Page 1

55-1522

STAMINA PRODUCTS

MADE IN CHINA

Product May Vary Slightly

From Pictured.

CAUTION:

! WARNING !

Exercise can present a he alth

risk. Consult a physician

before beginning any exercise

program with this equipment.

If you feel faint or dizzy,

immediately discontinue use

of this equipment. Serious

bodily injury can occur if this

equipment is not assembled

and used correctly. Serious

bodily injury can also occur if

all instructions are not

followed. Keep others and

pets away from equipment

when in use. Always make

sure all bolts and nuts are

tightened prior to each use.

Follow all safety instructions in

this manual.

When calling for parts or

service, please specify the

following number.

Weight on this product should not exceed 300 lbs.

Class H equipment: This equipment is for home

use only. It is not for commercial use.

1.

2.

2006, 02

2040 N. Alliance, Springfield, MO 65803

Customer Service Number

1 (800) 375-7520

www.staminaproducts.com

This Product is Produced Exclusively by

2006 Stamina Products, Inc.

Owner's Manual

Page 2

SAFETY INSTRUCTIONS

2

WARNING:

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

Read the Warning Label posted on the Front Base Frame.

The Core Training Inversion System should only be used after a thorough review of the Owner's

Manual.

We recommend that two people be available for assembly of this product.

Do not use the Core Training Inversion System alone. Always have a helper available in case

assistance is needed in recovering from the decline position.

Always use the Seat Belt. Make sure the Seat Belt is securely fastened before inverting.

You must understand how to recover from the inverted position before using the Core Training

Inversion System. Read the LEVER OPERATION section on page 15

BEFORE using the Core

Training Inversion System.

Do not allow children to use or play on the Core Training Inversion System.

Keep small children and pets away from the Core Training Inversion System at all times.

The Core Training Inversion System should not be used by persons weighing more tha n 300 lbs.

The Core Training Inversion System should not be used by persons over 6 feet 6 inches tall.

Keep hands and feet away from moving parts.

It is recommended that you place this exercise equipment on an equipment mat.

Use the Core Training Inversion System only on a level surface.

W ear appropriate clothing when exercising; do not wear loose clothing that could become caught in

the Core Training Inversion Syste m.

Be sure that there is enough room for the seat to rotate completely.

Use the Core Training Inversion System only as de scribed in the manual.

The safety level of the Core Training Inversion System can be maintained only if it is examined

regularly for damage and wear.

This equipment is for home use only. It is not for commercial use.

Maintenance Instructions 16

Warranty 17

Product Parts Drawing 18

Parts List 19

Notes 21

Fax/Mail Ordering Form 22

Safety Instructions 2

Before Y ou Begin 4

Hardware Identification Chart 5

Assembly Instructions 6

Operational Instructions 13

Storage 16

TABLE OF CONTENTS

Page Page

Extreme obesity

Glaucoma, retinal detachment or conjunctivitis

Pregnancy

Spinal injury, Cerebral Sclerosis, or acutely swollen joints

Middle ear infection

High blood pressure, Hypertension, Recent stroke or Transient ischemic attack

Heart or circulatory disorders for which you are being treated

Hiatus hernia or Ventral hernia

Bone weaknesses including Osteoporosis, Unhealed fractures, Medullary pins, or

Surgically implanted orthopedic supports.

Use of anti-coagulants including Aspirin in high doses.

WARNING: Before using this equipment you should consult with your personal physician to see if

inversion equipment is appropriate for you. Do not use this equipment without your physician's

approval. Do not use this equipment if you have any of the following conditions or ailments:

To reduce the risk of serious injury, read the following safety instructions before

using the

Core Training Inversion System.

Page 3

THANK YOU FOR PURCHASING THE

Core Training Inversion System

Simply follow the few assembly instructions set forth in this manual.

Within a few minutes you will be getting

your body into shape and on your way to achieving

a ha ppier and healthier lifestyle.

Should you have any que stions,

please call our Customer Service Department toll-free number,

1 (800) 375-7520

Monday - Friday, 8:00 A.M. - 5:00 P.M., Central Time.

CALL US FIRST

3

Page 4

BEFORE YOU BEGIN

Thank you for choosing the Core Training

Inversion System. W e ta ke great pride in producing

this quality product and hope it will provide many

hours of quality exercise to make you feel better , look

better and enjoy life to its fullest.

Yes, it's a proven fact that a regular exercise

program can improve your physical and mental

health. Too often, our busy lifestyles limit our time

and opportunity to exercise. The Core Training

Inversion System provides a convenient a nd simple

method to begin your assault on getting your body in

sha pe and a chieving a ha ppier and healthier lifestyle.

