Stamford P0, P1 Service And Maintenance Instructions

P0/P1 AC Generators

INSTALLATION, SERVICE AND

MAINTENANCE

English

Original Instructions

A040J847 (Issue 4)

Table of Contents

1. FOREWORD......................................................................................................................... 1

2. SAFETY PRECAUTIONS...................................................................................................... 3

3. SAFETY DIRECTIVES AND STANDARDS.......................................................................... 7

4. INTRODUCTION................................................................................................................... 9

5. AUTOMATIC VOLTAGE REGULATORS (AVR)................................................................. 13

6. APPLICATION OF THE GENERATOR............................................................................... 15

7. INSTALLATION INTO THE GENERATING SET................................................................ 19

8. SERVICE & MAINTENANCE.............................................................................................. 29

9. FAULT FINDING ................................................................................................................. 49

10. PARTS IDENTIFICATION................................................................................................... 67

11. TECHNICAL DATA.............................................................................................................. 71

12. SPARES AND AFTER SALES SERVICE........................................................................... 73

13. END OF LIFE DISPOSAL ................................................................................................... 75

A040J847 (Issue 4) i

-

This page is intentionally blank.

ii A040J847 (Issue 4)

1 Foreword

1.1 The Manual

This manual contains guidance and instructions for the installation, servicing and

maintenance of the generator.

Before operating the generator, read this manual and make sure that all personnel who work

on the equipment have access to the manual and all additional documentation supplied with

it. Misuse and failure to follow the instructions, and the use of non-approved parts, may

invalidate the product warranty and lead to potential accidents.

This manual is an essential part of the generator. Make sure that the manual is available to

all users throughout the life of the generator.

The manual is written for skilled electrical and mechanical technicians and engineers, who

have prior knowledge and experience of generating equipment of this type. If in doubt,

please seek expert advice or contact your local Cummins Generator Technologies

subsidiary.

Information in this manual was correct when published. It may be superseded due to our

policy of continuous improvement. Please visit www.cumminsgeneratortechnologies.com for

latest documentation.

NOTICE

A040J847 (Issue 4) 1

-

This page is intentionally blank.

2 A040J847 (Issue 4)

2 Safety Precautions

2.1 Safety Information and Notices used in this manual

Danger, Warning and Caution panels are used in this manual to describe the sources of

hazards, their consequences and how to avoid injury. Notice panels emphasise important or

critical instructions.

DANGER

Danger indicates a hazardous situation which, if not avoided, WILL result in death or serious

injury.

WARNING

Warning indicates a hazardous situation which, if not avoided, COULD result in death or

serious injury.

CAUTION

Caution indicates a hazardous situation which, if not avoided, COULD result in minor or

moderate injury.

NOTICE

Notice refers to a method or practice which can result in product damage, or to draw

attention to additional information or explanations.

2.2 Skill Requirements of Personnel

WARNING

Service and maintenance procedures should only be carried out by experienced and qualified

engineers, who are familiar with the procedures and the equipment.

2.3 Risk Assessment

WARNING

A risk assessment should be performed by the user/operating company to establish all

personnel-related risks. All affected users must be trained on the identified risks. Access to

the Power Plant/Generating Set during operation must be restricted to persons who have

been trained on these risks.

2.4 Personal Protective Equipment (PPE)

WARNING

All persons operating, servicing, maintaining or working in or with a power plant or a

generating set must wear appropriate Personal Protective Equipment (PPE).

A040J847 (Issue 4) 3

-

Recommended PPE includes:

• Ear and Eye Protection

• Head and face protection

• Safety footwear

• Overalls that protect the lower arms and legs

Ensure that all persons are fully aware of the emergency procedures in case of accidents.

2.5 Noise

Generators emit noise. Wear appropriate ear protection at all times. Maximum A-weighted

noise emissions may reach 97 dB(A). Contact the supplier for application-specific details.

2.6 Electrical Equipment

CAUTION

All electrical equipment can be dangerous if not operated correctly. Always install, service

and maintain the generator in accordance with this manual.

Work that requires access to electrical conductors must comply with all applicable local and

national electrical safety procedures for the voltages involved and any site specific rules.

Always use genuine branded replacement parts.

2.7 Lock Out/Tag Out

Isolate the generator from all sources of mechanical and electrical energy before starting

service or maintenance work. Adopt a suitable lock-out/tag out process.

