Standex NR522SSG/0R, NR241SSG/0R, NR522SSS/0R, NR524SSS/0R, NR524SSG/0R Installation, Operation And Maintenance Instructions

...Page 1

1 06/11 Rev. B 127717

REFRIGERATORS AND F REEZERS

Installation, Operation and

Maintenance Instructions

INSPECTION

When the equipment is received, all items should be carefully checked against the bill of lading

to insure all crates and cartons have been received. All units should be inspected for

concealed damage by uncrating the units immediately. If any damage is found, it should be

reported to the carrier at once, and a claim should be filed with the carrier. This equipment has

been inspected and tested in the manufacturing facility and has been crated in accordance

with transportation rules and guidelines. Manufacturer is not responsible for freight loss or

damage.

INSTALLATION

GENERAL

After the unit crate and crate base have been removed, locate the casters or legs found inside

the cabinet. (Not applicable for Roll-In models). Attach the casters or legs to the unit base by

screwing them into the same threaded fittings that were used to secure the crate base to the

cabinet. Insure that the legs or casters are screwed completely into the base. The cabinet

should also be levelled when it is placed in its permanent location.

For shipping purposes, the condensing unit compressor is secured on the extra low

temperature models. Remove the spring clips and loosen the mounting bolts prior to

operation. See the label attached to the condensing unit.

If the doors are out of alignment on the cabinet, the doors can be adjusted. This can be

accomplished by opening the door(s) and loosening the screws that hold both the top and

bottom hinges to the cabinet. After adjusting the door so that it is aligned correctly, tighten the

screws to securely hold the hinges in place.

VAPORIZER INSTALLATION

Some of the Refrigerators and all of the Extra Low Temperature Freezers require the

installation of the condensate vaporizer which is shipped inside the unit compartment. The

vaporizer should be mounted to the cabinet bottom. Reference View 1. In lieu of the vaporizer,

these units can be plumbed to a floor drain following local plumbing codes. The Freezers,

Pass-Thru and Roll-In Refrigerators use a hot gas vaporizer. Customer installation is not

required.

Total Restaurant Supply - https://totalsupply1.com - Toll Free 1-800-944-9304 - Local 507-288-9454

