Page 1

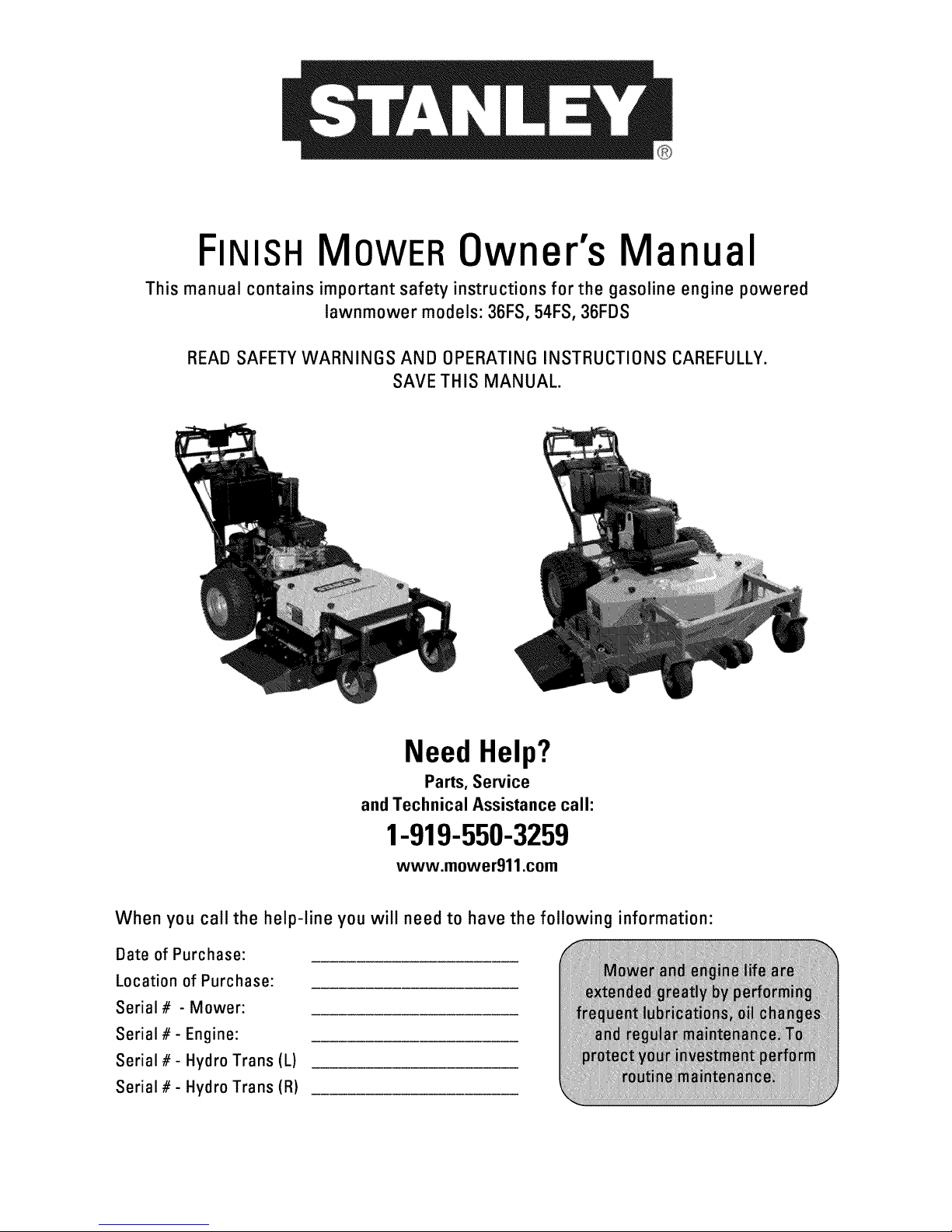

FINISH MOWER Owner's Manual

This manual contains important safety instructions for the gasoline engine powered

lawnmower models: 36FS, 54FS, 36FDS

READ SAFETYWARNINGS AND OPERATING INSTRUCTIONS CAREFULLY.

SAVE THIS MANUAL.

Need Help?

Parts, Service

and Technical Assistance call:

1-919-550-3259

www.mower911.com

When you call the help-line you will need to have the following information:

Date of Purchase:

Location of Purchase:

Serial# - Mower:

Serial # - Engine:

Serial # - Hydro Trans (L)

Serial # - Hydro Trans (R)

Page 2

36FS,54FS

Copyright@ 2009 by GXi Outdoor Power, LLC.All rights reserved.

No part of this publication can be reproduced or distributed without prior written permission of GXi Outdoor Power, LLC

Clayton, NC 27520 USA.

is a registered trademark of The Stanley Works or its affiliates and

is used under license by GXi Outdoor Power, LLC

GXi Outdoor Power, LLCreserves the right to discontinue or change specifications or design at anytime without notice

and without incurring any obligation whatsoever.

The information and specifications included in this publication were in effect atthe time of approval for printing.

This manual contains important safety instructions for Finish Mowers

READSAFETYWARNINGS AND OPERATINGINSTRUCTIONS CAREFULLY

SAVE THESEINSTRUCTIONS.

This owner's manual is considered a permanent part of the finish mower and should

remain with the finish mower if resold.

Rev:Mar2011 STANLEY®Finish Mower

Page 3

Contents

Safety Information and Warnings .........................................................................1

Operation Safety Precautions ...............................................................................2

Safety Decals ............................................................................................................3

Product Specifications ...........................................................................................4

Control Panel and Lawn Mower Components ....................................................5

Assembly Instructions

Step 1:FrontWheel Assembly .......................................................................6

Step 2: Mower Assembly ................................................................................7

Step 3: Wire Harness Assembly and Connections .....................................8

Step 4: Throttle and Choke Cable Connections ...........................................8

Step 5: Fuel Tank Connections .......................................................................9

Step 6: Brake Set-up .........................................................................................9

Operating Instructions

Starting the Engine.........................................................................................10

Operating the Mower .....................................................................................10

36FS,54FS

Disengaging Hydrostatic Drive Units ...........................................................11

Return to Neutral .............................................................................................11

Mowing ............................................................................................................12

Changing the Height of Cut...........................................................................13

Removing the Blades .....................................................................................13

Spindle Brake Inspection and Replacement ..............................................14

General Maintenance ...........................................................................................15

Maintenance Schedule ........................................................................................16

Service Adjustments ..............................................................................................17

Lubrication Points ..................................................................................................19

Deck Interchange ...................................................................................................19

Troubleshooting ......................................................................................................20

Limited Warranty and Service .............................................................................22

Aboutthis Manual

Congratulations on the purchase of your new STANLEY commercial mower. We at GXi Outdoor Power are confident that

this mower will provide excellent performance, outstanding quality, and great durability when operated and maintained

as directed in this manual.

1. This manual contains assembly, operating, safety, adjustment, maintenance, and troubleshooting instructions.

BEFOREOPERATING YOUR LAWN MOWER, CAREFULLYREADTHIS MANUAL IN ITS ENTIRITY.

2. This owner's manual is considered a permanent part of the mower. It must be available to all operators and/or

person(s) servicing the mower. Should the mower be resold, this manual must remain with the mower.

3. All information, illustrations, and specifications contained in this manual were in effect at the time of the

publication. GXi Outdoor Power reserves the right to add, delete or modify specifications and/or designs without

notice.

