Stallion SLC938 User Manual

Model: SLC938

Sunliner Coach - Corona, California U.S.A.

Sunliner Coach (a Stallion Bus Industries Company) is pleased to provide you, our

customer, with the highest quality product available on the market today. We strive to

ensure that all our vehicles meet or exceed all applicable Federal, State, and Local laws

and statutes for safety and operability for varied on-the-road usage requirements.

The vehicles manufactured by Sunliner Coach are constructed with ease of operation

and economical durability in mind, for the life of the coach and its operating systems.

We take great pride in producing a cost-effective product for your use and for the safety

and comfort of your passengers.

Every component of this transportation system is vital to the safety and durability of this

vehicle and at no time should any system or part be neglected, removed, or altered in

any manner that will compromise safety or operability of the vehicle or the safety and

well-being of passengers and the operator.

It is the responsibility of the owner of this coach to maintain all systems and

components in serviceable and working condition. Always maintain and operate this

coach with parts and information provided by Sunliner Coach for many years of troublefree driving, and a safe and comfortable travel experience.

PLEASE READ BEFORE OPERATING THIS VEHICLE

THIS OPERATOR MANUAL MUST REMAIN WITH THE VEHICLE THROUGHOUT ITS

SERVICE LIFE, AND MUST BE TRANSFERRED TO ANY FUTURE OWNERS OR

OPERATORS AS AN IMPORTANT PART OF THIS TRANSPORTATION SYSTEM.

Stallion Bus Industries (“the manufacturer”) will, at its discretion, add to or edit this

document as needed to provide the owner with any updates required by law or with

information affecting the operation or safety of this coach. Stallion Bus Industries

reserves all rights to this document in its entirety, and any copying, duplication, or

changes to this manual are strictly prohibited, unless specific permission is granted by

the manufacturer to the licensed operator or owner of this coach. Please submit any

questions regarding this document to:

Stallion Bus Industries

1592 Jenks Dr. Corona, CA 92880

(951) 737-7777

http://www.stallionbus.com

THANK YOU FOR CHOOSING STALLION BUS PRODUCTS FOR YOUR TRANSPORTATION NEEDS.

GENERAL INFORMATION

EXTERIOR COMPONENTS

INTERIOR COMPONENTS

CONTROLS

MECHANICAL

TRANSMISSION

ELECTRICAL

ACCESSORIES / OPTIONS

1- GENERAL INFORMATION

Sunliner Coach - Corona, California U.S.A.

GENERAL INFORMATION

VEHICLE IDENTIFICATION NUMBER (VIN)

The Vehicle Identification Number is stamped on a plate located inside the vehicle on the upper step

adjacent to the curbside wall.

The D.O.T. Certification Plate certifies that the vehicle complies with all Federal Motor Vehicle Safety

Standards for operation of a vehicle on public roadways in effect at the time of manufacture. This plate is

located on the first step on the aisle side of the driver’s seat.

Information such as manufacturer’s name and address, date of manufacture, gross vehicle weight, tire

type and pressures, and are also on this plate. Refer to the VIN whenever requesting service parts, recall

information.

GENERAL INFORMATION

The ultimate responsibility for the safe operation of a motor vehicle is the duty of the operator. In

the case of motor coach transport, many individual lives may be endangered if certain commonsense items are ignored or dismissed. Due to the nature of tort law and damages compensation

law, it is of the utmost importance that you, the operator, take it upon yourself to insure that your

vehicle and all of its systems are in operable condition and have been maintained to all pertinent

specifications of the manufacturer and state and federal regulations.

Before operating the vehicle, be sure to check the following:

• Tires – visually inspect for damage, low pressure, or uneven wear. If applicable per your

operating agency, check the tire pressures and adjust as required.

• Inspect underside of coach for any fluid leaks or damage. Check undercarriage for

obstructions and debris.

• Make sure that windshield, exterior mirrors, headlights, and windows are clean.

• Check all lights (interior, exterior, and instruments) for function

• Adjust exterior and interior mirrors for best view from the driver’s position

• Walk down the aisle and check for loose items on the seats, stanchions, and overhead

storage areas. Secure any loose items before travel.

• Check all emergency exits and windows

• Inspect for presence and contents of First Aid Kit.

• Visually check the fire extinguisher for service pressure and inspection date.

• Test the entertainment system and public address system for function.

• Check function of lavatory (if so equipped)

After starting the vehicle, check the following:

• Check for any service lamps or warning lights

• Listen for any unusual sounds or engine noise

• Adjust seat for best driving position and comfort

• Check function of brakes and brake system air pressure

• Test air conditioning and heating

PRE-TRIP INSPECTION CHECKLIST

DATE ________________ VEHICLE ____________________

MILEAGE: START: _________________ END: ____________________

DAILY TOTAL: _________________

INSPECT AND CHECK BELOW: NOTE DEFECTS BELOW:

MECHANICAL

1. ENGINE OIL ______________________ __________________________

2. COOLANT LEVEL _________________ __________________________

3. WASHER FLUID LEVEL ____________ __________________________

4. HYDRAULIC OIL __________________ __________________________

5. BELTS, HOSES ___________________ __________________________

6. ENGINE GENERAL ________________ __________________________

7. BRAKES _________________________ __________________________

8. STEERING _______________________ __________________________

9. TRANSMISSION ___________________ __________________________

EXTERIOR

1. TIRES __________________________ __________________________

2. MIRRORS _______________________ __________________________

3. HEADLIGHTS ____________________ __________________________

4. TAIL LIGHTS _____________________ __________________________

5. BODY DAMAGE ___________________ __________________________

6. WINDSHIELD WIPERS _____________ __________________________

7. DOORS & WINDOWS _______________ __________________________

SAFETY EQUIPMENT

1. FIRE EXTINGUISHER ______________ __________________________

2. FLARES _________________________ __________________________

3. FIRST AID KIT ____________________ __________________________

4. RADIO __________________________ __________________________

5. WHEELCHAIR LIFT ________________ __________________________

6. EMERGENCY EXITS _______________ __________________________

MAINTENANCE ITEMS: _____________________________________________________

FUEL ADDED: _______________ GAL. OIL ADDED: _______________ QT.

MILEAGE AT FUELING: ________________ OTHER MAINT.: __________________

------------------------------------------------------------ ------------------------------------------------------

DRIVER SIGNATURE MECHANIC SIGNATURE

EMERGENCY PROCEDURES

In the event of accident, if the vehicle can be moved over to the shoulder of the road or at

least out of traffic flow, DO SO IMMEDIATELY.

IF SAFE TO DO SO, request that all passengers exit the vehicle and stand away from the

vehicle until it is secured.

• Make sure that all passengers exit the vehicle in an orderly and safe manner.

• Check for injuries among the passengers

• If there are any special needs passengers (non-ambulatory, wheelchair-bound), seek help

from fellow passengers to remove them from the vehicle.

• Triage any injuries – anyone bleeding or unconscious must be attended to first.

• Radio or call for medical personnel immediately if there are any injured passengers.

• Administer first aid until professional medical help arrives.

In the event of fire, get the vehicle out of traffic IMMEDIATELY.

• Park in an open area away from underpasses or bridges if possible.

• Shut down the vehicle.

• Open the doors and make sure that all passengers exit the vehicle in an orderly and safe

manner. Direct all passengers away from the vehicle and a safe distance from the roadway.