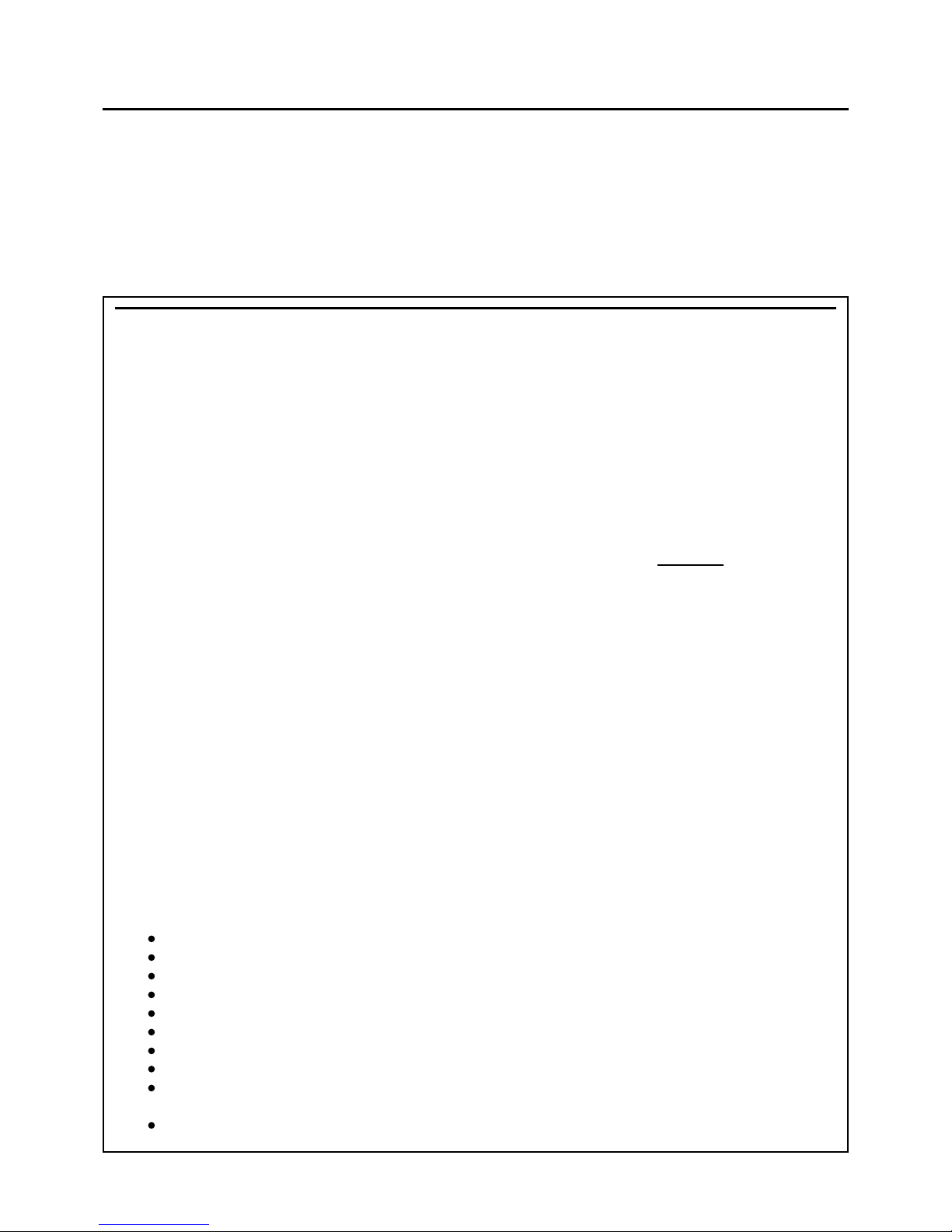

Before reading further, please review the drawing

below and familiarize yourself with the parts that are

labeled.

Read this manual carefully before using the Core

Training Inversion System.

Although Stamina tries to manufa cture its products

with the finest materials and uses the highest

standards of ma nufacturing, occasionally a part that

does not fit, is the incorrect size, or is otherwise

inappropriate is found. Even with the highest

inspection and quality controls in place these things

will happen occasionally. Please do not return the

product. For your convenience, Stamina has a

Customer Service Department with a toll-free

number. If a part is missing, does not fit, is the

incorrect size, or is otherwise inappropriate, please

call 1 (800) 375-7520 (in the U.S.) between 8:00 A.M.

and 5:00 P.M. Central Ti me, Monday through Friday .

Our operators will be able to assist you with your

problem and the parts will be mailed directly to your

house.

4

Left Pivot Arm

Stand B

Right Front Frame

Handrail

Back Cushion

Stand A

Handrail

Lever

Seat Cushion

Leg Support Cushion

Rear Fra me

Foam Pad

Left Front Frame

THE FOLLOWING TOOLS ARE INCLUDED FOR ASSEMBLY :

Allen Wrench (4mm)

Allen Wrench (6mm)

