Standard Pump SP-CPVC, SP-CPVC-HH, SP-PP, SP-PHT, SP-PHT-HH Operating Instructions Manual

...

Standard Pump Operating Instructions and Parts Manual (OIPM-IND-0713)

Standard Pump

Industrial Drum Pump Models:

SP-PP, SP-PHT, SP-CPVC, SP-AL, SP-PVDF & SP-SS

Description

Standard’s Drum Pumps are designed to

transfer a variety of materials from 55 gallon

drums and tanks. Standard Pump offers

several different pumps, each designed

for specific applications. Before operating,

please confirm that the pump’s materials of

construction are suitable for the application.

Unpacking

Cartons should be handled with care to avoid

damage from dropping, etc. After unpacking,

inspect carefully for any damage that may

have occurred during transit. Check for loose,

damaged or missing parts.

General Safety Information

The responsibility for safe assembly,

installation, and operation ultimately rests

with the operator. Read and understand ALL

safety precautions and operating instructions

before operation. Careless pump operation

can result in serious injury.

1. Before operating the pump, read and

understand these operating instructions.

2. The operator should wear suitable

protective clothing including the

following: face mask, safety shield or

goggles, gloves, apron, and safety

shoes.

3. Before operating, verify the materials

being pumped are compatible with the

pump’s “wetted components."

4. All Federal, State, and local safety codes

should be followed.

5. Verify that the motor voltage

corresponds to proper electrical supply.

6. Before plugging motor into power

supply, make sure the motor switch is in

the OFF position. For Air Motors ensure

inlet valve is closed before attaching air

line.

7. Before operation, confirm all pump

connections are properly tightened.

8. First pump clean water in order to

familiarize yourself with the pump’s

operation, flow rate, discharge pressure

and motor speed.

9. Before starting the pump, confirm the

discharge hose is securely fastened to

the receiving vessel in order to prevent

splashing.

10. Never leave pump unattended during

operation.

11. Do not submerge the motor in any liquid.

12. When finished using the pump, flush

the pump by pumping water or an

appropriate cleaning solution. Do not

use flammable or combustible cleaning

solutions.

13. Never carry the motor by the power

cord.

14. Never store pump in container. Always

rinse pump thoroughly and hang on wall

bracket or ensure pump tube is stored in

an upright and vertical position.

When pumping

flammable or

combustible products or operating in a

hazardous duty environment, the SP-AL

or SP-SS Series pump must be used in

conjunction with an explosion proof

motor. Please contact the factory or an

authorized distributor with any questions

regarding this matter.

Assembly

1. Remove the pump and motor from

packaging.