• Call for assistance from firefighters and emergency personnel.

• DO NOT ATTEMPT TO PUT OUT AN ENGINE FIRE WITH THE PORTABLE FIRE

EXTINGUISHER. This unit is for small, localized fires only.

• If possible, turn off the electrical disconnect switch in the engine compartment. DO NOT

ATTEMPT TO OPEN THE REAR ENGINE DOOR IF THE VEHICLE IS ENGULFED IN

FLAMES.

If the vehicle has rolled over or has gone off the road, direct passengers to the doors,

emergency exit windows, or roof hatches. Assist all passengers with egress, then call for help.

As in the previous sections, triage any injuries and administer first aid until emergency

personnel arrive.

MAINTEMANCE MANUAL:

Refer to Freightliner’s Shuttle Bus Chassis Operator’s and Maintenance Manual

furnished with your Sunliner Coach. The follow maintenance operations must be

included ;

Fastener Torque Checking: Bus Body to Chassis Anchorage fasteners must be torqued

at the recommended intervals. Maintenance interval for this operation is M2.

Same procedure as 31-01 frame fastener torque checking is to follow, always be sure to

check bus frame to chassis rail anchorage at front and back of pass-through luggage

compartment.

Torque Specifications: Table 5 for ASME Thread Fasteners with dry plain threads.

Flanged Grade 8 Bolt , Grade G nut 5/8-11 : 190 lbf-ft ( 258 N-m)

Torque Specifications: Table 6 for Metric Thread Fasteners with plated threads.

Class 10.9 Bolt , Class 10 Nut M 16-2.0 : 148 lbf-ft (201 N-m)

Drive Belt Inspecting: Air Conditioner Compressor and Alternator drive belts must be

check at the recommended intervals. Maintenance interval for this operation is M1.

COACH CARE & MAINTENANCE

CLEANING

The cleaning information provided in this section is

regarded as recommended cleaning practices.

Cleaning results will vary depending on the age

and condition of the material to be cleaned and the

condition of the stain. Always clean stains promptly

to prevent setting or etching into the material.

NOTE: Never use stain protection products on new

fabrics. To prevent permanent staining of fabrics,

clean stains as soon as possible. Incorrect

treatment of stains can lead to permanent

discoloration or worse staining. Refer to a cleaning

specialist for removal of stubborn stains.

Caution: Custom fabrics and materials may

require different cleaning and maintenance

practices. Consult your dealer for specialized

cleaning requirements.

SEAT UPHOLSTERY

Firmly beat the fabric with a wood paddle or similar

blunt object to loosen superficial dust and dirt.

Vacuum the seat fabric in the direction of the

stitching using an upholstery nozzle.

Note: The abrasive nature of dirt and dust will

reduce fabric life. Always vacuum upholstery

regularly.

Removal of Stains and Marks

Use one of the two methods described below to

remove stains from wool plush fabrics:

Method One:

1. Apply a non-flammable solvent, such as dry-

cleaning solvent (Perchloroethylene) to the

stained area with a clean white rag.

2. Wipe the stain, starting at the outer edges and

working inward, frequently turning the cloth.

3. Blot the stained area frequently with a dry white

cloth to prevent stain rings from excess solvent.

Warning: Use solvents in a well-ventilated area,

away from ignition sources and open flame. Keep

all windows and doors of the vehicle being cleaned

open – use appropriate breathing apparatus or

fume masks.

Method Two:

1. Wet the stain with a solution of household

detergent and lukewarm water. Do not flood or

over-soak the stain.

2. Wipe the stain with a damp cloth, rinsing

the cloth after each application.

Caution: Do not use soap, soap powder,

ammonia, bleach, or any cleaning products

containing these ingredients.

Beverage Stains

Remove beverage stains as per method one. If the

stain persists, repeat method one using methylated

spirits (95% ethanol) in place of solvent.

Alcoholic Beverage Stains

Remove these stains by wetting the stain with

water, then cleaning per method two.

Burns

Scrape the burned area using a knife or razor

blade, the cleaning per method two. Consult an

upholstery specialist if the burned area is

extensive.

Cosmetics

Remove stains left by cosmetics by using method

one followed by method two.

Ink Stains

Remove ink stains by following method two. If stain

persists, apply a warm oxalic acid solution. Rinse

thoroughly with lukewarm water.

Blood, Urine, or Vomit

Remove by sponging or wiping away excess solid

matter first. Then clean per method two.

Copying Ink / Ball-Point Pen Ink

Treat with methylated spirits, blotting frequently to

prevent stain spread, followed by method two.

Felt-Tip Pen Ink / Permanent Marker Ink

Wipe thoroughly with a clean cloth soaked in MEK,

followed by method two.

Oil, Grease, and Paint

Remove excess using a knife. Treat per method

one followed by method two. Repeat if stain

persists.

COACH CARE & MAINTENANCE

Rust

Remove per method two. Apply a warm oxalic acid

solution to the stained area. Rinse with water.

Tar

Soften tar with benzene or naphtha. Treat per

method one followed by cleaning per method two.

Chewing Gum

Scrape excess with spatula. Soften remainder with

cyclohexane. Carefully scrape off stains with a

sharp knife or razor blade.

PLASTIC AND VINYL

Clean plastic and vinyl surfaces with a clean damp

cloth or sponge. DO NOT use cleaners or polishes

on chromed plastic trim. For marks on vinyl trim,

use a lukewarm all-purpose cleaner or a MILD

saddle soap. Remove water spots and soap traces

with a clean damp cloth, chamois, or sponge. Dry

with a clean soft cloth.

Remove grease, tar, or oil stains with a clean cloth

or sponge and an all-purpose vinyl cleaner.

Apply a colorless vinyl or leather protectant to

maintain luster and pliability of the plastic material.

WINDOWS / GLASS SURFACES

Clean glass surfaces and the inside of windows

with a solution of 10% vinegar in purified water.

WINDSHIELD

To prevent wiper streaking, keep all silicone sparys

away from the windshield. Remove road film,

insect residue, and wax buildup from windows with

lukewarm soap and water solution or an alcoholbased liquid cleaner. If a chamois is used for

wiping or polishing glass, it must only be used for

glass surfaces.

Wiper Blades

In cold weather conditions, loosen wiper blades

from windshield to prevent tearing. Periodically

remove wiper blades and clean the rubber with an

alcohol-based cleaner. Wipe dry with a clean cloth

or sponge.

STAINLESS STEEL

Use a stainless steel cleaner and follow the

manufacturer’s directions. AVOID using abrasive

pads or steel wool to clean stainless steel surfaces.

FORMICA

Formica surfaces may be cleaned with a solution of

warm water and household detergent; methylated

spirits, or mineral turps. Clean with a mild abrasive

and water solution (scouring powder) if needed.

CARPET

Vacuum carpeting regularly to prolong carpet life.

Clean per manufacturer’s instructions. Natural-fiber

carpet, polyester / nylon carpet, and synthetic

(plastic) carpeting each are cleaned and de-stained

in different ways. Always consult manufacturer’s

recommendations first before attempting removal

of any stain from fiber / woven flooring materials.

RUBBER

Only use purified water or glycerin to remove stains

from rubber components. NEVER use solvents or

detergents on natural or synthetic rubbers or foam.

