P0/P1 AC Generators

INSTALLATION, SERVICE AND

MAINTENANCE

English

Original Instructions

A040J847 (Issue 4)

Table of Contents

1. FOREWORD......................................................................................................................... 1

2. SAFETY PRECAUTIONS...................................................................................................... 3

3. SAFETY DIRECTIVES AND STANDARDS.......................................................................... 7

4. INTRODUCTION................................................................................................................... 9

5. AUTOMATIC VOLTAGE REGULATORS (AVR)................................................................. 13

6. APPLICATION OF THE GENERATOR............................................................................... 15

7. INSTALLATION INTO THE GENERATING SET................................................................ 19

8. SERVICE & MAINTENANCE.............................................................................................. 29

9. FAULT FINDING ................................................................................................................. 49

10. PARTS IDENTIFICATION................................................................................................... 67

11. TECHNICAL DATA.............................................................................................................. 71

12. SPARES AND AFTER SALES SERVICE........................................................................... 73

13. END OF LIFE DISPOSAL ................................................................................................... 75

A040J847 (Issue 4) i

-

This page is intentionally blank.

ii A040J847 (Issue 4)

1 Foreword

1.1 The Manual

This manual contains guidance and instructions for the installation, servicing and

maintenance of the generator.

Before operating the generator, read this manual and make sure that all personnel who work

on the equipment have access to the manual and all additional documentation supplied with

it. Misuse and failure to follow the instructions, and the use of non-approved parts, may

invalidate the product warranty and lead to potential accidents.

This manual is an essential part of the generator. Make sure that the manual is available to

all users throughout the life of the generator.

The manual is written for skilled electrical and mechanical technicians and engineers, who

have prior knowledge and experience of generating equipment of this type. If in doubt,

please seek expert advice or contact your local Cummins Generator Technologies

subsidiary.

Information in this manual was correct when published. It may be superseded due to our

policy of continuous improvement. Please visit www.cumminsgeneratortechnologies.com for

latest documentation.

NOTICE

A040J847 (Issue 4) 1

-

This page is intentionally blank.

2 A040J847 (Issue 4)

2 Safety Precautions

2.1 Safety Information and Notices used in this manual

Danger, Warning and Caution panels are used in this manual to describe the sources of

hazards, their consequences and how to avoid injury. Notice panels emphasise important or

critical instructions.

DANGER

Danger indicates a hazardous situation which, if not avoided, WILL result in death or serious

injury.

WARNING

Warning indicates a hazardous situation which, if not avoided, COULD result in death or

serious injury.

CAUTION

Caution indicates a hazardous situation which, if not avoided, COULD result in minor or

moderate injury.

NOTICE

Notice refers to a method or practice which can result in product damage, or to draw

attention to additional information or explanations.

2.2 Skill Requirements of Personnel

WARNING

Service and maintenance procedures should only be carried out by experienced and qualified

engineers, who are familiar with the procedures and the equipment.

2.3 Risk Assessment

WARNING

A risk assessment should be performed by the user/operating company to establish all

personnel-related risks. All affected users must be trained on the identified risks. Access to

the Power Plant/Generating Set during operation must be restricted to persons who have

been trained on these risks.

2.4 Personal Protective Equipment (PPE)

WARNING

All persons operating, servicing, maintaining or working in or with a power plant or a

generating set must wear appropriate Personal Protective Equipment (PPE).

A040J847 (Issue 4) 3

-

Recommended PPE includes:

• Ear and Eye Protection

• Head and face protection

• Safety footwear

• Overalls that protect the lower arms and legs

Ensure that all persons are fully aware of the emergency procedures in case of accidents.

2.5 Noise

Generators emit noise. Wear appropriate ear protection at all times. Maximum A-weighted

noise emissions may reach 97 dB(A). Contact the supplier for application-specific details.

2.6 Electrical Equipment

CAUTION

All electrical equipment can be dangerous if not operated correctly. Always install, service

and maintain the generator in accordance with this manual.

Work that requires access to electrical conductors must comply with all applicable local and

national electrical safety procedures for the voltages involved and any site specific rules.

Always use genuine branded replacement parts.

2.7 Lock Out/Tag Out

Isolate the generator from all sources of mechanical and electrical energy before starting

service or maintenance work. Adopt a suitable lock-out/tag out process.

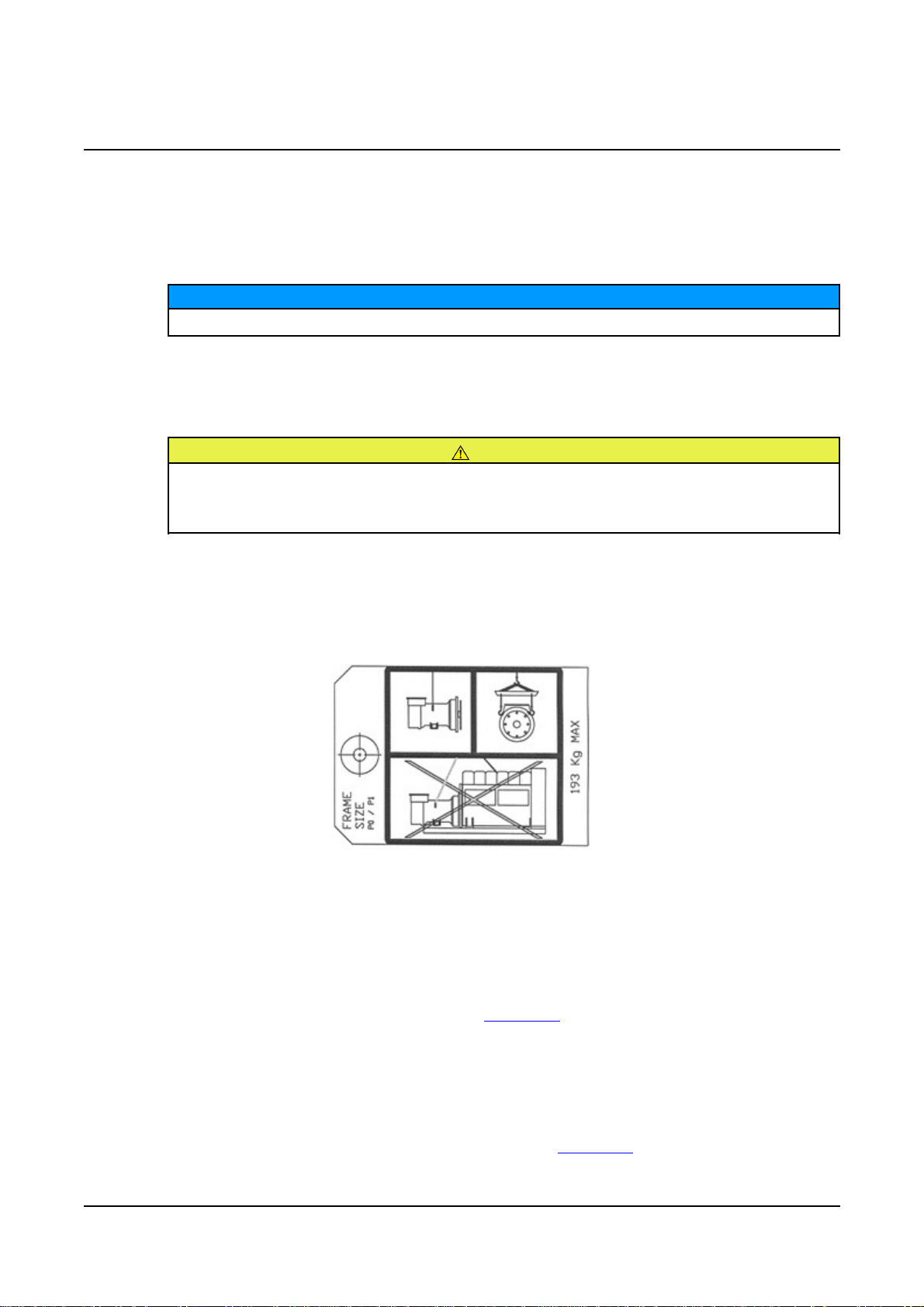

2.8 Lifting

The lifting points provided are designed for lifting the generator only. Do not use the

generator lifting points to lift the complete generating set (generator coupled to motive power

source).

Do not remove the lifting label attached to one of the lifting points.

CAUTION

WARNING

WARNING

2.9 Generator Operating Areas

WARNING

In the event of catastrophic failure, machine parts may be ejected from the generator air

inlet/outlet (shaded regions of diagram). Do not place controls near the air inlet/outlet and

restrict personnel from these regions during machine running.

4 A040J847 (Issue 4)

2.10 Hazard Warning Labels

Hazard warning labels are fixed to the generator. If the original labels are missing, damaged

or painted over, replace them with the spare set supplied in a wallet attached to the

generator. Label locations are shown on the back of the label set.

-

2.11 General Guidance

NOTICE

These safety precautions are for general guidance and supplement your own safety

procedures and all applicable laws and standards.

A040J847 (Issue 4) 5

-

This page is intentionally blank.

6 A040J847 (Issue 4)

3 Safety Directives and Standards

STAMFORD AC generators meet applicable European safety directives, and national and

international standards relevant to generators. The generator must be operated within the

limits specified in the relevant standards and within the parameters on the generator rating

plate.

Marine generators meet the requirements of all the major marine classification societies.

3.1 European Directives: EC Declaration of Conformity for Incorporation

Each generator supplied in the European Economic Area (EEA) is supplied with an EC

Declaration of Conformity for Incorporation into an electricity generating set. It is the

responsibility of the generating set manufacturer to ensure that the complete generating set

complies with EC Directives and standards.

Our authorized representative in the European Community is Mr Jeffrey Matthews,

Engineering Director, Cummins Generator Technologies Ltd.