2940 Hwy 14 W, Rochester, MN 55901

Page 2

2 06/11 Rev. B 127717

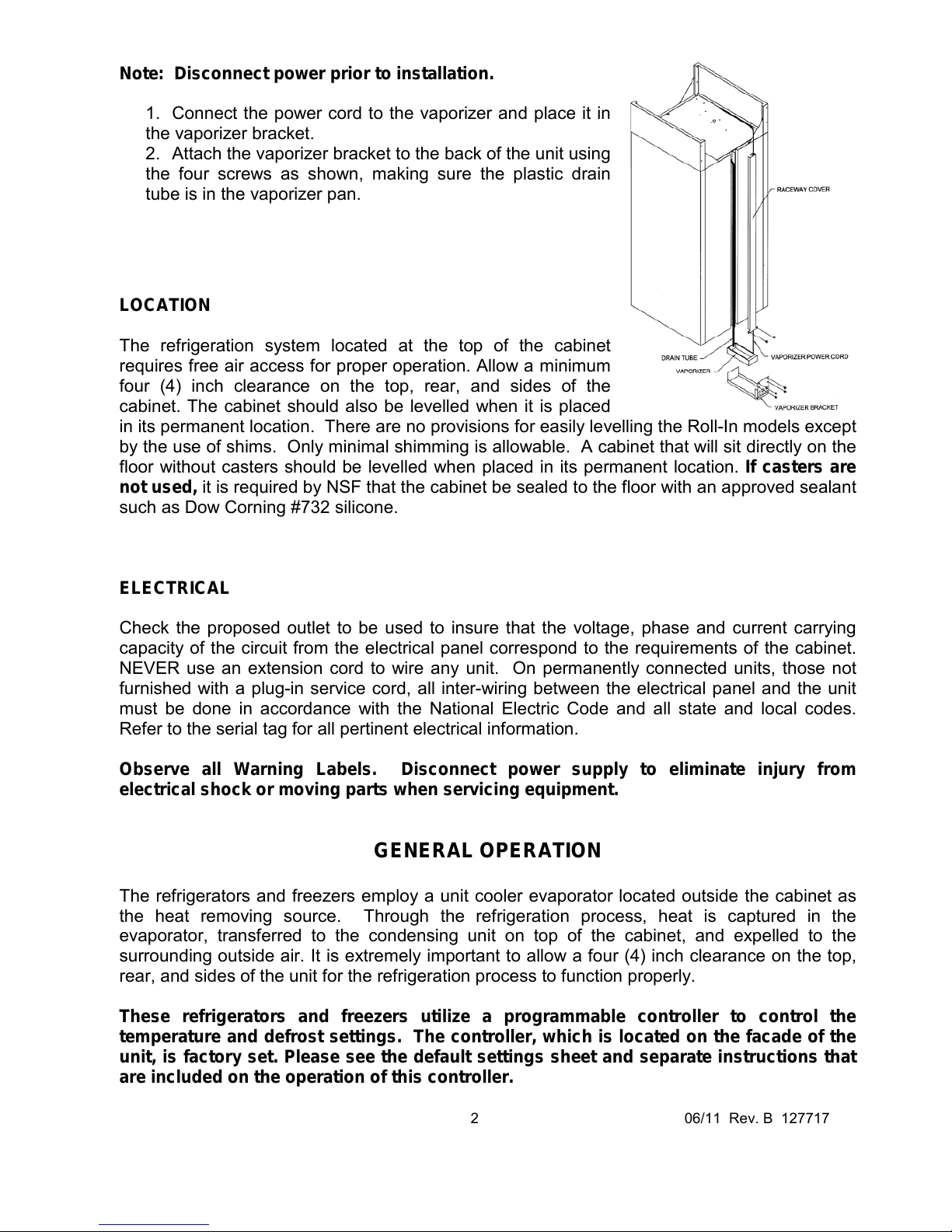

Note: Disconnect power prior to installation.

1. Connect the power cord to the vaporizer and place it in

the vaporizer bracket.

2. Attach the vaporizer bracket to the back of the unit using

the four screws as shown, making sure the plastic drain

tube is in the vaporizer pan.

LOCATION

The refrigeration system located at the top of the cabinet

requires free air access for proper operation. Allow a minimum

four (4) inch clearance on the top, rear, and sides of the

cabinet. The cabinet should also be levelled when it is placed

in its permanent location. There are no provisions for easily levelling the Roll-In models except

by the use of shims. Only minimal shimming is allowable. A cabinet that will sit directly on the

floor without casters should be levelled when placed in its permanent location. If casters are

not used, it is required by NSF that the cabinet be sealed to the floor with an approved sealant

such as Dow Corning #732 silicone.

ELECTRICAL

Check the proposed outlet to be used to insure that the voltage, phase and current carrying

capacity of the circuit from the electrical panel correspond to the requirements of the cabinet.

NEVER use an extension cord to wire any unit. On permanently connected units, those not

furnished with a plug-in service cord, all inter-wiring between the electrical panel and the unit

must be done in accordance with the National Electric Code and all state and local codes.

Refer to the serial tag for all pertinent electrical information.

Observe all Warning Labels. Disconnect power supply to eliminate injury from

electrical shock or moving parts when servicing equipment.

GENERAL OPERATION

The refrigerators and freezers employ a unit cooler evaporator located outside the cabinet as

the heat removing source. Through the refrigeration process, heat is captured in the

evaporator, transferred to the condensing unit on top of the cabinet, and expelled to the

surrounding outside air. It is extremely important to allow a four (4) inch clearance on the top,

rear, and sides of the unit for the refrigeration process to function properly.

These refrigerators and freezers utilize a programmable controller to control the

temperature and defrost settings. The controller, which is located on the facade of the

unit, is factory set. Please see the default settings sheet and separate instructions that

are included on the operation of this controller.

Total Restaurant Supply - https://totalsupply1.com - Toll Free 1-800-944-9304 - Local 507-288-9454

2940 Hwy 14 W, Rochester, MN 55901

Page 3

3 06/11 Rev. B 127717

REFRIGERATORS

During the operation of a refrigerator unit, frost will periodically form on the coil surface. Each

time the compressor cycles "off", the evaporator fans will continue to run, which will keep the

internal temperature uniform and at the same time remove any frost build up on the coil. The

water produced will collect in the unit cooler drain pan and travel down the drain tube to the

condensate vaporizer.

