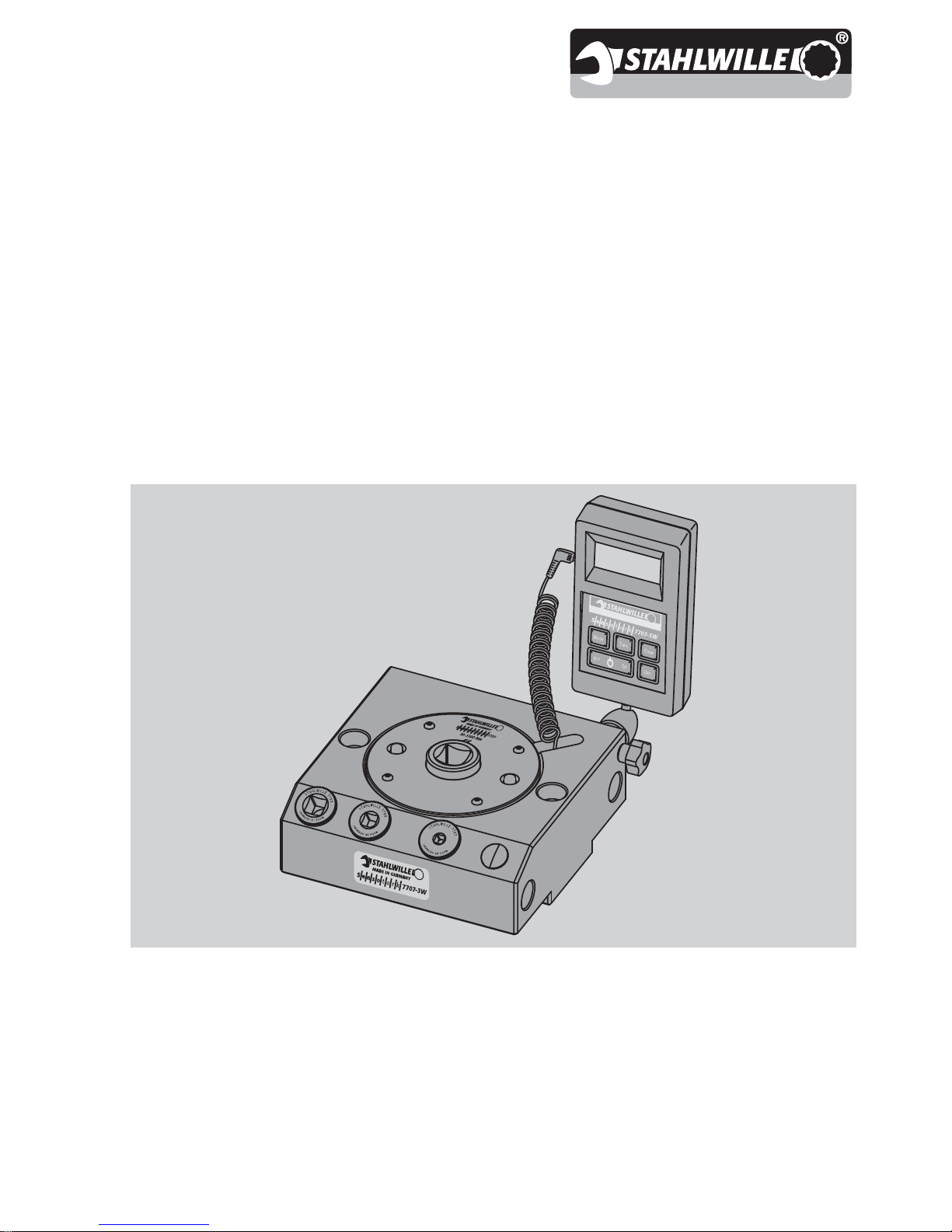

Stahlwille 7707-1-2W, 7707-1W, 7707-1-3W, 7707-2W, 7707-2-2W Operating Instructions Manual

...