Combination Wrench

Rear Ba se Frame

Left Handrail Support

Spring Knob

Front Base Frame

Warning Label

Page 5

5

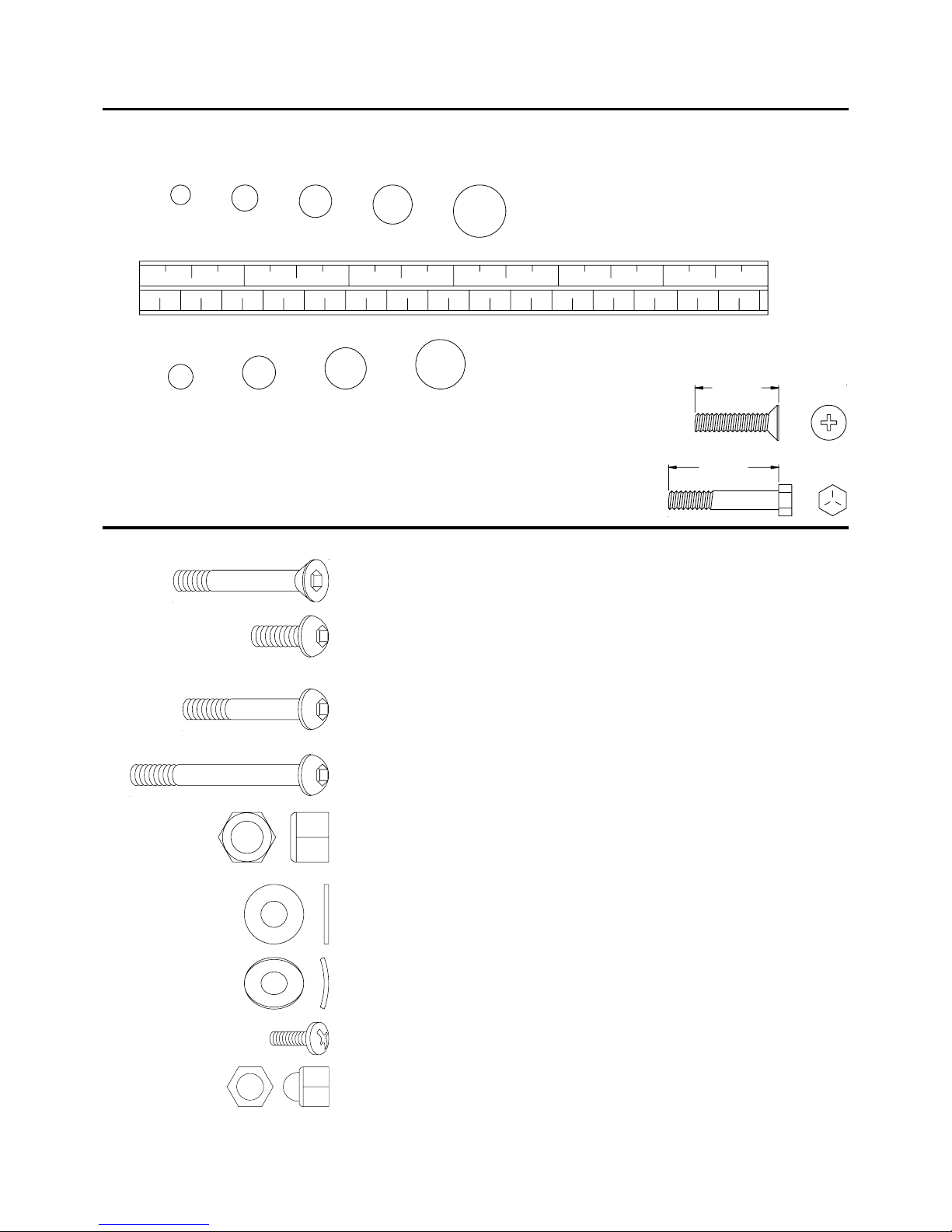

Part No. and Description Qty

40 Acorn Nut (M5 x 0.8) 1

54 Bolt, Flat Head (M6 x 1 x 50mm) 4

38 Screw, Round He ad (M5 x 0.8 x 18mm) 1

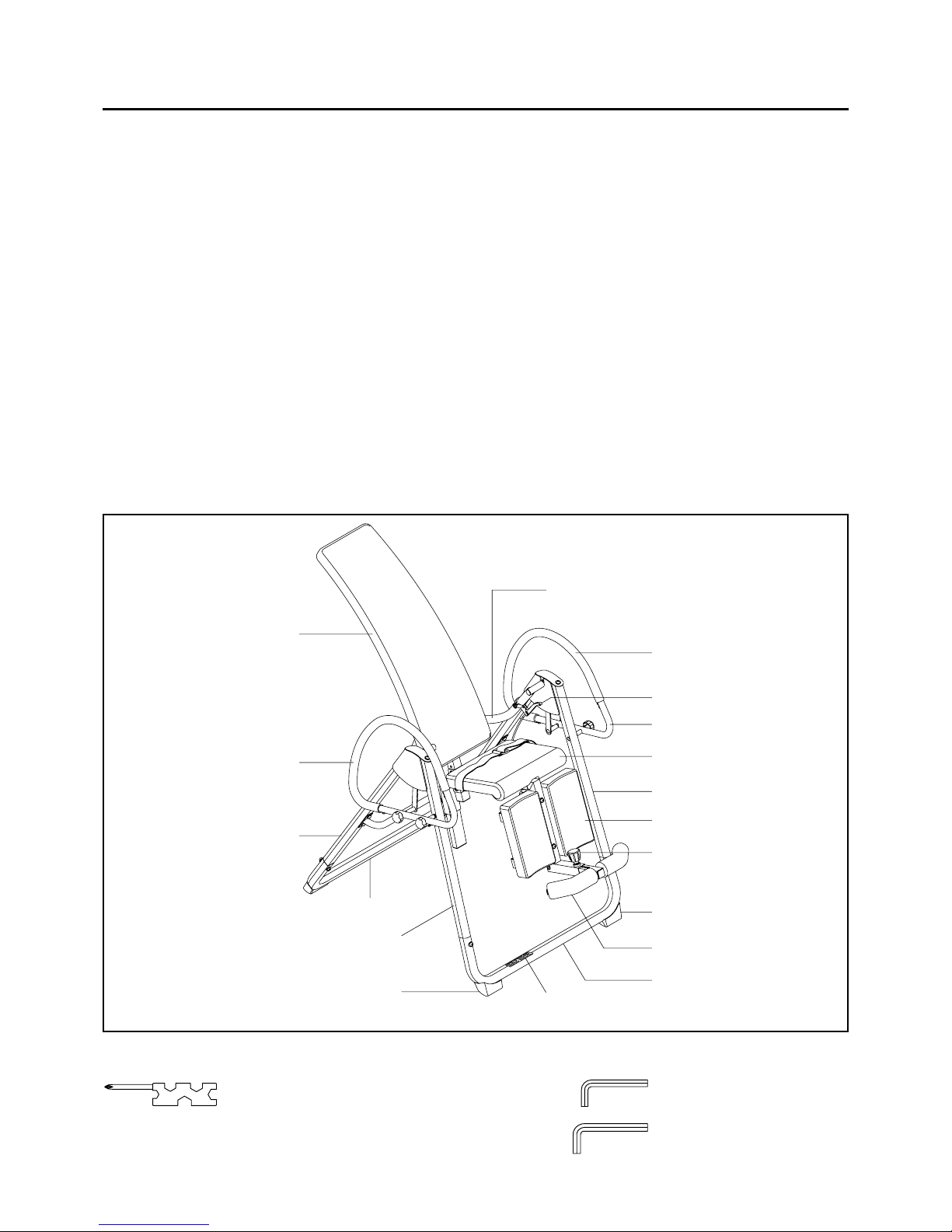

HARDWARE IDENTIFICATION CHART

Place washers, the end of bolts or screws on the circles to check for the

correct size. Use the small scale to check the sizes of bolts and screws.

This chart is provided to help identify the hardware used in the assembly process.

After unpacking the unit, open the hardware bag and make sure that you have the following items:

length

length

mm.

in.

INCHES

MILLIMETERS

11/2021/2 31/2 41/2 51/2 61/2

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150

6 8 10 12

3/16" 5/16" 1/2"3/8"1/4"

NOTICE: The length of all kinds of screws and bolts are not included

themselves head, except the flat head screws and bolts.

1. Some of the hardware items listed may be attached to other parts.

2. Bolt length is measured from the bottom of the bolt head to the end of the bolt.

NOTE:

69 Arc Washer (M8) 4

55 Bolt, Button Head (M6 x 1 x 15mm) 2

58 Bolt, Button Head (M8 x 1.25 x 15mm) 22

59 Bolt, Button Head (M8 x 1.25 x 30mm) 8

56 Bolt, Button Head (M6 x 1 x 47mm) 1

57 Bolt, Button Head (M6 x 1 x 65mm) 2

60 Bolt, Button Head (M8 x 1.25 x 55mm) 4

61 Bolt, Button Head (M8 x 1.25 x 60mm) 4

62 Bolt, Button Head (M10 x 1.5 x 90mm) 2

63 Nylock Nut (M6 x 1) 6

64 Nylock Nut (M8 x 1.25) 10

65 Nylock Nut (M10 x 1.5) 2

66 Washer (M6) 11

67 Washer (M8) 42

68 Washer (M10) 2

39 Washer (M5) 1

Page 6

ASSEMBLY INSTRUCTIONS

Place all parts from the box in a cleared area and position them on the floor in front of you. Remove all

packing materi als from your area a nd pla ce them ba ck into the box. Do not dispose of the pa cking materials

until assembly is completed. Read each step carefully before beginning. If you are missing a part please

call our toll-free number for assistance 1 (800) 375-7520 or e-mail us at :

