Stamford AC generators, UCI 224, UCI 274, UCM 224, UCM 274 Installation & Maintenance Manual

...

Installation, Service & Maintenance

Manual

AC generators with the following for prefixes:

UCI; UCM; UCD 224 & 274 .

SAFETY PRECAUTIONS

Before operating the generating set, read the generating

set operation manual and this generator manual and

become familiar with it and the equipment.

SAFE AND EFFICIENT OPERATION

CAN ONLY BE ACHIEVED IF THE

EQUIPMENT IS CORRECTLY

OPERATED AND MAINTAINED.

Many accidents occur because of failure to follow

fundamental rules and precautions.

ELECTRICAL SHOCK CAN CAUSE

SEVERE PERSONAL INJURY OR

DEATH.

Observe all WARNING/CAUTION notices.

• Ensure installation meets all applicable safety and

local electrical codes. Have all installations

performed by a qualified electrician.

• Do not operate the generator with protective covers,

access covers or terminal box covers removed.

• Disable engine starting circuits before carrying out

maintenance.

• Disable closing circuits and/or place warning notices

on any circuit breakers normally used for connection

to the mains or other generators, to avoid accidental

closure.

Observe all IMPORTANT, CAUTION, WARNING, and

DANGER notices, defined as:

Important ! Important refers to hazard or unsafe

method or practice which can result in

product damage or related equipment

damage.

Caution refers to hazard or unsafe

method or pr actice w hic h can r esult

in product damage or personal

injury.

Warning refers to a hazard or unsafe

method or practice which CAN result

in severe personal injury or possible

death.

Danger refers to immediate hazards

which WILL result in severe personal

injury or death.

Due to our policy of continuous improvement, details in this manual which

were correct at time of printing, may now be due for amendment.

Information included must therefore not be regarded as binding.

Front Cover Photograph

This photograph is representative only. Several variations are available

within the range of generators covered by this manual.

Warnin

g

!

Danger !

Caution !

FOREWORD

The function of this book is to provide the user of the

Stamford generator with an understanding of the

principles of operation, the criteria for which the generator

has been designed, and the installation and maintenance

procedures. Specific areas where the lack of care or use

of incorrect procedures could lead to equipment damage

and/or personal injury are highlighted, with WARNING

and/or CAUTION notes, and it is important that the

contents of this book are read and understood before

proceeding to fit or use the generator.

STAMFORD Service, Sales and Technical staff of are

always ready to assist and reference to the company for

advice is welcomed.

Incorrect installation, operation,

servicing or replacement of parts can

result in severe personal injury or

death, and/or equipment damage.

Service personnel must be qualified

to perform electrical and mechanical

service.

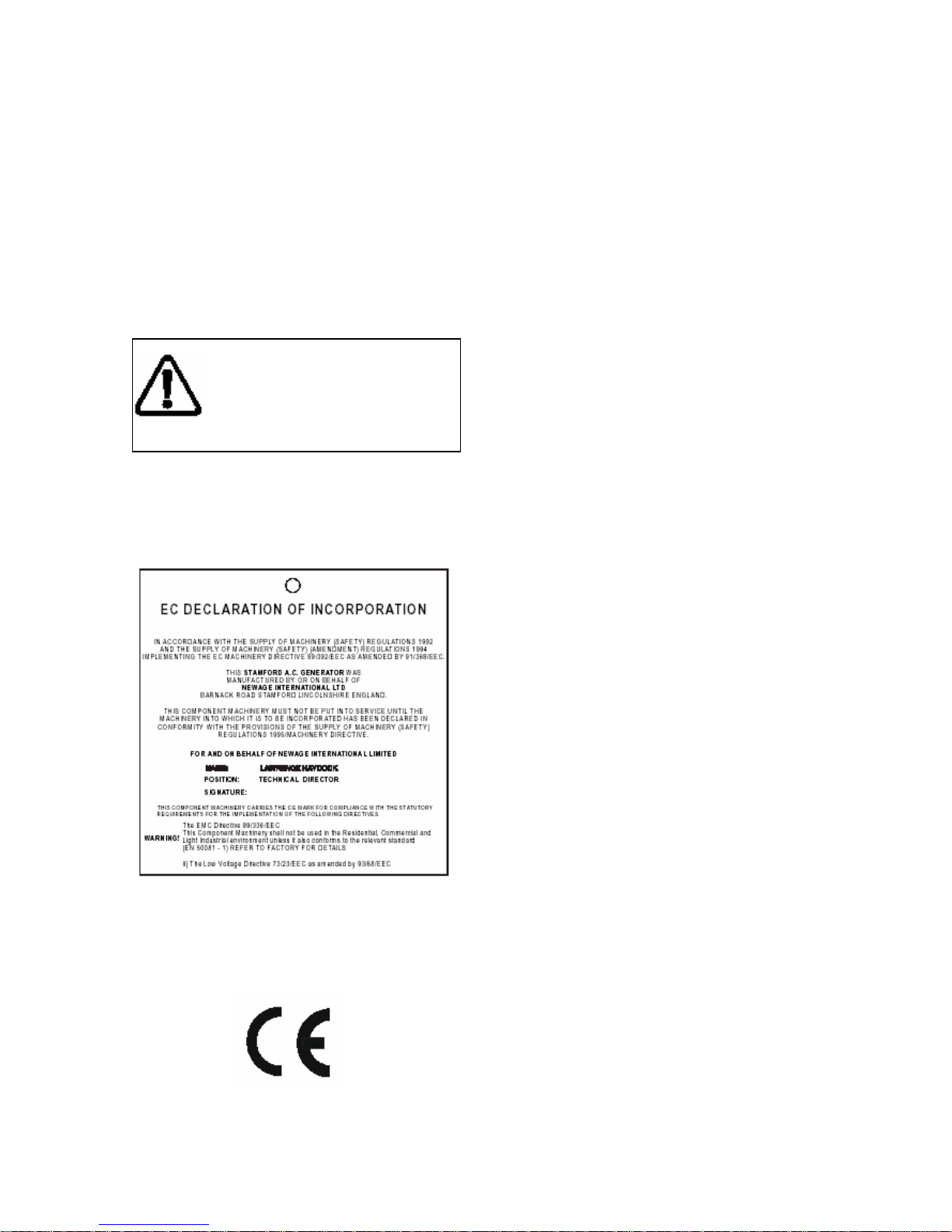

EC DECLARATION OF INCORPORATION

All Stamford generators are supplied with a declaration of

incorporation for the relevant EC legislation, typically in

the form of a label as below.

Under the EC Machinery Directive section 1.7.4. It is the

responsibility of the generator set builder to ensure the

generator identity is clearly displayed on the front cover

of this book.

ELECTROMAGNETIC COMPATIBILITY

Additional Information

European Union

Council Directive 89/336/EEC

For installations within the European Union, electrical

products must meet the requirements of the above

directive, and STAMFORD ac generators are supplied on

the basis that:

• They are to be used for power-generation or related

function.