2. Inspect all contents for damage.

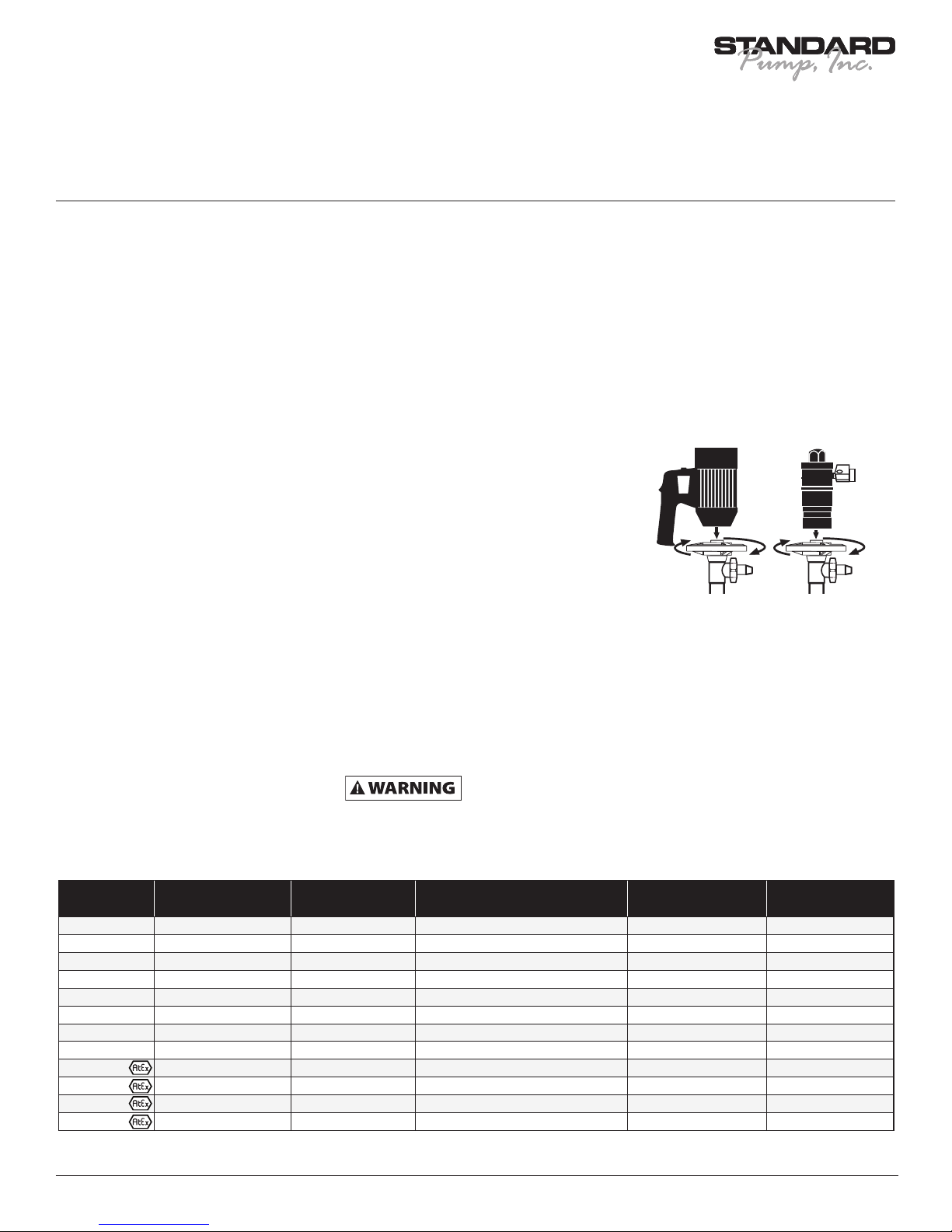

3. Couple the motor to the pump tube by

using the Hand Wheel. (See figure 1).

Figure 1

Drum Pump Specications

Model

SP-CPVC CPVC 190º F (90º C) CPVC, Carbon, Hastelloy C, PVDF, PTFE 35 gpm (132 l/min) 16 psi (1,1 bar)

SP-CPVC-HH CPVC 190º F (90º C) CPVC, Carbon, Hastelloy C, PVDF, PTFE 16 gpm (60 l/min) 32 psi (2,2 bar)

SP-PP Polypropylene 130º F (55º C) PP, Carbon, Hastelloy C, PTFE 35 gpm (132 l/min) 16 psi (1,1 bar)

SP-PP-HH Polypropylene 130º F (55º C) PP, Carbon, Hastelloy C, PTFE 16 gpm (60 l/min) 32 psi (2,2 bar)

SP-PHT Polypropylene 175º F (80º C) PP, Carbon, Hastelloy C, PTFE 35 gpm (132 l/min) 16 psi (1,1 bar)

SP-PHT-HH Polypropylene 175º F (80º C) PP, Carbon, Hastelloy C, PTFE 16 gpm (60 l/min) 32 psi (2,2 bar)

SP-PVDF PVDF (Kynar®) 175º F (80º C) PVDF, Carbon, Hastelloy C, PTFE 35 gpm (132 l/min) 16 psi (1,1 bar)

SP-PVDF-HH PVDF (Kynar®) 175º F (80º C) PVDF, Carbon, Hastelloy C, PTFE 16 gpm (60 l/min) 32 psi (2,2 bar)

*SP-SS SS316 175º F (80º C) SS316, Carbon, PTFE 35 gpm (132 l/min) 16 psi (1,1 bar)

*SP-SS-HH SS316 175º F (80º C) SS316, Carbon, PTFE 16 gpm (60 l/min) 32 psi (2,2 bar)

*SP-AL Aluminum 175º F (80º C) Aluminum, Carbon, PTFE & SS316 35 gpm (132 l/min) 16 psi (1,1 bar)

*SP-AL-HH Aluminum 175º F (80º C) Aluminum, Carbon, PTFE & SS316 16 gpm (60 l/min) 32 psi (2,2 bar)

* When operating in Hazardous Duty applications a pump must be used in conjunction with an explosion proof motor or air motor.

