Stallion CWI-B1512 Owner's Manual

OWNER S MANUAL

’

MODEL

NO:

CWI-B1512

15” WOOD WORKING BANDSAW

SAFETY RULES

WARNING: FAILURE TO FOLLOW THESE RULES MAY RESULT IN

SERIOUS PERSONAL INJURY.

1. FOR YOUR OWN SAFETY, READ INSTRUCTION MANUAL BEFORE

OPERATING THE TOOL. Learn the tool’s application and limitations as well

as the specific hazards peculiar to it.

2. KEEP GUARDS IN PLACE and in working order.

3. ALWAYS WEAR EYE PROTECTION. Wear safety glasses. Everyday

eyeglasses only have impact resistant lenses; they are not safety glasses.

Also use face or dust mask if cutting operation is dusty. These safety glasses

must conform to ANSI Z87.1 requirements.

Note: Approved glasses have Z87 printed or stamped on them.

4. REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to

see that keys and adjusting wrenches are removed from tool before turning it

on.

5. KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

6. DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use power tools in

damp or wet locations, or expose them to rain. Keep work area well lighted.

7. KEEP CHILDERN AWAY. All visitors should be kept safe distance from work

area.

8. MAKE WORKSHOP KID PROOF with padlocks, master switches, or by

removing starter keys.

9. DON’T FORCE TOOL it will do the job better and safer at the rate for which it

was not designed.

10.USE RIGHT TOOL. Don’t force tool or attachment to do a job for which it

was not designed.

SAFTEY RULES ...............................................................

ADDITIONAL SAFETY RULES .........................................

GROUNDING INSTRUCTIONS ........................................

WARNING PLATES ...........................................................

TABLE ADJUSTMENT .......................................................

TABLE ALIGNMENT ..........................................................

FENCE ALIGNMENT .........................................................

BLADE CHANGES ............................................................

WHEEL ALIGNMENT .......................................................

FENCE INSTALL ...............................................................

FENCE ADJUSTMENT.......................................................

1

4

6

9

14

16

16

17

18

21

23

FEATURE .........................................................................

10

BODY PARTS BREAKDOWN ...........................................

BODY PARTS LIST ...........................................................

TABLE PARTS BRAKDOWN ............................................

TABLE PARTS LIST ..........................................................

S MODEL PARTS BREAKDOWN .....................................

S MODEL PARTS LIST .....................................................

26

28

29

30

31

25

FENCE ASSY PARTS BREAKDOWN ...............................

FENCE ASSY PARTS LIST ...............................................

WIRING DIAGRAM ............................................................

32

33

34

1

SAFETY RULES

WARNING: FAILURE TO FOLLOW THESE RULES MAY RESULT IN

SERIOUS PERSONAL INJURY.

1. FOR YOUR OWN SAFETY, READ INSTRUCTION MANUAL BEFORE

OPERATING THE TOOL. Learn the tool’s application and limitations as well

as the specific hazards peculiar to it.

2. KEEP GUARDS IN PLACE and in working order.

3. ALWAYS WEAR EYE PROTECTION. Wear safety glasses. Everyday

eyeglasses only have impact resistant lenses; they are not safety glasses.

Also use face or dust mask if cutting operation is dusty. These safety glasses

must conform to ANSI Z87.1 requirements.

Note: Approved glasses have Z87 printed or stamped on them.

4. REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking t

o

s

ee that keys and adjusting wrenches are removed from tool before turning it

on.

5. KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

6. DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use power tools in

damp or wet locations, or expose them to rain. Keep work area well lighted.

7. KEEP CHILDERN AWAY. All visitors should be kept safe distance from work

area.

8. MAKE WORKSHOP KID PROOF with padlocks, master switches, or by

removing starter keys.

9. DON’T FORCE TOOL it will do the job better and safer at the rate for which it

was not designed.

10.USE RIGHT TOOL. Don’t force tool or attachment to do a job for which it

was not designed.

2

21.CHECK DAMAGED PARTS. Before further use of the tool, a guard or other

part that is damaged should be carefully checked to determine that it will

operate properly and perform its intended function-check for alignment of

moving parts, binding of moving parts, breakage of parts, mounting, and any

other conditions that may affect its operation. A guard or other part that is

damaged should be properly repaired or replaced.

