STALEX BS-712R Operation Manual

METAL CUTTING BAND SAW

Model: BS-712R

Specifications

Cutting Capacity: 7’’ Round (180mm)

7’’X12’’ Rectangle (180x300mm)

Blade Speed: 86-132-178-260 FPM 60Hz

72-110-148-217 FPM 50Hz

Blade Size: 3/4’’x0.032’’x93’’ (19X0.9X2360mm)

Operation Manual

SAFETY

1. Know your band saw. Read the operator’s Manual carefully. Learn the

operations, applications and limitations as well as the specific potential

hazards peculiar to this band saw.

2. This unit is equipped with a three prong (grounded) plug for your

protection against shock hazards and should be plugged directly into a

property grounded three prong receptacle. Where a two prong wall

receptacle is encountered. It must be replaced with a properly

grounded three prong receptacle in accordance with the National

Electrical Code and Local Codes and Ordinances.

3. Use only 3-wire extension cords that have 3-prong grounding type

plugs.

4. Replace or repair damaged or worn cord immediately.

5. Keep guards in place and in working order.

6. Be especially careful when using band saw in vertical position to keep

fingers and hands out of path of blade.

7. Wear ear protection if exposed to long periods of very noisy shop

operations.

8. Use safety goggles, hardhat and safety shoes. Also use face or dust

mask if cutting operation is dusty.

9. Wear proper apparel. No loose clothing or jewelry to get caught in

moving parts. Do not wear a tie or gloves.

10. Don’t overreach. Keep your proper footing and balance at all times.

11. Secure work. Always use the vise to hold work. Clamp securely. Never

handhold the work with saw in horizontal position.

12. Keep work area clean. Cluttered areas and benches invite accidents.

13. Avoid dangerous environment. Don not use the band saw in damp or

wet location. Keep work area well illuminated.

14. Don’t force tool. It will do the job better and safer at the rate for which it

was designed.

15. Disconnect power cord before adjusting and servicing and before

changing blade.

16. Safety is a combination of operator’s common sense and alertness at

all times when the saw is being used.

17. Never stand on tool. Serious injury could occur if the tool is tipped or if

the cutting tool is accidentally contacted.

18. Check damaged parts. Before further use of the tools, a guard or other

parts that it will operate to assure that it will operate properly

19. And perform its intend function-check for alignment of moving parts;

binding of moving parts, breakage of parts, mounting and any other

conditions that may affect its operation. A guard or other part that is

damaged should be properly repaired or replaced.

20. When moving the saw, ALWAYS have the head lowered to the

horizontal position.