2.8 Lifting

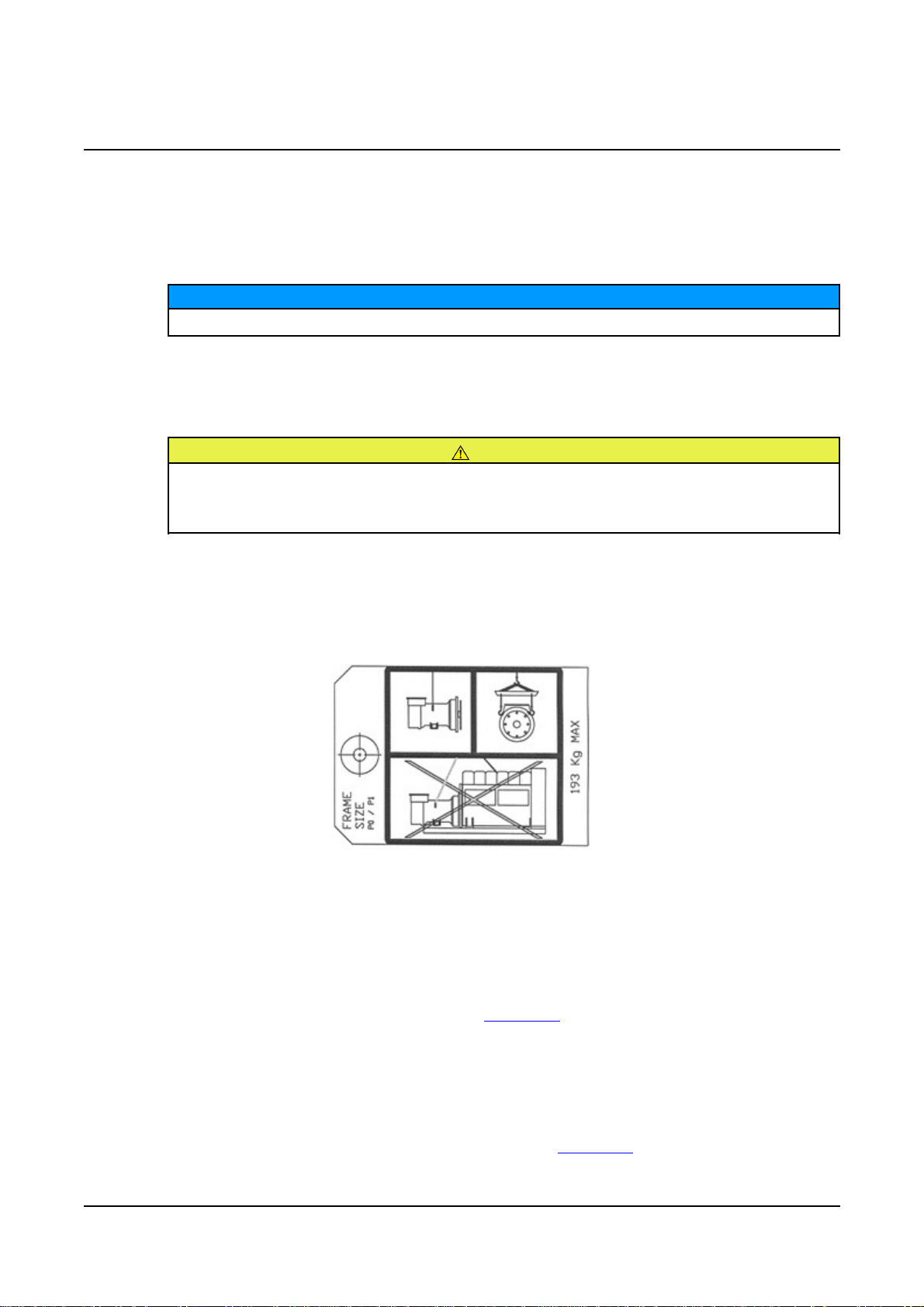

The lifting points provided are designed for lifting the generator only. Do not use the

generator lifting points to lift the complete generating set (generator coupled to motive power

source).

Do not remove the lifting label attached to one of the lifting points.

CAUTION

WARNING

WARNING

2.9 Generator Operating Areas

WARNING

In the event of catastrophic failure, machine parts may be ejected from the generator air

inlet/outlet (shaded regions of diagram). Do not place controls near the air inlet/outlet and

restrict personnel from these regions during machine running.

4 A040J847 (Issue 4)

2.10 Hazard Warning Labels

Hazard warning labels are fixed to the generator. If the original labels are missing, damaged

or painted over, replace them with the spare set supplied in a wallet attached to the

generator. Label locations are shown on the back of the label set.

-

2.11 General Guidance

NOTICE

These safety precautions are for general guidance and supplement your own safety

procedures and all applicable laws and standards.

A040J847 (Issue 4) 5

-

This page is intentionally blank.

6 A040J847 (Issue 4)

3 Safety Directives and Standards

STAMFORD AC generators meet applicable European safety directives, and national and

international standards relevant to generators. The generator must be operated within the

limits specified in the relevant standards and within the parameters on the generator rating

plate.

Marine generators meet the requirements of all the major marine classification societies.

3.1 European Directives: EC Declaration of Conformity for Incorporation

Each generator supplied in the European Economic Area (EEA) is supplied with an EC

Declaration of Conformity for Incorporation into an electricity generating set. It is the

responsibility of the generating set manufacturer to ensure that the complete generating set

complies with EC Directives and standards.

Our authorized representative in the European Community is Mr Jeffrey Matthews,

Engineering Director, Cummins Generator Technologies Ltd.