22.DIRECTION OF FEED. Feed work into a blade or cutter against the direction

of rotation of the blade or cutter only.

23.NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF.

Don’t leave tool until it comes to a complete stop.

24.MAME SURE TOOL IS DISCONNECTED from power supply while motor is

being mounted, connected or reconnected.

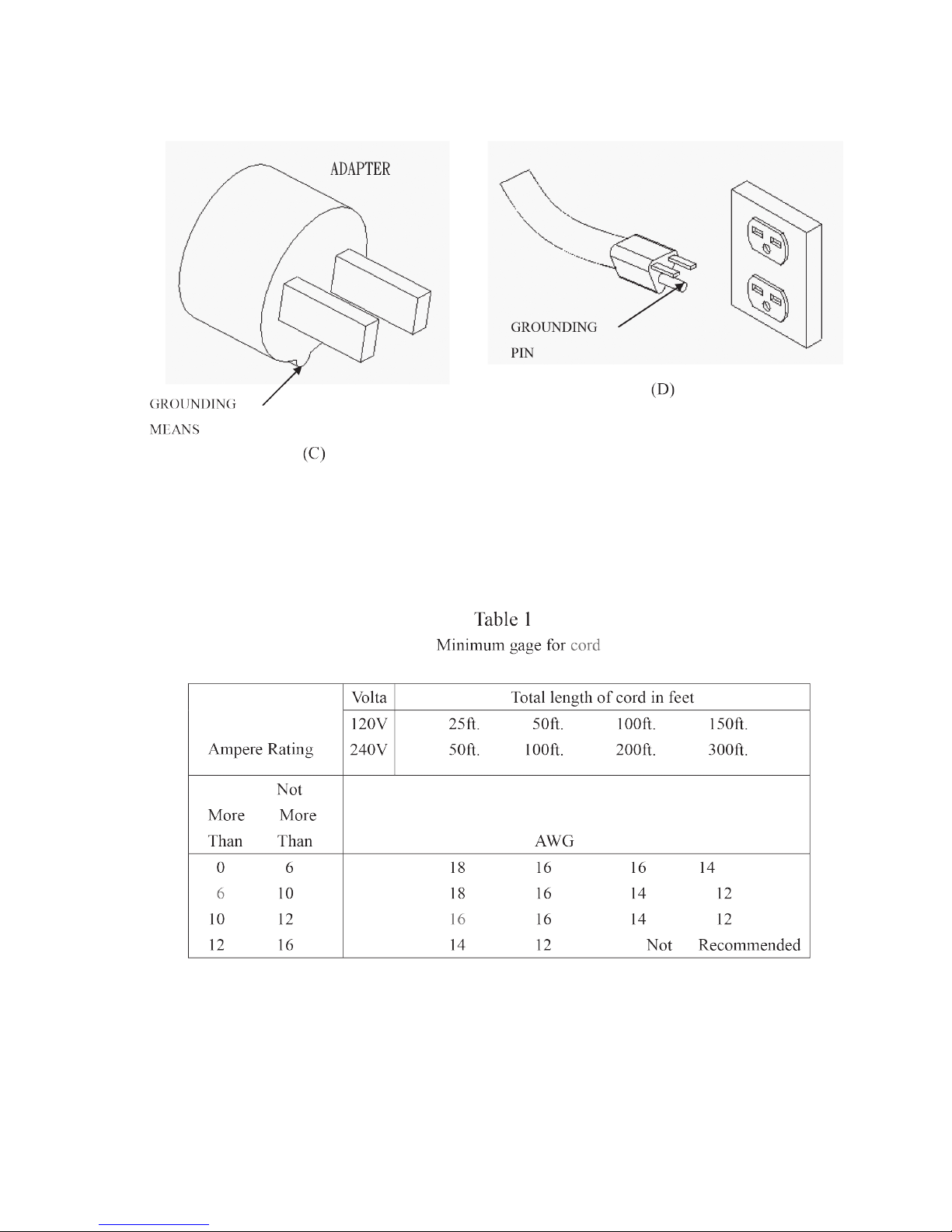

11.USE PROPER EXTENSION CORD. Make sure your extension cord is in

g

ood condition. When using an extension cord, be sure to use one heavy

enough to carry the current your product will draw. An undersized cord will

cause a drop in line voltage resulting in loss of power and overheating. Table

1 shows the correct size to use depending on cord length and nameplate

ampere rating. If in doubt, use the next heavier gage. The smaller the gage

number, the heavier the cord.

