Stahlwille multipower MP100-1500 Instructions For Use Manual

7

GB

Instructions for use

1. Intended use

The MULTIPOWER torque multiplier may only be used

for tightening and loosening screw joints. It is not to be

used for lifting loads or for applying a permanent torque,

for example as a tensioning device. We shall not be

held liable for any damage, injury or interruptions

in operations resulting from non-observance of this

operating manual or improper use.

2. Description of the product

and intended use

The MP100-1500 is a compact torque multiplier tool that

enables screw joints to be tightened and loosened when

higher torques (up to 1500 N m) are required and simple

manual force is no longer effective. The MP100-1500

features a torque multiplier ratio of 1:5 and is particularly

well suited to use with fastener sizes between M20

and M30.

This MULTIPOWER tool is constructed symmetrically and

will generate a constant rotary drive motion in 8° steps if

oscillating 60° drive input is applied.

Angle controlled tightening of joints is easily achieved

thanks to the angle scale printed on the tool.

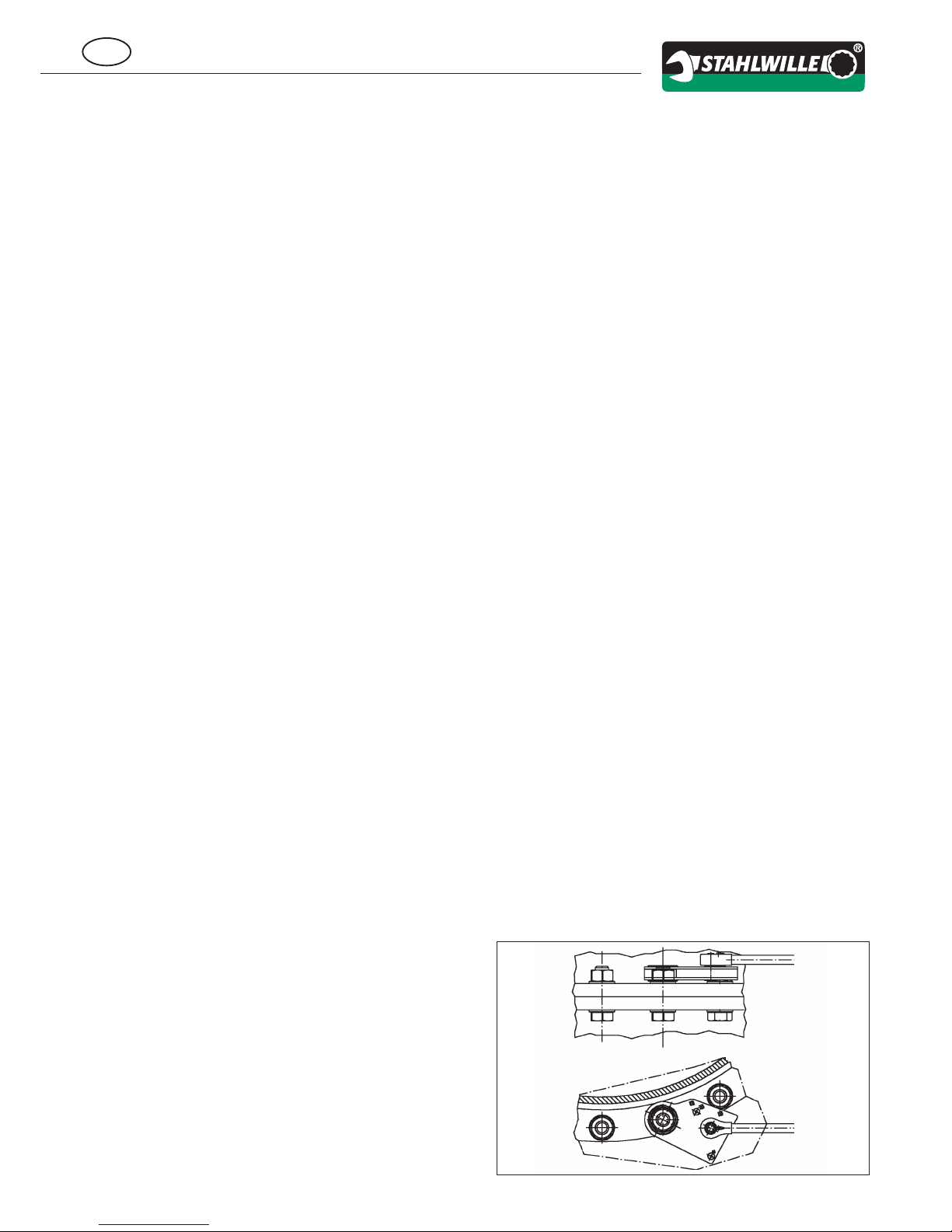

The directions of rotation for tightening and loosening

are marked on the MULTIPOWER tool. To reverse the

direction of rotation, simply turn the MULTIPOWER over.

3. Technical specifications

Max. output torque: 1500 Nm

Max. driving torque: 300 Nm

Torque transmission ratio: 1:5

Gearbox ratio: 5,62:1

Drive: mechanical via

1/2" square drive

Take-off: internal hex drive, size 41

Torque monitoring: with torque wrench

Angle monitoring: angle scale; 8° per

rocking input action

Change of direction: clockwise/anticlockwise

by turning the tool over

Non-return lock: ratchet pawl

Adjustment mechanism: continuous; ratchet

Hex inserts: sizes 30, 32, 36

+1" outer square drive

Max. weight of MULTIPOWER: 1,890 g

Weight of torque absorption arm:550 g

Max. head radius: R35