FREEZERS

After shutting the door on freezer models, a short amount of time must be allowed before the

door can be reopened. This is due to the tight seal maintained between the door and the

cabinet. Waiting a few moments for the pressure to equalize permits the door to be opened

easily.

A positive defrost is required to remove frost from the coil in freezer models. This is

accomplished by energizing heaters during the defrost cycle that are positioned on the coil

surface. The programmable controller is factory set to allow four defrosts per day.

As the preset defrost time is reached, the controller automatically terminates the refrigeration

process by turning off the condensing unit and unit cooler fan motors, and energizes the

defrost heaters. As the coil temperature increases, the frost begins to melt producing water

which runs down the coil to the unit cooler drain pan and exits through the drain tube to the

vaporizer. After all the frost has been removed and the coil temperature reaches

approximately 50°F [10ºC], the defrost is terminated through the action of the defrost

termination control located on the unit cooler, and the refrigeration process resumes. In order

to insure that any excess water remaining on the coil is not sprayed into the cabinet interior,

and all heat generated by the defrost is removed, the unit cooler fans will not operate until

the coil temperature reaches approximately 25°F [-4ºC].

Note: Running a cold wall model freezer in an unconditioned environment may result in frost

build-up inside the cabinet.

GENERAL MAINTENANCE

PERIODIC CLEANING

Beginning with the initial installation, the interior surfaces of the cabinet should be periodically

wiped down with a solution of warm water and baking soda. This solution will remove any

odors from spillage that has occurred. The exterior of the cabinet should also be cleaned

frequently with a commercial grade of glass cleaner.

Monthly cleaning of the condenser will aid the heat transfer characteristics of the refrigeration

system and increase its efficiency. To accomplish this, remove the cover panel from the

cabinet and use a wire brush to loosen any dirt particles that are attached to the fins. Use a

vacuum cleaner to remove the loosened particles. Failure to keep the condenser coil clean

and clear of obstructions could result in temperature loss and damage to the

compressor.

The shelving and pilasters should be periodically cleaned. The shelving should be removed

from the cabinet interior and washed with warm water and mild detergent using a soft bristle

brush or may be washed in a dishwasher large enough to accommodate the shelving size.

Pilasters may be removed from the cabinet interior by using a Philips screwdriver. Unscrew the

Philips head screws securing the pilasters to the cabinet interior walls. Retain the screws in a

Total Restaurant Supply - https://totalsupply1.com - Toll Free 1-800-944-9304 - Local 507-288-9454

2940 Hwy 14 W, Rochester, MN 55901

Page 4

4 06/11 Rev. B 127717

secure place for re-installation. Wash the pilasters with warm water and a mild detergent in a

suitable place suitable for this effort such as a deep sink. A soft bristle brush is recommended

to reach the interior area of the pilasters. Re-install the pilasters and shelving when the

cleaning procedure is complete.

Drain connections to the evaporator pan and the evaporator pan should be periodically

cleaned to prevent any build up of debris, fungi, etc. See the cleaning instructions on the

following page (B13351).

See the instructions below for cleaning the evaporator drain pan.

All moving parts have been permanently lubricated and will generally require no

maintenance.

Door hinges should also be periodically cleaned. The door(s) must be removed to gain

adequate access to the hinges. See the illustrations on next page for solid door and glass door

removal.

Total Restaurant Supply - https://totalsupply1.com - Toll Free 1-800-944-9304 - Local 507-288-9454

2940 Hwy 14 W, Rochester, MN 55901

Page 5

5 06/11 Rev. B 127717

SOLID DOOR REMOVAL FOR HINGE CLEANING

1. Open door to stay position, locate top hinge of door.

2. Remove screws for hinge.

After screws are removed, grasp top hinge firmly and

allow the hinge bracket to close to the door.

!!CAUTION!! Hinge under high tension Pinch point hazard

3. Once tension has been removed lift door up to

remove. Wipe area clean with mild soap, do not

use abrasives.

4. Reverse steps to re-install.

Total Restaurant Supply - https://totalsupply1.com - Toll Free 1-800-944-9304 - Local 507-288-9454

2940 Hwy 14 W, Rochester, MN 55901

Page 6

6 06/11 Rev. B 127717

GLASS DOOR REMOVAL FOR HINGE CLEANING

1. Open door, locate door heater power cord (if

applicable) and remove screw.

