Stamford BC, BC164A, BC164B, BC164C, BC164D Installation, Service & Maintenance Manual

...

Installation, Service & Maintenance Manual for

STAMFORD BC

Range of Generators

SAFETY PRECAUTIONS

First Steps to Safe Operation

Read this manual, obey all Warnings and Cautions, and become familiar with the product.

Warnings & Notices used in this manual

The various warnings are out lined below and appear in the text in this format. Warnings and Cautions

appear at the appropriate position in the, to which they refer.

Warning: Information that draws attention to the risk of injury or death.

Caution: Information that draws attention to the risk of damage to the product, process or

surroundings.

Note: Used to convey, or draw attention to, additional information or explanations.

Notes appear after the text to which they refer.

Skill requirements of personnel

Service and maintenance procedures should only be carried out by experienced and qualified engineers,

who are familiar with the procedures and the equipment. Before any intrusive procedures are carried out,

ensure that the engine is inhibited and the generator is electrically isolated.

Electrical Equipment

All electrical equipment can be dangerous if not operated correctly. Always service and maintain the

generator in accordance with this manual. Always use genuine ‘STAMFORD’ replacement parts.

Warning: Electrical shock can cause injury or death. Ensure that all personnel operating,

servicing, maintaining or working near this equipment are fully aware of

the emergency procedures in case of accidents.

Before removing the protective covers to carry out service maintenance or repair, ensure that the engine

is inhibited and the generator is electrically isolated. The AVR access covers are designed to be removed

while the generator is on load.

Lifting

Lift the generator using the points provided with the aid of a spreader and chains. The angle on the

chains must be vertical during the lift. Do not lift single bearing generators without the, securely fitted,

transit bar. When removing the transit bar just prior to offering the generator up to the engine, be aware

that the rotor is not securely held in the generator. Keep the generator in the horizontal plane to when the

transit bar is not fitted.

Warning: The lifting points provided are designed for lifting the generator only. Do not lift

the Generating Set by the generator’s lifting points.

Note: Due to our policy of continuous improvement, details in this manual which were correct at time of

going to print and may now be due for amendment. Information included must therefore not be regarded

as binding.

Copyright 2010

2

TD_BC MAN GB_10.06_03_GB

Foreword

The Manual

Before operating, the generating set read this manual and all additional documentation supplied with it.

Great care has been taken with the design of this product to ensure that it is safe to operate. Misuse and

the failure to follow the safety precautions contained in the manual are potential causes of accidents.

Read the manual and make sure that all personnel who work on the equipment have access to the

manual. The manual should be considered as part of the product and should remain with the product.

Make sure that the manual is available to all users throughout the life of the product.

Scope

This manual contains guidance and instructions for the Installation, Servicing and Maintenance of the

generator.

It is not possible, within the scope of the manual, to teach the basic electrical and mechanical skills

required to safely carry out the procedures enclosed. The manual is written for skilled electrical and

mechanical technicians and engineers, who have prior knowledge and experience of generating

equipment of this type.

We offer a range of training courses that cover all aspects of STAMFORD generators.

Generator Designation

B C 1 8 4 D 1 (example)

BC - Generator type

I -

Applications,

I = Industrial, M = Marine.

1 - Frame size

8 18 = centre height in cm.

4 - Number of poles, 2 or 4

C - Core Size

1 - Number of bearings, 1 or 2

The Product

The product is an AVR controlled, self excited synchronous ‘ac

generator’. Designed for incorporation into a generating-set. (A

generating-set is defined as ‘machinery’ in European directives).

Serial Number Location

Each generator has a unique serial number stamped into the upper

section of the drive end of the frame.

The serial number is also shown on the nameplate.

Two other labels are located inside the terminal box, both fixed inside

of the terminal box, one on the sheet metal work and the other on the

main frame of the generator. Neither of these two labels is

considered to be permanently fixed.

Rating Plate

The generator has been supplied with a self-adhesive rating plate label to enable fitting after final

assembly and painting. Stick the nameplate to the outside of the non-drive end of the terminal box. The

surface in the area where a label is to be stuck must be flat, clean, and any paint finish must be fully dry

before attempting to attach label. Recommended method for attaching label is peel and fold back

sufficient of the backing paper to expose some 20 mm of label adhesive along the edge which is to be

located against the sheet metal protrusions. Once this first section of label has been carefully located and

stuck into position progressively peel off the backing paper and smooth down with a clean cloth. The

adhesive will achieve a permanent bond in 24 hours.

A factory fitted metal nameplate is available for some applications.

Caution. Do not exceed the parameters marked on the rating plate.

TD_BC MAN GB_10.06_03_GB

3

Copyright 2010

Contents

SAFETY PRECAUTIONS ............................................................................................................................ 2

F

IRST STEPS TO SAFE OPERATION

W

ARNINGS & NOTICES USED IN THIS MANUAL

S

KILL REQUIREMENTS OF PERSONNEL

E

LECTRICAL EQUIPMENT

L

IFTING

.................................................................................................................................................... 2

FOREWORD ................................................................................................................................................ 3

T

HE MANUAL

S

COPE

G

ENERATOR DESIGNATION

T

HE PRODUCT

S

ERIAL NUMBER LOCATION

R

ATING PLATE

CONTENTS .................................................................................................................................................. 4

INTRODUCTION .......................................................................................................................................... 6

G

ENERAL DESCRIPTION

S

ELF-EXCITED

M

AIN STATOR POWERED AVR

F

OR PARALLEL OPERATION

A

UXILIARY WINDING

T

RANSFORMER CONTROLLED GENERATORS

S

TANDARDS

E

UROPEAN DIRECTIVES

APPLICATION OF THE GENERATOR ....................................................................................................... 9

E

NVIRONMENTAL PROTECTION

A

IRBORNE CONTAMINATES

H

IGH HUMIDITY ENVIRONMENTS

V

IBRATION

B

EARINGS

INSTALLATION INTO THE GENERATING SET ...................................................................................... 12

D

ELIVERY

H

ANDLING THE GENERATOR

S

TORAGE

A

FTER STORAGE

R

OTOR BALANCING

G

ENERATOR VIBRATION, FREQUENCY

S

IDE LOADS

C

OUPLING ARRANGEMENTS

BCA, S

E

ARTH ARRANGEMENT

P

AINT FINISH

W

ARNING LABELS

PRE-R

D

IRECTION OF ROTATION

P

HASE ROTATION

V

OLTAGE AND FREQUENCY

AVR

ADJUSTMENT

A

CCESSORIES

AUTOMATIC VOLTAGE REGULATORS ................................................................................................. 19

INITIAL START-UP .....................................................................................E

A

CCESSORIES

INSTALLATION ON SITE .......................................................................................................................... 25

............................................................................................................................................ 3

..................................................................................................................................................... 3