All generators meet the following Standards and Directives:

Directives:

• 2004/108/EC EMC Directive

• 2006/95/EC Low Voltage Directive

• 2006/42/EC Machinery Directive

Standards:

• EN 61000-6-1 Electromagnetic Compatibility, Generic Standards - Immunity for

residential, commercial and light-industrial environments

• EN 61000-6-2 Electromagnetic Compatibility, Generic Standards - Immunity for

industrial environments

A040J847 (Issue 4) 7

-

• EN 61000-6-4 Electromagnetic Compatibility, Generic Standards - Emission standard

for light-industrial environments

• EN ISO 12100-1 Safety of Machinery, Basic concepts, general principles for design Basic terminology, methodology

• EN ISO 12100-2 Safety of Machinery, Basic concepts, general principles for design Technical principles

• EN ISO 14121-1 Safety of Machinery, Risk assessment - Principles

• EN 60034-1 Rotating electrical machines - Rating and performance

• BS ISO 8528-3 Reciprocating internal combustion engine driven alternating current

generating sets - alternating current generators for generating sets

• BS 5000-3 Rotating electrical machines - Generators to be driven by reciprocating

internal combustion engines - Requirements for resistance to vibration

NOTICE

Once the generator is built into a generating set, it is the responsibility of the generating set

manufacturer to ensure that the generating set complies with the relevant specifications and

standards.

3.2 Additional Information for EMC Compliance

STAMFORD generators are designed to meet EMC emissions and immunity standards for

industrial environments. Document reference N4/X/011 outlines additional equipment that

may be required when the generator is installed in residential, commercial and light industrial

environments.

The installation ‘earth/ground’ arrangements require the connection of the generator frame to

the site protective earth conductor using a minimum lead length.

Installation, maintenance and servicing must be carried out by adequately trained personnel

fully aware of the requirements of the relevant EC directives.

NOTICE

Cummins Generator Technologies is not liable for EMC compliance if unauthorised parts, not

of STAMFORD brand, are used for maintenance and servicing.

3.3 Additional Information for CSA Compliance

To comply with Canadian Standards Association (CSA) regulations, all external wiring and

components must be rated at the generator rated voltage shown on the rating plate label.

8 A040J847 (Issue 4)

4 Introduction

4.1 General Description

P0/P1 generators are of brushless rotating field design, available up to 600V, 50Hz (1500

RPM, 4 pole and 3000 RPM, 2 pole) or 60Hz (1800 RPM, 4 pole and 3600 RPM, 2 pole),

and built to meet B.S. 5000 Part 3 and other international standards.

P0/P1 are self-excited, with excitation power derived from the main output windings using

the AS480 AVR.

4.2 Serial Number Location

A unique serial number is stamped into the top of the generator frame near the drive end

and shown on the rating plate and tracking labels on the side of the generator frame.

4.3 Rating Plate

The fixed rating plate label states the intended operating parameters of the generator.

The generator could overheat if operated outside the parameters specified on the rating plate.

Overheating can cause catastrophic failure and injury from ejected debris. Always operate

the generator within the rated parameters.

WARNING

4.4 Product Authentication

The STAMFORD high security, anti-counterfeit hologram is located on the Tracking

Label. Check that the dots are visible around the STAMFORD logo when viewing the

hologram from different angles and the word "GENUINE" appears behind the logo. Use a

flashlight to see these security features in low ambient light. Check that the generator is

genuine by entering the unique 7 character hologram code at www.stamford-

avk.com/verify.

FIGURE 1. GLOBAL STAMFORD AC GENERATOR NAMEPLATE, COMPRISING RATING PLATE

(ABOVE) AND TRACKING LABEL (BELOW)

A040J847 (Issue 4) 9

-

FIGURE 2. DOTS VISIBLE IN LEFT, RIGHT, UPPER AND LOWER VIEWS OF 3D HOLOGRAM

10 A040J847 (Issue 4)

4.5 Self-Excited AVR Controlled Generators

4.5.1 Main Stator Powered AVR

The AVR provides closed loop control by sensing the generator output voltage at the main

stator windings and applying voltage to the exciter stator. Voltage induced in the exciter

rotor, rectified by the rotating diodes, magnetises the main rotor which induces voltage in the

main stator windings. The AVR is also powered by the main stator.

-

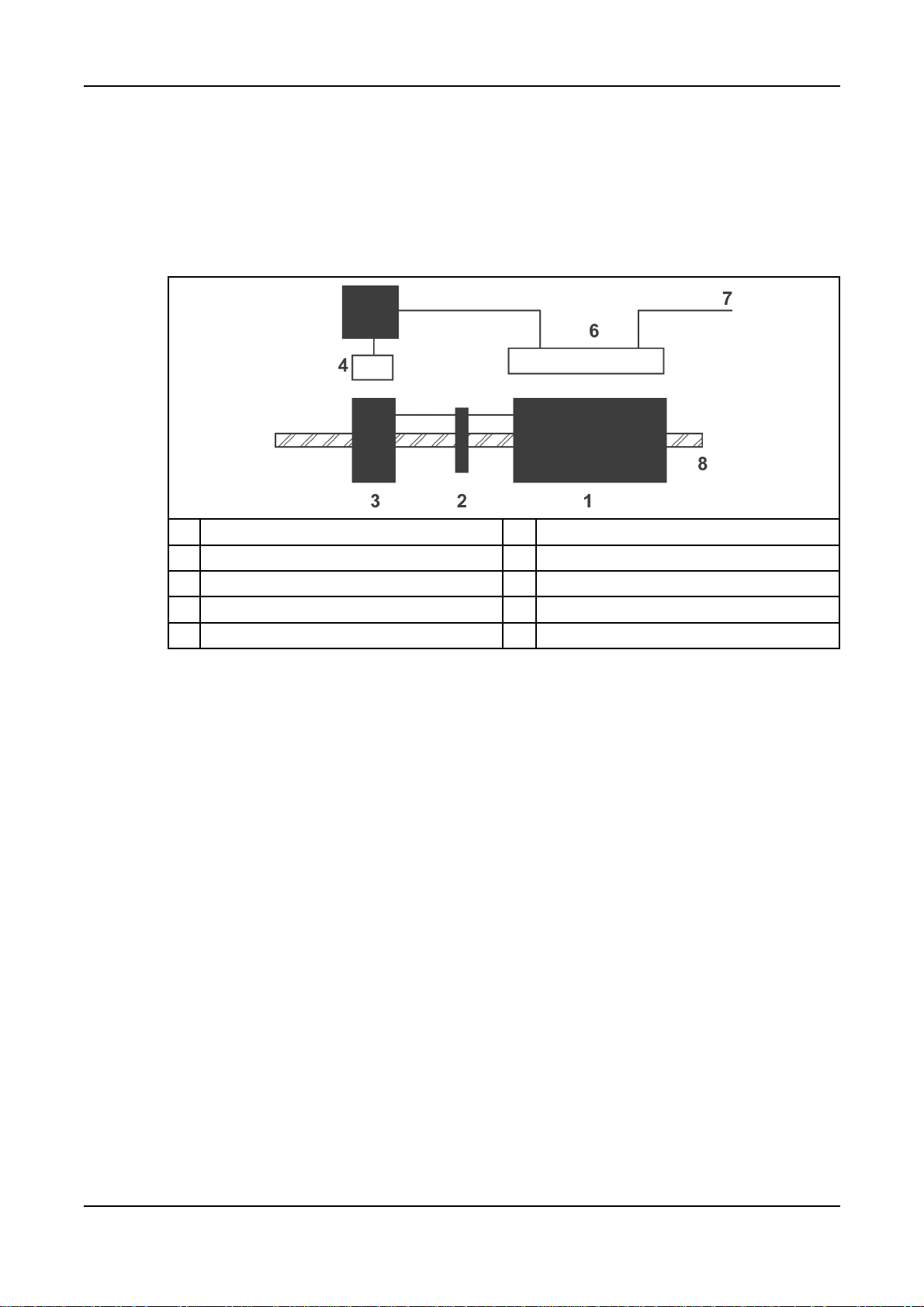

No. Description No. Description

1 Main rotor 5 AVR

2 Rotating diodes 6 Main stator

3 Exciter rotor 7 Output

4 Exciter stator 8 Shaft

4.6 Separately-Excited AVR Controlled Generators

4.6.1 Excitation Boost System (EBS)

The EBS is a self-contained optional unit, attached to the non-drive end of the generator.

The EBS unit consists of the Excitation Boost Controller (EBC) and an Excitation Boost

Generator (EBG). Under fault conditions, or when the generator is subjected to a large

impact load such as a motor starting, the generator voltage drops. The EBC senses the drop

in voltage and engages the output power of the EBG. This additional power feeds the

generator’s excitation system, supporting the load until the generator voltage recovers or

breaker discrimination removes the fault.