4. If you ever have questions in regards to the operation, maintenance or safety of your mower, please contact the

GXi Parts & Service, LLCat 1-919-550-3259.

Rev:Mar2011 STANLEY®Finish Mower

Page 4

Safety Information and Warnings 36FS,54FS

Safety Information

STANLEY lawn mowers are designed to give safe

and dependable service if operated according to

instructions. Read and understand this owner's

manual before operating your lawn mower.

Emission Control System Information

The U.S. and California Clean Air Acts

EPA and California regulations require all

manufacturers to furnish written instructions

describing the operation and maintenance of

emission control systems. The following instructions

and procedures must be followed in order to keep

the emissions from your engine within the emission

standards.

Safety Label Locations

Safety labels are located on your mower to warn

you of potential hazards. Read them carefully. If a

label comes off or becomes hard to read, contact

your GXi Parts and Service, LLCfor a replacement.

Operator Responsibility

Be sure that anyone who operates the lawn mower

receives proper instruction. Know howto stop the

lawn mower quickly in case of emergency.

Understand the use of all controls and components.

Children should not operate the lawn mower without

parental supervision.

AWA""'"o

I

Mower Inspection

For your safety, inspect the lawn mower before each

use. Before you begin your inspection, be sure the

following conditions are met: the lawn mower should

be on a flat and level surface, with the ignition switch

off, the key removed, and the blades disengaged. Also,

disconnect the spark plug wires from the spark plugs

and ground them against the engine to prevent

inadvertent starting.

1. Walk around the mower and look for any fluid

spills or leaks on or underneath the mower.

Remove any and all excessive debris, dirt, and

fluids.

2. Look for signs of damage or excessive wear.

Check the tightness of all nuts, bolts, pins, and

screws. Tighten any that may be loose and

replace anythat are missing.

3. Be sure the safety interlock controls are

operating properly so that the engine cannot be

started unless the ground speed control lever is

in neutral and the blades are disengaged.

4. Check the mower blades for any damage or

abnormal wear. Replace in sets so that they are

balanced.

5. Check the tire pressure on all four tires. Do not

exceed the recommended maximum indicated

on the tire.

6. Check the belts for proper wear and correct

tension. See pages 16and 17for instructions.

7. Check engine oil and air filters as recommended

in the engine manufacturer's manual.

WARNING! Do not use your STANLEY lawn mower to

carry passengers. Keep bystanders, helpers, pets and

children at asafe distance from the machine while it is

in operation since rotating blades can throw rocks and

other items, causing serious injury. Check the area

before you begin mowing for stones, sticks, wire, and

other foreign objects. These objects may become

projectiles when struck by the mower.

I I

WARNING! Wear protective clothing while mowing.

Long pants and safety glasses help reduce the risk of

injury from thrown objects. Adequate footwear, such as

steel toe shoes with aggressive soles, is recommended

to help protect your feet and maintain traction on slopes

or uneven grounds. Always wear hearing protection.

Rev Mar2011

_DANGER IA

I

DANGER: GASOLINE IS HIGHLY FLAMMABLE AND

EXPLOSIVE. Do not add fuel while the engine is

running or is hot. Keep open flames, sparks, and heat

away from the fuel and store fuel in containers

specifically designed for that purpose. ADD FUEL

OUTDOORS ONLY AND IFTHE FUEL IS SPILLED, DO

NOT START THE ENGINE. Manually push the mower

away from the spill and wipe up immediately.

STANLEY'_Finish Mower

Page 5

Operation Safety Precautions 36FS,54FS

Equipment OperationiSafety Precautions

1. Do not operate the engine in a confined space

where dangerous carbon monoxide fumes can

collect. Carbon monoxide is odorless,

tasteless, and can be fatal.

2. Mow only in daylight.

3. Make sure the mower is in neutral and the

blades are disengaged before attempting to

start the engine.

4. Be extremely careful when operating the

mower on aslope or when the grass is damp

or wet. Reduced traction could cause sliding.

5. Do not stop or start suddenly when going

uphill. Use extreme caution when changing

directions while operating on a slope.

6. Avoid steeps slopes. Never use riding

attachments on slopes since there is an

increased riskthat they might roll over.

7. Never mow by pulling the mower back towards

you because you might slip.

8. Watch for pedestrian or vehicular traffic when

moving the mower while not in use (i.e.,

loading, unloading or transporting).

9. Never operate the mower with defective guards

or shields, or without the safety devices

securely mounted in place.

10. Never direct discharge of material toward

bystanders nor allow anyone near the mower

during operation.

11. Do not change the governor settings or over

speed the engine.

12. Always stop the engine when you leave the

mower, even for a moment.

13. To help reduce the fire hazard, keep the engine

and the area around the engine free of grass,

leaves or any other type of foreign material.

14. Beware of cutting edges. Always wear gloves

for safety when performing blade maintenance

activities. Beware on multiple blade units since

the rotation of one blade may cause the rotation

of the other blade.

15. Do not operate the mower with the grass chute

deflector in the raised position. Serious injury

could occur.

f

Before setting up your STANLEY mower,

disconnect the spark plug wires from the

spark plugs and ground them against the

engine to prevent inadvertent starting. This

step should be taken as a precaution

whenever you are working on this machine.

isconnect the safety system. Make sure that

he safety interlock system is fully operational

ANGER: Do not bypass, modify, alter or "1

ach time before mowing.

ure you are familiar with all of the

Before attempting to use your mower, make

components and have read the manual.

Need Help?

Parts,Service

andTechnicalAssistancecall:

Rev Mar2011

1-919-550-3259

www.mower911.com

STANLEY'_Finish Mower

2

Page 6

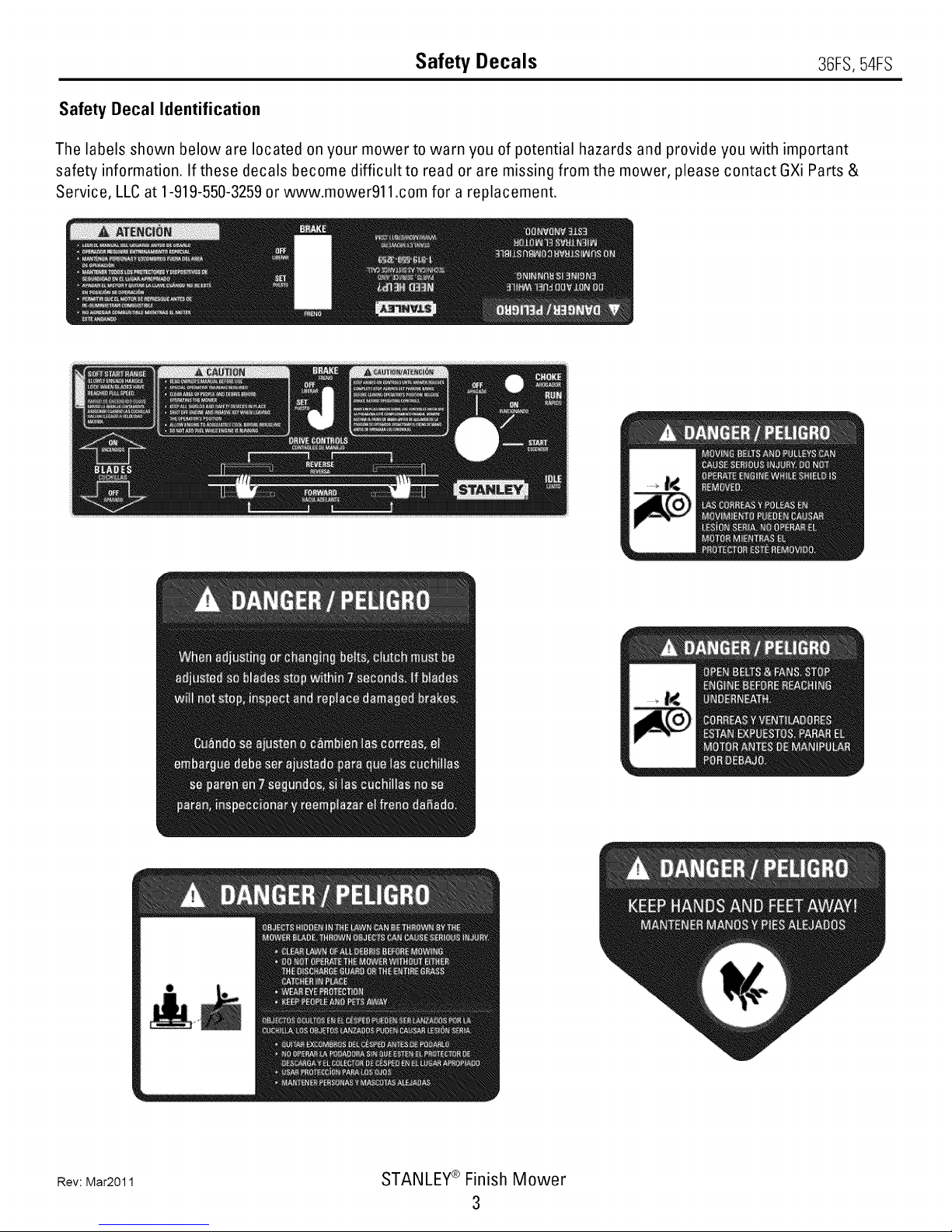

Safety Decals 36FS,54FS

Safety Decal Identification

The labels shown below are located on your mower to warn you of potential hazards and provide you with important

safety information. If these decals become difficultto read or are missing from the mower, please contact GXi Parts &

Service, LLC at 1-919-550-3259 or www.mower911.com for a replacement.

Rev: Mar2011

STANLEY®Finish Mower

3

Page 7

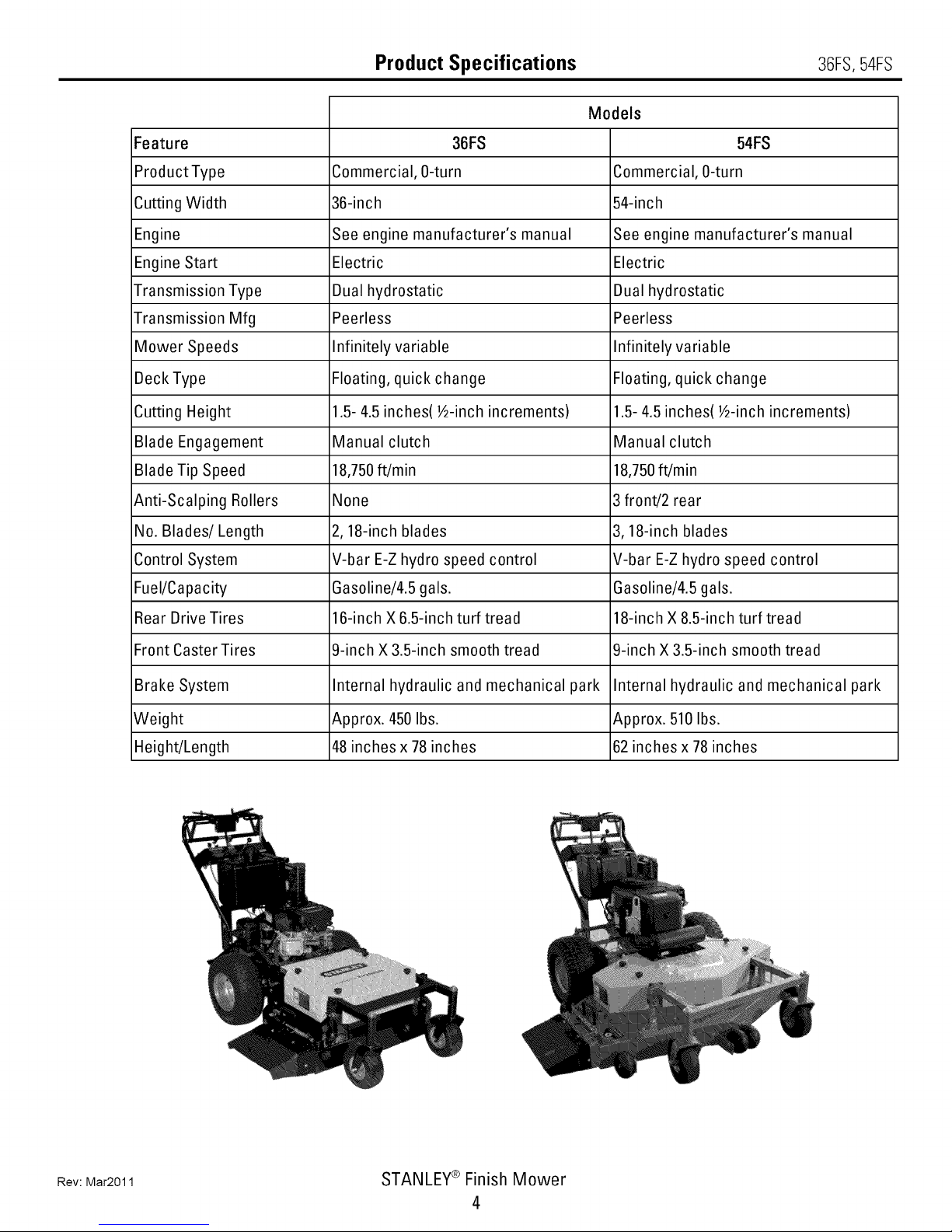

Product Specifications 36FS,54FS

Models

Feature 36FS 54FS

Product Type Commercial, 0-turn Commercial, 0-turn

Cutting Width 36-inch 54-inch

Engine See engine manufacturer's manual See engine manufacturer's manual

Engine Start Electric Electric

Transmission Type Dual hydrostatic Dual hydrostatic

Transmission Mfg Peerless Peerless

Mower Speeds nfinitely variable Infinitely variable

Deck Type Floating, quick change Floating, quick change

Cutting Height 1.5- 4.5inches( ½-inch increments) 1.5- 4.5 inches( ½-inch increments)

Blade Engagement Manual clutch Manual clutch

Blade Tip Speed 18,750ft/min 18,750ft/min

Anti-Scalping Rollers None 3 front/2 rear

No. Blades/Length 2, 18-inch blades 3, 18-inch blades

Control System V-bar E-Z hydro speed control V-bar E-Z hydro speed control

Fuel/Capacity Gasoline/4.5 gals. Gasoline/4.5 gals.