Dimensions: 165x105x30 mm

Torque absorption arm: 400 mm

(when attached)

4. Safety regulations

This tool has been manufactured in accordance

with all applicable safety regulations. Always use the

MP100-1500 in conjunction with a torque wrench to

provide power input.

The maximum input torque of 300 N m must never be

exceeded as otherwise the tool, in particular its ratchet

and lever mechanisms, may be damaged. Before using

the tools, check carefully to see that it is ready for use

and functioning correctly (refer to Section 6.3):

Warning: Using accessories and inserts other than those

recommended in this operating manual may lead to

malfunctioning of the tool and even cause injury.

Note: Repairs must always be carried out by qualified

experts using only original spares as otherwise there

may be an increased risk of injury to the user.

Never use MULTIPOWER tools or reduction adapters that

are worn or damaged. They must always perfectly fit the

nut or bolt to be tightened or loosened.

Danger: When using the MP100-1500, always wear

protective goggles.

5. Torque absorption

For the torque to be effectively transferred, the

MULTIPOWER must always be steadied. The steadying

action for the MULTIPOWER may be provided by the tool

itself or, for greater distances, using a torque absorption

arm.

Important: Note that the torque wrench will always rotate

in the opposite direction to that of the MULTIPOWER.

Warning: Never steady the MULTIPOWER against parts

that are loose or likely to give. The reactive force from the

MULTIPOWER might cause such parts to break off and

cause injury to people in the vicinity or damage to other

objects.

6. Using the MULTIPOWER

6.1 Analysing the tightening job:

• Tighten or loosen the joint?

• Clockwise or anticlockwise?

• What size is the fastener (M...)?

• What size spanner or insert is needed?

• Is there a suitable steady point for the torque

absorption arm?