Material of

Construction

Maximum Liquid

Temperature

Wetted Materials Maximum Flow Rate

1

Discharge

Pressure

Standard Pump Operating Instructions and Parts Manual (OIPM-IND-0713)

Industrial Drum Pumps Models:

SP-PP, SP-PHT, SP-CPVC, SP-AL, SP-PVDF & SP-SS

Pump Package Specications

Electric Motor Pump Packages

Model HP Voltage Phase Meter Wetted Components

9400 1 110V 1 No Polypropylene, Carbon, Hastelloy C, PVC, Viton®, PTFE 39" (1000 mm) 6 ft. (1,83 meters) Polypropylene

9401 1 220V 1 No Polypropylene, Carbon, Hastelloy C, PVC, Viton®, PTFE 39" (1000 mm) 6 ft. (1,83 meters) Polypropylene

9402 1 110V 1 No Polypropylene, Carbon, Hastelloy C, PVC, Viton®, PTFE 47" (1200 mm) 6 ft. (1,83 meters) Polypropylene

9403 1 220V 1 No Polypropylene, Carbon, Hastelloy C, PVC, Viton®, PTFE 47" (1200 mm) 6 ft. (1,83 meters) Polypropylene

9414 1 110V 1 No SS316, PTFE, Carbon, PVC, PTFE 39" (1000 mm) 6 ft. (1,83 meters) SS316

9415 1 220V 1 No SS316, PTFE, Carbon, PVC, PTFE 39" (1000 mm) 6 ft. (1,83 meters) SS316

9416 1 110V 1 No SS316, PTFE, Carbon, PVC, PTFE 47" (1200 mm) 6 ft. (1,83 meters) SS316

9417 1 220V 1 No SS316, PTFE, Carbon, PVC, PTFE 47" (1200 mm) 6 ft. (1,83 meters) SS316

9420 1 110V 1 No PVDF, Carbon, Hastelloy C, Alphasyn, Viton®, PTFE 39" (1000 mm) 6 ft. (1,83 meters) PVDF

9421 1 220V 1 No PVDF, Carbon, Hastelloy C, Alphasyn, Viton®, PTFE 39" (1000 mm) 6 ft. (1,83 meters) PVDF

9422 1 110V 1 No PVDF, Carbon, Hastelloy C, Alphasyn, Viton®, PTFE 47" (1200 mm) 6 ft. (1,83 meters) PVDF

9423 1 220V 1 No PVDF, Carbon, Hastelloy C, Alphasyn, Viton®, PTFE 47" (1200 mm) 6 ft. (1,83 meters) PVDF

9430 1 110V 1 No

9431 1 220V 1 No

9432 1 110V 1 No

9433 1 220V 1 No

9500 1 110V 1 Ye s

9501 1 220V 1 Ye s

9502 1 110V 1 Ye s

9503 1 220V 1 Ye s

9510 1 110V 1 Ye s

9511 1 220V 1 Ye s

9512 1 110V 1 Ye s PVDF, Carbon, Hastelloy C, Alphasyn, PTFE 47" (1200 mm) 6 ft. (1,83 meters) PVDF

9513 1 220V 1 Ye s

9460 1 110V 1 No Aluminum, Carbon, PTFE & SS316 39" (1000 mm) 6 ft. (1,83 meters) Aluminum

9461 1 220V 1 No Aluminum, Carbon, PTFE & SS316 39" (1000 mm) 6 ft. (1,83 meters) Aluminum

9462 1 110V 1 No Aluminum, Carbon, PTFE & SS316 47" (1200 mm) 6 ft. (1,83 meters) Aluminum