Rear Drive Tires 16-inch X 6.5-inch turf tread 18-inch X 8.5-inch turf tread

Front Caster Tires 9-inch X 3.5-inch smooth tread 9-inch X 3.5-inch smooth tread

Brake System Internal hydraulic and mechanical park Internal hydraulic and mechanical park

Weight Approx. 450 Ibs. Approx. 510 Ibs.

Height/Length 48 inches x 78 inches 62 inches x 78 inches

Rev: Mar2011

STANLEY®Finish Mower

4

Page 8

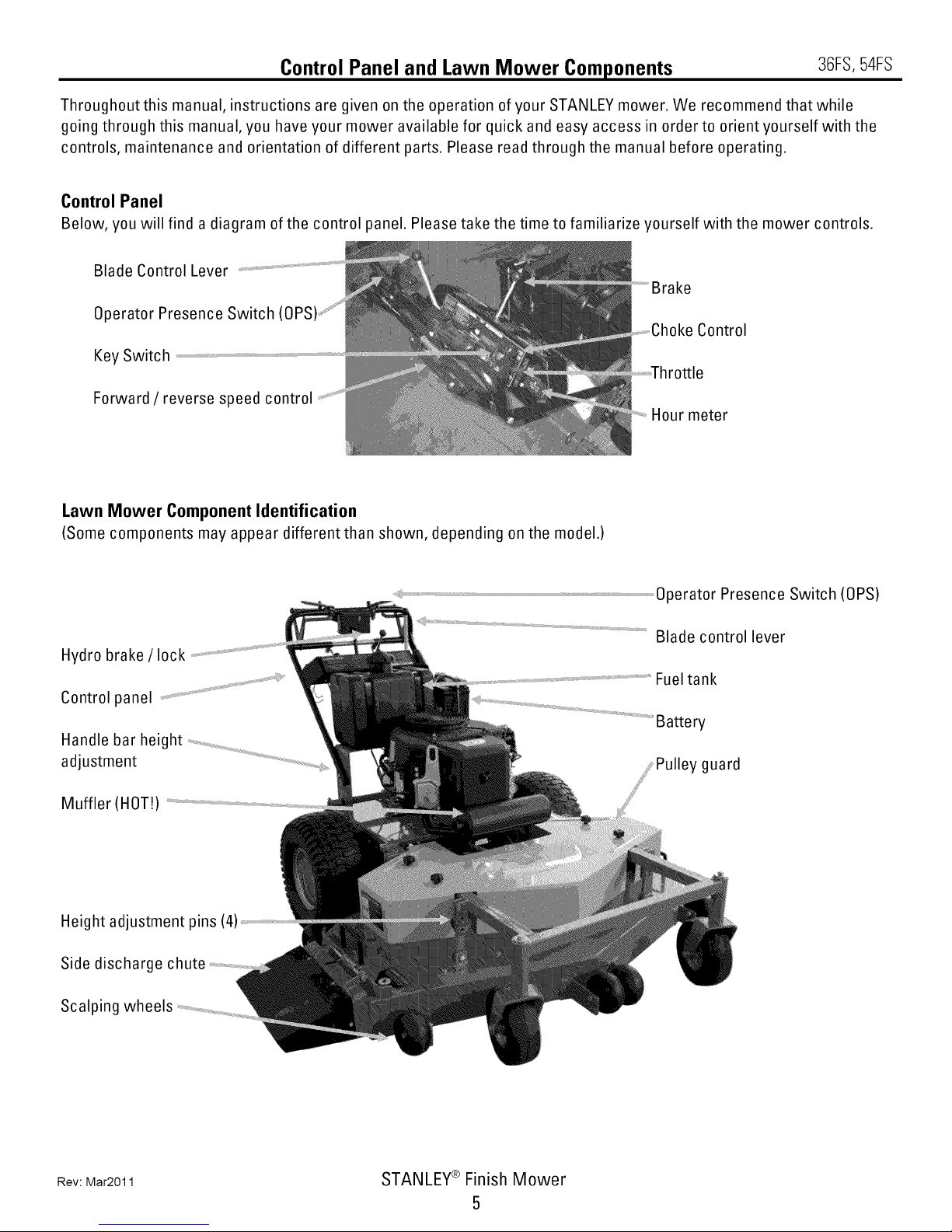

Control Panel and Lawn Mower Components 36FS,54FS

Throughout this manual, instructions are given on the operation of your STANLEY mower. We recommend that while

going through this manual, you have your mower available for quick and easy access in order to orient yourself with the

controls, maintenance and orientation of different parts. Please read through the manual before operating.

Control Panel

Below, youwill find a diagram ofthe control panel.Pleasetake the time to familiarize yourself with the mower controls.

Blade Control Lever

Operator Presence Switch

Control

Key Switch

Forward / reverse speed control

Lawn Mower ComponentIdentification

(Somecomponents mayappear different than shown, dependingon the model.)

Hydro brake /lock

Control panel

Handle bar height

adjustment

Muffler (HOT!)

Hour meter

Operator Presence Switch (0PS)

Blade control lever

Fuel tank

attery

,,,Pulley guard

Height adjustment pins (4)

Side discharge chute

Scalping wheels

Rev: Mar2011

STANLEY®Finish Mower

5

Page 9

AssemblyInstructions 36FS,54FS

Step 1: Front Wheel Assembly

Note: Some mowers may be shipped with the front

wheels pre-assembled.

A. Remove packaging materials surrounding the

front wheels and remove the bolt threaded into

the front wheel. Retain this bolt and washer for

future use.

B.

Unscrewthe fastener holding the bolt to the

steel shipping rack. Set the nut and bolt aside. It .....

will be re-used in the mower assembly process.

C.

Remove the mower from the steel shipping rack.

D.

Slide the front wheel pivot shaft through the

sleeve. If the fit is tight, apply some grease to

the pivot shaft.

E.

Secure the shaft in place with the bolt and

hardware that were provided with the wheel.

F.

Repeat steps A through E for the second front

wheel.

e.

Apply grease to the front wheel sleeve grease

fittings when complete.

Rev: Mar2011

STANLEY®Finish Mower

6

Page 10

Step 2: Mower Assembly Instructions

A. Attach handle bars using the upper hole

position setting. Using this hole position sets

the handle bars several inches lower. Use the

lower hole position raising the handle bar

location by several inches for comfort, if

necessary. These hole positions can also be

used for adjusting the handle bar location for

operators of different heights and arm lengths.

Select the height that is most comfortable for

you.

B.

Reconnect the four (4) connecting rods from

the control panel to the chassis pivot points as

shown in the picture to the right. The rod

connections are secured with an initial preset

for the upper hole position (lower handle bar

position). If the lower hole position (upper

handle bar position) is used, the rod

connections must be adjusted.

AssemblyInstructions 36FS,54FS

C.

Should the pivot ends on the connecting rods

be rotated during assembly, minor adjustments

may be required to achieve full travel on each

control handle. The control handles located

directly on top of the handle bars should

have full travel forward and stop

approximately 1/8-inch before the V-plate

strikes the handle bar. This positioning

provides full forward speed and the correct

restricted speed in reverse. Make minor

adjustments to the position of the threaded

connecting rod attachment to achieve this

control positioning.

