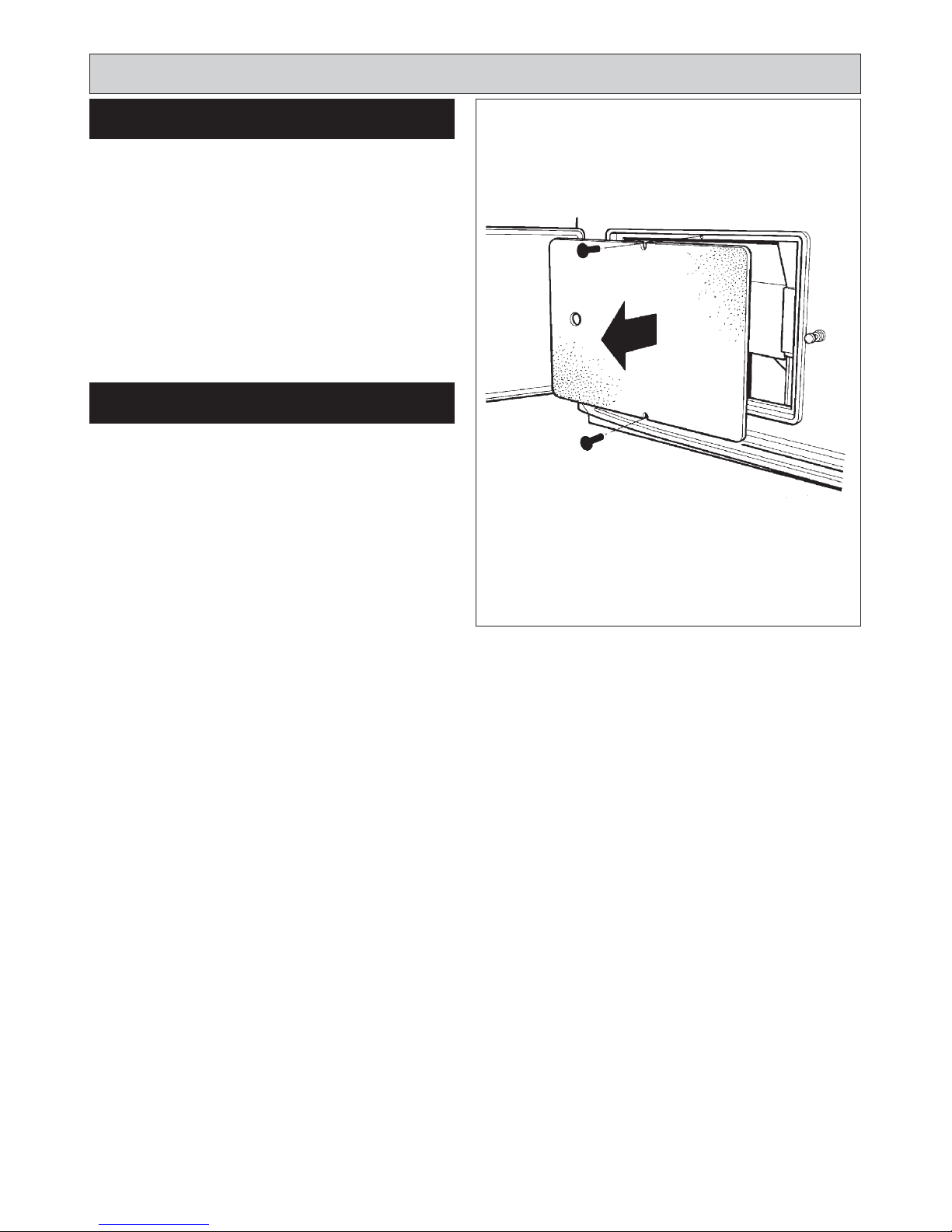

SEE FIG. 1

1. Open up the bottom burner access door. Remove

door and put in a safe place.

2. Remove 2 inner panel securing screws and remove

panel.

