Page 1

Program Controller SE-707

© 2018 by STANGE Elektronik GmbH

Subject to technical modifica tions

1

Operating Manual

Program Controller

SE-707

Documentation: October 2018

Page 2

Program Controller SE-707

© 2018 by STANGE Elektronik GmbH

2 Subject to technic al modifications

Table of Contents

1 GENERAL ........................................................................................................................................................................... 5

1.1 INFORMATION ABOUT THE OPERATING MANUAL ...................................................................................................................... 5

1.2 SYMBOL DECLARATION ...................................................................................................................................................... 5

1.3 EU-CONFORMITY ............................................................................................................................................................ 6

1.4 LIABILITY AND WARRANTY .................................................................................................................................................. 7

1.5 COPYRIGHT PROTECTION .................................................................................................................................................... 7

2 SAFETY .............................................................................................................................................................................. 8

2.1 INTENDED USE ................................................................................................................................................................. 8

2.2 ELECTROMAGNETIC COMPATIBILITY (EMC) ............................................................................................................................ 8

2.3 EMC SAFEGUARDING ........................................................................................................................................................ 8

2.4 GROUNDING OF INACTIVE METAL PARTS ................................................................................................................................. 9

2.5 PE CONNECTION .............................................................................................................................................................. 9

2.6 UNEARTHED OPERATION .................................................................................................................................................... 9

2.7 RESPON SIBILITY OF THE OPERATOR ....................................................................................................................................... 9

2.8 OPERATING PERSONAL .....................................................................................................................................................10

2.9 MAINTENANCE ...............................................................................................................................................................10

2.10 CLEANING THE FR ONT PANEL ............................................................................................................................................10

2.11 REPAIR S......................................................................................................................................................................10

2.12 MANUFACTURER-ADDRESS .............................................................................................................................................11

2.13 TECHNIC AL SUPPORT .....................................................................................................................................................11

2.14 DISPOSAL ....................................................................................................................................................................11

3 TRANSPORT, PACKING AND STORAGE ............................................................................................................................12

3.1 TRANSPORT INSPECTION ...................................................................................................................................................12

3.2 PACKING .......................................................................................................................................................................12

3.3 STORAGE ......................................................................................................................................................................12

4 TECHNICAL DATA .............................................................................................................................................................13

4.1 HARDWARE CHARACTERISTICS ............................................................................................................................................13

4.2 SOFTWARE SPECIFICATIONS ...............................................................................................................................................15

4.3 FUNCTION BASIC DATA .....................................................................................................................................................16

5 INSTALLATION OF THE INDUSTRIAL CONTROL .................................................................................................................18

5.1 GUIDEL INES FOR THE INSTALLATION OF THE SE-707 ................................................................................................................18

5.2 GENERAL MOUNTING INSTRUCTIONS ....................................................................................................................................18

5.3 INSTALLATION DIMENSION .................................................................................................................................................19

5.4 INSTALLATION DEPTH .......................................................................................................................................................20

5.5 FRONT PANEL INSTALLATION ..............................................................................................................................................21

6 START-UP .........................................................................................................................................................................22

6.1 GUIDEL INES FOR GROUNDING AND WIRING ...........................................................................................................................22

6.2 OVERVIEW OF THE CONNECTIONS ........................................................................................................................................23

6.2.1 Function of the LED's at the back of the device .....................................................................................................24

6.2.2 Turn-switch for PLC operating mode selection......................................................................................................25

6.2.3 System Watchdog ...............................................................................................................................................25

6.2.3.1 General ............................................................................................................................................................25

6.2.3.2 Mode of operation ...........................................................................................................................................25

6.2.3.3 System logger entry ..........................................................................................................................................26

6.2.4 The alarm relay ...................................................................................................................................................26

6.2.4.1 General ............................................................................................................................................................26

6.2.4.2 Mode of operation ...........................................................................................................................................26

6.3 MOUNTING / DISMOUNTING THE SD CARD ............................................................................................................................27

6.4 CONNECTING THE POWER SUPPLY........................................................................................................................................28

6.5 PACKAGING THE CAN CABLE WITH SHIELD CONNECTION ...........................................................................................................29

6.6 CONNECTING THE PROGRAMMING INTERFACE RJ45 ................................................................................................................30

Page 3

Program Controller SE-707

© 2018 by STANGE Elektronik GmbH

Subject to technical modifica tions

3

6.7 CONNECTION CAN ......................................................................................................................................................... 31

6.8 CONNECTION OF THE ALARM SOCKET ................................................................................................................................... 33

6.9 CONNECTION OF THE PROFIBUS-DP-SLAVE INTERFACE (OPTION) ............................................................................................ 33

6.10 CONNECTION OF THE PROFINET IO DEVICE (SLAVE) INTERFACE (OPTION) ................................................................................ 37

6.11 CONNECTION OF A PC WITH THE SE-707 ........................................................................................................................... 39

6.11.1 Cabling ............................................................................................................................................................. 39

6.12 SETTINGS OF THE PC FOR ETHERNET COMMUNICATION .......................................................................................................... 39

6.12.1 Separation of automation network and company/office network ...................................................................... 39

6.12.2 Length of the network line (segment length) ..................................................................................................... 40

6.12.3 Requirements ................................................................................................................................................... 40

6.12.4 Settings Windows 7/10 ..................................................................................................................................... 40

6.12.5 Settings of the IP-address in the device ............................................................................................................. 41

7 OPERATION ..................................................................................................................................................................... 42

7.1 START-UP B EHAVIOUR ..................................................................................................................................................... 42

7.2 SHUTDO WN BEHAVIOUR .................................................................................................................................................. 42

7.3 START-UP B EHAVIOUR / STARTING ...................................................................................................................................... 43

8 OPERATING DIALOGUE OF THE CONTROL SOFTWARE ..................................................................................................... 44

8.1 OPERATION .................................................................................................................................................................. 44

8.1.1 Start screen ........................................................................................................................................................ 45

8.1.2 Programmer ....................................................................................................................................................... 45

8.1.3 Manual operation for set value and tracks (”Manual”) ........................................................................................ 46

8.1.4 Program curve .................................................................................................................................................... 46

8.1.5 Program jump .................................................................................................................................................... 47

8.1.6 Automatic Program Start .................................................................................................................................... 47

8.1.7 Program change in actual segment ..................................................................................................................... 48

8.1.8 Editing of the operating program ........................................................................................................................ 48

8.1.9 Controller ........................................................................................................................................................... 49

8.1.10 Control Zone Detail View .................................................................................................................................. 49

8.1.11 PID Parameter .................................................................................................................................................. 50

8.1.12 Control zone tolerance values / limit values....................................................................................................... 51

8.1.13 Plant overview .................................................................................................................................................. 51

8.1.14 Alarms .............................................................................................................................................................. 52

8.1.15 Alarm history .................................................................................................................................................... 53

8.1.16 Process data actual values ................................................................................................................................ 53

8.1.17 Process data limit values................................................................................................................................... 54

8.1.18 Process data tolerance values ........................................................................................................................... 54

8.1.19 Process data formula value ............................................................................................................................... 54

8.1.20 Operating-Hours Meter (Option) ....................................................................................................................... 55

8.1.21 Data Logger (Option) ........................................................................................................................................ 55

8.1.22 Logger Graph (Option) ...................................................................................................................................... 56

8.1.23 Logger Header (Option) .................................................................................................................................... 57

8.1.24 Program start with data logger (Option) ........................................................................................................... 57

8.1.25 Configuration ................................................................................................................................................... 57

8.1.26 Login ................................................................................................................................................................ 58

8.1.27 Login Level Authorisation .................................................................................................................................. 59

8.2 PROGRAM .................................................................................................................................................................... 61

8.2.1 Program overview .............................................................................................................................................. 61

8.2.2 Creating programs.............................................................................................................................................. 61

8.2.3 Programming segments...................................................................................................................................... 62

8.2.4 Copy programs ................................................................................................................................................... 62

8.2.5 Delete programs ................................................................................................................................................. 63

8.2.6 Load programs to the operating mode ................................................................................................................ 63

8.2.7 Sort programs .................................................................................................................................................... 63

8.2.8 Store and load program list ................................................................................................................................ 64

8.2.9 Loops ................................................................................................................................................................. 65

8.3 CONFIGURATION ............................................................................................................................................................ 66

8.3.1 Standard Settings ............................................................................................................................................... 67

Page 4

Program Controller SE-707

© 2018 by STANGE Elektronik GmbH

4 Subject to technic al modifications

8.3.1.1 Station Name.................................................................................................................................................................. 67

8.3.1.2 Display screen ................................................................................................................................................................ 67

8.3.1.3 Host Interface ................................................................................................................................................................. 68

8.3.1.4 Siemens Modbus Connection (Option) ............................................................................................................................ 69

8.3.1.5 Programmer ................................................................................................................................................................... 69

8.3.1.6 User interface ................................................................................................................................................................. 70

8.3.2 Hardware ............................................................................................................................................................71

8.3.2.1 CAN Inputs/Outputs ....................................................................................................................................................... 71

8.3.2.2 Hardware Options .......................................................................................................................................................... 72

8.3.2.2.1 Profinet IO Device Interface ......................................................................................................................................... 73

8.3.2.2.2 Profibus-DP Slave interface .......................................................................................................................................... 76

8.3.2.2.3 PROFIBUS Function Description .................................................................................................................................... 78

8.3.3 Functions ............................................................................................................................................................86

8.3.3.1 Digital and analogue inputs/outputs ............................................................................................................................... 86

8.3.3.2 Actual values .................................................................................................................................................................. 87

8.3.3.3 Analogue outputs ........................................................................................................................................................... 94

8.3.3.4 Free linearization curves ................................................................................................................................................. 96

8.3.3.5 Set values ....................................................................................................................................................................... 98

8.3.3.6 Control zones ............................................................................................................................................................... 101

8.3.3.7 Tolerances .................................................................................................................................................................... 122

8.3.3.8 Limit values .................................................................................................................................................................. 125

8.3.3.9 Alarm monitoring ......................................................................................................................................................... 128

8.3.3.10 Formula / constants .................................................................................................................................................... 132

8.3.3.11 PLC Statement List ...................................................................................................................................................... 134

8.3.3.12 Analogue Variables ..................................................................................................................................................... 140

8.3.3.13 Digital tracks ............................................................................................................................................................... 142

8.3.3.14 Process steps .............................................................................................................................................................. 143

8.3.3.15 Analogue multiplexers ................................................................................................................................................ 144

8.3.3.16 BCD/BIN Decoders ...................................................................................................................................................... 145

8.3.4 Special Functions ............................................................................................................................................... 148

8.3.4.1 C-Level (Option) ............................................................................................................................................................ 148

8.3.4.2 Humidity Calculation..................................................................................................................................................... 152

8.3.4.3 Data Logger (Option) .................................................................................................................................................... 153

8.3.4.4 Operating-Hours Meter (Option) ................................................................................................................................... 163

8.3.5 User Administration .......................................................................................................................................... 164

8.3.5.1 User ............................................................................................................................................................................. 164

8.3.5.2 User Groups ................................................................................................................................................................. 165

8.3.5.3 Automatic user login ..................................................................................................................................................... 167

8.3.5.4 User Profile Modbus ..................................................................................................................................................... 167

8.3.6 Settings ............................................................................................................................................................. 168

8.3.6.1 Date / Time .................................................................................................................................................................. 168

8.3.6.2 Language dialogue ........................................................................................................................................................ 169

8.3.6.3 Program Graph Pen Settings ......................................................................................................................................... 169

8.3.7 Administrate configuration ................................................................................................................................ 170

8.3.7.1 Load configuration ........................................................................................................................................................ 170

8.3.7.2 Save configuration ........................................................................................................................................................ 170

8.3.7.3 Import configuration from SE-5xx or SE-4xx device ........................................................................................................ 171

8.3.7.4 Import licence file ......................................................................................................................................................... 171

8.3.7.5 Reset configuration/programs (general reset) ............................................................................................................... 171

8.3.8 Update Firmware and/or license update ............................................................................................................ 172

8.3.8.1 Requirements ............................................................................................................................................................... 172

8.3.8.2 Execution of the update process ................................................................................................................................... 172

8.3.9 Hardware test ................................................................................................................................................... 173

8.3.9.1 Device information ....................................................................................................................................................... 173

8.3.9.2 Software information.................................................................................................................................................... 173

8.3.9.3 Licence information ...................................................................................................................................................... 174

8.3.9.4 Device health................................................................................................................................................................ 174

8.3.9.5 Digital In-/Outputs ........................................................................................................................................................ 174

8.3.9.6 Save diagnosis data....................................................................................................................................................... 174

INDEX ................................................................................................................................................................................. 175

Page 5

Program Controller SE-707

© 2018 by STANGE Elektronik GmbH

Subject to technical modifica tions

5

1 General

1.1 Information about the operating manual

This operating manual shall put the user into the position to install, put into operation, administrate and service the device

properly.