parts@staminaproducts.com

6

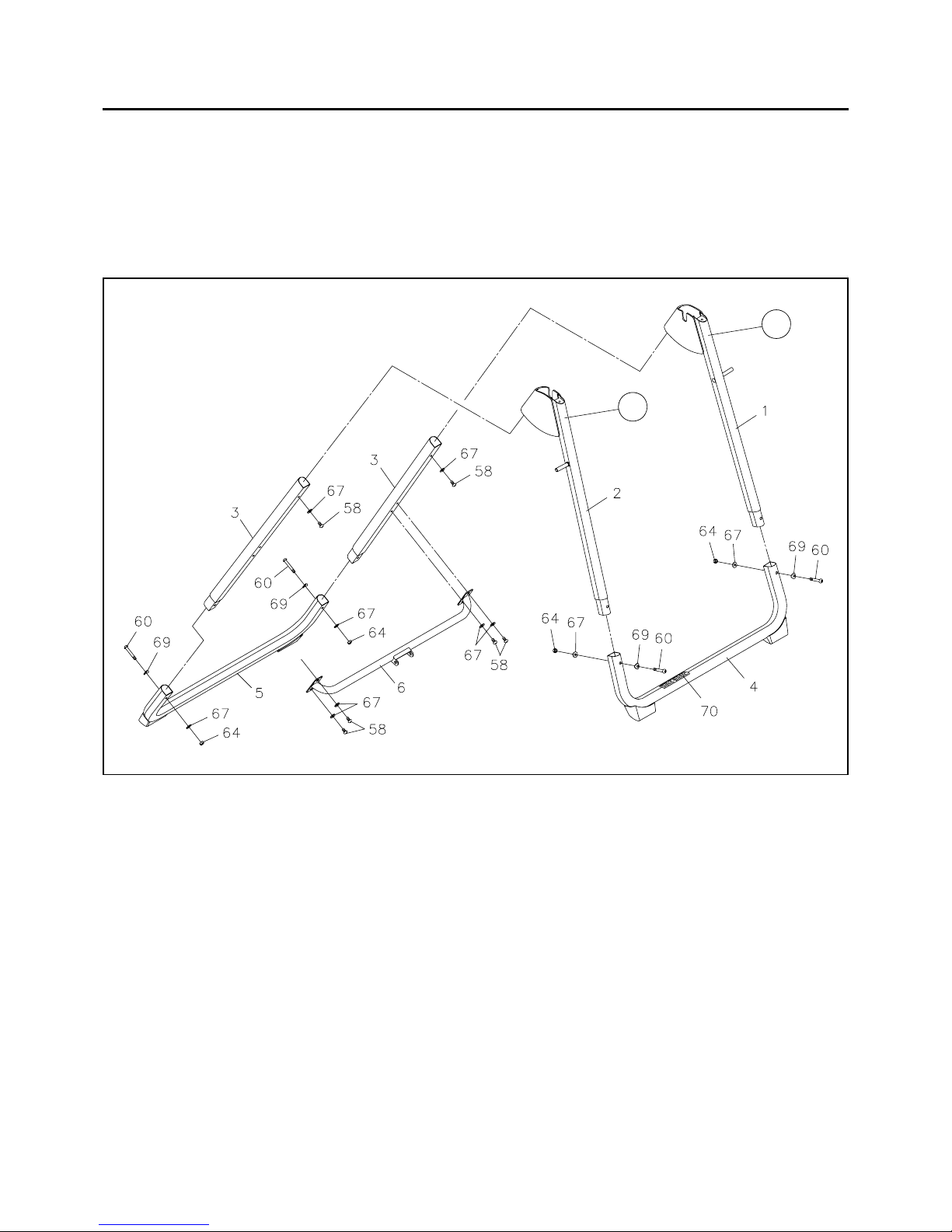

STEP 1: There is a "L" decal on the LEFT FRONT FRAME(1), and a "R" de cal on the RIGHT FRONT

FRAME(2). Insert the LEFT and RIGHT FRONT FRAMES(1, 2) into the FRONT BASE FRAME(4),

the one with WARNING LABEL(70), and secure with BUTTON HEAD BOLTS(M8 x 55mm)(60),

ARC WASHERS(M8)(69), WASHERS(M8)(67), and NYLOCK NUTS(M8)(64). Insert the REAR

FRAMES(3) into the REAR BASE FRAME(5) and se cure with BUTTON HEAD BOL TS(M8 x 55mm)

(60), ARC W ASHERS(M8)(69), W ASHERS(M8)(67), and NYLOCK NUTS(M8)(64). Do not tighten

the bolts until

STEP 3.

STEP 2: Slide the upper ends of the REAR FRAMES(3) into the Brackets on the FRONT FRAMES

(1, 2) and secure with BUTTON HEAD BOLTS(M8 x 15mm)(58), and WASHERS(M8)(67). Do not

tighten the bolts until

STEP 3.

STEP 3

NOTE:

Attach the CROSSING FRAME(6) onto the REAR FRAMES(3) with BUTTON HEAD BOLTS

(M8 x 15mm)(58) and WASHERS(M8)(67). Tighten all of the bolts.

Attach the CROSSING FRAME(6) so that the long flat surface of the center bracket is on top as

shown in the illustration.