5

PREPARATION

BURNER ACCESS

Burner Removal

FIG. 1 DESN 514813

Page 6

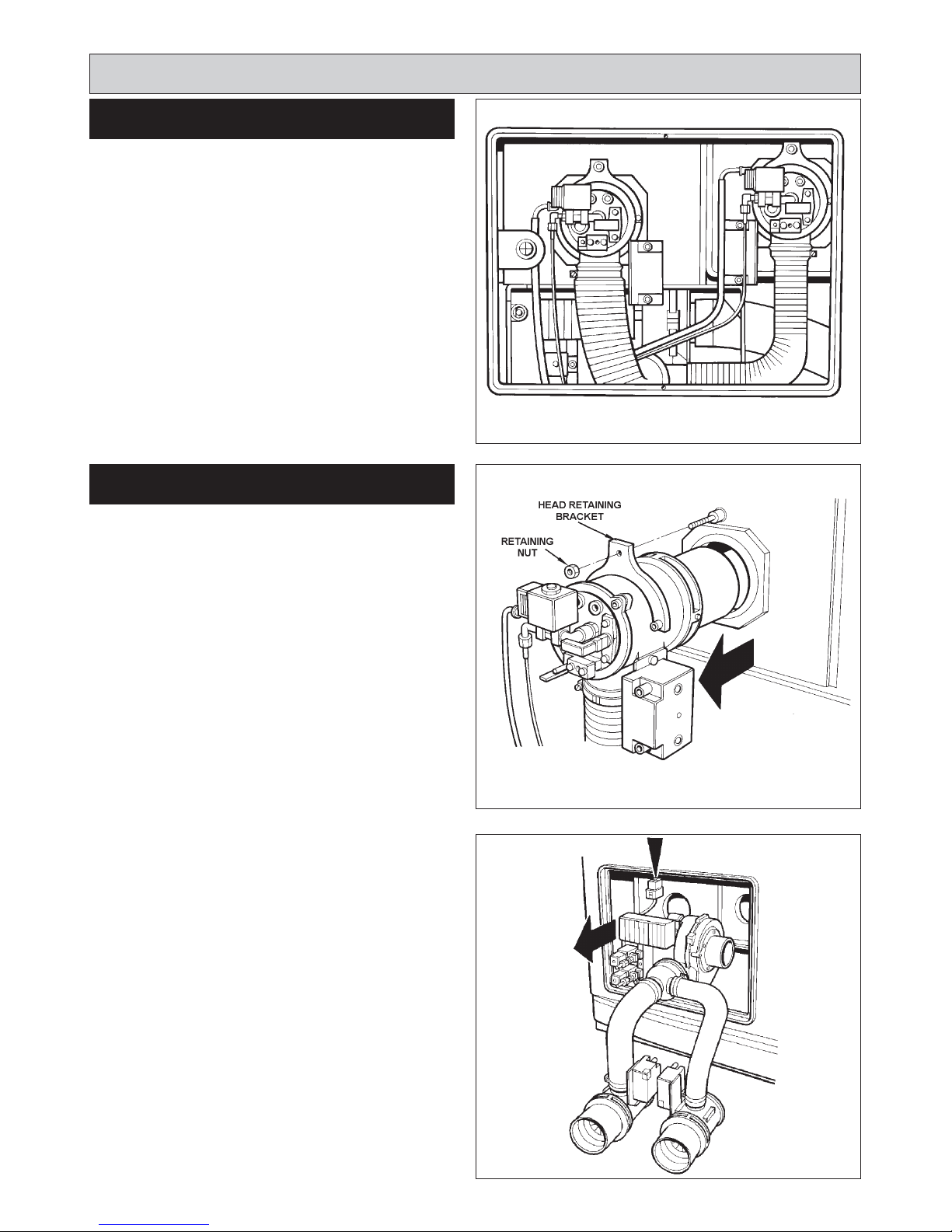

IMPORTANT: DURING BURNER REMOVAL CARE

MUST BE TAKEN NOT TO DAMAGE THE INSULATION

BOARDS.

SEE FIGS. 2, 3 & 4

1. Undo the burner locking nut and remove head

retaining bar.

2. Withdraw burner head.

SEE FIG. 3

3. Place a sheet on the floor in front of the cooker to act

as a working area.

4. Disconnect the 12-pin plug from above the burner.

5. Disconnect air intake.

SEE FIG. 4

6. Slacken 2 M6 fixings and remove flue safety

thermostat.

7. Withdraw burner unit.

6

BURNER REMOVAL

FIG. 2

FIG. 3

FIG. 4

DESN 514814

DESN 514847

DESN 514815

Burner Removal

BURNER HEAD REMOVAL

Page 7

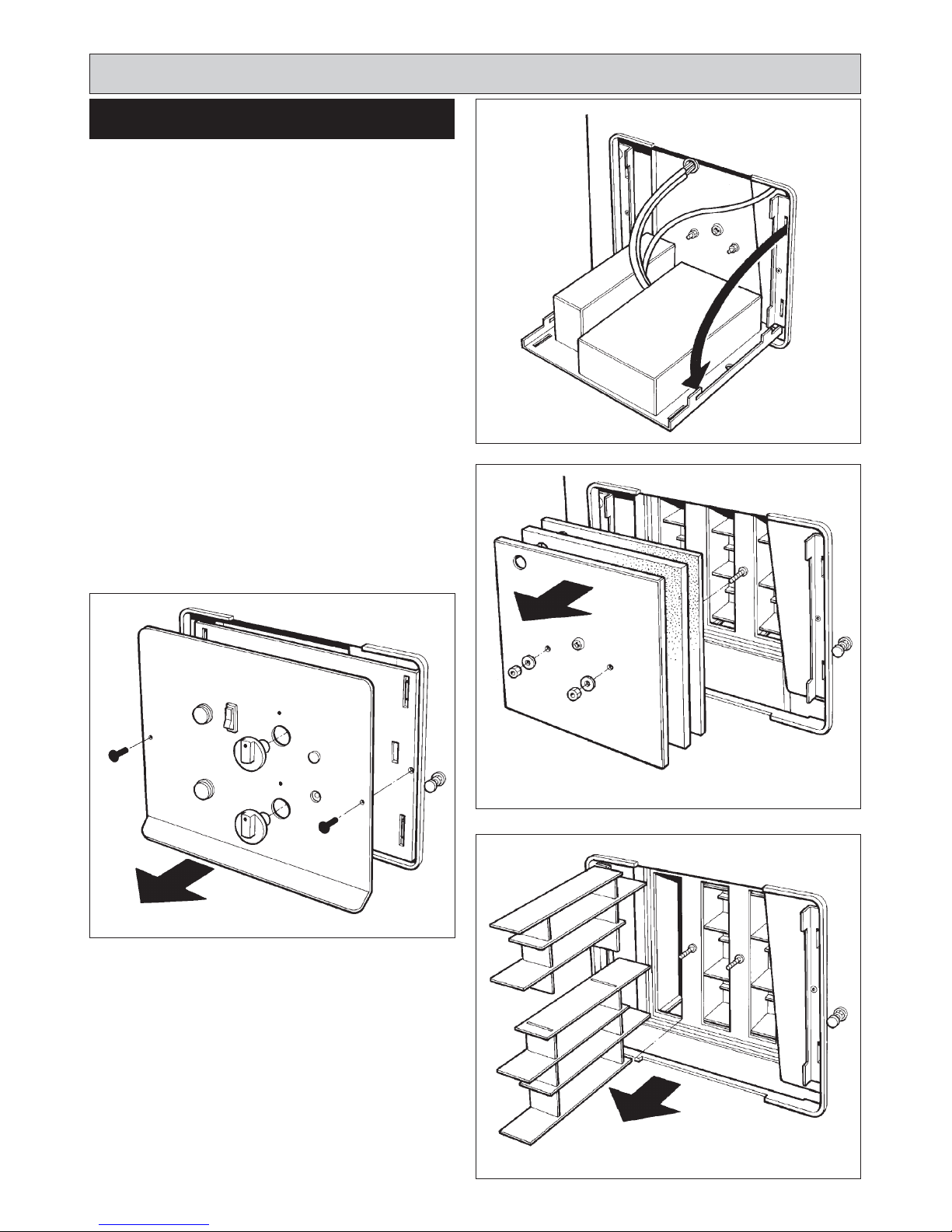

IMPORTANT: DURING CLEANING CARE MUST BE

TAKEN NOT TO DAMAGE THE INSULATING

BOARDS.

