Stallion CWI-B1412 Setup And Operation Manual

Setup and Operation Manual

Stallion CWI-B1412

Features

• Gold Anodized Dovetail Ceramic Blade Guides

• Optional Dual Ball Bearing Blade Guides

• Deluxe Easy Glide Ball Bearing Fence

• Bright Light LED Viewing Strip

• Robust Cast Iron Table Trunnion Bracket

• Cast Iron 14” Wheels

• Quick Release Blade Tension

• Blade Tracking View Window

• One Piece Welded Steel Frame for Rigidity

• Dual Voltage Motor with Overload Protection

Specications

• Blade Length: 112”

• Blade Capacity: 1/8”–3/4”

• Blade Speed: 3250 FPM

• Table tilt range: –5° to 45°

• Table Size: 16” x 20”

• Floor to Table Height: 36.5”

• Throat: 13.5”

• Max Height of Cut: 12”

• Fence: Steel w/ anodized aluminum sides, T-style

• Dust port diameter: 4”

• Motor speed: 1725 RPM

• Floor Space: 33” x 30” x 72”

• Shipping weight: 253 lbs

• Motor (pre-wired 120V): 1.75 HP, 120/240V 14/7 A

Thank you for choosing this CWI Woodworking Technologies model B1412 14" Floor Model 1.5 HP Band-

saw. This saw has been carefully tested and inspected before shipment and if properly used and maintained,

will provide you with years of reliable service. For your safety, as well as to ensure optimum performance

please read this manual before assembling, installing and operating the unit.

This manual is not a substitute for formal woodworking instruction. If you are not sure about the safety of

performing a certain operation or procedure, do not proceed until you can conrm, from knowledgeable and

qualied sources, that it is safe to do so. Keep this manual for future reference.

CWI Woodworking Technologies

1608 St. James Street, Winnipeg, MB

Canada R3H 0L2

1-888-389-4752 Ext 101 • 1-204-783-6867

Five Year Limited Warranty:

All tools sold by CWI Woodworking Technologies used for hobby, or educational applications are warranted

for a period of 5 years (60 months) from the date of purchase. CWI Woodworking Technologies agrees to

repair or replace any part or component, which upon examination, proves to be defective in either workmanship or material to the original purchaser during this 5-year warranty period, subject to the “conditions and

exceptions” as listed below. This warranty may not be transferred.

To le a claim:

To le a claim under our Standard 5-year Limited Warranty all defective parts, components or machinery

must be returned freight or postage prepaid to CWI’s main warehouse or your closest CWI dealer for inspection and approval for replacement.

A copy of the original proof of purchase must be sent with the return of the product being claimed for warranty. Include information clearly stating the model and serial number of the tool and an explanation of the

complaint or defect in material or workmanship.

Conditions and Exceptions:

This coverage is extended to the original purchaser only. This warranty does not apply to electrical components, CNC machinery, defects due directly or indirectly to misuse, abuse, negligence, accidents, damage in handling or transport, repairs, alterations, lack of maintenance or normal wear and tear. Under no

circumstances will CWI be liable for incidental or consequential damages resulting from defective products.

All other warranties, expressed or implied, whether of merchantability, tness for purpose, or otherwise are

expressly disclaimed by CWI. This warranty does not cover products used for commercial or industrial purposes. This limited warranty does not apply to accessory items such as blades, drill bits, sanding discs or

belts and other related items. Repairs made without the written consent of CWI Woodworking Technologies

will void all warranty.

CNC machinery, electrical components or tools used for commercial or industrial or purposes are warranted

for a period of one year from date of original purchase.