V-plates

Rev: Mar2011

STANLEY®Finish Mower

7

Page 11

AssemblyInstructions 36FS,54FS

Step 3: Wire Harness Assembly and Connections

The pre-wired handle bar assembly has a total of four

(4) connections. Routethe wire harness as shown in

the top right photo and make the following

connections indentified by number in the other

photos:

1. Route the smaller, white, 2-pin connector through

a hole inthe chassis and connect it to the blade

activation safety switch 2-pin connector. :

2. Connect the larger, 5-pin connector to the mating

connector atthe rear of the engine.

3. Connect the black wire to a ground lug located

the back or side ofthe engine.

4. If equipped, attach the yellow wire to the bottom

of the starter motor solenoid on the engine, with

the positive (red) battery cable.

Attach the positive (red) and ground (black) battery

terminal wires to the battery to provide power to the

electric starter.

Note: Battery ground should beto the engine block.

Once all connections are made, use the provided

black wire-ties to strap the wire harness into place

permanently to the handle bars and chassis.

Step 4: Throttle and Choke Cable Connections

The throttle and choke are shown in the adjacent

photo. See instructions for connecting them to the

engine in the Engine Owner's Manual provided.

Rev: Mar2011

STANLEY®Finish Mower

8

Page 12

AssemblyInstructions 36FS,54FS

Step 5: Fuel tank connections

Locate the fuel tank on the fuel tank bracket with the

recessed area pointing toward the rear so any spills

away from the engine. Align the fuel valve in the center of the

clearance hole. Place the fuel tank straps into position,

wrapping them around the tank and the bracket.

Once the fuel tank and straps are in place, securely tighten

the straps using the bolts provided. Next, firmly attach

fuel line to the fuel valve nipple. Tighten all connections

ensure they are firm and secure so the fuel system is ti

attached.

DANGER I

DANGER GASOLINE IS HIGHLY FLAMMABLE AND

EXPLOSIVE. FUELLEAKS, A LOOSEFUELTANK, ORA LOOSE

FUELVALVE CAN LEAD TO SEVEREINJURY OR DEATH.

ENSUREALL CONNECTIONS ARE SECUREAND INSPECT

THOROUGHLY FORANY POTENTIAL LEAKS IN THE FUEL

SYSTEM. IF YOU FIND A LOOSECONNECTION 0RA LEAK,

MAKE AN IMMEDIATE REPAIR ORASK FORASSITANCE

FROM A PROFESSIONAL MECHANIC ORSERVICECENTER.

Step 6: Brake Set-up

1. Set the brake bar 3/4-1 inch from the tire.

Note: Verify tire

pressure. Do not exceed

the recommended

maximum.

.

With the brake pivot

leaning slightly

forward, install

washer and pin.

Rev: Mar2011

. Slide the brake handle to the bottom of the slot then

connectthe brake pivotto the brake handle.

.

Slide the brake handle to

the Set position to clamp

the brake bar againstthe

tire.

Note: If more or less brake

force is necessary or desired,

repeat the procedure, changing the gap in Step 1.

STANLEY®Finish Mower

9

Page 13

Operating Instructions 36FS,54FS

Starting the Engine

I DANGER I

DANGER: Exhaust contains poisonous carbon

monoxide, a colorless and odorless gas. Breathing

exhaust can cause loss of consciousness and may

lead to death. Do not operate the engine in a

confined space where dangerous carbon monoxide

fumes can collect.

NOTE: Be sure to add fresh unleaded gasoline and fill

the engine with manufacturers recommended motor oil

before starting your mower.

. Make sure the shut off

valve, located at the bottom

ofthetank, isinthe ON

position.

2. Make sure the brake is set.

3. Make sure the blade control lever is in the OFF

position.

4. Pull CHOKEif necessary.

5. Turn the key clockwise to the START position and

allow itto return to the ON position when the

engine starts.

6. When the engine starts to run and the key returns

to the ON position, push CHOKEoff.

Operating the Mower

1. Make sure the brake has been

moved to the OFFPosition.

2. Push down and hold the operator

presence control levers on the

handle bar with both hands.

3. The forward and reverse levers are

spring loaded to the

neutral position.

4. To drive the mower

forward, slide both

hands slightly back on

the handle bar and

gently squeeze the

forward levers toward

the handle bar. The forward speed is directly

proportional to the degree these forward levers are

moved toward the handle bar.

5. To turn the mower left, either release some

pressure onthe left lever (decreasing the speed of

the left wheel), increase the pressure of the right

lever (increasing the speed of the right wheel), or

both. The degree of the turn is directly proportional

to the amount of movement of these levers.

6. To turn the mower right, perform the lever

movements described in step 5 above with the

opposite levers.

7. To stop the forward motion of the mower, release

the forward levers. The spring loaded feature of the

hydrostatic drive returns the levers to the neutral

position and stops the mower.

8. To drive the mower backwards, slide both hands

slightly forward on the handle bar and gently press

the reverse levers toward the handle bar.

9. When in the neutral position, the hydraulic system

prevents the mower from moving easily. However,

on agrade, the mower can move very slowly (with

the engine off or running). Be sure to setthe

manual parking brake any time the mower is left

unattended or is being transported.

10. To physically move the mower when the engine is

NOT running, disengage the hydrostatic drive units.

Rev: Mar2011

STANLEY®Finish Mower

10

Page 14

Operating Instructions 36FS,54FS

Disengaging Hydrostatic Drive Units

Before physically moving the mower when the engine is

NOT running, the hydrostatic drive units need to be

disengaged into free-wheel mode.

To disengage these hydro units:

1. Remove the hydro tool stored under the hydro unit.

2. Use the hook on the hydro tool to pull the hydro

release pin back and out.

Repeat onthe other side.

It may be necessary to

bump the hydro carrier

forward for easier free-

wheeling.

CAUTION! Never bump, hit or

push the actual hydros.

To return to operation mode:

1. Slide the hydro tool

through the hydro

tensioner. Pull until the

pin sets. Repeat on the

other side. If the pin

partially sets, tap the pin.

2. Replace the hydro tool to storage under the hydro

unit.

Return to Neutral

If the mower creeps or will not stop as desired when

the handles are in neutral position, adjustments are

necessary.

CAUTION: Be sure the engine is OFF before you

open the hydro access panel.

1. Remove the bolts to

access hydro panel.

.

Using an 8mm

wrench, reach through

the bottom of the hydro

panel to the return-to-

neutral set pin bolts.

Loosen bolts on the

side that needs

adjusting.

.

Be sure the brake is inthe OFFposition. In a safe

operator position, start the engine.

4.

With the engine running, slowly move the handle

on the side needing adjustment until that side

comes to a complete stop. If the mower creeps

forward, pull handle in reverse, If the mower

creeps backward, pull the handle forward.

.

When the mower stops moving completely the

hydro is in the neutral position.

.

Turn off the engine.

7.

Slowly tighten the bolts without moving the plate.

8.

With the bolts tightened, move to a safe operator

position and start the engine.

.

If the creep has returned, repeat the process.

Multiple iterations may be required.

DANGER ]

Rev: Mar2011

DANGER! Make certain the engine comes to a

complete stop before putting you hands in the

access panel.

10. Reinstall hydro access panel.

STANLEY®Finish Mower

11

Page 15

Mowing

36FS,54FS

I

WARNING

WARNING! Thoroughly inspect the area where you

plan to use the mower. Look for items such as stones,

sticks, wire, and other foreign objects. If struck by the

mower, these and other objects may become

projectiles that could lead to serious injury or death.