Boiler access is made by opening the top left hand control

door.

1. Remove two cooker control knobs.

2. Remove 2 retaining screws and lift the control panel

free of the aperture.

3. Remove 2 retaining nuts and withdraw burner access

panel.

4. The baffles are assembled in two stacks, it maybe

necessary to slightly lift the top stack of baffles and

withdraw bottom baffle stack first, then withdraw the

second stack of baffles.

Each heat exchanger has 3 rows of baffles.

5. Ensure baffles and flueways are clear of debris and refit baffle stacks as illustrated in Fig 8.

NOTE: One baffle configuration for all three models.

6. Carefully vacuum any debris that has fallen into the

burner chamber.

7. Re-assemble in reverse order.

7

HEAT EXCHANGER CLEANING

Cleaning

FIG. 5

FIG. 7

DESN 514816

DESN 514818

FIG. 6 DESN 514850

FIG. 8 DESN 514819

Page 8

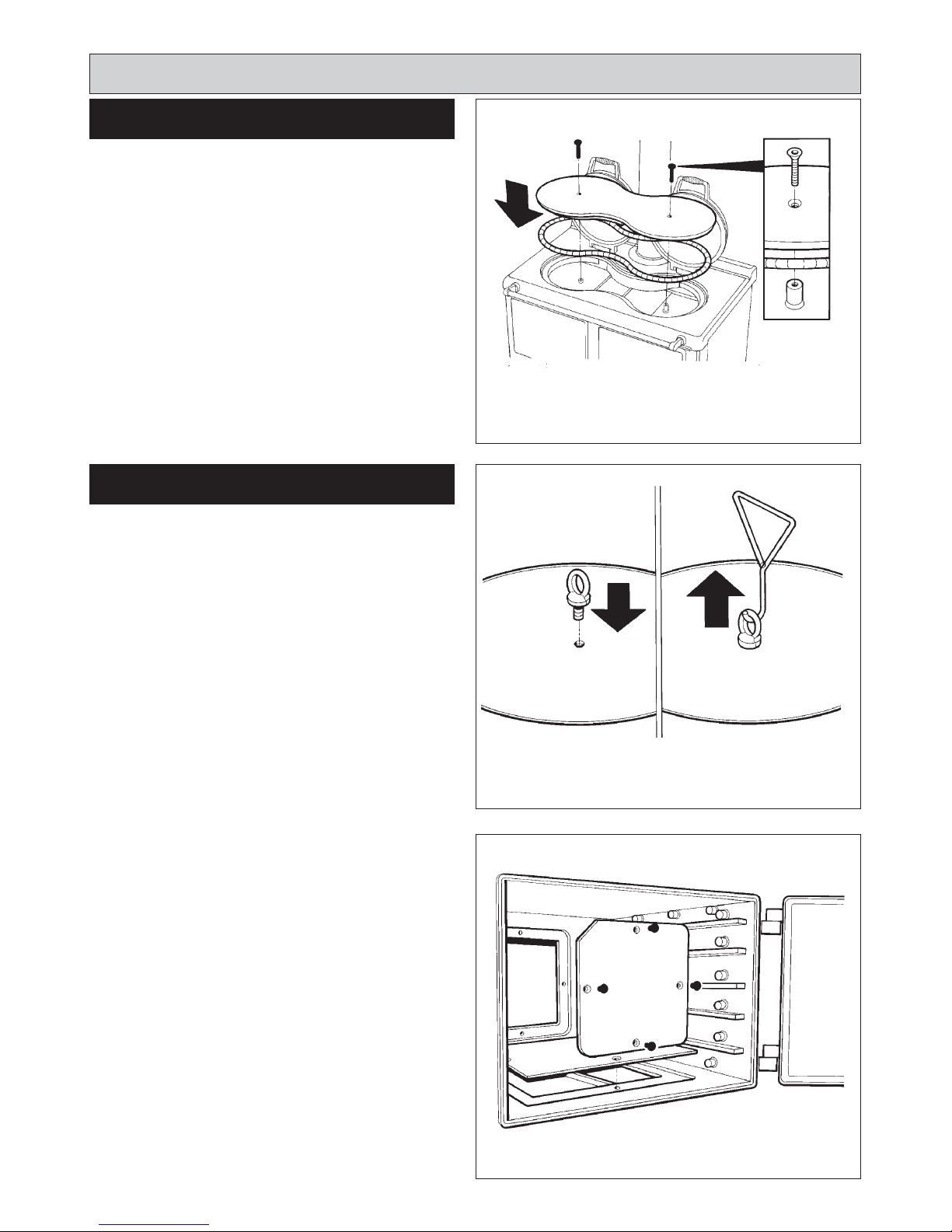

1. Lift up two insulating lids on the top of the cooker.

2. Using a 7mm allen key, unscrew 2 countersunk

retaining bolts. (See Fig. 9).

3. Insert M12 eye hooks into hotplate. (See Fig. 10).

4. Using lifting hooks, lift hotplate vertically and withdraw.

5. Re-assemble in reverse order, noting that it is

recommended to coat the countersunk bolts with antiseize compound prior to fitting.

SEE FIG. 11

1. Remove the top oven door and place in a safe

position.

2. Remove rear and base access doors use hex. driver.

3. Thoroughly clean top, side and base flueways through

access apertures with brush.

4. Remove all debris with vacuum cleaner.

5. Replace rear and base access doors. Secure in

position using hex. driver.

6. Brush and clean in between hotplate ribs on

underside.

7. Examine soft rope seal located around hotplate

aperture in top plate and rope seal on hotspot.

Replace if frayed or damaged.

8. Replace hotplate ensuring the underside ribs lie over

the boiler and that it seals to the top plate.