.......................................................................................................................................... 3

.......................................................................................................................................... 3

AVRC

. ............................................................................................................................................ 6

.............................................................................................................................................. 10

.............................................................................................................................................. 10

............................................................................................................................................... 12

............................................................................................................................................... 12

............................................................................................................................................ 13

INGLE BEARING COUPLING ALIGNMENT

.......................................................................................................................................... 17

UNNING CHECKS

........................................................................................................................................ 18

............................................................................................................................................... 22

........................................................................................................................... 2

........................................................................................................................ 3

............................................................................................................................ 6

ONTROLLED GENERATORS

.................................................................................................................................. 6

. ........................................................................................................................... 7

........................................................................................................................ 9

.................................................................................................................................... 12

................................................................................................................................. 12

............................................................................................................................ 17

................................................................................................................................... 17

........................................................................................................................... 17

........................................................................................................................ 17

................................................................................................................................... 17

.................................................................................................................................. 18

............................................................................................................ 2

............................................................................................. 2

........................................................................................................ 2

....................................................................................................................... 3

........................................................................................ 6

................................................................................................................... 6

....................................................................................................................... 6

.............................................................................................. 6

.................................................................................................................. 9

................................................................................................................. 9

..................................................................................................................... 12

...................................................................................................... 12

..................................................................................................................... 13

........................................................................................ 14

..................................................................................................................... 18

RROR! BOOKMARK NOT DEFINED

.

Copyright 2010

4

TD_BC MAN GB_10.06_03_GB

SERVICE AND MAINTENANCE ............................................................................................................... 27

S

ERVICE

W

P

ROCEDURE FOR INSULATION TESTING

M

T

YPICAL DRYING OUT CURVE

A

IR FILTERS

M

R

EMOVAL AND REPLACEMENT OF COMPONENT ASSEMBLIES

................................................................................................ E

INDING CONDITION

.............................................................................................................................. 27

................................................................................................... 28

ETHODS OF DRYING OUT GENERATORS

................................................................................................ 28

.................................................................................................................. 29

........................................................................................................................................... 30

AINTENANCE

........................................................................................................................................ 31

RROR! BOOKMARK NOT DEFINED

................................................................... 37

SPARES AND AFTER SALES SERVICE ................................................................................................. 41

.

TD_BC MAN GB_10.06_03_GB

5

Copyright 2010

INTRODUCTION

General Description

The BC16/18 range of generators is of brushless rotating field design, available up to 660V/50Hz (1500

rpm, 4 pole and 3000 rpm, 2 pole) or 60Hz (1800 rpm, 4 pole and 3600 rpm, 2 pole), and built to meet

B.S. 5000 Part 3 and international standards.

The BC16/18 range are self-excited with excitation power derived from the main output windings, using

either the AS440 AVR or transformer controlled excitation system.

Self-Excited AVR Controlled Generators

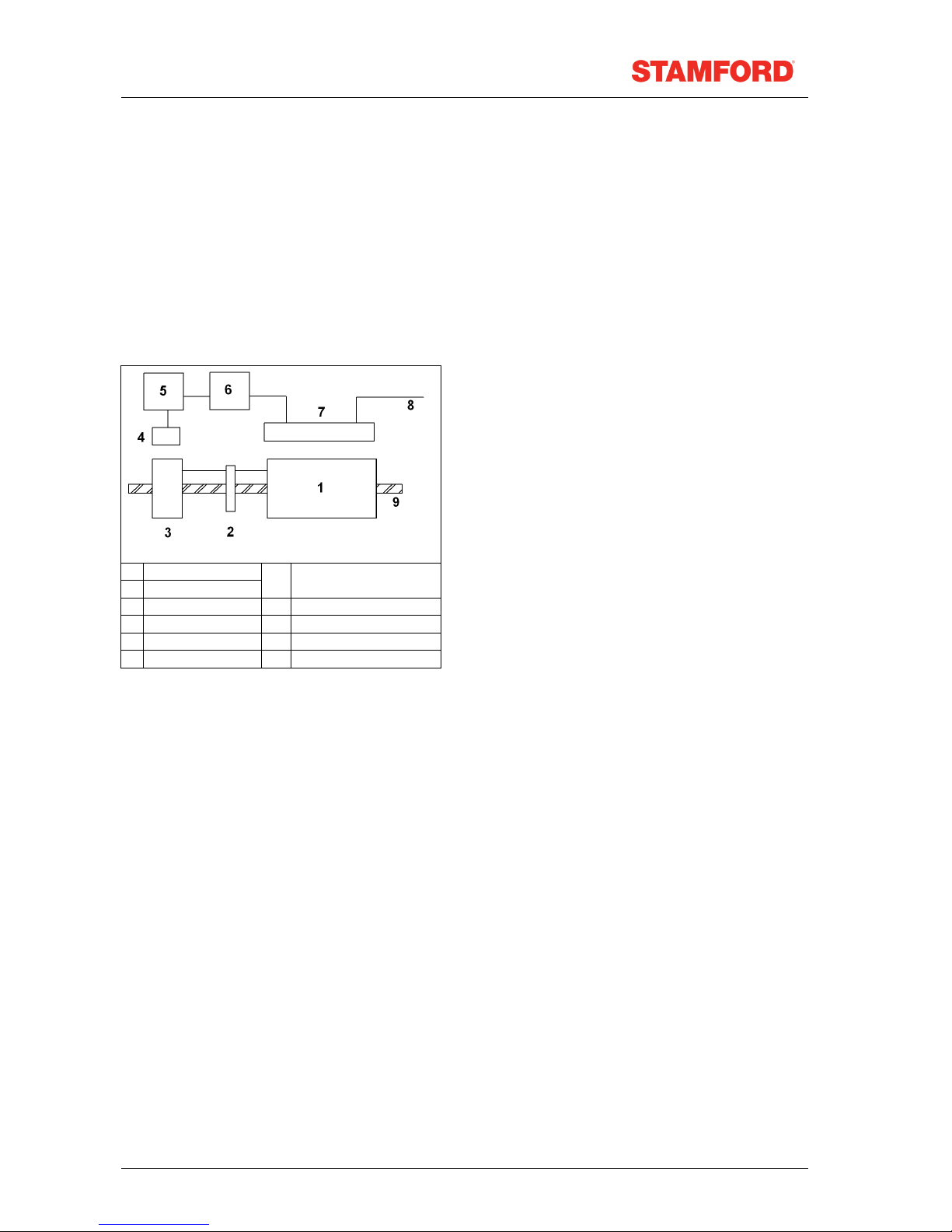

Main Stator Powered AVR

The main stator provides power for excitation of the

exciter field via the SX460 AVR which is the

controlling device governing the level of excitation

provided to the exciter field. The AVR responds to a

voltage-sensing signal derived from the main stator

winding. By controlling the low power of the exciter

field, control of the high power requirement of the

main field is achieved through the rectified output of

1 Main rotor

2 Rotating diodes

6 Isolating transformer

(if fitted)

3 Exciter rotor 7 Main stator

4 Exciter stator 8 Output

5 AVR 9 Shaft

the exciter armature. The AVR senses average

voltage on two phases ensuring close regulation. In

addition it detects engine speed and provides voltage

fall off with speed, below a pre-selected speed (Hz)

setting, preventing over-excitation at low engine

speeds and softening the effect of load switching to

relieve the burden on the engine. The detailed

function of the AVR circuits and their adjustment are

covered in the load testing section.