• Measure the length of the arm required

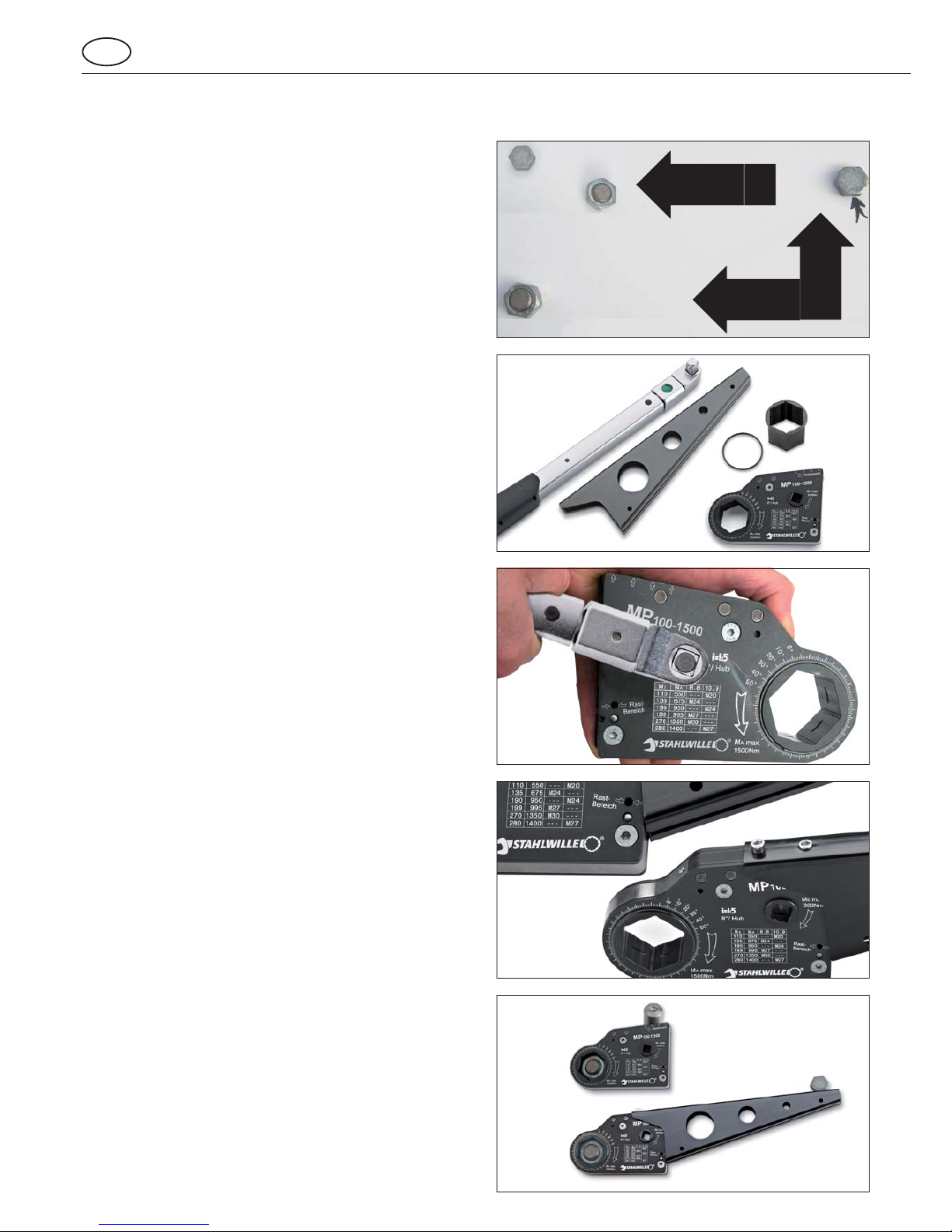

6.2 Get the required accessories together:

• Torque wrench with permanent

1

/2" square drive

• Reduction adapter, if size < 41.

• O-ring to secure the adapter

• Torque absorption arm, if steady distance

exceeds 140 mm.

• If necessary, additional spanner or wrench.

for the other end of a two-ended fastener.

6.3 Functional check of the MP100-1500:

• Check general state of the MP100-1500 torque

multiplier

➩ Any cracks, deformations, wear are not permitted.

• Using a torque wrench, move the drive back and

fore between the endstops (approx. 70°).

➩ Check that take-off wheel action and steps are

smooth.

➩ Oscillating, clearly audible pawl and ratchet

action.

6.4 Fitting the torque absorption arm:

• The arm is only necessary if the steady point is

more than 140 mm from the fulcrum.

➩ Put the torque absorption arm on as shown

and secure with the two M6 screws.

6.5 Positioning the MP100-1500 for

tightening/loosening:

• Place the MULTIPOWER on the fastener the right

way round for the required direction of rotation

(see arrows on housing).

• Swing the MULTIPOWER as far as the absorption arm

endstop (audible click as the ratchet re-engages).

• Set the cut-out value for the torque wrench in

accordance with the printed scale on the MP or the

table in Section 9.

➩ Input torque must be ≤ 300 N m.

• Fit the torque wrench into the input square drive and

fix it in the required position.

Fastener can be

tightened/loosened without

torque absorption arm

Fastener can be

tightened/ loosened without

torque absorption arm

8

GB

Instructions for use

Loading...

Loading...