9463 1 220V 1 No Aluminum, Carbon, PTFE & SS316 47" (1200 mm) 6 ft. (1,83 meters) Aluminum

9610 1 110V 1 No SS316, Carbon, PTFE 39" (1000 mm) 6 ft. (1,83 meters) SS316

9611 1 220V 1 No SS316, Carbon, PTFE 39" (1000 mm) 6 ft. (1,83 meters) SS316

9612 1 110V 1 No SS316, Carbon, PTFE 47" (1200 mm) 6 ft. (1,83 meters) SS316

9613 1 220V 1 No SS316, Carbon, PTFE 47" (1200 mm) 6 ft. (1,83 meters) SS316

CPVC, Polypropylene, Carbon, Hastelloy C, PVC,

Viton®, PVDF, PTFE

CPVC, Polypropylene, Carbon, Hastelloy C, PVC,

Viton®, PVDF, PTFE

CPVC, Polypropylene, Carbon, Hastelloy C, PVC,

Viton®, PVDF, PTFE

CPVC, Polypropylene, Carbon, Hastelloy C, PVC,

Viton®, PVDF, PTFE

Polypropylene, Carbon, Hastelloy C, PVC, Viton®,

Ceramic, PVDF, Halar, PTFE

Polypropylene, Carbon, Hastelloy C, PVC, Viton®,

Ceramic, PVDF, Halar, PTFE

Polypropylene, Carbon, Hastelloy C, PVC, Viton®,

Ceramic, PVDF, Halar, PTFE

Polypropylene, Carbon, Hastelloy C, PVC, Viton®,

Ceramic, PVDF, Halar, PTFE

PVDF, Carbon, Hastelloy C, Alphasyn, Viton®, Ceramic,

Halar, PTFE

PVDF, Carbon, Hastelloy C, Alphasyn, Viton®, Ceramic,

Halar, , PTFE

PVDF, Carbon, Hastelloy C, Alphasyn, Viton®, Ceramic,

Halar, PTFE

Immersion

Length

39" (1000 mm) 6 ft. (1,83 meters) Polypropylene

39" (1000 mm) 6 ft. (1,83 meters) Polypropylene

47" (1200 mm) 6 ft. (1,83 meters) Polypropylene

47" (1200 mm) 6 ft. (1,83 meters) Polypropylene

39" (1000 mm) 6 ft. (1,83 meters) Polypropylene

39" (1000 mm) 6 ft. (1,83 meters) Polypropylene

47" (1200 mm) 6 ft. (1,83 meters) Polypropylene

47" (1200 mm) 6 ft. (1,83 meters) Polypropylene

39" (1000 mm) 6 ft. (1,83 meters) PVDF

39" (1000 mm) 6 ft. (1,83 meters) PVDF

47" (1200 mm) 6 ft. (1,83 meters) PVDF

Hose Length

Nozzle

Material

Air Motor Pump Packages

Model HP Air Consumption Meter Wetted Components Immersion Length Hose Length Nozzle Material

9604 0.5 22 CFM (10.4 L/sec) @ 90 psi (6,2 ba r) No SS316, PTFE, Carbon, UHMWPE, PTFE 39" (1000 mm) 6 ft. (1,83 meters) SS316

9605 0.75 28 CFM (13.2 L/sec) @ 90 psi (6,2 bar) No SS316, PTFE, Carbon, UHMWPE, PTFE 39" (1000 mm) 6 ft. (1,83 meters) SS316

9606 0.05 22 CFM (10.4 L/sec) @ 90 psi (6,2 bar) No SS316, PTFE, Carbon, UHMWPE, PTFE 47" (1200 mm) 6 ft. (1,83 meters) SS316

9607 0.75 28 CFM (13.2 L/sec @ 90 psi (6,2 bar) No SS316, PTFE, Carbon, UHMWPE, PTFE 47" (1200 mm) 6 ft. (1,83 meters) SS316

9464 0.75 28 CFM (13.2 L/sec @ 90 psi (6,2 bar) No Aluminum, Carbon, PTFE & SS316 39" (1000 mm) 6 ft. (1,83 meters) Aluminum

9465 0.75 28 CFM (13.2 L/sec @ 90 psi (6,2 bar) No Aluminum, Carbon, PTFE & SS316 47" (1200 mm) 6 ft. (1,83 meters) Aluminum

®

Viton is a registered trademark of DuPont Dow Elastomers.