Note: After cleaning rubber with a moistened cloth

or sponge, apply a thin layer of rubber protectant to

maintain suppleness and weather resistance.

FLOORING

Wash the floor regularly to maintain its original

texture and appearance. Clean vinyl floors with

manufacturer’s recommended non-ionic cleaner or

household all-purpose cleaner. Encrusted oil stains

or rubber streaks may be removed with thinner.

Remove excess detergent solution with a wet/dry

vacuum or mop. Rinse floor with a 10% solution of

liquid laundry bleach and warm water.

Polish dry floor with a high-speed buffer equipped

with a red Scotchbrite™ pad.

Mop floor periodically with a 5% solution of

household liquid bleach and warm water.

VEHICLE EXTERIOR

The exterior finish of any vehicle is subject to

damage from pollutants and abrasive airborne

particles. Frequent washing and waxing of the

exterior will protect the finish and luster of painted

surfaces.

COACH CARE & MAINTENANCE

Install keyhole protectors to prevent water

penetration. Rinse off vehicle with water to remove

loose dirt. Wash vehicle with a quality car wash

soap, using a sponge or cotton mitt. Rinse off

thoroughly with water. Dry with terry towels or

chamois.

NOTE: Always use cool water for rinsing and

washing. Hot water can damage paint and plastic

trim.

NOTE: When using high pressure washers, do not

spray directly into fresh air vents or radiator or

condenser doors. High pressure water jets can

damage or perforate condenser cooling fins.

Wash the undercarriage with a high-pressure

washer to remove caked-on dirt and road salt.

Thoroughly clean the inner fenders, wheel interiors,

bumpers, exhaust system, and any exposed

brackets. Spray underside of vehicle first and allow

to soak before cleaning. Exhaust system must be

cool before cleaning.

Perform corrosion prevention treatment per

manufacturer’s recommendations at least every

two years.

Oil, Tar, Asphalt Stains

Remove tar and oil stains as soon as possible with

an approved automotive tar remover or naphtha.

Clean the area with car wash soap and water. Dry,

then wax with quality automotive protectant wax.

Insect Residue / Bird Droppings

Remove insect stains and bird droppings

immediately to prevent etching of painted surfaces

and discoloration of plastics. Use lukewarm water

and mild car wash soap or commercial bug / tar

remover for insect residue. Follow with a quality

wax to protect cleaned areas.

Tree Sap

Wash off immediately with lukewarm soap and

water. Do not allow tree sap to harden on painted

surfaces or rubber / vinyl trim.

LAVATORY MAINTENANCE

Lavatory with recirculated system

Flush water in the lavatory is recirculated from the

sump tank. If two tanks are used, the upper tank is

the primary sump and the lower tank is the

auxiliary sump. When the main sump tank water is

too soiled for recirculation, the driver can dump it

into the auxiliary tank until a suitable dump location

can be reached. The main sump tank is then filled

with fresh water to begin the cycle again.

The optional top tank holds 13 gallons and the

lower tank holds 13 gallons .

The sump tank may be equipped with a heating

element to prevent freezing during cold weather.

Routine draining and filling of lavatory tanks should

be done prior to parking the vehicle overnight in

freezing weather.

1- Water inlet connector

2- Pressure tank

3- Dump valve

COACH CARE & MAINTENANCE (cont.)

FILLING THE SUMP TANK

Fill the sump tank to half capacity through the water

inlet connector and throw in a packet of commercial

toilet deodorant thru lavatory toilet.

DRAINING THE SUMP TANK

Drain the sump tank once recirculating water in the

toilet is soiled. If equipped with the optional auxiliary

sump tank, drain the lower sump tank contents first by

opening it’s knife gate valve, then drain the upper tank.

Caution: Lavatory tanks should be serviced only at

suitably equipped stations.

Warning: It is illegal to dump sump tank contents in any

location other than a designated service dump station.

When a complete tank draining is required, clean main

tank by repeating the draining and filling operations

with the drain valves open. Once done, close the

valves and drop in a packet of commercial toilet

deodorant into the toilet before starting the final filling of

the main tank.

Warning: The toilet deodorant package contains

chemicals that will irritate the skin. Use rubber gloves

when handling.

Caution: When cold weather is expected, both sump

tanks must be drained if the coach will be parked

overnight or for an extended period of time.

Note: Due to the heat it produces, there is less

likelihood of the tanks freezing while the engine is on.

Note: Sump tank may be equipped with an optional intank heater that automatically comes on when the

temperature of the water drops below 35°F (2°C), or a

thermal valve that automatically opens the drain valve

at the same temperatures.

COACH CARE & MAINTENANCE (cont.)

Wheels and Tires

It is of utmost importance that tires are kept inflated to

their respective recommended pressure at all times.

Tire pressure should be checked before starting the

day’s run, while the tires are cold. Maintaining the tires

at recommended pressure will lengthen the life of the

tires and will insure safe travel and even tire wear.

Note: Recommended inflation pressures are part of the

Coach Final Record found in the Maintenance Manual

provided for your coach. The cold tire inflation

pressures are on the DOT Certification Plate.

Warning: Do not exceed maximum inflation pressure.

Incorrect tire pressure hastens tire wear and could lead

to loss of driving control.

Warning: If replacement tires are different from those

described on the vehicle certification plate, adjust

pressure to specifications listed in the Tire and Rim

Association Manual.

Doors

Open, then close all exterior doors and windows.

Check for tightness and good sealing.

Tools and Spares

Make sure the vehicle is equipped with the following: a

wheel nut wrench, door keys, reflectors, a jack, and a

serviceable fire extinguisher.

Air System

Drain water from main and accessory air tanks daily. If

the vehicle is supplied with an automatic drain valve,

assure it is functioning correctly after the system has

reached full pressure. See your maintenance manual.

Fuel / Water Separator

Open the drain valve on the bottom of the water

separator daily. Close valve after service.

Coolant Level

Check coolant level. Level is correct when visible at the

level window of the surge tank.

If coolant level is low, fill surge tank with a 50-50 mix

of ethylene glycol antifreeze and water. Refer to the

vehicle maintenance manual for further information.

Warning: Hot engine coolant is under pressure. Do

not open the coolant filler cap when the engine is hot.

Allow the engine to cool before adding coolant.

Wheel Bearings

Check wheel bearing covers for overheating during

fuel stops by touching the bearing caps. If

excessively hot, refer to service personnel.

Windshield Washer Reservoir

Check washer reservoir level. Add antifreeze washer

fluid for cold weather service.

Engine Oil

Check engine oil level with vehicle parked on flat

ground. Engage parking brake whenever checking

items in the engine compartment.

Belts

Inspect belts for looseness (noise) or cracking and

fraying.

Belt tension may be checked with a pressure gauge

– refer to maintenance manual section on engine

service.

Fire Extinguisher(s)

Inspect fire extinguishers for correct service pressure

and current inspection tag.

Emergency Exits

Check all emergency exits (doors, windows, roof

hatches, etc.) for correct operation and serviceable

condition.

2- EXTERIOR COMPONENTS

Sunliner Coach - Corona, California U.S.A.