All generators meet the following Standards and Directives:

Directives:

• 2004/108/EC EMC Directive

• 2006/95/EC Low Voltage Directive

• 2006/42/EC Machinery Directive

Standards:

• EN 61000-6-1 Electromagnetic Compatibility, Generic Standards - Immunity for

residential, commercial and light-industrial environments

• EN 61000-6-2 Electromagnetic Compatibility, Generic Standards - Immunity for

industrial environments

A040J847 (Issue 4) 7

-

• EN 61000-6-4 Electromagnetic Compatibility, Generic Standards - Emission standard

for light-industrial environments

• EN ISO 12100-1 Safety of Machinery, Basic concepts, general principles for design Basic terminology, methodology

• EN ISO 12100-2 Safety of Machinery, Basic concepts, general principles for design Technical principles

• EN ISO 14121-1 Safety of Machinery, Risk assessment - Principles

• EN 60034-1 Rotating electrical machines - Rating and performance

• BS ISO 8528-3 Reciprocating internal combustion engine driven alternating current

generating sets - alternating current generators for generating sets

• BS 5000-3 Rotating electrical machines - Generators to be driven by reciprocating

internal combustion engines - Requirements for resistance to vibration

NOTICE

Once the generator is built into a generating set, it is the responsibility of the generating set

manufacturer to ensure that the generating set complies with the relevant specifications and

standards.

3.2 Additional Information for EMC Compliance

STAMFORD generators are designed to meet EMC emissions and immunity standards for

industrial environments. Document reference N4/X/011 outlines additional equipment that

may be required when the generator is installed in residential, commercial and light industrial

environments.

The installation ‘earth/ground’ arrangements require the connection of the generator frame to

the site protective earth conductor using a minimum lead length.

Installation, maintenance and servicing must be carried out by adequately trained personnel

fully aware of the requirements of the relevant EC directives.

NOTICE

Cummins Generator Technologies is not liable for EMC compliance if unauthorised parts, not

of STAMFORD brand, are used for maintenance and servicing.

3.3 Additional Information for CSA Compliance

To comply with Canadian Standards Association (CSA) regulations, all external wiring and

components must be rated at the generator rated voltage shown on the rating plate label.

8 A040J847 (Issue 4)

4 Introduction

4.1 General Description

P0/P1 generators are of brushless rotating field design, available up to 600V, 50Hz (1500

RPM, 4 pole and 3000 RPM, 2 pole) or 60Hz (1800 RPM, 4 pole and 3600 RPM, 2 pole),

and built to meet B.S. 5000 Part 3 and other international standards.

P0/P1 are self-excited, with excitation power derived from the main output windings using

the AS480 AVR.

4.2 Serial Number Location

A unique serial number is stamped into the top of the generator frame near the drive end

and shown on the rating plate and tracking labels on the side of the generator frame.

4.3 Rating Plate

The fixed rating plate label states the intended operating parameters of the generator.

The generator could overheat if operated outside the parameters specified on the rating plate.

Overheating can cause catastrophic failure and injury from ejected debris. Always operate

the generator within the rated parameters.

WARNING

4.4 Product Authentication

The STAMFORD high security, anti-counterfeit hologram is located on the Tracking

Label. Check that the dots are visible around the STAMFORD logo when viewing the

hologram from different angles and the word "GENUINE" appears behind the logo. Use a

flashlight to see these security features in low ambient light. Check that the generator is

genuine by entering the unique 7 character hologram code at www.stamford-

avk.com/verify.

FIGURE 1. GLOBAL STAMFORD AC GENERATOR NAMEPLATE, COMPRISING RATING PLATE

(ABOVE) AND TRACKING LABEL (BELOW)