8

Cleaning

FIG. 11 DESN 514820

OVEN & HOTPLATE FLUEWAY

CLEANING

HOTPLATE REMOVAL

FIG. 9

FIG.10

DESN 514841

DESN 514858

Page 9

9

Burner Servicing

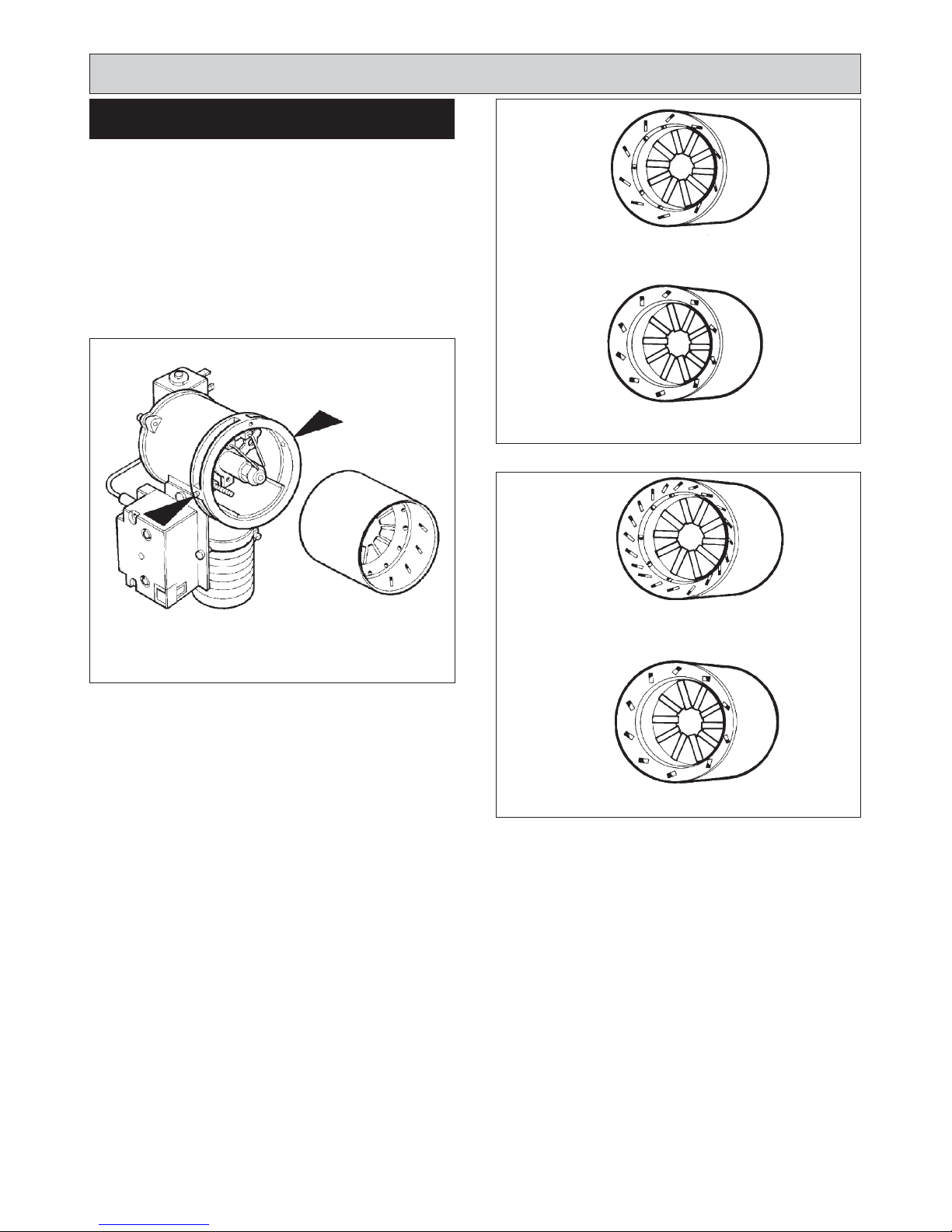

SEE FIG 12, 13A & 13B

It is recommended that each side of the burner is serviced

individually so as not to get the components from the two

burners mixed up.

The correct combination of burner blast tubes are shown.

To remove blast tube, slacken two grub screws, pull

forward.

120K

150K

INTRODUCTION

FIG. 12

FIG. 13B

FIG. 13A

DESN 512005

COOKER 10

VANES

COOKER 10

VANES

BOILER 10 VANES

5mm HOLES

10 LARGE SLOTS

BOILER 10 VANES

5mm HOLES

20 LARGE SLOTS

Page 10

SEE FIG. 14

1. Disconnect ignition leads.

2. Remove two socket head screws.

3. Remove head assembly complete.

4. Remove ignitor assembly, by removing countersunk

screw and clamp.

5. Unscrew nozzle from its holder with a correctly fitting

tubular spanner to avoid damage to hexagon.

Follow instructions in BURNER ACCESS, Steps 1 to 2, and

BURNER NOZZLE REMOVAL, Steps 1 to 5.

SEE FIG. 14

1. Disconnect ignition leads.

2. Remove 2 socket head screws.

3. Remove head assembly complete.

4. Remove ignitor assembly by removing countersunk

screw and clamp.

5. Fit new ignition electrode assembly, re-assemble in

reverse order.

6. Check electrode gap and re-set if necessary.

SEE FIG. 15

1. Replace nozzle by a new one of the same make and

specification.

2. Ensure that mating faces are clean.

3. Hold nozzle holder with correct spanner when

tightening nozzle.

4. Typically finger tight plus 1/4 turn with spanner is

sufficient.

DO NOT OVERTIGHTEN.

5. Ensure electrode gaps are correct.

10

Burner Servicing

BURNER NOZZLE REMOVAL

BURNER NOZZLE REPLACEMENT

FIG. 14 DESN 514823

3mm

FIG. 15 DESN 510538

IGNITOR REMOVAL

Page 11

SEE FIG. 16

Withdraw Photo Electric Cell from the burner head. Clean

PEC sensing end with a soft cloth taking care not to

scratch the light sensitive body. Re-insert PEC taking care

to insert the correct way round.