A040J847 (Issue 4) 11

-

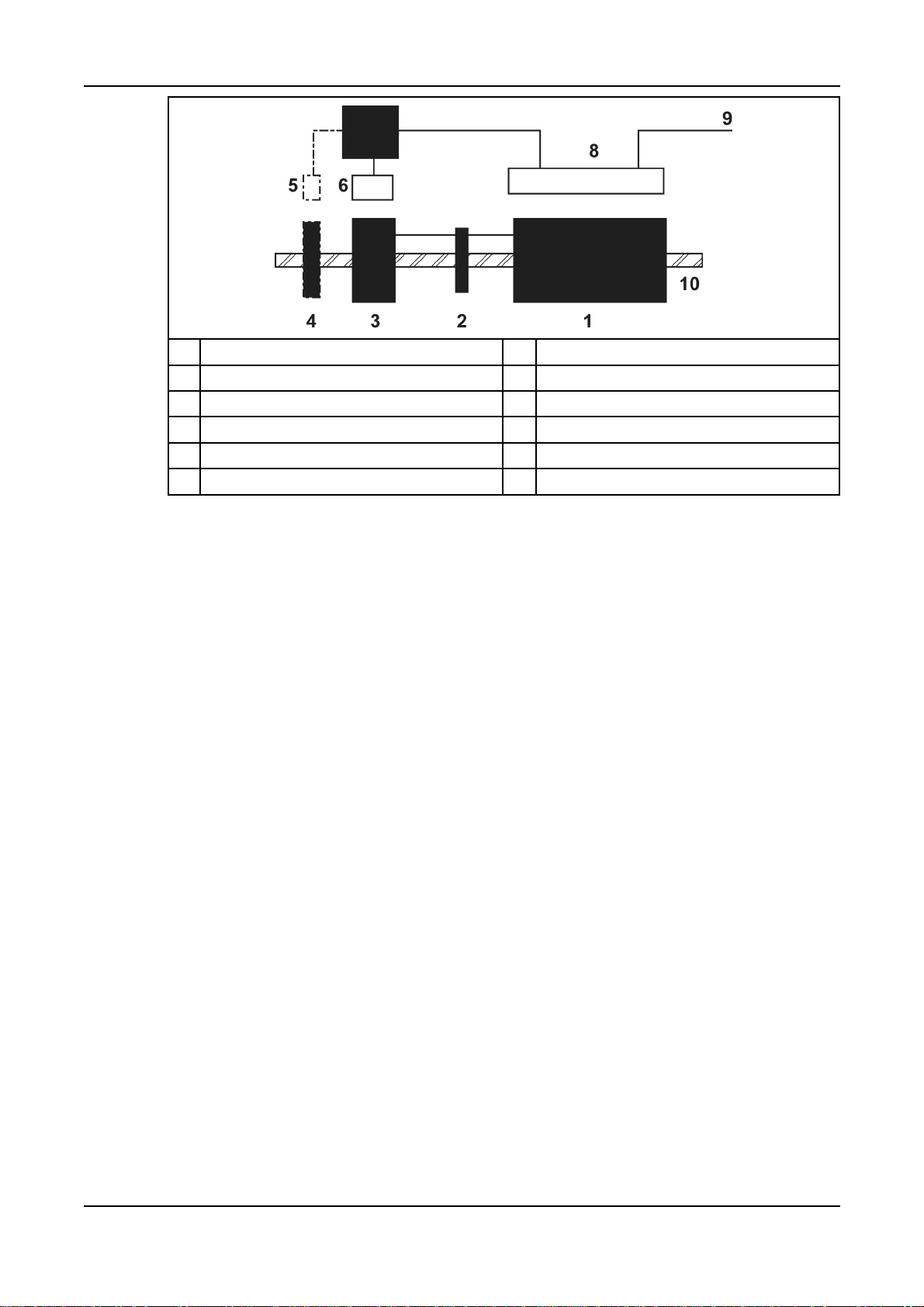

No. Description No. Description

1 Main rotor 6 Exciter stator

2 Rotating diodes 7 AVR & EBS

3 Exciter rotor 8 Main stator

4 EBG rotor (optional) 9 Output

5 EBG stator (optional) 10 Shaft

12 A040J847 (Issue 4)

5 Automatic Voltage Regulators (AVR)

Cummins Generator Technologies offer a selection of Automatic Voltage Regulators (AVRs)

designed and built to achieve maximum performance from the range of STAMFORD

brushless AC generators. Self-excited and separately-excited types are available, from lowcost analogue to sophisticated digital control. All STAMFORD AVRs are encapsulated to

provide environmental protection, and are mounted on anti-vibration mounts for added

mechanical protection.

All STAMFORD AVRs have the following features:

• connections to a remote hand trimmer accessory for fine control of the generator output

voltage

• ‘Under-Frequency Roll-Off’ (UFRO) protection to reduce the generator output voltage if

speed falls below a threshold, and

• connections to power factor and droop accessories for sharing reactive load in parallel

with other generators or mains utility.

AVR specification, installation and adjustment information is available in the AVR manual

supplied with the generator, or at www.cumminsgeneratortechnologies.com

NOTICE

AVR analogue inputs must be fully floating (galvanically isolated from ground), with

an insulation strength of 500 V a.c.

5.1 Self-Excited

A self-excited AVR receives power from the generator output terminals. The AVR controls

the generator output voltage by automatic adjustment of the exciter stator field strength.

5.1.1 AS480

The AS480 achieves voltage regulation of ±1.0%. The design employs surface mount

technology, custom mouldings and heatsink in a compact assembly.

The AVR includes the following extra features:

• connections to an Excitation Boost System accessory, and

• connection of a lead assembly for low voltage (100 V to 120 V a.c.) sensing.

5.2 AVR Accessories

Accessories to support AVR functions are factory-fitted or supplied separately with

instructions for fitting and wiring by a competent technician.

5.2.1 Hand Trimmer (for remote voltage adjustment)

A hand trimmer can be fitted in a convenient position (typically in the generator set control

panel) and connected to the AVR to provide fine adjustment of the generator voltage. The

hand trimmer value and the adjustment range obtained is as defined in the Technical

Specification. Refer to wiring diagram before removing the shorting link and connecting the

hand trimmer.

A040J847 (Issue 4) 13

-

5.2.2 Droop Transformer (for parallel operation – generator to generator)

A droop transformer can be fitted in a defined position in the generator main output wiring

and connected to the AVR to enable parallel operation with other generators. The

adjustment range is as defined in the Technical Specification. Refer to wiring diagram before

removing the shorting link and connecting the droop transformer. The droop transformer

MUST be connected in the correct main output terminal for proper operation (details are as

shown in the machine wiring diagram).

5.2.3 Excitation Boost System (with AS480 AVR only)

An add-on pilot winding and permanent-magnet rotor assembly is available to enhance the

motor-starting and overload performance of the AS480 AVR. This is fitted to the non-driveend bracket of the generator as a single integrated assembly and connects into the AVR via

four ‘faston’ connections. During motor-starting or other heavy overloads the unit

automatically provides additional excitation support as demanded by the AVR. An internal

over-excitation system prevents prolonged overload from damaging the generator.

5.2.4 Low Voltage Link/Selector

The AS480 AVR can be configured for low voltage working between 100 V a.c. and 120 V

a.c. with a special lead assembly which connects between the generator main terminals and

AVR input terminal ‘S1’. In low-voltage operating mode the overload performance of the

control system is reduced. The EBS will not work at low voltage.

14 A040J847 (Issue 4)

6 Application of the Generator

It is the customer's responsibility to make sure that the selected generator is suitable for the

final application.

CAUTION

Overloading a generator may lead to catastrophic failure.

6.1 Environment

STAMFORD generators are protected to IP23 as standard. IP23 is not adequate protection

for use outdoors without additional measures.

Ambient Temperature -15 °C to 40 °C

Relative Humidity < 60%

Altitude < 1000 m

The generator has been designed for the environment shown in the table. The generator can

operate outside these conditions if it is rated accordingly: The nameplate gives details. If the

operating environment is changed after purchase, refer to the factory for a revised generator

rating.

6.2 Air Flow

Make sure that the air inlets and outlets are not obstructed when the generator is running.

6.3 Airborne Contaminants

Contaminants such as salt, oil, exhaust fumes, chemicals, dust and sand will reduce the

effectiveness of the insulation and the life of the windings. Consider using air filters and an

enclosure to protect the generator.

6.4 Humid Conditions

The water carrying capacity of air depends on temperature. If the air temperature falls below

its saturation point, dew may form on the windings reducing the electrical resistance of the

insulation. In humid conditions additional protection may be required, even if the generator is

fitted inside an enclosure. Anti-condensation heaters are supplied on request.

6.5 Anti-condensation heaters

WARNING

Power to the anti-condensation heater is supplied from a separate source. Before

doing any work on the heater, make sure the power is isolated and locked off.

Anti-condensation heaters raise the air temperature around the windings to deter

condensation forming in humid conditions when the generator is not operating. Best practice

is to energise the heaters automatically when the generator is off.

A040J847 (Issue 4) 15

-

6.6 Enclosures

Fit an enclosure to protect the generator from adverse environmental conditions. Make sure

that air entering the generator is of adequate flowrate, free from moisture and contaminants,

and below the maximum ambient temperature on the rating plate.

Make sure there is sufficient access around the generator for safe maintenance.

P0 and P1 generators have round end brackets that will create an air flow pattern that differs

from previous generators of this size. The air flow should be modeled to identify and prevent

hot air from recirculating within the enclosure.

6.7 Vibration

STAMFORD generators are designed to withstand the vibration levels encountered on

generating sets built to meet the requirements of ISO 8528-9 and BS 5000-3. (Where ISO

8528 is taken to be broad band measurements and BS5000 refers to the predominant

frequency of any vibrations on the generating set).

Exceeding either of the above specifications will have a detrimental effect on the life of the

bearings and other components, and may invalidate the generator warranty.

NOTICE

6.7.1 Definition of BS5000–3

Generators shall be capable of continuously withstanding linear vibration levels with

amplitudes of 0.25mm between 5Hz and 8Hz and velocities of 9.0mm/s r.m.s. between 8 Hz

and 200 Hz, when measured at any point directly on the carcass or main frame of the

machine. These limits refer only to the predominant frequency of vibration of any complex

waveform.

6.7.2 Definition of ISO 8528-9

ISO 8528-9 refers to a broad band of frequencies; the broad band is taken to be between 10

Hertz and 1000 Hertz. The table below is an extract from ISO 8528-9 (Table C.1, value 1).

This simplified table lists the vibration limits by kVA and speed for acceptable operation of

standard generating set designs.