Read and understand the operating manual completely, in particular the chapter security, before the beginning of the

installation work! Comply with the operating manual, in particular the safety references as well as the regulations for the

prevention of industrial accidents, valid for the area of application, absolutely.

Always pass the device together with the operating manual to a third party.

1.2 Symbol declaration

Important safety-relevant references are characterized by symbols in this manual. Comply with the references absolutely, in

order to avoid accidents, damages to persons and physical damage.

WARNING!

This symbol marks dangers which result in impairment of health, injuries, lasting physical injury or to

death, as well as substantial property damage.

Keep the displayed references to the operational safety absolute exactly and behave in these cases

particular carefully.

WARNING! Danger by electric current!

This symbol makes attentive to dangerous situations by electric current. In case of non-observance of

the safety references the danger of heavy injuries or death exists like substantial damage to property.

The executed work may be implemented only by an instructed electrical specialist.

ATTENTION ! Consider ESD electronic protective measures!

Electrostatic unloading may destroy electronic components.

ATTENTION !

This symbol marks references, whose non-observance can result in damages, malfunctioning and/or loss

of the device.

Note

This symbol emphasizes hints and information, which are to be considered for an efficient and trouble

free operation of the device.

Page 6

Program Controller SE-707

© 2018 by STANGE Elektronik GmbH

6 Subject to technic al modifications

1.3 EU-Conformity

We, the company

Gutenbergstr. 3

D-51645 Gummersbach

declare under sole responsibility, that the product

Name: Program Controller

Type: SE-707

fulfils the requirements of the standard

EN 61000-6-4:2007+A1:2011 Emission

EN 61000-6-2:2005 Interference resistance

and therefore corresponds to the regulations of the EU-Directive 2014/30/EU (electromagnetic compatibility).

Gummersbach, 2018-06-25 P. Jaspert (Managing Director)

_________________________________ _________________________________

Place and Date of Issue Name, authorized Signature

The device was tested in a typical situation.

If modifications are made without our agreement this declaration loses its validity.

The device does not fall into the range of application of the low-voltage directive EEC 73/23/EEC (electrical equipment for the

use within certain voltage limits (low-voltage directive); changed by 93/68/EEC)

(This declaration follows closely to EN 45 014)

Page 7

Program Controller SE-707

© 2018 by STANGE Elektronik GmbH

Subject to technical modifica tions

7

1.4 Liability and warranty

All specifications and notes in this manual were arranged with consideration of the valid regulations, the current engineering

level of development as well as our realizations and experiences of many years.

The translation of the manual was likewise provided after best knowledge. We cannot take over a liability for translation

errors however. Considerably applies the provided German version of this manual.

The actual scope of supply can deviate with special equipment, the demands of additional order options or due to newest

technical changes possibly from the explanations and graphic representations described here. Please contact the

manufacturer if you have questions.

Note!

This manual is to be perused before the beginning of all work on and with the device, in particular before the

start-up! For damage and troubles, which result from the non-observance of the manual, the manufacturer

does not take over liability.

The manual is to be put aside and directly accessible with the device for all persons, who work on or with the device. The

assignment of the manual to third party is not permitted and obligates if necessary to compensation. Further requirements

reserved.

We reserve technical changes at the device in the context of the improvement of the performance characteristics and the

advancement.

1.5 Copyright protection

The manual is to be kept in confidence. It is exclusively intended for persons employed at and with the device. The

assignment of the manual to third party is inadmissible without written agreement of the manufacturer. With requirement

please contact the manufacturer.

Note !

The content-wise specifications, texts, designs, pictures and other representations are copyrighted and are

subject to further industrial property rights. Each abusive utilization is liable to prosecution.

Page 8

Program Controller SE-707

© 2018 by STANGE Elektronik GmbH

8 Subject to technic al modifications

2 Safety

This section gives an overview of all important safety aspects for an optimal protection of the personnel as well as safe and

trouble free operation of the device.

Additionally the individual chapters contain concrete safety references, marked by symbols, for the prevention of direct

dangers. Beyond those pictograms, signboards and markings are present at the device, which have to be kept in constantly

readable condition.

2.1 Intended use

The industrial control exclusively serves for the control of machines and plants, which are build according to the applicable

regulations and equipped with all necessary safety installations.

The operational reliability is ensured only by the intended use of the device.

ATTENTION !

Each use of the device going beyond the intended use and/or different use is forbidden and is

considered as not intended. In particular the use of the device for the control or as replacement of

safeguarding equipment in the sense of the machine directive (98137 EG) is not permitted.

Requirements of any kind against the manufacturer and/or its authorized persons because of damage

on the basis of not intended use of the device are excluded.

For all damages on the basis of not intended use the operator is responsible alone.

Among the intended use also the correct adherence of the operating ranges as well as the installation-,

operation- and cleaning instructions.

2.2 Electromagnetic compatibility (EMC)

Before installing an EMC planning is necessary, even though devices fulfil the EMC requirements. Disturbance sources

(galvanic, inductive and capacitive coupling) as well as radiation coupling come to consideration thereby.

2.3 EMC safeguarding

The following requirements should be kept, in order to safeguard EMC:

• Inactive metal parts must have a correct and extensive grounding.

• Wires and devices have a correct shielding.

• Wiring and line run must be executed correctly.

• The electric equipment is grounded and has a uniform reference potential.

• Special applications need specific EMC measures.

Page 9

Program Controller SE-707

© 2018 by STANGE Elektronik GmbH

Subject to technical modifica tions

9

2.4 Grounding of inactive metal parts

The influence of coupled interferences can be reduced, if all inactive metal parts (switch cabinet, switch cabinet door,

mounting plates, top hat rails etc.) are connected extensive and low-impedance with each other. The uniform reference

potential area results for control elements for this reason.

• In the range of bolted connections the insulating layer must be removed in case of painted eloxadized or isolated

metal parts. It has to be cared for corrosion protection of junctions.

• Connection of all free moving groundable components (cabinet doors, separate mounting plates, etc.) by using short

bonding straps to large surface areas.

• No use of aluminium parts if possible, because the oxidation of aluminium is inappropriate for grounding.

2.5 PE connection

Connect ground and PE connection (protective earth) centrally.

2.6 Unearthed operation

The relevant safety regulations and standards must receive attention in case of unearthed operation.

2.7 Responsibility of the operator

The device may be operated only in technically perfect and safe condition.

Apart from the operational safety notes in this manual are to be considered and kept the generally valid safety regulations

and regulations for the prevention of industrial accidents for the area of application of the device as well as the valid

environmental regulations.

The operator and the personnel authorized by him are responsible for the trouble free operation of the device as well as for

clear definitions over the cognizance during installation, operation, maintenance and cleaning.

The specifications of the manual must be complied completely and without restrictions!

The operator must guarantee beyond that, that

• all further instructions and safety instructions are summarized in an operating instruction in accordance with work

appliance use regulation, which result from the hazard judgement of the employments at the device.

• this manual is integrated into the plant documentation.

• maintenance and inspection intervals are to be kept.

• device, operating equipment and waste products resulting with the manufacturing are disposed environmentally

compatible and in agreement with legal regulations.

Page 10

Program Controller SE-707

© 2018 by STANGE Elektronik GmbH

10 Subject to technic al modifications

2.8 Operating personal

The industrial control may be served only by authorized technical personnel. The service personnel must have been

instructed particularly about arising dangers.

As technical personnel is considered, who can judge the transferred work and recognize possible dangers due to his technical

training, knowledge and experiences as well as knowledge of the relevant regulations.

ATTENTION !

This device may only be used for the applications described in the technical descriptions, and only in connection

with devices or components from other manufacturers which have been approved or recommended by STANGE.

This product can only function correctly and safely if it is transported, stored, set up, and installed correctly, and

operated and maintained as recommended.

2.9 Maintenance

Battery

The storage battery serves for the backup of the real-time clock and the remanent PLC data. With complete charge, the

storage battery has a holding time of approx. 8-10 weeks. In order to avoid data loss, it should be paid attention to the fact

that the device is switched off not longer than this time. With completely empty storage battery a time of 48 hours operation

is needed, until the storage battery has again its full capacity.

Transport

For the transport of the device is to be used excluding the original packaging.

2.10 Cleaning the front panel

The glass of the front panel is treated on the surface in order to permanently minimise light reflections and the adhesion of

finger prints.

A soft, dry cloth is adequate and provides good service for cleaning the front panel.

2.11 Repairs

Repairs at SE-707 may only be made by STANGE Elektronik GmbH. In this case please contact the technical support of

STANGE Elektronik GmbH.

For making changes at the device not described in this document, no liability is accepted.

Page 11

Program Controller SE-707

© 2018 by STANGE Elektronik GmbH

Subject to technical modifica tions

11

2.12 Manufacturer-Address

Manufacturer:

STANGE Elektronik GmbH

Gutenbergstr. 3

51645 Gummersbach

Germany

Fon: +49 (0)2261 - 95790

Fax: +49 (0)2261 - 55212

E-Mail: info@stange-elektronik.de

Homepage: www.stange-elektronik.com

2.13 Technical Support

Support:

Fon: +49 (0)2261 – 957939

Fax: +49 (0)2261 - 55212

E-mail: support@stange-elektronik.de

2.14 Disposal

STANGE units can be recycled. Send back the device delivered free to STANE Elektronik GmbH for disposal. Or contact a

certified electronic waste disposal centre for environmentally acceptable recycling and disposal of your old devices.

Particularly to be considered is:

• The device contains a lithium storage battery.

• The device contains LED background lighting.

Materials:

Housing: Stainless steel

Front frame: Aluminium

Board: 1. quality

Front glass: Float glass ESG (tempered safety glass)

Page 12

Program Controller SE-707

© 2018 by STANGE Elektronik GmbH

12 Subject to technic al modifications

3 Transport, Packing and Storage

3.1 Transport inspection

Examine supply with receipt immediately for completeness and transport damages.

Do not accept delivery or only under reservation with outwardly recognizable transport damage. Note the damage on

transportation document/delivery note of the carrier. Start reclamation.

Reclaim hidden damages immediately after recognizing (at the latest within 8 days (date of receipt)) in writing, because

claims for damages can be made valid only within the valid complaint periods.

3.2 Packing

For the transport of the device is to be used excluding the original packaging.

3.3 Storage

Keep packages up to the assembly locked and considering of the environmental conditions for storage.