Should the cell show signs of distortion or cracking,

replacement will be necessary. See ‘PEC Replacement’ Page 17.

SEE FIG. 17

1. Remove pozi screws, pull off fan case inlet.

2. Clean between the blades of the fan impellor with a

small brush and remove any residue.

Re-assemble the burner in reverse order.

NOTE: Burner head gaskets should be renewed at each

service.

11

Burner Servicing

PHOTO ELECTRIC CELL (PEC)

CLEANING

FIG. 17 DESN 514824

FIG. 16 DESN 514848

FAN CLEANING

RE-ASSEMBLE BURNER

Page 12

SEE FIG. 14

To carry out servicing on the oil pump. Turn off the oil line

isolating valve near to the appliance.

SEE FIG. 18

1. Remove 4 socket head screws

2. Remove filter.

3. Wash with clean petrol or paraffin.

4. Re-assemble in reverse order.

1. Turn OFF the line isolating valve fitted prior to the oil

line filter.

2. Follow manufacturers instructions to remove filter

element from the housing, taking care to collect

kerosene residue from the filter housing.

3. Wash filter thoroughly in clean petrol or paraffin.

4. Re-assemble in reverse order.

NOTE: Flexible fuel hose (s) must be replaced every 2

years.

INTRODUCTION

Oil Pump Servicing

12

FIG. 18 DESN 512002

OIL PUMP STRAINER CLEANING

COVER

STRAINER

SEAL

FUEL INLET

OIL LINE FILTER CLEANING

Page 13

SEE FIG. 20

Disconnect the flexible oil pipe line at the pump inlet, open

the stop valve slowly and run off some of the oil into a

receptacle to establish an air free supply to the pump.

Remake the connection oil tight and leave valve open.

SEE FIG. 19

Remove the bleed screw from the manifold and fit an oil

pressure gauge with R 1/8 connection to check the pump

output pressure.

Set the boiler burner time clock to continuous and turn the

boiler thermostat to maximum. The boiler burner should

run on pre-purge for 7-15 seconds. With the ignition spark

energised. The oil solenoid valve should open allowing

the burner to fire.

Until all the air from the oil pump is flushed out there may

be some flame instability resulting in the burner locking

out. This will be shown by the burner stopping and the

reset button will be illuminated in the control box. IN THIS

EVENT, WAIT AT LEAST ONE MINUTE, then press the

reset button to restart. (See Fig. 21).

SEE FIG. 19

Whilst the burner is running, vent air from the pump by

slackening the pressure gauge port sufficient to allow air

to bleed out. When bubble free oil seeps out re-tighten.

SEE FIG. 20

With the burner running check the oil pressure on the

pressure gauge.

If the pressure gauge is not indicating the correct reading

then adjust the pressure by turning the pressure regulator

clockwise to increase or anti-clockwise to decrease the

pressure until the pressure gauge reads 10 bar

(145Ibf/In

2

).

13

BLEED AIR FROM OIL SUPPLY

SWITCH ON ELECTRICITY

VENT OIL PUMP

Re-commissioning

FIT PRESSURE GAUGE

FIG. 19

FIG. 20

DESN 514825

DESN 511997

OIL

PRESSURE

ADJUSTMENT

ADJUST OIL PRESSURE

FIG. 21 DESN 514807

Page 14

SEE FIG. 22

After 15 minutes of the boiler burner running.

Remove the collar infill trim and lift up the enamelled flue

collar. Support the flue collar above the cooker.

NOTE: The LH sampling screw is for the boiler and the

RH sampling screw is for the cooker.

Remove the plugging screw and insert the sensing end of

a portable indicator to check the CO

2 (Carbon Dioxide)

level. Adjust the boiler burner air intake until a reading of

11.0/11.5% is recorded on the indicator.

SEE FIG. 23

Remove the CO

2 sampling tube and using the same hole

for flue sampling, insert the sensing end of a Baccarach

Smoke Pump and check that the smoke in the boiler

flueways does not exceed No. 2 on the scale.

Replace the plugging screw.

Switch off the boiler burner.

COOKER BURNER - SEE FIG. 23

Switch on cooker burner.

After 15 minutes of the cooker burner running.

Repeat the above procedures for the cooker burner. To

sample the flue gases from the cooker burner, remove the

RH plugging screw and insert sensing end of a portable

indicator to check CO

2 level. The cooker burner should be

set to 11.0/11.5% maximum Smoke No. 2.

Replace the plugging screw on completion.