• They are to be applied in one of the following

environments:

Portable (open construction - temporary site supply)

Portable (enclosed - temporary site supply)

Containerised (temporary or permanent site supply)

Ship-borne below decks (marine auxiliary power)

Commercial vehicle (road transport / refrigeration

etc) Rail transport (auxiliary power)

Industrial vehicle (earthmoving, cranes etc)

Fixed installation (industrial - factory / process plant)

Fixed installation (residential, commercial and light

industrial - home / office / health)

Energy management (Combined heat and power

and/or peak lopping)

Alternative energy schemes

.

• The standard generators are designed to meet the

‘industrial’ emissions and immunity standards.

Where the generator is required to meet the

residential, commercial and light industrial emissions

and immunity standards reference should be made

to document reference N4/X/011, as additional

equipment may be required.

• The installation earthing scheme involves co nnection

of the generator frame to the site protective earth

conductor using a minimum practical lead length.

• Maintenance and servicing with anything other than

factory supplied genuine STAMFORD parts will

invalidate warranty and our liability for EMC

compliance.

• Installation, maintenance and servicing is carried out

by adequately trained personnel fully aware of the

requirements of the relevant EC directives

Warnin

g

!

CONTENTS

SAFETY PRECAUTIONS

FOREWORD 1

CONTENTS 2&3

SECTION 1 INTRODUCTION 4

1.1 INTRODUCTION 4

1.2 DESIGNATION 4

1.3 SERIAL NUMBER LOCATION

AND IDENTITY NUMBER LOCATION 4

1.4 RATING PLATE AND CE MARKING 4

SECTION 2 PRINCIPLE OF OPERATION 5

2.1 SELF-EXCITED AVR CONTROLLED GENERATORS 5

2.2 PERMANENT MAGNET GENERATOR (PMG) EXCITED AVR CONTROLLED GENERATORS 5

2.3 AVR ACCESSORIES 5

2.4 TRANSFORMER CONTROLLED GENERATORS 5

SECTION 3 APPLICATION OF THE GENERATOR 6

SECTION 4 INSTALLATION - PART 1 8

4.1 LIFTING 8

4.2 ASSEMBLY 8

4.2.1 NO FOOT OPTION 8

4.2.2 TWO BEARING GENERATORS 9

4.2.3 SINGLE BEARING GENERATORS 9

4.3 EARTHING 9

4.4 PRE-RUNNING CHECKS 9

4.4.1 INSULATION CHECK 9

4.4.2 DIRECTION OF ROTATION 10

4.4.3 VOLTAGE AND FREQUENCY 10

4.4.4 AVR SETTINGS 10

4.4.4.1 TYPE SX460 AVR 10

4.4.4.2 TYPE SX440 AVR 10

4.4.4.3 TYPE SX421 AVR 11

4.4.4.4 TYPE MX341 AVR 11

4.4.4.5 TYPE MX321 AVR 11

4.4.5 TRANSFORMER CONTROLLED

EXCITATION SYSTEM (Series 5) 12

4.5 GENERATOR SET TESTING 12

4.5.1 TEST METERING/CABLING 12

4.6 INITIAL START-UP 12

4.7 LOAD TESTING 13

4.7.1 AVR CONTROLLED GENERATORS - AVR ADJUSTMENTS 13

4.7.1.1 UFRO (Under Frequency Roll Off)

(AVR Types SX460, SX440, SX421, MX341 and MX321) 13

4.7.1.2 EXC TRIP (Excitation Trip) 14

4.7.1.3 OVER/V (Over Voltage) 14

4.7.1.4 TRANSIENT LOAD SWITCHING ADJUSTMENTS 14

4.7.1.5 RAMP BUILD UP TIME 15

4.7.2 TRANSFORMER CONTROLLED GENERATORS TRANSFORMER ADJUSTMENT 15

4.8 ACCESSORIES 15

SECTION 5 INSTALLATION - PART 2 16

5.1 GENERAL 16

5.2 GLANDING 16

5.3 EARTHING 16

5.4 PROTECTION 16

5.5 COMMISSIONING 16

CONTENTS

SECTION 6 ACCESSORIES 17

6.1 REMOTE VOLTAGE ADJUST (ALL AVR TYPES) 17

6.2 PARALLEL OPERATION 17

6.2.1 DROOP 17

6.2.1.1 SETTING PROCEDURE 18

6.2.2 ASTATIC CONTROL 18

6.3 MANUAL VOLTAGE REGULATOR (MVR) MX341 and MX321 AVR 18

6.4 OVERVOLTAGE DE-EXCITATION BREAKER

SX421 and MX321 AVR 18

6.4.1 RESETTING THE BREAKER 19

6.5 CURRENT LIMIT - MX321 AVR 19

6.5.1 SETTING PROCEDURE 19

6.6 POWER FACTOR CONTROLLER (PFC3) 20

SECTION 7 SERVICE AND MAINTENANCE 21

7.1 WINDING CONDITION 21

7.1.1 WINDING CONDITION ASSESSMENT 21

7.1.2 METHODS OF DRYING OUT GENERATORS 21

7.2 BEARINGS 23

7.3 AIR FILTERS 23

7.3.1 CLEANING PROCEDURE 23

7.4 FAULT FINDING 23

7.4.1 SX460 AVR - FAULT FINDING 23

7.4.2 SX440 AVR - FAULT FINDING 24

7.4.3 SX421 AVR - FAULT FINDING 24

7.4.4 TRANSFORMER CONTROL - FAULT FINDING 24

7.4.5 MX341 AVR - FAULT FINDING 25

7.4.6 MX321 AVR - FAULT FINDING 25

7.4.7 RESIDUAL VOLTAGE CHECK 26

7.5 SEPARATE EXCITATION TEST PROCEDURE 26

7.5.1 GENERATOR WINDINGS, ROTATING DIODES and

PERMANENT MAGNET GENERATOR (PMG) 26

7.5.1.1 BALANCED MAIN TERMINAL VOLTAGES 26

7.5.1.2 UNBALANCED MAIN TERMINAL VOLTAGES 27

7.5.2 EXCITATION CONTROL TEST 27

7.5.2.1 AVR FUNCTION TEST 27

7.5.2.2 RANSFORMER CONTROL 28

7.5.3 REMOVAL AND REPLACEMENT OF COMPONENT

ASSEMBLIES 28

7.5.3.1 REMOVAL OF PERMANENT MAGNET GENERATOR (PMG) 28

7.5.3.2 REMOVAL OF BEARINGS 28

7.5.3.3 REMOVAL OF ENDBRACKET AND EXCITER STATOR 28

7.5.3.4 REMOVAL OF THE ROTOR ASSEMBLY 29

7.6 RETURNING TO SERVICE 29

SECTION 8 SPARES AND AFTER SALES SERVICE 30

8.1 RECOMMENDED SPARES 30

8.2 AFTER SALES SERVICE 30

SECTION 9 PARTS IDENTIFICATION 32

TYPICAL SINGLE BEARING GENERATOR (Fig. 11) 33

TYPICAL TWO BEARING GENERATOR (Fig. 12) 35

TYPICAL TWO BEARING (SERIES 5) GENERATOR (Fig. 13) 37

ROTATING RECTIFIER ASSEMBLY (Fig. 14) 38

SECTION 1

INTRODUCTION

1.1 INTRODUCTION

The UC22/27 range of generators is of brushless rotating field

design, available up to 660V/50Hz (1500 rpm) or 60Hz (1800

rpm), and built to meet BS5000 Part 3 and international

standards.