Warranty Information

Table Of Contents

Warranty ...........................................................2

Safety Rules ...........................................................4

Electrical Requirements

Grounding Instructions ................................................5

Circuit Capacity ...........................................................5

Converting the Motor to 240V.......................................5

Extension Cords ...........................................................5

Introduction ............................................................6

Identication of Main Parts and Components .........6

Unpacking

List of Contents ..........................................................7

Additional Tools Required .............................................7

Bandsaw Assembly

Initial Cleaning ............................................................8

Mounting the Table .......................................................8

Installing the Table Insert .............................................. 9

Installing the Fence

Installing the Fence Brackets .......................................9

Installing the Fence Rails ...........................................10

Measuring Tape

Installing the Measuring Tape ..................................... 10

Installing the Blade

Installing a Bandsaw Blade ........................................11

Removing a Bandsaw Blade ......................................11

Blade Orientation ........................................................12

Tensioning the Blade

Tension Scale ......................................................... 12

Turning Tension On/O ...............................................12

Checking Tension .......................................................12

Adjusting Blade Tracking

Checking Tracking ......................................................13

Adjusting Blade Tracking ............................................13

Table Stop Adjustment

Setting the Table Stop Bolt .........................................13

Setting the Table Tilt Pointer .......................................13

Squaring the Table

Squaring the Blade to the Miter Slot ...........................14

Squaring the Fence

Squaring the Fence to the Miter Slot ..........................14

Adjusting Fence Alignment ......................................... 14

Adjusting the Fence Height ........................................14

Guide Alignment

Guide Depth from Gullet .............................................15

Guide Distance from Blade.........................................15

Thrust Bearing Adjustment .........................................15

Dust Collector Connection

Collecting to a Dust Collector .....................................16

Ball Bearing Guides (optional accessory)