14

SET COMBUSTION AIR

Re-commissioning

FIG. 22

FIG. 23

DESN 514826

DESN 514823 A

CHECK SMOKE

Page 15

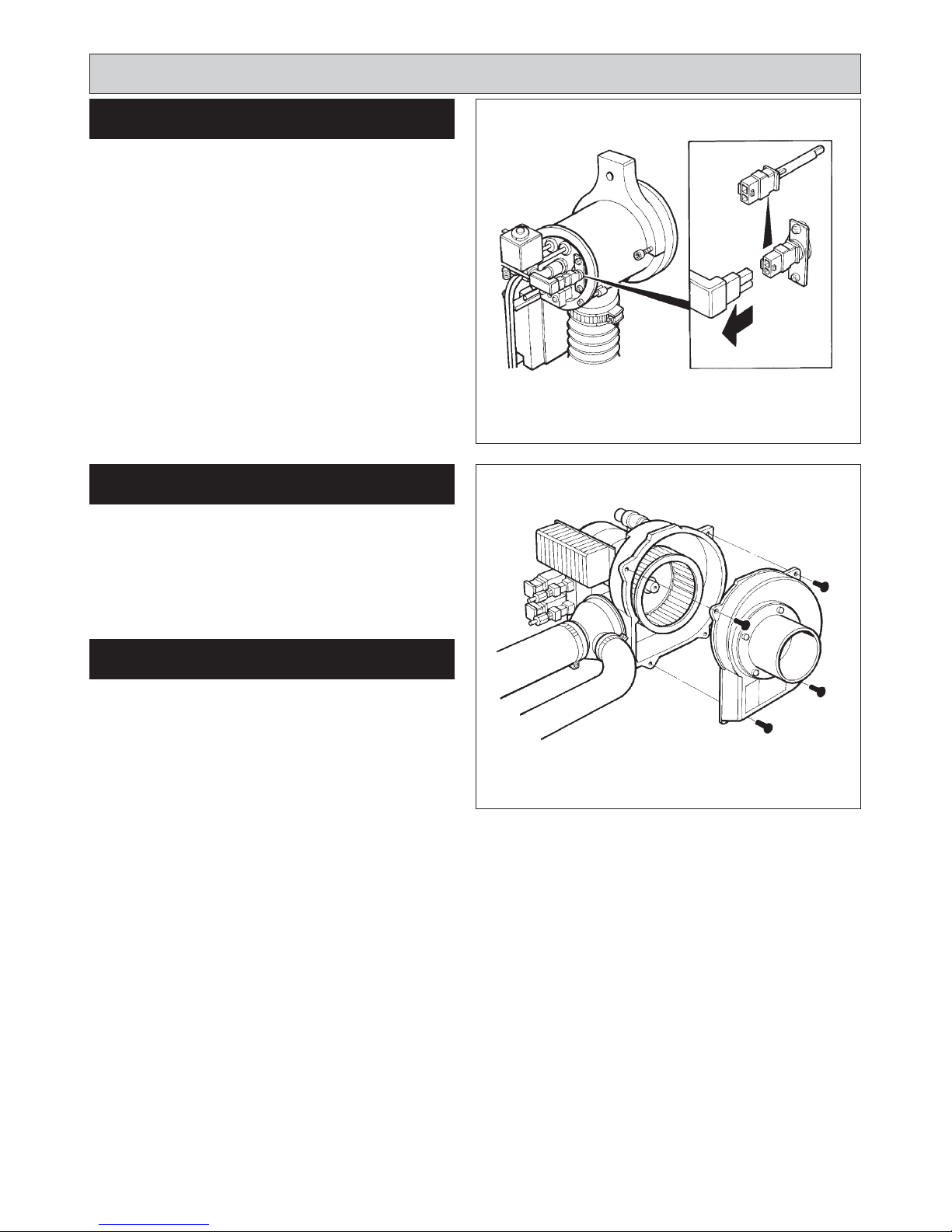

SEE FIG. 24

1. Remove 3-pin plug.

2. Disconnect oil pipe.

3. Remove 4 pozi drive screws, remove fan case inlet.

4. Undo grub screw, remove fan.

5. Remove 4 fixings, withdraw motor.

6. Re-assemble in reverse order.

NOTE: Ensure that gaskets and seals are in place and in

good condition.

15

FAN MOTOR

Replacement of parts (Burner)

FIG. 24 DESN 514828

Page 16

SEE FIG. 25

Follow instructions in sections BURNER ACCESS, Steps

1 to 2, BURNER REMOVAL, Step 4.

1. Remove both HT leads from ignitor.

2. Remove mains plug from ignitor.

3. Remove earth screw.

4. Remove 2 ignitor securing screws.

5. Remove ignitor.

6. Fit new ignitor, re-assemble in reverse order.

1. Open and remove top left hand control door, remove 2

retaining screws and cooker control knobs.

2. Lift and withdraw control panel and turn over.

3. Remove push-on connectors (noting position of each

connector).

4. Remove 2 relay fixing screws.

5. Fit new relay.

6. Re-assemble in reverse order.

SEE FIG. 27

Follow instructions in sections BURNER ACCESS, Steps

1 to 2, BURNER REMOVAL, Steps 1 to 5.

1. Slacken solenoid plug securing screw.

2. Remove plug.

3. Remove solenoid securing nut and washer.

4. Remove solenoid coil.

5. Fit new solenoid coil, re-assemble in reverse order.

16

IGNITOR PACK

FIG. 25

FIG. 26

DESN 514849

DESN 511991

FIG. 27 DESN 514829

RELAY

Replacement of parts (Burner)

SOLENOID COIL

Page 17

SEE FIG. 28

Follow instructions in section ELECTRICAL

COMPONENT ACCESS, Steps 1 to 4.

1. Undo centre fixing screw.

2. Gently pull control box away from base.

3. Fit new control box and re-assemble in reverse order.

SEE FIG. 29

Follow instructions in BURNER ACCESS, Steps 1 to 2.

1. Withdraw PEC from burner head.

2. Push in retaining clip and slide PEC out.

3. Fit new PEC.

4. Re-insert PEC taking care to insert the correct way

round.

SEE FIG. 30

Follow instructions in section BURNER ACCESS, Steps 1

to 2 and BURNER REMOVAL, Steps 1 to 5.

1. Isolate fuel supply.

2. Disconnect flexible hose. (This must be replaced every

2 years.

3. Remove solenoid plug.

4. Remove feed pipe.

5. Slacken three securing screws and remove pump.

6. Check drive, replace if worn or damaged.

7. Replace pump, re-assemble in reverse order.

17

Replacement of parts

(Burner)

FIG. 28 DESN 511992

FIG. 29 DESN 514848

CONTROL BOX

PEC

FIG. 30

DESN 511995

PUMP ACCESS

Page 18

BEFORE REMOVING SERVICE ACCESS COVERS

ENSURE THAT ALL ELECTRICAL ACCESS TO THE

APPLIANCE HAS BEEN SWITCHED OFF (SWITCH

OFF AND REMOVE PLUG.

SEE FIG.31 & 32

1. Remove the controls door and place in a safe position.

2. Remove both thermostat control knobs.

3. Remove the 2 cover panel fixing screws.

4. Disconnect cover panel. It will be necessary to

disconnect the push-on tags from the selector switch

and cooker ‘ON’ neon.

SEE FIG. 33

5. Lift control panel chassis and withdraw from aperture.

6. To fully access the rear of the control chassis, the

thermostat capillaries should be removed from their

pocket.