For Parallel operation

The AS440 AVR also incorporates circuits which, when used in conjunction with accessories, can provide

for parallel operation with 'droop' control.

Function and adjustment of the accessories, which can be fitted.

Inside the generator terminal box are covered in the accessories section of this book. Separate

instructions are provided with other accessories available for control panel mounting.

Auxiliary Winding

An auxiliary winding can also provide the power for excitation of the exciter field via the AS440 AVR to

provide short circuit maintenance when required.

Transformer Controlled Generators

The main stator provides power for excitation of the exciter field via a transformer rectifier unit. The

transformer combines voltage and current elements derived from the main stator output to form the basis

of an open-loop control system, which is self regulating in nature. The system inherently compensates for

load current magnitude and power factor and provides short circuit maintenance in addition to a good

motor starting performance. Three-phase generators normally have a three-phase transformer control for

improved performance with unbalanced loads but a single-phase transformer option is available. No

accessories can be provided with this control system.

Standards.

STAMFORD ac generators meet the relevant parts of national and international standards pertaining to

generators. The generator must be operated within the limits laid down in the relevant standards and

within the parameters on the generator rating plate.

Copyright 2010

6

TD_BC MAN GB_10.06_03_GB

Set. To reflect this each generator is

Marine generators meet the requirements of all the major marine classification societies.

European Directives.

AC generators sold for use in the European

Union must meet the relevant European

directives. An ac generator has no intrinsic

function; it must be have a mechanic input in

order to provide an electrical output. The

generator is supplied as a component part of a

Generatingsupplied with an ‘EC Declaration of

Incorporation’ in accordance the Machinery

Directive.

The ac generator meets the relevant directives

applicable to an ac generator (component part)

before it is incorporated into ‘machinery’.

The directives identified as pertaining to ac generators are:

The Machinery (Safety) Directive, 98/37/EEC.

The Low Voltage Directive, 73/23/EEC.

The EMC Directive, 89/336/EEC

The generator is CE marked; CE labels are supplied loose in case the generating set manufacturer needs

to paint the generating set before delivery to the end user.

Note: Once the generator is build into a generating-set (machinery), it is the responsibility

of the generating-set manufacture to ensure that the generating-set

complies with the relevant EC Directives.

It is contrary to the EC Directives to misrepresent compliance of the EC directives by displaying the CE

mark supplied with a component part of the product. The directive requires compliance to be assessed as

a component part, as the complete product and during installation on site.

Applications for use within the EU

STAMFORD ac generators are supplied on the basis that:

They are used for power generation or related functions.

They are to be applied in one of the following environments:

Portable (open construction – temporary site supply)

Portable (enclosed – temporary site supply)

Containerised (temporary or permanent site supply)

Ship – borne, below decks (marine auxiliary power)

Commercial vehicle (road transport / refrigeration etc.)

Road transport (auxiliary power)

Industrial vehicle (earthmoving, cranes etc.)

Fixed installation (Industrial – factory / process plant)

Fixed installation (residential, commercial and light industrial – home / office / health.)

Energy management (combined heat & power and/or peak lopping.)

Alternative energy schemes.

The standard generators are designed to meet the ‘industrial’ emissions and immunity standards. Where

the generator is required to meet the residential, commercial and light industrial emissions and

immunity standards reference must be made to document reference N4/X/011. This publication

outlines the additional equipment that may be required.

The installation ‘earth/ground’ arrangements require the connection of the generator frame to the site

protective earth conductor using a minimum lead length.

Maintenance and servicing with unauthorised parts, not of STAMFORD brand, will invalidate us from any

liability for EMC compliance.

Installation, maintenance and servicing are carried out by adequately trained personnel fully aware of the

requirements of the relevant EC directives.

TD_BC MAN GB_10.06_03_GB

7

Copyright 2010

Unsuitable Applications

Synchronous generators require a constant speed for power generation. Applications where the

generator is not run at a constant speed are not suitable for the standard generator. Such applications

may be possible within certain parameters. Contact the factory for advice, there is every possibility that

we can provide you with a satisfactory technical solution to meet your requirement.

Additional information for EMC compliance

Standard generators are designed to meet the ‘industrial’ emissions and immunity standards. Where the

generator is required to meet the residential, commercial and light industrial emissions and immunity

standards, reference must be made to document reference N4/X/011. This publication outlines the

additional equipment that may be required.

Copyright 2010

8

TD_BC MAN GB_10.06_03_GB

Application of the generator

Environmental Protection

STAMFORD generators are protected to IP23. IP23 is not adequate protection for use outdoors without

additional measures.

Ambient Temperature <40oC

Humidity <60%

Altitude <1000m

Air Flow

The airflow requirements for the generator can be found in the Data section at the back of this manual.

Ensure that the air inlets and outlets are not obstructed when the generator is running.

Airborne Contaminates

Contaminates such as salt, oil, exhaust fumes, chemicals, dust, sand, etc., will reduce the effectiveness

of the insulation and lead to premature failure of the windings. Consider using air filters or an enclosure to

protect the generator.

This table represents the normal operating conditions that the

generator is designed for. Operation outside of these parameters is

possible after due consideration and will be reflected on the

generator nameplate. If the operating environment for the generator

has changed after purchase, the rating of the generator needs to be

revised, refer to the factory for details.

Air Filters

Air filters are available on request. Filters present a restriction to the airflow so the rating of the generator

must be reduced by 5%. If the filters are supplied, factory fitted, the rating on the nameplate will include

the reduced rating. The filters can be up-fitted after delivery in which case the customer must apply the

power reduction.

Air filters remove airborne particulates above 3 microns. The frequency of changing and cleaning the

filters depend on the site conditions. We recommend that the filters are monitored frequently until a

suitable cycle of change is established.

Air filters do not remove water. Additional protection must be employed to prevent the filters from getting

wet. If the filters are allowed to get wet the airflow will be restricted and the generator will overheat. This

will reduce the life expectancy of the insulation leading to premature failure of the generator.

High Humidity environments

The humidity of the air will allow condensation to form on the windings if the temperature of the windings

falls below the dew point. The dew point is a relationship between the ambient temperature and humidity.

