Stahlin Enclosure Materials Technical Information

Technical Information

Enclosure Materials

Technical

Information

The choice of material is dependent on the concentration of

various corrosives present in the application environment and

other physical properties necessary to meet the design

specifications.

To begin the selection process, one must consider the

general atmosphere as well as the corrosive agents which

can be present in an application. Defining the corroding

agents and determining the concentration can be a complex

process. Usually several corrosive elements are present and

interactions are not always well documented.

Water (and water states such as ice, snow, mist, fog, vapor)

is the most common corrosive and is usually present to some

extent in every enclosure application. Each environment is

unique and all possible corrosive agents should be identified

for the intended enclosure application.

To select the best enclosure material for an application;

chemical resistance, physical strength and economic data are

presented in several tables beginning on the next page. In

Table 1 enclosure materials are rated on a continuum from

“Recommended” to “Limited or Unacceptable” in three broad

categories of chemicals. Since the chemical resistance

categories in the table are extremely broad, some materials

may perform well in specific corrosive environments within a

general category and it is best to consult the detailed

Chemical Resistance Information provided in Table 3.

Besides the enclosure material, the corrosion resistance of

windows, gaskets, latches, etc. must also be considered.

Table 4 provides corrosion resistance information that can be

used to select the commonly used materials for these

features.

Much of the chemical resistance information in Table 3 is

based on total immersion testing in the chemical for a

minimum of 30 days at 72°F. Some fiberglass test specimens

were evaluated using procedures outlined in ASTM D 543,

Test Method for Resistance of Plastics to Chemical

Reagents. The information in these tables is intended as a

guide only. Total immersion testing is considered quite severe

and the results may not necessarily reflect the

performance under actual field conditions. The user

assumes responsibility for selection of the material based on

the characteristics of the application environment.

Specifications for Stahlin Enclosure Back Panel Construction Materials

Fiberglass (FG)

Fiber reinforced polymer made of a plastic matrix reinforced by

fine fibers made of glass. The plastic matrix is a thermosetting

plastic made of polyester.

Carbon Steel (CS)

A low carbon, rolled steel produced by passing bar stock through

a set of rolls. Stahlin CS back panels are powder coated for

appearance and protection.

Technical

Infor matio n

Stahlin Enclosures•500 Maple Street, Belding, MI 48809 •Phone: 616-794-0700 •Fax: 616-794-3378 •www.stahlin.com

160

Stainless Steel (SS)

Stainless steel is defined as a steel alloy with a minimum of

11% chromium content by mass. Stainless steel is used where

both the properties of steel and resistance to corrosion are

required. Stahlin hardware and SS backpanels are fabricated

utilizing 3000 series stainless steel.

Aluminum (AL)

A lightweight metal that quickly forms a natural oxide layer to

resist corrosion. Stahlin fabricates back panels from Type 3003

H14 Aluminum, the highest strength non-heat treatable aluminum

alloy recommended for marine applications.