L

R

Page 7

ASSEMBLY INSTRUCTIONS

7

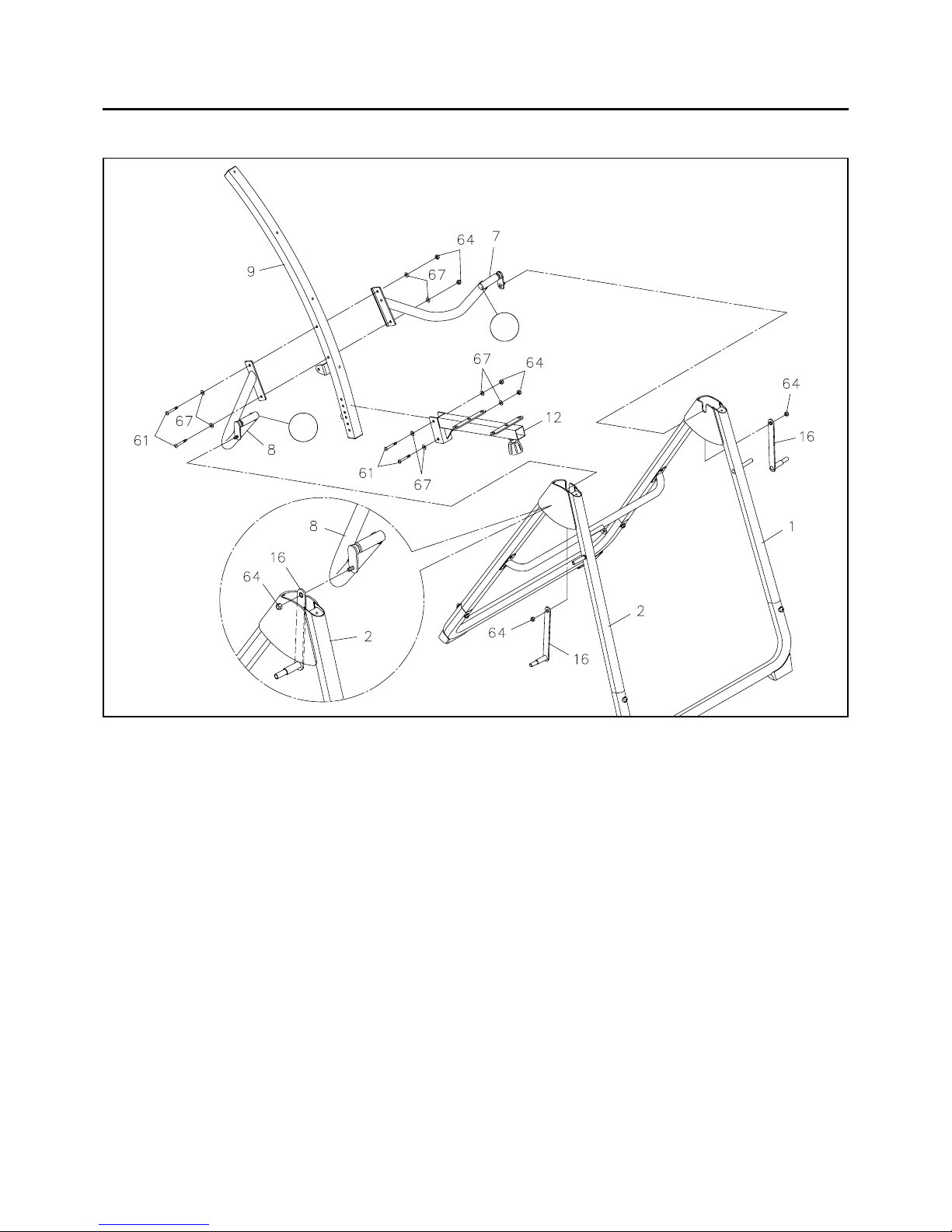

STEP 4

There is a "L" decal on the LEFT PIVOT ARM(7), and a "R" decal on the RIGHT PIVOT ARM(8).

Refer to the Inset drawing. Insert the LINKAGE(16) through the bra cket on the RIGHT FRONT FRAME(2),

then attach the LINKAGE(16) to the RIGHT PIVOT ARM(8) with NYLOCK NUT(M8)(64). DO NOT

OVER TIGHTEN THE NUT.

Attach the RIGHT PIVOT ARM(8) onto the RIGHT FRONT FRAME(2) by sliding the slots in the end of

the

RIGHT PIVOT ARM(8) into the slot on the RIGHT FRONT FRAME(2). Repeat on other side.

STEP 5: Pla ce the BACK FRAME(9) between the Brackets of the LEFT a nd RIGHT PIVOT ARMS(7,

8) and secure with BUTTON HEAD BOLTS(M8 x 60mm)(61), NYLOCK NUTS(M8)(64), and

WASHERS(M8)(67).

STEP 6: Attach the SEAT FRAME(12) onto the BACK FRAME(9) with BUTTON HEAD BOLTS

(M8 x 60mm)(61), NYLOCK NUT(M8)(64), and WASHERS(M8)(67).

SEAT FRAME HEIGHT ADJUSTMENT

There are adjustment holes on the BACK FRAME(9) allowing you to position the SEAT FRAME(12) at

three different heights. In the highest position, it is ea sier to invert but more dif ficult to recover from inversion.

In the lowest position, it is more difficult to invert but easier to recover from inversion. T all people may prefer

the lowest position and shorter people may prefer the highest position.

L

R

Page 8

ASSEMBLY INSTRUCTIONS

8

STEP 7

Attach the SLIDER SUPPORT(11) onto the Bracket on the CROSSING FRAME(6) with BUTTON

HEAD BOLT(M10 x 90mm)(62), NYLOCK NUT(M10)(65), and WASHER(M10)(68).

STEP 8

Straighten the CABLE(35) on the LEVER(36). Refer to the Inset drawing. The LEVER(36) should be

attached 4.5 inches lower tha n the shaft on the

LEFT PIVOT ARM(7). To attach the LEVER(36) onto the

LEFT PIVOT ARM(7), hook the CLIP(37) into slot in the LEVER(36) and secure the LEVER(36) in

position with

ROUND HEAD SCREW(M5 x 18mm)(38), W ASHER(M5)(39), and ACORN NUT(M5)

(40).

STEP 9

Gra sp the LEVER(36) and then Insert the BACK SUPPORT BAR(10) into the SLIDER SUPPORT(1 1).

Release the LEVER(36) to lock the BACK SUPPORT BAR(10) in one of the adjustment holes. Swing

the

BACK FRAME(9) to aline the Bracket on the BACK FRAME(9) with the Bushings on the top of the

BACK SUPPORT BAR(10), then secure with BUTTON HEAD BOLT(M10 x 90mm)(62), NYLOCK

NUT(M10)(65), and WASHER(M10)(68).

Page 9

ASSEMBLY INSTRUCTIONS

9

STEP 10

Attach the SUPPORT PLA TES(23) onto the BACK FRAME(9) with FLAT HEAD BOL TS(M6 x 50mm)

(54), WASHERS(M6)(66), and NYLOCK NUTS(M6)(63).

NOTE:

A

B

C

D

The lowest SUPPORT PLATE(23) is attached with a FLAT HEAD BOLT(M6 x 50mm)(54),

no washer and nut needed.

STEP 11

The BACK FRAME(9) is curved. Follow sequence A, B, C, and D as shown in the illustration to attach

the

BACK CUSHION(24) to the SUPPORT PLA TES(23) with BUTTON HEAD BOL TS(M8 x 15mm)

(58) and WASHERS(M8)(67).