In areas of high humidity additional protection may be required even if the generator is fitted inside an

enclosure.

Anti-condensation heaters

Anti-condensation heaters are designed to raise the temperature of the windings above the temperature

of the surrounding material so that the condensation will not form on the windings.

We recommend that anti-condensation heaters are fitted to all generators that are left switched off for any

period of time. The best practice is to wire the heaters such that the heaters come on when the generator

is switched off. This is particularly important in applications where high humidity is a significant problem.

Always check the condition of the generators windings before switching the generator on. If moisture is

observed carry out one or more of the drying-out methods outlined in the Service section of this manual.

Enclosures

An enclosure should be employed to protect the generator from adverse environmental conditions.

If the generator is to be fitted inside an enclosure, ensure that there is adequate airflow to support both

the engine and the generator. Ensure that the generator air supply is clean (free from moisture and

contaminates) and at or below the ambient temperature stated on the rating plate.

TD_BC MAN GB_10.06_03_GB

9

Copyright 2010

Vibration

STAMFORD generators are designed to withstand the vibration levels encountered on generating sets

built to meet the requirements of ISO 8528-9 and BS 5000-3. (Where ISO 8528 is taken to be broad band

measurements and BS5000 refers to the predominant frequency of any vibrations on the generating set).

Definition of BS5000 – 3

Generators shall be capable of continuously withstanding linear vibration levels with amplitudes of

0.25mm between 5Hz and 8Hz and velocities of 9.0mm/s rms between 8 Hz and 200 Hz, when measured

at any point directly on the carcass or mainframe of the machine. These limits refer only to the

predominant frequency of vibration of any complex waveform.

Definition of ISO 8528 - 9

ISO 8528-9 refers to a broad band of frequencies; the broad band is taken to be between 2 Hertz and 300

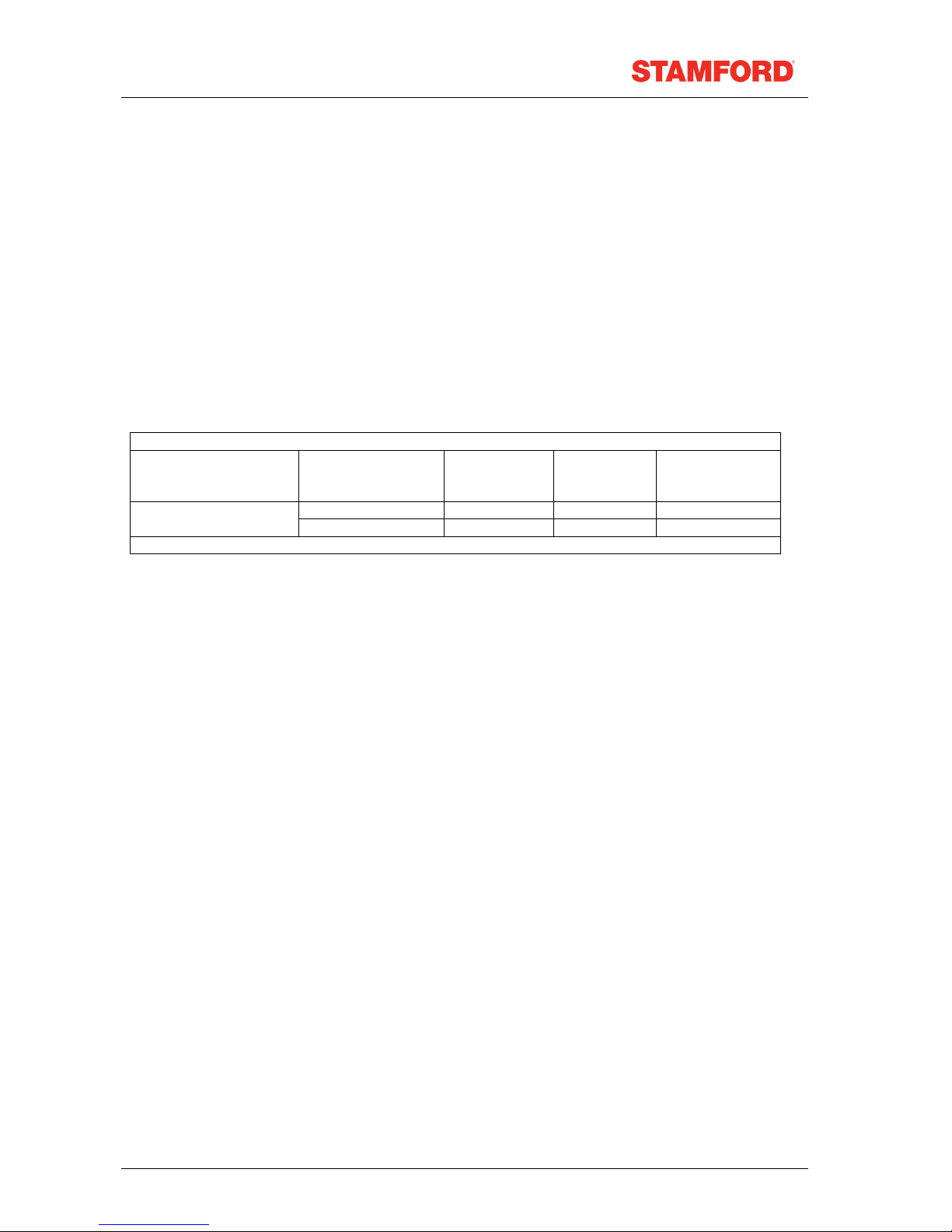

Hertz. The table below is an example from ISO 8528 - 9 (value 1). This simplified table lists the vibration

limits by kVA and speed for acceptable genset operation.

Vibration Levels As Measured On The Generator

Engine Speed Min -

The ‘Broad band’ is taken as 2 Hz - 300 Hz

Caution: Exceeding either of the above specifications will have a detrimental effect on the

1

Set Output Kva Vibration

Displacement

(S rms)

Vibration

Velocity

(V rms)

Vibration

Acceleration

(a rms)

<,50 kVA 0.64 mm 40 mm/sec 25 m/sec2 1500 – 1800 (rpm)

> 50 but < 125 0.4 mm 25 mm/sec 16 m/sec2

life of the bearings and other components. This will invalidate the

generator warranty.

Vibration Monitoring

We recommend that the set builder checks the vibration levels using vibration analysing equipment.

Ensure that the vibration levels of the generating set are within the levels stated in BS 5000-3 and ISO

8528-9. If the vibration levels are not within tolerance the genset builder should investigate the root cause

of the vibrations and eliminate them. The ‘best practice’ is for the genset builder to take initial readings as

a base line and the user to periodically monitor the genset and bearings to detect any deteriorating trend.

It will then be possible to plan ahead for bearing changes and eliminate vibration problems before

excessive damage to the generating set occurs.