12.WEAR PROPER APPAREL Do not wear loose clothing, gloves, neckties,

rings, bracelets, or other jewelry which may get caught in moving parts.

Nonslip footwear is recommended. Wear protective hair covering to contai

n

long hair.

11.USE PROPER EXTENSION CORD. Make sure your extension cord is in

good condition. When using an extension cord, be sure to use one heavy

enough to carry the current your product will draw. An undersized cord will

cause a drop in line voltage resulting in loss of power and overheating. Table

1 shows the correct size to use depending on cord length and nameplate

ampere rating. If in doubt, use the next heavier gage. The smaller the gage

number, the heavier the cord.

12.WEAR PROPER APPAREL Do not wear loose clothing, gloves, neckties,

rings, bracelets, or other jewelry which may get caught in moving parts.

Nonslip footwear is recommended. Wear protective hair covering to contain

long hair.

13.ALWAYS USE SAFETY GLASSES. Also use face or dust mask if cutting

operation is dusty. Everyday eyeglasses only have impact resistant lenses,

they are NOT safety glasses.

14.SECURE WORK. Use clamps or a vise to hold work when practical. It’s safer

than using your hand and it frees both hands to operate tool.

15.DON’T OVERREACH. Keep proper footing and balance at all times.

16.MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best and

safest performance. Follow instructions for lubricating and changing

accessories.

17.DISCONNECT TOOLS before servicing; when changing accessories, such

as blades, bits, cutters, and the like.

18.REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure switch is

in off position before plugging in.

19.USE RECONNENDED ACCESSORIES. Consult the owner’s manual for

recommended accessories. The use of improper accessories may cause risk

of injury or persons.

20.NEVER STAND ON TOOL Serious injury could occur if the tool is tipped or if

the cutting tool is unintentionally contacted.

3

21.CHECK DAMAGED PARTS. Before further use of the tool, a guard or other

part that is damaged should be carefully checked to determine that it will

operate properly and perform its intended function-check for alignment of

moving parts, binding of moving parts, breakage of parts, mounting, and any

other conditions that may affect its operation. A guard or other part that is

damaged should be properly repaired or replaced.

22.DIRECTION OF FEED. Feed work into a blade or cutter against the direction

of rotation of the blade or cutter only.

23.NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF.

Don’t leave tool until it comes to a complete stop.

24.MAME SURE TOOL IS DISCONNECTED from power supply while motor is

being mounted, connected or reconnected.

4

15. Make relief cuts before cutting long curves.

16. Do not cut material that is too small to be safely supported.

17. Support long heavy work from the floor.

18. Before leaving the machine, make sure the work area is clean.

19. Important: When the tool is not in use , the switch should be in the “OFF”

position and the power cord disconnected.

20. Do not remove jammed cutoff pieces until blade has stopped.

ON-OFF SWITCH PADLOCK – To safeguard the band saw from unauthorized

operation and to avoid accidental starting by children or other not qualified to use,

the use of padlock is required. To lock out the on – off switch, open the padlock,

insert through the hole of the switch on button and close the padlock. Place the

key in a location that is inaccessible to children and other not qualified to use the

tool.

SWITCH WITH KEY – The switch key must be inserted into the switch before

saw can operate. To lock the switch in the OFF position, remove the switch key

from the switch. Place the key in a location that is inaccessible to children and

others not qualified to use the tool.

SAVE THESE INSTRUCTIONS

ADDITIONAL SAFETY RULES FOR BAND SAWS

1. If you are not thoroughly familiar with the operation of band saws, obtain

advice from your supervisor, instructor or other qualified person.

2. Follow all wiring codes and recommended electrical connections. Make

certain that the tool is properly grounded.

3. Make all adjustments with the power “OFF”

4. Always maintain proper adjustment of blade tension, blade guides, and blade

support bearings.

5. Avoid awkward hand positions. A sudden slip could allow the hand to contact

the blade.

6. Do not attempt to saw stock that does not have a flat surface, unless a

suitable support is used.

7. Make sure blade is not contacting the workpiece before turning on the power

switch.

8. Always keep hands and fingers away from the blade when the machine is

running.