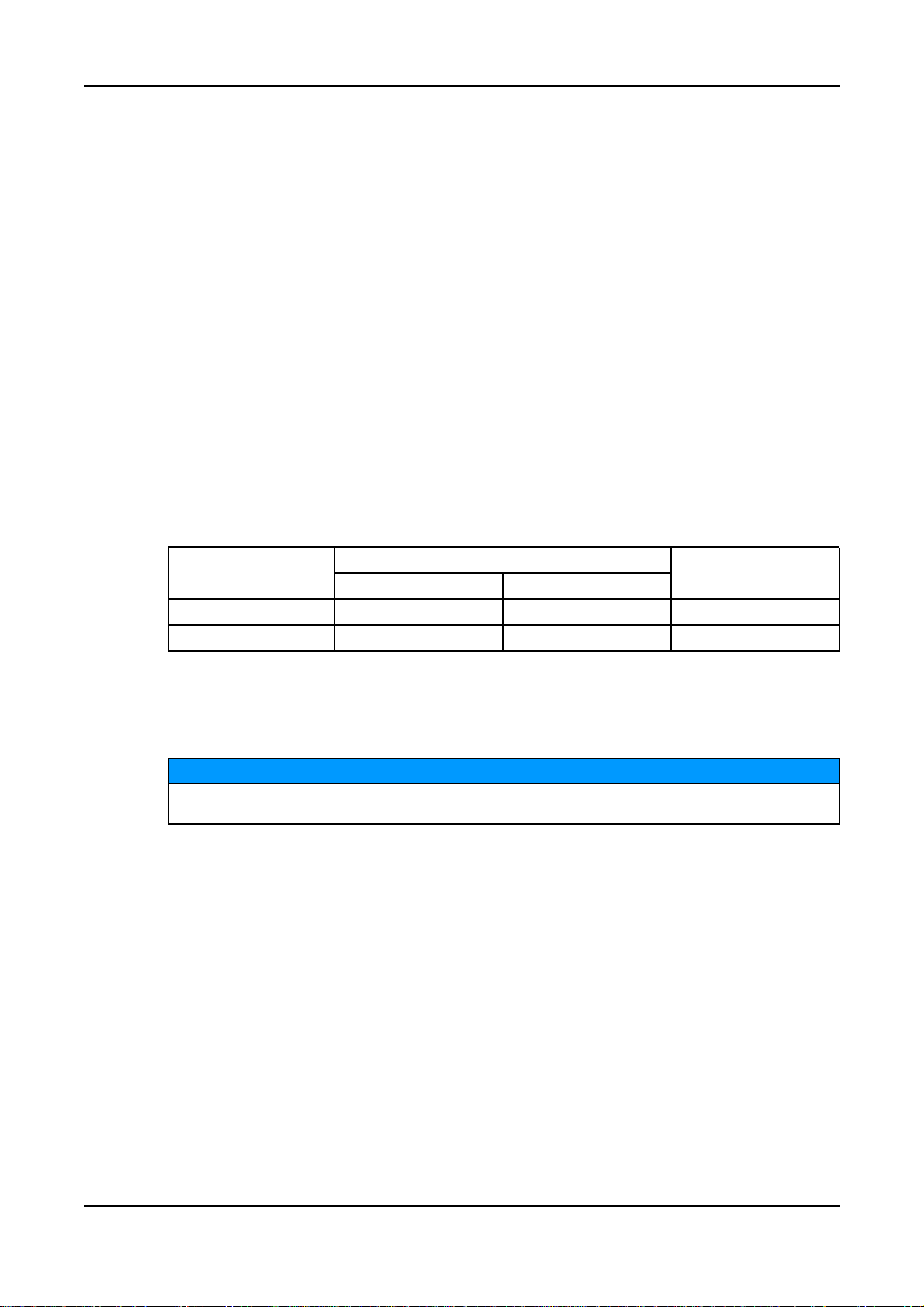

6.7.3 Linear Vibration Limits

Linear Vibration Levels As Measured On The Generator - P0/P1

Engine Speed Power Output Vibration Vibration Vibration

RPM S Displacement Velocity Acceleration

(min-1) (kVA) r.m.s. (mm) r.m.s. (mm/s) r.m.s. (mm/s2)

2000 ≤ RPM ≤ 3600 S ≤ 50 0.8 50 31

50 < S 0.64 40 25

1300 ≤ RPM < 2000 4 < S ≤ 50 0.64 40 25

50 < S ≤ 125 0.4 25 16

The broad band is taken as 10 Hz - 1000 Hz

16 A040J847 (Issue 4)

6.7.4 Linear Vibration Monitoring

We recommend using vibration analysing equipment to measure vibration. Check that

vibration of the generating set is below the limits stated in the standards. If vibration is above

the limits, the generating set builder should investigate the root causes and eliminate them.

Best practice is for the generating set builder to take initial readings as a reference and for

the user to periodically monitor vibration, according to the recommended service schedule,

to detect a deteriorating trend.

6.7.5 Excessive Vibration

WARNING

Excessive vibration can cause catastrophic failure of the generator, which could cause

personal injury.

If the measured vibration of the generating set is not within the limits:

1. The generating set manufacturer should change the generating set design to reduce

the vibration levels as much as possible.

2. Contact Cummins Generator Technologies to assess the impact on bearing and

generator life expectancy.

-

6.8 Bearings

6.8.1 Sealed Bearings

Sealed bearings are supplied pre-packed with grease and sealed for life. Sealed bearings do

not require re-greasing.

6.8.2 Bearing Life

Factors that reduce bearing life or lead to bearing failure include:

• Adverse operating conditions and environment

• Stress caused by misalignment of the generating set

• Vibration from the engine that exceeds the limits in BS 5000-3 and ISO 8528-9

• Long periods (including transportation) where the generator is stationary and subjected

to vibration can cause false brinelling wear (flats on the balls and grooves on the races)

• Very humid or wet conditions that cause corrosion and deterioration of the grease by

emulsification.

6.8.3 Health Monitoring of the Bearings

We recommend that the user checks the bearing condition, using vibration monitoring

equipment. Best practice is to take initial readings as a reference and periodically monitor

the bearings to detect a deteriorating trend. It will then be possible to plan a bearing change

at an appropriate generating set or engine service interval.

6.8.4 Bearing Service Life Expectancy

Bearing manufacturers recognise that service life of bearings depends on factors that are

outside their control: Rather than quote a service life, practicable replacement intervals are

based on the L10 life of the bearing, the type of grease and the recommendations of the

bearing and grease manufacturers.

A040J847 (Issue 4) 17

-

For general-purpose applications; if the correct maintenance is carried out, vibration levels

do not exceed the levels stated in ISO 8528-9 and BS5000-3, and the ambient temperature

does not exceed 50°C, plan to replace the bearings within 30,000 hours of operation.

If in doubt about any aspect of bearing life on STAMFORD generators, contact your nearest

supplier of STAMFORD generators or the Stamford factory.

18 A040J847 (Issue 4)

7 Installation into the Generating Set

7.1 Generator Dimensions

Dimensions are included in the data sheet specific to the generator model. Refer to the

rating plate to identify the generator model .

NOTICE

Data sheets are available from www.cumminsgeneratortechnologies.com

7.2 Lifting the Generator

CAUTION

The generator lifting points are designed to lift the generator only. Do not lift the complete

generating set (generator coupled to motive power source) by the generator lifting points.

Keep the generator horizontal when lifting. Fit the transit bar to single bearing generators to

keep the main rotor in the frame.

Lift the generator by shackle and pin attachment to the lifting points (lugs or eyes) provided.

A label attached to a lifting point shows the correct lifting arrangement. Use chains of

sufficient length, and a speader bar if necessary, to make sure that the chains are vertical

when lifting. Make sure that the capacity of the lifting equipment is sufficient for the

generator mass shown on the label.

FIGURE 3. LIFTING LABEL

7.3 Storage

If the generator is not to be used immediately, it must be stored in a clean, dry, vibration free

environment. We recommend the use of anti-condensation heaters.

Refer to Service and Maintenance section (Chapter 8) of this manual for further instructions

for the bearings of stored generators.

7.3.1 After Storage

After a period of storage, carry out ‘pre running checks’ to determine the condition of the

windings. If the winding are damp or the insulation is low, follow one of the ‘drying out

procedures’, in the Service and Maintenance section (Chapter 8) of this manual.

If the generator has been in storage for 12 months or more, replace the bearings.

A040J847 (Issue 4) 19

-

7.4 Vibration Frequencies

The main vibration frequencies produced by the generator are as follows:

• 4-pole 1500 RPM 25 Hz

• 4-pole 1800 RPM 30 Hz

• 2-pole 3000 RPM 50 Hz

• 2-pole 3600 RPM 60 Hz

Vibrations induced in the generator by the engine are complex. It is the responsibility of the

generating set designer to ensure that the alignment and stiffness of the bedplate and

mountings do not allow vibration to exceed BS5000 part 3 and ISO 8528 part 9 limits.

7.5 Side Loads

For belt-driven generators, make sure drive end and drive pulleys are aligned to avoid axial

load on the bearings. We recommend screw type tensioning devices to allow accurate

adjustment of belt tension whilst maintaining pulley alignment.

Belt and pulley guards must be provided by the generating set builder.

Important! Incorrect belt tensioning will result in excessive bearing wear.

2/4-Pole Side Load Shaft extension

Kg N

P0 92 900 82

P1 173 1700 82

7.6 Generating Set Coupling

NOTICE

Do not attempt to rotate the generator rotor by levering against the vanes of the cooling fan.

The fan is not designed to withstand such forces and will be damaged.

mm

Efficient operation and long component life depend on minimising mechanical stresses on

the generator. When coupled in a generating set, misalignment and vibration interactions

with the prime mover engine can cause mechanical stress.

20 A040J847 (Issue 4)

Generating sets need a substantial flat continuous bedplate to suit the installation site floor

loading, with engine and generator mounting pads to make a firm base for accurate

alignment. The height of all mounting pads must be within 0.25 mm for skid mounting, 3 mm

for non-adjustable anti-vibration mounts (AVM) or 10 mm for adjustable height AVMs. Use

shims to achieve level. The rotational axes of generator rotor and engine output shaft must

be coaxial (radial alignment) and perpendicular to the same plane (angular alignment). The

axial alignment of the generator and engine coupling must be within 0.5 mm, to allow for

thermal expansion without unwanted axial force on the bearings at operating temperature.

Vibration can occur by flexing of the coupling. The generator is designed for a maximum

bending moment not exceeding 17 kgm (125 lbs ft). Check the maximum bending moment

of the engine flange with the engine manufacturer.

Close-coupling of generator and engine can increase the rigidity of the generating set. Both

single and two bearing generators can be close-coupled. The generating set builder must

supply guarding for open-coupled applications.

To prevent rust during transit and storage, the generator frame spigot, rotor coupling plates

and shaft extension have been treated with a rust preventative coating. Remove this before

coupling the generating set.