A040J847 (Issue 4) 9

-

FIGURE 2. DOTS VISIBLE IN LEFT, RIGHT, UPPER AND LOWER VIEWS OF 3D HOLOGRAM

10 A040J847 (Issue 4)

4.5 Self-Excited AVR Controlled Generators

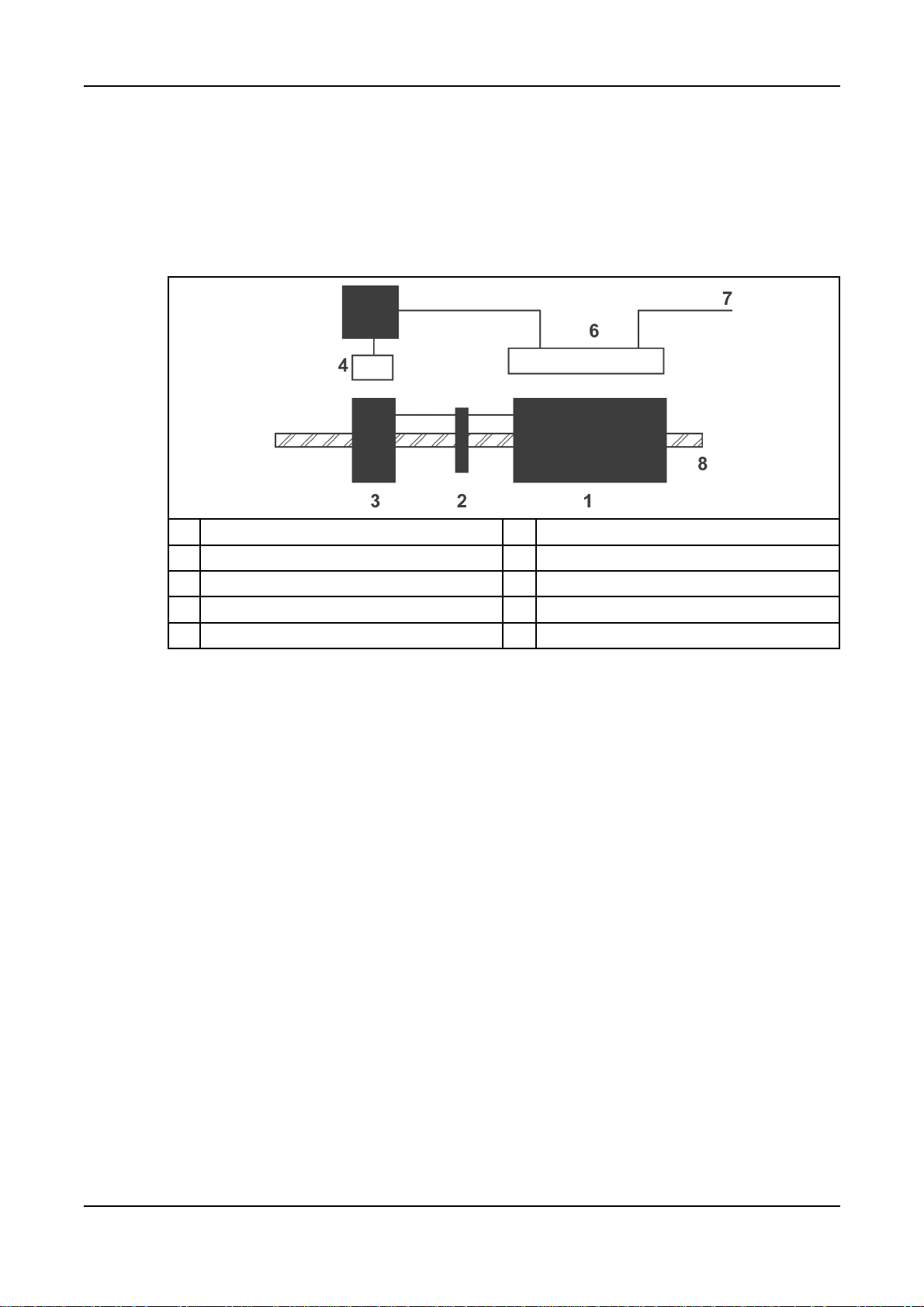

4.5.1 Main Stator Powered AVR

The AVR provides closed loop control by sensing the generator output voltage at the main

stator windings and applying voltage to the exciter stator. Voltage induced in the exciter

rotor, rectified by the rotating diodes, magnetises the main rotor which induces voltage in the

main stator windings. The AVR is also powered by the main stator.