9. Hold workpiece firmly against table and feed into blade at a moderate speed.

10. Made sure that the saw blade teeth point downward toward the table.

11. Adjust upper guide to just clear work piece.

12. Disconnect machine from the power source when making repairs.

13. Replace all guards after servicing.

14. Turn off band saw if the material is to be backed out of an uncompleted cut.

5

15. Make relief cuts before cutting long curves.

16. Do not cut material that is too small to be safely supported.

17. Support long heavy work from the floor.

18. Before leaving the machine, make sure the work area is clean.

19. Important: When the tool is not in use , the switch should be in the “OFF”

position and the power cord disconnected.

20. Do not remove jammed cutoff pieces until blade has stopped.

ON-OFF SWITCH PADLOCK – To safeguard the band saw from unauthorized

operation and to avoid accidental starting by children or other not qualified to use,

the use of padlock is required. To lock out the on – off switch, open the padlock,

insert through the hole of the switch on button and close the padlock. Place the

key in a location that is inaccessible to children and other not qualified to use the

tool.

SWITCH WITH KEY – The switch key must be inserted into the switch before

saw can operate. To lock the switch in the OFF position, remove the switch key

from the switch. Place the key in a location that is inaccessible to children and

others not qualified to use the tool.

6

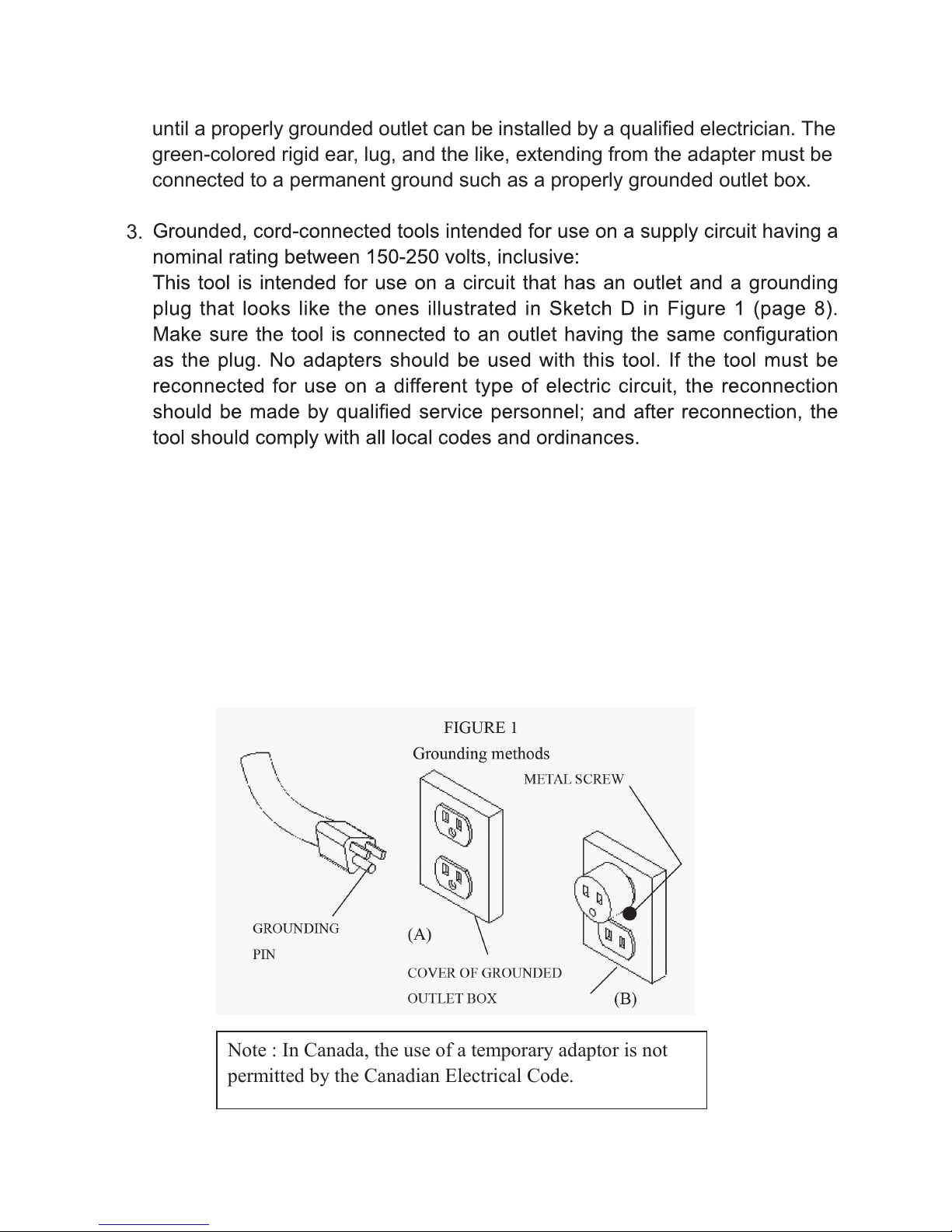

until a properly grounded outlet can be installed by a qualified electrician. The

green-colored rigid ear, lug, and the like, extending from the adapter must be

connected to a permanent ground such as a properly grounded outlet box.

3. Grounded, cord-connected tools intended for use on a supply circuit having a

nominal rating between 150-250 volts, inclusive:

This tool is intended for use on a circuit that has an outlet that looks like the

one illustrated in Sketch D in Figure 1. The tool has a grounding plug that

looks like the plug illustrated in Sketch D in Figure 1. Make sure the tool is

connected to an outlet having the same configuration as the plug. No adapter

is available or should be used with this tool. If the tool must be reconnected

for use on a different type of electric circuit, the reconnection should be made

by qualified service personnel; and after reconnection, the tool should comply

with all local codes and ordinances.

Note : In Canada, the use of a temporary adaptor is not

permitted by the Canadian Electrical Code.

GROUNDING

PIN

COVER OF GROUNDED

OUTLET BOX

METAL SCREW

(A)

(B)

FIGURE 1

Grounding methods

GROUNDING INSTRUCTIONS

1. All grounded, cord-connected tools:

In the event of a malfunction or breakdown, grounding provides a path of