Guide Depth from Gullet .............................................16

Guide Distance from Blade.........................................16

Thrust Bearing Adjustment .........................................17

Basic Controls

On/O Switch .........................................................17

Starting the Saw .........................................................17

Stopping the Saw .......................................................17

Guard Height Adjustment ...........................................17

Table Tilt Adjustment...................................................18

Basic Operation

Rip Cutting ..........................................................18

Resawing ..........................................................18

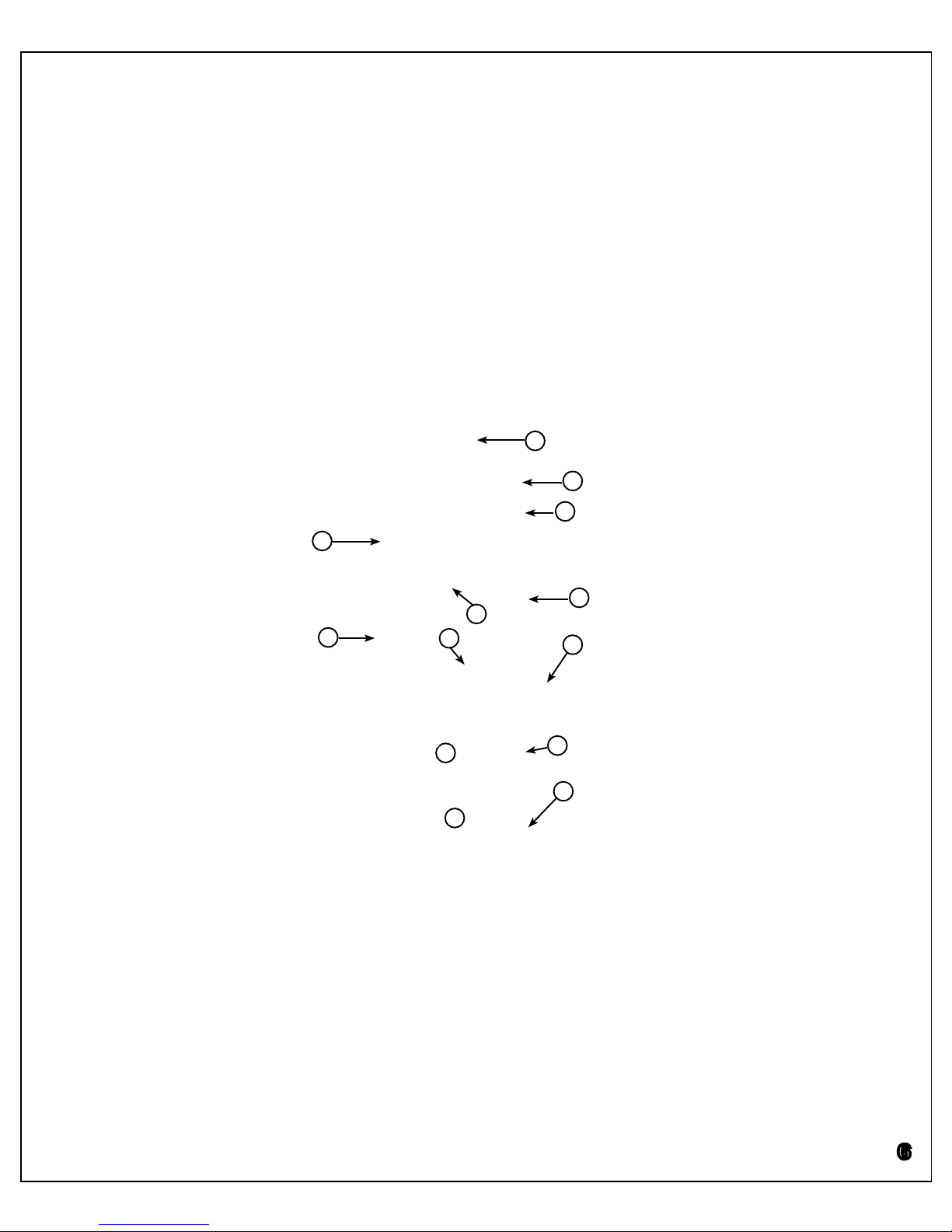

Adjusting for Drift ........................................................18

Measuring Drift ..........................................................19

Cross Cutting ..........................................................19

Bevel Cutting .........................................................19

Cutting Curves .........................................................19

Radius Chart ..........................................................19

Maintenance

Blades ..........................................................20

Guide Bearings .....................................................20

Wheel Tires ..........................................................20

Lower Wheel Brush ..............................................20

Motor Belt ..........................................................20

Parts List and Diagrams .................................... 21-25

To help ensure safe operation, take a moment to learn the machine’s applications and limitations, as well as po-

tential hazards. CWI Woodworking Technologies disclaims any real or implied warranty and holds itself harmless

for any injury that may result from improper use of its equipment.

Rules for Safe Operation

15. Use suitable support when cutting stock that does not

have a at surface. Always hold stock rmly against table.

16. Do not cut long stock without adequate outfeed support.

17. Avoid working from awkward or off balance positions.

Do not overreach while cutting, and keep both feet on the

oor.

18. Keep guards in place and in working order. If a guard

must be removed for maintenance or cleaning, be sure it is

properly reattached before using the saw again.

19. Never leave the machine running when not in use.

20. Use of parts and accessories NOT recommended by

CWI may result in equipment malfunction or risk of injury.

21. Never stand on machinery. Serious injury could result

if the tool is tipped over or if the blade is unintentionally

contacted.

22. Always disconnect tool from power before servicing or

changing accessories such as blades, or before performing any maintenance, cleaning or adjustments, or if the

machine will be left unattended.

23. Make sure that switch is in the OFF position before

plugging in the power cord.

24. Make sure the tool is properly grounded. If equipped

with a 3-prong plug it should be used with a three-pole

receptacle. Never remove the third prong.

25. Do not use this saw for other than its intended use. If

used for other purposes, CWI disclaims any real implied

warranty and holds itself harmless for any injury, which

may result from that use.

1. Do not operate the saw when tired, distracted, or under

the effects of drugs, alcohol or any medication that impairs

reexes or alertness.

2. The working area should be well lit, clean, and free of

debris.

3. Keep children and visitors at a safe distance when the

saw is in operation; do not permit them to operate the saw.

4. Childproof and tamper proof your shop and all machinery with locks, master electrical switches and switch keys,

to prevent unauthorized or unsupervised use.

5. Give your work your undivided attention. Even a momentary distraction can lead to serious injury.

6. Fine particulate dust is a carcinogen that can be

hazardous to health. Work in a well-ventilated area and

whenever possible use a dust collector and wear eye, ear

and respiratory protection.

7. Do not wear loose clothing, gloves, bracelets, neck-

laces, or other jewelry while the saw is in operation.

8. Be sure that tools, scrap, drinks and other clutter are

removed from the table surface before operating.

9. Keep hands away from the blade and all moving parts.

Use a brush, not your hands, to clear away chips and dust.

10. Adjust and position upper and lower blade guides

before cutting. Upper guard should be 1/8” above material

to be cut.

11. Adjust blade tension and tracking before cutting.

12. Always use a clean, properly sharpened blade. Dirty

or dull blades are unsafe and can lead to accidents.

13. Ensure blade has reached full speed before cutting.

14. Bandsaw blade teeth must point down toward table.

4

BEFORE CONNECTING THIS SAW TO THE POWER SUPPLY, VERIFY THAT THE SUPPLY VOLTAGE MATCHES THAT OF

THE MOTOR. INCORRECT SUPPLY VOLTAGE CAN RESULT IN SERIOUS INJURY TO THE USER AND DAMAGE TO THE MA-

CHINE. IF YOU ARE UNSURE OF THE SUPPLY OR EQUIPMENT VOLTAGE, CONTACT A QUALIFIED ELECTRICIAN BEFORE

ATTEMPTING TO USE THE SAW. DO NOT EXPOSE THIS SAW TO RAIN OR USE IT IN WET OR DAMP LOCATIONS.