To prevent movement of the rotor during transport, single bearing generators without an

excitation boost system (EBS) have a non-drive end (NDE) transit bracket fitted. Remove

the NDE cover, remove the NDE transit bracket and fastener from the rotor shaft, then refit

the NDE cover before coupling the generating set.

-

FIGURE 4. SINGLE BEARING GENERATOR ROTOR SHOWING COUPLING DISCS BOLTED TO

DRIVE END COUPLING HUB (AT RIGHT)

FIGURE 5. TWO BEARING GENERATOR ROTOR SHOWING SHAFT WITH KEYWAY FOR

FLEXIBLE COUPLING (AT RIGHT)

7.7 Single Bearing

1. If supplied, check that the bracket which supports the rotor underneath the fan hub is

fitted in position .

A040J847 (Issue 4) 21

-

2. Position the generator close to the engine and remove the drive end transit bracket that

keeps the rotor in place during transport.

CAUTION

Keep the generator horizontal to keep the rotor in place

3. Remove the air outlet covers from the drive end of the generator to access the coupling

and adaptor bolts.

4. If required, tighten the coupling disc bolts in the sequence shown above.

5. Check the torque of bolts that fasten the coupling discs to the DE coupling hub in a

clockwise direction around the bolt circle.

6. Make sure the coupling discs are concentric with the adaptor spigot. Use alignment

studs to ensure that the disc and the flywheel are in alignment.

7. Make sure the axial distance from the coupling mating face on the flywheel to the

mating face on the flywheel housing is within 0.5mm of nominal dimension. This

ensures that the engine crankshaft float is maintained and the generator rotor position

is neutral, allowing for thermal expansion. There is no axial pre-load thrust on the

engine or generator bearings.

8. Offer the generator to the engine and engage coupling discs and housing spigots at the

same time, pushing the generator towards the engine until the coupling discs are

against the flywheel face and the housing spigots are located.

CAUTION

Do not pull the generator to the engine using bolts through the flexible discs.

CAUTION

Failure to secure bolts can lead to excessive vibration, which in turn can lead to

catastrophic generator failure.

9. Fit heavy gauge washers under the heads of housing and coupling bolts. Screw in the

bolts evenly around the coupling assembly to maintain correct alignment.

22 A040J847 (Issue 4)

10. Tighten the bolts to fix the coupling disc to the flywheel, in the sequence shown above.

11. Check the torque of each bolt in a clockwise direction around the bolt circle to ensure

all the bolts are tight. Refer to the engine manufacturer’s manual for correct tightening

torque.

12. If a PMG is not fitted, remove the NDE transit bracket.

13. Replace all covers.

-

7.8 Two Bearing

A flexible coupling, designed to suit the specific engine/generator combination, is

recommended to minimise torsional vibration effects.

If a close coupling adaptor is used the alignment of machined faces must be checked by

offering the generator up to the engine. Shim the generator feet if necessary.

7.9 Pre-Running Checks

Before starting the generating set, test the insulation resistance of windings, check all

connections are tight and in the correct location. Ensure the generator air path is clear of

obstructions. Replace all covers.

7.10 Insulation Resistance Test

NOTICE

Disconnect the AVR and voltage transformers (if fitted) before this test. Disconnect and earth

all RTD and Thermistor temperature sensors (if fitted) before this test.

The resistance test must be carried out by a qualified person.

Generator Voltage Test Voltage (V) Minimum Insulation Resistance (MΩ)

You must dry out the generator windings if the measured insulation resistance is less than

the minimum value. See the Service & Maintenance section (Chapter 8) of this manual.

A040J847 (Issue 4) 23

(kV)

Up to 1 500 5 10

In Service Generator New Generator

-

7.10.1 High Voltage Test

Windings have been tested at high voltage during manufacture. Repeated high voltage tests

may degrade the insulation and reduce operating life. If a further test is required at

installation for customer acceptance, it must be done at a reduced voltage, V = 0.8 x (2 x

Rated Voltage + 1000). Once in service, any further tests for maintenance purposes must be

done after passing visual checks and insulation resistance tests, and at a reduced voltage, V

= (1.5 x Rated Voltage).

7.11 Direction of Rotation

The fan is designed for clockwise rotation, as viewed from the drive end of the generator

(unless otherwise specified when ordered). If the generator must run counter-clockwise,

please seek advice from Cummins Generator Technologies .

NOTICE

7.12 Phase Rotation

Main stator output is connected for a phase sequence of U V W when the generator runs

clockwise, as viewed from the drive end. If the phase rotation must be reversed, the

customer must re-connect the output cables in the terminal box. Ask Cummins Generator

Technologies for a circuit diagram of ‘reverse phase connections’.

7.13 Voltage and Frequency

Check that the voltage and frequency shown on the generator rating plate meet the

requirements of the generating set application.

24 A040J847 (Issue 4)

7.14 AVR Settings

The AVR is factory set for initial running tests. Check that the AVR settings are compatible

with your required output. Refer to detailed instructions in the AVR manual for on- and offload adjustments.

7.15 Electrical Connections

Incorrect electrical installation and system protection can cause personal injury. Installers

must be qualified to perform electrical installation work and are responsible for meeting the

requirements of any inspectorate, local electricity authority and site safety rules.

Fault current curves and generator reactance values are available on request from the

factory so that the system designer can calculate the necessary fault protection and/or

discrimination.

The installer must check that the generator frame is bonded to the generating set bedplate,

and must bond to site earth. If anti-vibration mounts are fitted between the generator frame

and its bedplate, a suitably-rated earth conductor must bridge across the anti-vibration

mount.

-

WARNING

Refer to wiring diagrams for electrical connection of the load cables. Electrical connections

are made in the terminal box. Route single core cables through the insulated or nonmagnetic gland plates supplied. Panels must be removed to be drilled or cut to prevent

swarf entering the terminal box or generator. After wiring, inspect the terminal box, remove

all debris using a vacuum cleaner if necessary and check that no internal components are

damaged or disturbed.

As standard, the generator neutral is not bonded to the generator frame. If required, neutral

may be connected to the earth terminal in the terminal box, by a conductor of at least one

half of the sectional area of a phase lead.

Load cables must be supported appropriately to avoid a tight radius at the point of entry into

the terminal box, clamped at the terminal box gland, and allow at least ±25 mm movement

by the generator set on its anti-vibration mountings, without causing excessive stress to the

cables and generator load terminals.

The palm (flattened part) of load cable lugs must be clamped in direct contact with the main

stator output conductors so that the whole palm area conducts the output current. The

tightening torque of fasteners is 6 to 6.6 Nm.

A040J847 (Issue 4) 25

-

7.16 Synchronisation

7.16.1 Parallel or Synchronising AC Generators

FIGURE 6. PARALLEL OR SYNCHRONISING AC GENERATORS

The quadrature droop current transformer (Droop CT) gives a signal proportional to reactive

current; the AVR adjusts excitation to reduce circulating current and allow each generator to

share reactive load. A factory-fitted droop CT is pre-set for 5% voltage drop at full-load zero

power factor. Refer to the supplied AVR manual for droop adjustment.

• The synchronising switch/breaker (CB1, CB2) must be of a type that will not cause

“contact bounce” when it operates.

• The synchronising switch/breaker must be adequately rated to withstand the

continuous full load current of the generator.

• The switch/breaker must be able to withstanding the rigorous closing cycles during

synchronising and the currents produced if the generator is parallelled out of

synchronism.

• The closing time of the synchronising switch/breaker must be under the control of the

synchroniser settings.

• The switch/breaker must be capable of operation under fault conditions such as short

circuits. Generator data sheets are available.

NOTICE

The fault level may include a contribution from other generators as well as from the

grid/mains utility.

The method of synchronising should be either automatic, or by check synchronising. The

use of manual synchronising is not recommended. The settings on the synchronising

equipment should be such that the generator will close smoothly.

CAUTION

Synchronising outside the following parameters may result in catastrophic failure of the

generator.

The Phase sequence must match

Voltage difference +/- 0.5%

Frequency difference 0.1 Hz/sec

Phase angle +/- 10

C/B closing time 50 ms

o

The settings for the synchronising equipment to achieve this must be within these

parameters.

26 A040J847 (Issue 4)

The voltage difference when paralleling with the grid/mains utility is +/- 3% .

-

A040J847 (Issue 4) 27

-

This page is intentionally blank.

28 A040J847 (Issue 4)

8 Service & Maintenance

8.1 Recommended Service Schedule

Refer to Safety Precautions section (Chapter 2) of this manual before starting any service

and maintenance activity.

Refer to Parts Identification section (Chapter 10) for an exploded view of components and

fastener information.

The recommended service schedule shows the recommended service activities in table

rows, grouped by generator subsystem. Columns of the table show the types of service

activity, whether the generator must be running, and the service levels. Service frequency is

given in running hours or time interval, whichever is sooner. A cross (X) in the cells where a

row intersects the columns shows a service activity type and when it is required. An asterisk

(*) shows a service activity done only when necessary.