Page 13

Program Controller SE-707

© 2018 by STANGE Elektronik GmbH

Subject to technical modifica tions

13

4 Technical data

4.1 Hardware characteristics

Display

Technology

TFT LCD 30.7 cm (12.1”)

Resolution

1280 x 800 pixels (WXGA)

Number of colours

16 Mil. colours

Backlight

LED Front

ESG glass 3 mm

Operation

Type

Capacitive Touch

Dimension

W x H x D

370 x 260 x 106 mm

Weight

approx. 3,7 kg

Protection class

Front

IP 65 (NEMA 12), according to EN 60529

Back

IP 20

Environmental

condition

Climate operation

0 ... 45 °C, 10 ... 90 % relative humidity, non-condensing

Climate storage

-20 ... 60 °C, 10 ... 90 % relative humidity, non-condensing

EMC interference resistance

EN 61000-6-2

Interference radiation

EN 61000-6-3

Power supply

Voltage

24 V DC (18 … 30 V)

Voltage drops

10 ms according EN 61000-6-2

Reverse voltage protection

Yes

Fuse

Solder fuse, 2 A slow-blow

Electrical isolation

Yes Current consumption

Typ. 500 mA at 24 VDC (for 2 min. after power-on 750 mA)

Power consumption

Typ. 20 W

Battery back-up

Battery type

Lithium battery

Data conservation

min. 8-10 weeks

Battery charge

Complete after approx. 48 hours operation

System time

Real-time clock (RTC)

Date/Time

Accuracy

50 ppm (max. 131 seconds deviation per month)

Time levelling

Manual or over network time server

Memory card

SD card

Data logger

Page 14

Program Controller SE-707

© 2018 by STANGE Elektronik GmbH

14 Subject to technic al modifications

Interfaces

Alarm output

Semiconductor relay output, 24V AC/DC, 300 mA,

contact type normally open contact, potential-free

Watchdog output

Semiconductor relay output, 24V AC/DC, 300 mA,

normally closed contact, potential-free

CAN

CANopen fieldbus,

9-pole SubminD connector, electrically isolated

USB 1 and 2

USB connection (female) for external storage medium (USBMemory-Stick)

Ethernet connector

Ethernet 10/100 Mbit/s, RJ45 female connector

Profibus-DP (optional !)

Profibus-DP Slave,

optional interface module,

9-pole SubminD connector, electrically isolated

Processor core

CPU

Freescale™ i.MX 6 ARM

Random access memory

1 GB DRAM

Memory for mains failure safe data

(PLC retain memory)

1 MB SRAM, battery backed

Page 15

Program Controller SE-707

© 2018 by STANGE Elektronik GmbH

Subject to technical modifica tions

15

4.2 Software specifications

Operating system

Windows Embedded Compact 7

PLC PLC with 3200 statements, 128 timers, programmable in STL

Functions

Controller

Up to 20 control zones (depending on stage of extension

)

Programmer

Programmer function with up to 30 set values and 64 control tracks

(depending on stage of extension)

Recipe management

Management of up to 99 recipes, Import/Export possibility over USB

Memory-Stick or STANGE ECS control system

Alarms

Alarm processing with up to 200 alarms and alarm history

(depending on stage of extension)

Data logger (optional!)

Up to 32 data channels (depending on stage of extension)

Operation and

visualization

- Ready-made graphical user interface installation possibility of

customer-specific screen pages and/or unit diagrams (depending on

stage of extension

)

- Administration of 8 operating levels (user profiles)

- Online language switching with Unicode language support

(Russian, Chinese etc.) (depending on stage of extension)

Control system

ECS

SE-707 are designed for STANGE ECS control system connection

"Open" control system interface

In the system the PLC program has priority over the

visualization.

Delays in the visualization may occur

during file transfers (such

as project downloads, FTP, WEB servers), or during

communication with the development system

(e.g. PLC

debugging) as the visualization has the lower priority.

The SD™ storage media (industrial grade) used by STANGE

Elektronik are suitable for the cyclic data recording. Only use the

storage media enclosed to the device.

No formatting of the storage media (loss of the boot sector)!