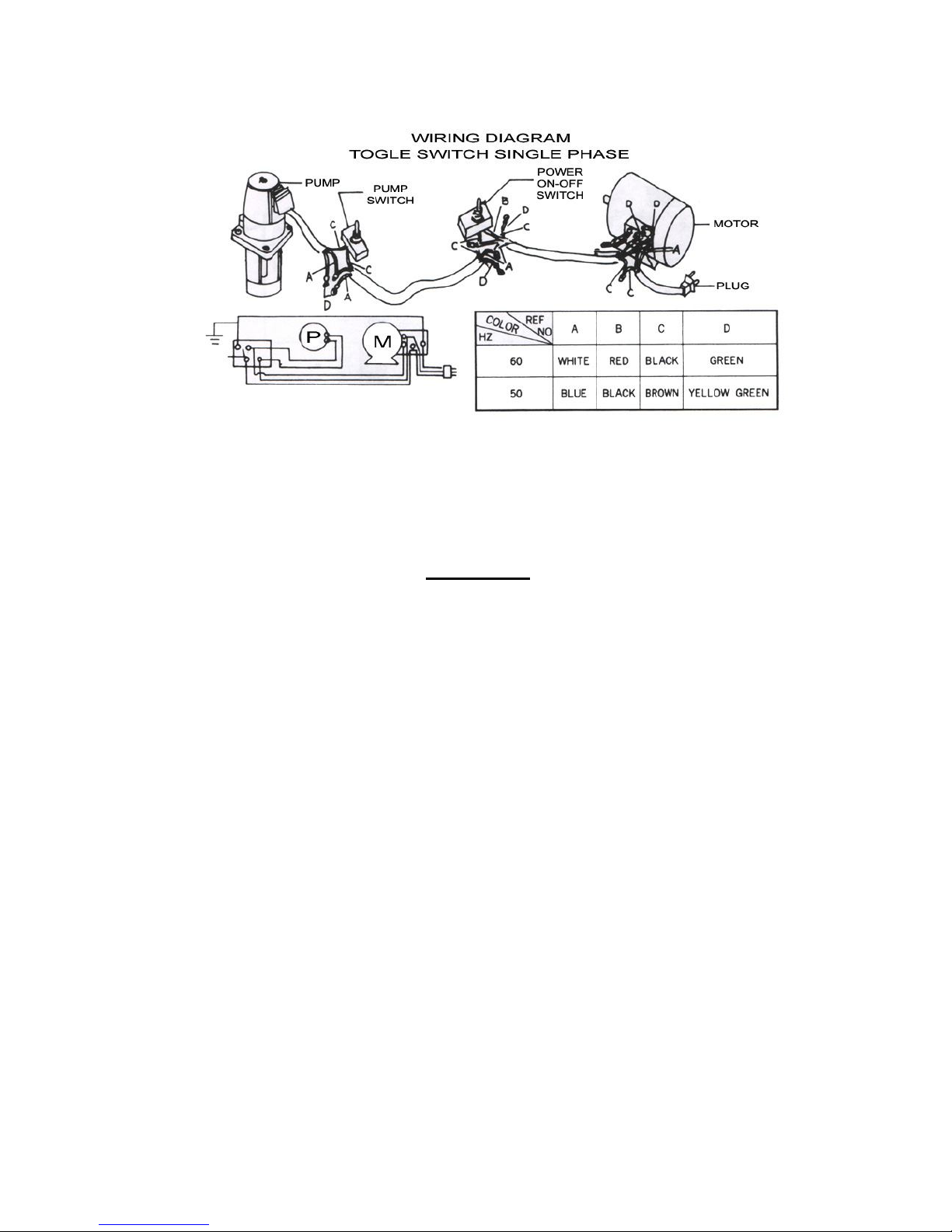

缺电路部分

IMPORTANT:

Coolant pump motor voltage must always be the same as machine motor

voltage.

ASSEMBLY

A 3/4 or 1 HP motor split phase or capacitor start is recommended for best

economical performance. Counter clockwise is required. Note that

rotation can be reversed by following directions given on terminal or

nameplate.

1. Assemble the motor Mounting plate to the head using the long bolt.

Note that the flat side of the plate faces up.

2. Assemble the guard plate to the head using the screw and lock washer

and the carriage bolt. Washer and wing nut are used to secure the

motor mounting plate to the guard plate through the slotted hole in the

guard plate. These components also serve to position and lock the

motor in place or proper speed/belt adjustment.

3. Place the spacer over the long bolt and secure it with the nut.

4. Secure the motor to the motor mounting plate with the four volts and

nuts. Note that the motor shaft is placed through the large opening in

the guard plate and must be parallel with the drive shaft.

5. Assemble the motor pulley, the smaller of the two provided to the

motor shaft. Note the larger diameter must be closest to the motor. Do

not tighten the set screw.

6. Assemble the driven pulley, the larger off the two provided to the

protruding drive shaft. Note the smaller diameter must be closest to the

bearing. Do not tighten the set screw.

7. Place the belt into one of the pulley groove and the other end into the

respective grooves of the second pulley.

8. Line up the belt and both pulleys such that the belt is running parallel in

the pulley grooves.

9. Tighten the set screws of both pulleys in this position.

10. Place the belt into proper pulley combination for proper blade speed.

See material cutting chart.

11. Adjust the position of the motor to obtain approximately 1/2’’

depression in the belt when applying pressure with your thumb.

12. Tighten the head screw holding the motor mounting plate to the guard

plate.

13. Connect the electrical harness to the motor terminal box. The motor

should be protected with a time delay fuse or circuit breaker with a

rated amperage slightly greater than the full-load amperage of the

motor.

INSTALLATION

The saw may be mounted on your own bench or stand. The rear end of

the saw must be mounted flush with the rear of the stand or bench to

permit vertical operation for this band saw. A steel your dealer for this

band saw. This stand has punched holes to effect easy assembly to the

base using eight standard bolts.

OPERATION

WORK SET UP

1. Raise the saw head to vertical position.

2. Open vise to accept the piece to be cut by rotating the wheel at the end

of the base.

3. Place work piece on saw bed. If the piece is long support the end.

4. Clamp work piece securely in vise

WORK STOP ADJUSTMENT

1. Loose the thumb holding the work stop casting to the shaft.

2. Adjust the work stop casting to the desired length position.

3. Rotate the work stop as close to the bottom of the cut as possible.

4. Tighten thumb screw.

5. Do not allow the blade to rest on the work while the motor is shut off.

CONVERTING FOR VERTICAL USE

Nothing, slitting, contour work may be done with the saw in the vertical

position in the following manner:

1. Rotate the head to the vertical position.

2. Assemble a 10’’x10’’ table (an option that may be purchased from your

dealer to the guide bar using the screws provided and the guide bar

knob.)

BLADE SPEEDS

When using your band saw always change the blade speed to best suit

the material being cut. The material cutting shaft given suggested settings

for several materials.