least resistance for electric current to reduce the risk of electric shock. This

tool is equipped with an electric cord having an equipment-grounding

conductor and a grounding plug.

The plug must be plugged into a matching outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

Do not modify the plug provided – if it will not fit the outlet, have the proper

outlet installed by a qualified electrician.

Improper connection of the equipment-grounding conductor can result In a

risk of electric shock. The conductor with insulation having an outer surface

that is green with or without yellow stripes is the equipment-grounding

conductor. If repair or replacement of the electric cord or plug is necessary, do

not connect the equipment-grounding conductor to a live terminal.

Check with a qualified electrician or service personnel if the grounding

instructions are not completely understood, or if in doubt as to whether the

tool is properly grounded.

Use only 3-wire extension cords that have 3-prong grounding plugs and

3-pole receptacles that accept the tool’s plug.

Repair or replace damaged or worn cord immediately.

2. Grounded, cord-connected tools intended for use on a supply circuit having a

nominal rating less than 150 volts:

This tool is intended for use on a circuit that has an outlet that looks like the

one illustrated in Sketch A in Figure 1. The tool has a grounding plug that

looks like the plug illustrated in Sketch A in Figure 1. A temporary adapter,

which looks like the adapter illustrated in Sketches B and C, may be used to

connect this plug to a 2-pole receptacle as shown in Sketch B if a properly

grounded outlet is not available. The temporary adapter should be used only

7

until a properly grounded outlet can be installed by a qualified electrician. The

green-colored rigid ear, lug, and the like, extending from the adapter must be

connected to a permanent ground such as a properly grounded outlet box.

3. Grounded, cord-connected tools intended for use on a supply circuit having a

nominal rating between 150-250 volts, inclusive:

This tool is intended for use on a circuit that has an outlet that looks like the

one illustrated in Sketch D in Figure 1. The tool has a grounding plug that

looks like the plug illustrated in Sketch D in Figure 1. Make sure the tool is

connected to an outlet having the same configuration as the plug. No adapter

is available or should be used with this tool. If the tool must be reconnected

f

or use on a different type of electric circuit, the reconnection should be made

by qualified service personnel; and after reconnection, the tool should comply

with all local codes and ordinances.

Note : In Canada, the use of a temporary adaptor is not

permitted by the Canadian Electrical Code.