Electrical Requirements

If you are unsure about whether or not your receptacle

is grounded, check with a qualied electrician or service

person.

Circuit Capacity

Make sure that the circuit used to power your saw is

properly sized to handle the saw and any other equipment that is powered by the circuit. If the circuit breaker

trips regularly, equipment connected to the circuit is

drawing more amperage than the breaker can handle.

Move some equipment to another circuit or have a

licensed electrician install a higher capacity circuit. If the

circuit is not overloaded and the breaker continues to

trip when the saw is used, there may be a fault with the

saw’s motor. Contact a licensed electrician or CWI.

Converting the Saw to 240V

The motor is pre-wired for use with a 120VAC power

supply. The saw can be converted for use with 240V

single phase, but it is recommended that a qualied

electrician perform this conversion. Follow the wiring

diagram below to change the motor to 240V. It is also

recommended to change the saw’s plug to a NEMA

6-15P type plug to prevent accidental usage on a 120V

circuit.

Minimum Wire Size of Extension Cord

Equipment

Current

Rating

(Amperes)

Length of extension cord (feet)

115V 25 50 100 150

230V 50 100 200 300

Wire size (AWG)

5 or less 18 16 16 14

6-10 18 16 14 12

10-12 16 16 14 12

12-16 14 12

Not recommended

C

B

A

Grounding Instructions

In the event of an electrical malfunction or short circuit,

grounding reduces the risk of electric shock to the operator. The motor of this machine is wired for 120V and

is equipped with a 3-conductor cord (A) and a 3-prong

grounded plug (B) to t a matching grounding type receptacle (C).

Extension Cords

If you need to use an extension cord to power the saw,

always use a 3-prong extension cord with grounding pin

and a matching 3-prong receptacle. Repair or replace

a damaged extension cord or plug immediately. Make

sure the cord rating is suitable for the amperage listed

on the motor ID plate. An undersized extension cord

will cause a drop in line voltage resulting in loss of saw

power and dangerous overheating of the extension

cord. The table below shows the recommended minimum wire size for extension cord usage. The smaller

the number, the heavier the gauge.

5

240V

Motor

120V

Switch

Motor

To Plug

Overload

LED Strip

Switch

To Plug

Overload

LED Strip

6

Identication of Main Parts and Components

A- 14” Woodworking Bandsaw

B- Work Table

C- Rip Fence

D- On/O Switch

E- Quick Release Blade Tension Lever

F- 4” Dust Inlet

G- Gold Anodized Dovetail Ceramic Blade Guides

H- Rip Fence Locking Handle

I- Blade Tracking View Window

J- Wheel Door Lock Knobs

K- LED Worklight

L- 1.75 HP Motor

A

B

C

D

E

F

G

I

J

K

H

This saw has been designed for cutting solid wood as well as manufactured wood materials such as plywood, wood

panelling, particleboard, MDF, and other wood based products. This saw is not designed for cutting metals or any

other non-wood product.

This saw is designed for use with bandsaw blades having a width from 1/8” to 3/4”, and a length of 112”. With the

ceramic blade guides raised to their highest position and the table set at 90º, the maximum resaw capacity is 12”. The

work table can be tilted 5° to the left, and 45° to the right.

Pay close attention to the saw’s balance when lifting it; the saw is very heavy and could topple causing injury or machine damage. Use a forklift to lift the saw and ensure another person helps guide the machine into place. Once set,

the saw can be levelled and mounted to the oor or machine mounts for safety and stability.