Enclosure Materials

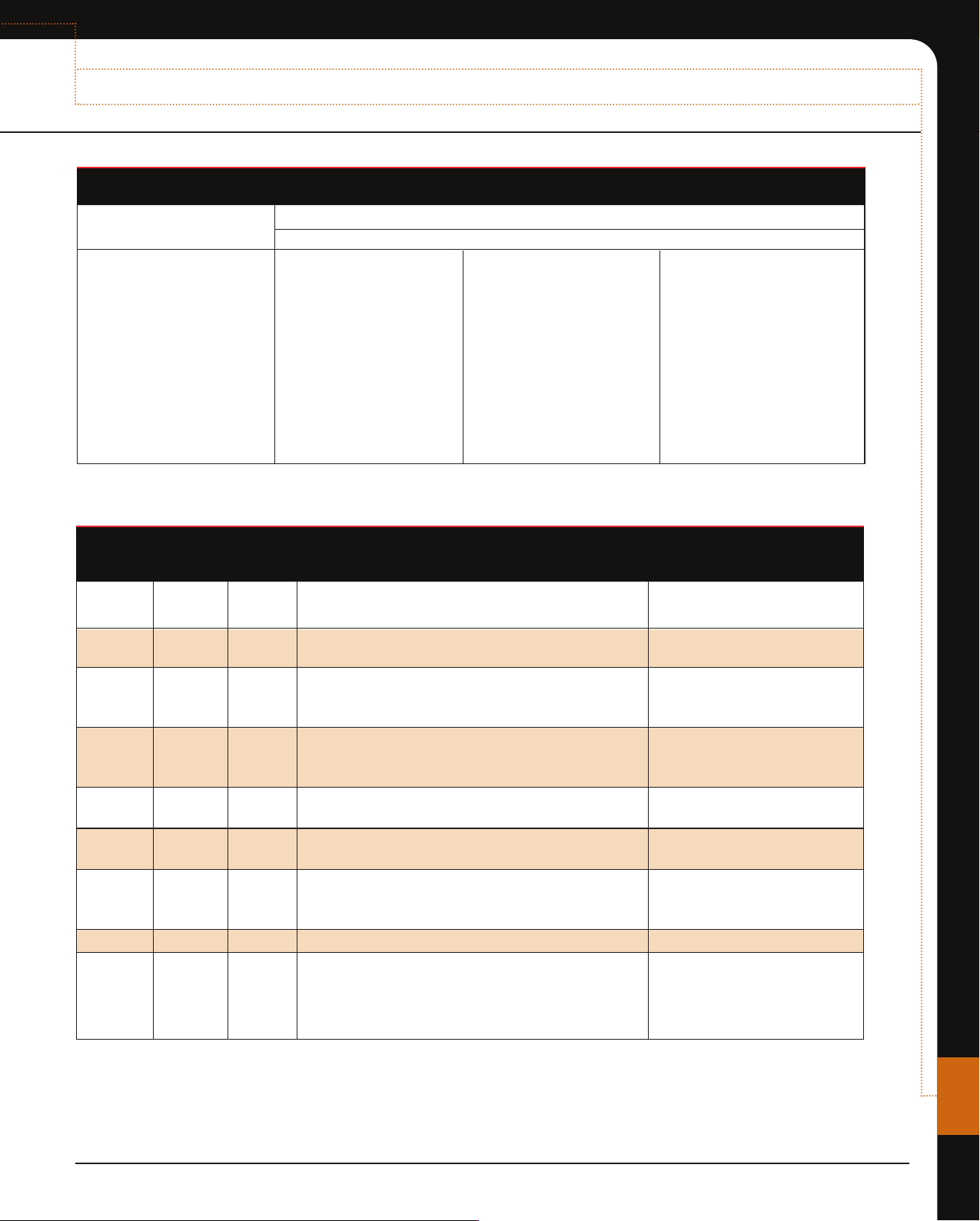

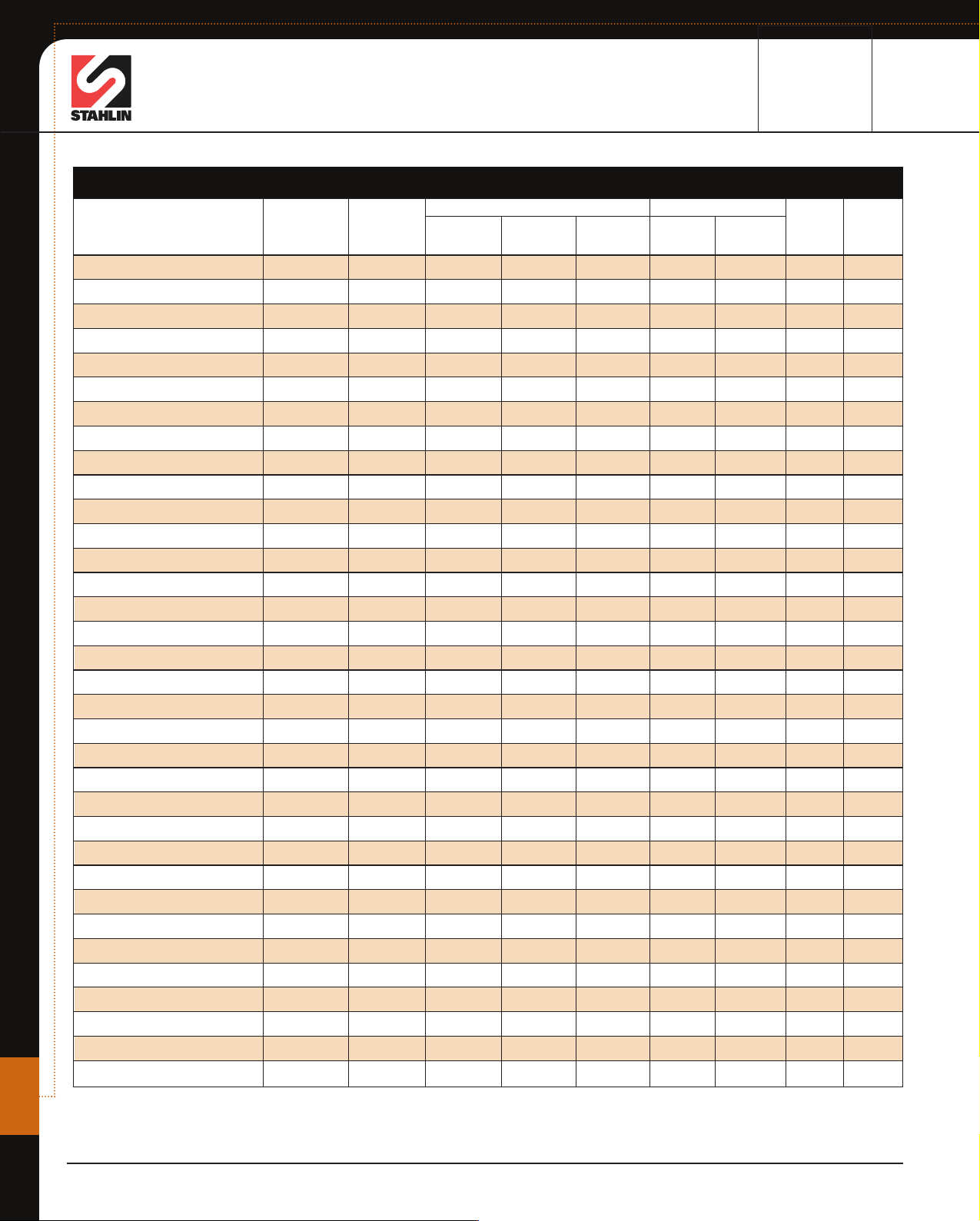

TABLE 1. BROAD CATEGORIES OF ENCLOSURE MATERIAL CHEMICAL RESISTANCE

CONTINUUM GENERAL CATEGORY OF CHEMICALS

OF USE Acids Alkalines Solvents

➡ ➡ ➡ ➡ ➡ ➡ ➡ ➡

Stainless Steel Fiberglass Stainless Steel

Recommended Stainless Steel Aluminum

Fiberglass Powder Coated Steel

Acceptable PC PC

PVC Galvanized Steel Galvanized Steel

Powder Coated Steel Powder Coated Steel

Limited or

Unacceptable

Aluminum PVC PC

Galvanized Steel Aluminum PVC

Fiberglass

TABLE 2. RELATIVE MATERIAL STRENGTH AND COST

COMPARISON OF COMMONLY USED ENCLOSURE MATERIALS

MATERIAL PHYSICAL RELATIVE APPLICATION TEMPERATURE

Aluminum Average Average Indoor and Outdoor, Marine, Solvents, Petrochemical None for enclosure applications

Fiberglass Average Low- Indoor and Outdoor for continuously damp and highly -40°F(C) to 250°F(121°C)

Mild Steel: High Average Indoor and Outdoor where the respective coating None for enclosure applications.

