Stairs SD Series, SV Series, SVN Series, SC Series, SA Series Installation And Operating Instructions Manual

Submersible Pump

INSTALLATION AND

OPERATING INSTRUCTIONS

2

:

EC DECLARATION OF CONFORMITY

according to the following EC Directives

- Machinery Directive : 2006/42EC/ as amended by 98/37/EC

- Electromagnetic Compatibility Directive : 2004/108/EC

The undersigned, K. T. Hsien, representing STAIRS INDUSTRIAL CO., LTD. / NO.27, LANE

267, HUACHENG RD., SINJHUANG CITY, TAIPEI COUNTY 242, TAIWAN, R.O.C.. manufacturer,

declares that the machine described hereafter:

Electric Pump (1~, 3~, 50HZ, 60HZ)

Model :

Provided that it is used and maintained in accordance with the general accepted codes of good

practice and the recommendations of the instructions manual, meet the essential safety and

health requirements of the

Machinery Directive, and Electromagnetic Compatibility Directive.

For the most specific risks of this machine, safety and compliance with the essential

requirements of the Directive has been based on elements of:

EN 809, EN 60335-1, EN 60335-2-41, EN 61000-6-1:2007, EN 61000-6-3:2007

SD.., SV.., SVN.., SC.., SA.. series

Date: 11.01.2012

Signature

Qualification: Factory Manager

3

SD/SV/SVN/SC/SA Series Submersible Pumps

H

2

H

1

Installation

1.

Check

Insulation resistance

With the motor and cable (excluding the power supply cable) immersed in water, use a Megger to measure

the insulation resistance between ground and each phase of the motor, and again between each phase of

the motor. The Megger should indicate an insulation resistance of not

making the measurement, keep the power supply cable off the ground.

An

auxiliary

the

following before beginning

measurement:

pump

is

recommended

installation.

to

be kept on hand

in

case

of emergency.

less

than

20mega ohms

.

While

2. Installation-

(1) !

(2) This pump must not be installed on its

(3) Install the pump at a location in the tank

(4) If there is a flow of liquid inside the tank,

(5) Do not permit end of discharge piping to

(6) !

(7) For automatic pumps, install the floats as

WARNING

should cable be pulled while the pump is

being transported or installed.

Attach a chain or rope to the grip and

install the pump.

side or operated a dry condition. Ensure

that it is installed upright on a secure

base.

where there is the least turbulence.

support the piping where appropriate.

Install piping so that air will not be

entrapped. If piping must be installed in

such a way that air pockets are

unavoidable, install an air release valve

wherever such air pockets are most likely

to develop.

be submerged, as backflow will result

when the pump is shut down.