2. Remove black

spacer clip.

3. Pry open hinge stay to clear stop pin.

4. Locate hinge tension tool (Taped on door upon delivery).

Insert tool in spring notch on bottom of door, push

toward cabinet and then release front trigger. Skip this

step for doors with full length handles.

5. Once tension has been removed lift door up to remove.

6. Remove screws for

hinge.

7. Wipe clean with

mild soap.

Note: reverse process to install door.

Total Restaurant Supply - https://totalsupply1.com - Toll Free 1-800-944-9304 - Local 507-288-9454

2940 Hwy 14 W, Rochester, MN 55901

Page 7

7 06/11 Rev. B 127717

MAINTENANCE SERVICE AND ANALY SIS GUIDE

REFRIGERATION SYSTEMS - ALL MODELS

MALFUNCTION POSSIBLE CAUSE SOLUTION

Compressor will not start - 1. Service cord unplugged 1. Plug in service cord

no hum 2. Fuse blown or removed 2. Replace fuse

3. Overload tripped 3. Determine reasons and correct

4. Control stuck open 4. Repair or replace

5. Wiring incorrect 5. Check wiring against the diagram

Compressor will not start - 1. Improperly wired 1. Check wiring against the diagram

hums but trips on overload 2. Low voltage to unit 2. Determine reason and correct

protector 3. Starting capacitor defective 3. Determine reason and replace

4. Relay failing to close 4. Determine reason, correct or replace

Compressor starts and runs, 1. Low voltage to unit 1. Determine reason and correct

but short cycles on overload 2. Overload defective 2. Check current, replace overload protector

protector 3. Excessive head pressure 3. Check ventilation or restriction in

refrigeration system

4. Compressor hot-return gas hot 4. Check refrigerant charge, fix leak if necessary

Compressor operates long 1. Short of refrigerant 1. Fix leak, add charge

or continuously 2. Control contact stuck 2. Repair or replace

3. Evaporator coil iced 3. Determine cause, defrost manually

4. Restriction in refrigeration system 4. Determine location and remove restriction

5. Dirty condenser 5. Clean condenser

Compressor runs fine, but 1. Overload protector 1. Check wiring diagram

short cycles 2. Cold control 2. Differential too close - widen

3. Overcharge 3. Reduce charge

4. Air in system 4. Purge and recharge

5. Undercharge 5. Fix leak, add refrigerant

Starting capacitor open, 1. Relay contacts stuck 1. Clean contacts or replace relay

shorted or blown 2. Low voltage to unit 2. Determine reason and correct

3. Improper relay 3. Replace

Relay defective or burned out 1. Incorrect relay 1. Check and replace

2. Voltage too high or too low 2. Determine reason and correct

Refrigerated space too warm 1. Control setting too high 1. Reset control

2. Refrigerant overcharge 2. Purge refrigerant

3. Dirty condenser 3. Clean condenser

4. Evaporator coil iced 4. Determine reason and defrost

5. Not operating 5. Determine reason, replace if necessary

Standard temperature system 1. Control setting is too low 1. Reset the control

freezes the product 2. Control points stuck 2. Replace the control

Objectionable noise 1. Fan blade hitting fan shroud 1. Reform or cut away small section of shroud

2. Tubing rattle 2. Locate and reform

3. Vibrating fan blade 3. Replace fan blade

4. Condenser fan motor rattles 4. Check motor bracket mounting, tighten

5. General vibration 5. Compressor suspension bolts not loosened

on applicable models - loosen them

6. Worn fan motor bearings 6. Replace fan motor

Pan Area 1. No cooling 1. Make sure switch is in the "on" position

2. Too cold 2. Adjust temperature control - see instructions

under pan area

3. Too warm 3. Adjust temperature control - see instructions

under pan area

Total Restaurant Supply - https://totalsupply1.com - Toll Free 1-800-944-9304 - Local 507-288-9454