All service levels in the recommended service schedule can be purchased directly from

Cummins Generator Technologies Customer Service Department,

Telephone: +44 1780 484732,

Email: service-engineers@cumminsgeneratortechnologies.com

A040J847 (Issue 4) 29

-

TABLE 1. RECOMMENDED SERVICE SCHEDULE

SERVICE ACTIVITY TYPE SERVICE LEVEL

X = required

System

* = if necessary

Generator rating X X

Bedplate arrangement X X

Coupling arrangement X X * X

Environmental

conditions and X X X X X X

cleanliness

Ambient temperature

(inside & outside)

Complete machine damage, loose parts & X X X X X X

earth bonds

Generator

Guards, screens,

warning and safety X X X X X X

labels

Maintenance access X X

Electrical nominal

operating conditions & X X X X X X X

excitation

Vibration X X X X X X X

Condition of windings X X X X X X

Insulation resistance of

all windings (PI test for X X * * X X

MV/HV)

Insulation resistance of

rotor, exciter and PMG

Windings

Temperature sensors X X X X X X X

Customer settings for

temperature sensors

Condition of bearings X X X

Bearing(s) X * X

Temperature sensors X X X X X X X

Bearings

Customer settings for

temperature sensors

All generator/customer

connections and

cabling

Generator running

Inspect

Test

Clean

Replace

Commission

Post Commission

250 hrs / 0.5 year

Level 1

1000 hrs / 1 year

Level 2

X X X X X X

X X X

X X

X X

X X X X X X

10,000 hrs / 2 years

Level 3

30,000 hrs / 5 years

Terminal Box

30 A040J847 (Issue 4)

SERVICE ACTIVITY TYPE SERVICE LEVEL

X = required

System

* = if necessary

Initial AVR & PFC set

up

AVR & PFC settings X X X X X X

Customer connection of

auxiliaries

Function of auxiliaries X X X X X X

Synchronisation

settings

Synchronisation X X X X X X X

Controls & Auxiliaries

Anti condensation

heater

Diodes and varistors X X X X X

Diodes and varistors

Rectifier

Generator running

Inspect

Test

Clean

Replace

X X X

X X X X X

X X

X * X

X X

Commission

Post Commission

250 hrs / 0.5 year

Level 1

1000 hrs / 1 year

Level 2

10,000 hrs / 2 years

-

Level 3

30,000 hrs / 5 years

Air inlet temperature X X X X X X X

Air flow (rate &

direction)

Condition of fan X X X X X X

Cooling

Condition of air filter

(where fitted)

Air filters (where fitted) X X * * *

X X X

X X X X X X

1. Proper service and repair are vital to the reliable operation of your generator and the

safety of anyone coming into contact with the generator.

2. These service activities are intended to maximise the life of the generator but shall not

vary, extend or change the terms of the manufacturer's standard warranty or your

obligations in that warranty.

3. Each service interval is a guide only, and developed on the basis that the generator

was installed and is operated in accordance with the manufacturer's guidelines. If the

generator is located and/or operated in adverse or unusual environmental conditions,

the service intervals may need to be more frequent. The generator should be

continually monitored between services to identify any potential failure modes, signs of

misuse, or excessive wear and tear.

A040J847 (Issue 4) 31

-

8.2 Bearings

8.2.1 Introduction

The generator rotor is supported by a bearing at the non-drive end (NDE) and by either a

bearing or a coupling to the prime mover at the drive end (DE). If possible, turn the rotor of

an out of service generator at least six revolutions every month to lubricate the bearing

surfaces with grease and re-position the rotating elements to avoid false brinelling. If rotation

is not possible and the storage period is over two years, replace the bearings before putting

the generator into service

8.2.2 Safety

Safety guards must be removed to replace bearings. To prevent injury, isolate the generating

set from all energy sources and remove stored energy. Use lock and tag safety procedures

before starting work.

External surfaces may be very hot. Exposed skin can suffer serious and permanent burns,

depending on the temperature and contact time. Avoid contact or wear protective gloves.

DANGER

WARNING

Store removed parts and tools in static- and dust-free conditions, to prevent damage or

contamination.

A bearing is damaged by the axial force needed to remove it from the rotor shaft. Do not

reuse a bearing.

A bearing is damaged if the insertion force is applied through the bearing balls. Do not press

fit the outer race by force on the inner race, or vice versa.

Do not try to turn the rotor by levering against the cooling fan vanes. The fan will be

damaged.

8.2.3 Replace Bearings

Follow the steps below, in order:

1. Follow the Remove Non-Drive End section to access NDE bearing

2. If the DE bearing is to be replaced, follow the Remove Drive End section to access DE

bearing.

3. Assemble and fit the new NDE bearing (and DE bearing, as required) onto the rotor

shaft, following the Assemble Bearing section .

4. If the DE bearing has been replaced, follow the Assemble Drive End section to refit

DE components.

5. Follow the Assemble Non-Drive End section to refit NDE components.

NOTICE

8.2.3.1 Requirements

Sealed bearings

Personal Protective Wear mandatory site PPE.

Equipment (PPE)

32 A040J847 (Issue 4)

Wear heat-resistant gloves for handling heated parts.

Consumables Thin disposable gloves

Large plastic bags (to store parts)

Parts NDE bearing

DE bearing (if fitted)

O rings

Tools Induction heater (with protective sleeve on bar)

Torque wrench

Bearing extraction three-legged puller

Rotor support packing

8.2.3.2 Remove Non-Drive End

EBS, anti-condensation heaters and temperature sensors are generator options. Ignore

references to these items if they are not fitted.

1. Turn off the anti-condensation heater and isolate from supply.

2. Remove the terminal box lid.

3. If an Excitation boost system (EBS) is fitted

-

a. Remove the AVR cover.

b. Disconnect the EBS cable connectors from the DR, EB, F1 and F2 terminals of the

AVR.

c. Cut cable ties and withdraw the cable back to the EBS.

d. Remove the EBS unit end cover.

e. Remove the fastener that fixes the EBS rotor to the main rotor shaft.

f. Remove the four fasteners that fix the EBS unit to the NDE bracket.

g. Remove the EBS stator and EBS rotor together as an assembly.

h. Put the EBS assembly into a plastic bag. Seal the bag to protect the parts from

debris.

4. Turn the main rotor so that the lowest rotor pole is vertical and will support the rotor

weight when the bearing is removed.

5. Disconnect the heater.

6. Label and disconnect the main stator leads and output (load) leads from the main

terminals in the terminal box.

7. Remove the NDE cover.

8. Remove the fasteners that fix the NDE bracket and terminal box assembly to the main

frame.

9. Support and tap the NDE bracket with a mallet to release it from the frame.

10. Carefully slide the NDE bracket away from the generator and set aside. Take care to

avoid damaging the attached exciter stator windings on the exciter rotor.

11. Disconnect the thermistor for sensing main stator winding temperature.

8.2.3.3 Remove Drive End

1. Remove NDE components first, following Remove Non-Drive End.

2. Remove the DE air outlet screen.

A040J847 (Issue 4) 33

-

3. Disconnect the generator from the prime mover.

4. Remove the fasteners that fix the DE bracket to the main frame.

5. Support and tap the DE bracket with a mallet to release it from the frame.

6. Remove the DE bracket.

8.2.3.4 Fit The Bearing

1. Heat the bearing and use the bearing extraction puller to remove the old bearing from

the rotor.

2. Fit the new bearing components:

a. Clean off the preservative oil with a lint-free cloth.

b. Heat the bearing to 20 ºC above ambient temperature, but not over 100 ºC, in the

induction heater.

c. Smear anti-fretting grease onto the bearing housing and fit the 'o' ring.

d. Slide the bearing over the rotor shaft, pushing it firmly against the seating

shoulder.

e. Oscillate the assembly (including inner race) 45 degrees in both directions, to

ensure bearing is seated. Hold the bearing in place while it cools and contracts

onto the rotor shaft.

f. Fit the wavy washer (DE only).

3. Record bearing change on the Service Report.

8.2.3.5 Assemble Drive End

1. Slide the DE bracket onto the rotor shaft and locate over the DE bearing assembly.

2. Refit the DE bracket onto the frame.

3. Recouple the generator to the prime mover.

4. Refit the DE air outlet screen.

8.2.3.6 Assemble Non-Drive End

EBS, anti-condensation heaters and temperature sensors are generator options. Ignore

references to these items if they are not fitted.

1. Reconnect the thermistor for sensing main stator winding temperature

2. Slide the NDE bracket and terminal box assembly onto the rotor shaft and locate over

the NDE bearing.

3. Fix the NDE bracket to the frame.

4. Turn the rotor by hand to check bearing alignment and free rotation.

5. Refit the NDE cover.

6. Reconnect the main stator leads and output (load) leads.

7. Reconnect the heater.

8. Refit the EBS assembly and fix the EBS rotor to the rotor shaft.

9. Feed the EBS cable through the terminal box and reconnect to the AVR.

10. Refit the EBS end cover and air inlet cover.

11. Refit the terminal box lid.

12. Reconnect the supply to the anti-condensation heater.

34 A040J847 (Issue 4)

8.3 Controls

8.3.1 Introduction

An operating generator is a harsh environment for control components. Heat and vibration

can cause electrical connections to loosen and cables to fail. Routine inspection and test

can identify an issue before it becomes a failure that incurs unplanned downtime.

8.3.2 Safety

This method involves removing safety covers to expose potentially live electrical

conductors. Risk of serious injury or death by electrocution. To prevent injury,

isolate the generating set electrically and prevent accidental mechanical movement.

Disconnect the prime mover engine battery. Use lock and tag safety procedures and

prove that the generating set is isolated from all energy sources before starting

work.

-

DANGER

8.3.3 Requirements

Personal Protective Wear mandatory site PPE

Equipment (PPE)

Consumables

Parts

Tools Multimeter

8.3.4 Inspect and Test

1. Remove the terminal box lid

2. Check the tightness of fasteners securing the load cables.

3. Check that cables are firmly clamped at the terminal box gland, and allow ±25 mm

movement by a generator on anti-vibration mounts.

4. Check that all cables are anchored and unstressed within the terminal box.

5. Check all cables for signs of damage.

6. Check that AVR accessories and current transformers are correctly fitted, and cables

pass centrally through current transformers.

7. If an anti-condensation heater is fitted

Torque wrench

a. Isolate the supply and measure the electrical resistance of the heater element(s).

Replace the heater element if open circuit.

b. Test the supply voltage to the anti-condensation heater at the heater connection

box. 120 V or 240 V a.c. (depending on cartridge option and shown on a label)

should be present when the generator is stopped.

8. Check that AVR and AVR accessories fitted in the terminal box are clean, securely

fitted on anti-vibration mounts, and the cable connectors are firmly attached to the

terminals.

A040J847 (Issue 4) 35

-

9. For parallel operation, check that the synchronisation control cables are securely

connected.

10. Refit and secure the terminal box lid.

8.4 Cooling System

8.4.1 Introduction

Stamford generators are designed to meet standards supporting EU Safety Directives, and

are rated for the effect of operating temperature on winding insulation.

BS EN 60085 (≡ IEC 60085) Electrical insulation – Thermal Evaluation and Designation

classifies insulation by the maximum operating temperature for a reasonable service life.