Vibration checks should be made every 3 months.

Excessive Vibration levels

If the vibration levels of the generating set are not within the parameters quoted above:

Consult the genset builder; the genset builder should address the genset design to reduce the vibration

levels as much as possible.

Discuss, with us, the impact of not meeting the above levels on both bearing and generator life

expectancy.

When requested, or it is deemed necessary, we will work with the genset builder in an attempt to find a

satisfactory solution.

Bearings

Sealed for life or re-greasable bearings are fitted to the P range of generators. The bearings are fitted

within machined housings, these housings form an assembly located and bolted, within the end brackets.

All of the have bearings have pressed steel cages and are type C3. The grease used is a high

specification synthetic compound that must not be mixed with grease with a different specification.

Re-greasable Bearings

When re-greasable bearings are fitted the bearing housings incorporate fittings for pipe work to an

external grease nipple. Generators with re-greasable bearings are supplied with information labels

advising the user of grease type, re-lubrication frequency, and the quality of grease to be used. These

Copyright 2010

10

TD_BC MAN GB_10.06_03_GB

instructions must be followed. The information is repeated in the Data section of this manual. The bearing

housing has a grease escapement slot at the bottom of the outer area. At the drive end the grease,

expelled from the escapement slot, will discharge into the coupling area. At the non-drive end the grease,

from escapement slot, is deflected by a metal plate to ensure that it cannot foul the Permanent Magnet

Generator (PMG). The sheet metal cover over the PMG has a slot at the bottom to enable the excess

grease to escape.

Bearing Life

Factors that effect bearing life:

The life of a bearing in service is subject to the working conditions and the environment:

High levels of vibration from the engine or misalignment of the set will stress the bearing and reduce its

service life. If the vibration limits set out in BS 5000-3 and ISO 8528-9 are exceeded bearing life will

be reduced. Refer to ‘Vibration’ below.

Long stationary periods in an environment where the generator is subject to vibration can cause false

brinnelling, which puts flats on the balls and grooves on the races, leading to premature failure.

Very humid atmospheric or wet conditions can emulsify the grease causing corrosion and deterioration of

the grease, leading to premature failure of the bearings.

Health Monitoring of the Bearings

We recommend that the user check the bearing condition, using monitoring equipment, to determine the

state of the bearings. The ‘best practice’ is to take initial readings as a base line and periodically monitor

the bearings to detect a deteriorating trend. It will then be possible to plan a bearing change at an

appropriate generating set or engine service interval.

Bearing 'Service Life' Expectancy

Bearing manufacturers recognise that the “service life” of their bearings is dependent upon many factors

that are not in their control; they cannot therefore quote a “service life”.

Although “service life” cannot be guaranteed, it can be maximised by attention to the generating set

design. An understanding of the generating set’s application will also help the user to maximise the

service life expectancy of the bearings. Particular attention should be paid to the alignment, reduction of

vibration levels, environmental protection, maintenance and monitoring procedures.

We do not quote life expectancy figures for bearings, but suggests practicable replacement intervals

based on the L10 life of the bearing, the type of grease and the recommendations of the bearing and

grease manufacturers.

For general-purpose applications: providing the correct maintenance is carried out, vibration levels do not

exceed the levels stated in ISO 8528-9 and BS5000-3, and the ambient temperature does not exceed

50°C. Plan to replace bearings within 30,000 hours of operation.

It is important to note that bearings in service, under good operating conditions, can continue to run

beyond the recommended replacement period. It should also be remembered that the risk of bearing

failure increases with time.

If in doubt about any aspect of the ‘bearing life’ on STAMFORD generators, contact your nearest supplier

of STAMFORD generators or contact the Stamford factory direct.

TD_BC MAN GB_10.06_03_GB

11

Copyright 2010

Installation into the Generating Set

The generator is supplied as a component part for installation into a ‘generating set’.

Delivery

Upon receipt of the generator, check the generator for damage that may have occurred during transport.

Also check that the rating-plate details are correct and as ordered for the application.

Handling the generator

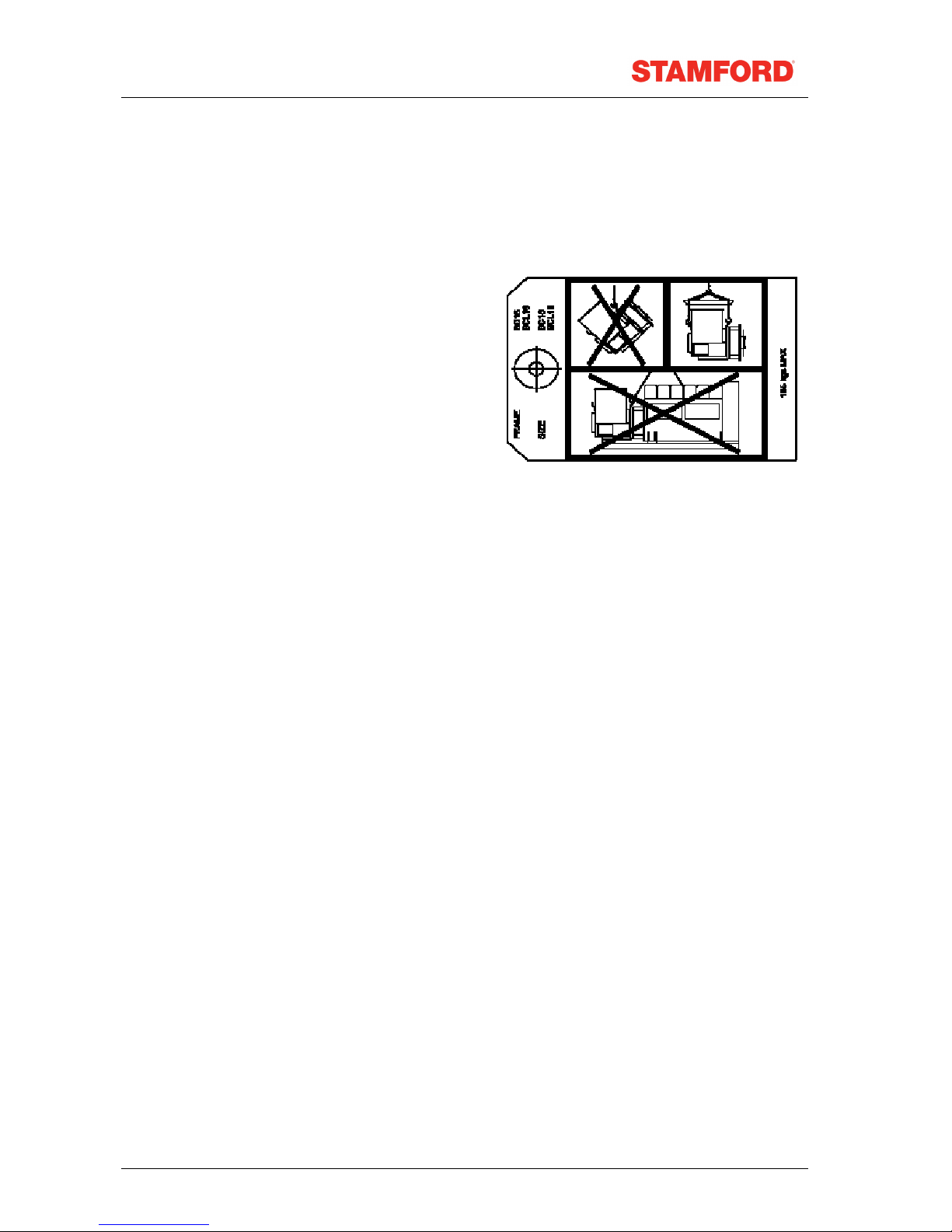

When lifting the generator use a spreader bar to ensure

that the angle on the lifting chains are vertical to the

lifting position on the generator.