Operating Instructions

STAHLWILLE

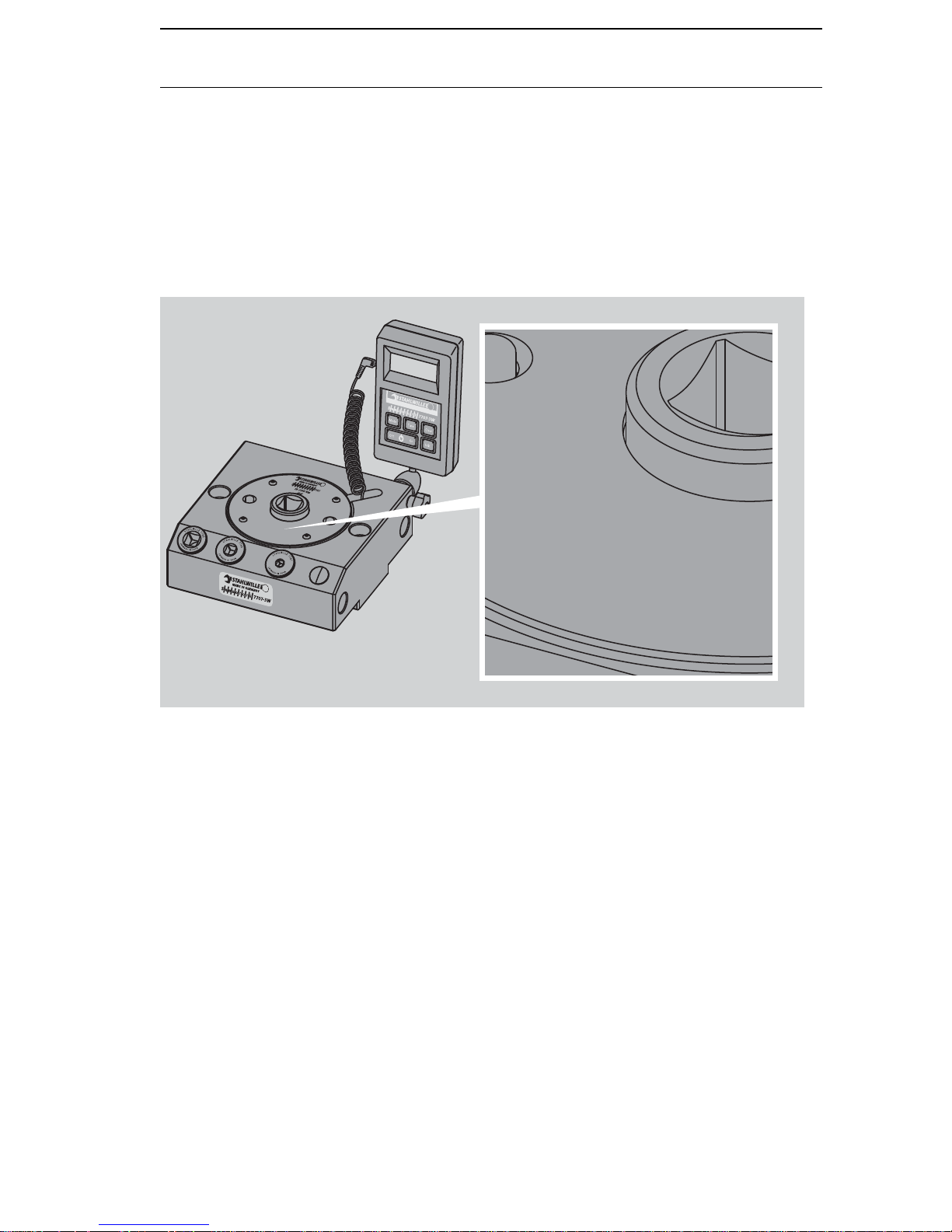

Sensotork Electronic Workshop Torque Tester

7707-1-2W, 7707-1-3W, 7707-1W, 7707-2W,

7707-2-1W, 7707-2-2W and 7707-3W

Please ensure you read these Operating Instructions carefu lly to ensure

you operate the equipment correctly and safely and keep these

instructions in an accessible place.

91979782

402150001

EN

Preface

These Operating Instructions will assist you in using the electronic

workshop torque testers,

models 7707-1W, 7707-1-2W, 7707-1-3W, 7707-2W, 7707-2 -1W,

7707-2-2W and 7707-3W,

safely,

economically and

in accordance with the intended purpose.

Target group for these Operating Instructions

The Operating Instructions are design for use with the electronic

workshop torque testers models 7707-1W, 7707-1-2W,

7707-1-3W, 7707-2W, 7707-2-1W, 7707-2-2W, 7707-3W.

The information contained in the Operating Instructions is for

authorised, qualified, instructed personnel. It is assumed that these

people will have generally applicable technical knowledge.

Any person

transporting,

setting up,

dismantling,

operating,

servicing or

disposing

of this electronic torque tester for torque wrenches or torque

screwdrivers is expected to have read and understood the

corresponding sections of these Operating Instructions.

If, for any reason, you do not understand any of the in forma tion in

these Operating Instructions or feel there is some important

information missing, please contact Eduard Wille GmbH & Co. KG.