2940 Hwy 14 W, Rochester, MN 55901

Page 8

Model

BTU @ 100°F Solid Dr

& 86°F Glass Dr

Refrig't Voltage Amps Exp valve

ELEC

VAPORIZER

NR241SSS/0R

850 @ +28°F EVAP

R134a 115/60/1 0.53 YES NO

NR241SSG/0R

1260 @ +28°F EVAP

R134a 115/60/1 0.53 YES NO

NR242SSS/0R

850 @ +28°F EVAP

R134a 115/60/1 0.53 YES NO

NR242SSG/0R

1260 @ +28°F EVAP

R134a 115/60/1 0.53 YES NO

NR522SSS/0R

1580 @ +28°F EVAP

R134a 115/60/1 0.9 YES NO

NR522SSG/0R

2450 @ +28°F EVAP

R134a 115/60/1 0.9 YES NO

NR524SSS/0R

1580 @ +28°F EVAP

R134a 115/60/1 0.9 YES NO

NR524SSG/0R

2450 @ +28°F EVAP

R134a 115/60/1 0.9 YES NO

NR803SSS/0R

2250 @ +28°F EVAP

R134a 115/60/1 1.1 YES NO

NR803SSG/0R

3580 @ +28°F EVAP

R134a 115/60/1 1.1 YES NO

NR806SSS/0R

2255 @ +28°F EVAP

R134a 115/60/1 1.1 YES NO

NR806SSG/0R

3580 @ +28°F EVAP

R134a 115/60/1 1.1 YES NO

PR242SSS/0R

925 @ +28°F EVAP

R134a 115/60/1 0.53 YES NO

PR242SSG/0R

1860 @ +28°F EVAP

R134a 115/60/1 0.53 YES NO

PR524SSS/0R

1715 @ +28°F EVAP

R134a 115/60/1 0.9 YES NO

PR524SSG/0R

3655 @ +28°F EVAP

R134a 115/60/1 0.9 YES NO

PR806SSS/0R

2170 @ +28°F EVAP

R134a 115/60/1 1.1 YES NO

PR806SSG/0R

5110 @ +28°F EVAP

R134a 115/60/1 1.1 YES NO

WR331SSS/0R

1370@ +28°F EVAP

R134a 115/60/1 0.76 YES NO

WR722SSS/0R

2635@ +28°F EVAP

R134a 115/60/1 1.36 YES NO

PWR332SSS/0R

1500@ +28°F EVAP

R134a 115/60/1 1.0 YES NO

PWR724SSS/0R

2875@ +28°F EVAP

R134a 208-230/60/1 1.82 YES NO

NF241SSS/0R

1820 @ -10°F EVAP

R404a 115/60/1 4.7 YES NO

NF242SSS/0R

1820 @ -10°F EVAP

R404a 115/60/1 4.7 YES NO

NF522SSS/0R

2855 @ -10°F EVAP

R404a 115/60/1 6.9 YES NO

NF524SSS/0R

2855 @ -10°F EVAP

R404a 115/60/1 6.9 YES NO

NF803SSS/0R

3505 @ -10°F EVAP

R404a 115/60/1 7.4 YES NO

NF806SSS/0R

3505 @ -10°F EVAP

R404a 115/60/1 7.4 YES NO

NX211SSS/0R

3015@ -35°F EVAP

R404a 115/60/1 7.2 YES YES

NX211SSG/0R

4140 @ -35°F EVAP

R404a 115/60/1 7.2 YES YES

NX482SSS/0R

3520 @ -35°F EVAP

R404a 115/60/1 11.6 YES YES

NX482SSG/0R

5835 @ -35°F EVAP

R404a 115/60/1 11.6 YES YES

NOTES:

1) Cord and plug are not supplied with these units

2) Compressor size to be determined by a qualified refrigeration technician based on the delivered BTU rating

at the unit and actual jobsite requirements.

3) BTU rating shown is the required BTU's at the evap coil.

4) Standard five year compressor warranty does not apply to these units.

5) Condensate removal is the responsibility of the customer. A short drain line exiting the unit cooler section on

the top of the cabinet is provided for the purpose of extending.

6) Legs are standard on remote systems as they are generally hard piped to the condensing unit.

7) The solenoid valve mounted on the cabinet is factory wired to the control. No connections are required between

the cabinet and the remote compressor.

REMOTE REFRIGERATION DATA

8 06/11 Rev. B 127717

Total Restaurant Supply - https://totalsupply1.com - Toll Free 1-800-944-9304 - Local 507-288-9454

2940 Hwy 14 W, Rochester, MN 55901

Loading...

Loading...