-

No. Description No. Description

1 Main rotor 5 AVR

2 Rotating diodes 6 Main stator

3 Exciter rotor 7 Output

4 Exciter stator 8 Shaft

4.6 Separately-Excited AVR Controlled Generators

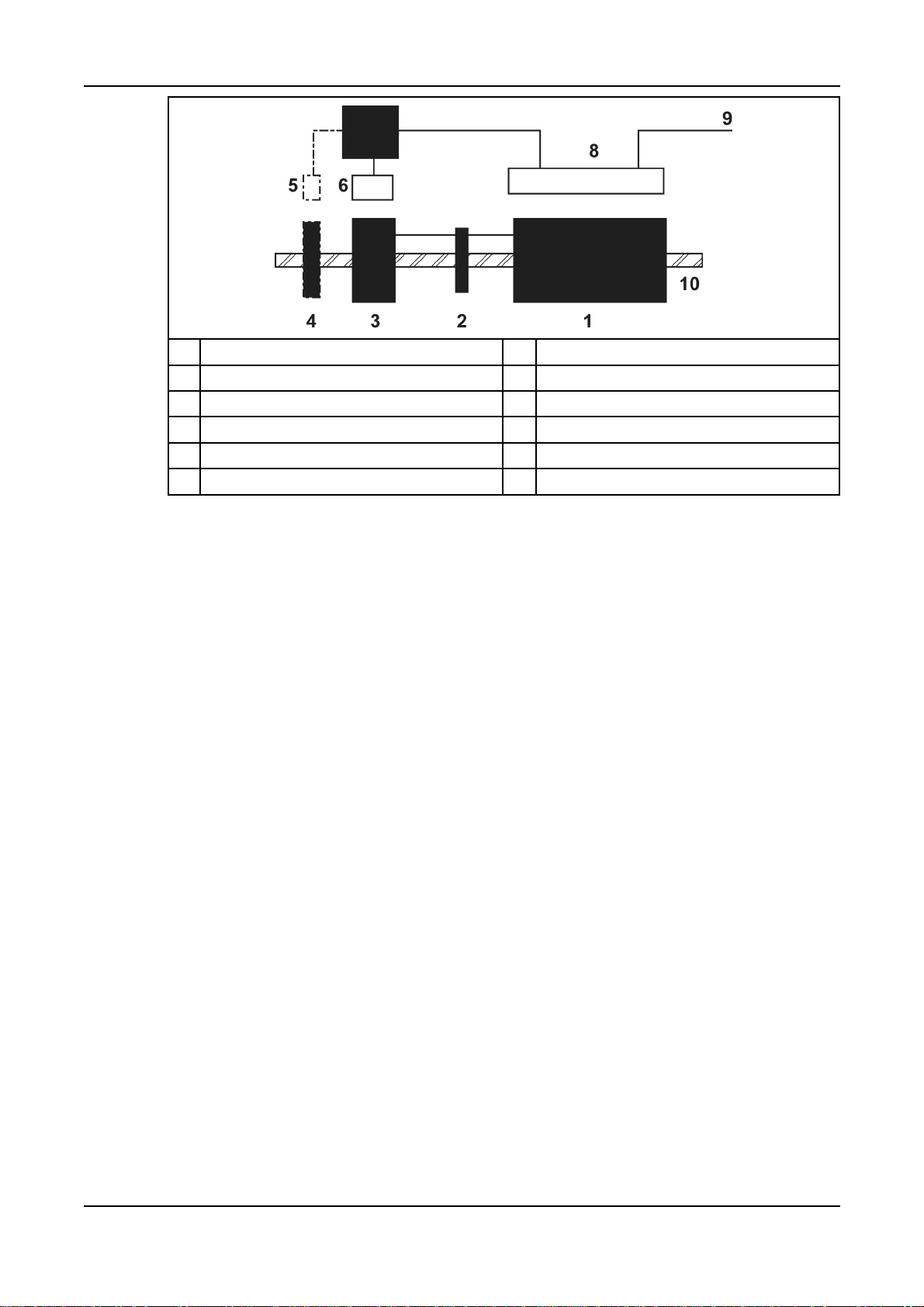

4.6.1 Excitation Boost System (EBS)

The EBS is a self-contained optional unit, attached to the non-drive end of the generator.

The EBS unit consists of the Excitation Boost Controller (EBC) and an Excitation Boost

Generator (EBG). Under fault conditions, or when the generator is subjected to a large

impact load such as a motor starting, the generator voltage drops. The EBC senses the drop

in voltage and engages the output power of the EBG. This additional power feeds the

generator’s excitation system, supporting the load until the generator voltage recovers or

breaker discrimination removes the fault.

A040J847 (Issue 4) 11

-

No. Description No. Description

1 Main rotor 6 Exciter stator

2 Rotating diodes 7 AVR & EBS

3 Exciter rotor 8 Main stator

4 EBG rotor (optional) 9 Output

5 EBG stator (optional) 10 Shaft

12 A040J847 (Issue 4)

5 Automatic Voltage Regulators (AVR)

Cummins Generator Technologies offer a selection of Automatic Voltage Regulators (AVRs)

designed and built to achieve maximum performance from the range of STAMFORD

brushless AC generators. Self-excited and separately-excited types are available, from lowcost analogue to sophisticated digital control. All STAMFORD AVRs are encapsulated to

provide environmental protection, and are mounted on anti-vibration mounts for added

mechanical protection.

All STAMFORD AVRs have the following features:

• connections to a remote hand trimmer accessory for fine control of the generator output

voltage

• ‘Under-Frequency Roll-Off’ (UFRO) protection to reduce the generator output voltage if

speed falls below a threshold, and

• connections to power factor and droop accessories for sharing reactive load in parallel

with other generators or mains utility.

AVR specification, installation and adjustment information is available in the AVR manual

supplied with the generator, or at www.cumminsgeneratortechnologies.com

NOTICE

AVR analogue inputs must be fully floating (galvanically isolated from ground), with

an insulation strength of 500 V a.c.

5.1 Self-Excited

A self-excited AVR receives power from the generator output terminals. The AVR controls

the generator output voltage by automatic adjustment of the exciter stator field strength.

5.1.1 AS480

The AS480 achieves voltage regulation of ±1.0%. The design employs surface mount

technology, custom mouldings and heatsink in a compact assembly.

The AVR includes the following extra features:

• connections to an Excitation Boost System accessory, and

• connection of a lead assembly for low voltage (100 V to 120 V a.c.) sensing.

5.2 AVR Accessories

Accessories to support AVR functions are factory-fitted or supplied separately with

instructions for fitting and wiring by a competent technician.

5.2.1 Hand Trimmer (for remote voltage adjustment)

A hand trimmer can be fitted in a convenient position (typically in the generator set control

panel) and connected to the AVR to provide fine adjustment of the generator voltage. The

hand trimmer value and the adjustment range obtained is as defined in the Technical

Specification. Refer to wiring diagram before removing the shorting link and connecting the

hand trimmer.

A040J847 (Issue 4) 13

-

5.2.2 Droop Transformer (for parallel operation – generator to generator)

A droop transformer can be fitted in a defined position in the generator main output wiring

and connected to the AVR to enable parallel operation with other generators. The

adjustment range is as defined in the Technical Specification. Refer to wiring diagram before

removing the shorting link and connecting the droop transformer. The droop transformer

MUST be connected in the correct main output terminal for proper operation (details are as

shown in the machine wiring diagram).

5.2.3 Excitation Boost System (with AS480 AVR only)

An add-on pilot winding and permanent-magnet rotor assembly is available to enhance the

motor-starting and overload performance of the AS480 AVR. This is fitted to the non-driveend bracket of the generator as a single integrated assembly and connects into the AVR via

four ‘faston’ connections. During motor-starting or other heavy overloads the unit

automatically provides additional excitation support as demanded by the AVR. An internal

over-excitation system prevents prolonged overload from damaging the generator.