Contents

Introduction to the Operating Instructions . . . . . . . . . . . . . . 5

Structural features of the information on dangers . . . . . . . . . . . 5

Structural features of notices referring to property damage . . . . 5

Availability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Addenda . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Conventions used in these Instructions . . . . . . . . . . . . . . . . . . . 6

Fundamental safety instructions . . . . . . . . . . . . . . . . . . . . . . 7

Intended purpose and field of application . . . . . . . . . . . . . . . . . . 7

Obligations relating to the Operating Instructions . . . . . . . . . . . . 8

CE symbol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Fundamental safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . 9

Technical description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Transport, items supplied, storage . . . . . . . . . . . . . . . . . . . . 19

Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Items included . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Optional accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Preparing and mounting the electronic workshop torque

tester . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

General fitting instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Mounting the electronic workshop torque tester . . . . . . . . . . . . 29

Attaching the display unit . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Attaching the display unit to the mounting block . . . . . . . . . . . 32

Fixing the display unit on the stand . . . . . . . . . . . . . . . . . . . . . 36

EN

Inserting and removing transducers . . . . . . . . . . . . . . . . . . .38

Inserting the transducer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Releasing the transducer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Connecting the display unit . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Connecting a USB-adapter (optional) . . . . . . . . . . . . . . . . . . . .44

Switching the display unit on and off . . . . . . . . . . . . . . . . . .45

Testing a torque wrench or torque screwdriver . . . . . . . . . .47

Inserting the torque wrench or torque screwdriver . . . . . . . . . . .48

Reading off measurements via the display unit . . . . . . . . . . . . .51

Testing indicating torque wrenches or torque screwdrivers . . . .54

Maintenance and cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Repairs, calibration and adjustment . . . . . . . . . . . . . . . . . . .62

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Introduction to the Operating Instructions

!

!

!

Structural features of the information on dangers

The following categories of notices are contained in these

operating instructions:

DANGER

Notices containing the word DANGER

warn of hazards which lead directly to

severe or fatal injuries.

WA R NING

Notices containing the word WARNING

warn of hazards which may possibly

lead to severe or fatal injuries.

CAUTION

Notices containing the word CAUTION

warn of hazards which may possibly

lead to slight to moderate injuries.

Structural features of notices referring to property

damage

ATTENTION!

Notices containing the word ATTENTION warn of

possible property damage.

5

EN

Availability

If these Operating Instructions should be mislaid or become

unusable, replacement copies are available from Eduard Wille

GmbH & Co. KG. If you have not yet registered your device, you

will need the following details to place your order:

The number of the transducer

The name of your local distributor

The date of purchase of the device

The order number is to be found in the bottom left-hand corner of

the title page.

Addenda

As legal regulations for the machine location relating to

accident prevention and

environmental protection change,

you are required to amend or add to these Operating Instructions.

Conventions used in these Instructions

Throughout these Operating Instructions, certain typographical

conventions have been used. This is to underline whether a text is

descriptive,

a list of points or

a list of actions

to be carried out.

These instructions provide special information on the most

economic use of the electronic workshop torque tester for

torque wrenches or torque screwdrivers.

6

Fundamental safety instructions

!

Intended purpose and field of application

Only use the electronic workshop testers for the purpose of testing

torque wrenches or torque screwdrivers as described in these

instructions. The 7707-1-3W electronic workshop tester is

designed for the calibration and adjustment of indicating and

clicking torque screwdrivers as well as for general torque

measurement.

The 7707-1W, 7707-1-2W, 7707-2W, 7707-2-1W, 7707-2-2W and

7707-3W electronic workshop torque testers are intended for the

calibration and adjustment of indicating and clicking torque

wrenches as well as for simply measuring torque.

Any use not conforming to the intended use of the electronic

workshop torque tester as described herein can result in damage

to property and even personal injury.The "intended purpose"

includes full adherence to the information contained in this

instruction booklet, in particular the safety instructions and

technical tolerance limits.

Furthermore, it is essential to observe all the laws and reg ulations

in force at the location where the tool is to be used.

STAHLWILLE will not accept any liability for damage or injury

occurring from use that does not conform with the intended use.

DANGER

Danger due to independent conversions

or modifications to the electronic

workshop tester.

Make sure that no conversions are

carried out on the electronic workshop

tester.

7

EN

Obligations relating to the Operating Instructions

The user of the electronic workshop torque tester for torque

wrenches or torque screwdrivers is responsible for ensuring that

these Operating Instructions are readily available wherever the

electronic workshop tester is in use. Always keep the Operating

Instructions close to the electronic torque tester.