18

ELECTRICAL COMPONENT

ACCESS

Replacement of parts

(Electrical controls)

FIG. 31 DESN 514816

FIG. 33 DESN 514830

FIG. 32 DESN 514850

Page 19

Replacement of parts

(Electrical controls)

FIG. 34 DESN 514830

19

Page 20

SEE FIG. 35

Follow instructions in section ELECTRICAL

COMPONENT ACCESS, Steps 1 to 6.

1. Undo the two screws on the front of the chassis which

hold the thermostat in place.

2. Remove the two push-on connectors from back of

thermostat.

3. Replace thermostat. Take care to push thermostat

phial correctly into the pocket provided. The

thermostat should be mounted with tag P at the right

hand side.

4. Re-connect push on connector wires. The GREY wire

to 1 and WHITE wire to P.

To complete, follow instructions in RE-ASSEMBLE, Steps

1 to 6.

SEE FIG. 36

Follow instructions in section ELECTRICAL

COMPONENT ACCESS, Steps 1 to 6.

1. Undo the two screws on the front of the chassis which

hold the thermostat in place.

2. Remove the three push on connectors from back of

thermostat.

3. Replace thermostat. The thermostat should be

mounted with tag P at the left hand side. Take care to

push on thermostat phial correctly into the pocket

provided.

4. Re-connect push on connector wires. The GREY wire

from the pump to P, the other BROWN wire to 2 and

the YELLOW to 1.

To complete, follow instructions in section REASSEMBLE, Steps 1 to 6.

Replacement of parts

(Electrical controls)

TO FIT NEW BOILER CONTROL

THERMOSTAT

20

FIG. 35 DESN 514747

TO FIT NEW BOILER PUMP

OVERRUN THERMOSTAT

FIG. 36 DESN 514851

Page 21

SEE FIG. 37

Follow instructions in section ELECTRICAL

COMPONENT ACCESS, Steps 1 to 6.

1. Undo the two screws on the front of the chassis which

holds the thermostat in place.

2. Remove the two push on connectors from the back of

the thermostat. Open oven door to access the

thermostat phial which passes into the oven at top LH

corner.

3. Remove LH side plate, slacken screw where the phial

passes through RH side and rotate. Slacken screw

front phial mounting bracket and rotate.

4. Replace thermostat, thermostat phial should be repositioned in the same position as removed.

To complete follow instructions in section REASSEMBLE, Steps 1 to 6.

SEE FIG. 38

Follow instructions in section ELECTRICAL

COMPONENT ACCESS, Steps 1 to 6.

1. Undo the central hexagon nut on the front of the

chassis which holds the thermostat in place.

2. Remove the push on connectors from back of

thermostat.

3. Replace thermostat. Take care to push thermostat

phial correctly into the pocket provided.

4. Re-connect push on connector wire as Fig. 33.

To complete follow the instructions in section REASSEMBLE, Steps 1 to 6.

Replacement of parts

(Electrical controls)

TO FIT NEW COOKER SAFETY

OVERHEAT THERMOSTAT

21

FIG. 37 DESN 514747

TO FIT NEW BOILER SAFETY

OVERHEAT THERMOSTAT

PINK

RED

FIG. 38 DESN 514852

Page 22

SEE FIG. 39

Follow instructions in section ELECTRICAL

COMPONENT ACCESS, Steps 1 to 6.

1. Undo the two screws on the front of the chassis which

holds the thermostat in place.

2. Remove the two push on connectors from back of

thermostat.

3. Open roasting oven door to access thermostat phial

and capillary which will pass into the oven at the top.

4. Where the phial passes through the roasting oven

side, slacken screw front phial, mounting bracket and

rotate.

5. Replace thermostat. The thermostat should be

mounted with tag P at the right hand side. Reposition

the phial in same position as removed.

6. Re-connect push on connector. The VIOLET to P2,

PINK to P and BLACK to P1.

NOTE: Ensure phials do not make contact with oven

castings.

To complete follow instructions in RE-ASSEMBLE, Steps

1 to 6.

SEE FIG. 40

Follow instructions in section ELECTRICAL

COMPONENT ACCESS, Steps 1 to 4.

1. To remove switch from the cover panel press the two

toggles at top and bottom of switch, push switch

through panel.

2. Push replacement switch into aperture and click into

place. The switch should be fitted with terminal 1 at the

top.

To complete follow the instructions in section REASSEMBLE, Steps 3 to 6.

Replacement of parts

(Electrical controls)

22

TO FIT NEW SELECTOR SWITCH

FIG. 39 DESN 514831

TO FIT NEW OVEN CONTROL

THERMOSTAT

FIG. 40 DESN 510553 A

Page 23

1. Locate thermostat phials into boiler pocket.

2. Locate the base of the control chassis into the bottom

of the doorway aperture, tilt the chassis backwards

into position and secure with the four screws.

3. Thread the two wires for the selector switch through

the aperture and connect them onto the rear of the

selector switch fitted in the outer panel. Connect the

VIOLET and BLUE wires to the COOKER ON neon.

Connect the ORANGE wire on 1 and the PURPLE wire

on 2.

4. Refix the outer panel in position and secure with the 2

screws.

5. Replace the thermostat knobs.

6. Replace the controls door.

Replacement of parts

(Electrical controls)

23

FIG. 41 DESN 514832

RE-ASSEMBLE

Page 24

When the programmer switches OFF the boiler channel

then the water circulating pump will be switched off. If

during the period shortly after this the residual heat in the

appliance causes the water temperature in the boiler to

rise above 65°C then the pump overrun thermostat will

change over. This will switch on the circulating pump.

BOILER

This thermostat is a safety cut-out device which is

intended to operate if the other controls fail. This control

will “lock-out” and switches everything off except for the

programmer clock and the “Pump Overrun” facility.

This thermostat has to be manually reset once the

temperature has cooled down.

COOKER

This thermostat is a safety cut-out device which operates

if the control thermostat fails.

This thermostat automatically resets once the

temperature has cooled down.