EXTERIOR COMPONENTS

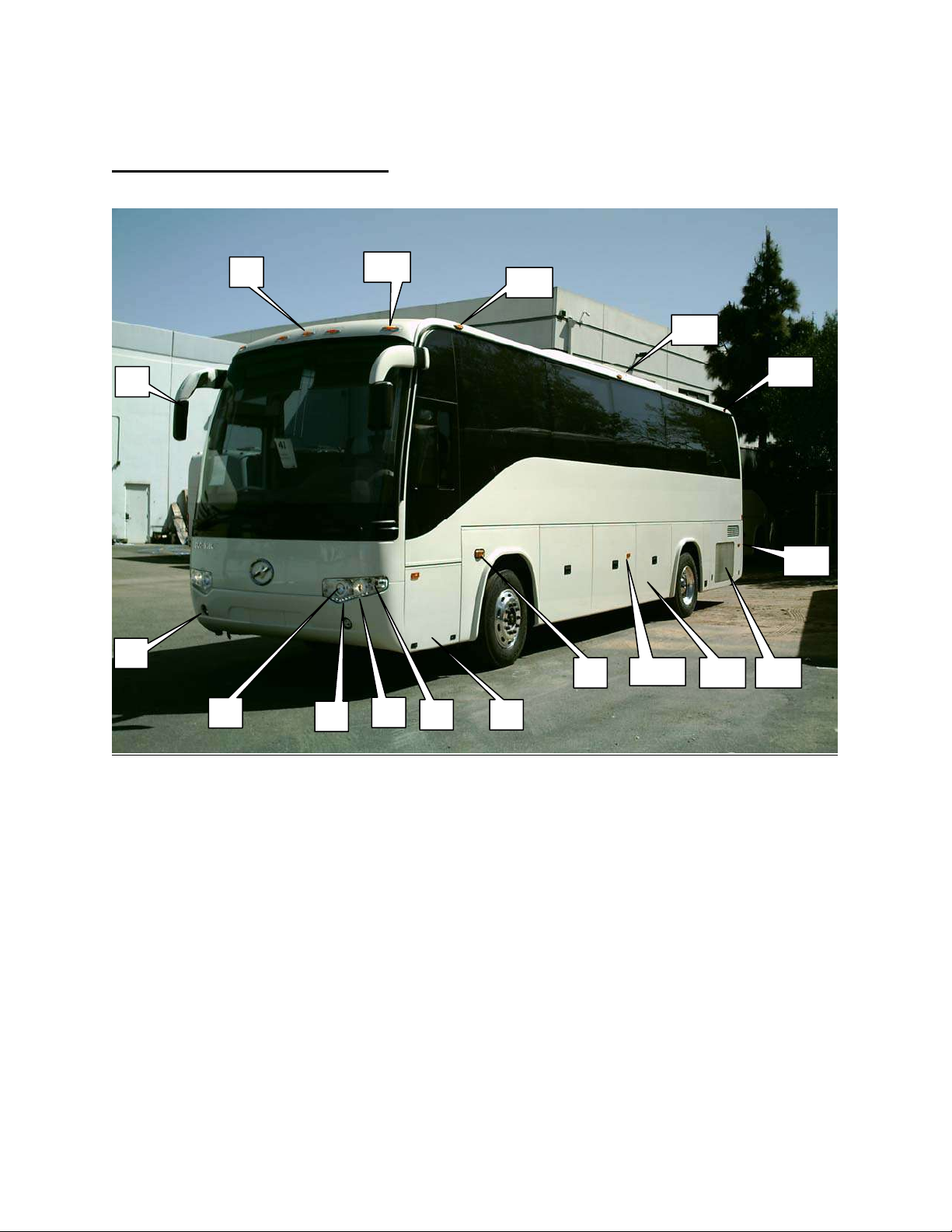

FRONT AND STREET SIDE

2

3

4

1

5

17

16

15

14

13

11

6

7 8

129

1. Front Identification Lamps (Yellow) 9. Front Side Turn Signal

2. Side View Mirrors (Left & Right) 10. Side reflector / marker lamp (Yellow)

3. Fog Lights 11. Luggage Compartments (3), Streetside

4. High Beam Headlights 12. Radiator Access Door

5. LED Parking Lamps 13. Side reflector / marker lamp rear (Red)

6. Low Beam Headlights 14. Side Marker Lamp, Rear (Red

7. Front Park / Turn Lamps 15. Side Marker Lamp, Center (Yellow )

8. Main Electrical Compartment 16. Side marker Lamp, Front(Yellow)

17. Front Clearence lamp, Front(Yellow)

REAR

EXTERIOR COMPONENTS

3

9 8

7

1

2

4

5

6

1. High-Mounted Brake Lights 4. Rear red reflectors

2. Rear View Camera 5. Engine Compartment Door

3. Rear Lamp Assemblies: 6. Rear License Bracket & Lamp

Taillights 7. Rear Clearance Lamps (Red)

Turn Signals 8. Rear Identification Lamps (Red)

Back-Up (Reverse) Lamps 9. Vent ( lavatory-equipped models)