Galvanized Low provides acceptable protection in a mildly corrosive

Painted environment.

Stainless High Average- Indoor and Outdoor in highly corrosive applications. None for enclosure applications.

Steel High Food and Dairy Processing or Marine.

Acrylic Average Low Enclosure Windows. Weatherable, Scratch Resistant. -31°F(-35°C) to 180°F(82°C)

Poly- Average Low- Enclosure Windows. Not recommended for direct -31°F(-35°C) to 248°F(120°C)

carbonate Average sunlight, exposure to organic solvents and

Nylon Average Low Cord Grip, Hinges, Latches. -22°F(-30°C) to 212°F(100°C)

Gaskets:

Neoprene Low Low Oil Resistance. Seams may be a problem -40°F(C) to 225°F(107°C)

Silicone Low Average Oil Resistance Temperature & Chemical Resistance. -40°F(-40°C) to 350°F(175°C)

Urethane Low Average Water and Oil Resistance, Chemical Resistance. -40°F(C) to 200°F(93°C)

RELATIVE

STRENGTH COST CONDITIONS LIMITATIONS

Sulfates, Nitrates and Specific Acids.

Average corrosive environments. Petrochem, Water Treatment, Stahlin

Food Processing, Coating, Salts and Chemicals, Solar. -76°F to 274°F (-60°C to 134°C)

Good resistance to Solvents.

concentrated alkalis.

Detailed material strength information is beyond the scope of this catalog and should be obtained from a materials reference;

however, Table 2 provides some relative data to help with this selection.

Stahlin Enclosures•500 Maple Street, Belding, MI 48809 •Phone: 616-794-0700 •Fax: 616-794-3378 •www.stahlin.com

161

Infor matio n

Technical

Technical Information

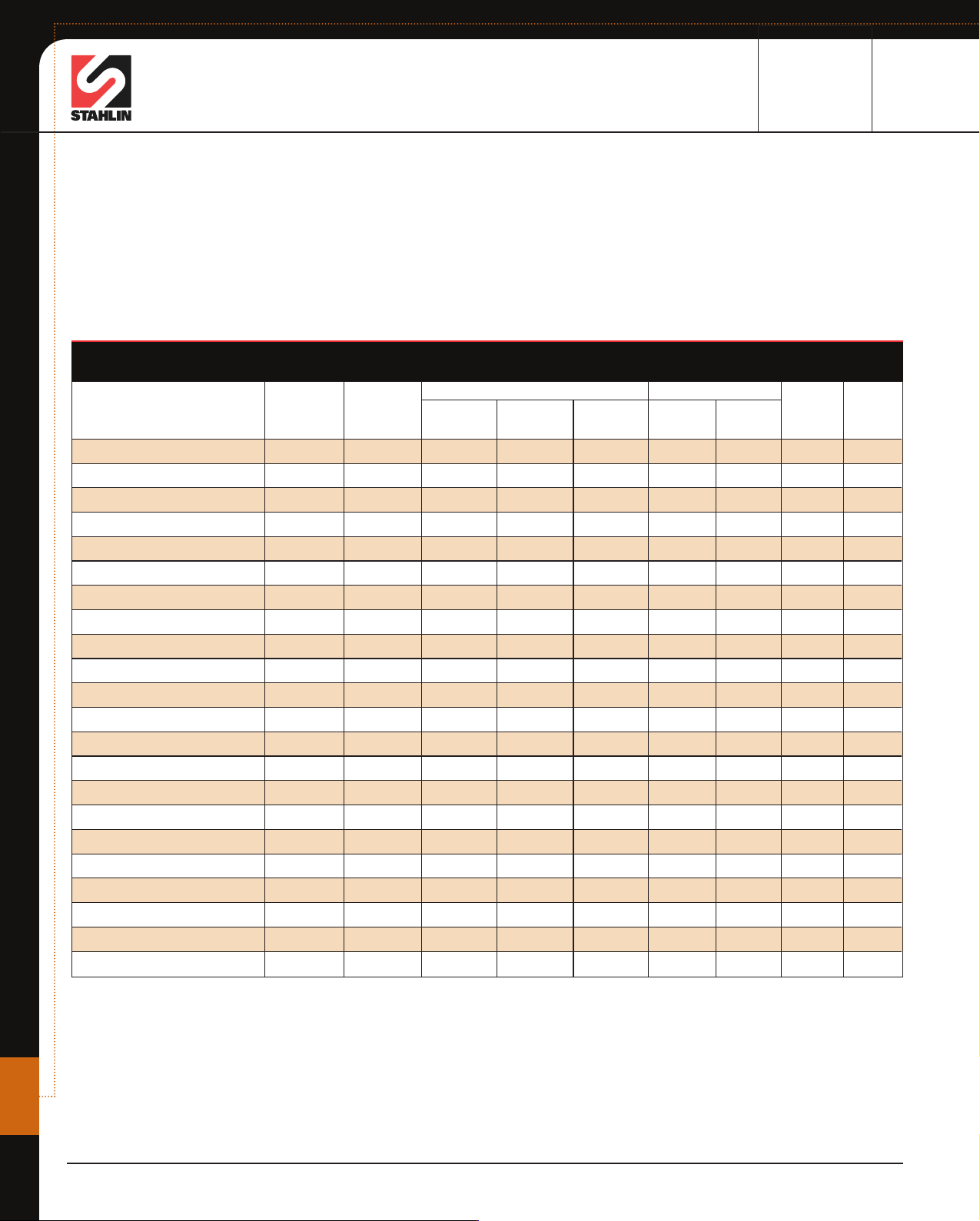

Chemical Resistance – Material

KEY:

S = Superior Resistance/Completely Unaffected under all Conditions

L = Limited Resistance, Some Chemical Attack May Occur Over Time

M = Moderate Resistance, Superficial Effects only, Testing Recommended

U = Unsatisfactory, Severe/Chemical Attack in a relatively short time

– = No Data Available

TABLE 3. CHEMICAL RESISTANCE OF FIBERGLASS MATERIALS AND ENCLOSURE ACCESSORIES

Technical

Information

Fiber

Glass Polyester Urethane Gal- Type Type

CHEMICAL Aluminum Polyester Powder Enamel vanized 304 316 PC PVC

Acetyldehyde SU———SSUU

Acetic Acid (10%) LSUUUSUSU

Acetone SLLULSSUU

Aluminum Chloride (10%) USUUUUMSS

Aluminum Sulfate (10%) LSUUUUSSS

Ammonia Gas LS———SS——

Ammonium Chloride USUUUSSSS

Ammonium Hydroxide (10%) SLUUUSSUS

Ammonium Nitrate (10%) MSUUUSSUS

Ammonium Phosphate (10%) LMSLUSMS—

Ammonium Sulfate SS———SSSS

Aniline LU———SSUL

ASTM #1 Oil SSSSSSSL—

ASTM #3 Oil SSSSSSSL—

Axle Grease SSSSSSSL—

Benzene SS——SSSUL

Boric Acid (10%) MSUUUSSSL

Bromine ULUUUUUUU

Butyl Acetate ML———SSUU

Butyric Acid US———SSUU

Calcium Chloride (10%) LSUUULSSL

Calcium Hydroxide (10%) USUUUSSSL

Steel Stainless Steel

Technical

Infor matio n

Stahlin Enclosures•500 Maple Street, Belding, MI 48809 •Phone: 616-794-0700 •Fax: 616-794-3378 •www.stahlin.com