Page 16

Program Controller SE-707

© 2018 by STANGE Elektronik GmbH

16 Subject to technic al modifications

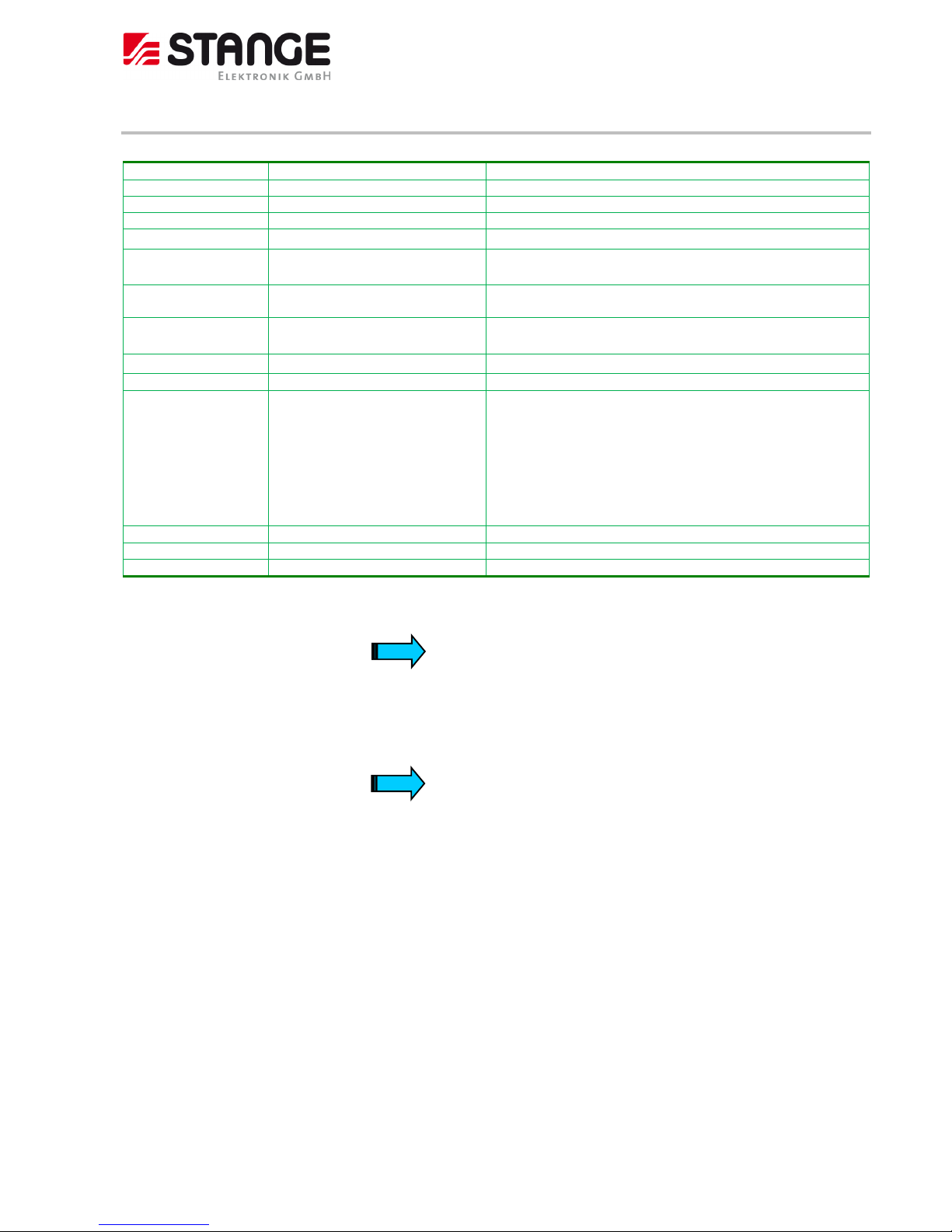

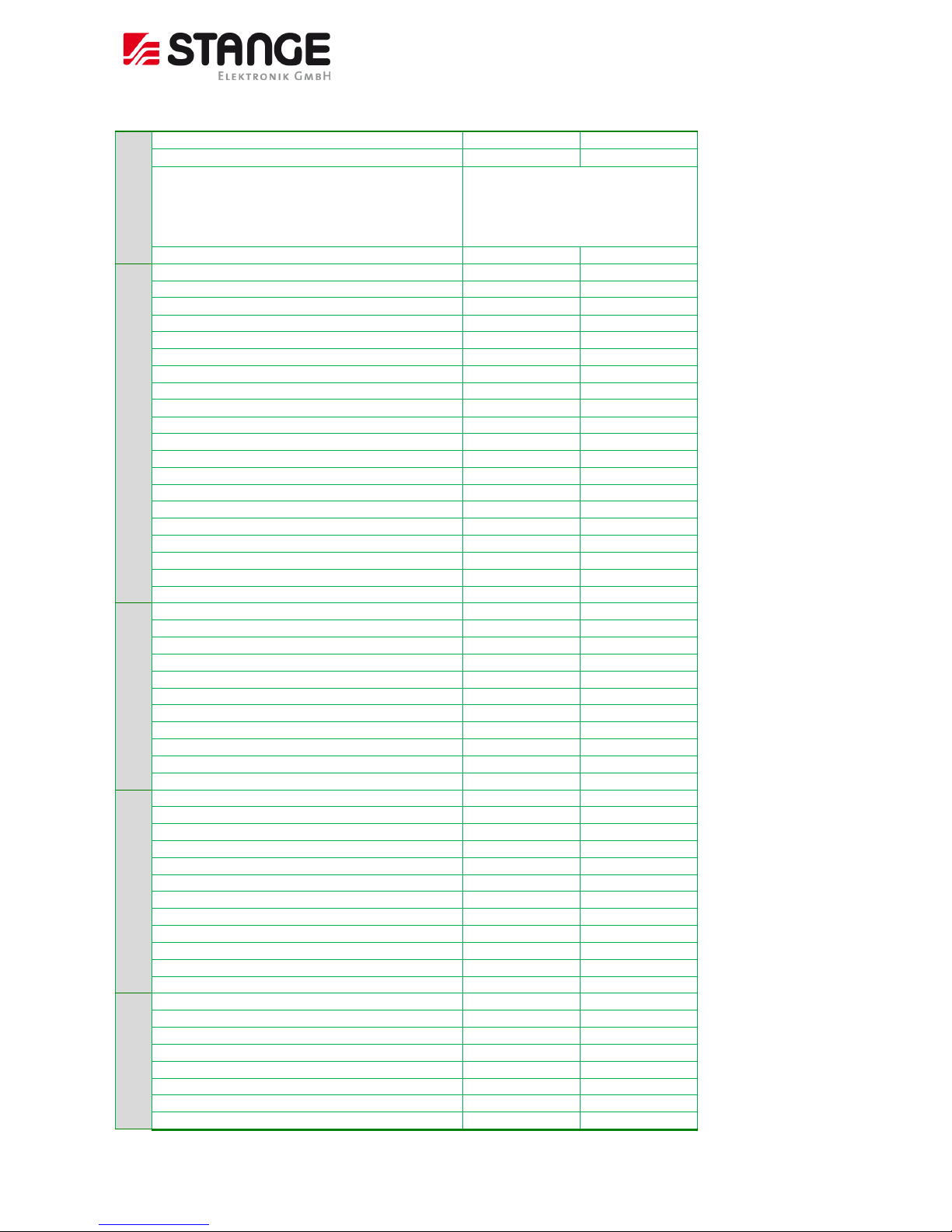

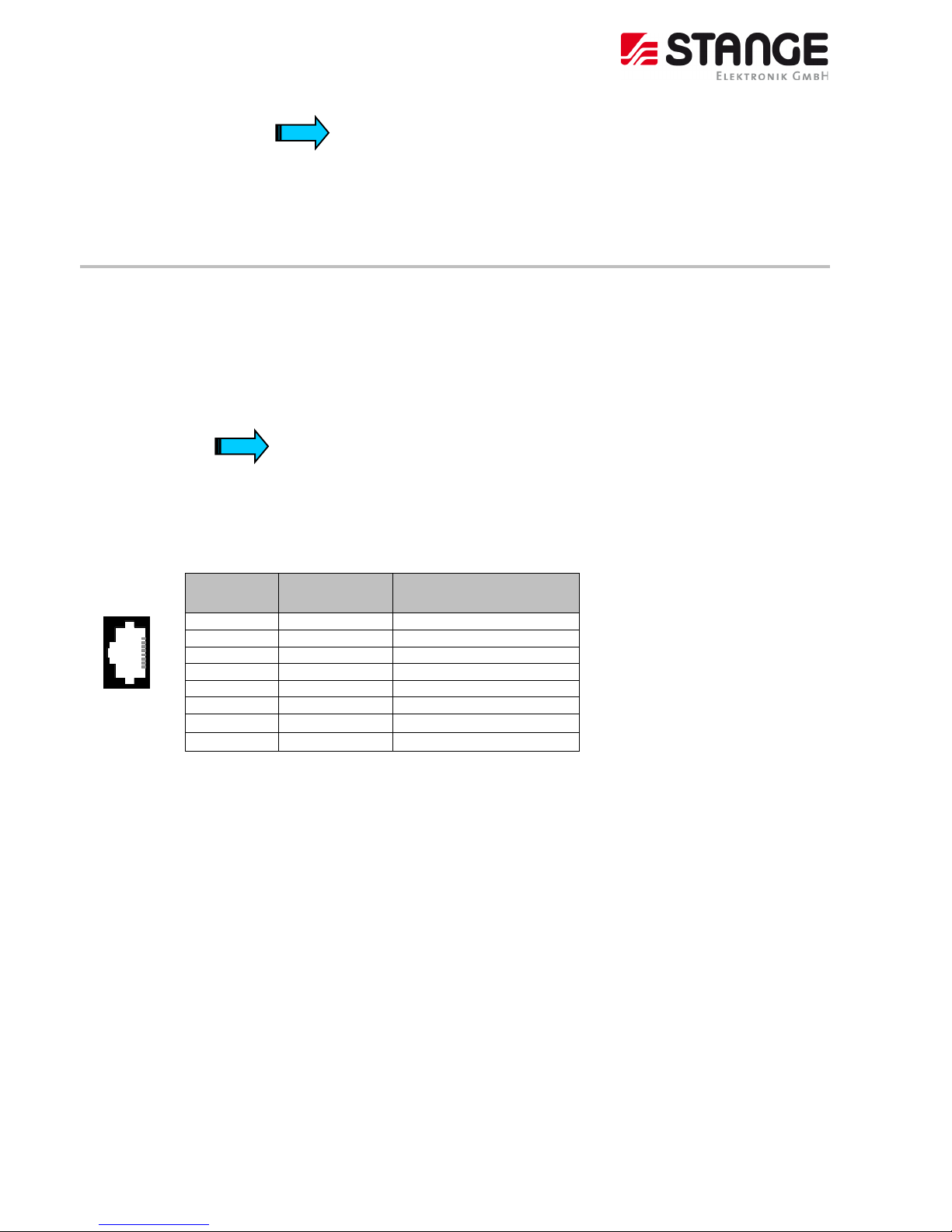

4.3 Function basic data

Function

SE-707/Ext

SE-707/Basic

General

Instrument name

SE-707

SE-707

Instrument code

702001

702000

Instrument code MODB US

72

72

Number of function units (Unit’s)

1

1

Operating dialog languages

4

4

Value descriptions (SV, AV etc.)

24 characters

24 characters

Dimension text

10 characters

10 characters

Number range in case of several values

-9.99999e15 ..

+9.99999e15

-9.99999e15 ..

+9.99999e15

User administration

Number of users total

32

32

Maximum number of logged in users at the same time

10

10

User prof ile

8

8

Login name, maximum length

15 characters

15 characters

Password, maximum length

40 characters

40 characters

User name

40 characters

40 characters

Comment field

1024 characters

1024 characters

I/O’s

Digital inputs

200

64

Digital outputs

200

64

Number of actual values

48

16

Number of average value per actual value

50

50

Number of correction point per actual value

5

5

Free linearization, pair of values

64

64

Number of analogue values

32

16

Maximum CAN node number

15

2

Several individual functions

Number of set values

30

8

Number of digital tracks

64

32

Alarms, external

200

64

Alarms, internal (but only partly used!)

40

40

Alarm history, number of entries

300

150

Alarm text length

100 characters

100 characters

Limit values

40

16

Tolerances

40

16

Formula

20

8

Formula term

31

31

Constants

40

40

Analogue variables

80

80

Number of Modbus data words

200

200

Variables string length

32 characters

32 characters

Analogue value multiplexer

10

5

BCD/BIN decoder

5

5

Page 17

Program Controller SE-707

© 2018 by STANGE Elektronik GmbH

Subject to technical modifica tions

17

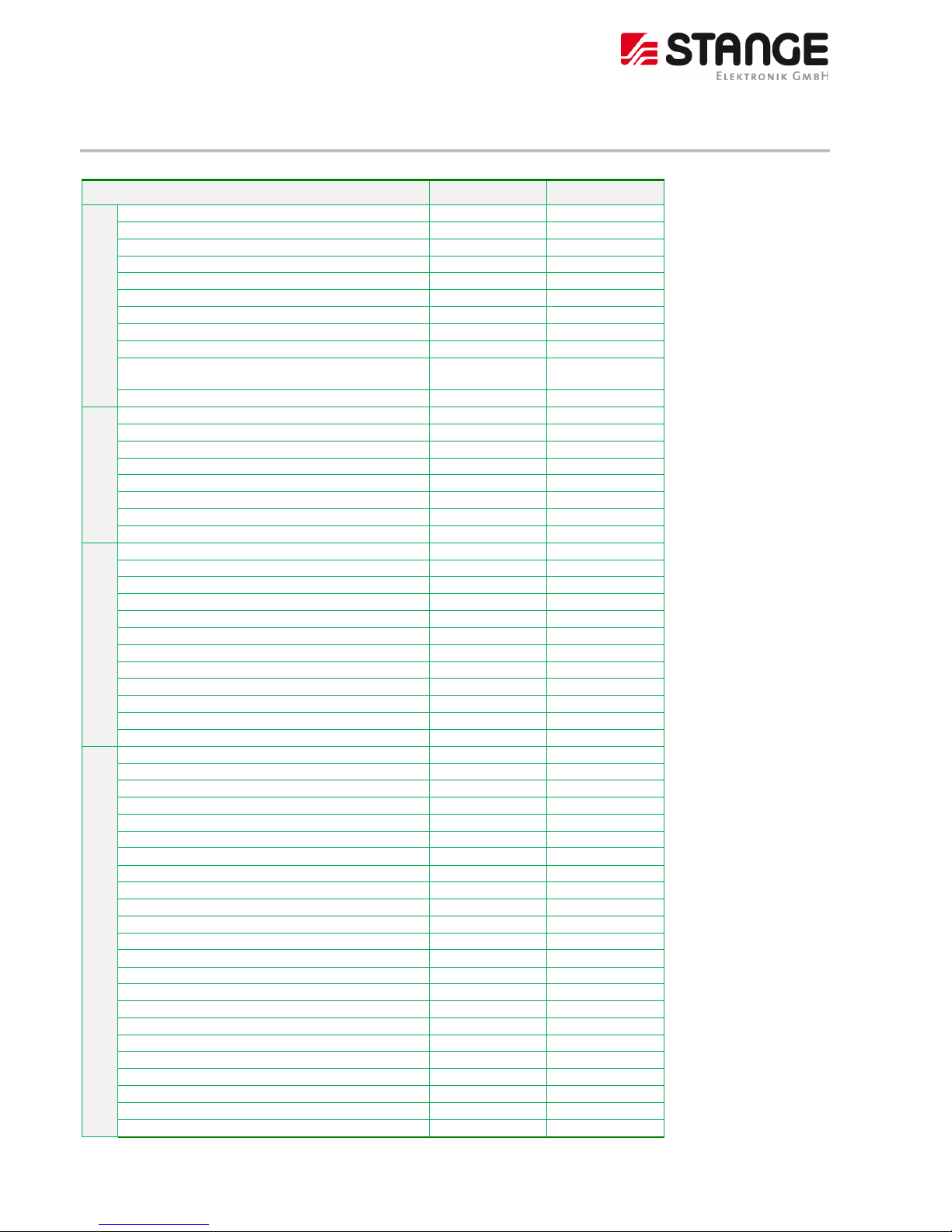

Controller

Number of control zones

20

8

PID sets per control zone

8

8

Controller types

2P heating, 2P cooling, 2P-PID heating,

2P-PID heating, PID heating, PID cooling,

PID / PID, PID / 2P, PID / 2P-PID, 2P-PID /

PID, 2P-PID / 2P 2P-PID / 2P-PID, 2P /

PID, 2P / 2P-PID, 2P / 2P, 3 point step

Programmer

Number of time axis

1

1

Program name length

32

32

Set values

30

8

Digital tracks

64

32

Process steps

50

50

Program segments (inclusive start segment)

201

201

Maximum segment time

999:59:59

999:59:59

Maximum program time

1 year

1 year

Loops

8

8

Loop segments

1000000

1000000

Max. number of repetitions

9999

9999

Program archive, number of programs

250

99

Program number range

1..9999

1..9999

Program graphics, number of pins set value

6 6 Program graphics, set value pages

5

2

Program graphics, number of pins digital tracks

6

6

Program graphics, digital tracks pages

11

6

PLC

PLC instructions

3200

3200

Digital input variables

800

800

Digital output variables

800

800

PLC function inputs

1146

1146

PLC function outputs

1615

1615

Flag, not zero voltage safe

256

256

Flag, zero voltage safe

256

256

Comment text length (only monolingual!)

50 characters

50 characters

Data Logger (option)

Number of data loggers

1

1

Number of log values

32

32

Number of header data

20

20 Maximum log data set number

100000

100000

Maximum alarm event number

10000

10000 File number log data directory

200

200

Number of columns log data archive

3 3 Pixel width archive display

380

380

Number of pens graphic display

16

16

Number of pen groups

5

5

Further Functions

Plant picture

Yes, option

Yes, option

Screensaver

Yes

Yes

C-level formula

2, option

1, option

Humidity calculation formula

2

1

Fieldbus interface „netJACK“, Profinet IO DEVICE

Yes, option

Yes, option

Fieldbus interface „netJACK“, Profibus-DP Slave

Yes, option

Yes, option

Page 18

Program Controller SE-707

© 2018 by STANGE Elektronik GmbH

18 Subject to technic al modifications

5 Installation of the industrial control

5.1 Guidelines for the installation of the SE-707

Separate the SE-707 device from heat, high voltage, and electrical noise

As a general rule for laying out the devices of your system, always separate the devices that generate high voltage and high

electrical noise from the low-voltage, logic-type devices such as the SE-707.

When configuring the layout of the SE-707 inside your panel, consider the heat-generating devices and locate the electronictype devices in the cooler areas of your cabinet. Operating any electronic device in a high-temperature environment will

reduce the product life.

Consider also the routing of the wiring for the devices in the panel. Avoid placing low voltage signal wires and

communications cables in the same tray with AC power wiring and high-energy, rapidly-switched DC wiring.

5.2 General mounting instructions

All SE-707 devices are mounted from the front, i.e. in a control panel. They are fastened from the rear with the supplied

fixing frame and 2 securing nuts.

All SE-707 devices can be operated up to a maximum ambient temperature of 45°C. The ambient temperature stated applies

to the area in the direct vicinity of the lower connectors, if the device is mounted vertically with unimpeded air convection

and a maximum operating height of 2000 m above sea level. The cooling slots must always be free in order to ensure the

proper cooling of the system.

The device can be mounted in an enclosure if the ambient temperature is taken into consideration. Provide a wall clearance

of at least 50 mm on all sides of the housing, so that sufficient air circulation is ensured. A minimum clearance of 75 mm

from active elements such as load current supply, transformers etc. must be ensured.