5.2.4 Low Voltage Link/Selector

The AS480 AVR can be configured for low voltage working between 100 V a.c. and 120 V

a.c. with a special lead assembly which connects between the generator main terminals and

AVR input terminal ‘S1’. In low-voltage operating mode the overload performance of the

control system is reduced. The EBS will not work at low voltage.

14 A040J847 (Issue 4)

6 Application of the Generator

It is the customer's responsibility to make sure that the selected generator is suitable for the

final application.

CAUTION

Overloading a generator may lead to catastrophic failure.

6.1 Environment

STAMFORD generators are protected to IP23 as standard. IP23 is not adequate protection

for use outdoors without additional measures.

Ambient Temperature -15 °C to 40 °C

Relative Humidity < 60%

Altitude < 1000 m

The generator has been designed for the environment shown in the table. The generator can

operate outside these conditions if it is rated accordingly: The nameplate gives details. If the

operating environment is changed after purchase, refer to the factory for a revised generator

rating.

6.2 Air Flow

Make sure that the air inlets and outlets are not obstructed when the generator is running.

6.3 Airborne Contaminants

Contaminants such as salt, oil, exhaust fumes, chemicals, dust and sand will reduce the

effectiveness of the insulation and the life of the windings. Consider using air filters and an

enclosure to protect the generator.

6.4 Humid Conditions

The water carrying capacity of air depends on temperature. If the air temperature falls below

its saturation point, dew may form on the windings reducing the electrical resistance of the

insulation. In humid conditions additional protection may be required, even if the generator is

fitted inside an enclosure. Anti-condensation heaters are supplied on request.

6.5 Anti-condensation heaters

WARNING

Power to the anti-condensation heater is supplied from a separate source. Before

doing any work on the heater, make sure the power is isolated and locked off.

Anti-condensation heaters raise the air temperature around the windings to deter

condensation forming in humid conditions when the generator is not operating. Best practice

is to energise the heaters automatically when the generator is off.

A040J847 (Issue 4) 15

-

6.6 Enclosures

Fit an enclosure to protect the generator from adverse environmental conditions. Make sure

that air entering the generator is of adequate flowrate, free from moisture and contaminants,

and below the maximum ambient temperature on the rating plate.

Make sure there is sufficient access around the generator for safe maintenance.

P0 and P1 generators have round end brackets that will create an air flow pattern that differs

from previous generators of this size. The air flow should be modeled to identify and prevent

hot air from recirculating within the enclosure.

6.7 Vibration

STAMFORD generators are designed to withstand the vibration levels encountered on

generating sets built to meet the requirements of ISO 8528-9 and BS 5000-3. (Where ISO

8528 is taken to be broad band measurements and BS5000 refers to the predominant

frequency of any vibrations on the generating set).

Exceeding either of the above specifications will have a detrimental effect on the life of the

bearings and other components, and may invalidate the generator warranty.

NOTICE

6.7.1 Definition of BS5000–3

Generators shall be capable of continuously withstanding linear vibration levels with

amplitudes of 0.25mm between 5Hz and 8Hz and velocities of 9.0mm/s r.m.s. between 8 Hz

and 200 Hz, when measured at any point directly on the carcass or main frame of the

machine. These limits refer only to the predominant frequency of vibration of any complex

waveform.

6.7.2 Definition of ISO 8528-9

ISO 8528-9 refers to a broad band of frequencies; the broad band is taken to be between 10

Hertz and 1000 Hertz. The table below is an extract from ISO 8528-9 (Table C.1, value 1).

This simplified table lists the vibration limits by kVA and speed for acceptable operation of

standard generating set designs.