162

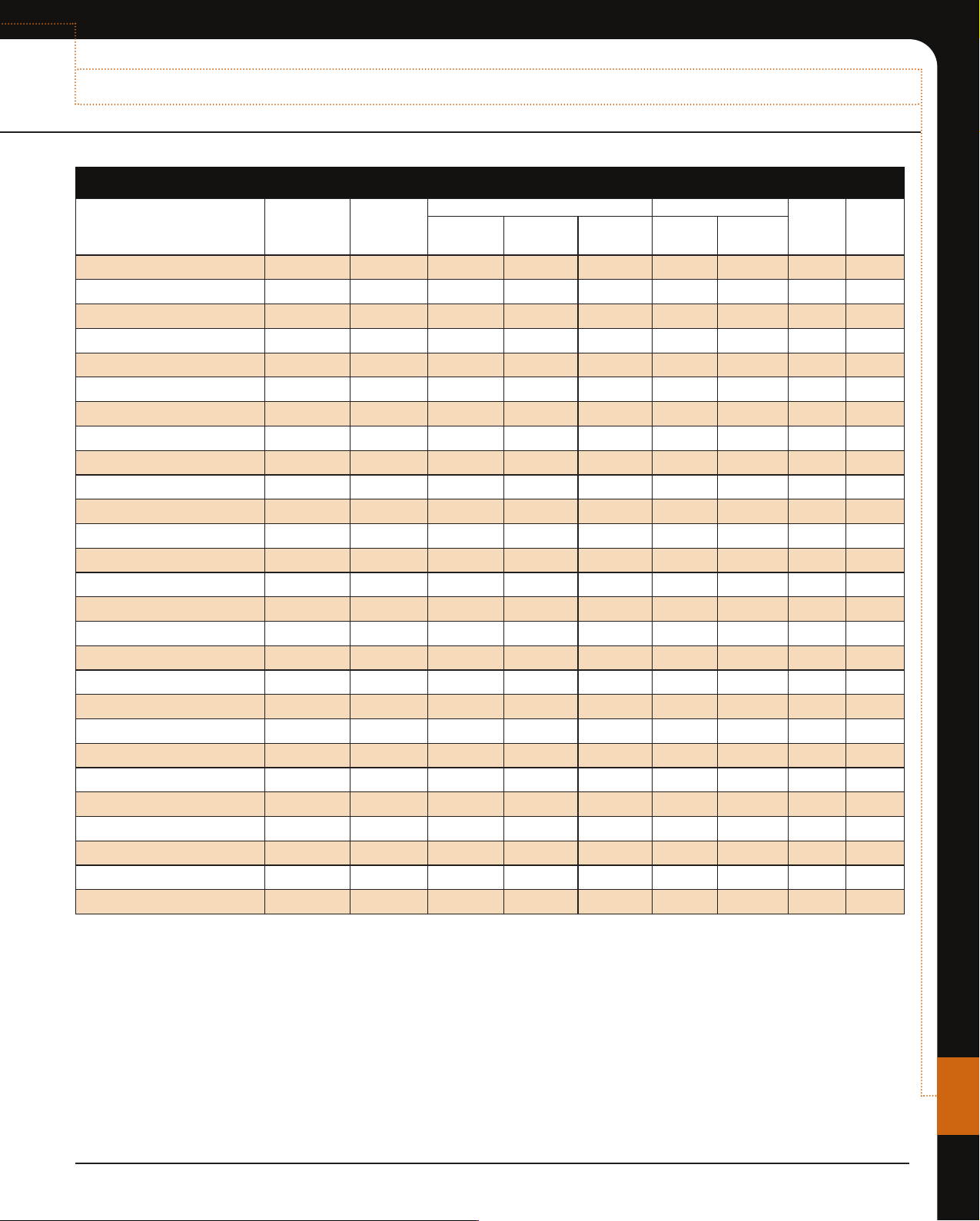

Chemical Resistance – Material

TABLE 3. Continued

Fiber

Glass Polyester Urethane Gal- Type Type

CHEMICAL Aluminum Polyester Powder Enamel vanized 304 316 PC PVC

Calcium Hypochlorite (10%) LMUUUUMLL

Calcium Sulfate MSUUUSSSL

Carbolic Acid (25%) MLUUUSSU

Carbon Disulfide SL———SSUU

Carbon Tetrachloride SMUSSUSU

Chlorine (dry) SS———SSUU

Chlorine (water) 5-10 ppm MLSUUU—SS

Chlorobenzene SS——SSSU

Chloroform LU———SSUU

Chrome Plating Solution ULUUULLS—

Chromic Acid SS———UUUU

Citric Acid (10%) UMUUUSSSL

Copper Sulfate US———SSSS

Creosote LL———SSU—

Cutting Fluid (5 Star) 10% SSUUUSSL—

Cutting Fluid (Castrol 980 H) SSSUUSSL—

Cutting Fluid (Norton 205) USUUUSSS—

Cutting Fluid (Rustlick) 10% MSUUUSSS—

Cutting Oil (Dark) SSSSSSSS—

Diethyl Ether SS———SSUU

Ethyl Alcohol SSMUSSSMS

Ethylene Dichloride SL—————UU

Ethylene Glycol SSSSUSSSS

Ferric Chloride USUUUSUSS

Ferric Nitrate —S———SSSS

Ferric Sulfate MS———SSSS

Fluorine SU———M—LU

Formaldehyde SS———LSSL

Formic Acid USUUUMSS—

Fuel Oil (#2) SSMSSSMLS

Gasoline SM———SSUS

Glycerine SS——SSSSS

Hydraulic Brake Fluid SSUUSSSU—

Hydraulic Oil SSSSSSSLS

Steel Stainless Steel

Infor matio n

Technical

Stahlin Enclosures•500 Maple Street, Belding, MI 48809 •Phone: 616-794-0700 •Fax: 616-794-3378 •www.stahlin.com