Warning: The generator lifting points are

designed to lift the generator

only. Do not lift the complete

generating set by the generator

lifting points.

Single bearing generators have a transit bar fitted at the drive end. This bar holds the rotor in position

during transit. The transit bar should be left in position until it is necessary to remove it to allow the

generator to be coupled to the engine.

Warning: If the generator is moved without the transit bar be aware that the rotor

could fall out of the frame. When moving the generator always keep it in

the horizontal plane, this will reduce the risk of the rotor falling out.

Storage

If the generator is not to be used immediately, it must be stored in a clean, dry, vibration free

environment. If anti-condensation heaters are fitted, switch them on. If heaters are not fitted use other

means to ensure that condensation cannot form on the windings.

Spin the shaft by hand every month to prevent flat spots in the bearings and to free up the grease.

After Storage

After a period of storage, carry out ‘pre running checks’ to determine the condition of the windings. If the

winding are damp or the insulation is low, follow one of the ‘drying out procedures’, in the Service section

of this manual. Replace the bearing after 12 months in storage. (See the Maintenance section)

Rotor balancing

Dynamic balancing of the generator rotor assembly has been carried out during manufacture in

accordance with BS 6861 Part 1 Grade 2.5 to ensure vibration limits of the generator are in accordance

with BS 4999 Part 142.

Generator Vibration, Frequency

The main vibration frequencies produced by the component generator are as follows:

4-pole 1500 r.p.m. 25 Hz

4-pole 1800 r.p.m. 30 Hz

2-pole 3000 r.p.m. 50 Hz

2-pole 3600 r.p.m. 60 Hz

However, vibrations induced by the engine are complex and contain frequencies of 1.5, 3, 5 or more

times the fundamental frequency of vibration. These induced vibrations can result in generator vibration

levels higher than those derived from the generator itself. It is the responsibility of the generating set

Copyright 2010

12

TD_BC MAN GB_10.06_03_GB

designer to ensure that the alignment and stiffness of the bedplate and mountings are such that the

vibration limits of BS5000 part 3 and ISO 8528 part 9 are not exceeded.

In standby applications where the running time is limited and reduced life expectancy is accepted, higher

levels than specified in BS5000 part 3 can be tolerated, up to a maximum of 18mm/sec.

Side Loads

In the case of belt driven generators, ensure alignment of drive end and driven pulleys to avoid axial load

on the bearings. Screw type tensioning devices are recommended to allow accurate adjustment of belt

tension whilst maintaining pulley alignment.

Belt and pulley guards must be provided by the set builder.

Important ! Incorrect belt tensioning will result in excessive bearing wear.

2/4-Pole

Side Load

kgf N

Shaft extension mm

BC16 92 900 82

BC18 173 1700 82

Coupling Arrangements

Single and two bearing arrangements are available both arrangements can be close coupled. Both

arrangements also need a firm level foundation.

Two bearing generators require a substantial bedplate with engine/generator mounting pads to ensure a

good base for accurate alignment. Close coupling of the engine to the generator can increase the overall

rigidity of the set. A flexible coupling, designed to suit the specific engine/generator combination, is

recommended to minimise the torsional effects.

Accurate alignment of single bearing generators is essential, vibration can occur due to the flexing of the flanges

between the engine and generator. A substantial bedplate with engine/generator mounting pads is required.

For the purposes of establishing set design the bending moment at the engine flywheel housing to

generator adaptor interface should not exceed 125ft.lb. (17 kgm).

The maximum bending moment of the engine flange must be checked with the engine manufacturer.

Torsional vibrations occur in all engine-driven shaft systems and may be of a magnitude to cause

damage at certain critical speeds. It is therefore necessary to consider the torsional vibration effect on the

generator shaft and couplings.

It is the responsibility of the generator set manufacturer to ensure compatibility, and for this purpose

drawings showing the shaft dimensions and rotor inertias are available for customers to forward to the

engine supplier. In the case of single bearing generators coupling details are included.

Caution: Torsional incompatibility and/or excessive vibration levels can cause

damage or failure of the generator and/or engine components.

Coupling Two Bearing Generators

A flexible coupling should be fitted and aligned in accordance with the coupling manufacturer's

instruction.

If a close coupling adaptor is used the alignment of machined faces must be checked by offering the

generator up to the engine. Shim the generator feet if necessary. Ensure adaptor guards are fitted after

generator/engine assembly is complete. Open coupled sets require a suitable guard, to be provided by

the set builder.

Axial loading of the generator bearings should be avoided. Should it be unavoidable contact the factory

for advice.

Warning: Incorrect guarding and/or generator alignment can result in injury and/or

equipment damage.

TD_BC MAN GB_10.06_03_GB

13

Copyright 2010

Coupling Single Bearing Generators

Alignment of single bearing generators is critical. If necessary, shim the generator feet to ensure

alignment of the machined surfaces.

For transit and storage purposes the generator frame spigot and rotor coupling plates have been coated

with a rust preventative. This MUST BE removed before assembly to engine.

A practical method for removal of this coating is to clean the mating surface areas with a de-greasing

agent based on a petroleum solvent.

Warning: Care should be taken not to allow any cleaning agent to come into

prolonged contact with skin.

BCI, 4-pole Single Bearing Coupling Alignment

1) On the engine check the distance from the coupling mating face on the flywheel to the flywheel

housing mating face. This should be within 0.5mm of nominal dimension. This is necessary to

ensure that a thrust is not applied to the ac generator bearing or engine bearing.

2) Check that the bolts securing the flexible plates to the coupling hub are tight and locked into

position. Refer to the Data section of the manual for tightening torques. (75Nm : 55 lb/ft)

3) Remove air outlet covers from the drive end of the generator to gain access to coupling and

adaptor bolts. Check that coupling joint interfaces are clean and lubricant free.