Introduction

J

L

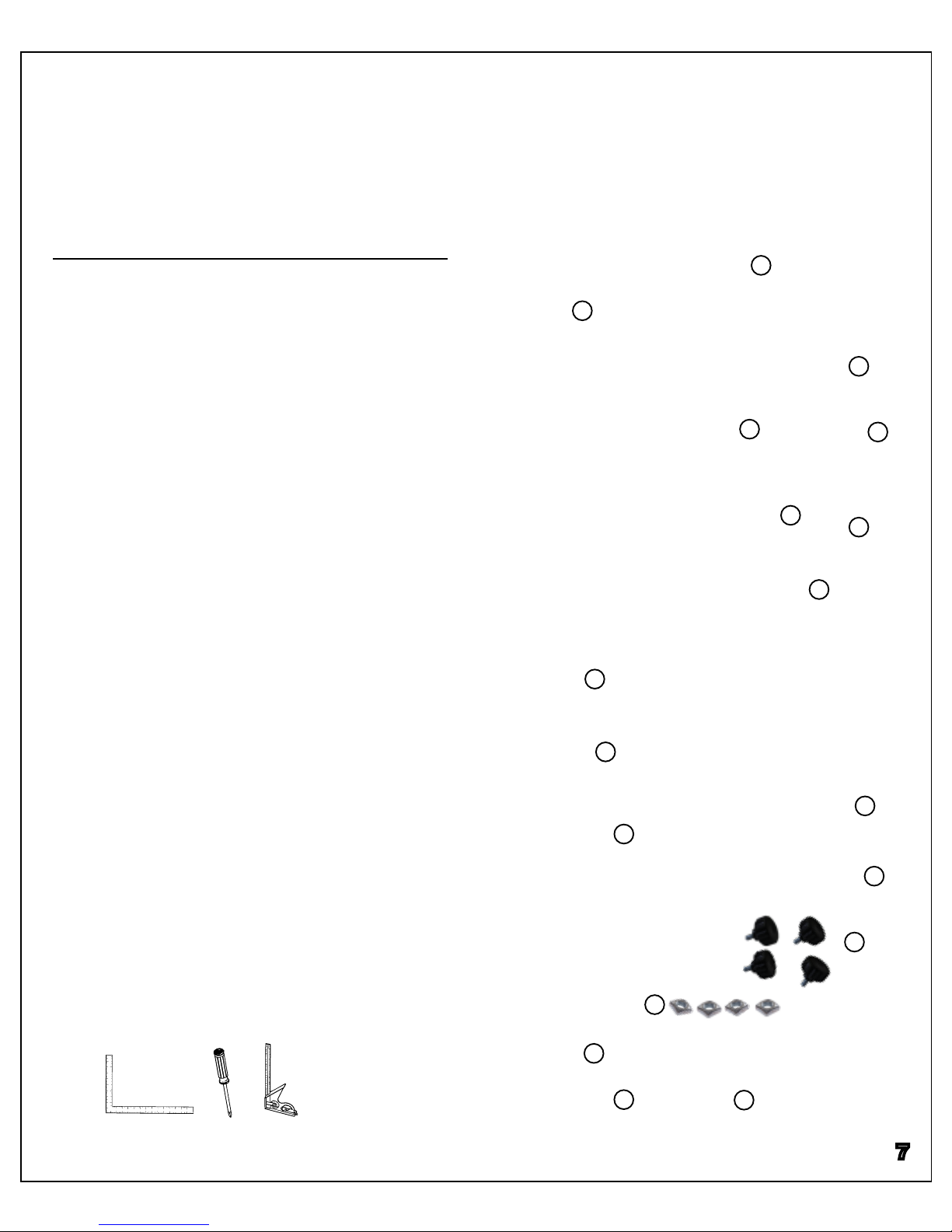

Carefully unpack and remove the saw and its components from the box and check for damaged or missing

items as per the list of contents below. Report any damaged or missing items to your CWI distributor immediately.

List of Contents Quantity

A- Saw ......................................................1

B- Table ......................................................1

C- Threaded lock knob .........................................2

D- Table insert ......................................................1

E- Table pin ......................................................1

F- Stamped wrench ..............................................1

G- Allen key ......................................................2

H- Hex head bolt & at washer .............................4

I- Front rail tube ....................................................1

J- Rear rail tube ....................................................1

K- Rip Fence ......................................................1

L- Large rail brackets............................................2

M- Small rail brackets ...........................................2

N- Lock knob with post .........................................4

O- Square nut ......................................................4

P- Measuring tape ................................................1

*Q- Upper ball bearing guide ................................1

*R- Lower ball bearing guide ................................1

*Optional Accessory

Additional Tools Required

In addition to the tools supplied with the saw, you will need the

following tools during assembly and setup:

• Phillips Head Screwdriver

• Machinist’s Square

• Straight Edge

• A Friend to Help Lift

Unpacking

^

j

h

A

D

B

E

J

N

H

K

O

7

C

F

M

G

I

Q

R

P

L

Initial Cleaning

The cast iron table is covered with a special protective coating to prevent rusting during shipping. Remove this coating using a rag and solvent (mineral

spirits or paint thinner). Most of the coating can be

carefully scraped o with a putty knife before solvent

cleaning. Take care not to scratch the table when

scraping.