163

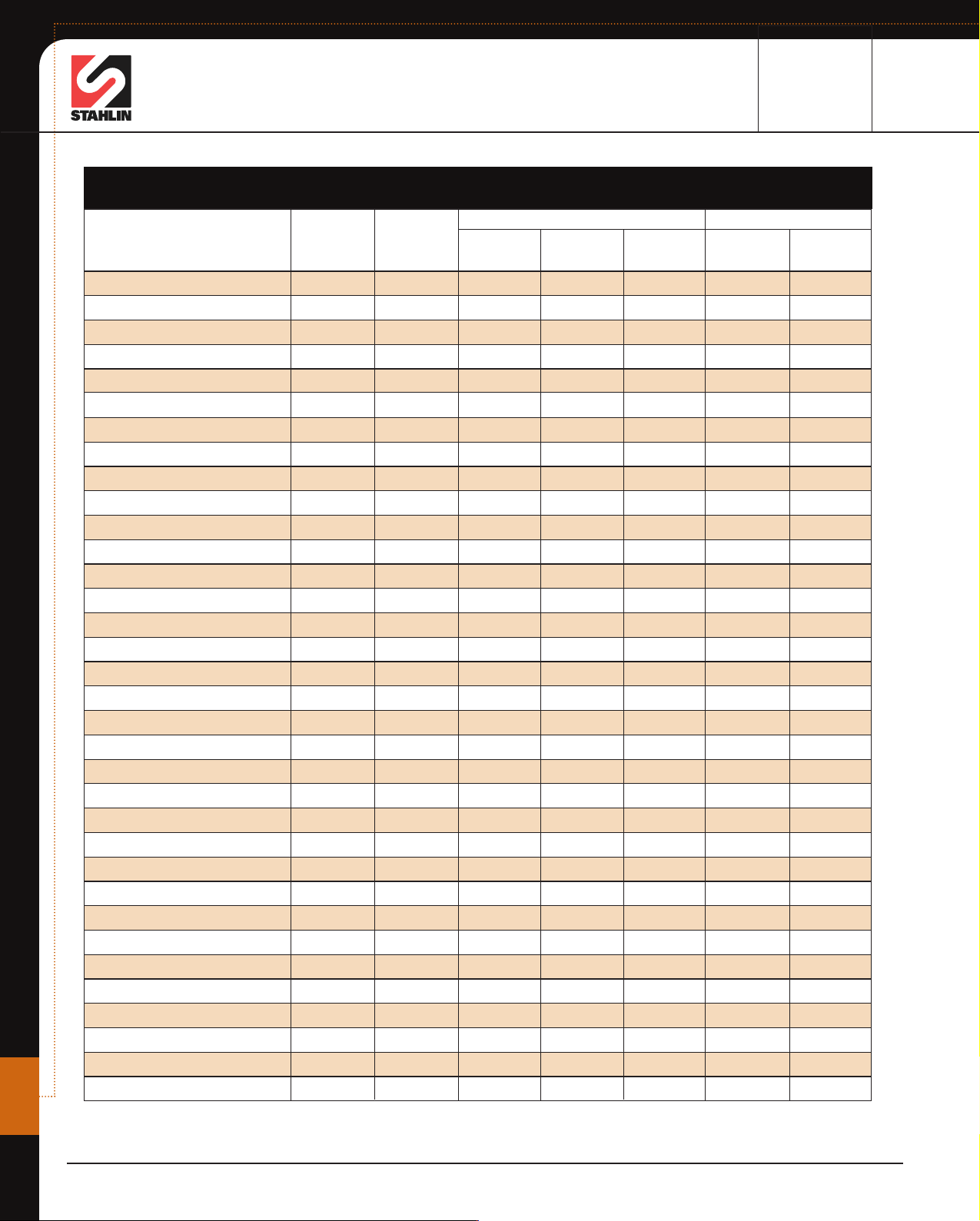

Technical Information

Chemical Resistance – Material

TABLE 3. Continued

Technical

Information

Fiber

Glass Polyester Urethane Gal- Type Type

CHEMICAL Aluminum Polyester Powder Enamel vanized 304 316 PC PVC

Hydrochloric Acid (10%) UMUUUUUSS

Hydrocyanic Acid SU———SSLL

Hydrofluoric Acid (20%) UUUUUUULL

Hydrogen Peroxide SM———LSSS

Hydrogen Sulfide MS———LSLL

Hypochlorus Acid US———————

Isopropyl Alcohol SSMUSSSS—

Kerosene SSSSSSSLS

Lacquer Thinner SSLUSSSUU

Lactic Acid MS———LSLL

Lime MM——————L

Liquid Dish Soap (10%) MSUUUSMSS

Lubricating Oils SS———SSS—

Magnesium Chloride (10%) LSUUUSSSL

Magnesium Hydroxide (10%) LSUUUSSSS

Mercuric Chloride (10%) UMUUUSUSL

Methyl Ethyl Ketone SL———SSUU

Methylene Chloride SSUUMSSUU

Milk SS———SSSS

Mineral Oil SS———SSSS

Mineral Spirits SSSSSSSLS

Motor Oil (10 weight) SSSSSSSSL

Nickel Salts LS———LSSS

Nitric Acid (10%) UMUUUSSLS

Nitrobenzene SL———SSUU

Oleic Acid SS———LSSL

Perchlorethylene SSSUSSSUL

Phosphoric Acid (25%) ULUUUSSSS

Phosphoric Acid (50%) UUUUUSSSS

Pickling Solution UMUUUSMS—

Potassium Carbonate (10%) USSSLSSSL

Potassium Chloride (25%) LSUUUSSSS

Potassium Hydroxide (25%) UUUUUMMUS

Potassium Nitrate (10%) USUUUSSSS

Steel Stainless Steel

Technical

Infor matio n

Stahlin Enclosures•500 Maple Street, Belding, MI 48809 •Phone: 616-794-0700 •Fax: 616-794-3378 •www.stahlin.com

164

Chemical Resistance – Material

TABLE 3. Continued

Fiber

Steel Stainless Steel

Glass Polyester Urethane Gal- Type Type

CHEMICAL Aluminum Polyester Powder Enamel vanized 304 316 PC PVC

Potassium Sulfate (10%) LSUUUSSSL

Soap (Igepal) 10% LSSUUSSSS

Sodium Bicarbonate (10%) LSSSUSSSS

Sodium Bisulfate (10%) ULUUUSSSS

Sodium Chloride (25%) LSUUUSSSS

Sodium Hydroxide UUUUUMMUS

Sodium Hypochlorite UMUUUSMLS

Sodium Nitrate (10%) MSUUUSSSS

Sodium Phosphate (10%) LSUUUSSSS

Sulfuric Acid (25%) USUUUSSSS

Sulfurus Acid (10%) UUUUUSSSS

Tannic Acid ((10%) LSUUUMMSS

Tetrahydrofuran MLUUUSSUU

Toluene SSLUSSSUU

Trichloroethylene SU———LSUU

Trisodium Phosphate LM—————SS

Turpentine SMMULSSSU

Vegetable Oils SS———SSSS

Vinegar MS———SSSL

Water, Industrial LSLLLSSSS

Water, Rain LSSLLSSS—

Water, Sea LSUUUSSSS

Water, Tap LSSLLSSSS

Xylene SSLUSSSUU

Zinc Acetate SS———SS——

Zinc Chloride LSSUUMSML

Zinc Sulfate SS———MSSS

Sources: Robroy Industries Reagent Testing Lab, Corrosion Resistant Materials Handbook, 4th Edition, Noyes Data Corp., Raw Material Vendors

Stahlin Enclosures•500 Maple Street, Belding, MI 48809 •Phone: 616-794-0700 •Fax: 616-794-3378 •www.stahlin.com