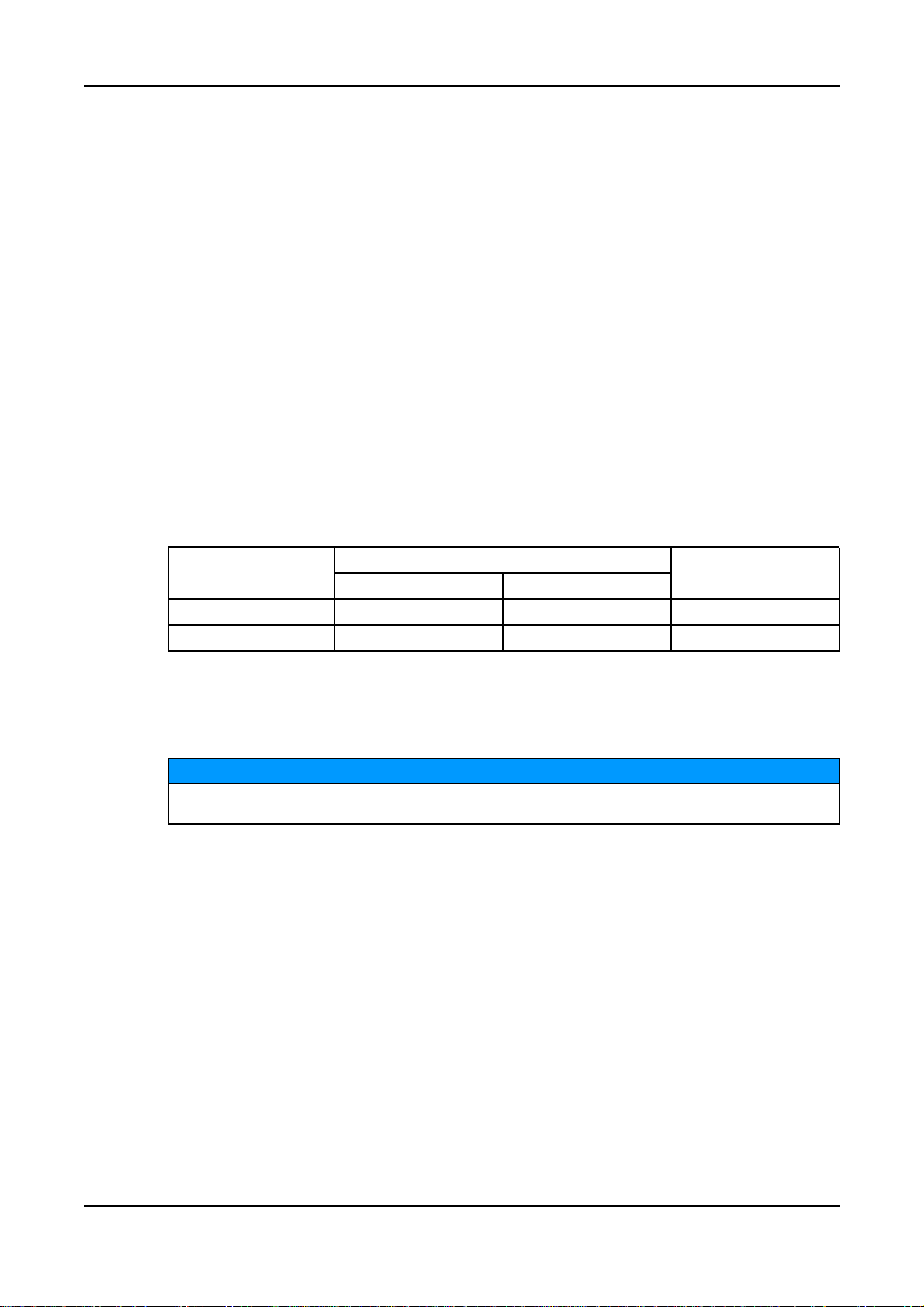

6.7.3 Linear Vibration Limits

Linear Vibration Levels As Measured On The Generator - P0/P1

Engine Speed Power Output Vibration Vibration Vibration

RPM S Displacement Velocity Acceleration

(min-1) (kVA) r.m.s. (mm) r.m.s. (mm/s) r.m.s. (mm/s2)

2000 ≤ RPM ≤ 3600 S ≤ 50 0.8 50 31

50 < S 0.64 40 25

1300 ≤ RPM < 2000 4 < S ≤ 50 0.64 40 25

50 < S ≤ 125 0.4 25 16

The broad band is taken as 10 Hz - 1000 Hz

16 A040J847 (Issue 4)

6.7.4 Linear Vibration Monitoring

We recommend using vibration analysing equipment to measure vibration. Check that

vibration of the generating set is below the limits stated in the standards. If vibration is above

the limits, the generating set builder should investigate the root causes and eliminate them.

Best practice is for the generating set builder to take initial readings as a reference and for

the user to periodically monitor vibration, according to the recommended service schedule,

to detect a deteriorating trend.

6.7.5 Excessive Vibration

WARNING

Excessive vibration can cause catastrophic failure of the generator, which could cause

personal injury.

If the measured vibration of the generating set is not within the limits:

1. The generating set manufacturer should change the generating set design to reduce

the vibration levels as much as possible.

2. Contact Cummins Generator Technologies to assess the impact on bearing and

generator life expectancy.

-

6.8 Bearings

6.8.1 Sealed Bearings

Sealed bearings are supplied pre-packed with grease and sealed for life. Sealed bearings do

not require re-greasing.

6.8.2 Bearing Life

Factors that reduce bearing life or lead to bearing failure include:

• Adverse operating conditions and environment

• Stress caused by misalignment of the generating set

• Vibration from the engine that exceeds the limits in BS 5000-3 and ISO 8528-9

• Long periods (including transportation) where the generator is stationary and subjected

to vibration can cause false brinelling wear (flats on the balls and grooves on the races)

• Very humid or wet conditions that cause corrosion and deterioration of the grease by

emulsification.

6.8.3 Health Monitoring of the Bearings

We recommend that the user checks the bearing condition, using vibration monitoring

equipment. Best practice is to take initial readings as a reference and periodically monitor

the bearings to detect a deteriorating trend. It will then be possible to plan a bearing change

at an appropriate generating set or engine service interval.

6.8.4 Bearing Service Life Expectancy

Bearing manufacturers recognise that service life of bearings depends on factors that are

outside their control: Rather than quote a service life, practicable replacement intervals are

based on the L10 life of the bearing, the type of grease and the recommendations of the

bearing and grease manufacturers.

A040J847 (Issue 4) 17

-

For general-purpose applications; if the correct maintenance is carried out, vibration levels

do not exceed the levels stated in ISO 8528-9 and BS5000-3, and the ambient temperature

does not exceed 50°C, plan to replace the bearings within 30,000 hours of operation.