Brake Lights

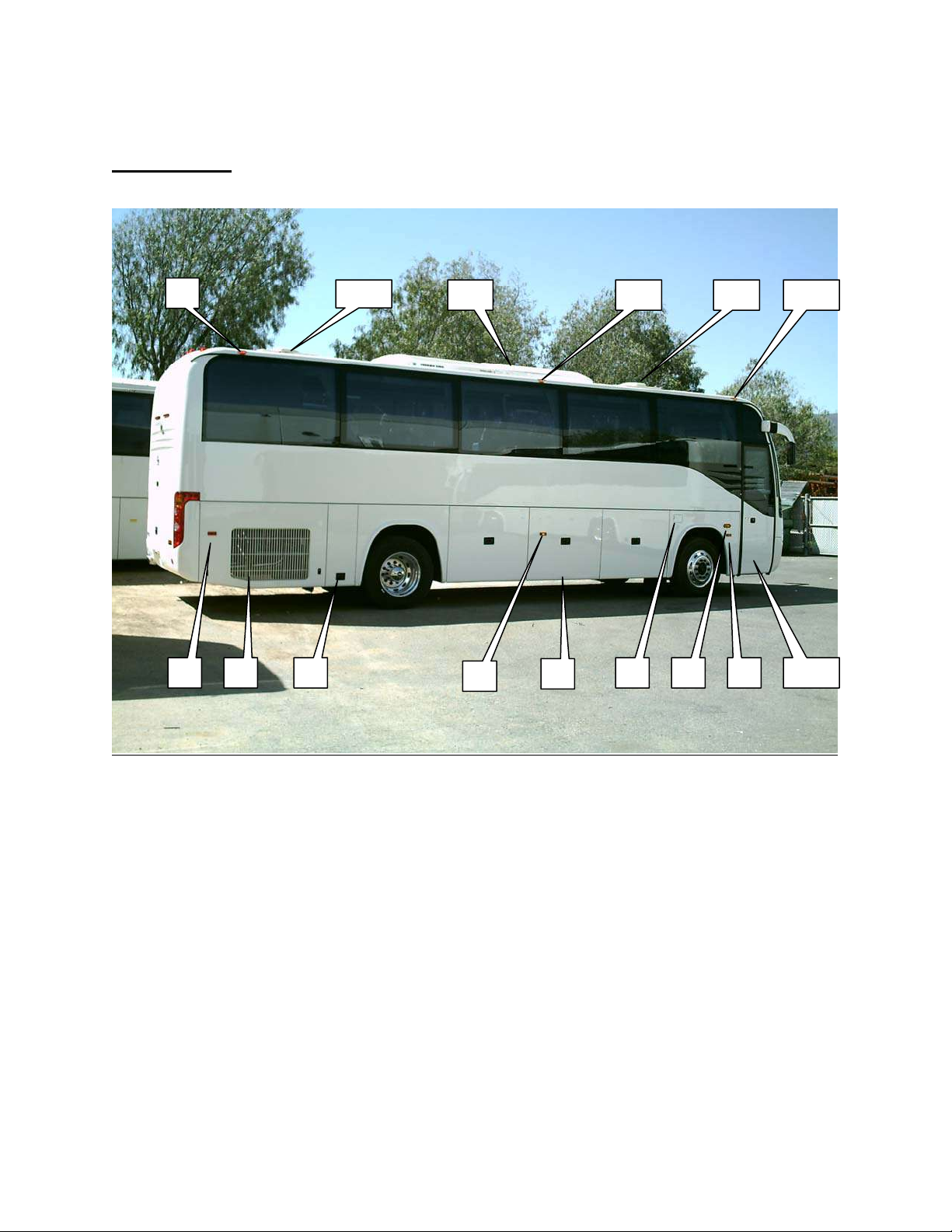

CURB SIDE

EXTERIOR COMPONENTS

1

2 3 4

14 13 12 11

5

6

9 87 10

1. Side marker Lamp, rear (Red) 9. Reflector / marker , Front (Yellow)

2. Reflector / marker , Rear (Red) 10. Entry Door

3. Preheater Compartment Door 11. Side marker Lamp, Front (Yellow)

4. Battery Compartment Door 12. Roof Hatch w/Fan, Forward

5. Reflector / marker , Center (Yellow) 13. Side marker Lamp , Center(Yellow)

6. Luggage Compartments (3), Curbside 14. Roof A/C Unit

7. Fuel Filler Door 15. Roof Hatch w/Fan, Aft

8. Side Turn Signal, Front

ENTRY DOOR

1

Main Entry Door (1) and Door Lock (2)

4

The entry door may be locked and unlocked manually by inserting the door key into the door key switch

(3), turn the key to the right (clockwise) then turn the door handle (2) to the left (counterclockwise) to

unlock. Turning the handle to the right (clockwise) will lock the door . Turn the key to its original position

and remove the key.

When the door is unlocked, you can opened it or closed it, through the use of the keychain remote control

provided with the vehicle or by inserting the door key into the door key switch (4). This remote is a

battery-powered radio-frequency device that transmits a short-range signal to the vehicle’s door open /

close mechanism. See next page for details of operation.

NOTE: The use of the Key Fob or Key Operated Entry Switch DOES NOT lock or unlock the door.

ENTRY DOOR

(Continued)

Door Remote

The door remote control unit has two functions – CLOSE and OPEN.

To access the function buttons, slide the protective cover downward to expose the two buttons. Press the

right (UNLOCK) button once to open the door.

To close the door, press the left (LOCK) button once.

Each time either button is pressed, the red LED at the top of the remote will light. Should the lamp fail to

illuminate when the buttons are pressed, the battery will need to be replaced. The door can only be

locked or unlocked manually with the key .

To replace the remote battery, carefully pry open the side of the remote case. The battery (#2032) is

located in the front (button side) of the case interior. Remove the old battery and fit the replacement cell

into the battery cavity with the positive (+) side of the battery facing downward. Press the case halves

back together and press a button to check function.

EMERGENCY DOOR RELEASE

In an emergency, the door may be released from the interior of the vehicle by turning the red emergency

air release knob clockwise (rigthwise). The air release valve is located above the first step on the curbside

of the bus.

Note: An other manual door release valve is located underneath the vehicle next to the step.

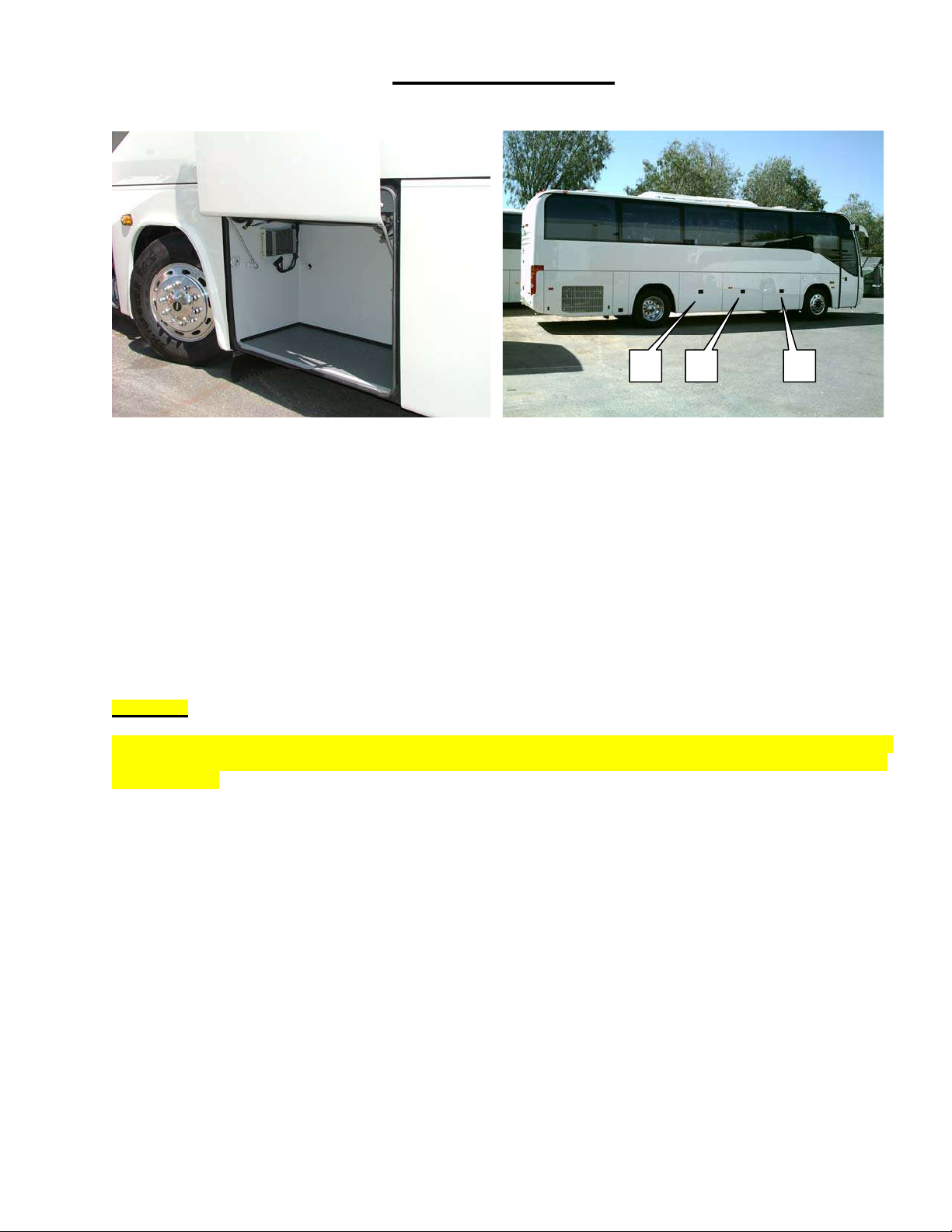

CARGO STORAGE

3 2 1

Front Streetside Cargo Compartment Curbside Cargo Compartment Doors

Three (3) doors on each side of the bus access the cargo / storage compartments.