All the UC22/27 range are self-excited with excitation power

derived from the main output windings, using either the

SX460/SX440/SX421 AVR. The UC22 is also available with

specific windings and a transformer controlled excitation

system.

A permanent magnet generator (PMG) powered excitation

system is available as an option using either the MX341 or

MX321 AVR.

Detailed specification sheets are available on request.

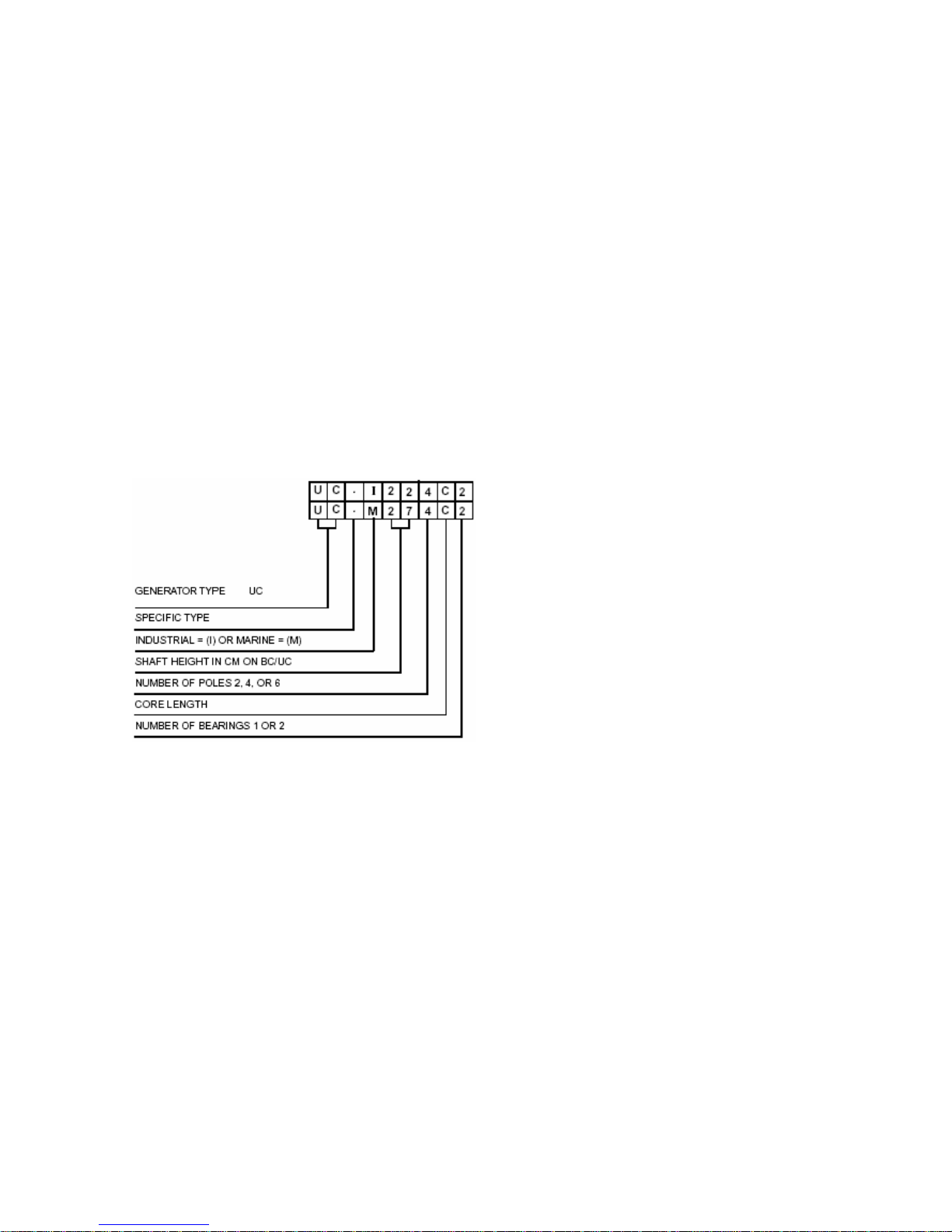

1.2 DESIGNATION

1.3 SERIAL NUMBER LOCATION AND IDENTITY

NUMBER LOCATION

Each generator is metal stamped with it’s own unique serial

number, the location of this number is described below.

UCI and UCM generators have their serial number stamped

into the upper section of the drive end frame to end bracket

adaptor ring, shown as item 31 in the parts lists at the back of

this book.

UCD generators have their serial number stamped into the

top of the drive end adaptor /fan shroud casting. If for any

reason this casting is removed, it is imperative that care is

taken to refit it to the correct generator to ensure correct

identification is retained.

Inside the terminal box two adhesive rectangular labels have

been fixed, each carrying the generators unique identity

number. One label has been fixed to the inside of the terminal

box sheet metal work, and the second label fixed to the main

frame of the generator.

1.4 RATING PLATE

The generator has been supplied with a self adhesive rating

plate label to enable fitting after final assembly and painting.

It is intended that this label will be stuck to the outside of the

terminal box on the left hand side when viewed from the

N.D.E. To assist with squarely positioning the label, location

protrusions have been made in the sheet metalwork.

A CE Mark label is also supplied loose for fitment after f inal

assembly and painting. This should be attached to an external

surface of the Generator at a suitable location where it will not

be obscured by the customer's wiring or other fittings.

The surface in the area where a label is to be stuck must be

flat, clean, and any paint finish be fully dry before attempting

to attach label. Recommended method for attaching label is

peel and fold back sufficient of the backing paper to expose

some 20 mm of label adhesive along the edge which is to be

located against the sheet metal protrusions. Once this first

section of label has been carefully located and stuck into

position the backing paper can be progressively removed, as

the label is pressed down into position. The adhesive will

achieve a permanent bond in 24 hours.

.