Page 10

ASSEMBLY INSTRUCTIONS

10

STEP 12: Refer to the Bottom View in the illustration. Attach the BELT GUIDES(27) onto the SEAT

CUSHION(25) with BUTTON HEAD BOLTS(M8 x 15mm)(58) and WASHERS(M8)(67). Make the

Securing Pad fa ce down and insert the

SEA T BEL T(26) through the BEL T GUIDES(27) under the SEAT

CUSHION(25). Move the SEA T CUSHION(25) to the center of the SEA T BEL T(26). Atta ch the SEAT

CUSHION(25) onto the SEAT FRAME(12) with BUTTON HEAD BOLTS(M8 x 15mm)(58) an d

WASHERS(M8)(67).

Securing Pad

must face down

BOTTOM VIEW

STEP 13: Rotate the SPRING KNOB(29) on the SEAT FRAME(12) counter clockwise until the knob

portion can be pulled. Pull down the

SPRING KNOB(29) then insert the LEG SUPPORT FRAME(13)

into the SEA T FRAME(12). Relea se the SPRING KNOB(29) to lock the LEG SUPPORT FRAME(13)

in one of the adjustment holes. Rotate the SPRING KNOB(29) clockwise to lock the LEG SUPPORT

FRAME(13) securely.

STEP 14: Rotate the SPRING KNOB(29) on the LEG SUPPORT FRAME(13) counter clockwise until

the knob portion can be pulled. Pull the

SPRING KNOB(29) then slide the FOAM SUPPORT(15)

completely into the LEG SUPPORT FRAME(13). Put a WASHER(M6)(66) onto the BUTT ON HEAD

BOLT(M6 x 47mm)(56) and insert the bolt halfway through the square tube on the LEG SUPPORT

FRAME(13), slide the bolt through the loop on the end of the SPRING(32), slide the bolt through the

square tube and secure with

NYLOCK NUT(M6)(63) and WASHERS(M6)(66). Press the SQUARE

PLUG(49) into the LEG SUPPORT FRAME(13). Slide the FOAM PADS(30) onto both sides of the

FOAM SUPPORT(15).

Page 11

ASSEMBLY INSTRUCTIONS

11

STEP 15

Attach the CUSHION SUPPORT TUBES(14) onto the LEG SUPPORT FRAME(13) with BUTTON

HEAD BOLTS(M6 x 65mm)(57), WASHERS(M6)(66), and NYLOCK NUTS(M6)(63).

STEP 16

Attach the LEG SUPPORT CUSHIONS(28) onto the CUSHION SUPPORT TUBES(14) with BUTTON

HEAD BOLTS(M8 x 30mm)(59) and WASHERS(M8)(67).

Page 12

ASSEMBLY INSTRUCTIONS

12

STEP 17

Attach the LEFT and RIGHT HANDRAIL ASSEMBLIES(17, 18) onto the SHAFTS in the LEFT and

RIGHT FRONT FRAMES(1, 2) and the LINKAGES(16) with the LOCKING KNOBS(21).

STEP 18

Verify that the handlebars function correctly before using the Core Training Inversion System. Move

the

BACK CUSHION(24) backward toward the inverted position. The HANDRAILS(17, 18) must move

forward a s the

BACK CUSHION(24) moves backward. If the HAND RAILS(17, 18) do not move forward

check

ASSEMBLY STEPS 4 and 17.

STEP 19

Attach the COVER PLATES(22) onto the LEFT and RIGHT FRONT FRAMES(1, 2) by hooking the

COVER PLATES(22) into the slots on the Brackets on the LEFT a nd RIGHT FRONT FRAMES(1, 2)

and secure with BUTTON HEAD BOLTS(M6 x 15mm)(55) and WASHERS(M6)(66).

Page 13

13

OPERATIONAL INSTRUCTIONS

GENERAL PRECAUTIONS

Do not use the Core Training Inversion System alone. Always have a helper available in case

assistance is needed in recovering from the decline position.

Check the

LEVER(36), CABLE(35), and SPRING PIN(34). Make sure the system works smoothly

BEFORE using the Core Training Inversion System.

Make sure that the FOAM PADS(30) and the LEG SUPPORT CUSHIONS(28) are holding your feet

properly.

Make sure that there is enough room f or the seat to rotate completely.

1.

2.

3.

4.

Proper adjustment of the

LEG SUPPORT

CUSHIONS(19) is very important.

Loosen the

SPRING KNOB(29) under the SEAT

FRAME(12).

Pull down the SPRING KNOB(29) and slide the

LEG SUPPORT FRAME(13) to adjust.

Sit on the machine to ma ke sure you feel comfortable

with the leg support.

Tighten the

SPRING KNOB(29) after adjustment.

1.

2.

3.

4.

SEAT FRAME HEIGHT ADJUSTMENT

LEG SUPPORT ADJUSTMENT

There are adjustment holes on the BACK FRAME

(9) allowing you to position the SEA T FRAME(12) at

three different heights.

In the highest position, it is easier to invert but more

difficult to recover from inversion. In the lowest position,

it is more difficult to invert but easier to recover from

inversion. Tall people may prefer the lowest position

and shorter people may prefer the highest position.

To adjust the height, remove the

BUTTON HEAD

BOLTS(M8 x 60mm)(61), NYLOCK NUTS(M8)

(64), and WASHERS(M8)(67) from the SEAT

FRAME(12). Then atta ch the SEAT FRAME(12) in

another position with the same hardware.

Page 14

OPERATIONAL INSTRUCTIONS

FOAM PAD USE AND ADJUSTMENT

Place your feet under the FOAM PADS(30) with your legs

between the

FOAM PADS(30) and the LEG SUPPORT

CUSHIONS(28).

Loosen the SPRING KNOB(29). Pull the SPRING KNOB(29)

and slide the FOAM P AD SUPPORT(15) toward you until your

legs are properly held between the

FOAM P ADS(30) and LEG

SUPPORT CUSHIONS(28).

T o relea se your feet or relax the grip, loosen a nd pull the SPRING

KNOB(29), then slide the FOAM PAD SUPPORT(13)

forward.

1.

2.

3.

14

THE SEAT BELT

CAUTION:

THE HANDRAILS

Always use the seat belt. Make sure the seat belt is

securely fastened before inverting.

Sit on the

SEAT CUSHION(25). Place both ends of the SEAT

BELT(26) on top of your upper legs and insert the end of the belt

through the metal rings a s shown in the illustration. Fold the end of

the belt over and secure it in pla ce with the hook a nd loop materi al.