4) Check that coupling discs are concentric with adaptor spigot. This can be adjusted by the use of

tapered wooden wedges between the fan and adaptor. Alternatively, the rotor can be suspended

by means of a rope sling through the adaptor opening.

5) Consider using alignment studs to ensure that the disc and the flywheel are in alignment.

6) Offer the generator to engine and engage both coupling discs and housing spigots at the same

time, pushing generator towards engine until coupling discs are against flywheel face, and the

housing spigots are located.

Caution: Do not pull the generator to the engine using bolts through the flexible

discs.

7) Fit housing and coupling bolts, taking care to use heavy gauge washers between coupling bolt

head and coupling disc. Tighten bolts evenly around assembly sufficiently to ensure correct

alignment.

8) Tighten housing bolts.

9) Tighten coupling disc to flywheel bolts. Refer to engine manufacturer’s manual for correct

tightening torque.

10) Remove rotor aligning aids, the sling, or wooden wedges and replace all covers.

Caution: Incorrect generator alignment can result in damage to the generator.

Warning: Failure to replace protective covers can result in injury.

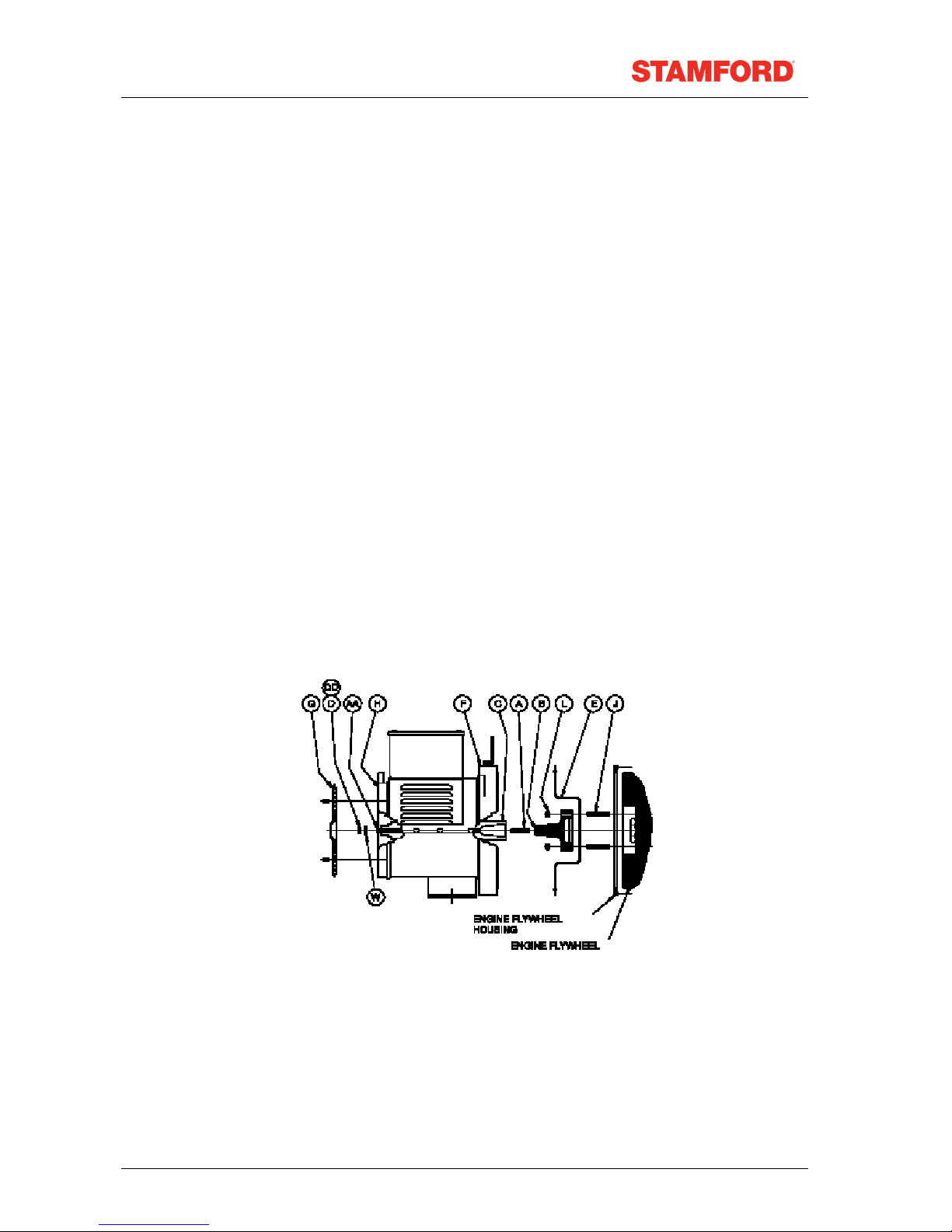

BCA, Single Bearing Coupling Alignment

Generators offered in the BCA range can be specified to suit different engine build configurations of

specific flywheel and flywheel housing combinations.

Important: It is most important that the appropriate generator build is ordered with

prior knowledge of the intended engine flywheel/housing arrangement.