GROUNDING

PIN

COVER OF GROUNDED

OUTLET BOX

METAL SCREW

(A)

(B)

FIGURE 1

Grounding methods

8

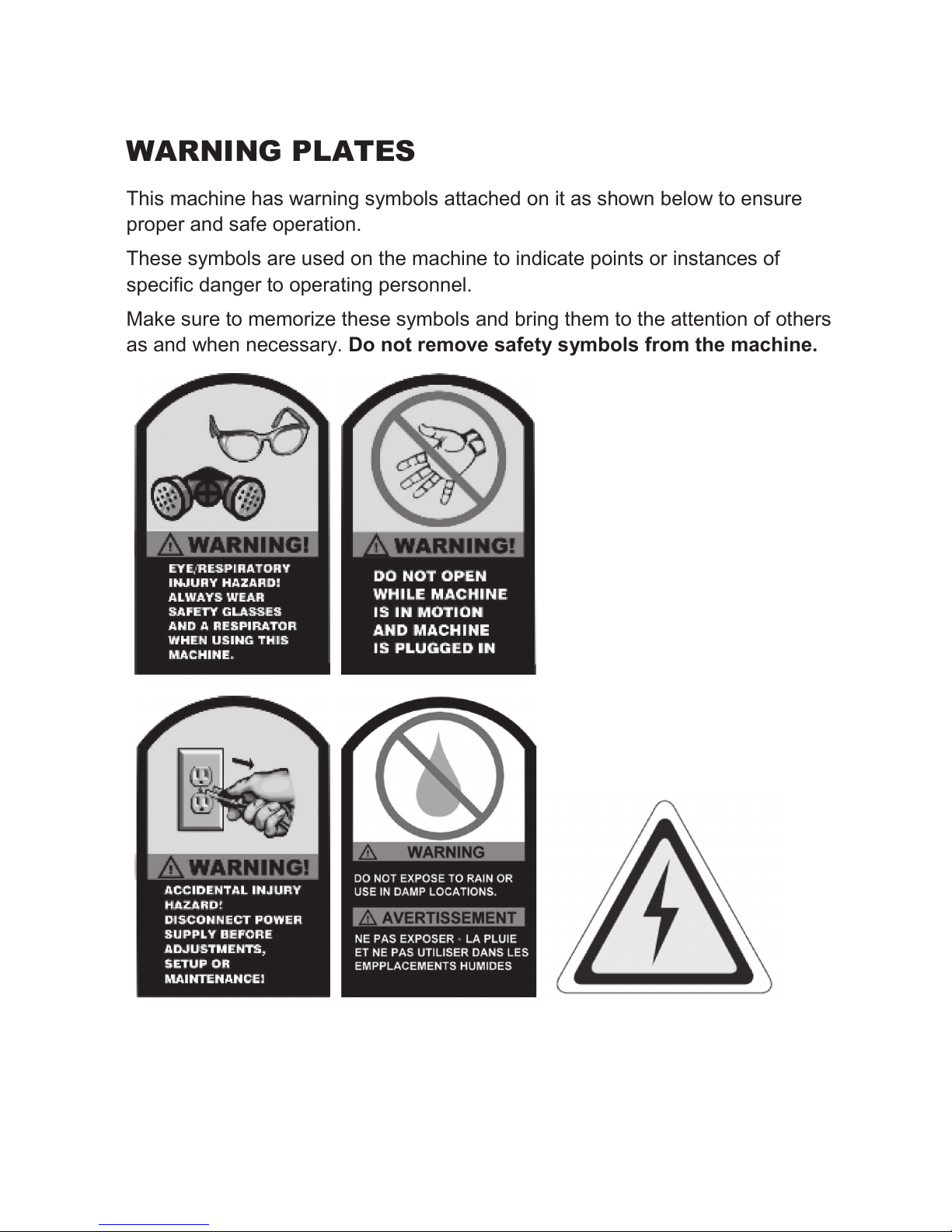

WARNING PLATES

This machine has warning symbols attached on it as shown below to ensure

proper and safe operation.

These symbols are used on the machine to indicate points or instances of

specific danger to operating personnel.

Make sure to memorize these symbols and bring them to the attention of others

as and when necessary. Do not remove safety symbols from the machine.

9

WARNING PLATES

This machine has warning symbols attached on it as shown below to ensure

proper and safe operation.

These symbols are used on the machine to indicate points or instances of

specific danger to operating personnel.

Make sure to memorize these symbols and bring them to the attention of others

as and when necessary. Do not remove safety symbols from the machine.

Loading...

Loading...