The forwardmost doors on each side are smaller separate compartments from the large pass-through

compartment that is accessed by the center and rear doors on each side.

The forward curbside cargo compartment contains the tools for changing the spare tire. the forward street-side

compartment house electrical components and the windshield water reservoir.

To open the compartment doors, pull out and up on the door handle and allow the door to rise upward.

CAUTION:

When closing the doors, BE SURE to keep fingers away from the door edges and inner frame. Stand slightly back

from the door and press downward on the outer face of the door to close. The door edges can be pinch points for

hands and feet.

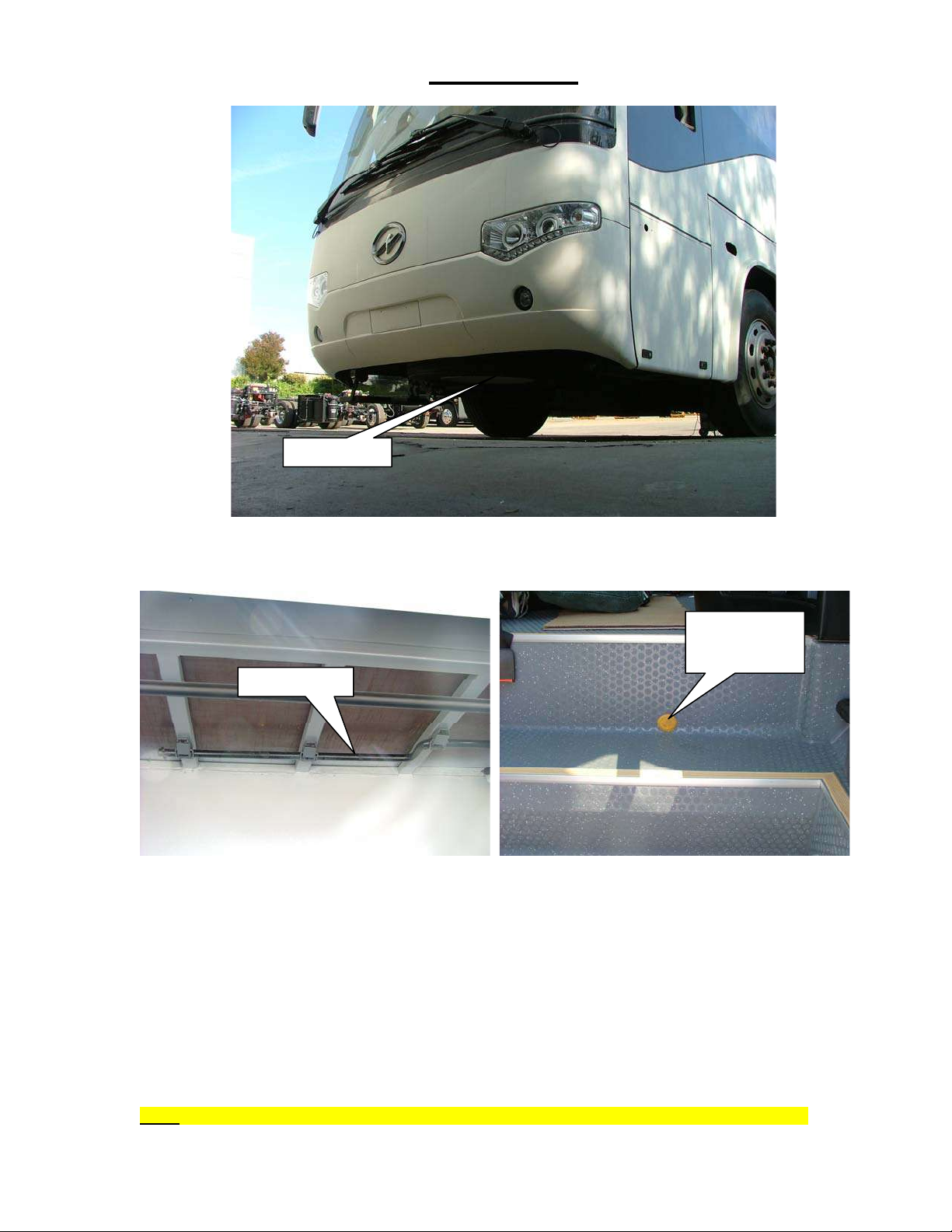

SPARE TIRE

SPARE TIRE

Spare Tire Location (1)

The spare tire is located underneath the vehicle, behind the front bumper.

TIRE GEAR

BOX ACCESS

TIRE CRANK

To access the tire, it must be lowered from its stowed position. The tire is secured in it’s location by two

1- 5/16” Gr 8 nuts and the gearbox chain. Once the nuts are removed, the tire hangs on the chain

mechanism. A crank is used to turn the mechanism and lower the tire.

Lower the spare tire by removing the crank from its stowed position in the forward curbside storage

compartment. Remove the gearbox access port cover at the step below the driver’s seat. Insert the

pinned end of the crank through the hole and into the mechanism receptacle. Remove the1-5/16” security

nuts then turn the crank counterclockwise (left) until the tire is on the ground. Remove the chain end from

the center of the wheel and bring the tire out and away from the vehicle.

Reverse the above steps to stow a tire under the vehicle.

Note: Make sure the tire is stowed securely (not loose and nuts tight) before driving away.

3- INTERIOR COMPONENTS

Sunliner Coach - Corona, California U.S.A.

DRIVER SEAT

DRIVER SEAT CONTROLS

The driver’s seat is a pneumatically-adjustable air-suspension seating system that will accommodate a

wide variety of operator physiques and that can be adjusted for extreme comfort by most users.

When getting ready to operate the vehicle for the first time, set the seat controls for best viewing height,

and then proceed to adjust the auxiliary functions such as seatback angle, cushion rake angle, lumbar

support, and suspension stiffness. Always set the seat for the safest and most comfortable position for

operating the vehicle and being able to access all controls and pedals.