165

Infor matio n

Technical

Technical Information

Technical

Information

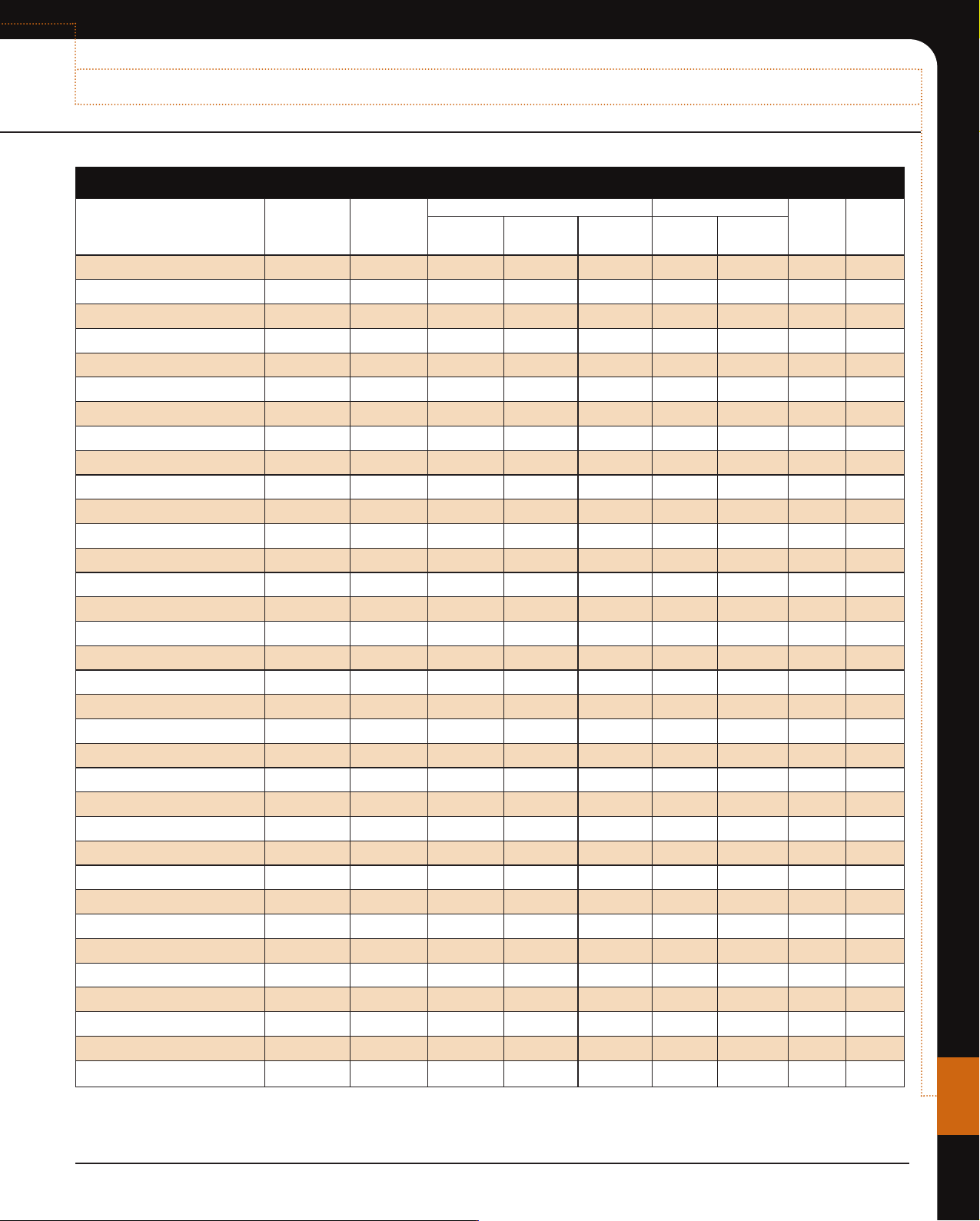

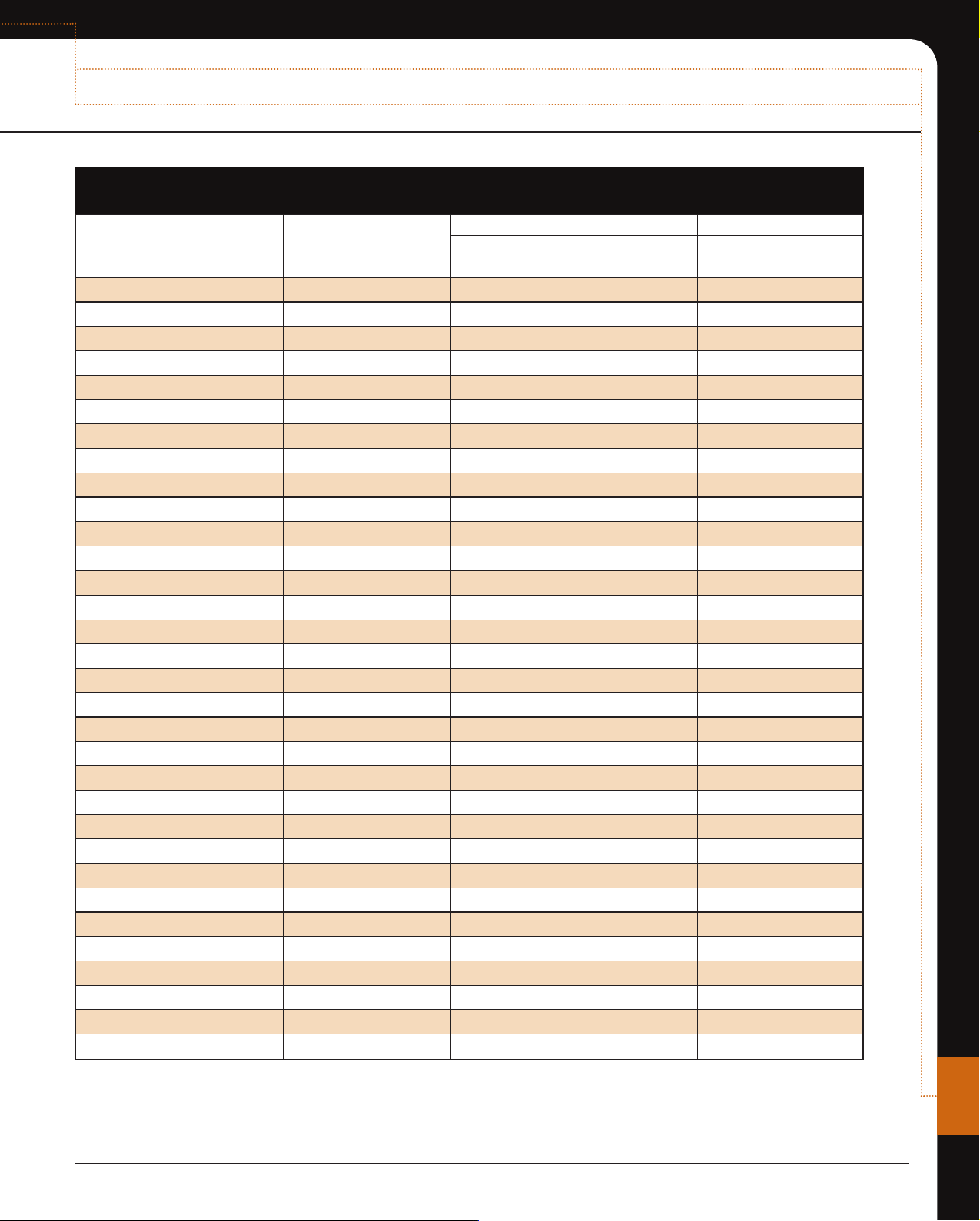

Chemical Resistance – Gaskets, Windows and Other

TABLE 4. SPECIFIC CHEMICAL RESISTANCE INFORMATION

OTHER MATERIALS USED FOR ENCLOSURE FEATURES

Gaskets Windows

Rigid Glass Neoprene Silicone Poly-

CHEMICAL PVC Nylon Rubber Rubber Urethane Acrylic carbonate

Acetyldehyde U—S S———

Acetic Acid (10%) LUUMLSS

Acetone USUSUUU

Aluminum Chloride (10%) SUSSSS S

Aluminum Sulfate (10%) SLUSSSS

Ammonia Gas —SS S—S—

Ammonium Chloride SUSSSSS

Ammonium Hydroxide (10%) S—L L SS U

Ammonium Nitrate (10%) SUUSSSU

Ammonium Phosphate (10%) —LU S SS S

Ammonium Sulfate SUSS———

Aniline SLUU—S—

ASTM #1 Oil ——M S S S M

ASTM #3 Oil ——U L S S M

Axle Grease ——L S S S M

Benzene USUU—U—

Boric Acid (10%) LSSSSSS

Bromine UUUUUL U

Butyl Acetate USUU—U—

Butyric Acid UUU————

Calcium Chloride (10%) SUSSSSS

Calcium Hydroxide (10%) S—U S LS S

Calcium Hypochlorite (10%) SUUSUMS

Calcium Sulfate SUSSSSS

Carbolic Acid (25%) ——U U U U U

Carbon Disulfide U—U——S—

Carbon Tetrachloride LSUUUSU

Chlorine (dry) L——————

Chlorine (water) 5-10 ppm L—L SSS S

Chlorobenzene USUU—L—

Chloroform UUUU—U—

Chrome Plating Solution ——U U U S S

Chromic Acid LUUM—U—

Citric Acid (10%) SLUSUSS

Technical