SECTION 2

PRINCIPLE OF OPERATION

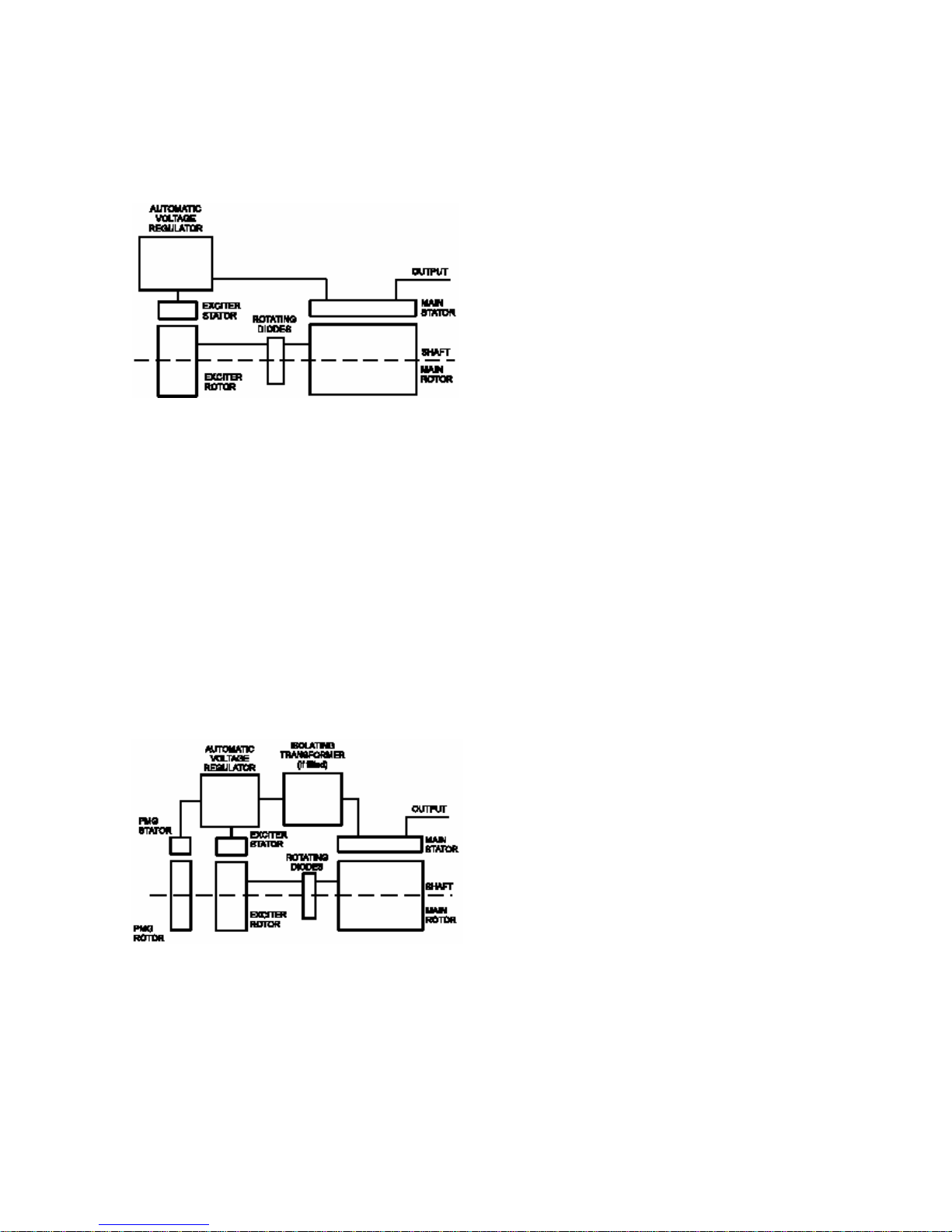

2.1 SELF-EXCITED AVR CONTROLLED

The main stator provides power for excitation of the exciter

field via the SX460 (SX440 or SX421) AVR which is the

controlling device governing the level of excitation provided to

the exciter field. The AVR responds to a voltage sensing

signal derived from the main stator winding. By controlling the

low power of the exciter field, control of the high power

requirement of the main field is achieved through the rectified

output of the exciter armature.

The SX460 or SX440 AVR senses average voltage on two

phases ensuring close regulation. In addition it detects engine

speed and provides voltage fall off with speed, below a preselected speed (Hz) setting, preventing over-excitation at low

engine speeds and softening the effect of load switching to

relieve the burden on the engine.

The SX421 AVR in addition to the SX440 features has three

phase rms sensing and also provides for over voltage

protection when used in conjunction with an external circuit

breaker (switchboard mounted).

2.2 PERMANENT MAGNET GENERATOR (PMG)

EXCITED - AVR CONTROLLED GENERATORS

The permanent magnet generator (PMG) provides power for

excitation of the exciter field via the AVR (MX341 or MX321)

which is the controlling device governing the level of excitation

provided to the exciter field. The AVR responds to a voltage

sensing signal derived, via an isolating transformer in the

case of MX321 AVR, from the main stator winding. By

controlling the low power of the exciter field, control of the

high power requirement of the main field is achieved through

the rectified output of the exciter armature.

The PMG system provides a constant source of excitation

power irrespective of main stator loading and provides high

motor starting capability as well as immunity to waveform

distortion on the main stator output created by non linear

loads, e.g. thyristor controlled dc motor.

The MX341 AVR senses average voltage on two phases

ensuring close regulation. In addition it detects engine speed

and provides an adjustable voltage fall off with speed, below a

pre-selected speed (Hz) setting, preventing over-excitation at

low engine speeds and softening the effect of load switching

to relieve the burden on the engine. It also provides overexcitation protection which acts following a time delay, to deexcite the generator in the event of excessive exciter field

voltage.

The MX321 provides the protection and engine relief features

of the MX341 and additionally incorporates 3 phase rms

sensing and over-voltage protection.

The detailed function of all the AVR circuits is covered in the

load testing (subsection 4.7).

2.3 AVR ACCESSORIES

The SX440, SX421, MX341 and MX321 AVRs incorporate

circuits which, when used in conjunction with accessories, can

provide for parallel operation either with 'droop' or 'astatic'

control, VAR/PF control and in the case of the MX321 AVR,

short circuit current limiting.

Function and adjustment of the accessories which can be

fitted inside the generator terminal box are covered in the

accessories section of this book.

Separate instructions are provided with other accessories

available for control panel mounting.

2.4 TRANSFORMER CONTROLLED GENERATORS

The main stator provides power for excitation of the exciter

field via a transformer rectifier unit. The transfor mer com bines

voltage and current elements derived from the main stator

output to form the basis of an open-loop control system, which

is self regulating in nature. The system inherently

compensates for load current magnitude and power factor

and provides short circuit maintenance in addition to a good

motor starting performance.

Three phase generators normally have a three phase

transformer control for improved performance with

unbalanced loads but a single phase transformer option is

available.

No accessories can be provided with this control system.