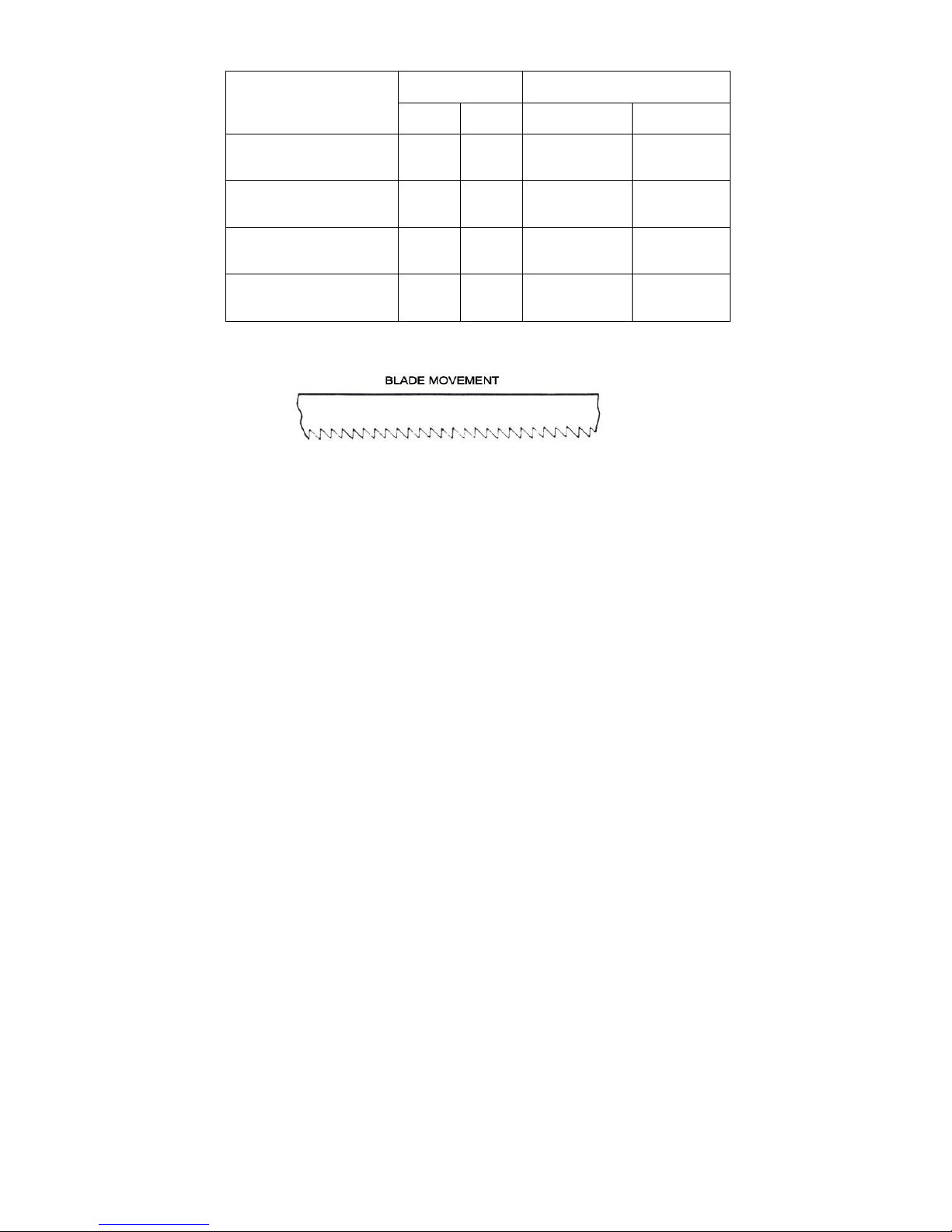

4 SPEED MATERIAL CUTTING CHART

Material

Speed F.P.M. Belt Groove Used

60Hz 50Hz Motor pulley Saw pulley

Tool, Stainless alloy

Steels, bearing bronze

86 72 Small Largest

Medium to high carbon 132 110 Medium Large

Low to medium carbon

Steels soft brass

178 148 Large Medium

Aluminum plastic 260 217 Largest Small

BLADE DIRECTION OF TRAVEL

Be sure the blade is assembled to the pulleys so that the vertical edge

engages the work piece first.

STARTING SAW

CAUTION: NEVER OPERATE SAW WITHOUT BLADE GUARDS IN

PLACE.

Be sure the blade is not in contact with the work when the motor is started.

Start the motor, allow the saw to come to full speed, and then begin the

cut by left the head down slowly onto the work. DO NOT DROP OR

FORCE. Let the weight of the saw head provide the cutting force. The

saw automatically shuts off at the end of the cut.

BLADE SELECTION

An 8-tooth per inch, general-use blade is furnished with this metal cutting

band saw. Additional blades in 4,6,8 and 10 tooth sizes are available. The

choice of the blade pitch is governed by the thickness of the work to be

cut; the thinner the work piece, the more teeth advised. A minimum of

three teeth should engage the work piece at all times for proper cutting. If

the teeth of the blade are so far apart that they straddle the work, severe

damage to the work piece and to the blade can result.

CHANGING BLADE

Raise saw head to vertical position and open the blade guards. Loosen

tension screw knob sufficiently to allow the saw blade to slip off the

wheels. Install the new blade with teeth slanting toward the motor as

follows:

1. Place the blade in between each of the guide bearings.

2. Slip the blade around the motor pulley (bottom) with the left hand and

hold in position.

3. Hold the blade taut against the motor pulley by pulling the blade

upward with the right hang which is placed at the top of the blade.

4. Remove left hand from bottom pulley and place it at the top aide of the

Loading...

Loading...