CE symbol

All electronic workshop torque testers conform with the EU

directives and regulations currently in force. The CE mark is to be

found on

the transducer,

the mains adaptor,

the front of the display unit

and the (optional) USB adaptor.

8

Fundamental safety instructions

!

The 7707-1W, 7707-1-2W, 7707-1-3W, 7707-2W, 7707-2-1W,

7707-2-2W and 7707-3W electronic workshop torque testers and

their display units are precision testing equipment and must be

treated with corresponding care. Avoid subjecting the tool to

physical knocks, chemicals or excessive temperatures beyond the

limits given in these instructions. Damp and dirt can cause

malfunctioning and lead to inaccurate readings.

CAUTION

Risk of injury due to overloading the

electronic workshop tester.

Only overload the electronic workshop

tester briefly.

Do not overload the electronic workshop

tester to more than 20% of the maximum

value.

9

EN

402150001

402150001

Technical description

Identification

All the transducers have a serial number on them and are supplied

with a works calibration certificate.

Serial number

Accuracy

The range of measurement is

Sensotork 7707-1-2W, 7707-1-3W: 0,2 to 10 N·m,

Sensotork 7707-1W: 0,4 to 20 N·m,

Sensotork 7707-2W: 2 to 100 N·m,

Sensotork 7707-2-1W: 4 to 200 N·m,

Sensotork 7707-2-2W: 8 to 400 N·m,

Sensotork 7707-3W: 25 to 1100 N·m.

10

The range of measurement according to the display variation of the

individual models can be found in the tables below.