SECTION 3

APPLICATION OF THE GENERATOR

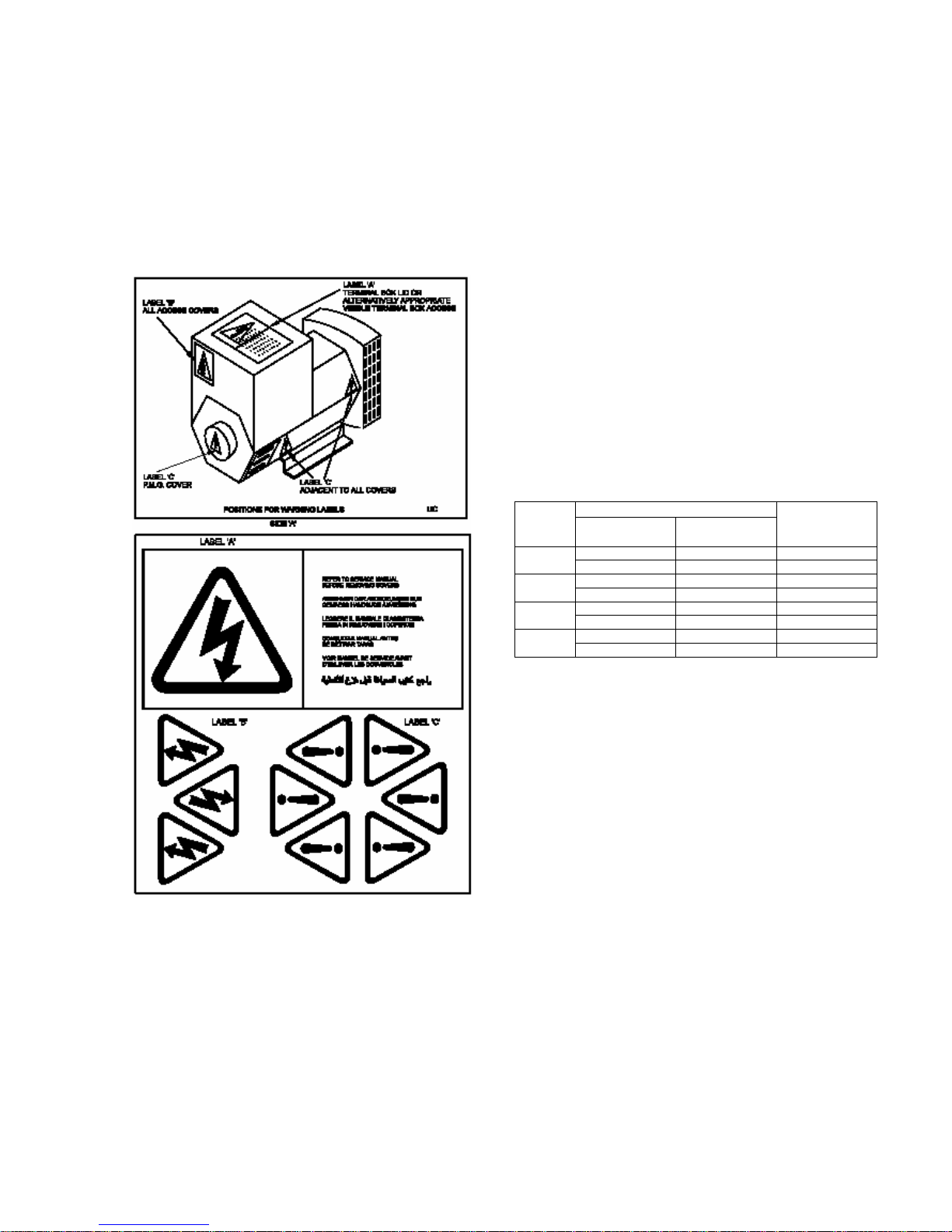

The generator is supplied as a component part for installation

in a generating set. It is not, therefore, practicable to fit all the

necessary warning/hazard labels during generator

manufacture. The additional labels required are packaged

with this Manual, together with a drawing identifying their

locations. (See below).

It is the responsibility of the generating set manufacturer to

ensure that the correct labels are fitted, and are clearly visible.

The generators have been designed for use in a maximum

ambient temperature of 40°C and altitude less than 1000m

above sea level in accordance with BS5000.

Ambients in excess of 40°C and altitudes above 1000m can

be tolerated with reduced ratings - refer to the generator

nameplate for rating and ambient. In the event that the

generator is required to operate in an ambient in excess of the

nameplate value or at altitudes in excess of 1000 metres

above sea level, refer to the factory.

The generators are of air-ventilated screen protected dripproof design and are not suitable for mounting outdoors

unless adequately protected by the use of canopies. Anticondensation heaters are recommended during storage and

for standby duty to ensure winding insulation is maintained in

good condition.

When installed in a clos ed cano py it must be ens ured t hat the

ambient temperature of the cooling air to the generator does

not exceed that for which the generator has been rated.

The canopy should be designed such that the engine air

intake to the canopy is separated from the generator intake,

particularly where the radiator cooling fan is required to draw

air into the canopy. In addition the generator air intake to the

canopy should be designed such that the ingress of moisture

is prohibited, preferably by use of a 2 stage filter.

The air intake/outlet must be suitable for the air flow given in

the following table with additional pressure drops less than or

equal to those given below :

Air Flow

Frame

50Hz 60Hz

Additional

(intake/outlet)

Pressure Drop

0.216m³/sec 0.281m³/sec 6mm water gauge

UC22

458cfm 595cfm (0.25”)

0.25m³/sec 0.31m³/sec 6mm water gauge

UCD22

530cfm 657cfm (0.25”)

0.514m³/sec 0.617m³/sec 6mm water gauge

UC27

1090cfm 1308cfm (0.25”)

0.58m³/sec 0.69m³/sec 6mm water gauge

UCD27

1230cfm 1463cfm (0.25”)

Important ! Reduction in cooling air flow or inadequate

protection to the generator can result in

damage and/or failure of windings.

Dynamic balancing of the generator rotor assembly has been

carried out during manufacture in accordance with BS 6861

Part 1 Grade 2.5 to ensure vibration limits of the generator are

in accordance with BS 4999 Part 142.

The main vibration frequencies produced by the component

generator are as follows:- :

4 pole 1500 rpm 25 Hz

1800 rpm 30 Hz

However, vibrations induced by the engine are complex and

contain frequencies of 1.5, 3, 5 or more times the fundamental

frequency of vibration. These induced vibrations can result in

generator vibration levels higher than those derived from the

generator itself. It is the responsibility of the generating set

designer to ensure that the alignment and stiffness of the

bedplate and mountings are such that the vibration limits of

BS5000 Part 3 are not exceeded.

In standby applications where the running time is limited and

reduced life expectancy is accepted, higher levels than

specified in BS5000 can be tolerated, up to a maximum of

18mm/sec.

Two bearing generators open coupled require a substantial

bedplate with engine/generator mounting pads to ensure a

good base for accurate alignment. Close coupling of engine to

generator can increase the overall rigidity of the set. For the

purposes of establishing set design the bending moment at

the engine flywheel housing to generator adaptor interface

should not exceed 1000ft.lb. (140 kgm). A flexible coupling,

designed to suit the specific engine/generator combination, is

recommended to minimise torsional effects.