Avoid the exposure of the flat screen to direct sunlight. The radiation from the sun (UV component) reduces the lifespan of

the LCD display.

ATTENTION !

The following must be ensured in order to prevent the device from overheating during operation:

- The cooling slots must always be free in order to ensure the proper cooling of the system.

- Avoid the exposure of the flat screen to direct sunlight.

- The mounting angle must not exceed ± 35° from the vertical

If these conditions cannot be met, the mounting of an external fan is recommended.

Page 19

Program Controller SE-707

© 2018 by STANGE Elektronik GmbH

Subject to technical modifica tions

19

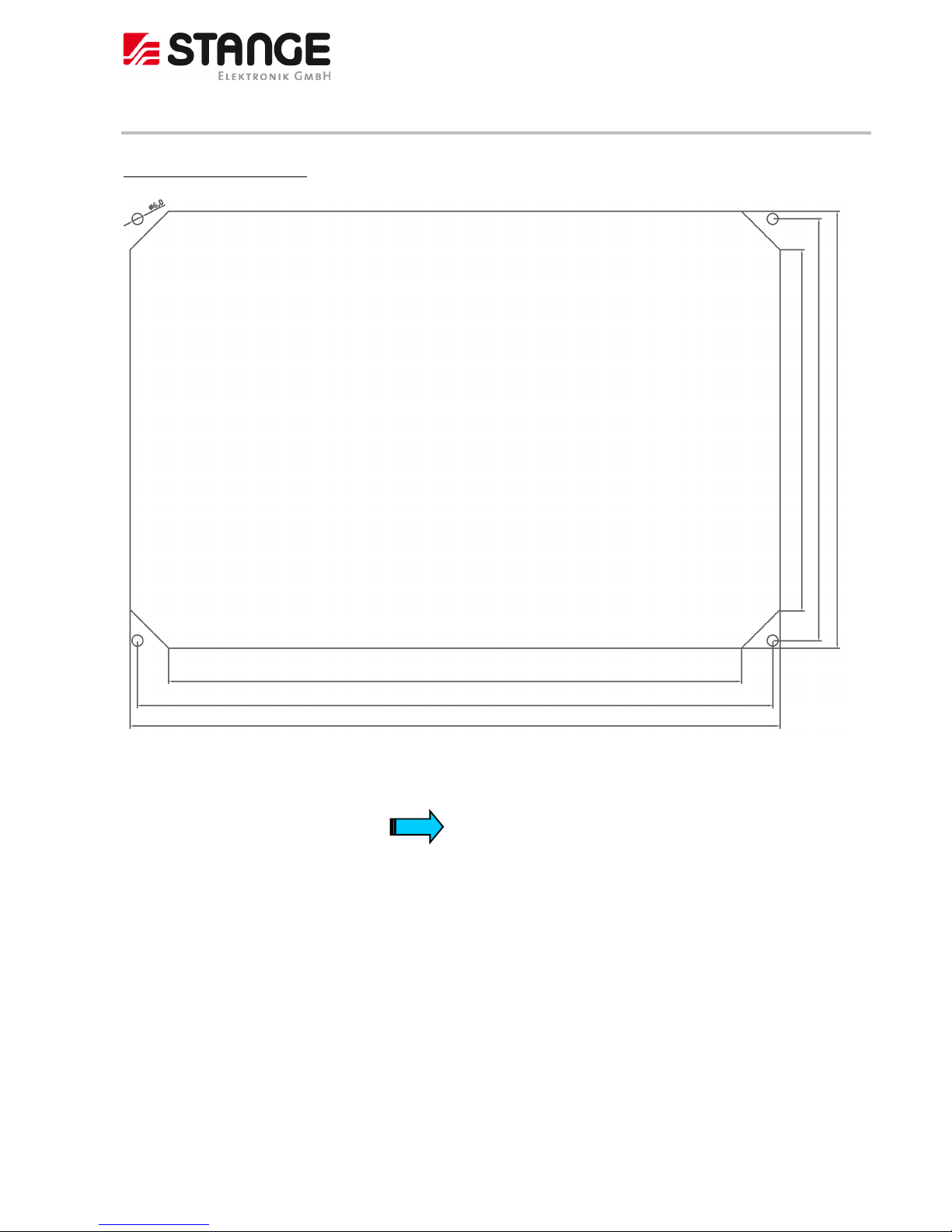

5.3 Installation dimension

Installation dimension SE-707:

The device requires a mounting cut-out of B x H: 354 x 238 mm +/-0,5mm

The thickness of the front panel may not exceed 7 mm.

For better sealing: Use mounting frame rearwards.

196,6

312,0

346,0

354,0

229,8

238,0

Page 20

Program Controller SE-707

© 2018 by STANGE Elektronik GmbH

20 Subject to technic al modifications

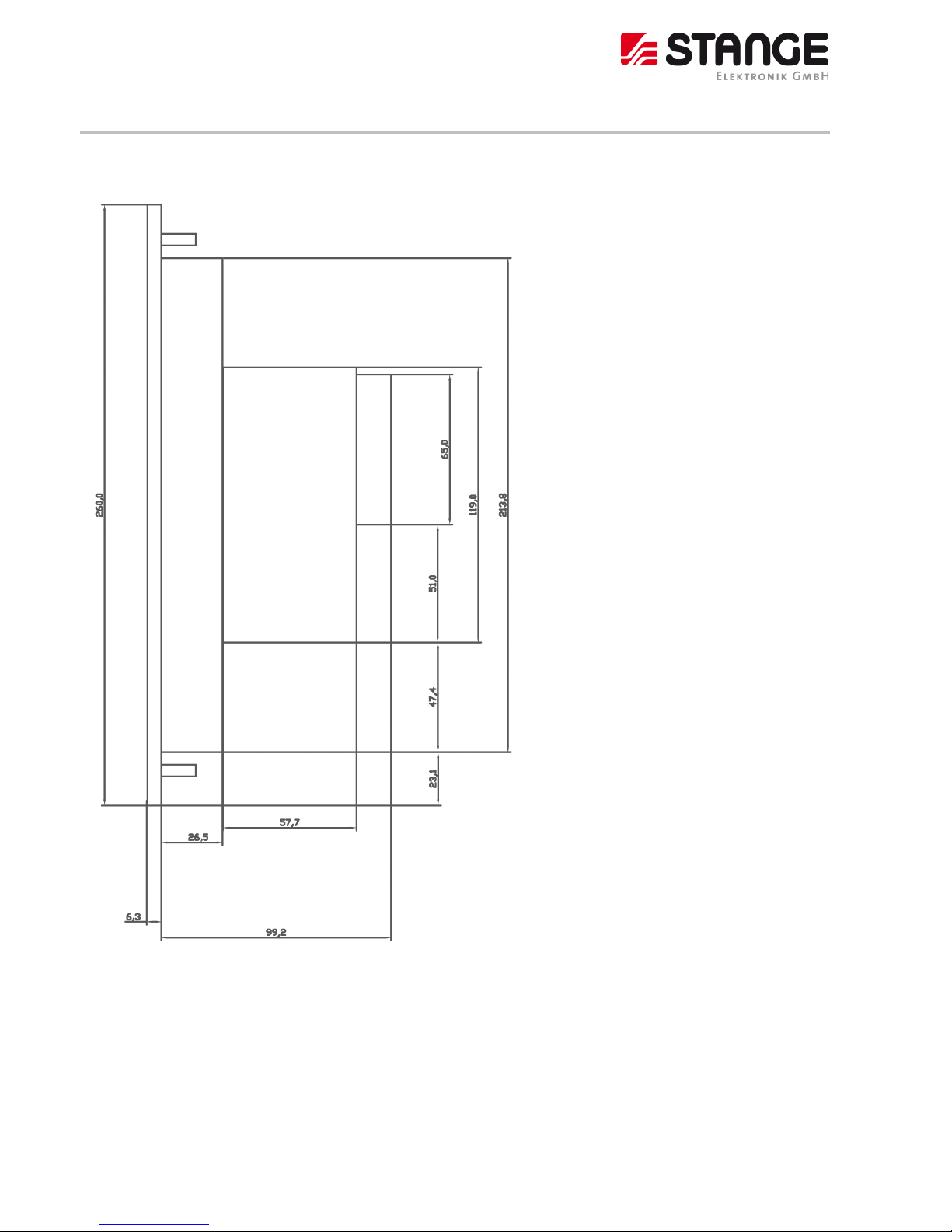

5.4 Installation depth

Installation depth SE-707:

The Installation depth for the SE-707: 99.2 mm.

Length of the mounting clips: 65 mm behind the mounting plate

Page 21

Program Controller SE-707

© 2018 by STANGE Elektronik GmbH

Subject to technical modifica tions

21

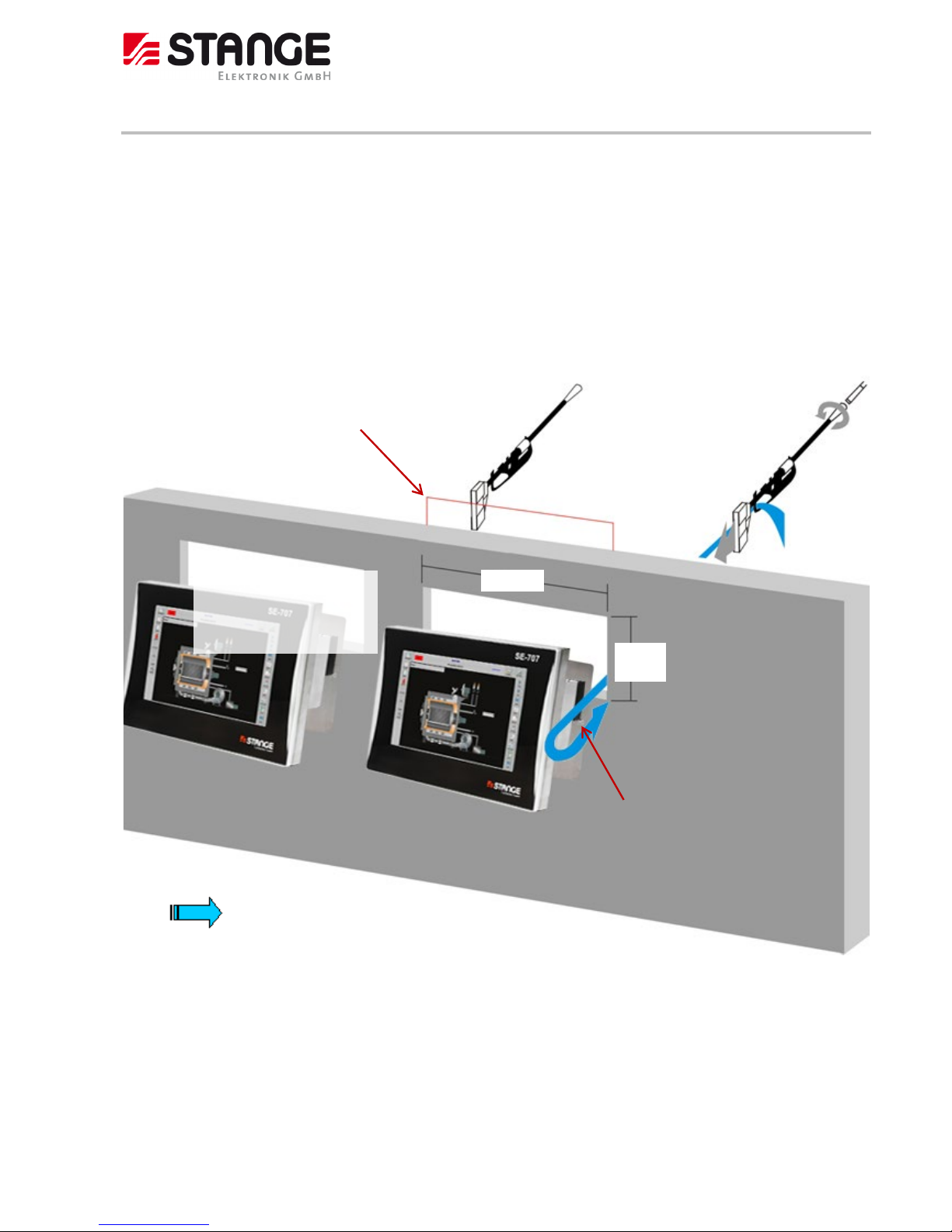

5.5 Front panel installation

Front panel installation SE-707:

A rectangular aperture is necessary for device installation in control panels and cabinets, etc.