If in doubt about any aspect of bearing life on STAMFORD generators, contact your nearest

supplier of STAMFORD generators or the Stamford factory.

18 A040J847 (Issue 4)

7 Installation into the Generating Set

7.1 Generator Dimensions

Dimensions are included in the data sheet specific to the generator model. Refer to the

rating plate to identify the generator model .

NOTICE

Data sheets are available from www.cumminsgeneratortechnologies.com

7.2 Lifting the Generator

CAUTION

The generator lifting points are designed to lift the generator only. Do not lift the complete

generating set (generator coupled to motive power source) by the generator lifting points.

Keep the generator horizontal when lifting. Fit the transit bar to single bearing generators to

keep the main rotor in the frame.

Lift the generator by shackle and pin attachment to the lifting points (lugs or eyes) provided.

A label attached to a lifting point shows the correct lifting arrangement. Use chains of

sufficient length, and a speader bar if necessary, to make sure that the chains are vertical

when lifting. Make sure that the capacity of the lifting equipment is sufficient for the

generator mass shown on the label.

FIGURE 3. LIFTING LABEL

7.3 Storage

If the generator is not to be used immediately, it must be stored in a clean, dry, vibration free

environment. We recommend the use of anti-condensation heaters.

Refer to Service and Maintenance section (Chapter 8) of this manual for further instructions

for the bearings of stored generators.

7.3.1 After Storage

After a period of storage, carry out ‘pre running checks’ to determine the condition of the

windings. If the winding are damp or the insulation is low, follow one of the ‘drying out

procedures’, in the Service and Maintenance section (Chapter 8) of this manual.

If the generator has been in storage for 12 months or more, replace the bearings.

A040J847 (Issue 4) 19

-

7.4 Vibration Frequencies

The main vibration frequencies produced by the generator are as follows:

• 4-pole 1500 RPM 25 Hz

• 4-pole 1800 RPM 30 Hz

• 2-pole 3000 RPM 50 Hz

• 2-pole 3600 RPM 60 Hz

Vibrations induced in the generator by the engine are complex. It is the responsibility of the

generating set designer to ensure that the alignment and stiffness of the bedplate and

mountings do not allow vibration to exceed BS5000 part 3 and ISO 8528 part 9 limits.

7.5 Side Loads

For belt-driven generators, make sure drive end and drive pulleys are aligned to avoid axial

load on the bearings. We recommend screw type tensioning devices to allow accurate

adjustment of belt tension whilst maintaining pulley alignment.

Belt and pulley guards must be provided by the generating set builder.

Important! Incorrect belt tensioning will result in excessive bearing wear.

2/4-Pole Side Load Shaft extension

Kg N

P0 92 900 82

P1 173 1700 82

7.6 Generating Set Coupling

NOTICE

Do not attempt to rotate the generator rotor by levering against the vanes of the cooling fan.

The fan is not designed to withstand such forces and will be damaged.

mm

Efficient operation and long component life depend on minimising mechanical stresses on

the generator. When coupled in a generating set, misalignment and vibration interactions

with the prime mover engine can cause mechanical stress.

20 A040J847 (Issue 4)

Generating sets need a substantial flat continuous bedplate to suit the installation site floor

loading, with engine and generator mounting pads to make a firm base for accurate

alignment. The height of all mounting pads must be within 0.25 mm for skid mounting, 3 mm

for non-adjustable anti-vibration mounts (AVM) or 10 mm for adjustable height AVMs. Use

shims to achieve level. The rotational axes of generator rotor and engine output shaft must

be coaxial (radial alignment) and perpendicular to the same plane (angular alignment). The

axial alignment of the generator and engine coupling must be within 0.5 mm, to allow for

thermal expansion without unwanted axial force on the bearings at operating temperature.

Vibration can occur by flexing of the coupling. The generator is designed for a maximum

bending moment not exceeding 17 kgm (125 lbs ft). Check the maximum bending moment

of the engine flange with the engine manufacturer.

Close-coupling of generator and engine can increase the rigidity of the generating set. Both

single and two bearing generators can be close-coupled. The generating set builder must

supply guarding for open-coupled applications.

To prevent rust during transit and storage, the generator frame spigot, rotor coupling plates

and shaft extension have been treated with a rust preventative coating. Remove this before

coupling the generating set.

To prevent movement of the rotor during transport, single bearing generators without an

excitation boost system (EBS) have a non-drive end (NDE) transit bracket fitted. Remove

the NDE cover, remove the NDE transit bracket and fastener from the rotor shaft, then refit

the NDE cover before coupling the generating set.

-

FIGURE 4. SINGLE BEARING GENERATOR ROTOR SHOWING COUPLING DISCS BOLTED TO

DRIVE END COUPLING HUB (AT RIGHT)

FIGURE 5. TWO BEARING GENERATOR ROTOR SHOWING SHAFT WITH KEYWAY FOR

FLEXIBLE COUPLING (AT RIGHT)

7.7 Single Bearing

1. If supplied, check that the bracket which supports the rotor underneath the fan hub is

fitted in position .

A040J847 (Issue 4) 21

Loading...

Loading...