Clear area of all debris.

Keep people and pets at a safe distance.

I

WARNING! Do not operate the mower with defective

guards, shields, or without the safety devices securely .....

in place.

1. When the mower is in position on the area to be

WARNING

i

mowed, hold the operator presence control down

with one hand.

.

With the other hand, SLOWLY push the blade

control lever forward to the ON position.

3. Slowly, and evenly, engage the forward and

reverse levers and begin mowing. To stop moving,

ease up on the levers or simply let go of the

controls.

4. To stop the blades, pull the blade control lever back

to the OFFposition.

Rev: Mar2011

STANLEY®Finish Mower

12

Page 16

Operating Instructions 36FS,54FS

Changing the Height of Cut

Your mower is equipped with an easily-adjustable

floating deck, which can be adjusted for cut heights of

1½ inches to 4½ inches in ½-inch increments.

Hew to Change the Cut Height

1. Hold one side ofthe deck bythe black handle.

2. Using your other hand, remove the retaining clip

and pin from the two brackets on that side of the

mower.

. Raise or lower the deck

until the hole in the height

adjust bar aligns with the

desired cut height hole on

the height adjust bracket.

.

Replace the height adjust

pins into the desired cut

height holes. All 4height

adjust pins must be setto

the same desired cut

height position.

.

Repeat the same adjust-

ment process with the

two height adjust pins /

brackets on the other side

of the mower deck.

Removing the Blades

Required tools: Two (2) 15/16" box end wrenches

I CAUTION

CAUTION! Beware of the cutting edges on the

blades, The rotation of one blade may cause

the other blade(s) to rotate, Always wear work

gloves when handling blades,

1. Park the mower on level ground and block the rear

wheels to prevent accidental rollback.

2. Raise the front end of the mower using a jack

stand.

3. Use one wrench to loosen nutAwhile holding bolt

B with the other wrench. (See adjacent photo.)

4. Slide the blade bolt down through the mower deck

and out.

5. To reinstall, insert the blade bolt through the

cutting deck.

.

Install the blade spacers that were removed, back

onto the blade bolt followed by the nut and tighten.

(See figure below.) IMPORTANT: The number of

spacers should always be the same on each blade

bolt. NEVERput the spacers belowthe blade.

Rev: Mar2011

STANLEY®Finish Mower

13

Page 17

Operating Instructions 36FS,54FS

Spindle Brake Inspection and Replacement

Blade and pulley brake inspections should be

performed every 50blade on and off cycles.

36-inch mowers have 1brake.

54-inch mowers have 2brakes.

1. Engage the blade handle (make certain the engine

cannot start) to pull the brakes off of the pulleys.

2. Remove the pulley guard from the deck.

3. Visually inspect the brake pads for wear. Make

certain that no metal has been touching the

pulleys.

4. The brake pad material should be approximately

1/8-inch thick. Replace the brakes if the material is

less than 1/16-inch thick.

Note: .....

Replacing both

brakes is

recommended

if replacement

of one brake is

required.

5. To replace the

brake, use a

pair of pliers to

remove the springs.

6. Remove the two mounting bolts and

disconnect the spring from the cable. _

7. Discard all ofthese parts. B0 NOT reuse springs.

New brakes are equipped with new springs for

proper braking.

8. Install the new brakes by reversing the procedure

in steps 5and 6.

9. Bisengagethe blade handle and inspect the brake

contact surface. All of the brake pad contacting

material should be contacting the bottom of the

pulley.

Before beginning service, park the mower on a level

surface, turn the blades off, turn the engine off, take

the key out of the switch, wait an adequate time to

make certain no blades are turning, and remove spark

plug wires from spark plugs.

Rev: Mar2011

Note: Springs may vary from those pictured based on

the particular application.

STANLEY®Finish Mower

14

Page 18

General Maintenance 36FS,54FS

The Importance of Maintenance

Regular maintenance is essential to ensure your

mower continues to deliver safe and high-quality

performance.

To help you properly care for your mower, the

following pages include a recommended maintenance

schedule, routine inspection procedures, and simple

maintenance procedures using basic hand tools.

Maintenance is the responsibility of the owner and

must be performed regularly. More difficult service

tasks or tasks that require special tools are best

handled by a recommended service technician or

other qualified mechanic.

The maintenance schedule described on page 15

applies to mowers used under normal operating

conditions. If you operate your mower under severe

conditions, such as sustained prolonged use or high-

temperature operations, or use it in unusually wet,

dusty or rocky conditions, consult your servicing

dealer for recommendations applicable to your

individual needs and use.

Be sure to use genuine STANLEY mower replacement

parts when servicing your mower to assure the best

quality, safety and performance for your mower.

Need Help? Parts, Service and Technical Assistance

Call: 1-919-550-3259 www.mower911.com

Fuel

I DANGER

DANGER: Gasoline is highly flammable and

explosive. Do not add fuel while the engine is

running or is hot. Keep open flames, sparks, and

heat away from the fuel and store fuel in containers

specifically designed for that purpose. Add fuel

outdoors only and if the fuel is spilled, do not start

the engine. Manually push the mower away from the

spill and wipe up immediately.

Refer to the Engine Owner's Manual for the type of fuel

to use.

A fuel shut off valve is located on

the bottom of the fuel tank. It is

recommended that the fuel be shut

off when transporting between job

sites and when storing the mower

for extended periods of time.

Engine Oil

CHECKENGINE 01L BEFOREEACH USE. Refer to the

Engine Owner's Manual for the type of oil to use, oil

change intervals, and the proper procedures to check

and change oil.

Blades

I CAUTION I

CAUTION! Before making any adjustments and/or

servicing to your STANLEY mower, make sure the

mower is on a flat and level surface, with the ignition

switch off, the key removed, and the blades

disengaged. Also, disconnect the spark plug wires

from the spark plugs and ground them against the

engine to prevent inadvertent starting.

If adjustment or maintenance is being performed after

operation of the mower, allowthe unit to cool since

heat build up could cause severe burns.

Tire Pressure

Incorrect tire pressure may cause the mower to pull to

one side and/or result in uneven cut. Always use

caution when filling the tires. NEVERexceed the

recommended tire pressure.

Air Filter

Refer to the Engine Owner's Manual for the

recommended maintenance.

Rev: Mar2011

I CAUTION I

CAUTION: Always wear work gloves when performing

blade maintenance and beware of the cutting edges.

Be sure the engine is off, the key removed, and the

spark plugwires are disconnected from the spark

plugs to prevent accidental contact.

Inspect blades on a daily basis for nicks, bends, and

excessive wear. If the blades are worn, cracked, bent,

or damaged, replace them before using the mower.

Choose genuine STANLEY mower replacement blades

to ensure quality and performance. (See page 13 for

blade removal instructions.)

When sharpening the blades, sharpen onlythe cutting

edges and try to maintain the original angle of the blade.

Do not make the cutting edge razor sharp. Remove the

same amount from each side of the blade so that

balance in maintained.