- Push the device into the aperture from the front side.

- Attach the delivered mounting frame on the back side.

- Place one of the enclosed clamps from the back on each side until the stroke is reached; the recess in the metal

plate of the clamp grips to a nipple on the side of the housing.

- Turn the screw clockwise; the device is pulled backwards and secured.

Installation diagram

Holding clamps

354 mm

238

mm

Mounting frame

Minimum distance

for side by side

mounted devices:

25 mm

Control panel

or

cabinet

Nipple

Note

The mounting frame is

only required if the

function of the sealing is

needed.

Page 22

Program Controller SE-707

© 2018 by STANGE Elektronik GmbH

22 Subject to technic al modifications

6 Start-up

6.1 Guidelines for Grounding and Wiring

Proper grounding and wiring of all electrical equipment is important to help ensure the optimum operation of your system

and to provide additional electrical noise protection for your application and the SE-707.

Requirements:

Before you ground or install wiring to any electrical device, ensure that the power to that equipment has been turned off.

Ensure that the power to any related equipment has been turned off.

Ensure that you follow all applicable electrical codes when wiring the SE-707 and related equipment. Install and operate all

equipment according to all applicable national and local standards. Contact your local authorities to determine which codes

and standards apply to your specific case.

Warning !

Attempts to install or wire the SE-707 or related equipment with power applied could cause

electric shock or faulty operation of equipment. Failure to disable all power to the SE-707 and

related equipment during installation or removal procedures could result in death or serious injury

to personnel, and/or damage to equipment.

Always follow appropriate safety precautions and ensure that power to the SE-707 is disabled

before attempting to install or remove the SE-707 or related equipment.

Always take safety into consideration as you design the grounding and wiring of your SE-707 system. Electronic control

devices, such as the SE-707, can fail and can cause unexpected operation of the equipment that is being controlled or

monitored. For this reason, you should implement safeguards that are independent of the SE-707 to protect against possible

personal injury or equipment damage.

Warning !

Control devices can fail in an unsafe condition, resulting in unexpected operation of controlled

equipment. Such unexpected operations could result in death or serious injury to personnel,

and/or damage to equipment.

Use an emergency stop function, electromechanical overrides, or other redundant safeguards that

are independent of the SE-707.

Page 23

Program Controller SE-707

© 2018 by STANGE Elektronik GmbH

Subject to technical modifica tions

23

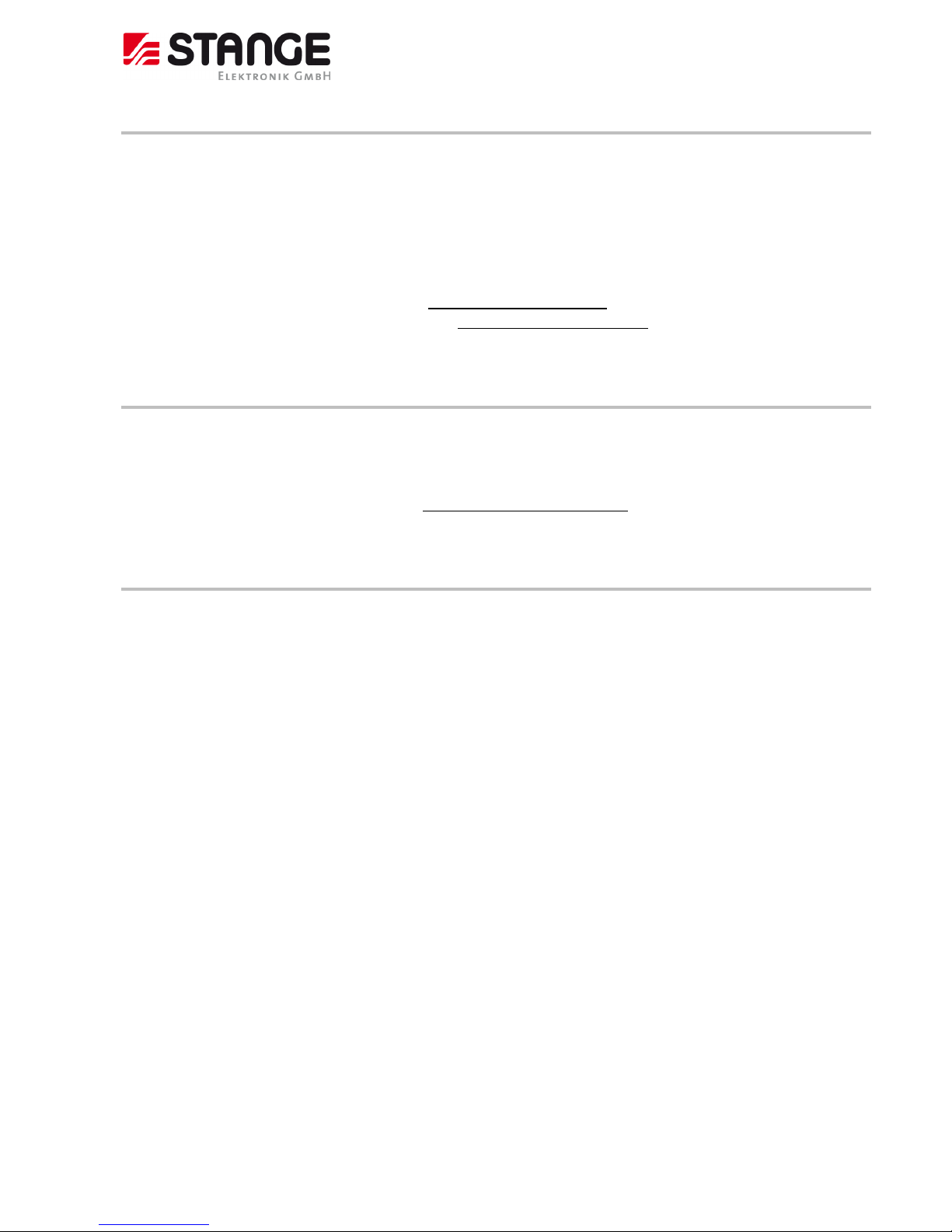

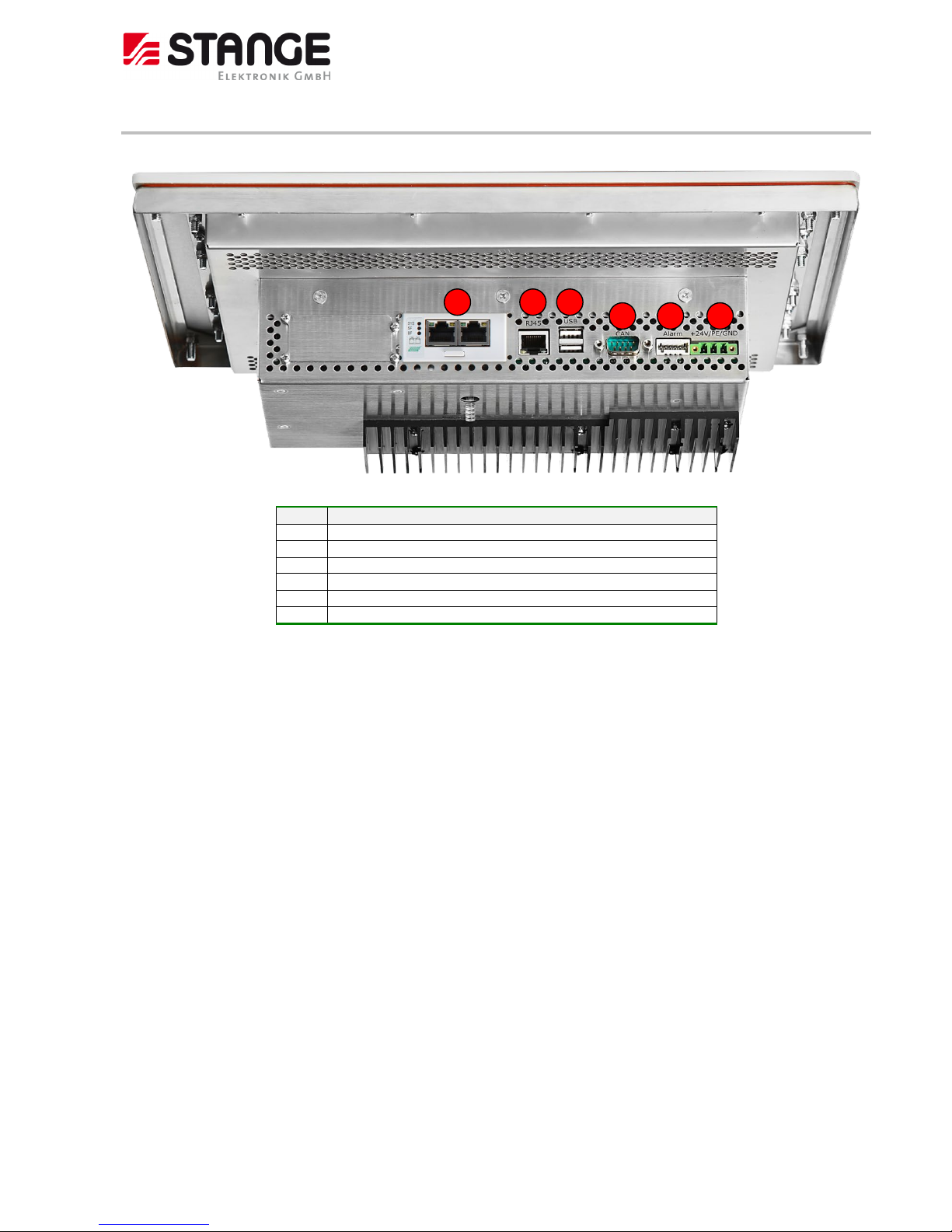

6.2 Overview of the connections

No.