Belt driven applications of t wo bearing gener ators require t he

pulley diameter and design to be such that the side load or

force applied to the shaft is central to the extension and does

not exceed the values given in the table below : -

Side Load

Frame

kgf N

Shaft

Extension

mm

UC22 408 4000 110

UC27 510 5000 140

In instances where shaft extensions greater than specified in

the table have been supplied reference must be made to the

factory for appropriate loadings.

Alignment of single bearing generators is critical and vibration

can occur due to the flexing of the flanges between the engine

and generator. As far as the generator is concerned the

maximum bending moment at this point must not exceed

1000ft.lb. (140kgm). A substanial bedplate with

engine/generator mounting pads is required.

It is expected that the generator will be incorporated into a

generating set operating in an environment, where the

maximum shock load experienced by the generator will not

exceed 3g. in any plane. If shock loads in excess of 3g are to

be encountered, anti-vibration mountings must be

incorporated into the generating set to ensure they absorb the

excess.

The maximum bending moment of the engine flange must be

checked with the engine manufacturer.

Generators can be supplied without a foot, providing the

option for customers own arrangement. See SECTION 4.2.1

for assembly procedure.

Torsional vibrations occur in all engine-driven shaft systems

and may be of a magnitude to cause damage at certain

critical speeds.

It is therefore necessary to consider the torsional vibration

effect on the generator shaft and couplings. It is the

responsibility of the generator set manufacturer to ensure

compatibility, and for this purpose drawings showing the shaft

dimensions and rotor inertias are available for customers to

forward to the engine supplier. In the case of single bearing

generators coupling details are included.

Important ! Torsional incompatibility and/or excessive

vibration levels can cause damage or failure

of generator and/or engine components.

The terminal box is constructed with removable panels for

easy adaptation to suit specific glanding requirements. Within

the terminal box there are insulated terminals for line and

neutral connections and provision for earthing. Additional

earthing points are provided on the generator feet.

The neutral is NOT connected to the frame.

The main stator winding has leads brought out to the

terminals in the terminal box.

No earth connections are made on the

generator and reference to site

regulations for earthing must be made.

Incorrect earthing or protection

arrangements can result in personal

injury or death.

Fault current curves (decrement curves), together with

generator reactance data, are available on request to assist

the system designer to select circuit breakers, calculate fault

currents and ensure discrimination within the load network.

Incorrect installation, service or

replacement of parts can result in severe

personal injury or death, and/or

equipment damage. Service personnel

must be qualified to perform electrical

and mechanical service.

Warnin

g

!

Warnin

g

!

SECTION 4

INSTALLATION - PART 1

4.1 LIFTING

Incorrect lifting or inadequate lifting

capacity can result in severe personal

injury or equipment damage. MINIMUM

LIFTING CAPACITY REQUIRED IS 750Kg.

Generator lifting lugs should NOT be used

for lifting the complete generator set.

Two lifting lugs are provided for use with a shackle and pin

type lifting aid. Chains of suitable length and lifting capacity

must be used. Lifting points are designed to be as close to the

centre of gravity of the generator as possible, but due to

design restrictions it is not possible to guarantee that the

generator frame will remain horizontal while lifting. Care is

therefore needed to avoid personal injury or equipment

damage. The correct lifting arrangement is shown on the label

attached to the lifting lug. (See sample below).

Single bearing generators are supplied fitted with a rotor

retaining bar at the non-drive end of the shaft.

To remove retaining bar :

1. Remove the four screws holding the sheet metal cover at

the non drive end and remove cover

2. Remove central bolt holding the retaining bar to the shaft

3. Refit sheet metal cover.

Once the bar is removed, to couple the rotor to engine, the

rotor is free to move in the frame, and care is needed during

coupling and alignment to ensure the frame is kept in the

horizontal plane.

Generators fitted with a PMG excitation system are not fitted

with retaining bar. Refer to frame designation to verify

generator type (subsection 1.2)

4.2 ASSEMBLY

During the assembly of the generator to the engine it will be

necessary firstly to carefully align, then rotate, the combined

generator rotor - engine crankshaft assembly, as part of the

construction process, to allow location, insertion and

tightening of the coupling bolts. This requirement to rotate the

combined assemblies exists for both single and two bearing

units.

During the assembly of single bearing units it is necessary to

align the generator's coupling holes with the engine flywheel

holes; it is suggested that two diametrically opposite location

dowel pins are fitted to the engine flywheel, over which the

generator coupling can slide into final location into the engine

flywheel spigot recess. The dowels must be removed and

replaced by coupling bolts before the final bolt tightening

sequence.

While fitting and tightening the coupling bolts it will be

necessary to rotate the engine crankshaft - generator rotor

assembly. Care should be taken to ensure that rotation is

carried out in an approved manner that ensures safe working

practice when reaching inside the machine to insert or tighten

coupling bolts, and that no component of the assembly is

damaged by nonapproved methods of assembly rotation.

Engine manufacturers have available a proprietary tool or

acility designed to enable manual rotation of the crankshaft

assembly. This must always be used, having been

engineered as an approved method of assembly rotation,

engaging the manually driven pinion with the engine flywheel

starter ring-gear.

Before working inside the generator,

during the aligning and fitting of coupling

bolts, care should be taken to lock the

assembly to ensure there is no possibility

of rotational movement.

4.2.1 NO FOOT OPTION

Generators can be supplied without a foot providing the option

for customers own arrangement. For details of mounting this

arrangement, see the general arrangement drawing supplied

with the generator. Alternatively refer to the STAMFORD

factory for a copy of the latest general arrangement drawing

showing the 'NO FOOT OPTION' appropriate to your

generator.

Warnin

g

!

Caution !

4.2.2 TWO BEARING GENERATORS

A flexible coupling should be fitted and aligned in accordance

with the coupling manufacturer's instruction. If a close

coupling adaptor is used the alignment of machined faces

must be checked by offering the generator up to the engine.

Shim the generator feet if necessary. Ensure adaptor guards

are fitted after generator/engine assembly is complete. Open

coupled sets require a suitable guard, to be provided by the

set builder. In the case of belt driven generators, ensure

alignment of drive and driven pulleys to avoid axial load on

the bearings. Screw type tensioning devices are

recommended to allow accurate adjustment of belt tension

whilst maintaining pully alignment. Side loads should not

exceed values given in SECTION 3. Belt and pulley guards

must be provided by the set builder.

Important ! Incorrect belt tensioning will result in

excessive bearing wear.

Incorrect guarding and/or generator

alignment can result in personal injury

and/or equipment damage.

4.2.3 SINGLE BEARING GENERATORS

Alignment of single bearing generators is critical. If necessary

shim the generator feet to ensure alignment of the machined

surfaces.

For transit and storage purposes the generator frame spigot

and rotor coupling plates have been coated with a rust

preventative.

This MUST BE

removed before assembly to engine.

A practical method for removal of this coating is to clean the

mating surface areas with a de-greasing agent based on a

petroleum solvent.