2

Standard Pump Operating Instructions and Parts Manual (OIPM-IND-0713)

Industrial Drum Pumps Models:

SP-PP, SP-PHT, SP-CPVC, SP-AL, SP-PVDF & SP-SS

SP-PP, SP-PHT, SP-CPVC, SP-PVDF Spare Parts List

Ref.

1

2

4

5

3

9

10

Number

1 Hand Wheel, Polypropylene 1842 1842 1842 1842 1

2 Pump Coupling, Nylon 1004* 1004* 1004* 1004* 1

3 Snap Ring, Steel 1508 1508 1508 1508 1

Bearing Unit Assembled – 2 each

4

Viton shielded bearings, spacer, snap ring, bearing can

5 V-Seal, Viton

8

11

6

7

18

V-Seal, PTFE - 4000 4000 4000

6 Drive Shaft, Hastelloy

27" (700 mm) 1543 1543 1543 1543 1

39" (1000 mm) 1544 1544 1544 1544 1

Description

®

P/N for

SP-PP

P/N for

SP-PHT

P/N for

SP-CPVC

P/N for

SP-PVDF

1038* 1038* 1038* 1038* 1

1000 - - - 1

Qty

47" (1200 mm) 1545 1545 1545 1545 1

50" (1270 mm) 1549 1549 1549 1549 1

60" (1500 mm) 1546 1546 1546 1546 1

72" (1800 mm) 1547 1547 1547 1547 1

12

7 Guide Sleeve, PTFE

27"(700 mm) 1516 1516 1516 1516 1

39" (1000 mm), 47" (1200 mm), 50" (1270 mm) 1514 1514 1514 1514

60" (1500 mm), 72" (1800 mm) 1661 1661 1661 1661 1

8 Discharge Housing 1028 6028 5028 4028 1

9 Wing Nut 1106 6106 5106 4106 1

10 Hose Barb

.75" (19 mm) 1051 6051 5051 4051 1

1" (25 mm) 1082 6082 5082 4082 1

11 Inner Tube,

27" (700 mm) 1600 6600 5600 4600 1

39" (1000 mm) 1601 6601 5601 4601 1

47" (1200 mm) 1602 6602 5602 4602 1

50" (1270 mm) 1623 6623 5623 4623 1

60" (1500 mm) 1615 6615 5615 4615 1

72" (1800 mm) 1616 6616 5616 4618 1

27" (700 mm) 1604 6604 5604 4604 1

14 15

13

16

12 Outer Tube,

39" (1000 mm) 1603 6603 5603 4603 1

47" (1200 mm) 1605 6605 5605 4605 1

50" (1270 mm) 1624 6624 5624 4622 1

60" (1500 mm) 1617 6617 5617 4617 1

72" (1800 mm) 1618 6618 5618 4619 1

13 Pump Housing (Includes Carbon Bushing) 1524* 6524* 5524* 4607* 1

14 High Volume Impeller, Polypropylene 1608* 6608* 5608* 4608* 1

15 High Pressure Impeller, PTFE 4608 HH 4608 HH 4608 HH 4608 HH 1

16 High Volume Pump Foot, Polypropylene 1609* 6609* - - 1

High Volume Pump Foot, PVDF - - 5609* 4609* 1

High Pressure Pump Foot, Polypropylene & PTFE 1609 HH 6609 HH - - 1

High Pressure Pump Foot, PVDF & PTFE - - 5609 HH 4609 HH 1

17 Repair Kit (*Includes Items 2, 5, 10, 13, & 14) 9050 9053 9052 9051 1

18 O-Ring, Viton

®

- 6695 - - 1

SP-PP, SP-PHT, SP-CPVC, SP-PVDF pumps should not be used to pump flammables.

3

Loading...

Loading...