Element

1

24 V DC power supply (+24V/PE/GND)

2

Alarm connector (A1,A2) for Watchdog and alarm output

3

CAN-connector 9 pol. Sub-D

4

USB 1 and 2

5

Ethernet RJ45

6

Option slot

6 1 4 5 2

3

Page 24

Program Controller SE-707

© 2018 by STANGE Elektronik GmbH

24 Subject to technic al modifications

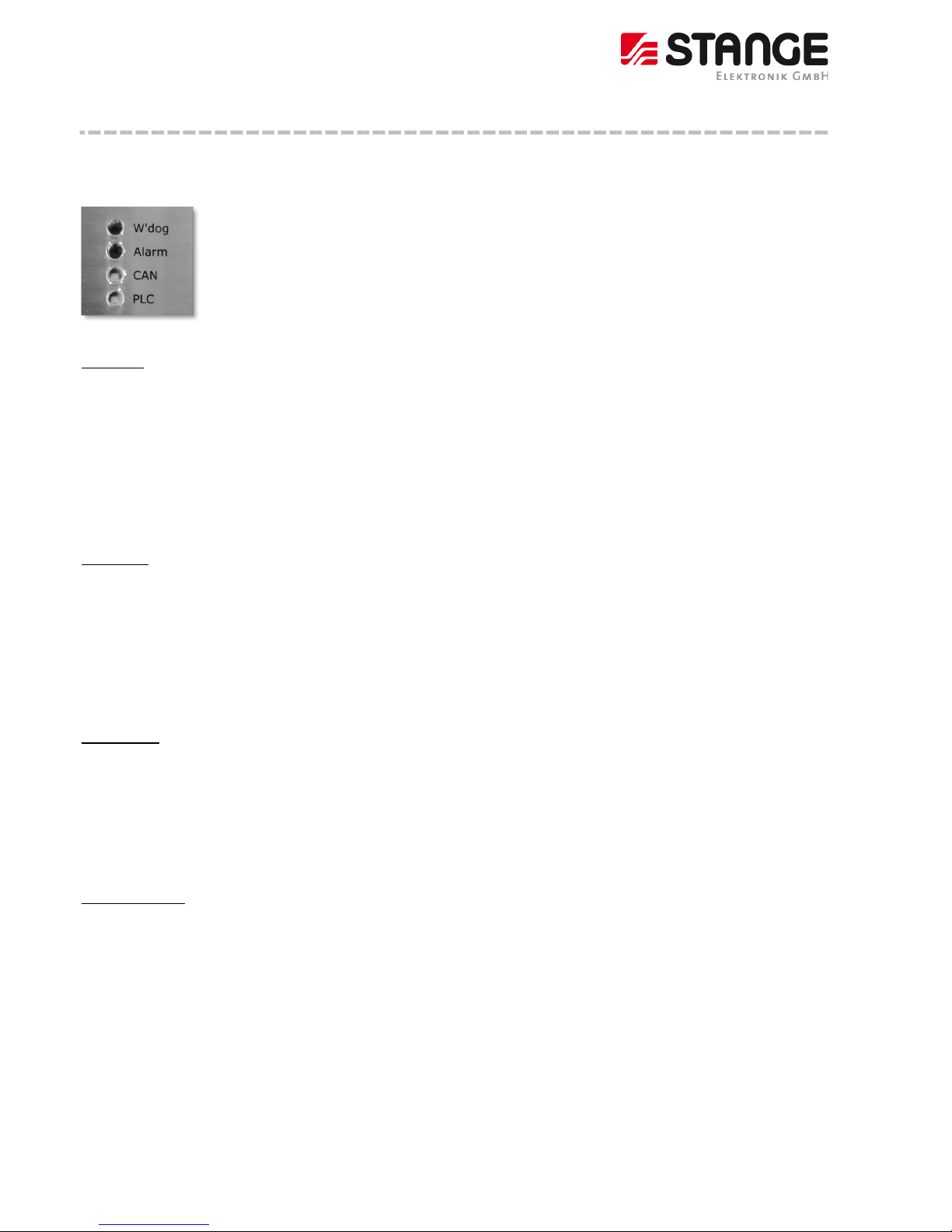

6.2.1 Function of the LED's at the back of the device

On the back of the device 4 LED's are located with the function described in the following:

LED4

LED3

LED2

LED1

LED 1: PLC

This LED gives information about the condition of the internal PLC:

- LED off: This is the condition during switching on the device until the normal device function is running

- LED flashes green: Device function running, PLC in the condition “RUN” (turn-switch position 0!)

- LED flashes yellow: The PLC is in the condition “STOP” (turn-switch position 1)

- LED flashes red: The PLC is in the condition “RESET” (turn-switch position 2)

- LED flashes red with 1 Hz: The PLC is in the condition “MEMORY RESET” (turn-switch position 3)

LED 2: CAN

This LED gives information about the condition of CANopen field bus function:

- LED flashes green: The field bus is running, all CAN slaves are online and no CAN slave configuration error is available!

- LED flashes red: CAN slaves not all online or CAN slave configuration error

- LED flashes red with 2 Hz: BusOff-Error

- LED off: CAN interface inactive, PLC is in condition „RESET“ (turn-switch position 2 or 3)

LED 3: Alarm

This LED gives information about possibly acknowledged alarms:

- LED off: No error or alarm processing inactive (PLC not running, turn-switch not in position 0)

- LED flashes red with 1 Hz: At least one new alarm is available

- LED flashes red: Only acknowledged alarms are available

LED 4: Watchdog

This LED gives information about the condition of the Watchdog:

- LED off: No error or device off

- LED flashes red: The Watchdog has triggered, a serious problem is available.

Page 25

Program Controller SE-707

© 2018 by STANGE Elektronik GmbH

Subject to technical modifica tions

25

6.2.2 Turn-switch for PLC operating mode selection

A turn-switch for PLC operating mode selection of the internal PLC is located on the on the back of the device.

The turn-switch has positions from 0 to 9, only the first 4 positions are assigned:

Position 0: PLC takes “RUN” condition

Position 1: The PLC goes to “STOP”;

Position 2: The PLC makes a “RESET”;

Position 3: The PLC makes a “Memory-RESET”;

Positions 4 to 9 are not defined and should not be used!

ATTENTION!

The turn-switch should always remain in position 0!

All other positions have important effects to the operation and also possibly on the safety of the plant and might only be

used by experienced personnel of the plant manufacturer!

The turn-switch may only be turned very slow from one position to another. If the switch is turned too fast, then a

condition may be jumped over or not be recognized.

6.2.3 System Watchdog

6.2.3.1 General

The SE-707 device hardware has a hardware watchdog with an output as potential-free semi-conductor relay output lead

through at a device connector.

If the Watchdog output is really evaluated depends on the discretion of the plant manufacturer!

6.2.3.2 Mode of operation

The “Good” state of the Watchdog output is a closed contact. If the device is turned off or the Watchdog drops-out, then the

relay contact opens.

The contact of the Watchdog relay is typically used in an emergency stop chain. The Watchdog contact can alternatively be

used for the triggering of an alarm light, however the connecting signal must be inverted with the help of a coupling relay

(break contact make-contact).

If the device Watchdog releases, a serious problem is existent, a normal operation of the plant is not given.

The Watchdog does not directly effect on the device, i.e., the control runs forward as far as it is possible.

If the Watchdog is dropped-out one-time, this state can only be removed by a hardware reset (i.e., power on/off).

Page 26

Program Controller SE-707

© 2018 by STANGE Elektronik GmbH

26 Subject to technic al modifications

With the Watchdog is monitored whether the PLC works correct i.e.:

1. It is monitored whether the PLC run time system runs.

2. It is monitored whether the PLC was stopped because of an error (division by zero, ... etc.).

3. It is monitored whether the PLC was stopped because of a software Watchdog overflow.

Please note: The Watchdog contact does not open if the PLC was brought to the “Stop” state with the turn-switch at the

device back-side or with the programming system!

The state of the Watchdog relay is represented from LED 4 on the device back-side:

LED 4 off: Device free from tension or Watchdog relay contact closed

LED 4 on: The Watchdog relay contact is opened, i.e., a serious problem is given

6.2.3.3 System logger entry

A system logger entry is generated if the watchdog triggers off. This entry can be read off together with other system events

by manufacturer´s support and give helpful notes in case of device repair.

Further system events are for example: device switching on and off, turning the turn-switch on the device rear side, etc.

Note: If a hardware defect is really existent it is not sure that such a system event entry could really be written to the file!

6.2.4 The alarm relay

6.2.4.1 General

At the back side of the SE-707 devices an alarm relay is lead through (floating semi-conductor relay output, make-contact).

If the alarm output is really evaluated in the plant, depends on the discretion of the plant manufacturer!

6.2.4.2 Mode of operation

The “good” state of the alarm relay is an opened contact.

For each single configured alarm can be freely determined in the alarm processing of the SE-707, whether there should be an

influence on the alarm relay in case of alarm, or not.

Only internal device alarms with alarm numbers >200 have influence on the alarm relay.

The alarm contact remains closed until no alarm is available with selected alarm relay activation, i.e. all these alarms must be

acknowledged and gone.

The turn-switch on the device rear side must be in position “RUN” so that the alarm contact displays correct. In all other

positions the alarm contact is opened.

Page 27

Program Controller SE-707

© 2018 by STANGE Elektronik GmbH

Subject to technical modifica tions

27

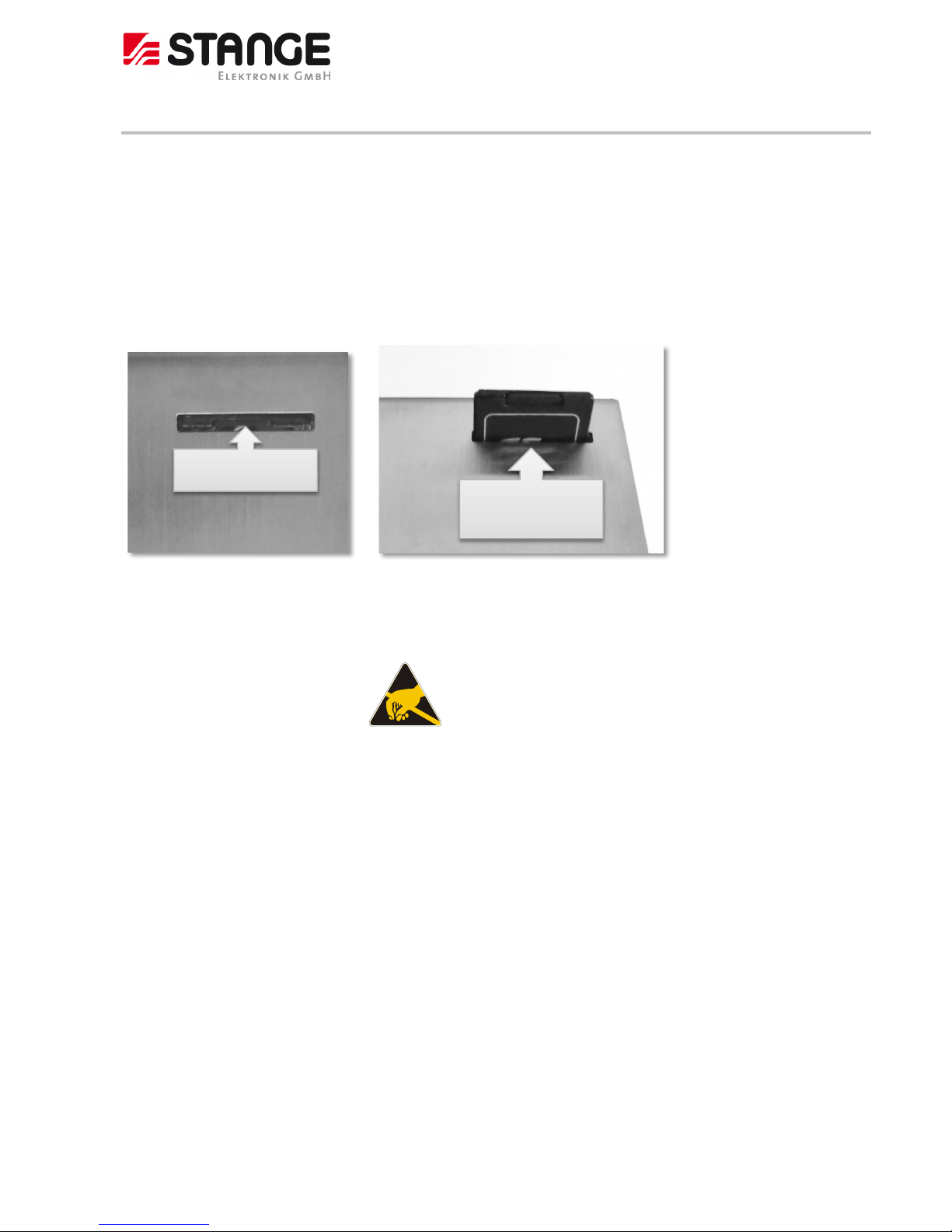

6.3 Mounting / dismounting the SD card

The mounting and/or dismounting of the SD™ medium is possible like follows:

• Press in the SD card slightly with a suitable object (e.g. a flat screwdriver) up to the stop. Afterwards pressing can be

stopped and the SD card is removed (SD card: large opening on the left side of the device).