Care should be taken not to allow any

cleaning agent to come into prolonged

contact with skin.

The sequence of assembly to the engine should generally be

as follows:

1. On the engine check the distance from the coupling

mating face on the flywheel to the flywheel housing

mating face. This should be within +/-0.5mm of nominal

dimension. This is n e cessary to ensure that a thrust is not

applied to the a.c. generator bearing or engine bearing.

1. Check that the bolts securing the flexible plates to the

coupling hub are tight and locked into position. Torque

tightening is 24.9kgfm (244Nm; 180 lb ft).

2a. UCD224 Only

Torque tightening is 15.29 kgfm (150Nm; 110 lb ft).

1. Remove covers from the drive end of the generator to

gain access to coupling and adaptor bolts.

1. Check that coupling discs are concentric with adaptor

spigot. This can be adjusted by the use of tapered

wooden wedges between the fan and adaptor.

Alternatively the rotor can be suspended by means of a

rope sling through the adaptor opening.

1. Offer the a.c. generator to engine and engage both

coupling discs and housing spigots at the same time,

finally pulling home by using the housing and coupling

bolts. Use heavy gauge washers between bolt head and

discs on disc to flywheel bolts.

1. Tighten coupling disc to flywheel. Refer to engine manual

for torque setting of disc to flywheel bolts.

1. Remove wooden wedges.

Incorrect guarding and/or generator

alignment can result in personal injury

and/or equipment damage.

4.3 EARTHING

The generator frame should be solidly bonded to the

generating set bedplate. If antivibration mounts are fitted

between the generator frame and its bedplate a suitably rated

earth conductor (normally one half of the cross sectional area

of the main line cables) should bridge across the antivibration

mount.

Refer to local regulations to ensure that

the correct earthing procedure has been

followed.

4.4 PRE-RUNNING CHECKS

4.4.1 INSULATION CHECK

Before starting the generating set, both after completing

assembly and after installation of the set, test the insulation

resistance of windings. The AVR should be disconnected

during this test. A 500V Megger or similar instrument should

be used. Disconnect any earthing conductor connected

between neutral and earth and megger an output lead

terminal U, V or W to earth. The insulation resistance reading

should be in excess of 5MΩ to earth. Should the insulation

resistance be less than 5MΩ the winding must be dried out as

detailed in the Service and Maintenance section of this

Manual.

Important ! The windings have been H.V. tested during

manufacture and further H.V. testing may

degrade the insulation with consequent

reduction in operating life. Should it be

necessary to demonstrate H.V. testing, for

customer acceptance, the tests must be

carried out at reduced voltage levels i.e.

Test Voltage= 0.8 (2 X Rated Voltage + 1000)

Caution !

Caution !

Caution !

Warnin

g

!

4.4.2 DIRECTION OF ROTATION

The generator is supplied to give a phase sequence of U V W

with the generator running clockwise looking at the drive end

(unless otherwise specified at the time of ordering). If the

generator phase rotation has to be reversed after the

generator has been despatched apply to factory for

appropriate w iring diagram s.

UCI224, UCI274, UCM224, UCM274

Machines are fitted with bi-directional fans and are suitable for

running in either direction of rotation.

UCD224, UCD274

Machines are fitted with uni-directional fans and are suitable

for running in one direction only.

4.4.3 VOLTAGE AND FREQUENCY

Check that the voltage and frequency levels required for the

generating set application are as indicated on the generator

nameplate.

Three phase generators normally have a 12 ends out

reconnectable winding. If it is necessary to reconnect the

stator for the voltage required, refer to diagrams in the back of

this manual.

4.4.4 AVR SETTINGS

To make AVR selections and adjustments remove the AVR

cover and refer to 4.4.4.1, 4.4.4.2, 4.4.4.3, 4.4.4.4 or 4.4.4.5

depending upon type of AVR fitted. Reference to the

generator nameplate will indicate AVR type (SX460, SX440,

SX421, MX341 or MX321).

Most of the AVR adjustments are factory set in positions

which will give satisfactory performance during initial running

tests. Subsequent adjustment may be required to achieve

optimum performance of the set under operating conditions.

Refer to 'Load Testing' section for details.