Although chemical contamination and electrical and mechanical stresses also contribute,

temperature is the dominant aging factor. Fan cooling maintains a stable operating

temperature below the insulation class limit.

If the operating environment differs from the values shown on the rating plate, rated output

must be reduced by

• 3% for class H insulation for every 5°C that the temperature of the ambient air entering

the cooling fan exceeds 40 °C, up to a maximum of 60 °C

• 3% for every 500m increase in altitude above 1000m, up to 4000 m, due to the reduced

thermal capacity of lower density air, and

• 5% if air filters are fitted, due to restricted air flow.

Efficient cooling depends on maintaining the condition of the cooling fan, air filters and

gaskets.

8.4.2 Safety

Safety screens must be removed to inspect the cooling fan. To prevent injury,

isolate the generating set from all energy sources and remove stored energy. Use

lock and tag safety procedures before starting work.

External surfaces may be very hot. Exposed skin can suffer serious and permanent

burns, depending on the temperature and contact time. Avoid contact or wear

protective gloves.

Where fitted, air filters remove particles above 5 microns from the generator cooling

air inlet. High concentrations of these particles can be released when handling the

filters, causing breathing difficulties and eye irritation. Wear effective respiratory

and eye protection.

DANGER

WARNING

CAUTION

NOTICE

Do not attempt to rotate the generator rotor by levering against the vanes of the

cooling fan. The fan is not designed to withstand such forces and will be damaged.

36 A040J847 (Issue 4)

Filters are designed to remove dust, not moisture. Wet filter elements can cause

reduced air flow and overheating. Do not allow filter elements to get wet.

8.4.3 Requirements

Personal Protective Wear mandatory site PPE

Equipment (PPE)

Consumables Lint-free cleaning cloths

Parts Air filters (if fitted)

Tools

8.4.4 Inspect and Clean

-

NOTICE

Wear eye protection

Wear respiratory protection

Thin disposable gloves

Air filter sealing gaskets (if fitted)

1. Remove the fan screen.

2. Inspect the fan for damaged vanes and cracks.

3. Re-install the fan screen.

4. Reinstate the generating set for running.

5. Make sure the air inlets and outlets are not blocked.

8.5 Coupling

8.5.1 Introduction

Efficient operation and long component life rely on minimising mechanical stresses on the

generator. When coupled in a generating set, misalignment and vibration interactions with

the prime mover engine can cause mechanical stress.

The rotational axes of generator rotor and engine output shaft must be coaxial (radial and

angular alignment).

Torsional vibration can cause damage to internal combustion engine shaft-driven systems, if

not controlled. The generating set manufacturer is responsible for assessing the effect of

torsional vibration on the generator: Rotor dimensions and inertia, and coupling details are

available on request.

8.5.2 Safety

NOTICE

Do not attempt to rotate the generator rotor by levering against the vanes of the cooling fan.

The fan is not designed to withstand such forces and will be damaged.

A040J847 (Issue 4) 37

-

8.5.3 Requirements

Personal Protective Wear mandatory site PPE

Equipment (PPE)

Consumables

Parts

Tools Dial gauge

Torque wrench

8.5.4 Inspect Mounting Points

1. Check the generating set bedplate and mounting pads are in good condition, not

cracked

2. Check that rubber in anti-vibration mounts has not perished

3. Check vibration monitoring historical records for a trend of increasing vibration

8.5.4.1 Single Bearing Coupling

1. Remove the DE adapter screen and cover to access the coupling

2. Check that the coupling discs are not damaged, cracked or distorted, and the coupling

disc holes are not elongated. If any are damaged, replace the complete set of discs.

3. Check tightness of bolts fixing the coupling discs to the engine flywheel. Tighten in the

sequence shown for generator coupling in the Installation chapter, to the torque

recommended by the engine manufacturer.

4. Replace the DE adapter screen and drip proof cover.

8.6 Rectifier System

8.6.1 Introduction

The rectifier converts alternating current (a.c.) induced in the exciter rotor windings into

direct current (d.c.) to magnetise the main rotor poles. The rectifier comprises two

semicircular annular positive and negative plates, each with three diodes. In addition to

connecting to the main rotor, the dc output of the rectifier also connects to a varistor. The

varistor protects the rectifier from voltage spikes and surge voltages that may be present on

the rotor under various loading conditions of the generator.

38 A040J847 (Issue 4)

Diodes provide a low resistance to current in one direction only: Positive current will flow

from anode to cathode, or another way of viewing it is that negative current will flow from

cathode to anode.

The exciter rotor windings are connected to 3 diode anodes to form the positive plate and to

3 diode cathodes to form the negative plate to give full wave rectification from a.c. to d.c.

The rectifier is mounted on, and rotates with, the exciter rotor at the non-drive end (NDE).

8.6.2 Safety

This method involves removing safety covers to expose live electrical conductors. Risk of

serious injury or death by electrocution from contact with conductors.

This method involves removing safety screens to expose rotating parts. Risk of serious

injury from entrapment. To prevent injury, isolate the generating set electrically and prevent

mechanical movement.

Disconnect the prime mover engine battery.

Use lock and tag safety procedures and prove that the generating set is isolated from all

energy sources before starting work.

Do not tighten a diode above the stated torque. The diode will be damaged.

-

DANGER

NOTICE

8.6.3 Requirements

Personal Protective Wear appropriate PPE.

Equipment (PPE)

Consumables Loctite 241 thread locking adhesive

Midland silicone heat sink compound type MS2623 or similar

Parts Full set of three anode lead diodes and three cathode lead diodes

Tools Multimeter

(all from the same manufacturer)

One metal-oxide varistor

Insulation Tester

Torque wrench

8.6.4 Test and Replace Varistor

1. Inspect the varistor.

2. Record varistor as faulty if there are signs of overheating (discolouration, blisters,

melting) or disintegration.

3. Disconnect one varistor lead. Store fastener and washers.

4. Measure the resistance across the varistor. Good varistors have a resistance greater

than 100 MΩ.

5. Record the varistor as faulty if the resistance is short circuit or open circuit in either

direction.

6. If the varistor is faulty, replace it and replace all diodes.

7. Reconnect and check that all leads are secure, washers fitted and fasteners tight.

A040J847 (Issue 4) 39

-

8.6.5 Test and Replace Diodes

1. Disconnect the lead of one diode where it joins the windings at the insulated terminal

post. Store fastener and washers.

2. Measure the voltage drop across the diode in the forward direction, using the diode test

function of a multimeter.

3. Measure the resistance across the diode in the reverse direction, using the 1000 V d.c.

test voltage of an insulation tester.

4. Diode is faulty if the voltage drop in the forward direction is outside the range 0.3 to 0.9

V, or the resistance is below 20 MΩ in the reverse direction.

5. Repeat steps 4 to 7 for the five remaining diodes.

6. If any diode is faulty, replace the full set of six diodes (same type, same manufacturer):

a. Remove diode(s).

b. Apply a small amount of heat sink compound only to the base of the replacement

diode(s), not the threads.

c. Check polarity of diode(s).

d. Screw each replacement diode into a threaded hole in the rectifier plate.

e. Apply 4.06 to 4.74 N m (36 to 42 lb in) torque to give good mechanical, electrical

and thermal contact.

f. Replace the varistor

7. Reconnect and check that all leads are secure, washers fitted and fasteners tight.

8.7 Temperature Sensors

8.7.1 Introduction

Stamford generators are designed to meet standards supporting EU Safety Directives, and

recommended operating temperatures. Temperature sensors (where fitted) detect abnormal

overheating of the main stator windings and bearing(s). Sensors are of two types Resistance Temperature Detector (RTD) sensors, with three wires, and Positive

Temperature Coefficient (PTC) thermistors, with two wires – which are connected to a

terminal block in the auxiliary or main terminal box. The resistance of Platinum (PT100) RTD

sensors increases linearly with temperature.

40 A040J847 (Issue 4)

TABLE 2. RESISTANCE (Ω) OF PT100 SENSOR BETWEEN 40 TO 180 °C

-

Temperature

(°C)

40.00 115.54 115.93 116.31 116.70 117.08 117.47 117.86 118.24 118.63 119.01

50.00 119.40 119.78 120.17 120.55 120.94 121.32 121.71 122.09 122.47 122.86

60.00 123.24 123.63 124.01 124.39 124.78 125.16 125.54 125.93 126.31 126.69

70.00 127.08 127.46 127.84 128.22 128.61 128.99 129.37 129.75 130.13 130.52

80.00 130.90 131.28 131.66 132.04 132.42 132.80 133.18 133.57 133.95 134.33

90.00 134.71 135.09 135.47 135.85 136.23 136.61 136.99 137.37 137.75 138.13

100.00 138.51 138.88 139.26 139.64 140.02 140.40 140.78 141.16 141.54 141.91

110.00 142.29 142.67 143.05 143.43 143.80 144.18 144.56 144.94 145.31 145.69

120.00 146.07 146.44 146.82 147.20 147.57 147.95 148.33 148.70 149.08 149.46

130.00 149.83 150.21 150.58 150.96 151.33 151.71 152.08 152.46 152.83 153.21

140.00 153.58 153.96 154.33 154.71 155.08 155.46 155.83 156.20 156.58 156.95

150.00 157.33 157.70 158.07 158.45 158.82 159.19 159.56 159.94 160.31 160.68

160.00 161.05 161.43 161.80 162.17 162.54 162.91 163.29 163.66 164.03 164.40

170.00 164.77 165.14 165.51 165.89 166.26 166.63 167.00 167.37 167.74 168.11

180.00 168.48

+1 °C + 2 °C +3 °C + 4 °C + 5 °C + 6 °C + 7 °C + 8 °C + 9 °C

PTC thermistors are characterised by a sudden increase in resistance at a reference

“switching” temperature. Customer-supplied external equipment may be connected to

monitor the sensors and generate signals to raise an alarm and to shutdown the generating

set.