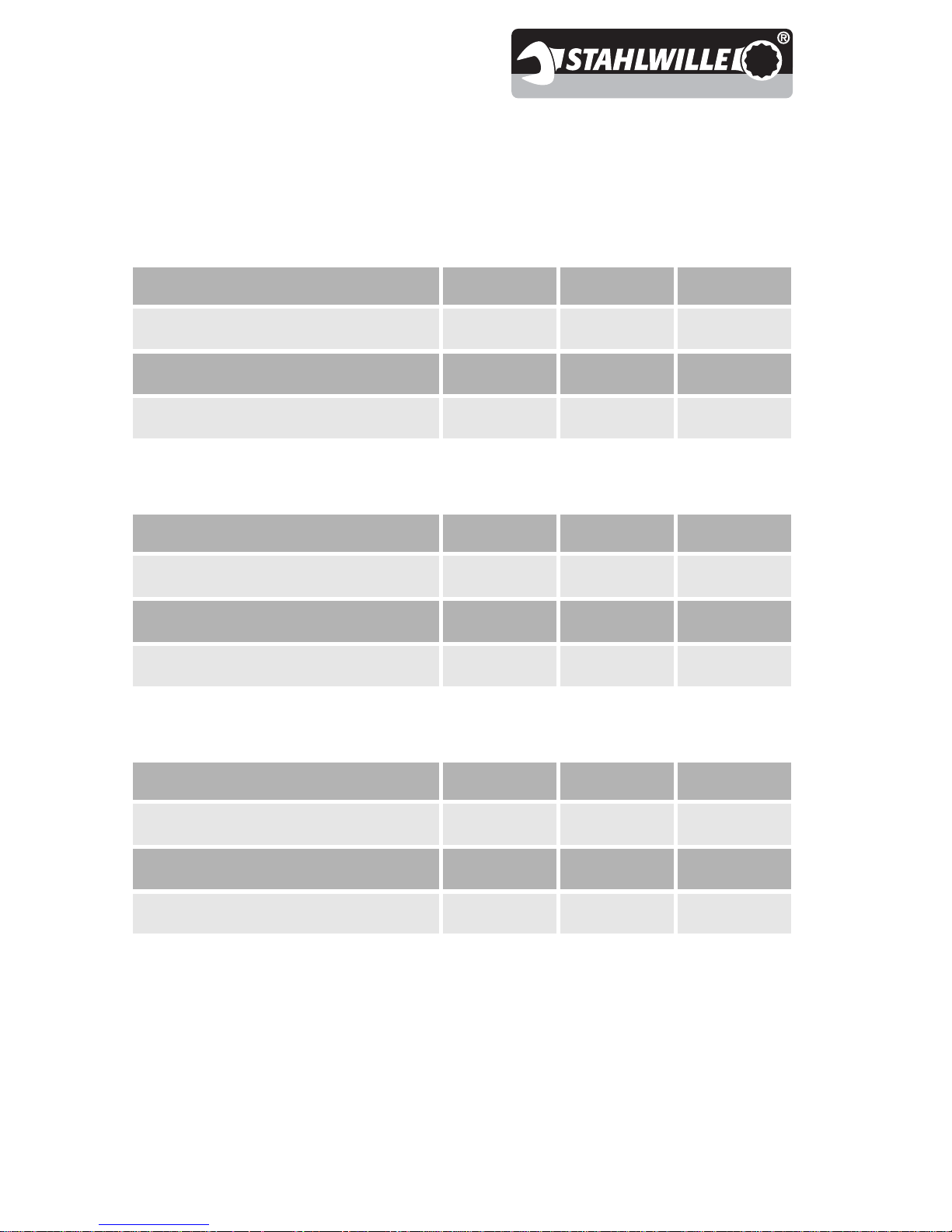

Sensotork 7707-1-2W, 7707-1-3W:

Display variation N·m ft·lb in·lb

± 1 % of value

± 0,5 % of value

± 0,25 % of value

0,2–10 0,15–7,4 1,8–88,5

1–10 0,75–7,5 9–88,5

2–10 1,5–7,5 17,5–88,5

Sensotork 7707-1W:

Display variation N·m ft·lb in·lb

± 1 % of value

± 0,5 % of value

± 0,25 % of value

0,4–20 0,3–15 3,5–177

2–20 1,5–15 18–177

4–20 3–15 35–177

Sensotork 7707-2W:

Display variation N·m ft·lb in·lb

± 1 % of value

± 0,5 % of value

± 0,25 % of value

2–100 1,5–74 18–885

10–100 7–74 89–885

12–100 9–74 106–885

11

EN

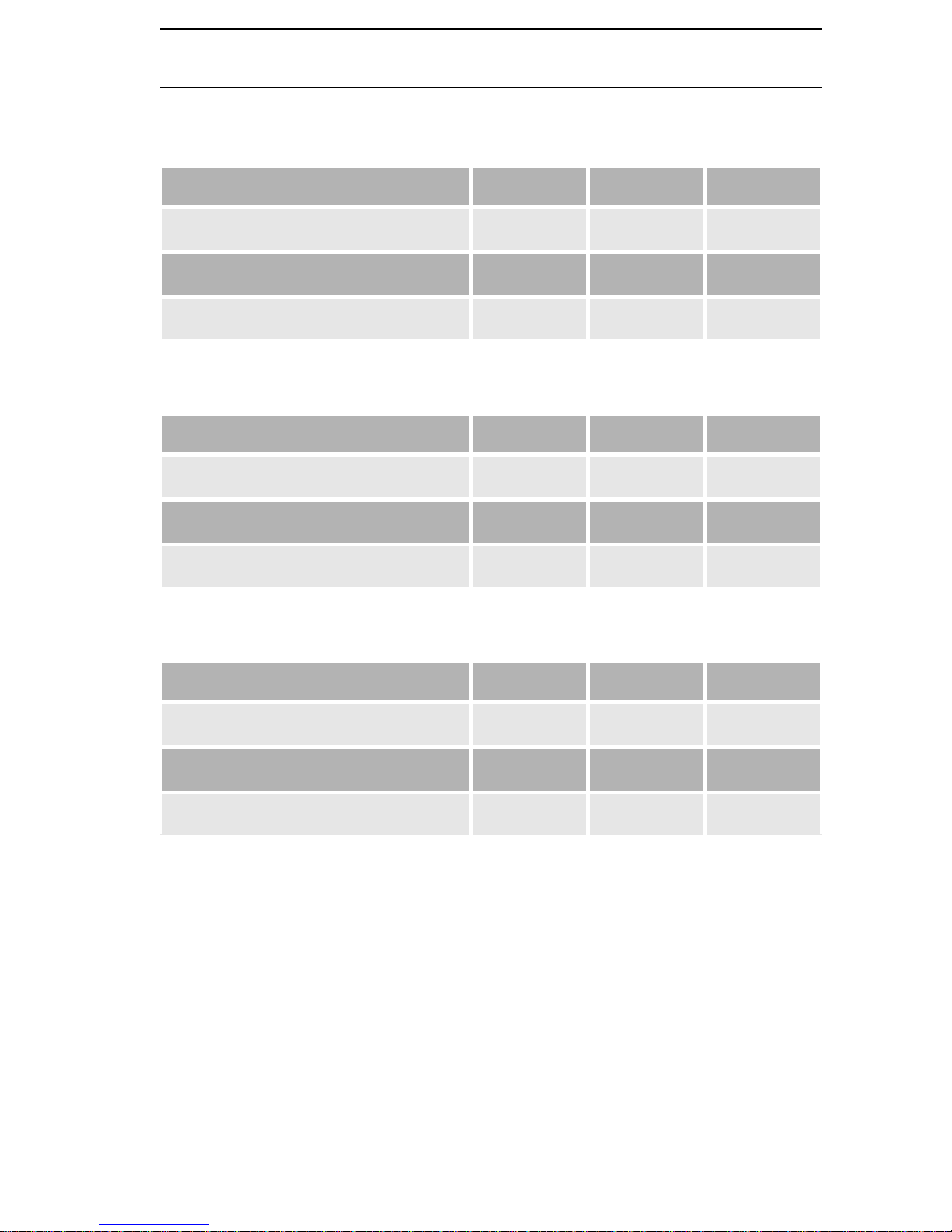

Sensotork 7707-2-1W:

Display variation N·m ft·lb in·lb

± 1 % of value

± 0,5 % of value

± 0,25 % of value

4–200 3–148 35–1770

20–200 15–148 177–1770

40–200 30–148 354–1770

Sensotork 7707-2-2W:

Display variation N·m ft·lb in·lb

± 1 % of value

± 0,5 % of value

± 0,25 % of value

8–400 6–295 71–3540

40–400 30–295 354–3540

80–400 59–295 708–3540

Sensotork 7707-3W:

Display variation N·m ft·lb in·lb

± 1 % of value

± 0,5 % of value

± 0,25 % of value

25–1100 18–812 221–9736

110–1100 81–812 974–9736

220–1100 162–812 1947–9736

Additional details can be seen from the calibration certificate

supplied with the unit.

Functional description

The torque to be determined is applied using an internal square

drive.