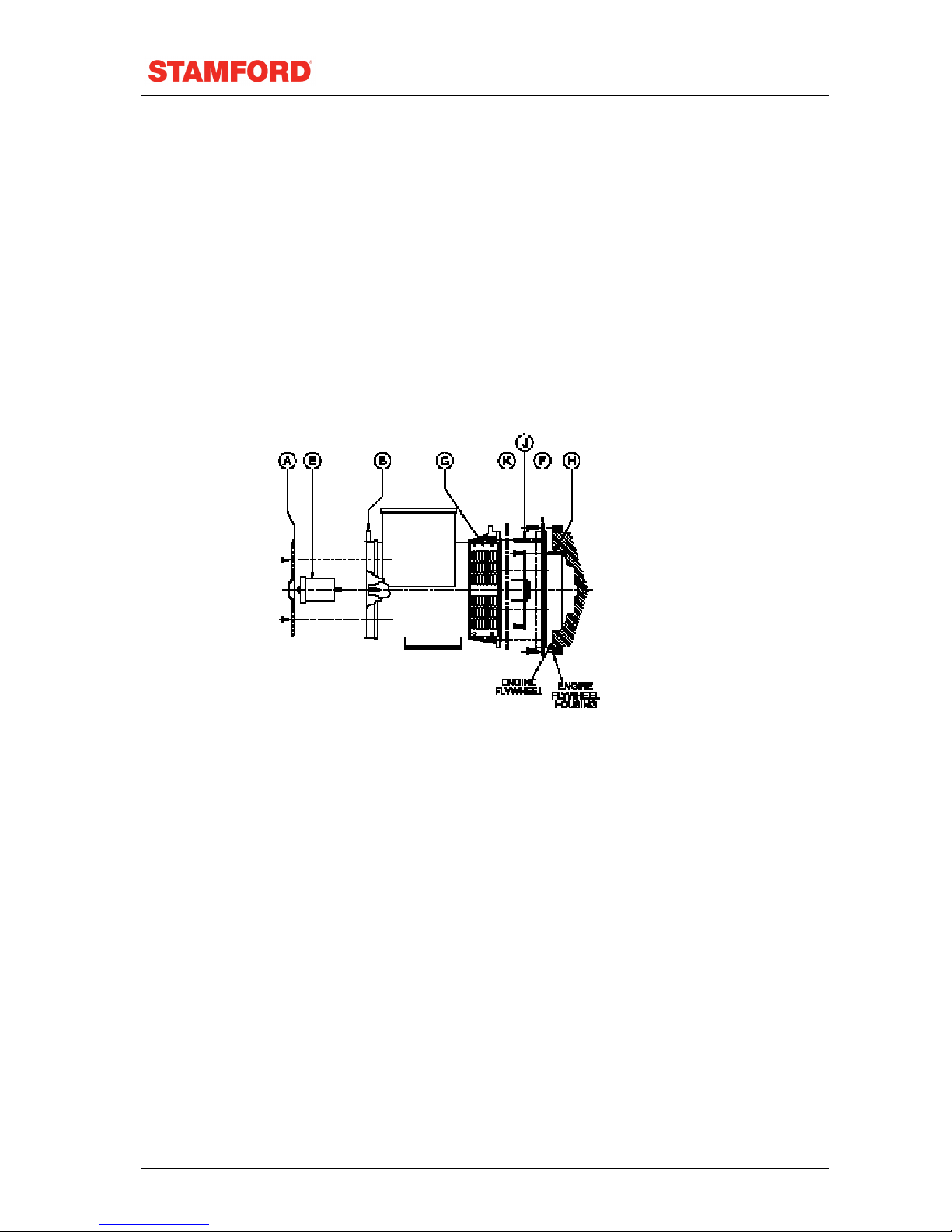

11) Remove louvered cover "A" from non-drive endbracket "B".

12) Assemble locating bar "E" ( No AF1609) by screwing into shaft.

13) Remove transit bar "K".

14) Remove side screens "G".

15) If the adaptor ring is an individual item, as indicated "F", bolted to the generator D.E. bracket,

remove from generator and fit to engine flywheel housing.

16) Thread two locating pins "H" into two top flywheel holes.

17) Fit two locating pins "J" into two top holes of the engine flywheel housing/adaptor location holes.

18) Pick up generator by the cast lifting lugs on both ends with 1/2 ton shackles (TO BS3032) or

lifting hooks using suitable lifting equipment.

Copyright 2010

14

TD_BC MAN GB_10.06_03_GB

19) Rotate generator rotor such that two top holes of coupling disc are in close axial alignment.

20) Push the generator rotor forward only half (50mm) the available movement provided by locating

bar "E". It may be necessary to tap bar "E" with a hide mallet to ease the bearing out of housing.

Important! Do not push the rotor forward too far. There is a risk that the rotor will rest

on the stator winding outhang resulting in winding damage especially if

any rotational movement occurs during alignment with pins "H".

21) Support the weight of the rotor at the coupling end whilst sliding the rotor forward to locate

coupling disc holes oversupport pins "H". Locating bar "E" will allow the rotor to move forward a

further 50mm, the total movement bar "E" allows being 100mm. With coupling discs positioned

against flywheel location fit securing screws and washers. Remove pins "H" and fit two final

securing screws and washers.

22) Push generator onto engine guiding adaptor over locating pins "J" and onto engine flywheel

housing location, or ring "F", secure with screws and washers. Remove pins and replace with two

screws and washers.

23) Remove locating bar "E". Replace M10 screw "C" for barring purposes.

24) Remove lifting tackle and replace side screens "G" and louvered cover "A".

ENGINE FLYWHEEL

ENGINE FLYWHEEL HOUSING

BCA, Single Bearing 2-Pole Generator To Engine Assembly Instructions (With Doweled

Flywheels)

Follow steps 1 – 5 from BCA, 4-pole instruction procedure.

Fit the two location dowels pins into appropriate diametrically opposite holes in engine flywheel, leaving

sufficient parallel diameter exposed to allow for positive location of the disc-spacer-ring and coupling

discs.

Fit the disc-spacer-ring over the two dowel pins and position firmly against the flywheel face.

Follow steps 6 – 8 from BCA 4-pole instruction procedure.

Rotate generator rotor such that the two coupling disc dowel holes align with flywheel dowel pins, and two

top holes of coupling discs are in close axial alignment with the two flywheel location pins "H".

Follow step 10 and 11 from BCA 4-pole instruction procedure.

Support the weight of the rotor at the coupling end whilst sliding the rotor forward to locate coupling disc

holes over support pins "H".

TD_BC MAN GB_10.06_03_GB

15

Copyright 2010

Important! Ensure coupling disc dowel pinholes are in correct alignment. With the

coupling disc positioned against flywheel location fit securing screws and

washers. Remove pins "H" and fit two final securing screws and washers.

Follow steps 12 – 14 from 4-pole instruction procedure.

BCL Taper Shaft Arrangements

This arrangement is used on the BCL style generators.

As with single bearing generators alignment is critical. If necessary shim the generator feet to ensure

alignment of the machined surfaces.

The following procedure should be adopted to assemble the generator to the engine:

25) Remove louvred end cover "G" from non drive end bracket "H" and M10 Hex Nut "D" from shaft

securing stud "AA".“ Remove transit bar "E" and withdraw stub shaft/shaft securing stud "A/B"

from rotor.

26) Ensure alternator, engine flywheel and flywheel housing locating spigots, faces and recesses are

free from paint or preservatives.

27) Locate stub shaft/shaft securing stud assembly "A"/"B" on engine flywheel spigot and secure with

studs "J", M12 hex. nut "L" or bolts. Refer to engine manual for torque settings.

28) Ensure both tapers are clean and free of burrs, oil or grease. Slide alternator complete with rotor

towards engine, ensuring that shaft securing stud "A" enters central hole in rotor shaft. Refer to

engine manual for torque settings.

29) Secure alternator adaptor "F" to engine flywheel housing. Tap adaptor into place before

tightening. Refer to engine manufacturer for torque setting.

30) Fit M10 Binx nut "DD" to protruding shaft securing stud "AA". M10 Binx nut tightening torque

45.0Nm (33.0 lbs.ft).

31) Fit louvred endcover "G" to non drive endbracket "H".

32) Check for excessive vibration at time of initial run-up.

Caution Incorrect guarding and/or generator alignment can result in personal injury

and/or equipment damage

Copyright 2010

16

TD_BC MAN GB_10.06_03_GB

Loading...

Loading...