Electrical Controls

PUMP OVERRUN FACILITY OVERHEAT SAFETY THERMOSTATS

24

Page 25

25

FIG. 42

Electrical Controls

SW/L COOKER

N/A

SW/L BOILER

N/A

PL - LIVE

PN - NEUTRAL

PL - LIVE

PN - NEUTRAL

L LIVE

N NEUTRAL

E EARTH

COOKER SWITCHED - LIVE

DO NOT USE

DO NOT USE

EXTERNAL PROGRAMMER - LIVE - MUST BE

CONNECTED DIRECTLY TO THIS SUPPLY

EXTERNAL PROGRAMMER - NEUTRAL

PUMP SUPPLY - LIVE (THE CIRCULATING PUMP MUST

BE CONNECTED DIRECTLY TO THIS SUPPLY)

PUMP SUPPLY - NEUTRAL (THE CIRCULATING PUMP

MUST BE CONNECTED DIRECTLY TO THIS SUPPLY)

3 AMP PERMANENT SUPPLY

NOTE:

The 3 channel programmer LIVE must be connected directly to the programmer LIVE supply from the cooker.

TERMINAL STRIP CONNECTIONS

BOILER SWITCHED - LIVE

Page 26

26

FIG. 43

Fault Finding

Page 27

Burners

Check that the burners have not gone to lock-out.

Causes of lock-out can be:-

z No ignition, ignition electrode incorrectly positioned or insulation cracked, spark generator fault.

z No oil supply.

z Poor combustion.

z Photo electric cell incorrectly positioned, cracked or needs cleaning.

z Live and Neutral connections reversed.

z Faulty control box.

z Faulty fire valve.

z Faulty relays.

REFER TO FLOW DIAGRAMS FOR ELIMINATION PROCEDURES.

General

You can carry out some checks on the controls before you need to access the controls compartment behind the control

door.

If only one of the burners is not running then the fault must be after the safety overheat thermostat.

Conversely if both burners are affected then the fault lies before the programmer connections.

For access to individual controls refer to section Replacement Parts and for wiring continuity checks refer to Figs. 37 and

38 for detailed and schematic wiring diagrams.

To check out the electrical wiring at the burners you will first have to access the burner chamber. Use the following

procedure:

1. Isolate the electrical power supply.

2. Open up the bottom burner access door. Remove door and put in a safe place.

3. Unscrew the 2 screws holding the inner panel in place and remove panel.

The external mains connections are made to a terminal block situated in the front left hand corner of the burner chamber.

Re-connect the electrical supply and that there is 230V power supply available across the mains input connection L & N

on the terminal block, if not then check connecting leads, fuses and whether power is available at mains plug.

If power is available across L & N then check to see whether the overheat cut-out switch has cut-out, if it has been reset

by pushing the centre with a small round tool (i.e. a pencil). Check for continuity across the cooker overheat thermostat.

Fault Finding

27

BURNER DOES NOT START

Page 28

Fault Finding

28

Information system

The information system communicates with the outside world using a LED (the used Flash-Code is similar to the Morse

Code). The messages are optically transmitted by flashing appropriately a LED. Using an (optional) additional terminal the

messages can be recorded and displayed in easily readable form.

Programming sequence display

The built-in microprocessor controls not only the programming sequence but the information system too. The individual

phases of the programming sequence are displayed as Flash-Code.

The following messages can be distinguished:-

FIG. 44

Page 29

Fault Finding

Lock-out diagnoses

In case of a failure the LED is permanently illuminated. Every 10 seconds the illumination is interrupted by a flash code

which indicates the cause of the error. Therefore the following sequence is performed which is repeated as long as the

unit is not reset.

Sequence:

Stray Light Monitoring

The stray light check is performed as the end of the pre-purge time for the duration as mentioned in the table of timings.

Low-voltage protection

at 220 / 240V nominal voltage

The mains voltage has to be more than 187V

eff

(94V

eff

) in order to allow the unit to perform a start-up.

The mains voltage is not only monitored in the start-up phase but also permanently during operation. If the voltage drops

below <160V

eff

(80V

eff

) during start-up or run time the control box goes into lock-out mode. If the voltage rises again, the

control box performs automatically a start-up as soon as the mains voltage is >187V

eff

(94V

eff

)

29

Page 30

30

Fault Finding

Page 31

Fault Finding

31

Page 32

32

Fault Finding

Page 33

33

Fault Finding

Page 34

34

Fault Finding

HIGH SMOKE NUMBERS

OIL SMELLS

INCORRECT

COMBUSTION

SETTINGS

RE-ADJUST

TO

INSTALLATION

INSTRUCTIONS

AIR INTAKE

BLOCKED

CHECK AIR

INLET TO

BURNER

NOZZLE FAULT

REPLACE

NOZZLE

FUMES ON

START UP

DOWN

DRAUGHT

CHECK WITH

GAUGE

OIL SOAKED

HEARTH

BURNER

FAULT

OIL LEAKS AT

PIPE FITTINGS

TAKE APART

AND

REMAKE AS

REQUIRED

LEAKS AT

TUBING

CONNECTORS

ENSURE END

OF TUBING

SQUARE

NUMEROUS

LOCK-OUTS

CURE THE

LOCK-OUT

CONDITION

ODOURS

IN

KITCHEN

OIL PRESSURE

INCORRECT

ADJUST TO

RECOMMENDED

SETTINGS

INCORRECT

COMPONENTS

USED ON

COMBUSTION

HEAD

SEE SERVICING

INSTRUCTIONS

INTERNAL

INSULATION

PANELS

INCORRECTLY

POSITIONED

OR

FAULTY

Page 35

35

Page 36

36

For further advice or information contact your

local distributor/stockist

With Waterford Stanley’s policy of continuous

product improvement, the Company reserves the

right to change specifications and make

modifications to the appliance described at any

time.

Supplied by

Waterford Stanley Ltd

Unit 210

IDA Industrial Estate

Cork Road

Waterford

Ireland

Tel: (051) 302300 Fax: (051) 302315

www.waterfordstanley.com

Loading...

Loading...