1. Seatback Angle Adjuster – pull upward, adjust seat then release.

2. Side Bolster Adjustment – Increases or decreases the side bolster stiffness

3. Lumbar Support Adjustment – Center of back

4. Lumbar Support Adjustment - Upper and lower back

5. Seat Height Adjustment – Push upward to raise seat height, downward to lower.

6. Suspension Stiffness – Slide backward to soften suspension, forward to stiffen.

7. Air Lock / Release – Push downward to deflate seat.

8. Seat adjustment forward / backward – pull upward, adjust seat then release handle.

9. Seat bottom adjustment forward /backward- pull upward, adjust seat then release.

10. Seat inclination adjustment- pull upward, adjust seat then release.

11. Armrest Adjuster – Rotate knob to achieve proper armrest angle.

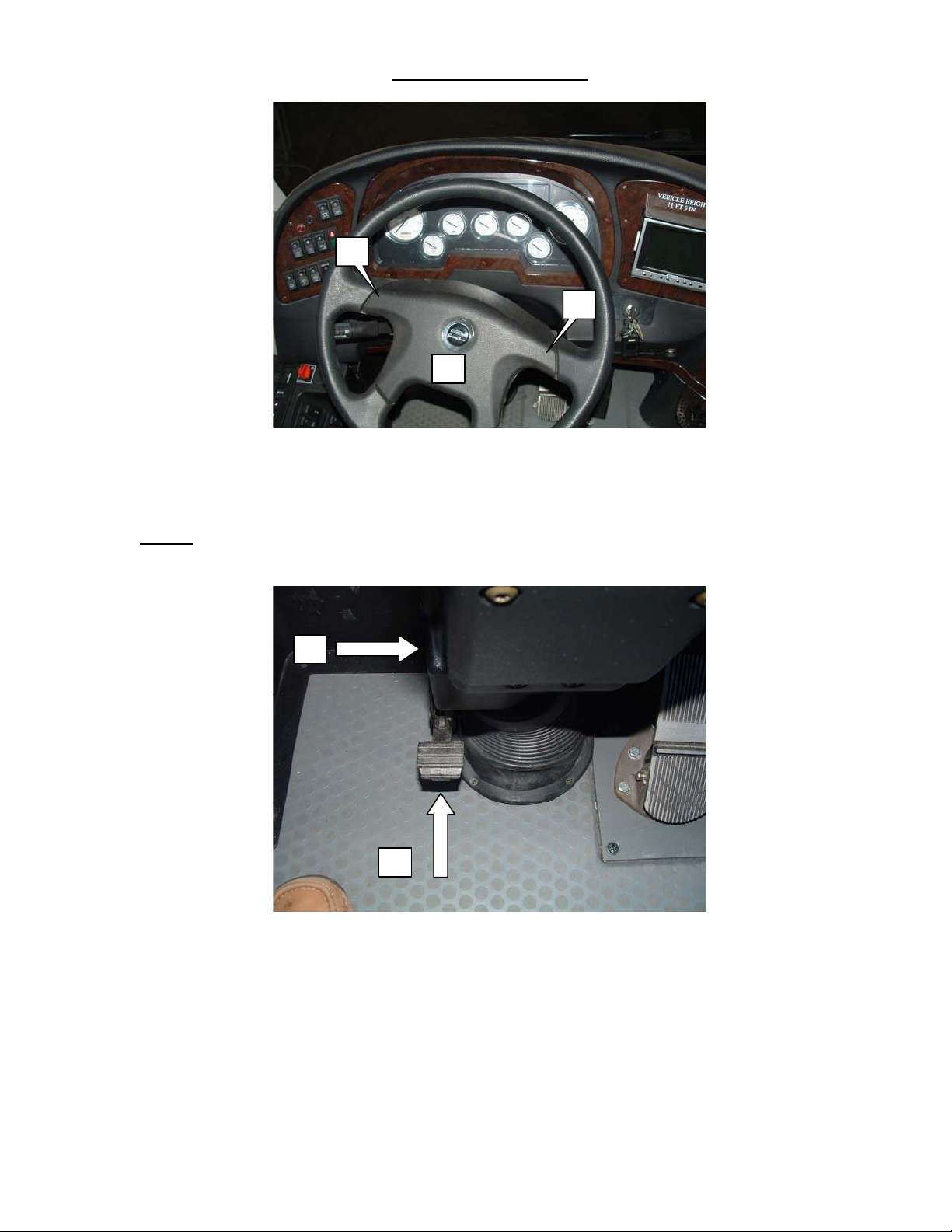

DASHBOARD

The instrument cluster, steering wheel, switch cluster, and warning lamp cluster

are located directly in front of the driver. This area comprises the main information

and control center for the operator.

2 3

1

7

8

1. Switch cluster #1 7. Steering wheel

2. Instrument Cluster 8. Multifunction stalk

3. Warning lamps cluster

4. Rear view camera monitor

5. Ignition Switch

6. 12V Power socket

4

5

6

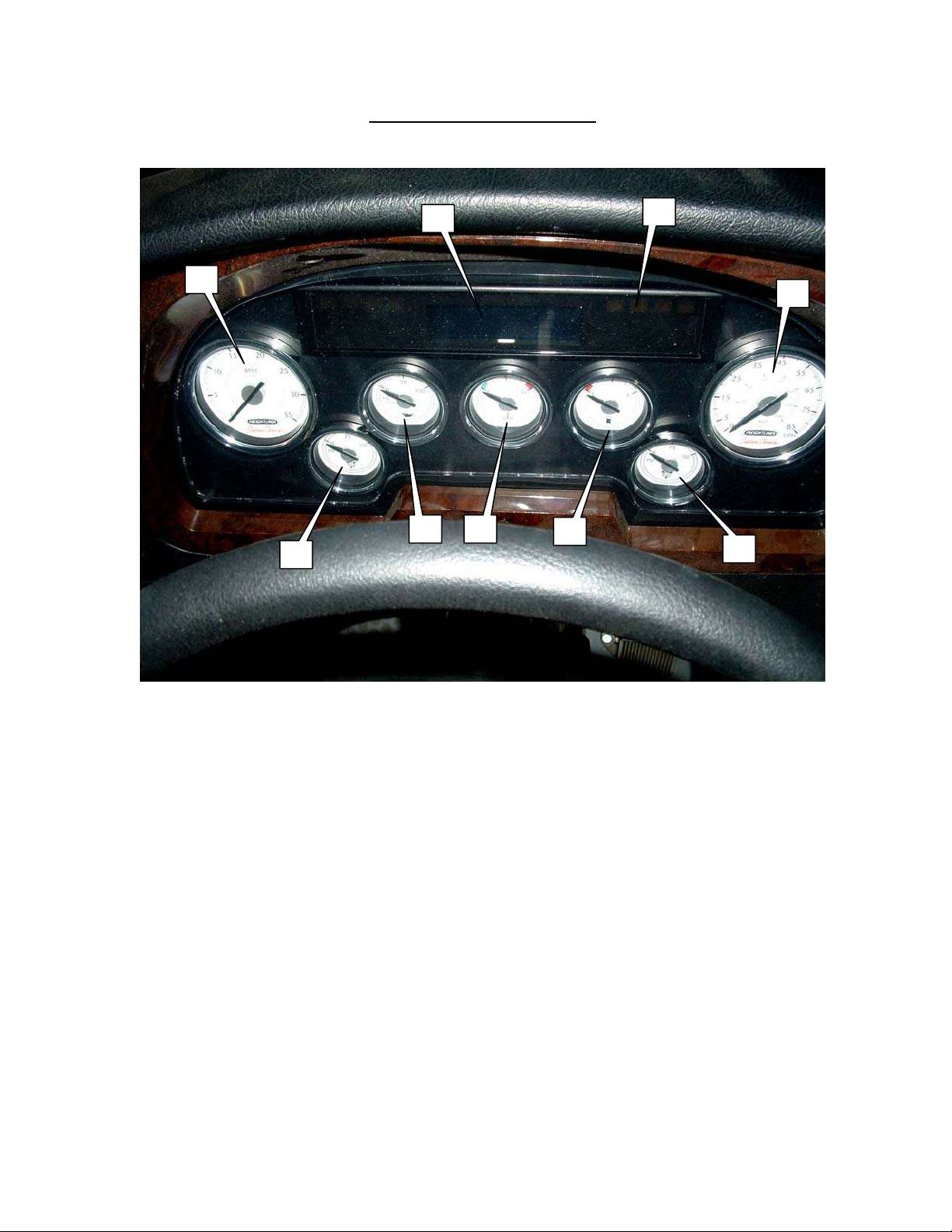

INSTRUMENT CLUSTER

1

2

8

3 4

9

7

5

6

1. Tachometer 7. Speedometer

2. Air Pressure – Main Tank 8. Service Information Display

3. Oil Pressure 9. Warning Lamps (Left & Right sides

of Lamp / Diagnostic panel)