WARNING

have an automatic operating system

bump operating water level near the

minimum operating level as the automatic

cut-off switch incorporated inside the

motor will be activated. To avoid dry

operation, install an automatic operating

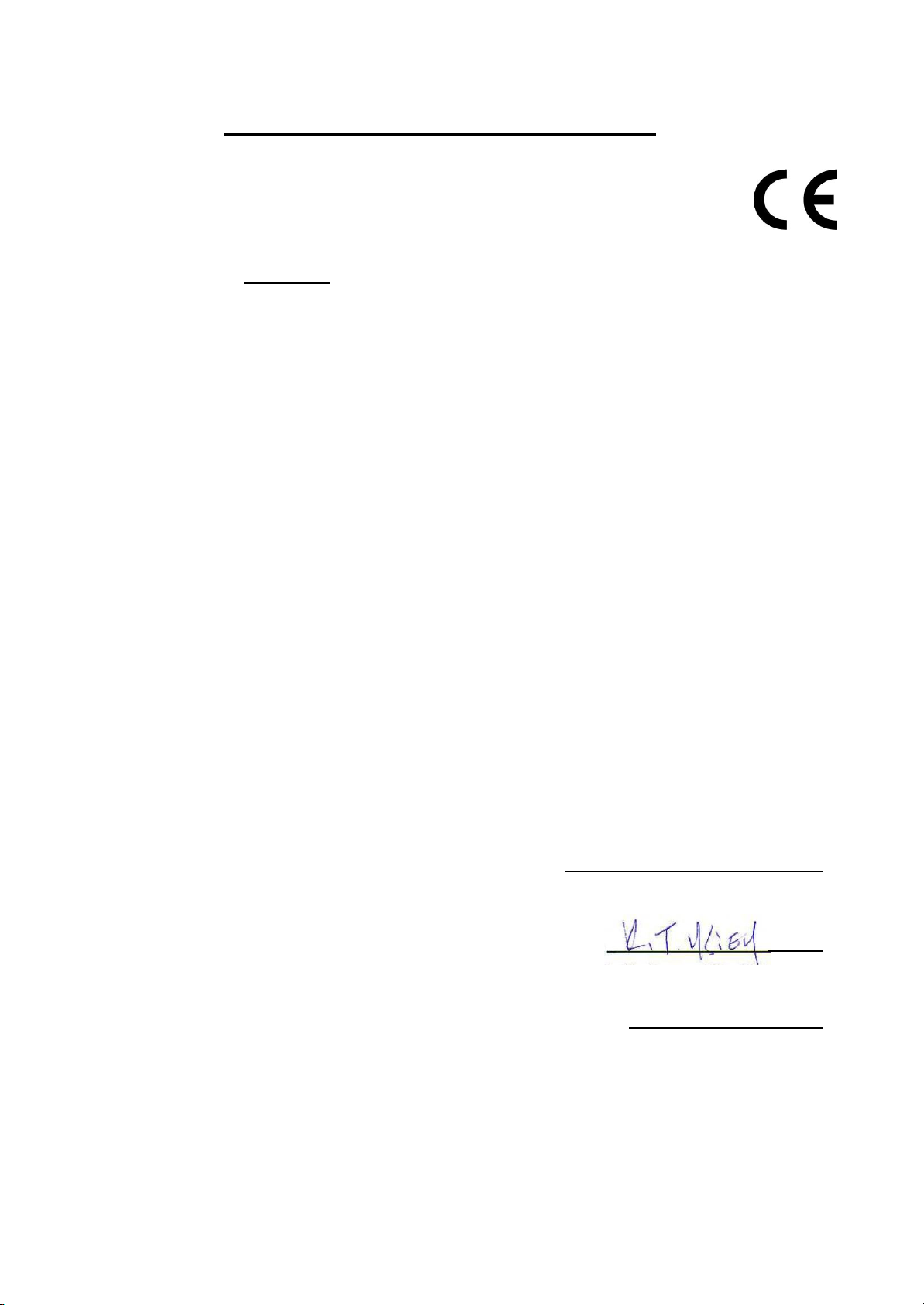

system, as shown in Fig-1 and maintain a

safe operating water level.

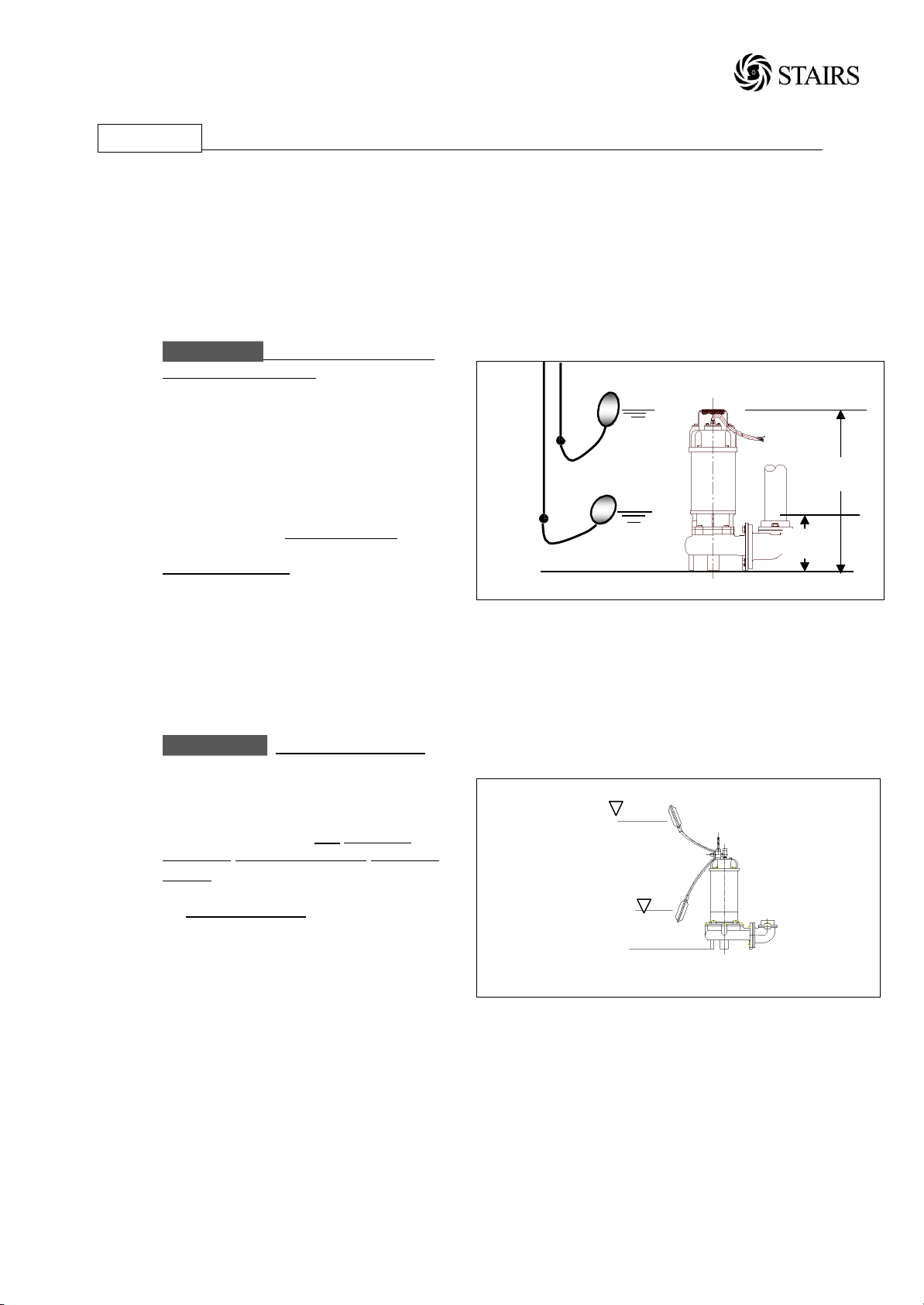

shown in Fig-2. The pump may not start

if a floats switch touches the wall of the

water tank or the piping. Install the floats

so that this will not happen.

: Under no circumstances

: Non-automatic pumps,

Fig-1

H1: Lowest water level (Motor flange)

H2: Operating water level

This must be above the top of the motor

Operating Water Level

Stop

Water Level

on

off

Fig-2

Loading...

Loading...