STANLEY®Finish Mower

15

Page 19

Item

Procedure

Maintenance Schedule 36FS,54FS

i i;i;; ;i;;;i;; ;i;; ;i;;;i;; ;i;; ;i;;;i;;;i;; ;i;;;i;;;i;; ;i;;;i;;;i

Break-in Every 8 hrs Every 40 hrs Every 100 hrs Every 200 hrs

first 5 hrs) (daily) (weekly) (Bi-weel<ly) (monthly)

Belts

Blades

Engine Air Filter

Engine Cooling Areas

Engine 0il

Engine 0il Filter

Engine Spark Plug

Inspect (adjust if

needed)

Inspect and Sharpen

Inspect (see Engine

Owner's Manual)

Clean (see Engine

Owner's Manual)

Check (see Engine

Owner's Manual)

Change (see Engine

Owner's Manual)

Change (see Engine

Owner's Manual)

Inspect (see Engine

Owner's Manual)

Fuel Filter

Fuel Line

Grease Fittings

Hardware

Mower Main Frame

Safety Interlock System

Tires

Spindle/Blade Brakes

Replace

Check

Refer to page 16

Check for proper

tightness

Remove debris from

under belt cover

Check Operations

and Switches

Check Air Pressure

X

Rev: Mar2011

STANLEY®Finish Mower

16

Page 20

Service Adjustments 36FS,54FS

I DANGER

DANGER: Before making any adjustments or servicing

your mower, make sure the mower is on level ground,

the blades are disengaged, the key is removed, the

engine is off and the spark plug wires are disconnected

from the spark plugs to prevent accidental contact. If

maintenance or adjustments are being performed after

operation of the mower, allow the unit to cool since

heat build up could cause severe burns.

Engine-to-Blade Belt Adjustment

1. Remove the deck cover and move the blade control

lever onthe control console to the ON position.

2. With approximately 10 pounds of pressure, push

the clutch pulleyto tighten the belt. The linkage

should stop approximately 1 inch before contacting

the stop bolt. Ifthe belt moves more than ½-inch,

move the blade control lever back to the OFF

position.

3. Loosen locking nut.

4. Rotate turnbuckle until desired tension is achieved

(approximately 1inch from stop bolt).

5. Tighten locking nut when finished.

6. Replace deck cover.

54-inch Blade-to-Blade Belt Adjustment

1. Remove the deck cover.

2. Ifthe belt moves more than ½-inch,

loosen the locking nutA and turn nut B

clockwise approximately 1-2 turns.

. Recheck the tension onthe blade-to-

blade belt. If it is still loose repeat step

Important: Do not over tighten the blade-to-blade belt. Over tension

can cause premature wear on belts and blade spindles.

4. Re-tighten locking nutB.

5. Replace deck cover.

Rev: Mar2011

STANLEY®Finish Mower

17

Page 21

Service Adjustments 36FS,54FS

Engine-to-Hydrostatic Drives Belt Adjustment

1. The engine-to-hydrostatic drives belt is located

underneath the rear deck. The belt should move

approximately 5/16-inch to 3/4-inch with three (3) to

five (5) pounds of pressure applied to the belt

midway between the transmission pulley and the

engine output shaft pulley.

When installing a new belt, the tension should be

higher than the running tension. It is not necessary

to keep the belt atthe greatest (smallest deflection)

tension during normal operation. Important: Do not

over-tighten the

belt.

2. Toadjustthe

belt, turn the nut

on the threaded

tension rod found

on the right, rear

corner of the

mower.

.

Do not over-

tighten. This could cause serious damage to the

hydraulic drive systems.

Safety System Adjustments

I WARNING I

WARNING: Do not bypass, modify, alter, or

disconnect the safety system. Make sure that the

safety interlock system is fully operational each time

before mowing. Failure to do so could present

danger to you and others around you.

There are generally three (3)ways to adjust the

sensitivity of a safety switch. Which is the most

appropriate way to adjust each switch depends upon

the application, location, and the nature of the problem

you are encountering.

Hydro System Adjustment

The hydrostatic drives are coupled to an actual drive

with a multi-v belt. Occasional retensioning of the belt

may be necessary. If performance decreases or hydro

control handles are activated and the wheels do not

turn, inspect the multi-v belt.

1. Remove the hydro

access panel.

.

Loosen jamb nut at

hydro tensioner.

3. Tighten nut to tighten belt. Belt tension should be

1/16-inch deflection under seven (7) of pressure.

4. Once tension is set, tighten the jamb nut and

reinstall the hydro access panel.

Method 1: Adjust location using the mounting

sc rews

1. Move the blade control lever to OFF.

2. Loosen screws (A) until safety switch (B) moves

freely.

3. Slide safety switch (B) firmly against blade bell

crank (C).

4. Tighten screws (A) and check that safety switch (B)

does not move.

Method 2: Adjust location using adjustment nuts on

switch body

1. Loosen locking nut(C) on the sensor shaft.

2. Adjust switch location by turning the nuts.

3. Tighten the locking nut when proper adjustment is

achieved.

Method 3: Relocate mounting holes

In rare cases where the components are misaligned,

the easiest means of adjusting the location is to

elongate the existing holes or add new holes to achieve

a tighter fit between the activation rod and the sensor.

Rev: Mar2011

STANLEY®Finish Mower

18

Page 22

Lubrication Points 36FS,54FS

To ensure proper lubrication of moving parts, GXi recommends that you lubricate the following components with a high-

quality, EP2 high-temperature-based grease or equivalent. Should the conditions of operation be more severe than

normal, the lubrication interval may need to be shortened. GTR/0PE grease is the recommended lubricant.

Lubrication Point Locations

36-inch mowers have 10lubrication points.

54-inch mowers have 12 lubrication points.

Lubricate after every 50 hours of usage

1. Front wheels (4 locations, 1 on each

wheel shaft and 1 on each wheel axle)

.

Spindles (2 locations on 36-inch and 3

locations on 54-inch mower decks): .......

Note: The lower spindle bearing

is sealed on the bottom and

open onthe top. The upper

spindle bearing is sealed on both

sides. Failure to frequently

replenish grease will cause

premature lower bearing failure.

Frequent application of grease to this bearing is critical

to achieving long spindle life in harsh duty

environments.

3. Mower deck idler pulley brackets

(1 location on36-inch and 2

locations on 52-inch models)

.

Blade activation rod supports (2

locations: one atthe

support under the fuel

tank bracket and one

adjacent to the engine.)

5. Hydraulic drive system

idler puller support (1

location)

Deck Interchange

Note: Before interchanging the optional attachment

deck, set the deck in the 1.5-inch cut height position and

be sure the hydro unit is disengaged (see page 11).

Remove the deck cover

by releasing the four (4)

knobs.

.

Disconnect the clutch tension rod connecting the

deck to the chassis.

. Remove the belt from

the engine pulley.

.

Using an 18 mm

wrench or socket,

remove the four (4)

deck retaining bolts.

5. Tilt handle bars forward and pull chassis from deck.

6. Reverse the steps to reconnect the optional

attachment deck.