Infor matio n

166

Stahlin Enclosures•500 Maple Street, Belding, MI 48809 •Phone: 616-794-0700 •Fax: 616-794-3378 •www.stahlin.com

Chemical Resistance – Gaskets, Windows and Other

TABLE 4. Continued

Gaskets Windows

Rigid Glass Neoprene Silicone Poly-

CHEMICAL PVC Nylon Rubber Rubber Urethane Acrylic carbonate

Copper Sulfate SLSS—U—

Creosote —UU U———

Cutting Fluid (5 Star) 10% ——U S S S M

Cutting Fluid (Castrol 980 H) —— L S S S L

Cutting Fluid (Norton 205) ——S S S S S

Cutting Fluid (Rustlick) 10% ——S S S S S

Cutting Oil (Dark) ——U S S S S

Diethyl Ether U——U—U—

Ethyl Alcohol S—L SSU M

Ethylene Dichloride U—U U—U—

Ethylene Glycol S—S SSS S

Ferric Chloride SULSLSS

Ferric Nitrate SUSM———

Ferric Sulfate SUSM———

Fluorine L——U———

Formaldehyde LUUM—S—

Formic Acid LSULLUS

Fuel Oil (#2) S—UUUS S

Gasoline SSUL—S—

Glycerine SSSS—S—

Hydraulic Brake Fluid ——U S UU U

Hydraulic Oil ——U S S S M

Hydrochloric Acid (10%) SUL LUS S

Hydrocyanic Acid S—S MM——

Hydrofluoric Acid (20%) LUUU—SM

Hydrogen Peroxide SUUM—S—

Hydrogen Sulfide S—UM———

Hypochlorus Acid ———————

Isopropyl Alcohol —— S S S S S

Kerosene S—U USS M

Lacquer Thinner —SU S LU U

Lactic Acid SLL——L—

Infor matio n

Technical

Stahlin Enclosures•500 Maple Street, Belding, MI 48809 •Phone: 616-794-0700 •Fax: 616-794-3378 •www.stahlin.com

167

Loading...

Loading...