WAR NING:

The Core T raining Inversion System feature s a set of Handrails

for added convenience a nd safety . The Ha ndrails are connected to

the Inversion Chair with linkages so that pulling on the Handrails

will move the Inversion Chair away from the inverted position toward

the upright position.

The

HANDRAILS(19) are to help you invert and help you return

from inversion to the upright position. Pull the

LEVER(36), gra sp

the right

HANDRAILS(19), and pull yourself to the upright position.

Make sure that the Handrails are functioning properly

before using The

Core Training Inversion Syste m.

Page 15

Start by sitting on the machine and leaning back on the back cushion with your hands at your side, or

resting on your thighs.

Pull and hold the LEVER(36) with your left ha nd. Use the handrail a nd your right hand to rotate the BACK

CUSHION(24) slowly backward.

Relea se the LEVER(36) to lock the Core Training Inversion Syste m in one of the four inversion positions.

It is recommended that the Core Training Inversion System be used for five or ten minutes each

morning, and again each evening.

Pull the LEVER(36), gra sp the right HANDLEBAR(19), and pull yourself to the upright position.

USING THE SEATED INVERSION SYSTEM

1.

2.

3.

4.

5.

15

OPERATIONAL INSTRUCTIONS

If you have difficulty pulling the LEVER(36),

you can take pressure off the spring pin by

pushing yourself backward or pulling yourself

forward.

Y ou must understand how to recover from the inverted position bef ore using the

Core Training

Inversion System. Read the LEVER OPERATION section above BEFORE using the

Core Training Inversion System.

CAUTION:

LEVER OPERATION

Pull the LEVER(36) with your left hand. Use your right

hand and the right handrail to push the

BACK

CUSHION(24) backward slowly. Release the

LEVER(36) to lock the Core Training Inversion

System in one of the four inversion positions as shown

in the illustrations below.

To return to the upright position, pull and hold the

LEVER(36) with your left hand. Use your right hand

and the right handrail to pull yourself to the upright

position.

NOTE:

1. 3. 4.2.

Position 1

Position 2

Position 3

Position 4

Seat Cushion

( Degrees From Horizontal )

Top of Back Cushion

( Degrees From Vertical )

Bottom of Back Cushion

( Degrees From Vertical )

59 degrees

71 degrees

84 degrees

96 degrees

64 degrees

76 degrees

89 degrees

101 degrees

97 degrees

109 degrees

122 degrees

134 degrees

Page 16

OPERATIONAL INSTRUCTIONS

SUGGESTIONS FOR USE

Begin slowly: Invert with the least amount of inversion angle. Stay inverted only as long as you are

comfortable. Return upright slowly.

Make gra dual changes: Increa se the a ngle only if it is comfortable. Increa se the a ngle only one adjustment

hole at a time. Increa se the ti me of use 1-2 minutes up to ten over a period of weeks. Add stretching a nd

sit-up exercises only after you are comfortable with inversion.

Watch your body: Come up slowly, dizziness after a session means you came up to fast. Wait awhile

after eating before using the Core Training Inversion System. If you get nauseous, do not fight it,

come up as soon as you feel queasy.

Invert regularly: We recommend one or two times a day depending upon your current condition. Try to

schedule it at the sa me times each day.

1.

2.

3.

4.

16

It is the sole responsibility of the user/owner to ensure that regular maintenance is performed.

Check the W arning Label, Back Support Bar, Seat Belt, Locking Knobs, Spring Knobs, Cushions, Foam

Pads, Spring, Lever, Cable, and Spring Pin for damage and wear .

Verify that all nuts a nd bolts are present a nd properly tightened. Repla ce missing nuts a nd bolts. T ighten

loose nuts and bolts.

Worn or damaged components shall be replaced immediately or the Core Training Inversion System

removed from service until repair is made.

Only Sta mina Products supplied components shall be used to maintain/repair the Core Training Inversion

System.

Keep your Core Training Inversion System clean by wiping with an absorbent cloth after use.

1.

2.

3.

4.

5.

6.

MAINTENANCE

The safety and integrity designed into the Core Training Inversion System can only be maintained

when the

Core Training Inversion Syste m is regularly exa mined for da mage a nd wear. Spe cial attention

should be given to the following:

To store the

Core Training Inversion System simply keep it in a clean dry place.

Move the

Core Training Inversion System by lifting the frame and moving slowly.

NOTE: T wo people are required to move the Core Training Inversion System.

1.

2.

STORAGE

Page 17

LIMITED WARRANTY

MODEL 55-1522

WARRANTY

17

Stamina Products, Inc. warrants that this product will be free from defects in materials and workmanship

under normal use, service and proper operation for a period of 90 days on the parts and 5 years on the

frame from the date of the original purchase from an authorized retailer. THIS WARRANTY SHALL NOT

APPLY TO ANY PRODUCT WHICH HAS BEEN SUBJECT TO COMMERCIAL USE, ABUSE, MISUSE,

ALTERATION OF ANY TYPE OR CAUSE OR TO ANY DEFECT OR DAMAGE CAUSED BY REPAIR,

REPLACEMENT , SUBSTITUTION OR USE WITH P ARTS OTHER THAN P ARTS PROVIDED BY ST AMINA

PRODUCTS, INC. Commercial use includes use of the product in athletic clubs, health clubs, spas,

gymnasiums, exercise facilities, and other public or semipublic facilities whether or not the product's use is

in furtherance of a profit making enterprise, and all other use which is not for personal, fa mily, or household

purposes.

T o i mplement this li mited warranty, send a written notice stating your name, date, a nd pla ce of purcha se a nd

a brief description of the defect along with your rece ipt to Stamin a Products, Inc. P .O. Box 1071, Springf ield

Missouri, USA, 65801-1071 or call us at 1 (800) 375-7520. If the defect is covered under this limited

warranty , you will be requested to return the product or part to us f or free repair or repla cement at our option.

NO ACTION FOR BREACH OF THIS LIMITED WARRANTY MA Y BE COMMENCED MORE THAN ONE

(1) YEAR AFTER THE DATE THE ALLEGED BREACH WAS OR SHOULD HAVE BEEN DISCOVERED.

NO ACTION FOR BREACH OF ANY IMPLIED WARRANTY MAY BE COMMENCED MORE THAN ONE

(1) YEAR AFTER DELIVERY OF THE PRODUCT TO THE PURCHASER. This limited warranty is not

transferable. IF ANY PART OF THE PRODUCT IS NOT IN COMPLIANCE WITH THIS LIMITED

WARRANTY OR ANY IMPLIED WARRANTY, THE REMEDY OF REPAIR OR REPLACEMENT IS THE

EXCLUSIVE REMEDY AVAILABLE T O YOU. In the event that the purchaser makes any claim under this

limited warranty or a ny implied warra nty , the Warra ntor reserves the right to require the product to be returned

for inspection, at the purchaser's expense, to the Warrantor's premises in Springfield, Missouri. Return of

the enclosed warranty registration card is not required for warranty coverage, but is merely a way of

establishing the date and place of purchase.