BS EN 60085 (≡ IEC 60085) Electrical insulation – Thermal Evaluation and Designation

classifies insulation of windings by the maximum operating temperature for a reasonable

service life. To avoid damage to windings, signals should be set, appropriate to the

insulation class shown on the generator rating plate.

TABLE 3. ALARM AND SHUTDOWN TEMPERATURE SETTINGS FOR WINDINGS

Windings insulation Max. Continuous Alarm temperature Shutdown

Class B 130 120 140

Class F 155 145 165

Class H 180 170 190

temperature (°C) (°C) temperature (°C)

Kluber Asonic GHY72 grease (an ester oil, with polyurea thickener) is recommended to

lubricate the non-drive end (NDE) bearing and drive end (DE) bearing (where fitted). To

detect overheating of bearings, control signals should be set according to the following table.

TABLE 4. ALARM AND SHUTDOWN TEMPERATURE SETTINGS FOR BEARINGS

Bearings Alarm temperature (°C) Shutdown temperature (°C)

Drive end bearing 45 + maximum ambient 50 + maximum ambient

Non-drive end bearing 40 + maximum ambient 45 + maximum ambient

A040J847 (Issue 4) 41

-

8.7.2 Safety

DANGER

The main terminal box cover must be removed to test temperature sensors. Risk of

serious injury or death by electrocution from contact with live electrical conductors.

To avoid injury; isolate the generating set from all energy sources and remove

stored energy. Use lock and tag safety procedures before starting work.

WARNING

External surfaces may be very hot. Exposed skin can suffer serious and permanent

burns, depending on the temperature and contact time. Avoid contact or wear

protective gloves.

8.7.3 Test PTC Temperature Sensors

1. Remove the auxiliary terminal box lid.

2. Identify the sensor leads at the terminal block and where each sensor is fitted.

3. Measure the resistance between the two wires.

4. Sensor is faulty if resistance shows open circuit (infinity Ω) or short circuit (zero Ω).

5. Repeat steps 3 to 5 for each sensor.

6. Stop the generator and inspect the change in resistance as the stator winding cools.

7. Sensor is faulty if resistance does not change or change is not smooth.

8. Repeat step 8 for each sensor.

9. Refit the auxilliary terminal box lid.

10. Contact Cummins Customer Service Help Desk to replace faulty sensors.

8.8 Windings

8.8.1 Introduction

Generator performance depends on good electrical insulation of the windings. Electrical,

mechanical and thermal stresses, and chemical and environmental contamination, cause the

insulation to degrade. Various diagnostic tests indicate the condition of insulation by

charging or discharging a test voltage on isolated windings, measuring current flow, and

calculating the electrical resistance by Ohm’s law.

When a DC test voltage is first applied, three currents can flow:

• Capacitive – to charge the winding to the test voltage (decays to zero in seconds),

• Polarising – to align the insulation molecules to the applied electric field (decays to

near-zero in ten minutes), and

• Leakage – discharge to earth where the insulation resistance is lowered by moisture

and contamination (increases to a constant in seconds).

42 A040J847 (Issue 4)

For an insulation resistance test, a single measurement is made one minute after a DC test

voltage is applied, when capacitive current has ended. For the polarization index test, a

second measurement is made after ten minutes. An acceptable result is where the second

insulation resistance measurement is a least double the first, because the polarization

current has decayed. In poor insulation, where leakage current dominates, the two values

are similar. A dedicated Insulation Tester takes accurate, reliable measurements and may

automate some tests.

8.8.2 Safety

Safety guards must be removed to test windings. To prevent injury, isolate the

generating set from all energy sources and remove stored energy. Use lock and tag

safety procedures before starting work.

The winding keeps an electrical charge after the insulation resistance test. Risk of

electric shock if the winding leads are touched. After each test, ground the winding

to earth with an earth rod for five minutes to remove the charge.

-

DANGER

WARNING

The Automatic Voltage Regulator (AVR) contains electronic components which

would be damaged by high voltage applied during insulation resistance tests. The

AVR must be disconnected before doing any insulation resistance test. Temperature

sensors must be grounded to earth before doing any insulation resistance test.

Damp or dirty windings have a lower electrical resistance and could be damaged by

insulation resistance tests at high voltage. If in doubt, test the resistance at low

voltage (500 V) first

8.8.3 Requirements

Personal Protective Wear mandatory site PPE

Equipment (PPE)

Consumables

Parts

Tools Insulation Test Meter

NOTICE

Multimeter

Milliohm Meter or Micro Ohmmeter

Clamp Ammeter

Infrared thermometer

A040J847 (Issue 4) 43

-

8.8.4 Test Windings Method

TABLE 5. TEST VOLTAGE AND MINIMUM ACCEPTABLE INSULATION RESISTANCE

FOR NEW AND IN-SERVICE GENERATORS

Test

Voltage

(V)

Main stator 500 10 5

EBS stator 500 5 3

Exciter stator 500 10 5

Exciter rotor, rectifier & main rotor 500 10 5

combined

Minimum Insulation Resistance at 1

minute (MΩ)

New In-service

1. Inspect the windings for mechanical damage or discolouration from overheating. Clean

the insulation if there is hygroscopic dust and dirt contamination.

2. For main stators:

a. Disconnect the neutral to earth conductor (if fitted).

b. Connect together the three leads of all phase windings (if possible).

c. Apply the test voltage from the table between any phase lead and earth.

d. Measure the insulation resistance after 1 minute (IR

1min

).

e. Discharge the test voltage with an earth rod for five minutes.

f. If the measured insulation resistance is less than the minimum acceptable value,

dry the insulation, then repeat the method.

g. Reconnect neutral to earth conductor (if fitted).

3. For EBS and exciter stators, and combined exciter and main rotors:

a. Connect together both ends of the winding (if possible).

b. Apply the test voltage from the table between the winding and earth.

c. Measure the insulation resistance after 1 minute (IR

d. Discharge the test voltage with an earth rod for five minutes.

e. If the measured insulation resistance is less than the minimum acceptable value,

dry the insulation, then repeat the method.

f. Repeat the method for each winding.

g. Remove the connections made for testing.

8.8.5 Dry the Insulation

Use the methods below to dry the insulation of the main stator windings. To prevent damage

as water vapour is expelled from the insulation, make sure the winding temperature does not

increase faster than 5 ºC per hour or exceed 90 ºC.

Plot the insulation resistance graph to show when drying is complete.

1min

).

44 A040J847 (Issue 4)

8.8.5.1 Dry with Ambient Air

In many cases, the generator can be dried sufficiently using its own cooling system.

Disconnect the cables from the X+ (F1) and XX- (F2) terminals of the AVR so there is no

excitation voltage supply to the exciter stator. Run the generating set in this de-excited state.

Air must flow freely through the generator to remove the moisture. Operate the anticondensation heater (if fitted) to assist the drying effect of the air flow.

After drying is complete, re-connect the cables between the exciter stator and AVR. If the

generating set is not put into service immediately, turn on the anti-condensation heater (if

fitted) and retest the insulation resistance before use.

8.8.5.2 Dry with Hot Air

Direct the hot air from one or two 1 to 3 kW electrical fan heaters into the generator air inlet.

Make sure each heat source at least 300mm away from the windings to avoid scorching or

over-heating damage to the insulation. Air must flow freely through the generator to remove

the moisture.

After drying, remove the fan heaters and re-commission as appropriate.

If the generating set is not put into service immediately, turn on the anti-condensation

heaters (where fitted) and retest the insulation resistance before use.

-

8.8.5.3 Plot IR Graph

Whichever method is used to dry out the generator, measure the insulation resistance and

temperature (if sensors fitted) of the main stator windings every 15 to 30 minutes. Plot a

graph of insulation resistance, IR (y axis) against time, t (x axis).

A typical curve shows an initial increase in resistance, a fall and then a gradual rise to a

steady state; if the windings are only slightly damp the dotted portion of the curve may not

appear. Continue drying for another hour after steady state is reached.

NOTICE

The generator must not be put into service until the minimum insulation resistance

is achieved.

A040J847 (Issue 4) 45

-

8.8.6 Clean the Insulation

Remove the main rotor to gain access to the main stator windings to remove dirt

contamination. Use clean warm water without detergents. Methods to remove and assemble

the drive end (DE) and non-drive end (NDE) support are given in the Replace Bearing

section of Service and Maintenance chapter.

8.8.6.1 Remove Main Rotor

The rotor is heavy, with a small clearance to the stator. Windings will be damaged if

the rotor drops or swings in the crane sling and hits the stator or frame. To avoid

damage, fit support packing and carefully guide the rotor ends throughout. Do not

allow the sling to touch the fan.

To remove the main rotor safely and easily, use the following special tools: a rotor

extension stub shaft, a rotor extension tube (of similar length to the rotor shaft) and

a height-adjustable V roller extension tube support. Refer to the factory for the

availability and specification of these tools.

NOTICE

NOTICE

1. Remove non-drive end bracket, see Remove Non-Drive End section.

2. For a two bearing generator, remove drive end bracket, see Remove Drive End

section.

3. For a one bearing generator, remove drive end adapter as follows:

a. Disconnect the generator from the prime mover.

b. Remove the DE adapter.

4. Fix the rotor shaft extension stub shaft to the main rotor at the non-drive end.

5. Fix the extension tube to the stub shaft.

6. Position the V roller support underneath the shaft extension tube, close to the generator

frame.

7. Raise the V roller support to lift the extension tube a small amount, to support the

weight of the main rotor at the non-drive end.

8. Use a crane sling to lift the rotor at the drive end a small amount, to support its weight.

9. Carefully move the crane sling away so that the rotor withdraws from the generator

frame, as the extension tube rolls on the V rollers, until the rotor windings are fully

visible.

10. Support the rotor on wooden blocks to prevent it rolling and damaging the windings.

11. Tightly bind the crane sling near the middle of the main rotor windings, near the rotor

centre of gravity.

12. Use a crane sling to lift the rotor a small amount, to test the rotor weight is balanced.

Adjust the crane sling as necessary.

13. Carefully move the crane sling away so that the rotor withdraws completely from the

generator frame.

14. Lower the rotor onto wooden block supports and prevent it rolling and damaging the

windings.