Rev: Mar2011

STANLEY®Finish Mower

19

Page 23

Troubleshooting 36FS,54FS

Problem

Engine will not start

Possible Causes Solution

1. Keyinthe OFFposition

2. Insufficient fuel in the tank

3. Air bubble in the fuel line

4. Fuel valve in OFFposition

5. Choke not ON

6. Choke linkage out of adjustment

7. Low engine oil

8. Blade control in ON position

9. Loose spark plug wire

10. Fouled spark plug

11. Plugged or dirty air filter

12. Bad gasoline

13. Plugged or dirty fuel filter

14. Safety switches out of

alignment or loose

15. Dead battery (electric start

models)

1. Turn keyto ON position

2. Add gasoline

3. Prime engine or shake bubble out

4. Turn valve ON

5. Turn choke ON

6. Refer to Engine Owner's Manual

7. Add engine oil

8. Push lever to OFFposition

9. Tighten wire or connections

10. Clean or replace the plug

11. Clean or replace the air filter

12. Brain and replace the gasoline

13. Replace the fuel filter

14. Adjust or tighten switches (p. 17) - read warnings!

15. Recharge or replace battery

To test whether the blade activation safety switches

are a contributing factor to the engine not starting,

depress the Operator Presence Switch on the handle

bars while trying to start the engine. If engine starts, a

safety switch adjustment is required

Engine will not keep

running/quits

Engine stops when blades

are engaged

Blades do not turn 1. Broken belt

Belts squeal when blades 1. Incorrectbelttension

are engaged 2. Excessive belt wear

1. Water in the fuel

2. Loose safety switch

3. Fuel valve is OFF

4. Dirty fuel filter

5. Dirty air filter

6. Low engine oil

1. Loose safety switch

2. Belt tension too high

3. Blades jammed with foreign

material

2. Loose belt

3. Blade activation linkage out of

adjustment.

1. Drain and replace fuel

2. Adjust switch (p. 17)

3. Turn fuel valve ON

4. Replace fuel filter

5. Clean or replace air filter

6. Add engine oil

1. Adjust switch (p. 17)

2. Adjust belt(p. 16 and 17)

3. Remove foreign material

Note: Firmly pushing the blade control lever into the

OFFposition to ensure the safety switch is fully

engaged can sometimes resolve this problem.

1. Replace belt

2. Adjust belt(p. 16 and 17)

3. Adjust linkage(p. 13)

1. Adjust belt tension

2. Replace belt

Belts slip when blades are 1. Incorrect belt tension

engaged 2. Excessive belt wear

Rev: Mar2011

1. Adjust belt tension

2. Replace belt

STANLEY®Finish Mower

20

Page 24

Troubleshooting 36FS, 54FS

Problem Possible Causes Solution

Mower will not move 1. Brake ON 1. Release brake on control panel

forward or reverse 2. Bypass levers pulled out 2. Ensure bypass pins are retracted

Cannot move mower 1. Bypass not engaged 1. Pull left and right bypass pins and set them in slots

when the engine is off in the chassis (p. 11)

Engine is overheating 1. Dirt in the fuel line 1. Replace fuel filter and flush tank

2. Dirty air filter 2. Clean or replace the air filter

3. Low engine oil 3. Add engine oil

4. Fouled spark plug 4. Replace spark plug

5. Misuse of the mower 5. Mow slower, wait for grass to dry out

6. Dull blades 6. Sharpen cutting blades

7. Spindle bearing failure 7. Take in for service

Grass not cut smoothly or

cleanly

Mower always pulls to

one side

1. Dull blades

2. Mowing too fast for conditions

3. Grass is wet or bent over

4. Blade is bent

5. Tire pressure not equal

6. Beck is set at uneven heights

7. Blades are set upside down

8. Excessive grass and debris

build up underneath the deck

1. Controls out of adjustment

2. Transmission failure

1. Sharpen blades

2. Slow down while cutting

3. Let grass dry to stand up

4. Replace blade

5. Add air pressure to low tires

6. Set deck at equal heights

7. Take blades off and install correctly

8. Clean out debris

1. Adjust controls (p. 11)

2. Take in for service

Rev: Mar2011

STANLEY®Finish Mower

21

Page 25

LimitedWarranty & Service 36FS,54FS

Length of Warranty: *(from the date of original retail purchase)

Products Covered by this

Warranty

Engine

Transmission

Mower frame

Belts, Tires, Battery

Attachments

Residential

Manufacturer's warranty

Manufacturer's warranty

Lifetime (original owner only)

90 days

1 yr limited

*LENGTHOFWARRANTY:Batteries supplied with applicable products as standard, original equipmentare covered bythis warranty

for a period of 90days from the date of original retail product purchase. Consumable parts such as oil, spark plugs,filters, and

blades are not covered bythis warranty.

To QualifyforthisWarranty

The product must be purchased in the United States from a dealer authorized byGXi OutdoorPower, LLCto sell those products. This

warranty applies to first retail purchaser/owner during the applicable warranty time period. SAVEYOURPROOFOFPURCHASE

RECEIPT.

What GXiOutdoor Power Will Repair or Replace under Warranty

GXiwill repair or replace, at its option, any partthat is proven to be defective in material or workmanship under normal use during

the applicable warranty time periodsubject to the exclusions stated herein.This warranty is void if the owner fails to follow the

prescribed maintenance and operating procedures described in this manual.This specifically refers to ensuring routine lubrications

and oil changes are made,that fuel stabilizer is used when the product is stored andthat the product is not overloaded.

Commercial Rental

Manufacturer's warranty Manufacturer's warranty

Manufacturer's warranty Manufacturer's warranty

Lifetime(original owner only) 90 days

90days 90 days

1yr limited 30day limited

GXihasthe right to recover warranty administration costs from the owner ifthe root cause of the malfunction isfound to be other

than defective material or workmanship. Inparticular, this warranty doesnot cover: contaminants in the fuel or oil; damage caused

by notfollowing the prescribed warnings and operating practices; failure to follow proper maintenance and storage procedures; and

physical damage dueto misuse,shipping, handling or storage.

Warranty repairs will be made without charge for parts and labor for the first year.

Anything replaced under warranty becomesthe property of GXi. Parts replaced underwarranty will beconsidered as part of the

original product and any warranty onthose parts will expire coincident with the original product warranty.

To Obtain Warranty Service

You must take the STANLEYproduct, accessory, replacement part,apparel or the power equipment onwhich the accessory or

replacement part is installed, and proof of purchase, at your expense,to any STANLEYservice location in the United States,who is

authorized to service that product, during the service location's normal businesshours. If you are unableto obtain warranty service,

or are dissatisfied with the warranty service you receive,take the following steps: First,contact the manager ofthe service center

involved; normally this will resolve the problem.However, if you should require further assistance,write or call the GXiParts &

Service, LLC1-919-550-3259.

Exclusions

This warranty does not cover: normalwear, contaminants inthe fuel or oil; damageas aresult of use in an application for which the

product was not designed; damage caused by incorporation or useof unsuitable attachments or parts, unauthorizedalteration, or

other misuse andneglector; damagecaused byfailure to followthe prescribed warnings, operating practices, proper maintenance

and storage procedures; parts affected or damaged byaccident and/or collision; damagedue to shipping, handling, storage or any

causes other than defects inmaterial or workmanship ofthe product.

Disclaimer of Consequential Damage and Limitationof Implied Warranties

GXidisclaims any responsibility for loss of time or useof the product,transportation, commercial loss, or anyother incidental or

consequential damage.Any implied warranties arelimited tothe duration ofthis written limited warranty.

THISWARRANTYIS VOIDIFTHE MANUFACTURINGDATEANDTHESERIALNUMBERONTHEEQUIPMENTHASBEENREMOVED

ORTHEEQUIPMENTHASBEENMODIFIED.

Rev: Mar2011

MN_ _M_t_ GREAT

......................................... J

STANLEY®Finish Mower

22

Loading...

Loading...