4. Coolant Temperature

5. Fuel Tank Level

6. Air Pressure – Auxiliary Tank

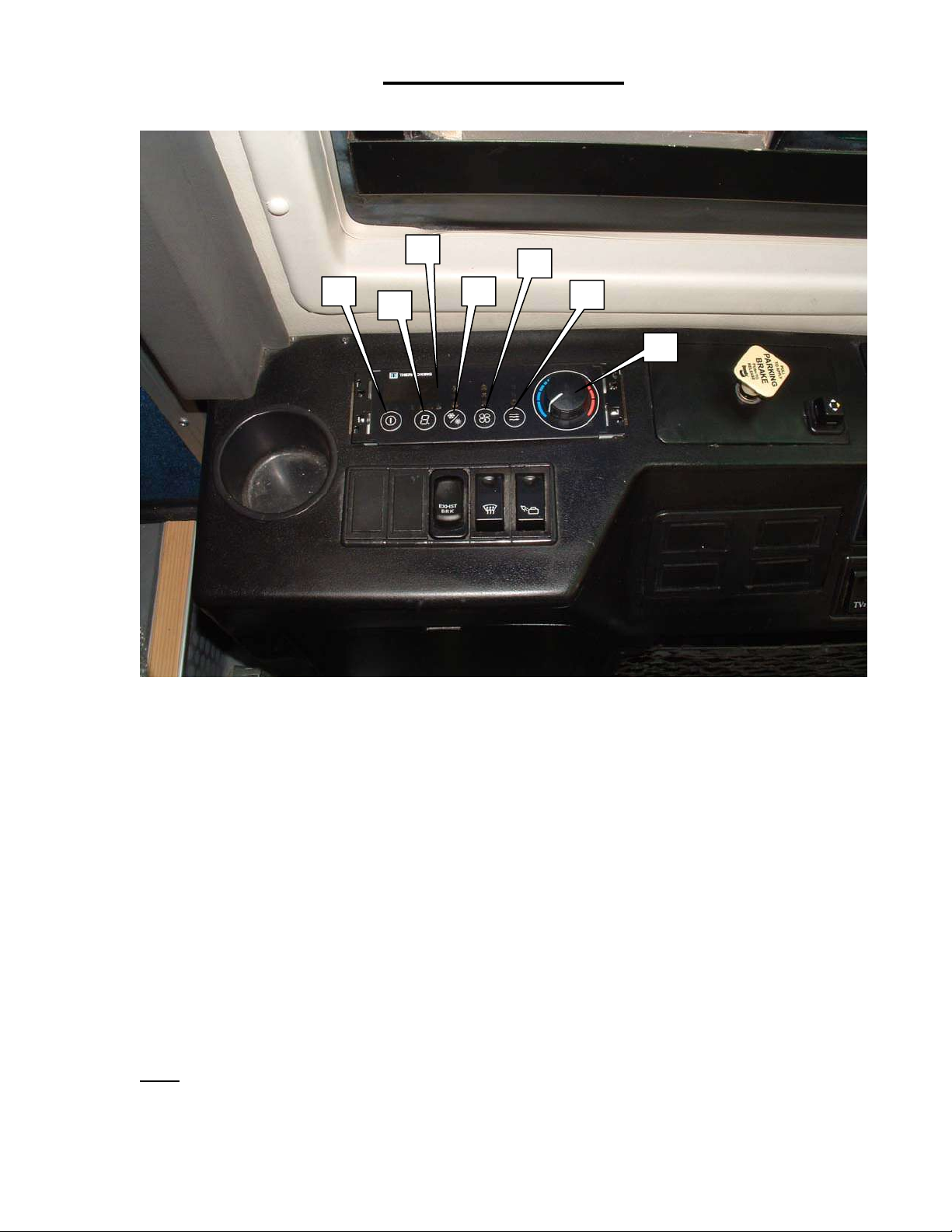

CONTROLS CONSOLE

The driver’s controls console is located on the left side of the driver’s compartment,

below the roadside front window. Most of the major controls for the vehicle are situated

within easy reach of the operator at this location.

4

5

3

2

1

6

7

8

9

10

11

12

1. Interior climate controller (A/C) 7. Switch clusterl #2

2. Parking Brake 8. Side storage pocket

3. Service Information Display Menu Switch 9. Luggage compartment lights

4. Transmission shift control 10. Windshield defroster fan and heat

5. Auxiliary heater ON/OFF switch 11. Exhaust brake ON/OFF

6. Mirror controls 12. Cup holder

13- Manual regeneration switch ( Exhaust Aftertreatment) Engine EPA 2007

13

A flashing AFTERTREATMENT DIESEL PARTICULATE FILTER lamp indicates that the

aftertreatment diesel filter needs to be regenerated at the next possible opportunity. Engine power

may be reduced automatically.

When this lamp is flashing, the operator should:

1- Change to more challenging duty cycle , such as highway driving , for at least 20 minutes.

2- Perform a stationary regeneration. Follow all instructions from Cummins Owners Manual

ISB 6.7L CM2150 furbished with your Sunliner Coach Bus ( pag, 1-19 to 1-25) bulletin

4021601.

STEERING WHEEL

1

1

2

The steering wheel and column are adjustable for steering wheel angle and overall column

height. The center pad on the steering wheel can be pressed at the upper outside edges (1)

or at the center (2) to activate the horns.

NOTE: Do not turn the steering wheel all the way to the right with the entry door open – the

right front tire will contact the door frame if the wheels are fully turned to the right.

3

4

The steering column height is adjusted with the lever (3) on the left side of the steering

column, below the steering wheel. Pull up on the lever, then pull up or push down on the

steering wheel to set the best height for the operator. Release the lever to lock it back into

position.

Adjust the steering wheel angle by pressing down on the pedal (4) at the base of the

column. Move the steering wheel into the best position and release the pedal to lock into

position.

NEVER adjust the steering while the vehicle is in motion or under power.

CLIMATE CONTROL

ThermoKing™ Climate Control Panel

The vehicle’s interior environment is managed by the ThermoKing™ Controller located on the side

control console. The controller functions by balancing heat, cooling, airflow, and intake air for maximum

comfort.

1. Power (On / Off)

2. Display Selector (Off / On / Interior Temp. / Exterior Temp.)

3. Display

4. Cooling / Heating Selector (Off / Heat / A/C)

5.

Fan Speed (Low / Medium / High)

6. Vent Position (Closed–Recirculate / 1/2 / Full Open)

7. Temperature Level (Blue zone = colder, Red zone = warmer)

Note: Do not power ON the A/C unless the engine is running.

Loading...

Loading...