12

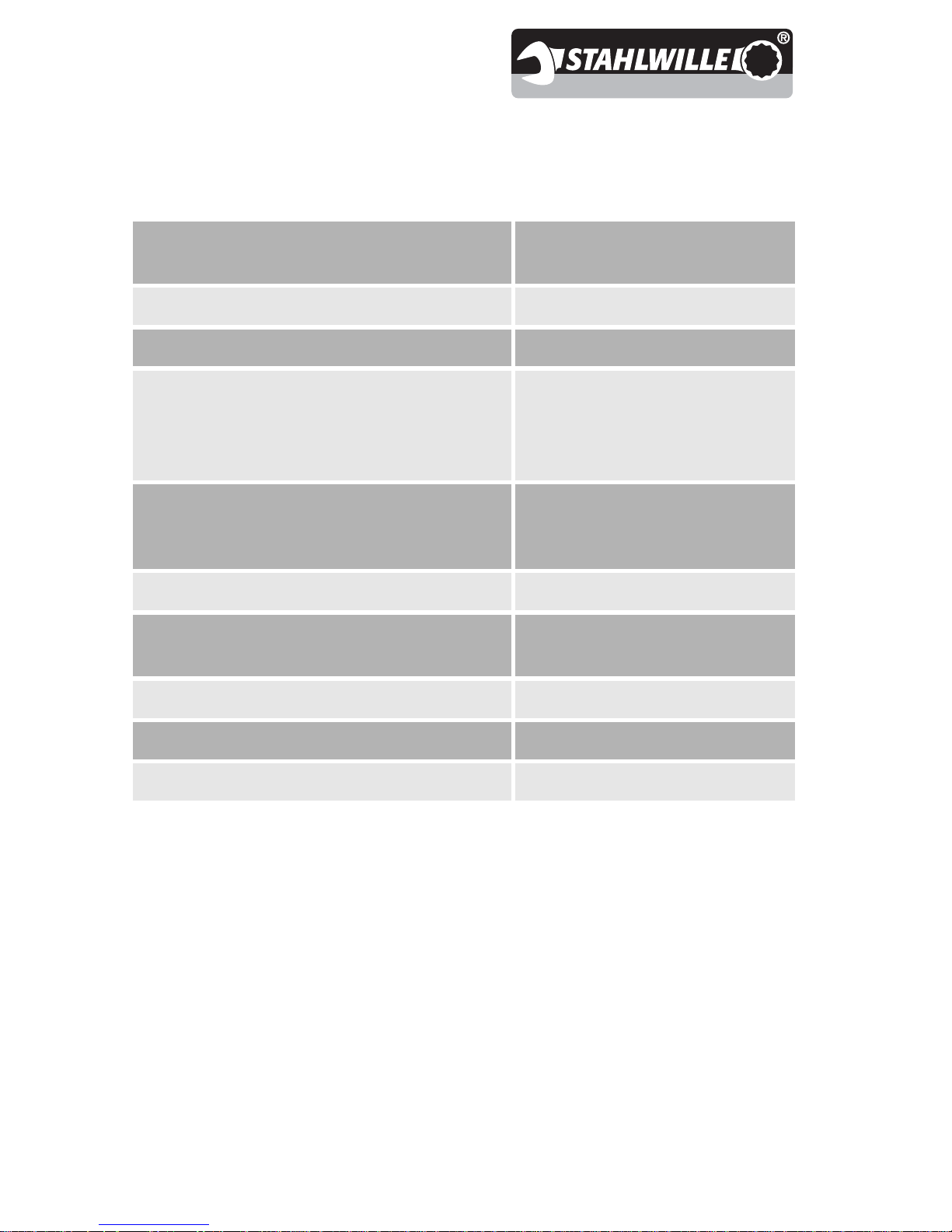

Technical specifications

7707-1-2W and 7707-1-3W

Weight of the electronic

workshop torque tester

Weight of the display unit 0.190 kg

Weight of the stand 0.480 kg

Dimensions of the electronic workshop

torque tester

Dimensions of the display unit width: 80 mm

Range of measurement 0.2–10 N·m

Rated value 10 N·m (with a maximum overload

6,255 kg

width: 180 mm

height: 215 mm

depth: 180 mm

height: 145 mm

depth: 38.5 mm

of 20% for a short time only)

Mains adapter power supply 110 V – 230 V AC

Display unit power supply 9–12 V DC

Transducer current consumption maximum 60 mA

13

EN

7707-1W

Weight of the electronic

workshop torque tester

Weight of the display unit 0,190 kg

Weight of the stand 0,480 kg

Dimensions of the electronic

workshop torque tester

Dimensions of the display unit width: 80 mm

Range of measurement 0,4–20 N·m

Rated value 20 N·m (with a maximum overload

6,255 kg

width: 180 mm

height: 215mm

depth: 180 mm

height: 145 mm

depth: 38,5 mm

of 20% for a short time only)

Power rating of the mains adaptor 110 V – 230 V AC

supply to the display unit 9–12 V DC

Current rating for a transducer / a display

unit, in total

maximum 60 mA

14

7707-2W

Weight of the electronic

workshop torque tester

7,025 kg

Weight of the display unit 0,190 kg

Weight of the stand 0,480 kg

Dimensions of the electronic

workshop torque tester

width: 180 mm

height: 215 mm

depth: 180 mm

Dimensions of the display unit width: 80 mm

height: 145 mm

depth: 38,5 mm

Range of measurement 2–100 N·m

Rated value 100 N·m (with a maximum overload

of 20% for a short time only)

Power rating of the mains adaptor 110 V – 230 V AC

supply to the display unit 9–12 V DC

Current rating for a transducer / a display

unit, in total

maximum 60 mA

15

EN

7707-2-1W

Weight of the electronic

workshop torque tester

Weight of the display unit 0,190 kg

Weight of the stand 0,480 kg

Dimensions of the electronic

workshop torque tester

Dimensions of the display unit width: 80 mm

Range of measurement 4–200 N·m

Rated value 200 N·m (with a maximum overload

7,511 kg

width: 180 mm

height: 215 mm

depth: 180 mm

height: 145 mm

depth: 38,5 mm

of 20% for a short time only)

Power rating of the mains adaptor 110 V – 230 V AC

supply to the display unit 9–12 V DC

Current rating for a transducer / a display

unit, in total

maximum 60 mA

16

7707-2-2W

Weight of the electronic

workshop torque tester

7,654 kg

Weight of the display unit 0,190 kg

Weight of the stand 0,480 kg

Dimensions of the electronic

workshop torque tester

width: 180 mm

height: 215 mm

depth: 180 mm

Dimensions of the display unit width: 80 mm

height: 145 mm

depth: 38,5 mm

Range of measurement 8–400 N·m

Rated value 400 N·m (with a maximum overload

of 20% for a short time only)

Power rating of the mains adaptor 110 V – 230 V AC

supply to the display unit 9–12 V DC

Current rating for a transducer / a display

unit, in total

maximum 60 mA

17

EN

7707-3W

Weight of the electronic

workshop torque tester

Weight of the display unit 0,190 kg

Weight of the stand 0,480 kg

Dimensions of the electronic

workshop torque tester

Dimensions of the display unit width: 80 mm

Range of measurement 25–1100 N·m

Rated value 1100 N·m (with a maximum

7,495 kg

width: 180 mm

height: 215 mm

depth: 180 mm

height: 145 mm

depth: 38,5 mm

overload of 20% for a short time

only)

Power rating of the mains adaptor 110 V – 230 V AC

supply to the display unit 9–12 V DC

Current rating for a transducer / a display

unit, in total

maximum 60 mA

18

Transport, items supplied, storage

Transport

Transport the electronic workshop torque tester, the transducer

and display unit only in the case supplied and ensure that t he case

cannot be dislodged and cannot fall in transit.