• When mounting a SD medium it must be inserted carefully and with the right direction into the opening and be

pressed as far as it will go with above mentioned screwdriver. The card locks if the tool pressure is taken away. Take

care for the correct orientation of the medium. The contact area is located to the device rear panel!

Attention: Electrostatic discharges may destroy electronic

components!

You must wear a grounded bracelet, or, if this is not practicable,

at least care for a potential equalization by touching a grounded

metal part like e.g. the device housing, if you work with the data

storage medium.

The SD™ medium must be kept in an antistatic box.

SD card slot

Press in the SD card

up to the stop

Page 28

Program Controller SE-707

© 2018 by STANGE Elektronik GmbH

28 Subject to technic al modifications

6.4 Connecting the power supply

The SE-707 device belongs to protection class 3. The system power supply must be provided with a 24VDC SELV voltage

(safety extra-low voltage). The internal voltage conditioning unit is equipped with a galvanic isolation. The PE connection is

directly connected to the housing potential. The device is protected with a 2AT soldered-in fuse. A reverse polarity protective

device is used to protect the device in the event of reversed poles. Operation, however, is only possible if the connection was

made correctly.

Connections for the SE-707 must comply with specific, local regulations.

The connection must be made as follows:

1) The cross-section of the power supply cable must be at least 0.75 mm² and a maximum of 2.5 mm².

2) A flexible lead or wire can be used for the connection, whereby the end should be equipped with a cable end

sleeve.

3) The current consumption must be taken into account when implementing the power supply. The functional earth

is not compulsory for operation. The PE connection is directly connected to the housing potential

The plug connector (socket connector with screw terminals) is supplied with the device for connection.

Connector assignment

Designation

Function

+24 V DC +24 V DC power supply

PE Functional ground

GND 0 V power supply

+24VDC PE GND

(plug con nector: P hönix MC 1.5/3-STF-5.08

Phönix Art. Nr. 1847369)

Page 29

Program Controller SE-707

© 2018 by STANGE Elektronik GmbH

Subject to technical modifica tions

29

6.5 Packaging the CAN cable with shield connection

The preparation of the data and signal cables is an important factor for the electromagnetic compatibility (EMC) of this

SE-707, both in terms of interference immunity and emission.

The RS232 interface and CAN interface are connected via D sub miniature plug connectors in accordance with DIN 41652.

Only use metal or metallised connector casings with a cable clamp for strain relief fastened or clamped on the connector. The

clamping of the cable shield ensures an optimum contact area and a low impedance connection with the connector casing of

the SE-707 program controller.

The following procedure is recommended for making the low-impedance connection for the cable shield:

1. Strip the cable.

2. Shorten the exposed shield braid by approx. 3 cm.

3. Turn back the braid over the cable sheath.

4. Use a heat shrinkable tubing or rubber grommet to cover the exposed cable sheath with the folded back shield braid

so that 5 to 8 mm of exposed cable shield is left at the sheath end and is cleanly covered at the back.

5. Fit the connector

6. The cable is then fastened at the exposed shield braid and the cable sheath below it directly underneath the cable

clamp strap of the connector casing.

ATTENTION: When using plastic plugs, with which the strain relief is not connected with the plug earth

connection, the screen network must be soldered on directly at the plug earth connection.

Connection SE

DSUB 9pol.

Socket

2

7

3

6

shield

4

5 220 Ohm terminal resistance

is active in the SE-707 via bridge

Plug housing

put shield on

plug housings

Line:

Execution: twisted in pairs with common shield. Shield presented on one side of the unit.

(e.g.: HELUKABEL “Li-2YCY” (2x2x0.22 / Order.-No.: 21111))

Connection CAN – Base or SIOS

DSUB 9pol.

Socket

2 CAN -Low

7 CAN-High

3

6

4

5

Plug housing

Line:

twisted in

pairs

Page 30

Program Controller SE-707

© 2018 by STANGE Elektronik GmbH

30 Subject to technic al modifications

Connection work should be carried out with special care in order to ensure

trouble-free operation.

The EMC values stated in the technical data can only be guaranteed if the

cables are prepared according to the following specifications.

6.6 Connecting the programming interface RJ45

The programming is carried out via the standard Ethernet interface (RJ45). The connection to the programming PC is

implemented using a standard Ethernet cable (1:1) via a hub or directly using a crosslink cable. The cables are also available as

an accessory.

Before the device is connected to the Ethernet network, the IP address of the device and the programming PC must be set.

IP addresses can be obtained from your system or network

administrator. IP addresses must be uniquely defined in an

Ethernet net

work. The IP address of all networks and of the

programming PC must be in the same subnet work (e.g.

192.168.0.xxx).

Connector assignment:

RJ45

connector

Pin-No.

Signal

Description

1 TXD- 2 TXD+ 3 RXD+

4 -

5 - 6 RXD-

Socket, 8pole

7

-

RJ45

8

-

Cables connected to the programming interface must be laid separately from the low-voltage cables.

1

2

3

4

5

6

7

8

Page 31

Program Controller SE-707

© 2018 by STANGE Elektronik GmbH

Subject to technical modifica tions

31

6.7 Connection CAN

The communication interface is defined in accordance with the CiA CAN Specification V2.0 part B. The fully-integrated CAN

unit supports the sending and receiving of frames with an 11-bit identifier. The type of configuration selected depends on the

software protocol. The baud rate can be selected in a wide range, and only the standard CiA baud rates are implemented

(recommended 125kBaud max.). The SE-707 is the master on the CAN bus.

Connector

Pin-No.

Signal

Description

1

2

CAN LOW

Negative

data

signal

3

4

5

6

7

CAN HIGH

Positive data signal

9pol

8

SubD

9

Case

Case

Cable shield

The CAN interface is isolated.

The max. Baud rate is 500kBit/s.

Recommended setting: 125kBit/s

The CAN terminating resistor is realized internally and a part of the

device, but must however be activated over a bridge from 4 to 5.

There is no power supply lead to the CAN

connector for external

devices.

5

9

4

8

3

7

2

6

1

Page 32

Program Controller SE-707

© 2018 by STANGE Elektronik GmbH

32 Subject to technic al modifications

Wiring instructions

The stations on the bus system are connected via fieldbus lines complying with ISO 11898. The cables must accordingly have

the following electrical characteristics:

Parameter

Abbreviation

Unit

Value

Value

Value

Note

min.

nom.

max.

Impedance

Z Ω 108

120

132

Measured betwee n two

signal lines

Specific

resistance

r

mΩ/m 70 For the receiver module,

the differential voltage on

the bus cable depends on

cable resistance between

it and t he sender

Cable delay

ns/m 5 The minimum delay

between tw

o points on

the bus is 0. The

maximum delay is

determined by the bit

timing and the delays of

the sender and receiver

circuits

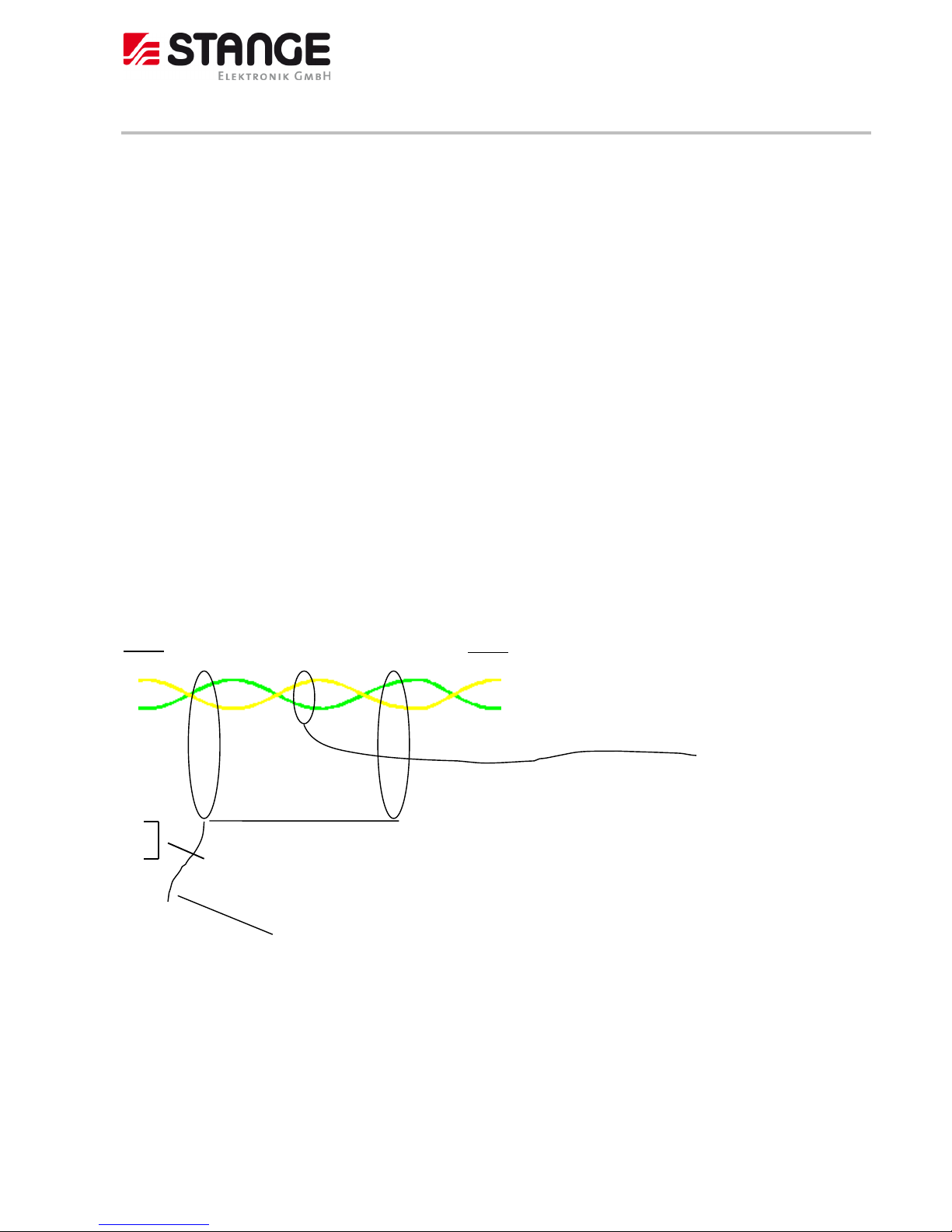

The figure shows the minimum wiring with shielding between two bus stations with the Sub-D connector as an example. A

bus terminating resistor (220 Ohm between Pin 2 and Pin 7) must be connected at the beginning and the end of each CAN

bus. Do not swap around the two signal wires!

For a detailed representation see chapter “Packaging the CAN

cable with shield connection”

Baud rate and cable lengths

Baud rate

Max. length

20 kBaud

1600m

50 kBaud

800m

100 kBaud

400m

125 kBaud

320m

250 kBaud

160m

500 kBaud

80m

Protective ground

Shield

Interface 1 Interface 2

Shield

Inside: twisted pair cable

Station

Station n

Bus terminating r esistor

Page 33

Program Controller SE-707

© 2018 by STANGE Elektronik GmbH

Subject to technical modifica tions

33

6.8 Connection of the alarm socket

An external signalling of internal collective alarms and the watchdog is possible via alarm connector.

Alarm Power

+ 24V PE GND

Technical data of the alarm relays:

Type:

semiconductor relay

Voltage:

24 V AC/DC max.

Current:

300 mA max.

On-resistance:

4 Ohm max.

Alarm connector: Wago multipole connector Art.-No. 733-106, maximum cross section: 0,5mm²

Function Watchdog and Alarm at SE-707:

Watchdog

No voltage

No

Yes

Alarm 1 - contact:

Open

Closed

Open

Internal alarm