Bandsaw Assembly

Do not apply solvent to painted metal or plastic surfaces as this could damage these surfaces. Once

the protective coating has been removed, a surface

protector such as paste wax should be applied to the

table for additional protection and to reduce friction

between the workpiece and table during operation.

Use a screwdriver and solvent soaked rag to clean

the coating out from the miter slots.

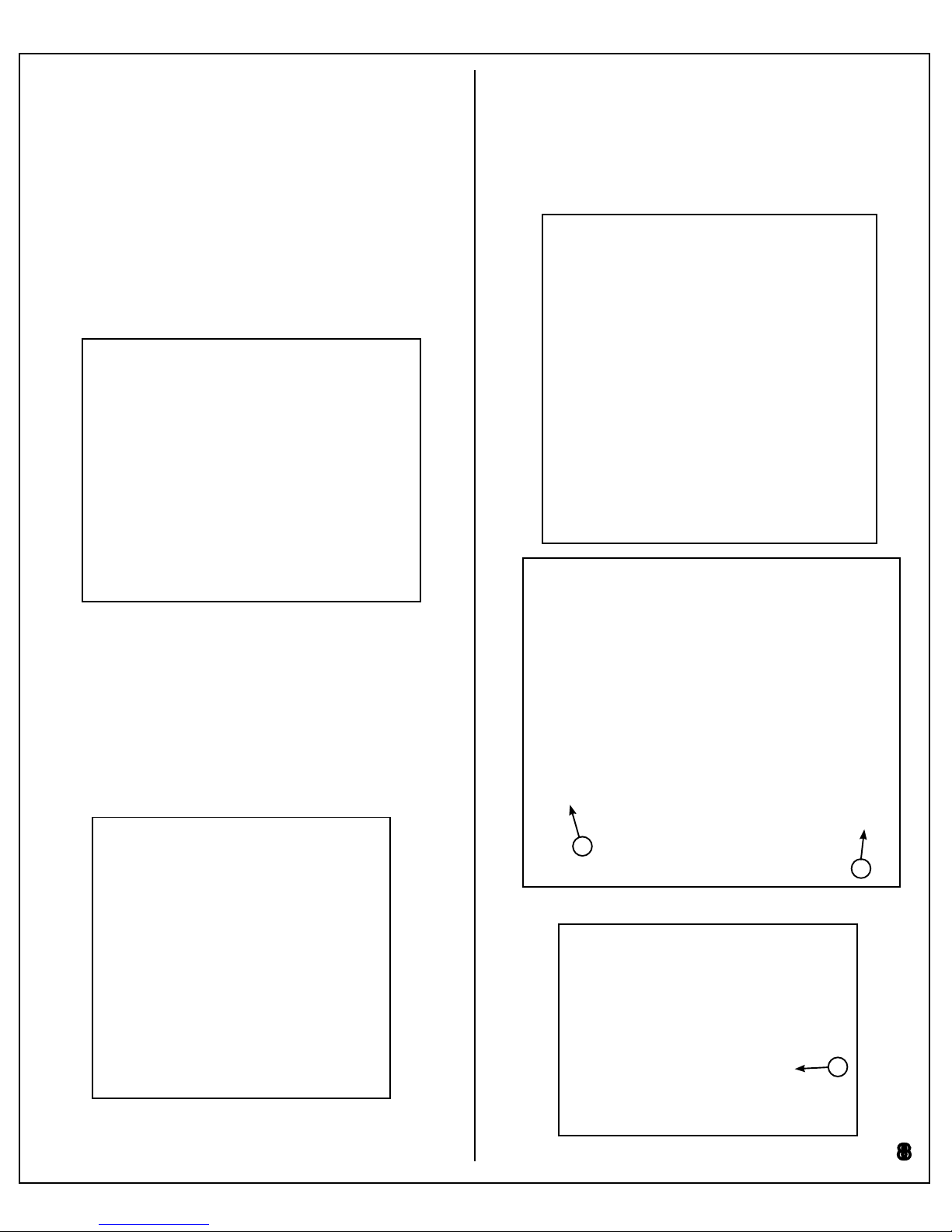

Mounting the Table

When the bandsaw table is installed, the trunnions on

the underside of the table (A) rest in the saw frame’s

trunnion supports (B), and the left side of the table rests

on the table tilt stop bolt (C).

8

A

A

C

B

B

To install the table, rst remove the table’s pin (D).

D

Loading...

Loading...