ATTENTION!

Damage to and decalibration of the electronic

workshop tester.

Do not expose the aluminium mounting block, the

transducer or the display unit to impacts.

Do not throw the electronic workshop tester or its

components.

19

EN

4021500

01

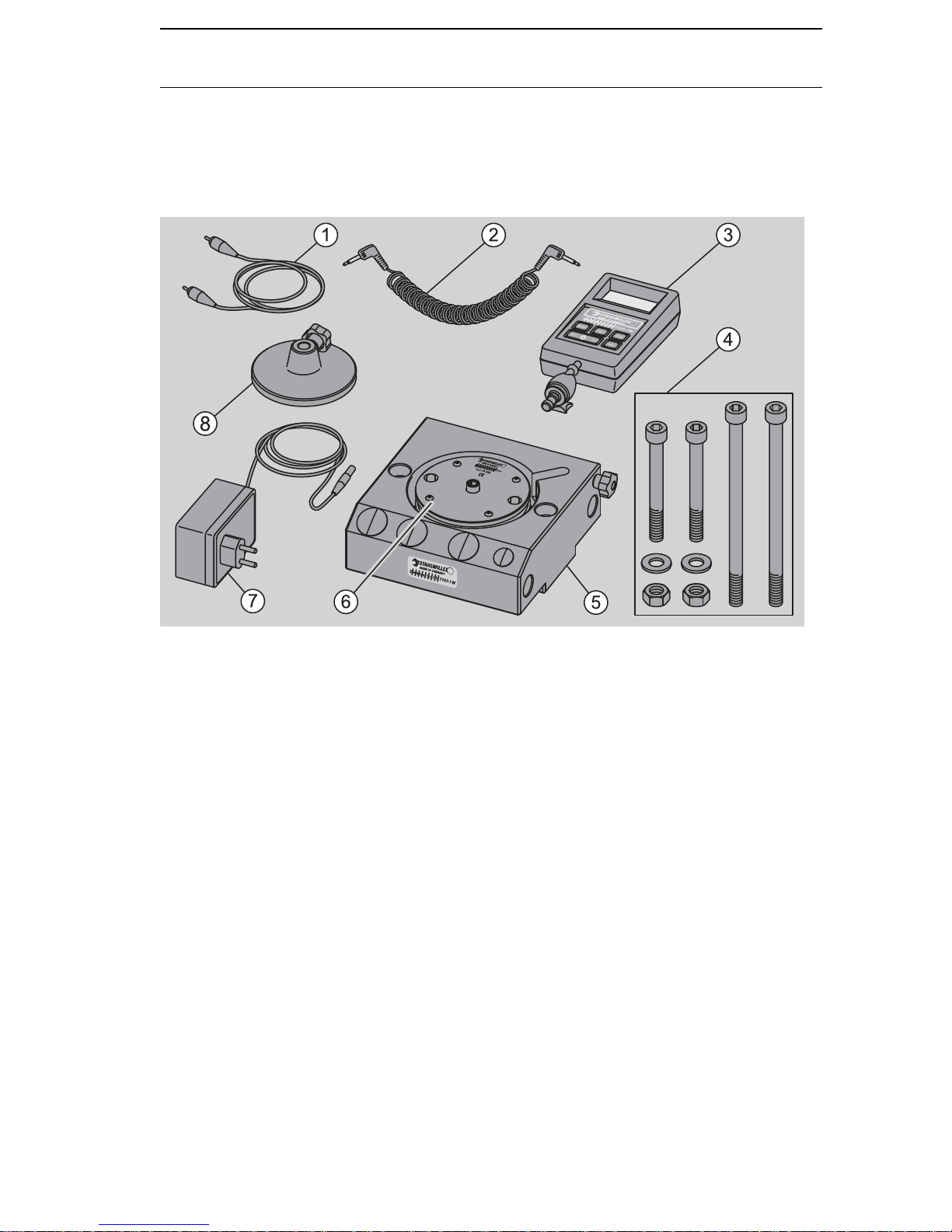

Items included

Electronic workshop torque tester, model 7707-1W

20

Loading...

Loading...