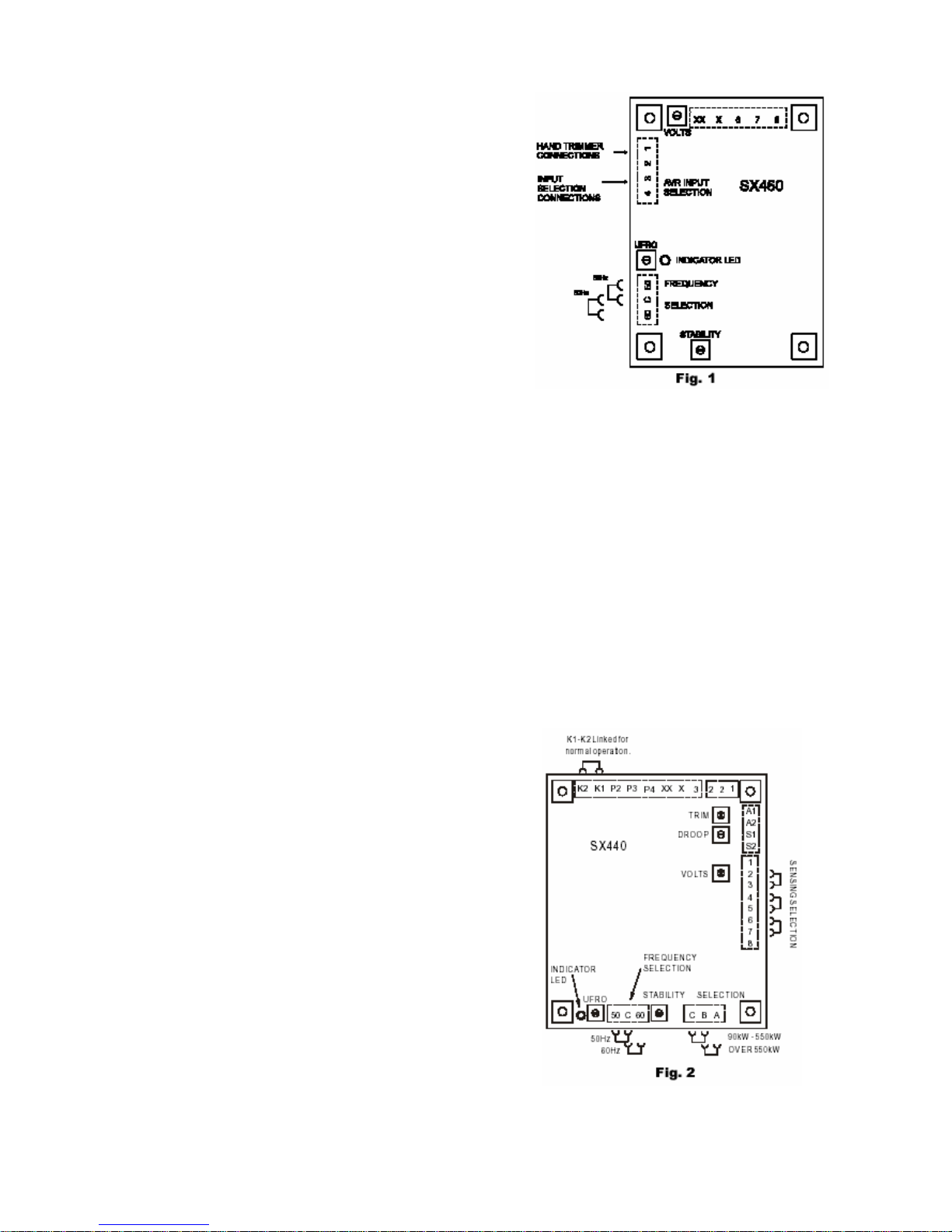

4.4.4.1 TYPE SX460 AVR

The following 'jumper' connections on the AVR should be

checked to ensure they are correctly set for the generating set

application. Refer to Fig. 1 for location of selection links.

1. Frequency selection

50Hz operation LINK C-50

60Hz operation LINK C-60

2. External hand trimmer selection

No external hand trimmer LINK 1-2

External hand trimmer required - REMOVE LINK 1-2 and

connect trimmer across

terminals 1 and 2.

3. AVR Input Selection

High voltage (220/240V) Input NO LINK

Low voltage (110/120V) Input LINK 3-4

Refer to diagram in the back of this manual to determine

wiring.

4.4.4.2 TYPE AS440 AVR

The following 'jumper' connections on the AVR should be

checked to ensure they are correctly set for the generating set

application.

Refer to Fig. 2 for location of selection links.

1. Frequency selection terminals

50Hz operation LINK C-50

60Hz operation LINK C-60

2. Stability selection terminals

Frame UC22 LINK A-C

Frame UC27 LINK B-C

3. Sensing selection terminals

LINK 2-3

LINK 4-5

LINK 6-7

4. Excitation Interruption Link

LINK K1-K2

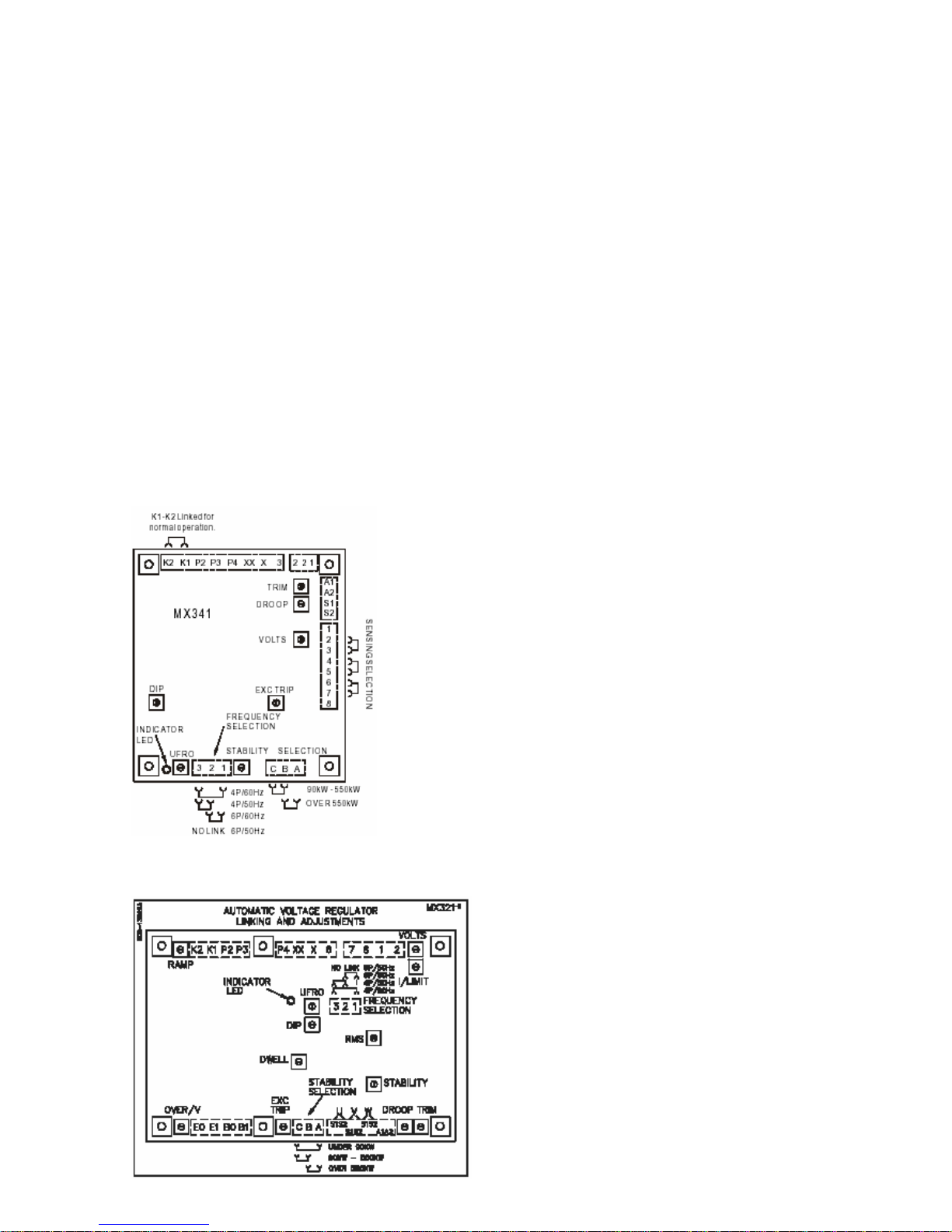

4.4.4.4 TYPE MX341 AVR

The following 'jumper' connections on the AVR should be

checked to ensure they are correctly set for the generating set

application.

Refer to Fig. 4 for location of setting links.

1. Frequency selection terminals

50Hz operation LINK 2-3

60Hz operation LINK 1-3

2. Stability selection terminals

Frame UC22 LINK A-C

Frame UC27 LINK B-C

3. Sensing selection terminals *

LINK 2-3

LINK 4-5

LINK 6-7

4. Excitation Interruption Link

LINK K1-K2

Fig. 4

4.4.4.5 TYPE MX321 AV R

The following 'jumper' connections on the AVR should be

checked to ensure they are correctly set for the generating set

application.

Refer to Fig. 5 for location of setting links.

Fig. 5

1. Frequency selection terminals

50Hz operation LINK 2-3

60Hz operation LINK 1-3

2. Stability selection terminals

Frame UC22 LINK A-C

Frame UC27 LINK B-C

3. Terminals K1 - K2

Excitation circuit breaker closed.

If this option not fitted, K1 - K2 linked at auxiliary terminal

block.

Loading...

Loading...