Stamin a Products, Inc. SHALL NOT BE LIABLE FOR THE LOSS OF USE OF ANY PRODUCT, LOSS OF

TIME, INCONVENIENCE, COMMERCIAL LOSS OR ANY OTHER INDIRECT, CONSEQUENTIAL,

SPECIAL OR INCIDENT AL DAMAGES DUE TO BREACH OF THE ABOVE WARRANTY OR ANY IMPLIED

WARRANTY.

This limited warra nty is the only written or express warranty given by Stamina Products, Inc. This warra nty

gives you specific legal rights, and you may also have other legal rights which vary from state to state.

ANY OTHER RIGHT WHICH YOU MAY HAVE, INCLUDING ANY IMPLIED WARRANTY OR

MERCHANT ABILITY OR FIT NESS FOR A P ARTICULAR PURPOSE, IS LIMITED IN DURA TION TO THE

DURA TION OF THIS WARRANTY.

The laws in some jurisdictions restrict the rights of manufacturers and distributors of consumer goods to

disclaim or limit implied warranties and consequential and incidental damages with respect thereto. If any

such law is found to be a pplicable, the foregoing disclai mers and li mitations of a nd on implied warranties a nd

consequential a nd incidental da mages with respect thereto shall be disregarded a nd shall be deemed not to

have been made to the extent necessary to comply with such legal restriction.

Page 18

PRODUCT PARTS DRAWING

BACK

FRONT

18

Page 19

19

1 Left Front Frame 1

2 Right Front Frame 1

3 Rear Frame 2

4 Front Base Frame /w Warning Label 1

5 Rear Base Fra me 1

6 Crossing Frame 1

7 Left Pivot Arm 1

8 Right Pivot Arm 1

9 Back Frame 1

10 Back Support Bar 1

11 Slider Support 1

12 Seat Frame 1

13 Leg Support Frame 1

14 Cushion Support Tube 2

15 Foam Support 1

16 Linkage 2

17 Left Handrail Support 1

18 Right Handrail Support 1

19 Handrail 2

20 Foam Grip 2

21 Locking Knob 4

22 Cover Plate 2

23 Support Plate 4

24 Back Cushion 1

25 Seat Cushion 1

26 Seat Belt 1

27 Belt Guide 2

28 Leg Support Cushion 2

29 Spring Knob 2

30 Foam Pad 2

31 Roll Pin 1

32 Spring 1

33 Connecting Block 1

34 Spring Pin/without Head 1

35 Cable 1

36 Lever 1

37 Clip 1

38 Screw , Round Head (M5 x 0.8 x 18mm) 1

39 Washer (M5) 1

40 Acorn Nut (M5 x 0.8) 1

41 Sleeve 1

42 Bushing 4

43 Bumper 1

44 Small Bumper 1

45 Stand A (front left) 2

46 Stand B (front right) 2

PARTS LIST

DIAGRAM# PART NAME QTY

Page 20

PARTS LIST

DIAGRAM# PART NAME QTY

47 Round Plug (22mm) 2

48 Square Plug (33.4mm x 33.4mm) 1

49 Square Plug (38mm x 38mm) 3

50 Rectangular Plug (20mm x 40mm) 4

51 Rectangular Plug (23.5mm x 53.5mm) 1

52 Screw , Round Head (M4 x 20mm) 4

53 Bolt, Round Head (M6 x 1 x 20mm) 2

54 Bolt, Flat Head (M6 x 1 x 50mm) 4

55 Bolt, Button Head (M6 x 1 x 15mm) 8

56 Bolt, Button Head (M6 x 1 x 47mm) 1

57 Bolt, Button Head (M6 x 1 x 65mm) 2

58 Bolt, Button Head (M8 x 1.25 x 15mm) 22

59 Bolt, Button Head (M8 x 1.25 x 30mm) 8

60 Bolt, Button Head (M8 x 1.25 x 55mm) 4

61 Bolt, Button Head (M8 x 1.25 x 60mm) 4

62 Bolt, Button Head (M10 x 1.5 x 90mm) 2

63 Nylock Nut (M6 x 1) 6

64 Nylock Nut (M8 x 1.25) 10

65 Nylock Nut (M10 x 1.5) 2

66 Washer (M6) 11

67 Washer (M8) 42

68 Washer (M10) 2

69 Arc Washer (M8) 4

70 Warning Label 1

71 Combination Wrench 1

72 Allen Wrench (4mm) 1

73 Allen Wrench (6mm) 1

74 Manual 1

75 Video Disc (DVD) 1

20

Page 21

NOTES

21

Page 22

IMPORT ANT : Before filling out the form below make sure you have the right information.

Refer to the parts list to make sure you're ordering the right parts!

Detach and Mail or Fax the Form Below

Stamina Products, Inc.

P.O. Box 1071

Springfield, MO 65801-1071

IMPORT ANT : We must have your phone number in order to process the order!

FAX/MAIL ORDERING FORM

Plea se do not return the product. For your convenience, Sta mina has a Customer Service Department with

a toll-free number. Should a part be missing or a defective part found, please call 1 (800) 375-7520

(in the U.S.) between 8:00 A.M. and 5:00 P .M. Central T i me, Monday through Friday or f ill out the fax sheet

ordering form below and fax it to (417) 889-8064. Our Customer Service Department will be able to assist

you with your problem and the part will be mailed directly to your house.

TELEPHONE

CUSTOMER SERVICE

Tel: 1 (800) 375-7520

FAX

CUSTOMER SERVICE

Fax: (417) 889-8064

MAIL

STAMINA PRODUCTS, INC.

ATTN: Customer Service

P.O. Box 1071

Springfield, MO. 65801-1071

ONLINE

CUSTOMER SERVICE

parts@staminaproducts.com

www.staminaproducts.com

Mr./Ms:

Address: Apt. #:

City: State: Zip Code:

Phone #: ( ) Work Phone #: ( )

Date Purchased:

Model #:

Purchased From:

P ART # DESCRIPTION QUANTITY

1 Rear Unit Assembly 1

EXAMPLE:

Loading...

Loading...